Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-32-00-030-005-B00 LPC/Intermediate Case Module - Remove The Fan Case, Center Bearing Housing, Oil Seal Tube, No. 1, 2, 3 Bearing Scavenge Tube, Hot Vent Tube, Seal, PTO Shaft, And Identification Plates, Disassembly-005

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Apply the approved penetrating oil before the removal of threaded parts. Let the parts soak before removal. For the approved oils and procedures, refer to the SPM TASK 70-64-00-640-501.

Discard all rubber seal rings removed in this procedure.

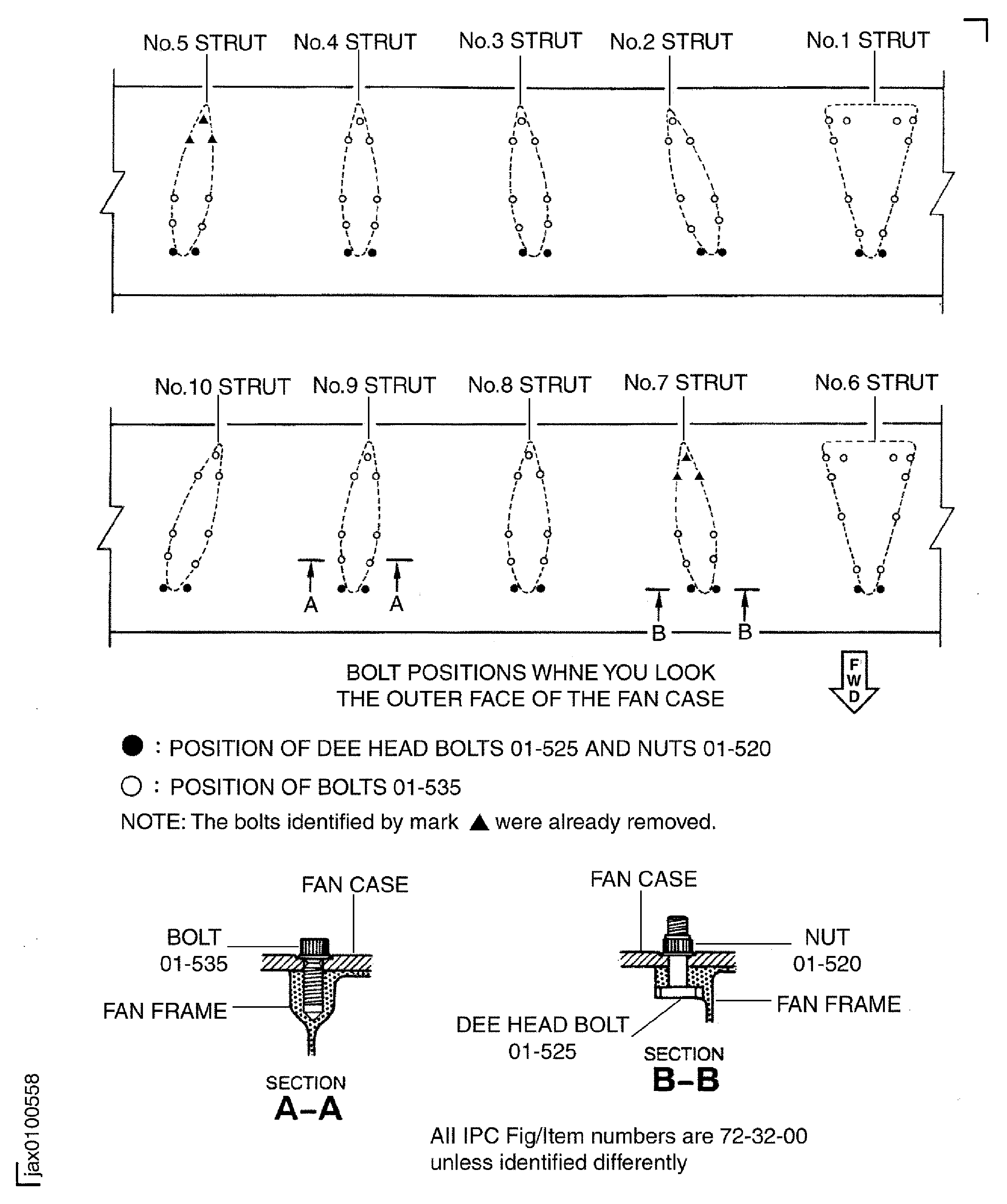

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

The No. 1 strut, which is the top position strut of the fan frame assembly, is identified by the five pressure tubes on the No. 1 strut leading edge.

This TASK gives the procedure to remove the fan case, the center bearing housing, the oil seal tube, the No. 1, 2, 3 bearing scavenge tube, the hot vent tube, the seal and the PTO shaft.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1J12010 Storage stand | 0AM53 | IAE 1J12010 | 1 | |

| IAE 1J12023 Hooking puller | 0AM53 | IAE 1J12023 | 1 | |

| IAE 1J12188 Puller bolt | 0AM53 | IAE 1J12188 | 1 | |

| IAE 1J12311 Turnover stand | 0AM53 | IAE 1J12311 | 1 | |

| IAE 1J12317 Turnover adapter | 0AM53 | IAE 1J12317 | 1 | |

| IAE 1J12327 Handling holder | 0AM53 | IAE 1J12327 | 1 | |

| IAE 1J12432 Base holder | 0AM53 | IAE 1J12432 | 1 | |

| IAE 1J12487 Rear sling | 0AM53 | IAE 1J12487 | 1 | |

| IAE 1J12494 Puller bolt set | 0AM53 | IAE 1J12494 | 1 | |

| IAE 1J12526 Hooking puller | 0AM53 | IAE 1J12526 | 1 | |

| IAE 1J12546 Holding fixture | 0AM53 | IAE 1J12546 | 1 | |

| IAE 1J12547 Hooking puller | 0AM53 | IAE 1J12547 | 1 | |

| IAE 1J12548 Holding fixture | 0AM53 | IAE 1J12548 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

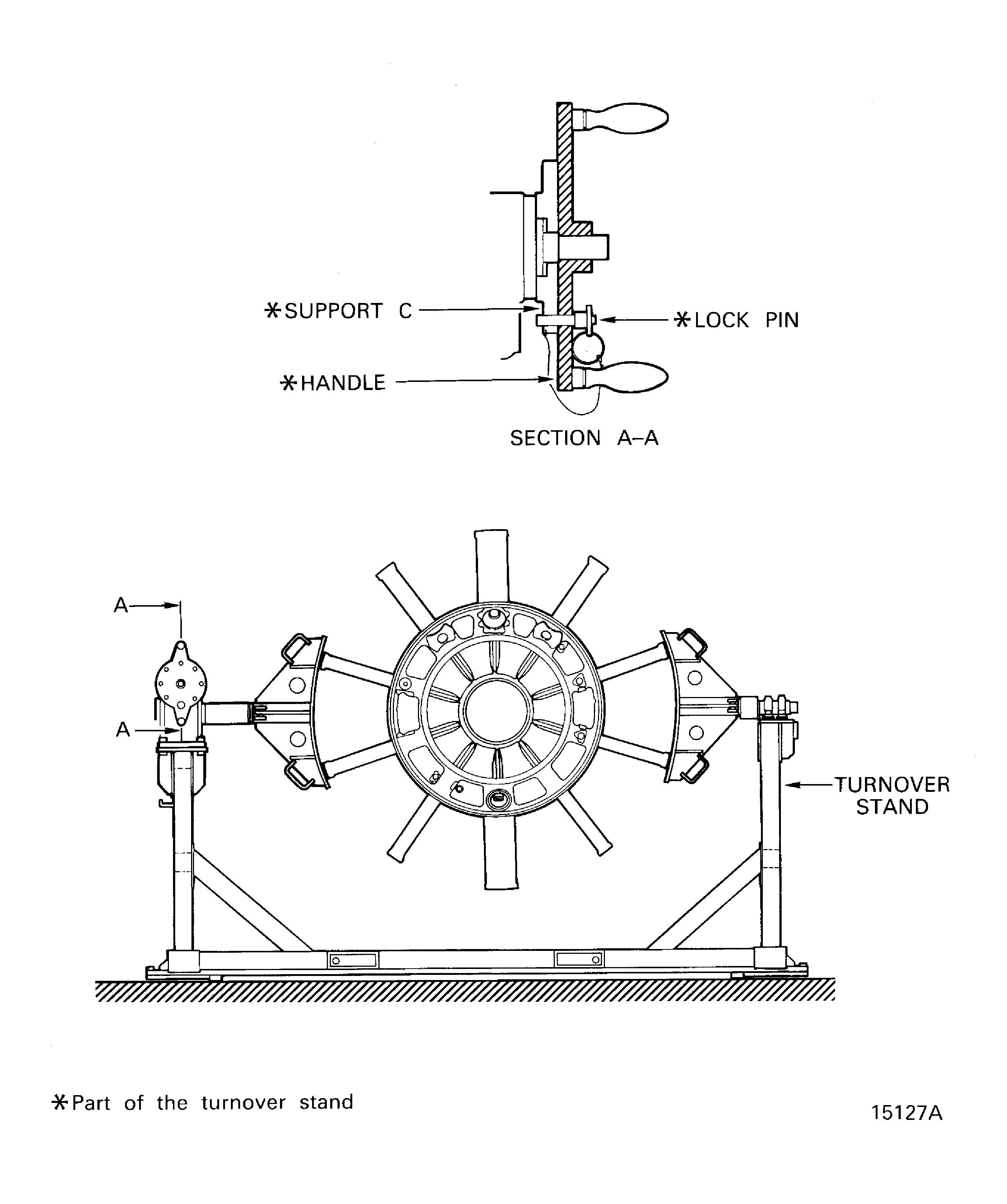

Make sure that the fan frame and fan case assembly is installed horizontally on the turnover stand. Refer to TASK 72-32-00-030-004-C00 (DISASSEMBLY-004, CONFIG-003).

SUBTASK 72-32-00-030-170 Remove the Front Bearing Compartment Rear Air Seal Assembly from the Frame Assembly

Refer to Figure.

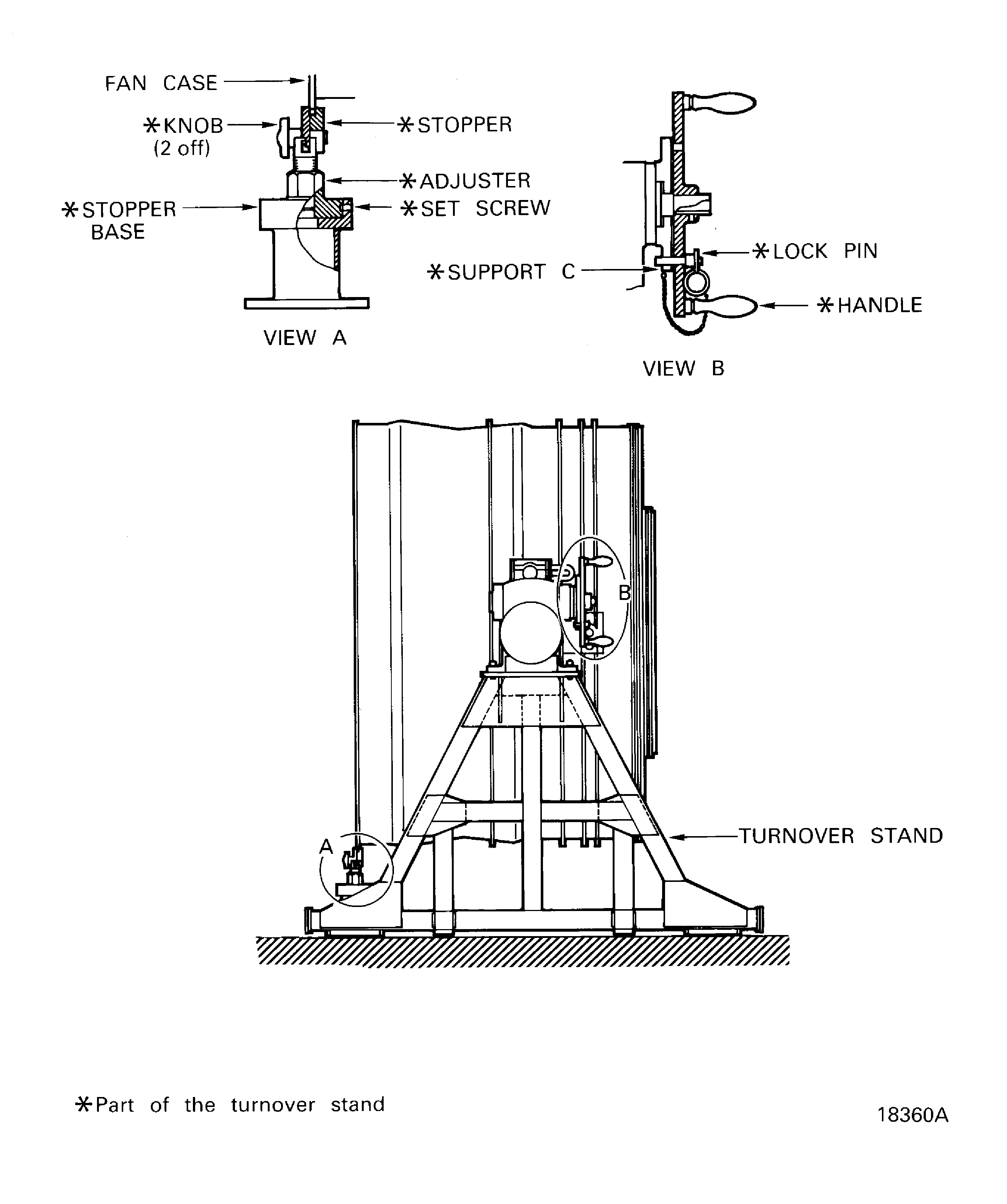

SUBTASK 72-32-00-030-171 Turn the Fan Frame and Fan Case Assembly to the Rear End Up Position

Refer to Figure.

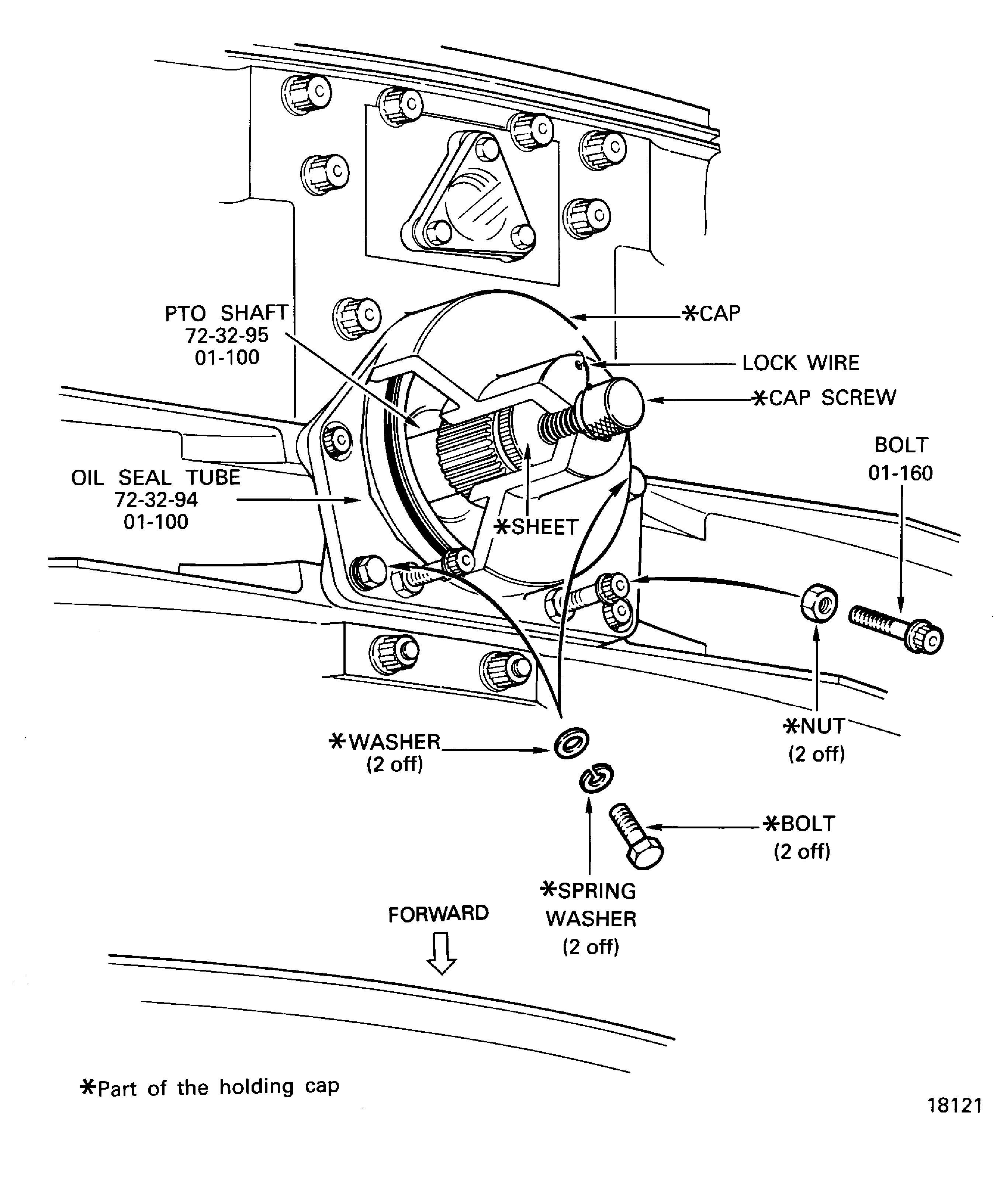

SUBTASK 72-32-00-030-172 Remove the Holding Cap from the Oil Seal Tube in the No. 6 Strut

NOTE

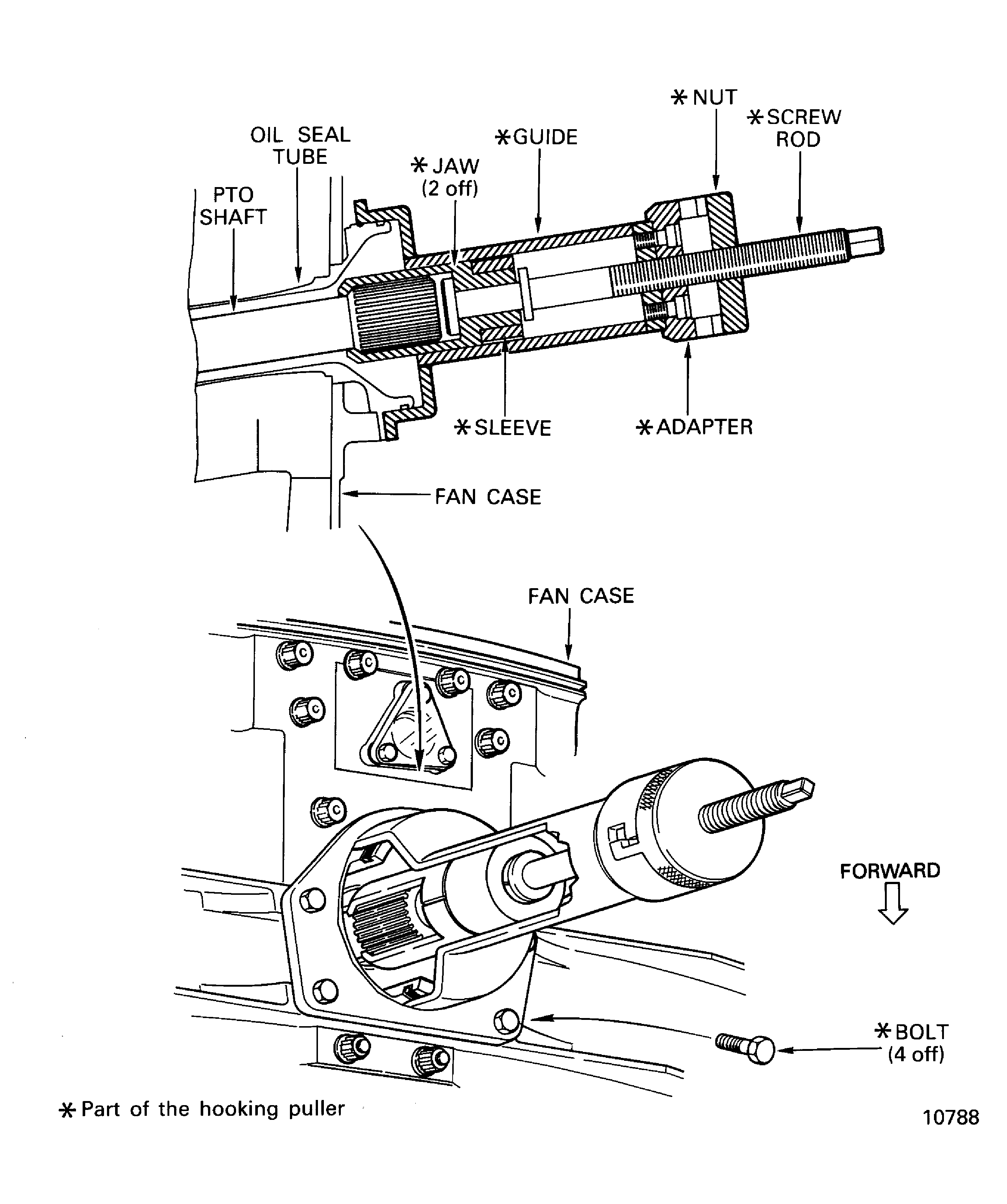

The holding cap is installed on to the oil seal tube in TASK 72-00-60-020-003-001 (REMOVAL-003), TASK 72-00-60-020-003-002 (REMOVAL-004) and TASK 72-32-00-430-011 (ASSEMBLY-011).Install IAE 1J12023 Hooking puller 1 off on to the PTO shaft and the oil seal tube.

SUBTASK 72-32-00-030-173 Remove the PTO Shaft from the Fan Frame Strut

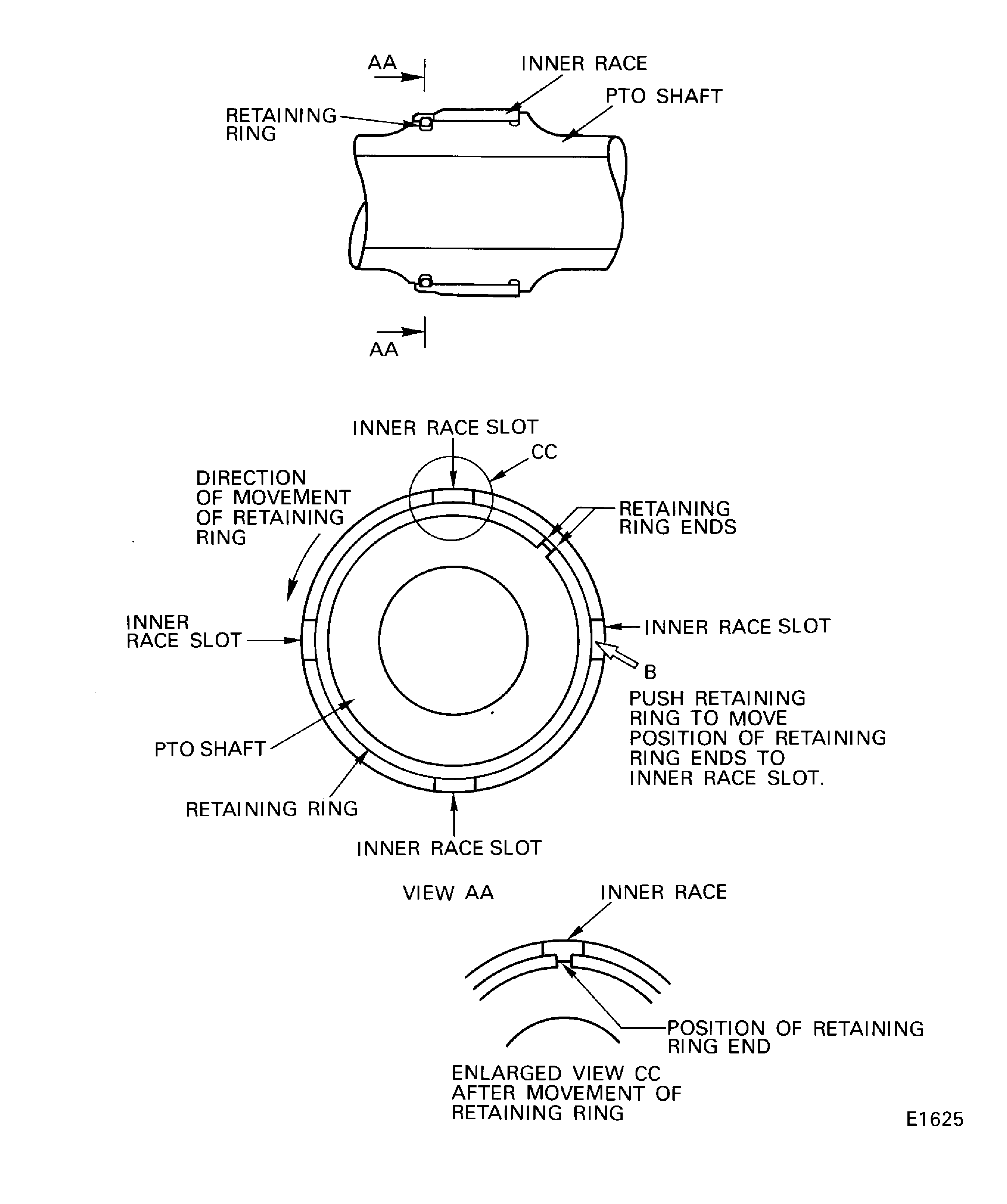

Install the IAE 1J12546 Holding fixture 1 off to the PTO shaft, and put the protrusions of the holding fixture in to the slots of the inner race to press the retaining ring.

Lubricate the bolt (part of the hooking puller) with CoMat 10-077 APPROVED ENGINE OILS.

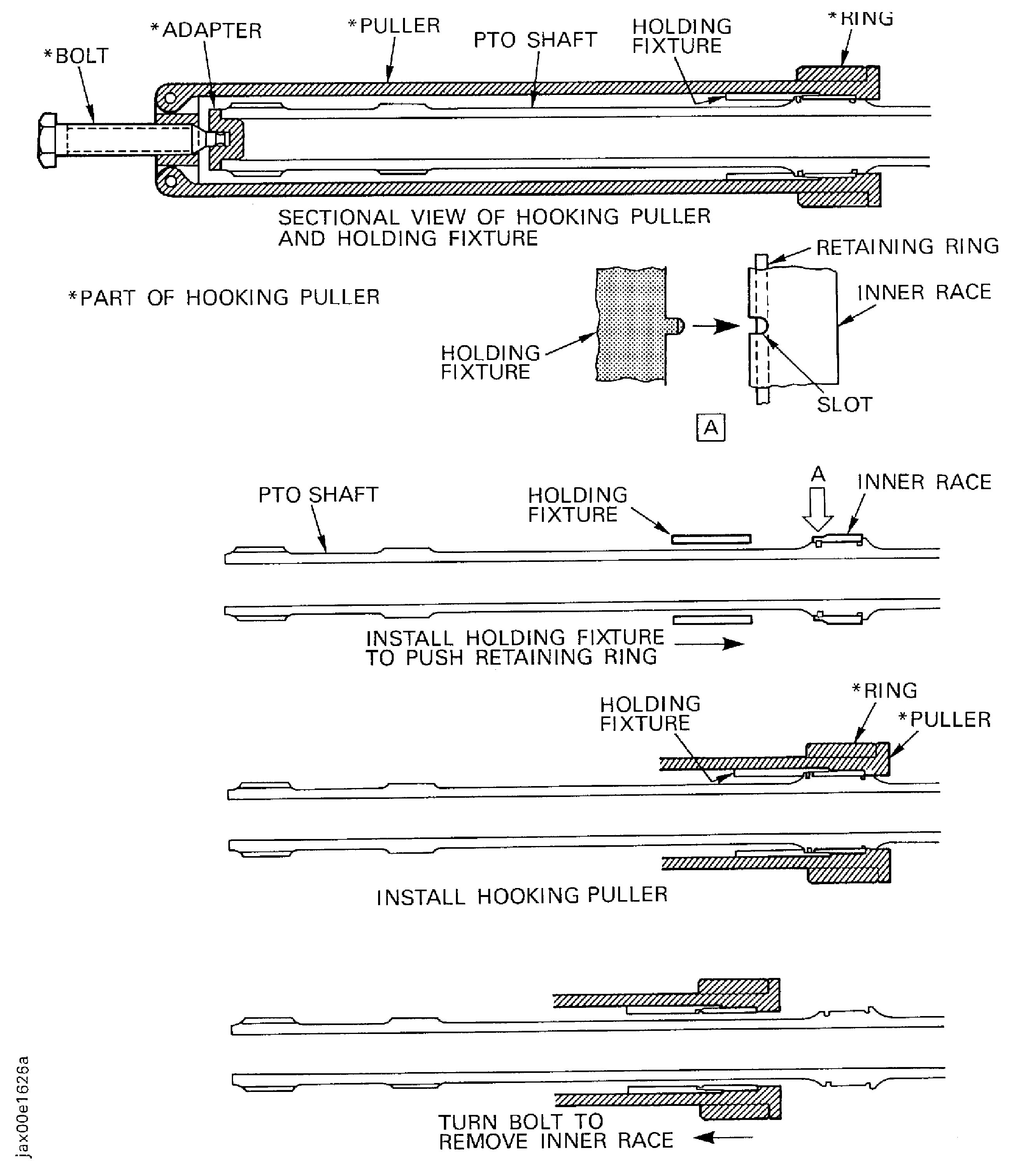

Install IAE 1J12547 Hooking puller 1 off to the PTO shaft and inner race assembly.

SUBTASK 72-32-00-030-207-A00 Remove the Inner Race from the PTO Shaft(Pre SBE 72-0214)

Refer to Figure.

Install the IAE 1J12548 Holding fixture 1 off to the PTO shaft and put the protrusions of the holding fixture in to the slots of the inner race to press the retaining ring.

Lubricate the bolt (part of the hooking puller) with CoMat 10-077 APPROVED ENGINE OILS.

Install the IAE 1J12547 Hooking puller 1 off to the PTO shaft and inner race assembly.

SUBTASK 72-32-00-030-207-B00 Remove the Inner Race from the PTO Shaft (SBE 72-0214)

SBE 72-0214: Provide a new PTO shaft bearing inner race and retaining ring

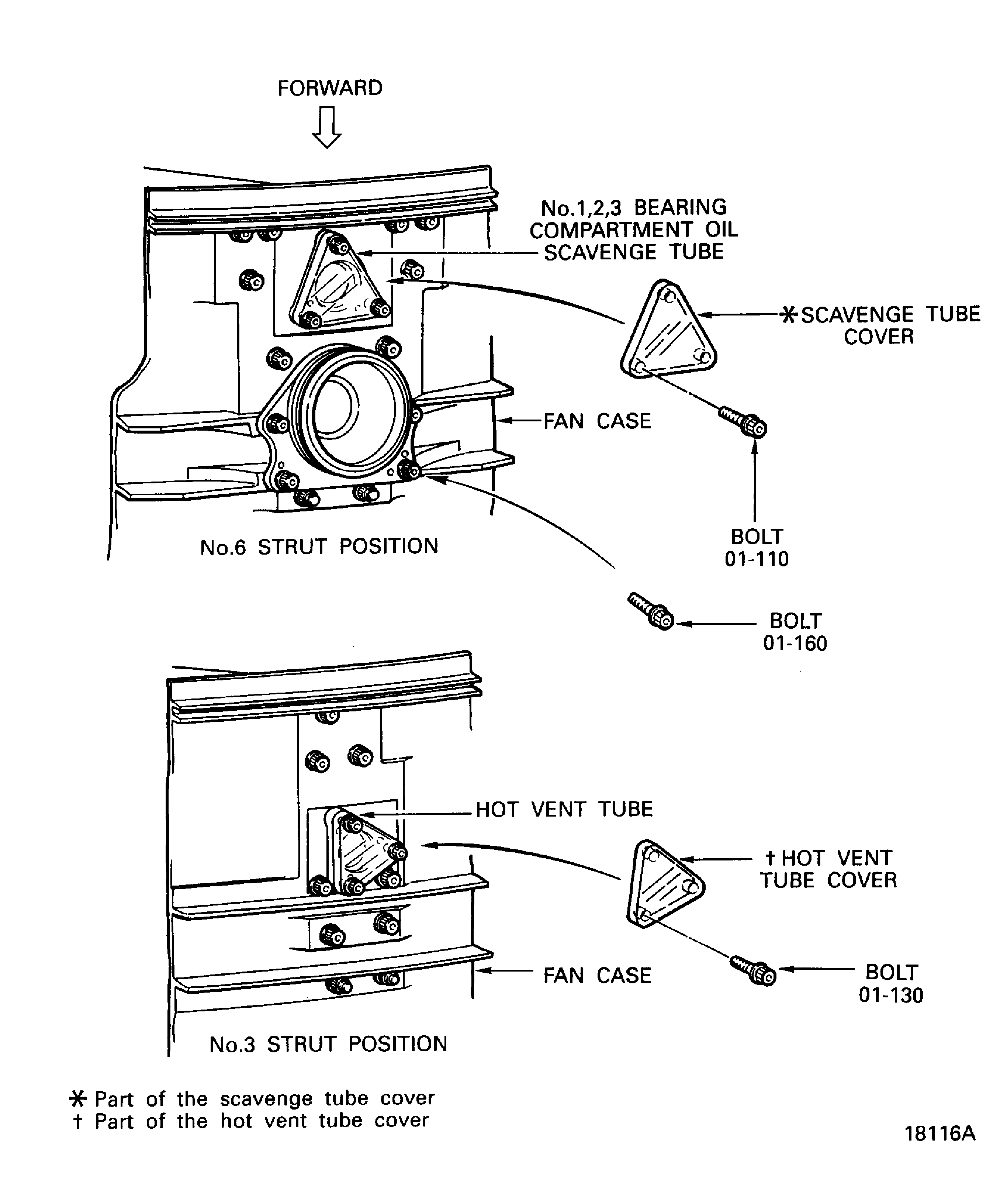

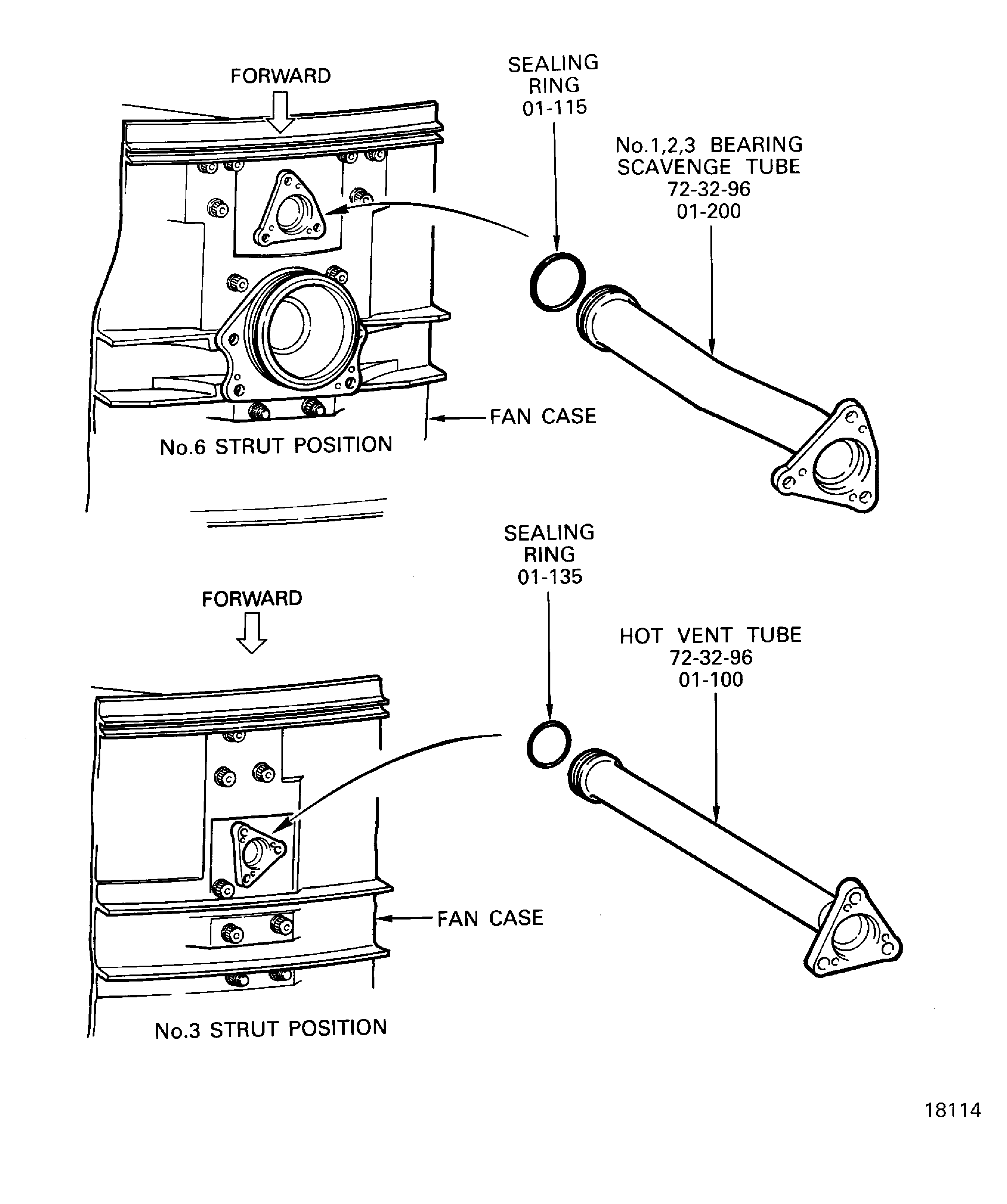

Remove the three bolts which attach the scavenge tube cover and the No. 1, 2, 3 bearing scavenge tube to the fan case, Figure. Remove the scavenge tube cover.

Install the three puller bolts (part of IAE 1J12494 Puller bolt set 1 off) in to the three threaded holes in the scavenge tube flange.

Remove the scavenge tube from the No. 6 strut, Figure.

Remove the three bolts which attach the hot vent tube cover and the hot vent tube to the fan case, Figure. Remove the hot vent tube cover.

Install the three puller bolts (part of IAE 1J12494 Puller bolt set 1 off) in to the three threaded holes in the hot vent tube flange.

Remove the hot vent tube from the No. 3 strut, Figure.

SUBTASK 72-32-00-030-174 Remove the No. 1, 2, 3 Bearing Scavenge Tube and the Hot Vent Tube from the No. 6 and No. 3 Struts

Refer to Figure.

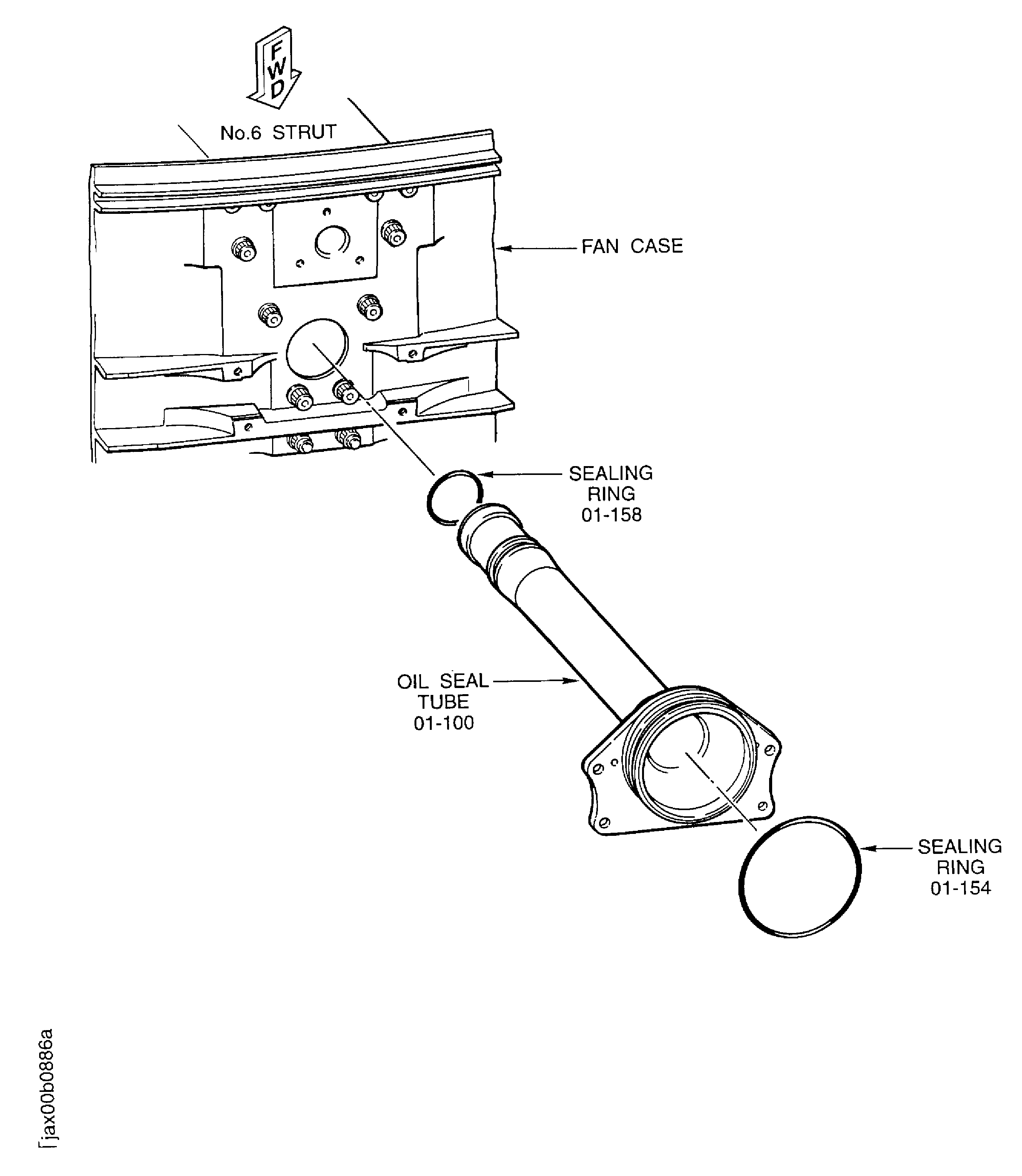

Install the three puller bolts (part of IAE 1J12494 Puller bolt set 1 off) in to the three threaded holes in the oil seal tube flange.

Remove the oil seal tube from the No. 6 strut.

SUBTASK 72-32-00-030-175 Remove the Oil Seal Tube from the No. 6 Strut

Refer to Figure.

Make sure that the fan frame assembly is installed, vertically with the rear end up, on the turnover stand. Refer to TASK 72-32-00-030-013 (DISASSEMBLY-014).

SUBTASK 72-32-00-030-176 Turn the Fan Frame Assembly to the No. 6 Strut Up Position

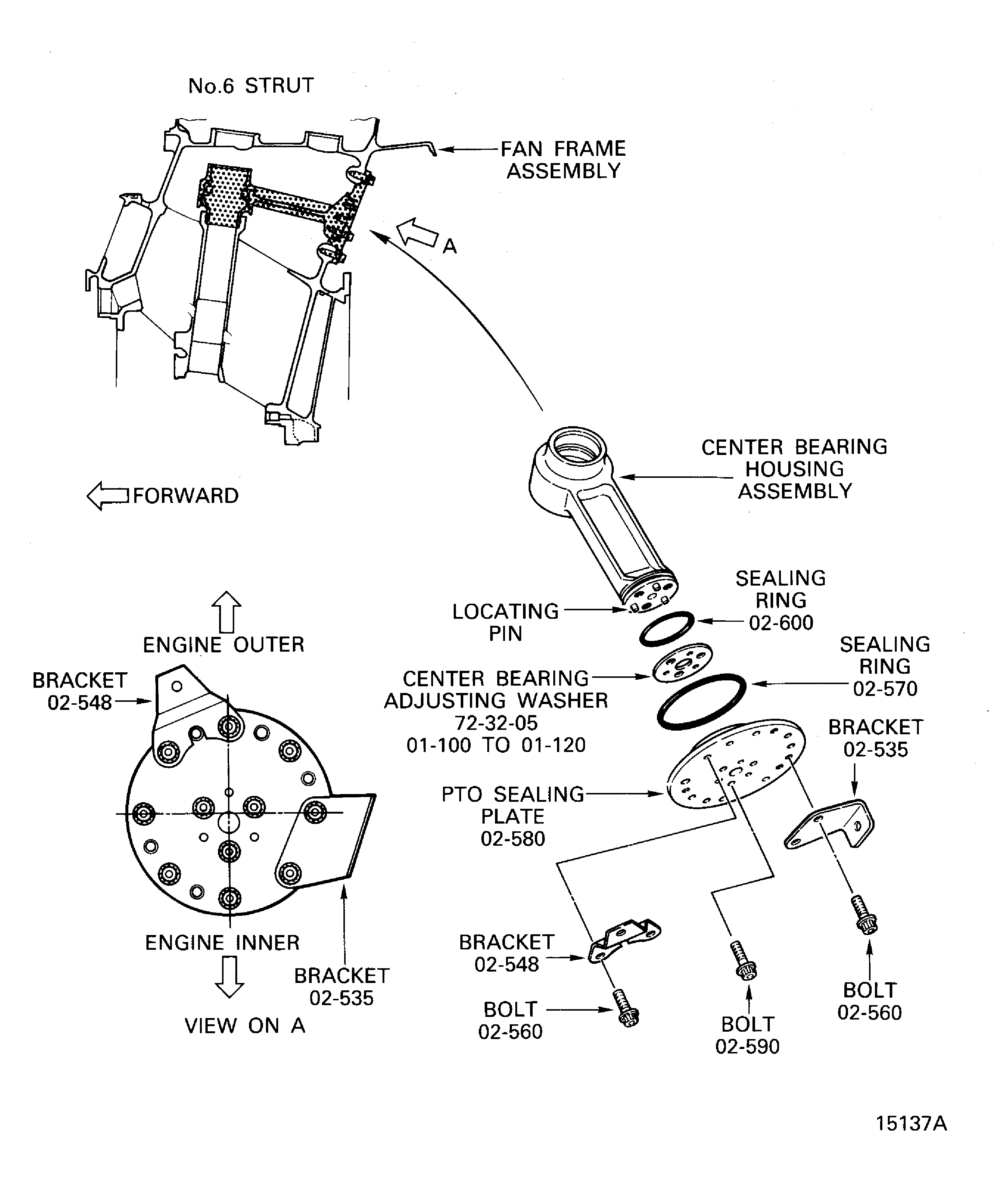

Install the three puller bolts (part of IAE 1J12188 Puller bolt 1 off) in to the three threaded holes in the PTO sealing plate.

Remove the PTO sealing plate from the fan frame assembly.

NOTE

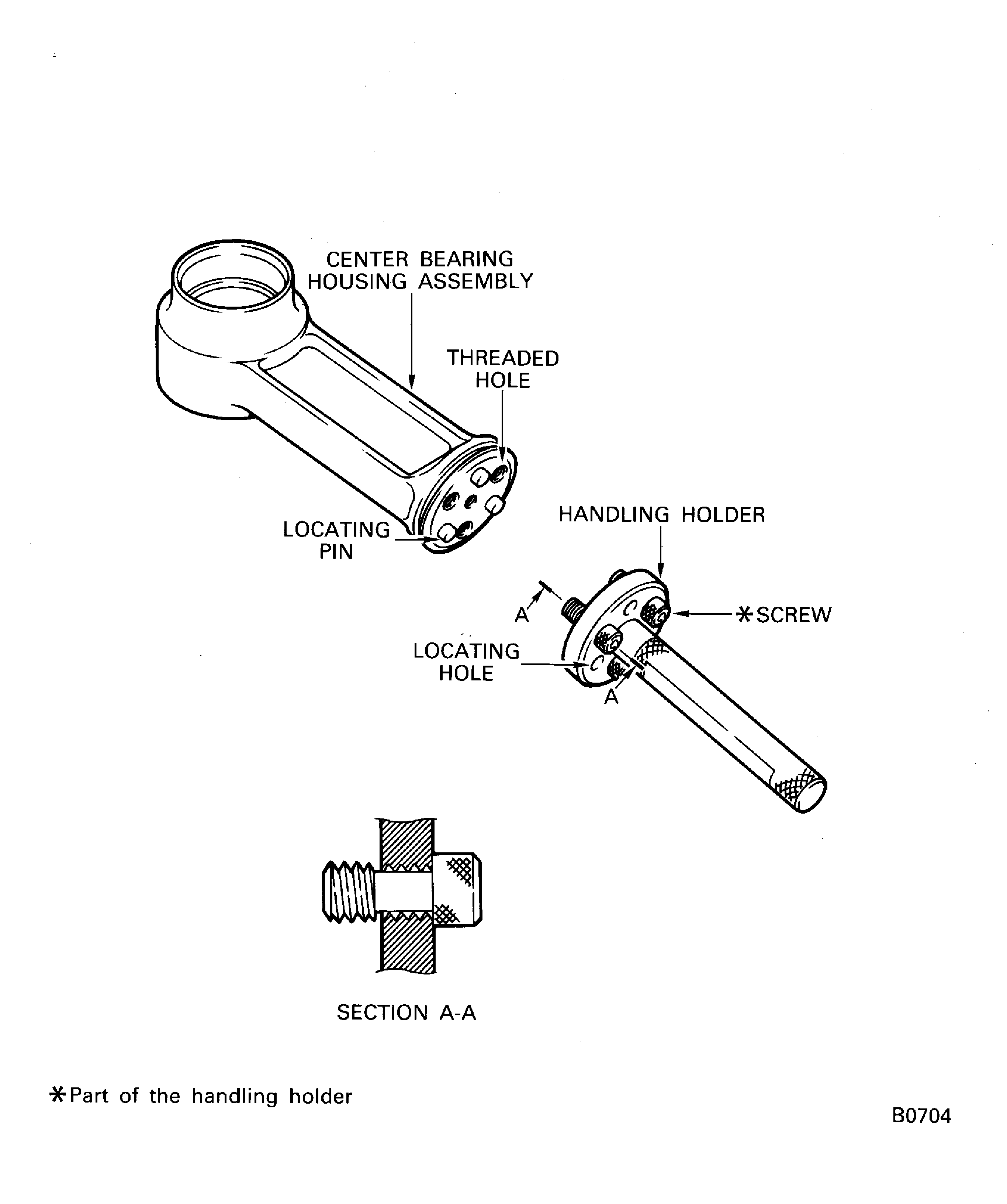

When you turn the screws. Keep the threads of screws released from the threads of handling holder. If the threads of screws are engaged with the threads of housing assembly and handling holder, you can not turn the screws.Attach the handling holder to the center bearing housing assembly and safety with the three screws. Tighten the screws.

Install IAE 1J12327 Handling holder 1 off to the center bearing housing assembly.

SUBTASK 72-32-00-030-177 Remove the Brackets, the PTO Sealing Plate, the Adjusting Washer and the Center Bearing Housing Assembly from the Fan Frame Assembly

Remove the seal carrier from the center bearing housing, Figure.

Install the center bearing housing on to the IAE 1J12432 Base holder 1 off, Figure.

Put IAE 1J12526 Hooking puller 1 off on to a work bench. Turn the nut (part of the hooking puller) clockwise until the holder (part of the hooking puller) fully moves in direction of the knob.

SUBTASK 72-32-00-030-178 Disassemble the Center Bearing Housing Assembly

Refer to Figure.

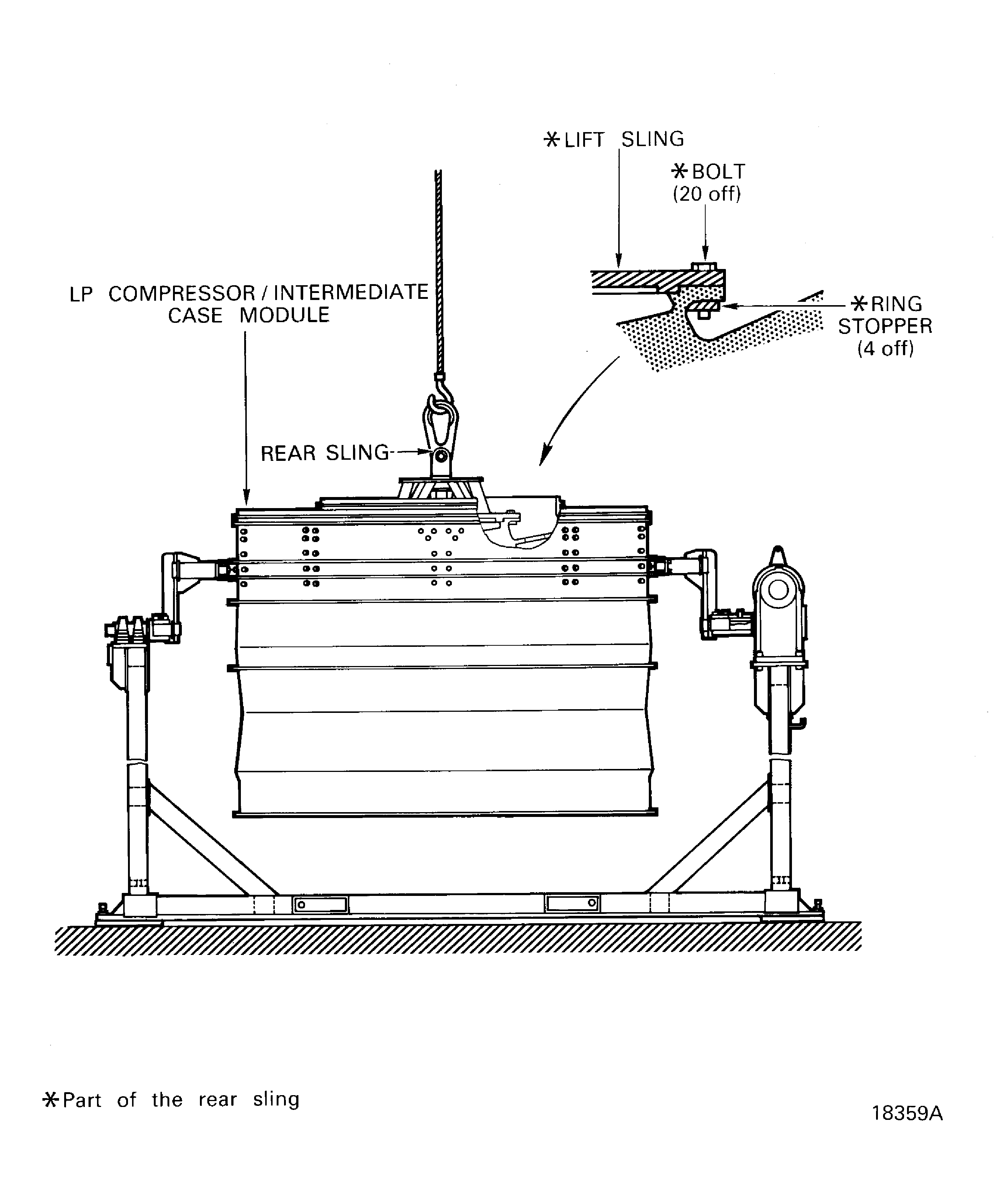

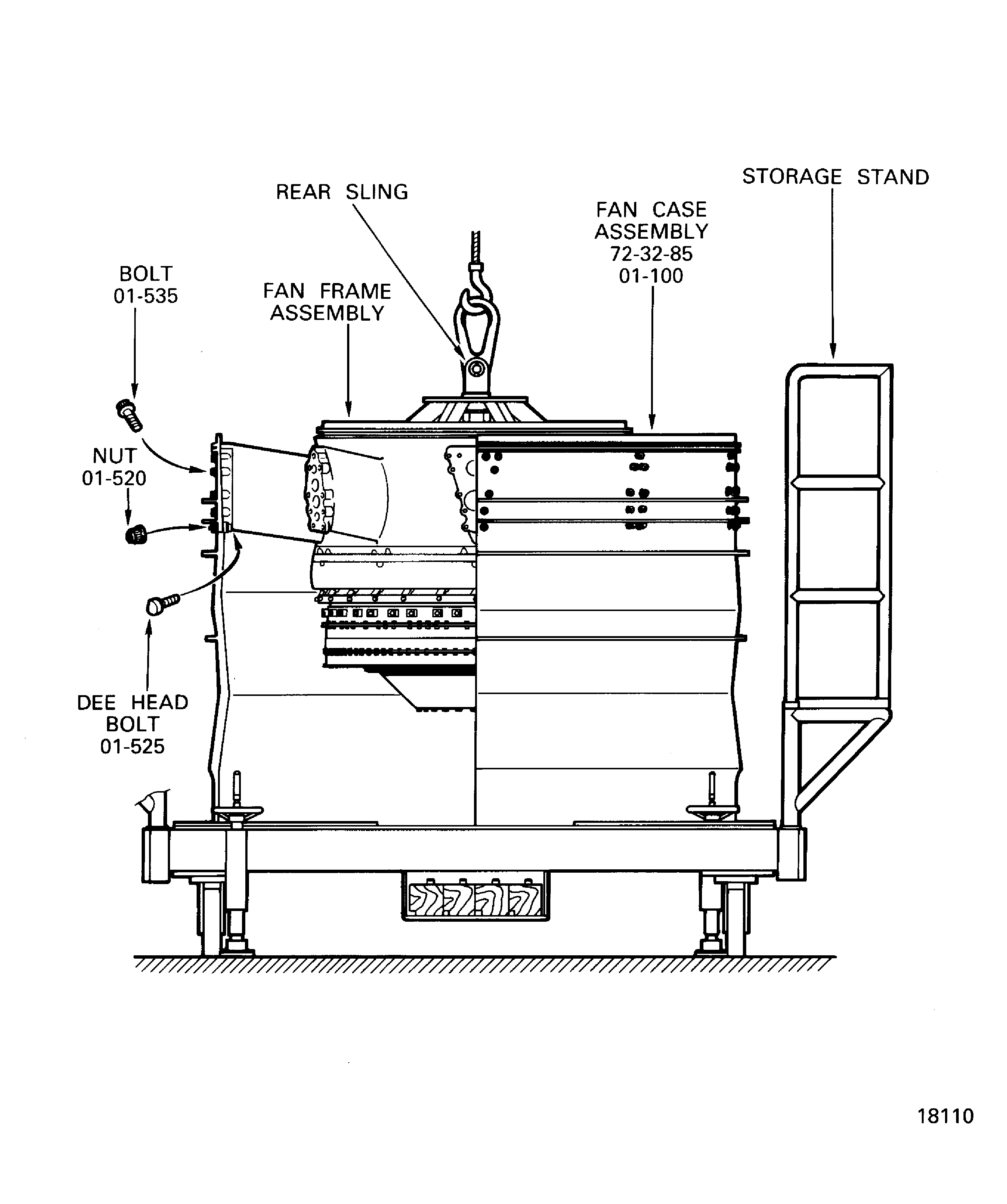

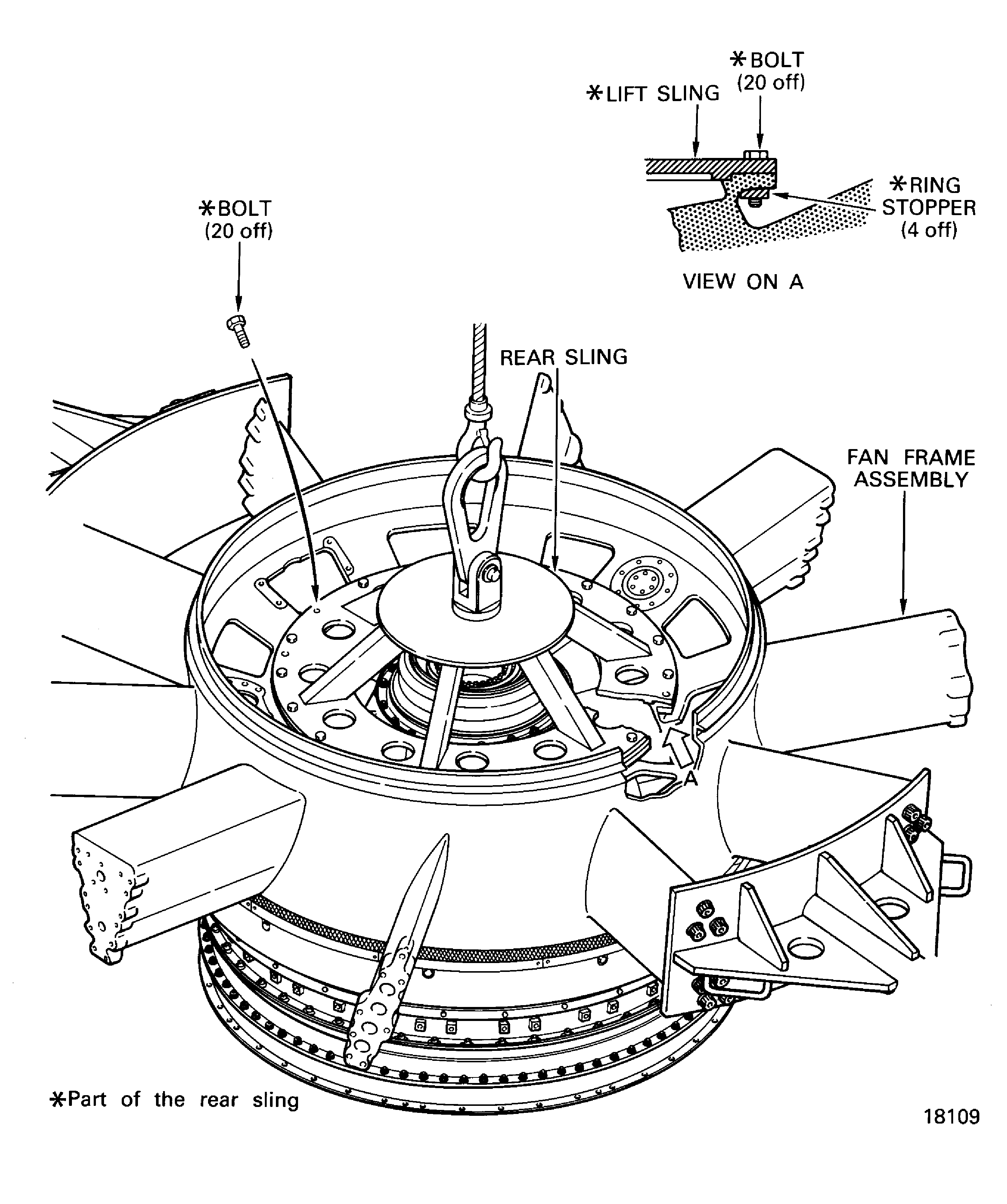

Attach a hoist to IAE 1J12487 Rear sling 1 off.

SUBTASK 72-32-00-030-179 Install the Rear Sling on to the Fan Frame Rear Flange of the Fan Frame and Fan Case Assembly

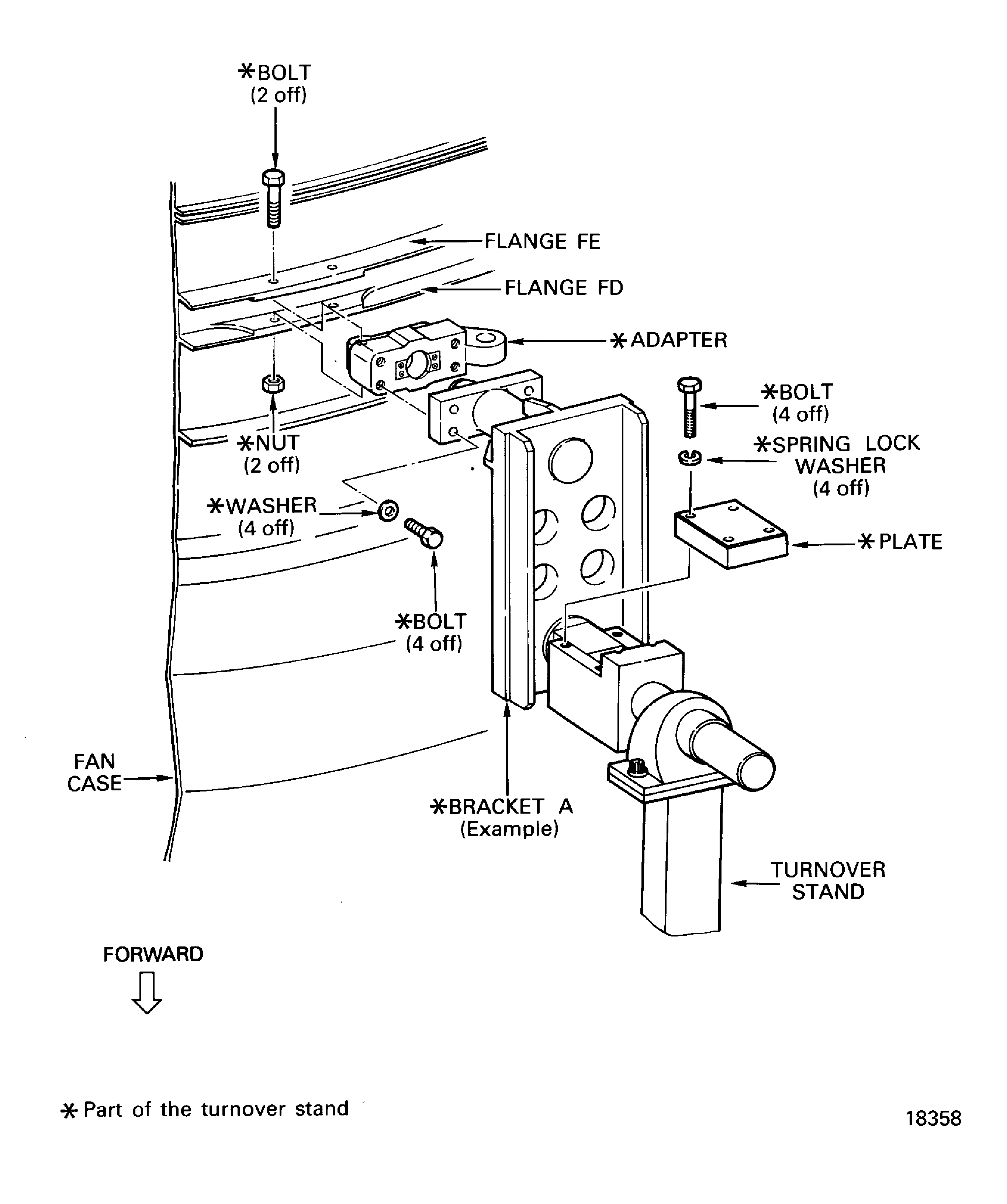

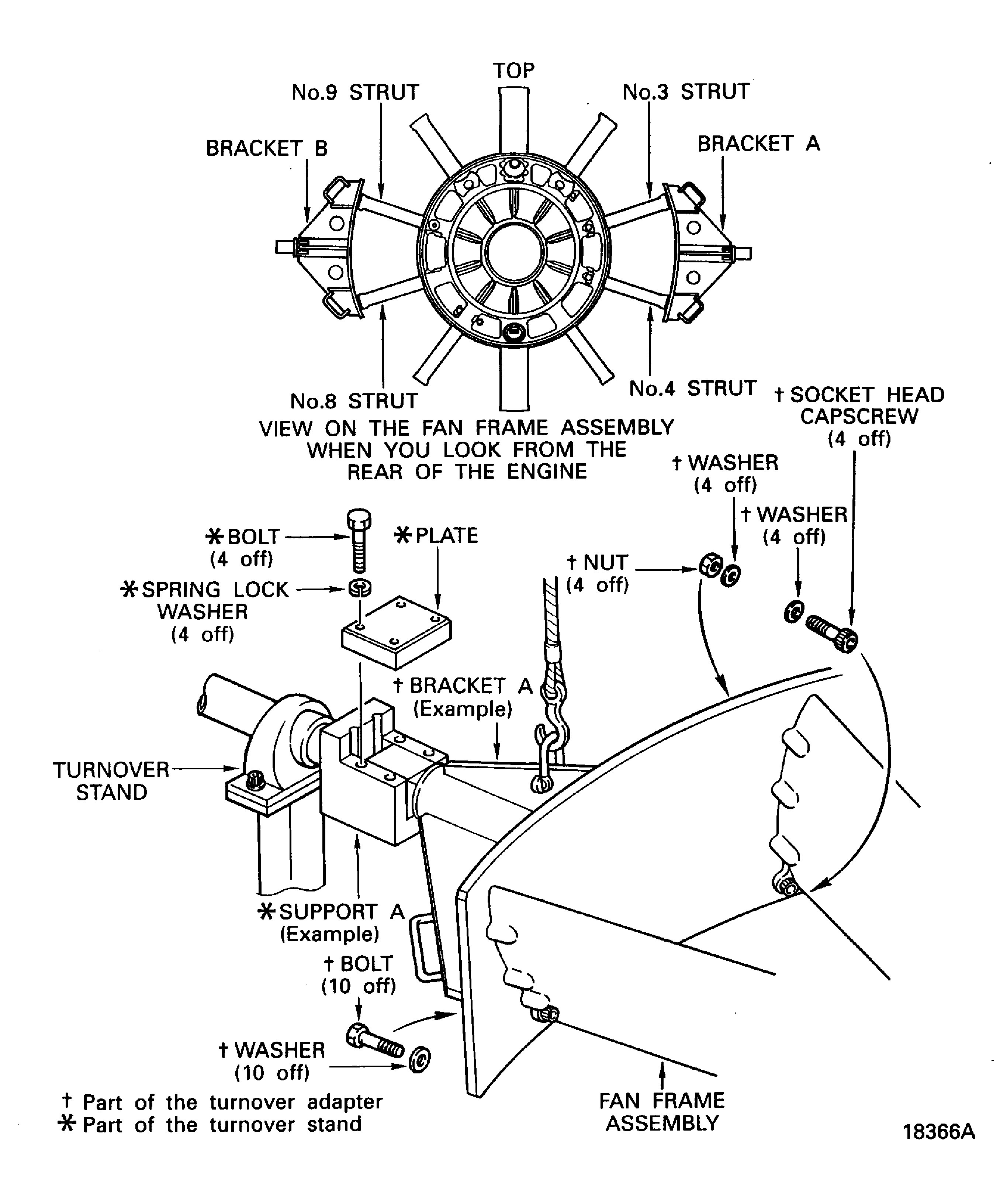

Remove the four bolts and washers which attach each plate to the supports A and B of the turnover stand, Figure.

Move the fan frame and fan case assembly on to IAE 1J12010 Storage stand 1 off, Figure.

SUBTASK 72-32-00-030-180 Move the Fan Frame and Fan Case Assembly from the Turnover Stand to the Storage Stand

Refer to Figure.

SUBTASK 72-32-00-030-181 Remove the Brackets A and B and Two Adapters from the Fan Case

Attach a second hoist to the shackle of the bracket A (part of IAE 1J12317 Turnover adapter 1 off).

Lift the bracket A and engage the square rod end of the bracket with the slot in the support A (part of IAE 1J12311 Turnover stand 1 off).

SUBTASK 72-32-00-030-183 Install the Brackets A and B to the Turnover Stand

SUBTASK 72-32-00-030-182-A00 Remove the Fan Frame Assembly from the Fan Case (Pre SBE 72-0435)

SUBTASK 72-32-00-030-182-B00 Remove the Fan Frame Assembly from the Fan Case (SBE 72-0435)

SBE 72-0435: Introduction of fan case, panel and bracket scalloped for No.4 scavenge tube reroute

Move the fan frame assembly adjacent to the brackets A and B, Figure.

NOTE

Do not tighten the bolts at this step.Align the 10 bolt holes in the bracket A with the 10 threaded holes in the No. 3 and No. 4 struts. Safety with the 10 bolts and washers (part of IAE 1J12317 Turnover adapter 1 off).

NOTE

Make sure that the holes in the support C and one of the eight holes in the handle are aligned. If necessary, turn the handle to make the two holes aligned.Install the lock pin in to position to lock the handle of the turnover stand, Figure.

SUBTASK 72-32-00-030-184 Install the Fan Frame Assembly to the Turnover Stand

Refer to Figure.

WARNING

DO NOT REMOVE THE REAR SLING UNTIL AFTER THE INSTALLATION OF THE LOCK PIN INTO THE HANDLE OF THE TURNOVER STAND. THIS CAN PREVENT THE ROTATION OF THE FAN FRAME AND FAN CASE ASSEMBLY AND INJURY TO PERSONS.Remove the 20 bolts and the four ring stoppers which attach the rear sling to the rear flange of the fan frame assembly.

SUBTASK 72-32-00-030-185 Remove the Rear Sling from the Fan Frame Rear Flange

Refer to Figure.

SUBTASK 72-32-00-030-186 Turn the Fan Frame Assembly to the Front End Up Position

Refer to Figure.

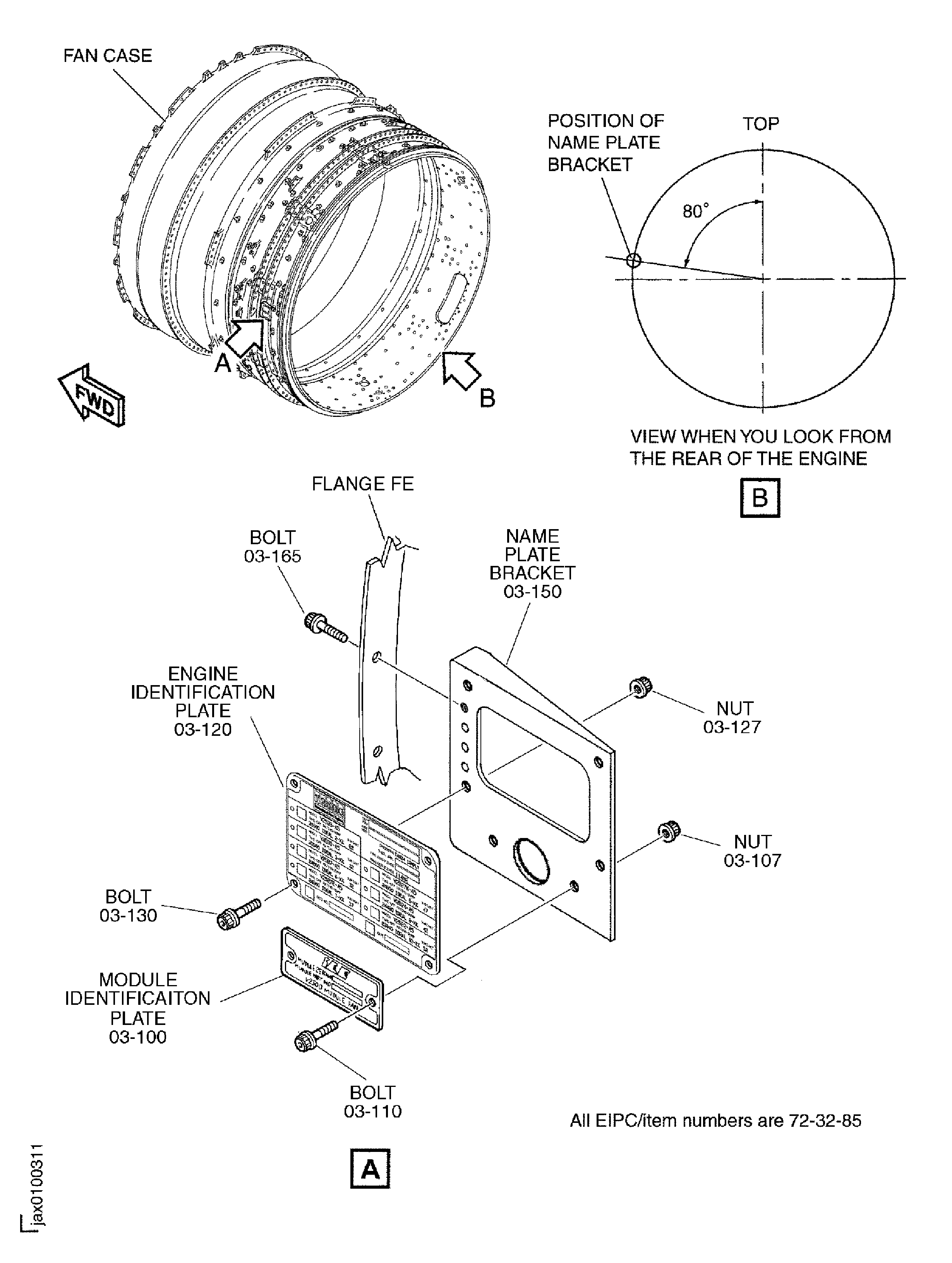

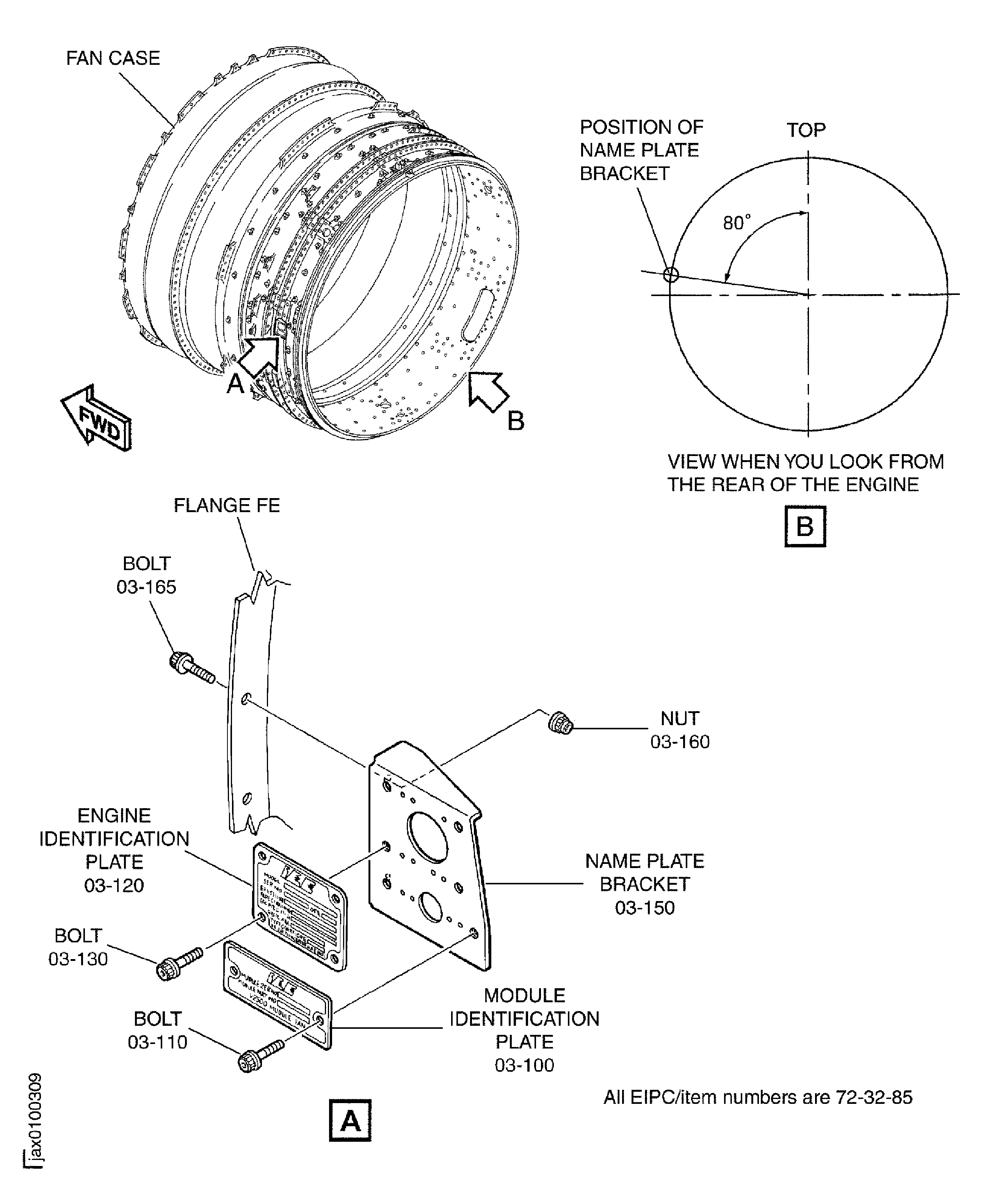

SUBTASK 72-32-00-030-230-A00 Remove the Name Plate Bracket, the Engine Identification Plate and the Module Plate from the Fan Case (Pre SBE 72-0378)

Refer to Figure.

SUBTASK 72-32-00-030-230-B00 Remove the Name Plate Bracket, the Engine Identification Plate and the Module Plate from the Fan Case (SBE 72-0378)

SBE 72-0378: New engine identification plate with designation of all A5 model ratings

Figure: Remove the front bearing compartment rear air seal assembly from the fan frame assembly

Remove the front bearing compartment rear air seal assembly from the fan frame assembly

Figure: Remove the stopper and release the lock pin to turn the fan frame and fan case assembly from horizontal to vertical

Remove the stopper and release the lock pin to turn the fan frame and fan case assembly from horizontal to vertical

Figure: Remove the holding cap from the oil seal tube

Remove the holding cap from the oil seal tube

Figure: Use the hooking puller to remove the PTO shaft

Use the hooking puller to remove the PTO shaft

Figure: Remove the oil seal tube from the No. 6 strut

Remove the oil seal tube from the No. 6 strut

Figure: Pre SBE 72-0214: Adjust the position of the reatining ring end

Pre SBE 72-0214: Adjust the position of the reatining ring end

Figure: Remove the inner race from the PTO shaft

Remove the inner race from the PTO shaft

Figure: Remove the covers from the scavenge tube and the hot vent tube

Remove the covers from the scavenge tube and the hot vent tube

Figure: Remove the scavenge tube and the hot vent tube from the No. 6 and No. 3 struts

Remove the scavenge tube and the hot vent tube from the No. 6 and No. 3 struts

Figure: Install the lock pin in to position to lock the handle of the turnover stand

Install the lock pin in to position to lock the handle of the turnover stand

Figure: Remove the PTO sealing plate, the adjusting washer and the center bearing housing assembly from the No. 6 strut

Remove the PTO sealing plate, the adjusting washer and the center bearing housing assembly from the No. 6 strut

Figure: Attach the handling holder to the center bearing housing assembly

Attach the handling holder to the center bearing housing assembly

Figure: View of the center bearing housing assembly

View of the center bearing housing assembly

Figure: Use the hooking puller to remove the outer roller bearing from the center bearing housing

Use the hooking puller to remove the outer roller bearing from the center bearing housing

Figure: Install the rear sling to the fan frame and fan case assembly

Install the rear sling to the fan frame and fan case assembly

Figure: Remove the fan frame and fan case assembly from the turnover stand

Remove the fan frame and fan case assembly from the turnover stand

Figure: Remove the fan frame assembly from the fan case

Remove the fan frame assembly from the fan case

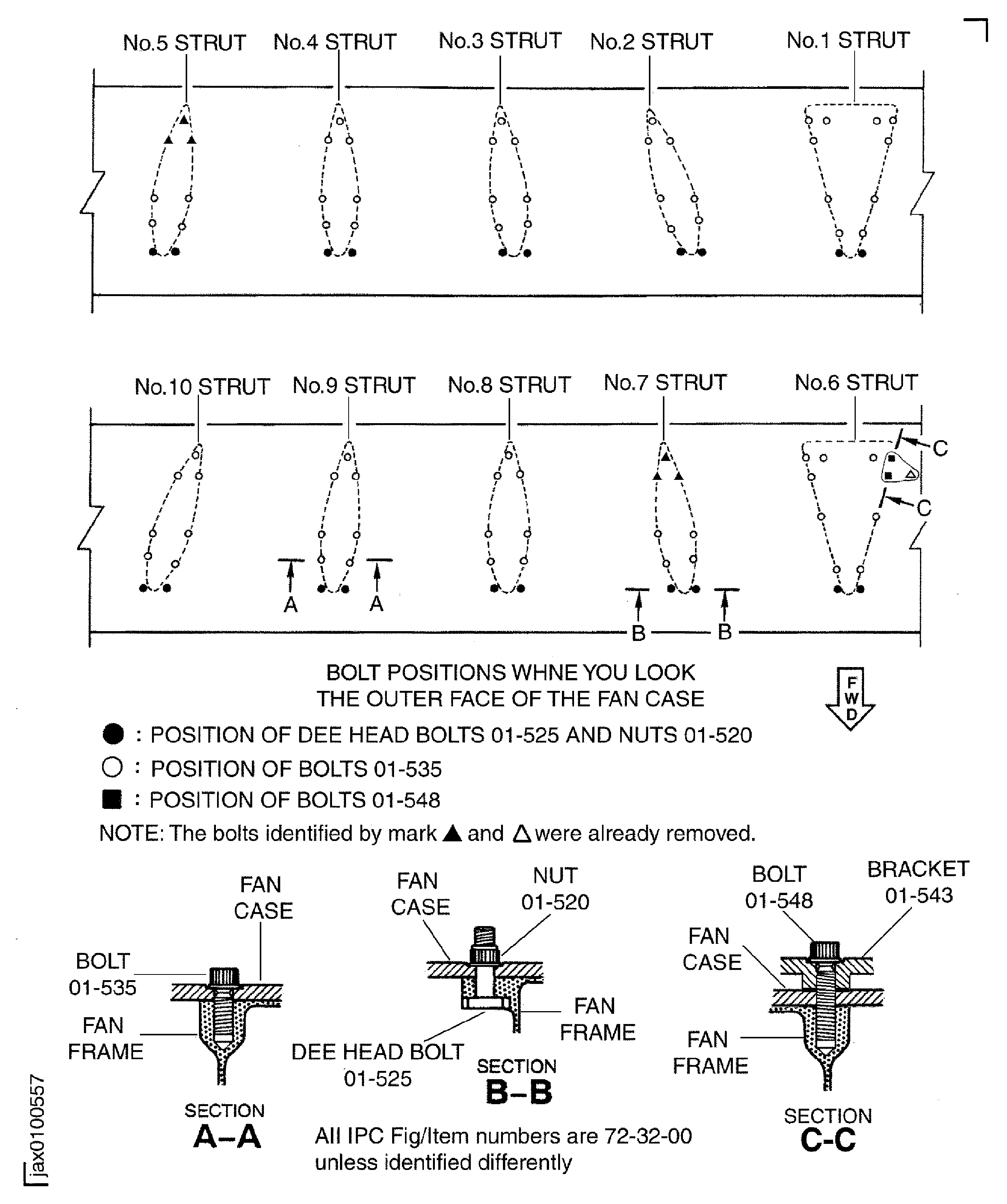

Figure: Pre SBE 72-0435: Position of the bolts to attach the fan frame to the fan case

Sheet 1

Figure: SBE 72-0435: Position of the bolts to attach the fan frame to the fan case

Sheet 2

Figure: Install the fan frame assembly to the turnover stand

Install the fan frame assembly to the turnover stand

Figure: Remove the rear sling from the fan frame assembly

Remove the rear sling from the fan frame assembly

Figure: Pre SBE 72-0378: Remove the name plate bracket, the engine identification plate and the module identification plate from the fan case

Sheet 1

Figure: SBE 72-0378: Remove the name plate bracket, the engine identification plate and the module identification plate from the fan case

Sheet 2