Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-32-70-440-001-B00 LPC Bleed Valve And Actuating System - Assemble, Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures refer to the SPM TASK 70-64-02-640-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in this procedure.

Lubricate all threads and mating faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify and install key washer, refer to the SPM TASK 70-42-03-400-501.

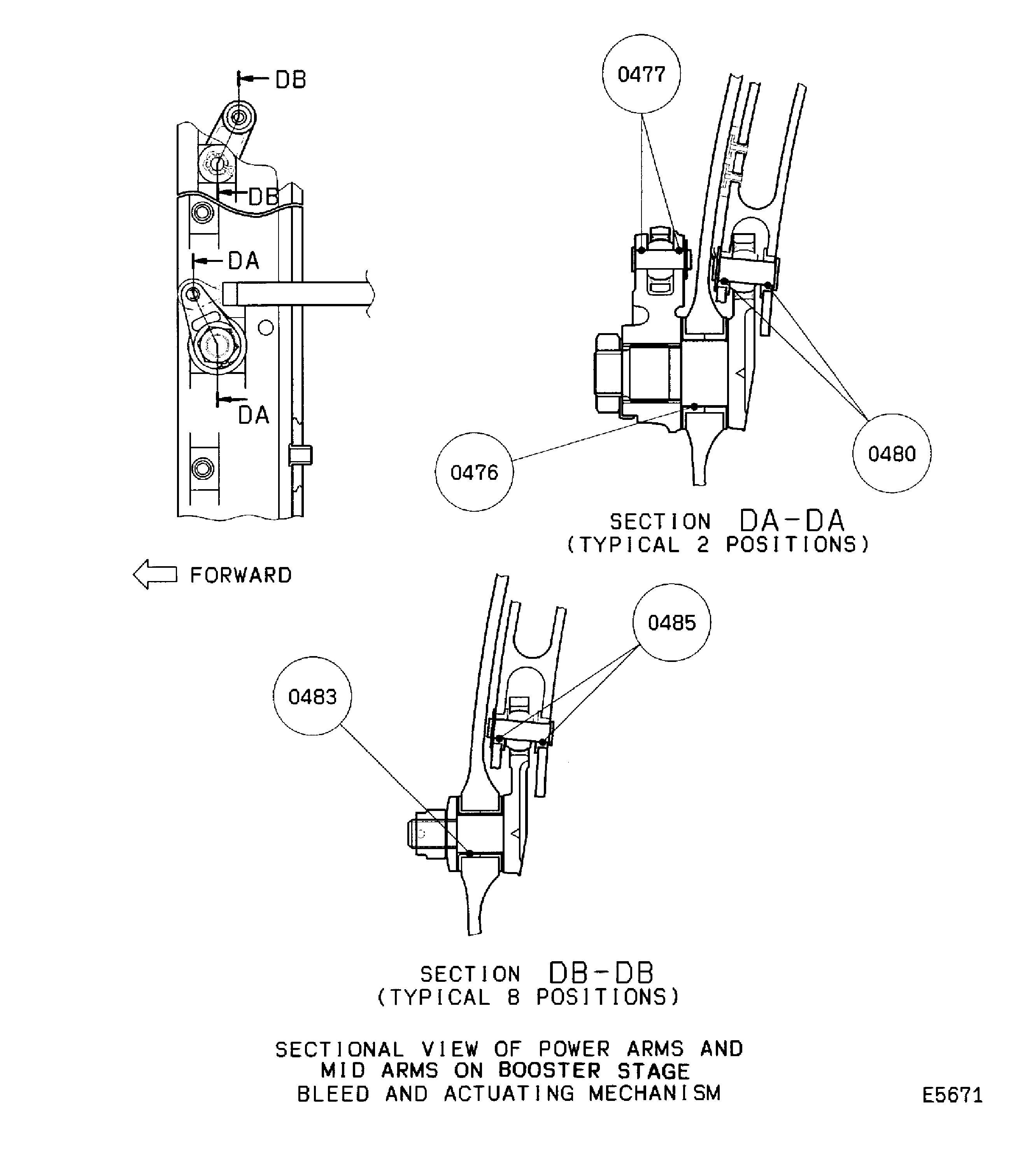

Refer to Figure. or the view of the booster stage valve and actuating mechanism.

The abbreviation Intf shows an interference or tight fit. This causes REJECT IF MORE THAN to become REJECT IF LESS THAN. The abbreviation Clear shows a clearance fit.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1J12543 TBD | 0AM53 | IAE 1J12543 | 1 | |

| IAE 1J12544 TBD | 0AM53 | IAE 1J12544 | 1 | |

| IAE 1J12209 Installation holder | 0AM53 | IAE 1J12209 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) | LOCAL | CoMat 10-108 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Retaining ring | 2 | |||

| Retaining ring | 8 | |||

| Split cotter pin | 8 | |||

| Key washer | 2 |

Safety Requirements

NONEProcedure

Refer to Figure.

Reference dimensions at Location 0476. If required, use the data written as a note in TASK 72-32-71-200-000 (INSPECTION-000).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0476

Sleeve Bearing V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-298), Inside Diameter

Lower Power Arm Assembly V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-455), Stem Outside Diameter

Sleeve Bearing Inside Diameter

0.8765

0.8755

0.0023

Lower Power Arm Outside Diameter

0.8750

0.0005

0.8742

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0476

Sleeve Bearing V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-298), Inside Diameter

Lower Power Arm Assembly V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-455), Stem Outside Diameter

Sleeve Bearing Inside Diameter

22.263

22.238

0.059

Lower Power Arm Outside Diameter

22.225

0.013

22.204

SUBTASK 72-32-70-220-083 Reference Fits and Clearances of the Sleeve Bearing and the Lower Power Arm Assembly at Location 0476

Refer to Figure.

Reference dimensions at location 0483. If required, use the data written as a note in TASK 72-32-71-200-000 (INSPECTION-000).

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0483

Sleeve Bearing V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-109), Inside Diameter

Mid Arm V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-100), Stem Outside Diameter

Sleeve Bearing Inside Diameter

0.5015

0.5005

0.0022

Mid Arm Outside Diameter

0.5000

0.0005

0.4993

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0483

Sleeve Bearing V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-109), Inside Diameter

Mid ArmV2500-A5-72-32-71-02A-941A-D (72-32-71, 02-100), Stem Outside Diameter

Sleeve Bearing Inside Diameter

12.738

12.713

0.056

Mid Arm Outside Diameter

12.700

0.013

12.682

SUBTASK 72-32-70-220-084 Reference Fits and Clearances of the Sleeve Bearing and the Mid Arm at Location 0483

Refer to Figure.

Reference dimensions at location 0480. If required, use the data written as a note in TASK 72-32-72-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0480

Valve Ring Assembly (72-32-72, 02-100), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-240), Outside Diameter

Valve Ring Bore

0.3126

0.3120

0.0012

Pin Outside Diameter

0.3120

0.0000

0.3114

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0480

Valve Ring Assembly (72-32-72, 02-100), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-240), Outside Diameter

Valve Ring Bore

7.940

7.925

0.030

Pin Outside Diameter

7.925

0.000

7.910

SUBTASK 72-32-70-220-085-A00 Reference Fits and Clearances of the Valve Ring Assembly and the Pin at Location 0480 (Pre SBE 72-0279)

Refer to Figure.

Reference dimensions at location 0480. If required, use the data written as a note in TASK 72-32-72-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0480

Valve Ring Assembly (72-32-72, 02-100), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-240), Outside Diameter

Valve Ring Bore

0.3126

0.3120

0.0015

Pin Outside Diameter

0.3117

0.0003

0.3111

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0480

Valve Ring Assembly (72-32-72, 02-100), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-240), Outside Diameter

Valve Ring Bore

7.940

7.925

0.038

Pin Outside Diameter

7.917

0.008

7.902

SUBTASK 72-32-70-220-085-B00 Reference Fits and Clearances of the Valve Ring Assembly and the Pin at Location 0480 (SBE 72-0279 and Pre SBE 72-0704)

Refer to Figure.

Reference dimensions at Location 0480. If required, use the data written as a note in TASK 72-32-72-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0480

Valve Ring Assembly LPC Bleed Valve Ring (72-32-72, 02-100), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-240), Outside Diameter

Valve Ring Bore

0.3107

0.3101

0.0015

Pin Outside Diameter

0.3098

0.0003

0.3092

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0480

Valve Ring Assembly LPC Bleed Valve Ring (72-32-72, 02-100), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-240), Outside Diameter

Valve Ring Bore

7.892

7.877

0.038

Pin Outside Diameter

7.869

0.008

7.854

SUBTASK 72-32-70-220-085-C00 Reference Fits and Clearances of the Valve Ring Assembly and the Pin at Location 0480 (SBE 72-0704)

Refer to Figure.

Reference dimensions at location 0485. If required, use the data written as a note in TASK 72-32-72-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 11. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0485

Valve Ring Assembly (72-32-72, 02-100), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-270), Outside Diameter

Valve Ring Bore

0.2501

0.2495

0.0012

Pin Outside Diameter

0.2495

0.0000

0.2489

Table 12. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0485

Valve Ring Assembly (72-32-72, 02-100), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-270), Outside Diameter

Valve Ring Bore

6.352

6.337

0.030

Pin Outside Diameter

6.337

0.000

6.322

SUBTASK 72-32-70-220-086-A00 Reference Fits and Clearances of the Valve Ring Assembly and the Pin at Location 0485 (Pre SBE 72-0279)

Refer to Figure.

Reference dimensions at location 0485. If required, use the data written as a note in TASK 72-32-72-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 13. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0485

Valve Ring Assembly (72-32-72, 02-100), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-270), Outside Diameter

Valve Ring Bore

0.2501

0.2495

0.0015

Pin Outside Diameter

0.2492

0.0003

0.2486

Table 14. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0485

Valve Ring Assembly (72-32-72, 02-100), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-270), Outside Diameter

Valve Ring Bore

6.352

6.337

0.038

Pin Outside Diameter

6.329

0.008

6.314

SUBTASK 72-32-70-220-086-B00 Reference Fits and Clearances of the Valve Ring Assembly and the Pin at Location 0485 (SBE 72-0279 and Pre SBE 72-0704)

Refer to Figure.

Reference dimensions at Location 0485. If required, use the data written as a note in TASK 72-32-72-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 15. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0485

Valve Ring Assembly LPC Bleed Valve Ring (72-32-72, 02-100), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-270), Outside Diameter

Valve Ring Bore

0.2482

0.2476

0.0015

Pin Outside Diameter

0.2473

0.0003

0.2467

Table 16. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0485

Valve Ring Assembly LPC Bleed Valve Ring (72-32-72, 02-100), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-270), Outside Diameter

Valve Ring Bore

6.304

6.289

0.038

Pin Outside Diameter

6.281

0.008

6.266

SUBTASK 72-32-70-220-086-C00 Reference Fits and Clearances of the Valve Ring Assembly and the Pin at Location 0485 (SBE 72-0704)

Refer to Figure.

Reference dimensions at location 0477. If required, use the data written as a note in TASK 72-32-71-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 17. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0477

Upper Power Arm V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-300), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 01-720), Outside Diameter

Upper Power Arm Bore

0.2506

0.2500

0.0017

Pin Outside Diameter

0.2495

0.0005

0.2489

Table 18. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0477

Upper Power Arm V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-300), Pin Hole Bore

Pin BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 01-720), Outside Diameter

Upper Power Arm Bore

6.365

6.350

0.043

Pin Outside Diameter

6.337

0.013

6.322

SUBTASK 72-32-70-220-087 Reference Fits and Clearances of the Upper Power Arm and the Pin at Location 0477

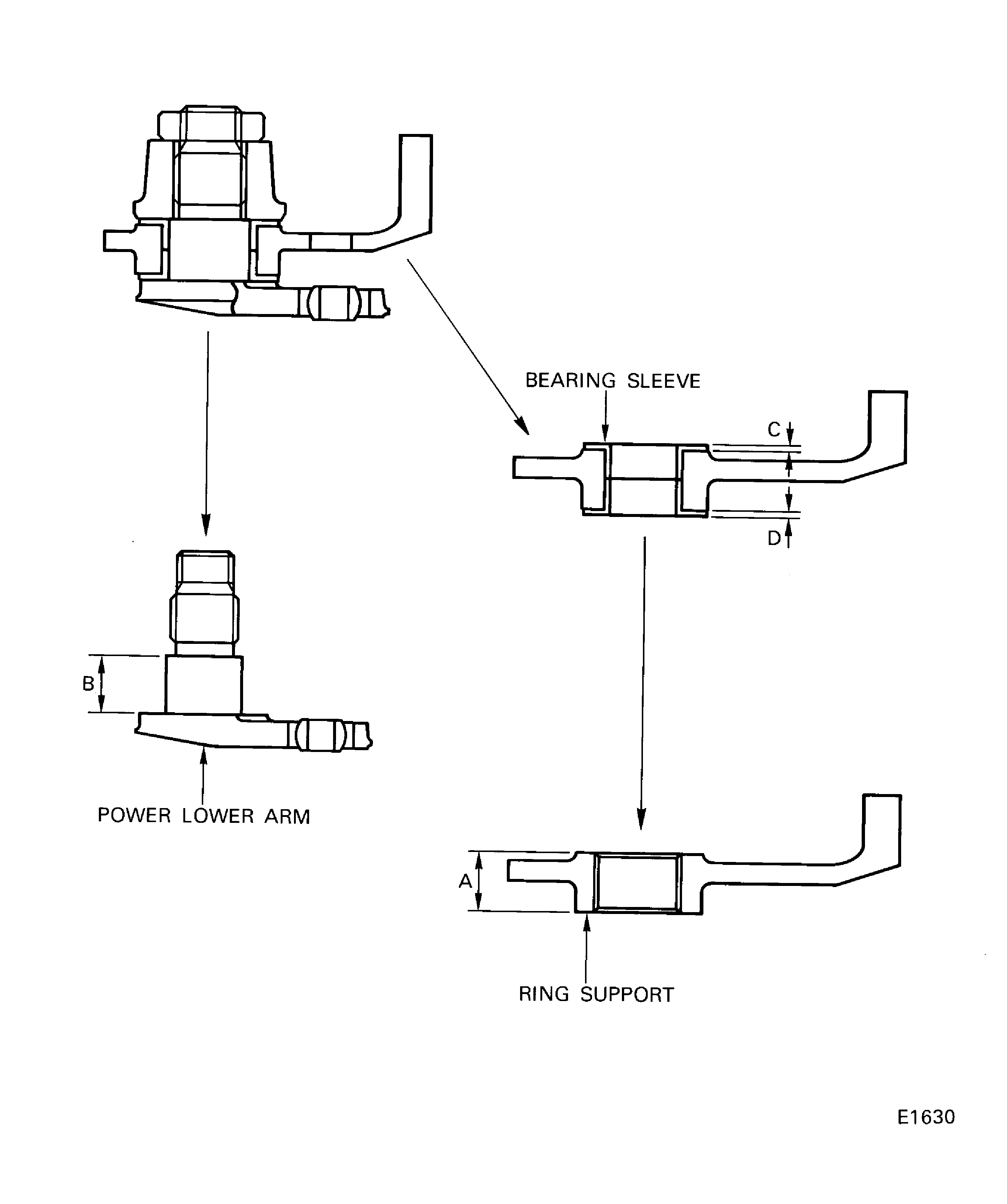

Find the other sleeve V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-279 , V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-281), V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-283), V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-285), V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-287), V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-289), V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-291), V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-293) or V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-295) for dimension C to be used on the table 1. The sum of the dimensions C and D must be nearest the dimension E.

CAUTION

DO NOT PUT TOO MUCH FORCE ON THE TEFLON LINER TO INSTALL THE ARMS ON THE SUPPORT RING. DAMAGE TO THE TEFLON LINER ON THE INSIDE OF THE BEARING SLEEVES CAN OCCUR.Install the power lower arm V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-455) and the power upper arm V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-300) on to the support ring V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-600).

Install V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-330) the washer and the nut V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-320). Hold the power lower arm with the IAE 1J12543 TBD 1 off and torque the nut to 826 lbfin to 914 lbfin (94.41 Nm to 103.24 Nm). Do not bend the keys of the washer.

If the friction torque is between 7 lbfin and 35 lbfin (0.8 Nm and 4 Nm), do Step.

SUBTASK 72-32-70-440-057 Install the Power Lower Arms (72-32-71, 02-455) and the Power Upper Arms (72-32-71, 02-300) on to the Support Ring (72-32-71, 02-600)

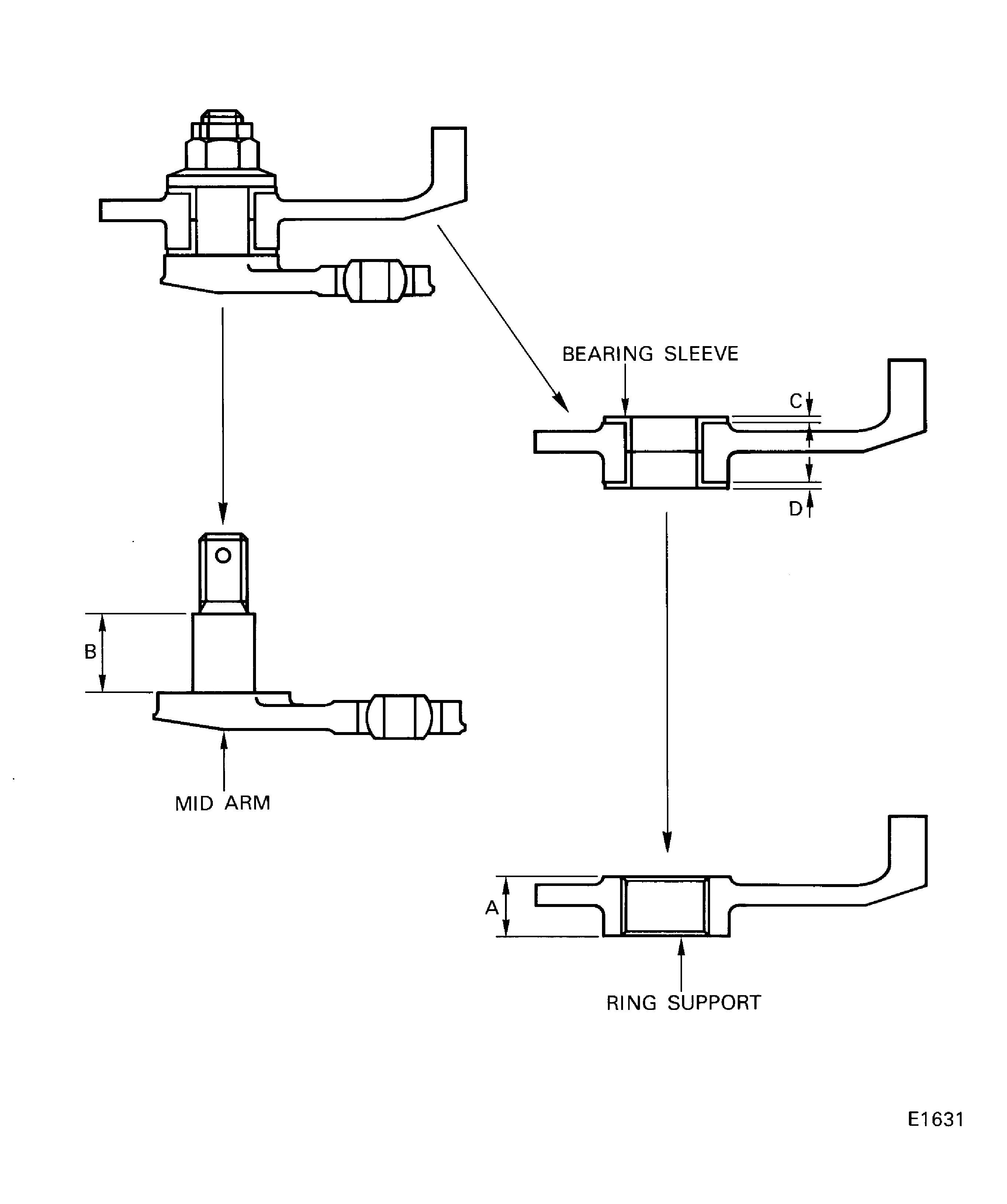

Find the other sleeve V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-089) , V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-091), V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-093), V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-095), V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-097), V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-099), V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-101), V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-103) and V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-105) for dimension C to be used on the table 2. The sum of the dimensions C and D must be nearest to the dimension E.

CAUTION

DO NOT PUT TOO MUCH FORCE ON THE TEFLON LINER TO INSTALL THE ARMS ON THE SUPPORT RING. DAMAGE TO THE TEFLON LINER ON THE INSIDE OF THE BEARING SLEEVES CAN OCCUR.Install the mid arm V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-100) on to the support ring V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-600).

Install the washer V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-120) and the castellated nut V2500-A5-72-32-71-02A-941A-D (72-32-71, 02-115). Hold the mid arms with IAE 1J12544 TBD 1 off and torque the nut to 154 lbfin to 286 lbfin (17.35 Nm to 32.35 Nm).

If the friction torque is between 3.1 lbfin and 16 lbfin (0.35 Nm and 1.8 Nm), do Step.

SUBTASK 72-32-70-440-058 Install the Mid Arms (72-32-71, 02-100) on to the Support Ring (72-32-71, 02-600)

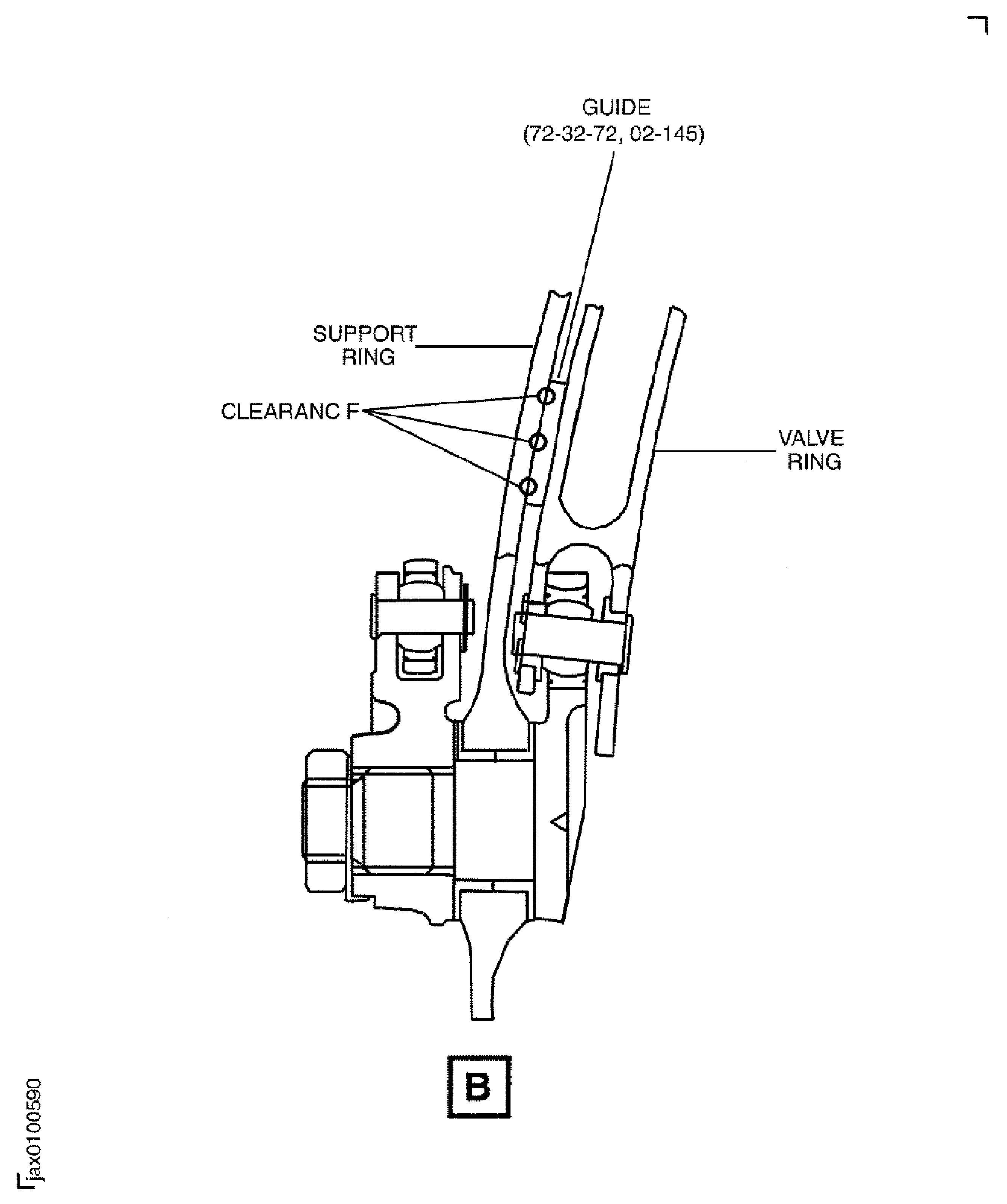

Refer to Figure.

Apply CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) to the two pins (02-240) with a brush or a non aerosol pump type spray bottle. Connect the valve ring to the power lower arms with the pins. Install new (02-220) retaining ring 2 off on the pins with IAE 1J12209 Installation holder 1 off.

Apply CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) to the eight pins (02-270) with a brush or a non aerosol pump type spray bottle. Connect the valve ring to the mid arms with the pins. Install new (02-275) retaining ring 8 off on the pins with the installation holder.

SUBTASK 72-32-70-440-059 Install the Valve Ring (72-32-72, 02-100) on to the Support Ring

Refer to Figure.

SUBTASK 72-32-70-440-060 Do an Interference Check between the Arms and the Valve Ring

WARNING

DO NOT BREATHE GAS FROM TEFLON BASED LUBRICANT. PUT A PROTECTION ON YOUR MOUTH. THE GAS CAN IRRITATE YOU.

CAUTION

MAKE SURE YOU SHAKE THE LUBRICANT NON AEROSOL PUMP TYPE SPRAY BOTTLE WELL BEFORE USE.Inject CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) into the space D around the two pins BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-240) with a non aerosol pump type spray bottle to fill overflowingly.

Inject CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) into the space D around the eight pins BOOSTER STAGE BLEED VALVE ACTUATING MECHANISM (72-32-70, 02-270) with a non aerosol pump type spray bottle to fill overflowingly.

Inject CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) into the clearance F around the 20 guides V2500-A5-72-32-72-02A-941A-D (72-32-72, 02-145) with a non aerosol pump type spray bottle to fill overflowingly.

SUBTASK 72-32-70-440-062 Lubricate the LPC Bleed Valve Mechanism

Figure: Install the Power Arms on to the Ring Support

Install the Power Arms on to the Ring Support

Figure: Install the Mid Arm on to the Ring Support

Install the Mid Arm on to the Ring Support

Figure: Bearing Sleeves Flange Thickness

Bearing Sleeves Flange Thickness

Figure: Install the Mid Arms, Power Upper Arms and Power Lower Arms on to the Support Ring

Install the Mid Arms, Power Upper Arms and Power Lower Arms on to the Support Ring

Figure: Install the Valve Ring on to the Support Ring

Install the Valve Ring on to the Support Ring

Figure: Make Sure the Arms do not Touch the Valve Ring

Make Sure the Arms do not Touch the Valve Ring

Figure: Lubricate the LPC Bleed Valve Mechanism

Sheet 1

Figure: Lubricate the LPC Bleed Valve Mechanism

Sheet 2

Figure: Lubricate the LPC Bleed Valve Mechanism

Sheet 3

Figure: The Power Arms and Mid Arms Assembly - Fits and Clearances

The Power Arms and Mid Arms Assembly - Fits and Clearances