Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

Post SBE 72-0560 (SELECTONE RETROFIT AND PRODUCTION STANDARD)

Common Information

TASK 72-41-00-440-003-C00 HPC Assembly - Replace HPC Stage 3, 4, 5 And 6 Blades - (HPC Surgical Strike Procedure), Special Procedure-003 - SBE 72-0560 (SelectOne Retrofit And Production Standard)

General

This TASK gives the procedure to replace the HP compressor stage 3, 4, 5 and 6 blades as part of the Surgical Strike workscope for engines, which have SBE 72-0560 (SelectOne Retrofit and production Standard) incorporated.

This TASK details the replacement of rotor blades by matching the residual out of balance of the replacement blades with that of the existing blades.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item numbers.

Overhaul processes referred to in the procedure by the TASK/SUBTASK number are in SPM.

For standard torque data and procedure refer to SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is identified with the symbol * after the torque value.

Special assembly tolerances are included in this procedure.

Lubricate all threads and mating faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

All the curvic teeth and mating faces must be cleaned with CoMat 01-001 SOLVENT, DELETED or CoMat 01-002 SOLVENT, DELETED. before assembly. Refer to SPM TASK 70-11-01-300-503. They must also be dry assembled unless told differently in the procedure.

All of the temporary marks made in this procedure must be removed after completion of this task.

The minimum necessary equipment and requirements.

The recommended method of achieving acceptable rotor blade tip grinding using a dummy HPC rotor.

The normal overhaul Engine Manual limits apply to the tip grinding dimensions. It is necessary to make an inspection record of the final assembly tip dimensions and clearances achieved during this procedure.

Replacement blades can be tip ground in the dummy rotor before the pattern of unbalance procedure is done for the blade stage needing replacement.

The recommended type weighing machine for blade weight measurement.

The weighing machine used in this procedure must be capable of a minimum weighing accuracy of between 0.0018 oz to 0.0053 oz (0.05 g to 0.15 g)

The recommended method to balance pattern a set of rotor blades.

The blade distribution computer program VX45 or alternative method IAE 1R19842 Blade distribution computer program X45 must be used. The program will be able to match (within a tolerance) the residual out of balance left by the removal of an existing blade set with the new set.

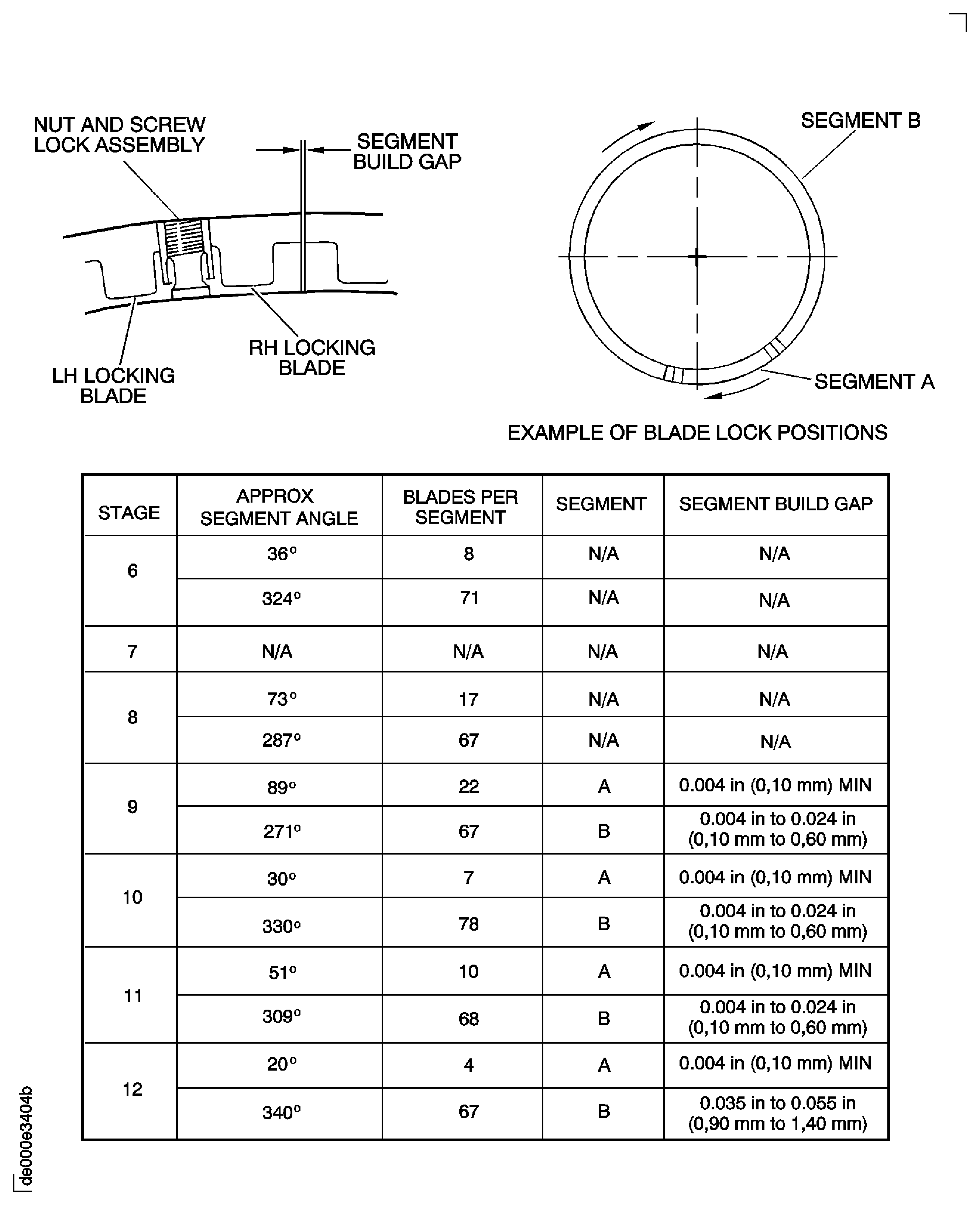

The program will also account for fixed blade positions, such as, the locking blades and the segments between the locking blades. An example of this is seen during the platform gap setting of the stage 6 blades.

NOTE

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Weighing machine | LOCAL | |||

| Dummy stage | LOCAL | 3 to 8 HP compressor | ||

| Dummy retaining plates | LOCAL | stages 3, 4 and 5 | ||

| Dummy lock plates | LOCAL | stages 3, 4 and 5 | ||

| Dummy set, nut and screw lock assembly | LOCAL | stage 6 (jacking screw and locknut assembly) | ||

| Moment weighing machine | LOCAL | with V2500 stage 3 blade moment weight fixtures | ||

| WM00 (80MM INTERFACE) | LOCAL | SCHENCK WM0 | ||

| WM00 (80MM INTERFACE) | LOCAL | SCHENCK WM0 | ||

| IAE 1R19767 Fixture | 0AM53 | IAE 1R19767 | ||

| IAE 1R19768 20mm Spacer | 0AM53 | IAE 1R19768 | ||

| IAE 1R18069 Rear anvil | 0AM53 | IAE 1R18069 | 1 | |

| IAE 1R18070 Front anvil | 0AM53 | IAE 1R18070 | 1 | |

| IAE 1R18071 Rear anvil | 0AM53 | IAE 1R18071 | 1 | |

| IAE 1R18072 Front anvil | 0AM53 | IAE 1R18072 | 1 | |

| IAE 1R18073 Rear anvil | 0AM53 | IAE 1R18073 | ||

| IAE 1R18074 Front anvil | 0AM53 | IAE 1R18074 | 1 | |

| IAE 1R18076 Slave lock plates | 0AM53 | IAE 1R18076 | ||

| IAE 1R18079 Drift | 0AM53 | IAE 1R18079 | 1 | |

| IAE 1R18080 Drift | 0AM53 | IAE 1R18080 | 1 | |

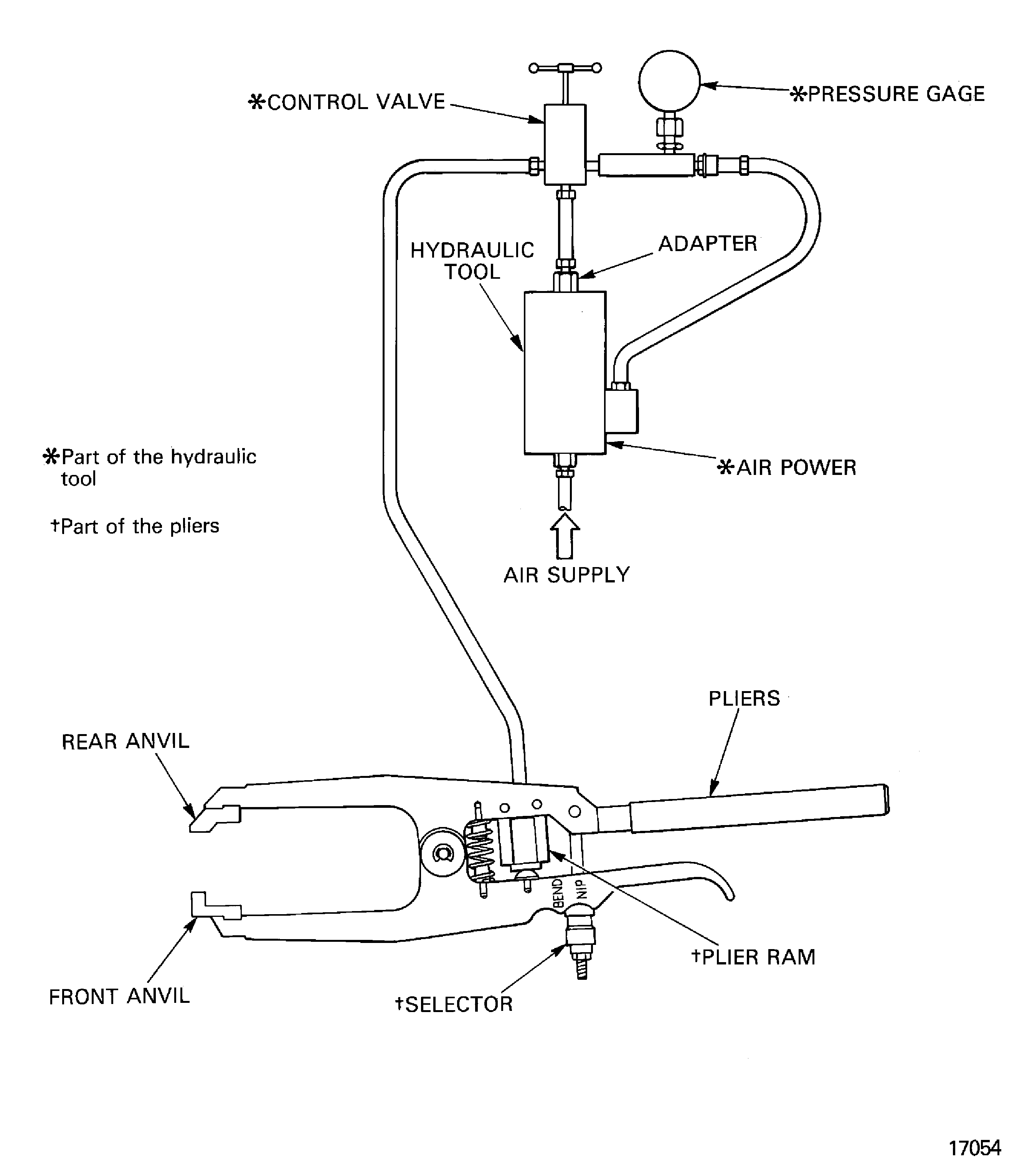

| IAE 1R18082 Pliers | 0AM53 | IAE 1R18082 | 1 | |

| IAE 1R18083 Hydraulic tool | 0AM53 | IAE 1R18083 | 1 | |

| IAE 1R18084 Pliers | 0AM53 | IAE 1R18084 | 1 | |

| IAE 1R18097 Drift | 0AM53 | IAE 1R18097 | 1 | |

| IAE 1R18245 Adapter | 0AM53 | IAE 1R18245 | 1 | |

| IAE 1R18590 Socket end | 0AM53 | IAE 1R18590 | 1 | |

| IAE 1R18683 Caliper adapter | 0AM53 | IAE 1R18683 | 1 | |

| IAE 1R18911 Drill | 0AM53 | IAE 1R18911 | 1 | |

| IAE 1R18914 Setting gage | 0AM53 | IAE 1R18914 | 1 | |

| IAE 1R19842 Blade distribution computer program X45 | 0AM53 | IAE 1R19842 | 1 | |

| IAE 1R19842 Blade distribution computer program X45 | 0AM53 | IAE 1R19842 | ||

| IAE 1R19811 Filing fixture | 0AM53 | IAE 1R19811 | 1 | |

| IAE 1R19812 Filing fixture | 0AM53 | IAE 1R19812 | ||

| IAE 1R19813 Filing fixture | 0AM53 | IAE 1R19813 | ||

| IAE 1R19842 Blade distribution computer program X45 | 0AM53 | IAE 1R19842 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-001 SOLVENT, DELETED | X111X | CoMat 01-001 | ||

| CoMat 01-002 SOLVENT, DELETED. | X111X | CoMat 01-002 | ||

| CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON | IE304 | CoMat 02-121 | ||

| CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON | K6835 | CoMat 02-122 | ||

| CoMat 02-130 POLAR GRAPH PAPER | LOCAL | CoMat 02-130 | ||

| CoMat 03-398 METAL SPRAYING STOPPING-OFFCOMPOUND | LOCAL | CoMat 03-398 | ||

| CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMEL | k3504 | CoMat 07-075 | ||

| CoMat 10-070 ANTI-SEIZE COMPOUND | LOCAL | CoMat 10-070 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Lockplates | Lockplates | 9 | (stage 3) | |

| Lockplates | Lockplates | 3 | (stage 4) | |

| Lockplates | Lockplates | 3 | (stage 5) |

Safety Requirements

NONEProcedure

NOTE

Start from this No.1 blade slot and number the blades in a clockwise direction when you look from the rear.

It is recommended that the same direction is used throughout all procedures.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON temporary marker or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON temporary marker to temporarily mark the stage 3 disk rim and adjacent blade. Use this correlation mark as a start point and mark each of the stage 3 blades with a number from 1 to 31.

Correlate the stage 3 blades.

With IAE 1R18079 Drift drift 1 off move the retaining plates around the disk to close up the space between them. This will give sufficient space to remove one blade, forwards, from the disk.

Remove the blades from the stage 3 disk.

SUBTASK 72-41-00-040-211 Remove the Stage 3 HP Compressor Blades

Refer to TASK 72-41-15-200-000.

If it is necessary to discard a stage 3 retaining plate then the replacement plate must be matched weighed and correlated with the unsatisfactory plate. Refer to Step.

Examine the removed stage 3 retaining plates.

SUBTASK 72-41-00-220-206 Examine the Stage 3 Blade Retaining Plates

Moment weigh the stage 3 compressor blades HPC Rotor Blades (72-41-15,01-200).

Weigh each of the particular retaining plate(s) to the nearest 0.0035 oz (0.100 g). Refer to the TASK 72-41-10-440-003-G00, SUBTASK 72-41-10-440-320.

NOTE

You only need to match weigh the retaining plate(s) if it requires replacement.Weigh the stage 3 retaining plate(s).

SUBTASK 72-41-00-440-230 Moment Weigh the Removed Stage 3 Blades and Weigh the Retaining Plate(s)

Refer to Figure.

Put the resulting pattern of the stage 3 moment weights in to the blade distribution program VX45 or alternative method IAE 1R19842 Blade distribution computer program X45. The resultant residual unbalance will be a measurement in gmm at an angle from the correlation datum point.

Record the residual unbalance, vector B. You must try to match the new set of blades with this target vector figure, refer to Step.

Determine the residual unbalance, distance A.

SUBTASK 72-41-00-440-231 Determine the Residual Unbalance of the Stage 3 Blades

Install dummy retaining plates into the grooves of the disk and blades.

It is not necessary to apply high heat resisting enamel to the mating surfaces of the plates during this part of the procedure.

Install one of the plates HPC Rotor Blades (72-41-15,01-050) into the two grooves.

Use IAE 1R18079 Drift drift 1 off to move the retaining plate around the disk in to the next blade groove.

NOTE

Install the stage 3 retaining plates.

Install (IAE 1R18076 Slave lock plates) slave lockplates 9 off in to the grooves of the blades and the disk.

SUBTASK 72-41-00-440-255 Install the Replacement Stage 3 Blades in the Dummy Rotor

Use a brush to apply CoMat 03-398 METAL SPRAYING STOPPING-OFFCOMPOUND to protect the stage 3 rotor airfoils. Apply the material to approximately two thirds of the blade airfoil length when measured from the blade tips.

NOTE

The de-mineralized water must have a conductivity of 20 micro siemens.Use de-mineralized water and a cloth or brush to remove CoMat 03-398 METAL SPRAYING STOPPING-OFFCOMPOUND from the blade airfoils.

Remove the temporary surface protection from the rotor blade airfoils.

Remove the stage 3 blades from the dummy rotor, refer to the procedure in Step.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON temporary marker or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON temporary marker to identify the blades.

Make sure that the new blades are marked with their positions 1 to 31 in the disk.

SUBTASK 72-41-00-324-009 Grind the Tips of the Replacement Stage 3 Blades

Refer to Figure.

NOTE

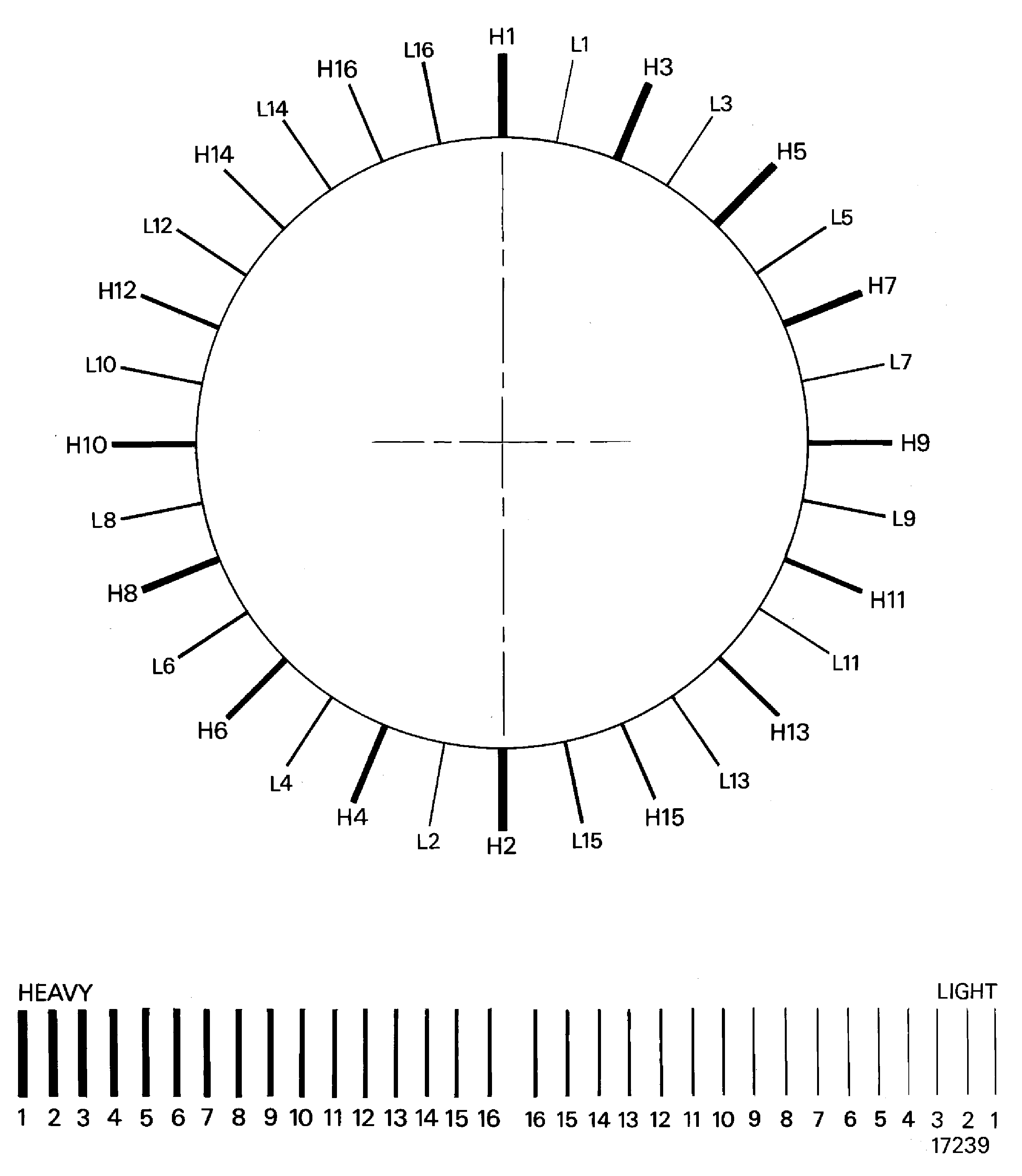

This will allow the program to produce an acceptable pattern satisfactorily.Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON temporary marker or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON temporary marker to identify the blades in an initial light-heavy-light sequence ready for assembly.

Weigh and record the moment weight of each blade in its sequence in the stage.

SUBTASK 72-41-00-440-232 Weigh the Removed Stage 3 Blades

Refer to Figure.

Record the results of the initial sequence from Step in the distribution program VX45 or alternative method IAE 1R19842 Blade distribution computer program X45 to calculate vector C.

Record the results of vector B in the blade distribution program VX45 or alternative method IAE 1R19842 Blade distribution computer program X45, refer to Step.

Record the results.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON temporary marker or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON temporary marker to identify the blades in the new sequence determined in step C.

Correlate the stage 3 blades.

SUBTASK 72-41-00-440-233 Do a Balance Patternation for the Replacement Stage 3 Blades

Apply CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMEL to the mating surfaces of the retaining plates.

Install one of the plates into the two grooves.

NOTE

You must make sure that if Repair VRS6630, TASK 72-41-11-300-023 (REPAIR-023) is done, the retaining plate is fitted centrally over any area(s) of material removed.Use IAE 1R18079 Drift drift 1 off to move the retaining plate around the disk in to the next blade groove.

Install the stage 3 retaining plates using previously correlated sequence.

Less than in Step.

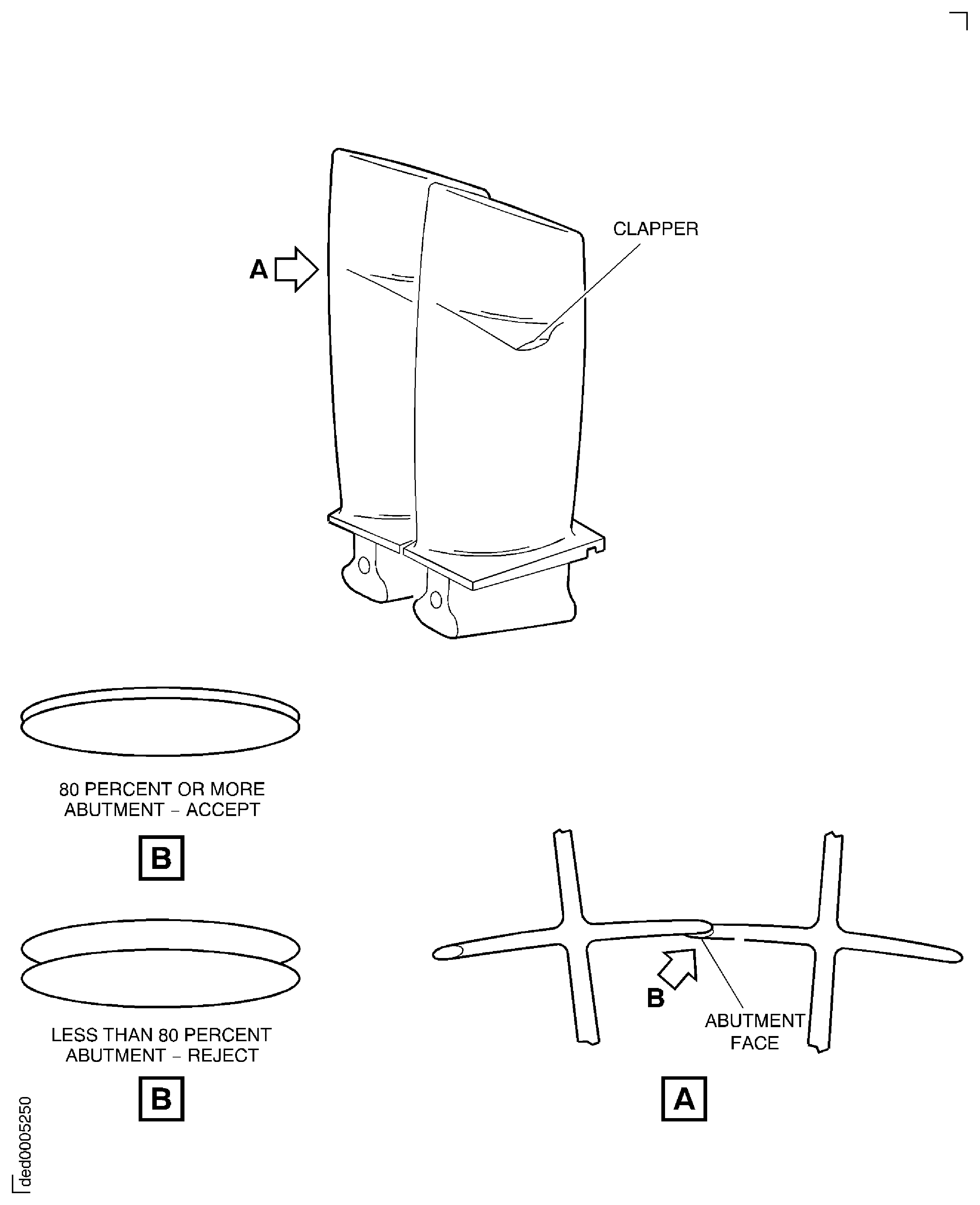

Make sure the clapper abutment face aligns with the adjacent clapper face.

Examine the Clapper Abutment Faces.

NOTE

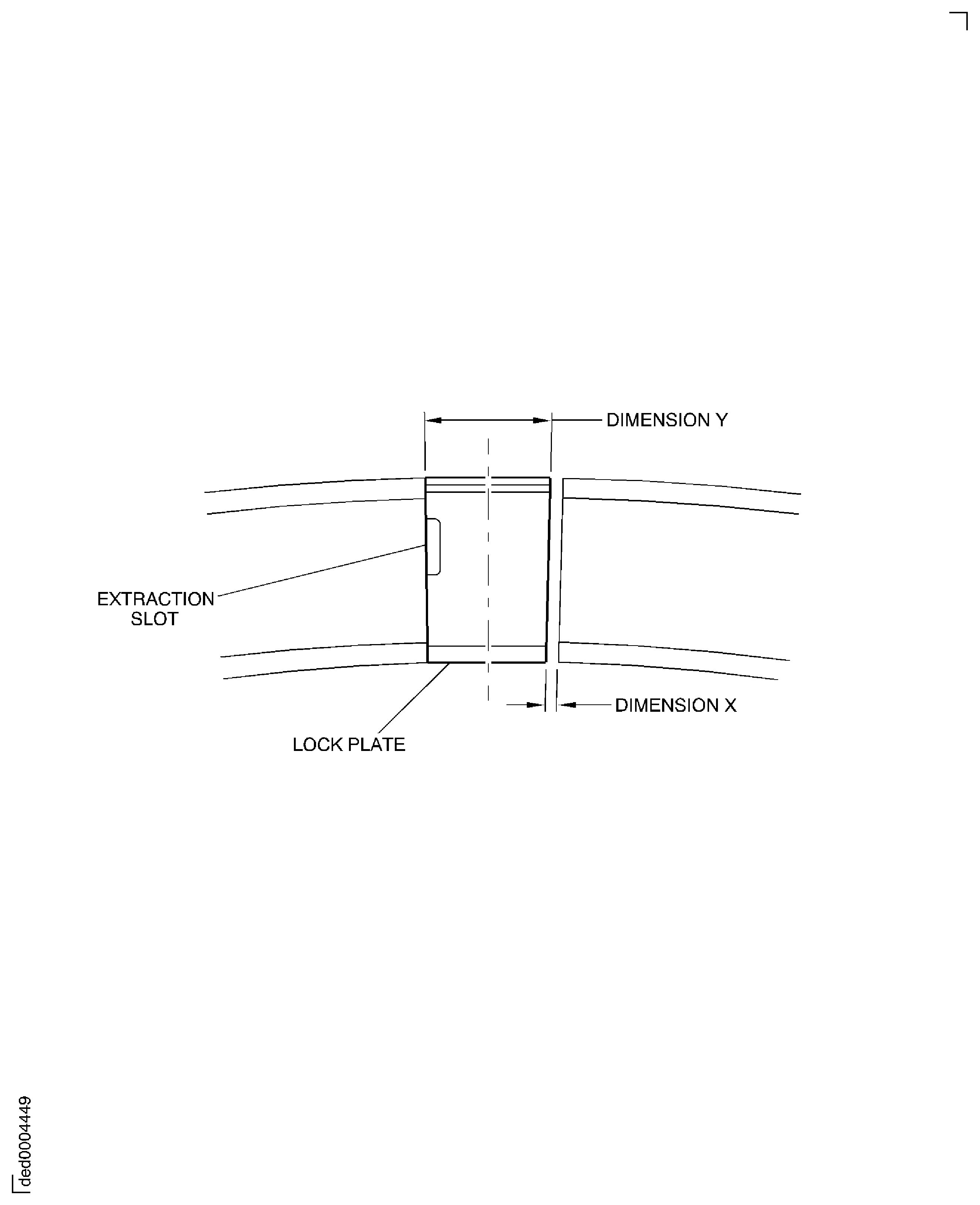

If the last lockplate overlaps a retaining plate go to Step.Install the nine stage 3 lockplates in position between the retaining plates. Use IAE 1R18079 Drift drift to move the lockplates and retaining plates around the disk until they touch. The lock plates must line up with a blade root. Measure the total clearance (dimension X) between a lockplate and a retaining plate.

NOTE

Remove metal from the minimum number of lockplates.Remove metal from the edge opposite the extraction slot.Install a lockplate in to IAE 1R19811 Filing fixture filing fixture 1 off and use a file to remove metal. The minimum permitted width (dimension Y) of the stage 3 lockplate after filing is 0.315 in. (8.00 mm).

If it is necessary to remove metal from a lockplate to get the correct plate clearance do the steps that follow:

Apply CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMEL to the mating surfaces of the disk and the lockplates.

NOTE

The lockplates must be in line with a blade root.You must make sure that if Repair, VRS6630 TASK 72-41-11-300-023 (REPAIR-023) is done, the lockplate is fitted centrally over any area(s) of material removed.Install the lockplates in position.

Install HPC Rotor Blades (72-41-15,01-125) stage 3 lockplates 9 off in to the grooves of the blades and the disk.

CAUTION

YOU MUST USE THE CORRECT ANVILS AND PLIERS FOR EACH STAGE WHEN LOCKING THE LOCKPLATES. IF YOU DO NOT USE THE CORRECT TOOLS YOU CAN DAMAGE THE LOCKPLATES.

CAUTION

LOCKPLATES THAT ARE DAMAGED IN ANY WAY DURING INSTALLATION, FOR EXAMPLE: OVER BENT, TWISTED OR NICKED SHOULD BE REPLACED WITH NEW PARTS. CORRECT ENGAGEMENT OF THE LOCKPLATES IS ESSENTIAL.Install IAE 1R18074 Front anvil front anvil 1 off and IAE 1R18073 Rear anvil rear anvil 1 off in to IAE 1R18084 Pliers pliers 1 off.

Lock the stage 3 lockplates in position.

SUBTASK 72-41-00-440-234 Install the Replacement Stage 3 Blades in the HP Compressor Rotor

NOTE

Start from this No.1 blade slot and number the blades in a clockwise direction when you look from the rear.

It is recommended that the same direction is used throughout all procedures.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON temporary marker or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON temporary marker to temporarily mark the stage 4 disk rim and adjacent blade. Use this correlation mark as a start point and mark each of the stage 4 blades with a number from 1 to 38.

Correlate the stage 4 blades.

With IAE 1R18080 Drift drift 1 off move the retaining plates around the disk to close up the space between them. This will give sufficient space to remove one blade, forwards, from the disk.

Remove the blades from the stage 4 disk.

SUBTASK 72-41-00-040-212 Remove the Stage 4 HP Compressor Blades

Refer to TASK 72-41-15-200-000.

If it is necessary to discard a stage 4 retaining plate then the replacement plate must be matched weighed and correlated with the unsatisfactory plate. Refer to Step.

Examine the removed stage 4 retaining plates HPC Rotor Blades (72-41-15,01-350).

SUBTASK 72-41-00-220-207 Examine the Stage 4 Blade Retaining Plates

Weigh the stage 4 compressor blades HPC Rotor Blades (72-41-15,01-500).

NOTE

You only need to match weigh the retaining plate(s) if it requires replacement.Weigh the stage 4 retaining plate(s) HPC Rotor Blades (72-41-15,01-350).

SUBTASK 72-41-00-440-235 Weigh the Removed Stage 4 Blades and Retaining Plates

Refer to Figure.

Put the resulting pattern of the stage 4 mass weights in to the blade distribution program VX45 or alternative method IAE 1R19842 Blade distribution computer program X45. The resultant residual unbalance will be a measurement in grams at an angle from the correlation datum point.

Record the residual unbalance, vector B. You must try to match the new set of blades with this target vector figure, refer to Step.

Determine the residual unbalance, distance A.

SUBTASK 72-41-00-440-236 Determine the Residual Unbalance of the Stage 4 Blades

It is recommended that a dummy set of retaining plates and lockplates are used for this part of the procedure and that these parts are not used again during subsequent compressor build operations.

It is not necessary to apply high heat resisting enamel to the mating surfaces of the plates during this part of the procedure.

Install one of the plates into the two grooves.

NOTE

You must make sure that if Repair VRS6630, TASK 72-41-11-300-023 (REPAIR-023) is done, the retaining plate is fitted centrally over any area(s) of material removed.Use IAE 1R18080 Drift drift 1 off to move the retaining plate around the disk in to the next blade groove.

NOTE

Install the stage 4 retaining plates.

NOTE

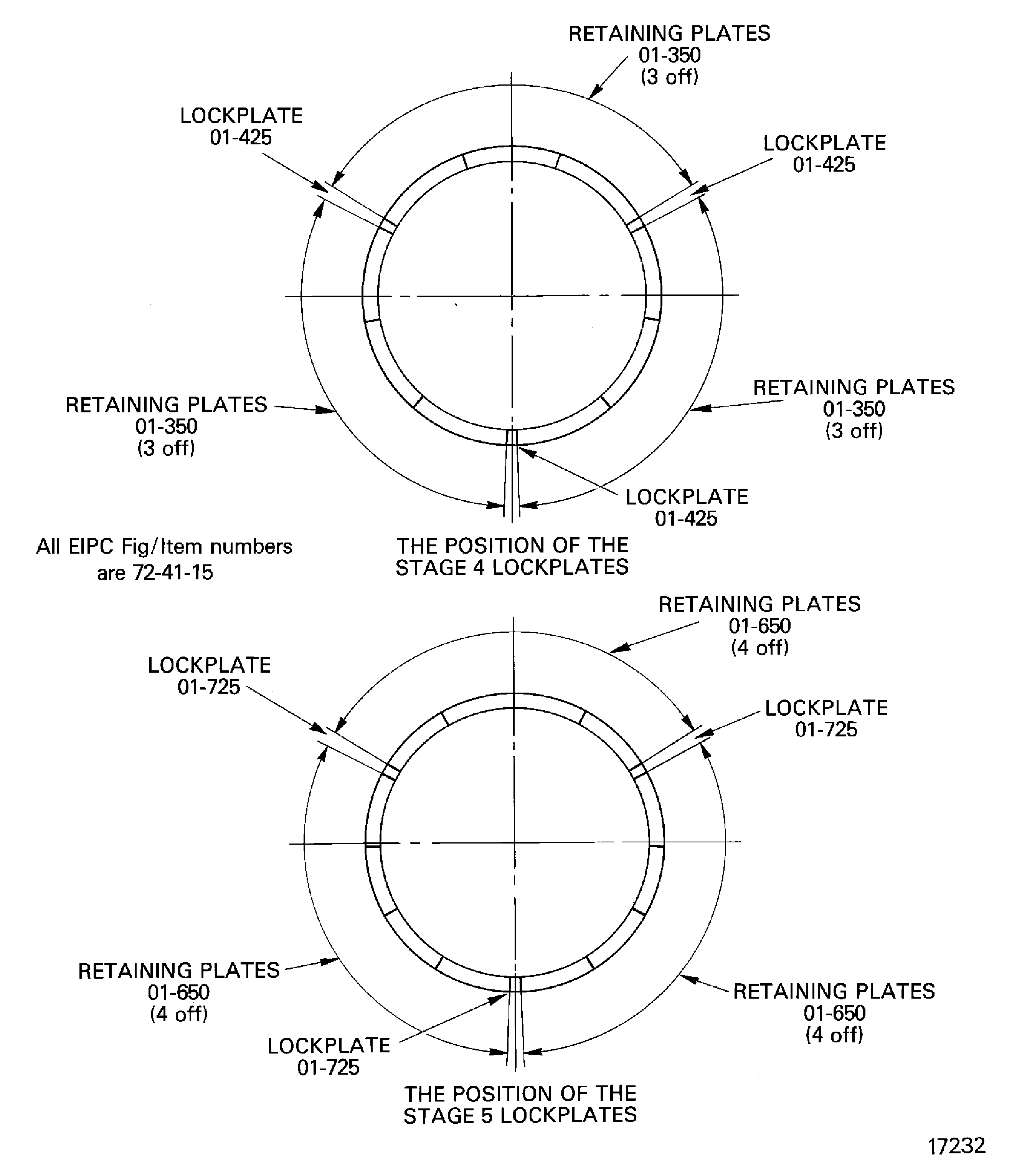

If the last lockplate overlaps a retaining plate go to Step.Install the three stage 4 lockplates in position between the retaining plates. Use IAE 1R18080 Drift drift to move the lockplates and retaining plates around the disk until they touch. Measure the total clearance (dimension X) between a lockplate and a retaining plate.

NOTE

Remove metal from the minimum number of lockplates.Remove metal from the edge opposite the extraction slot.Install a lockplate in to IAE 1R19812 Filing fixture filing fixture 1 off and use a file to remove metal. The minimum permitted width (dimension Y) of the stage 4 lockplate after filing is 0.402 in. (10.20 mm).

If it is necessary to remove metal from a lockplate to get the correct plate clearance do the steps that follow:

NOTE

The lockplates must be in line with a blade root.

You must make sure that if Repair VRS6630, TASK 72-41-11-300-023 (REPAIR-023) is done, the lockplate is fitted centrally over any area(s) of material removed.

Install the lockplates in position.

Install HPC Rotor Blades (72-41-15,01-425) stage 4 lockplates 3 off in to the grooves of the blades and the disk.

CAUTION

YOU MUST USE THE CORRECT ANVILS AND PLIERS FOR EACH STAGE WHEN LOCKING THE LOCKPLATES. IF YOU DO NOT USE THE CORRECT TOOLS YOU CAN DAMAGE THE LOCKPLATES.

CAUTION

LOCKPLATES THAT ARE DAMAGED IN ANY WAY DURING INSTALLATION, FOR EXAMPLE: OVER BENT, TWISTED OR NICKED SHOULD BE REPLACED WITH NEW PARTS. CORRECT ENGAGEMENT OF THE LOCKPLATES IS ESSENTIAL.Install IAE 1R18072 Front anvil front anvil 1 off and IAE 1R18071 Rear anvil rear anvil 1 off in to IAE 1R18084 Pliers pliers 1 off.

Lock the stage 4 lockplates in position.

SUBTASK 72-41-00-440-256 Install the Replacement Stage 4 Blades in the Dummy Rotor

Use a brush to apply CoMat 03-398 METAL SPRAYING STOPPING-OFFCOMPOUND to protect the stage 4 rotor airfoils. Apply the material to approximately two thirds of the blade airfoil length when measured from the blade tips.

Grind the tips of the replacement stage 4 blades installed in the dummy HP compressor rotor using the procedures given in TASK 72-41-10-440-004-C00.

NOTE

The de-mineralized water must have a conductivity of 20 micro siemens.Use de-mineralized water and a cloth or brush to remove CoMat 03-398 METAL SPRAYING STOPPING-OFFCOMPOUND from the blade airfoils.

Remove the temporary surface protection from the rotor blade airfoils.

Remove the stage 4 blades from the dummy rotor, refer to the procedure in Step.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON temporary marker or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON temporary marker to identify the blades.

Make sure that the new blades are marked with their positions 1 to 38 in the disk.

SUBTASK 72-41-00-324-013 Grind the Tips of the Replacement Stage 4 Blades

Refer to Figure.

NOTE

This will allow the program to produce an acceptable pattern satisfactorily.Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON temporary marker or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON temporary marker to identify the blades in an initial light-heavy-light sequence ready for assembly.

Weigh and record the mass of each blade in its sequence in the stage. Refer to Step.

SUBTASK 72-41-00-440-237 Weigh the Removed Stage 4 Blades

Refer to Figure.

Record the results of the initial sequence from Step in the blade distribution program VX45 or alternative method IAE 1R19842 Blade distribution computer program X45 to calculate vector C.

Record the results of vector B in the blade distribution program VX45 or alternative method IAE 1R19842 Blade distribution computer program X45, refer to Step.

Record the results.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON temporary marker or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON temporary marker to identify the blades in the new sequence determined in step D.

Correlate the stage 4 blades.

SUBTASK 72-41-00-440-238 Do a Balance Patternation for the Replacement Stage 4 Blades

Apply CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMEL to the mating surfaces of the retaining plates.

Install one of the plates into the two grooves.

NOTE

You must make sure that if Repair VRS6630, TASK 72-41-11-300-023 (REPAIR-023) is done, the retaining plate is fitted centrally over any area(s) of material removed.Use IAE 1R18080 Drift drift 1 off to move the retaining plate around the disk in to the next blade groove.

Install the stage 4 retaining plates.

NOTE

If the last lockplate overlaps a retaining plate go to step D.(3).Install the three stage 4 lockplates in position between the retaining plates. Use IAE 1R18080 Drift drift to move the lockplates and retaining plates around the disk until they touch. Measure the total clearance (dimension X) between a lockplate and a retaining plate.

NOTE

Remove metal from the minimum number of lockplates.Remove metal from the edge opposite the extraction slot.Install a lockplate in to IAE 1R19812 Filing fixture filing fixture 1 off and use a file to remove metal. The minimum permitted width (dimension Y) of the stage 4 lockplate after filing is 0.402 in. (10.20 mm).

If it is necessary to remove metal from a lockplate to get the correct plate clearance do the steps that follow:

Apply CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMEL to the mating surfaces of the disk and the lockplates.

NOTE

The lockplates must be in line with a blade root.

You must ensure that if Repair VRS6630, TASK 72-41-11-300-023 (REPAIR-023) has been carried out, the lockplate is fitted centrally over any area(s) of material removed.

Install the lockplates in position.

Install HPC Rotor Blades (72-41-15,01-425) stage 4 lockplates 3 off in to the grooves of the blades and the disk.

CAUTION

YOU MUST USE THE CORRECT ANVILS AND PLIERS FOR EACH STAGE WHEN LOCKING THE LOCKPLATES. IF YOU DO NOT USE THE CORRECT TOOLS YOU CAN DAMAGE THE LOCKPLATES.

CAUTION

LOCKPLATES THAT ARE DAMAGED IN ANY WAY DURING INSTALLATION, FOR EXAMPLE: OVER BENT, TWISTED OR NICKED SHOULD BE REPLACED WITH NEW PARTS. CORRECT ENGAGEMENT OF THE LOCKPLATES IS ESSENTIAL.Install IAE 1R18072 Front anvil front anvil 1 off and IAE 1R18071 Rear anvil rear anvil 1 off in to IAE 1R18084 Pliers pliers 1 off.

Lock the stage 4 lockplates in position.

SUBTASK 72-41-00-440-239 Install the Replacement Stage 4 Blades in the HP Compressor Rotor

NOTE

Start from this No.1 blade slot and number the blades in a clockwise direction when you look from the rear.It is recommended that the same direction is used throughout all procedures.Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON temporary marker or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON temporary marker to temporarily mark the stage 5 disk rim and adjacent blade. Use this correlation mark as a start point and mark each of the stage 5 blades with a number from 1 to 64.

Correlate the stage 5 blades.

With IAE 1R18080 Drift drift 1 off move the retaining plates around the disk to close up the space between them. This will give sufficient space to remove one blade, forwards, from the disk.

Remove the blades from the stage 5 disk.

SUBTASK 72-41-00-040-213 Remove the Stage 5 HP Compressor Blades

Refer to TASK 72-41-15-200-000.

If it is necessary to discard a stage 5 retaining plate then the replacement plate must be matched weighed and correlated with the unsatisfactory plate. Refer to Step.

Examine the removed stage 5 retaining plates HPC Rotor Blades (72-41-15,01-650).

SUBTASK 72-41-00-220-208 Examine the Stage 5 Blade Retaining Plates

Weigh the stage 5 compressor blades HPC Rotor Blades (72-41-15,01-800).

NOTE

You only need to match weigh the retaining plate(s) if it requires replacement.Weigh the stage 5 retaining plate(s) HPC Rotor Blades (72-41-15,01-650).

SUBTASK 72-41-00-440-240 Weigh the Removed Stage 5 Blades and Retaining Plates

Refer to Figure.

Put the resulting pattern of the stage 5 mass weights in to the blade distribution program VX45 or alternative method IAE 1R19842 Blade distribution computer program X45. The resultant residual unbalance will be a measurement in grams at an angle from the correlation datum point.

Record the residual unbalance, vector B. You must try to match the new set of blades with this target vector figure, refer to Step.

Determine the residual unbalance, distance A.

SUBTASK 72-41-00-440-241 Determine the Residual Unbalance of the Stage 5 Blades

NOTE

You must make sure that if Repair VRS6630, TASK 72-41-11-300-023 (REPAIR-023) is done, the retaining plate is fitted centrally over any area(s) of material removed.Install one of the plates into the two grooves.

Use IAE 1R18080 Drift drift 1 off to move the retaining plate around the disk in to the next blade groove.

NOTE

It is recommended that a dummy set of retaining plates and lockplates are used for this part of the procedure and that these parts are not used again during subsequent compressor build operations.It is not necessary to apply high heat resisting enamel to the mating surfaces of the plates during this part of the procedure.Install the stage 5 retaining plates.

Install the three stage 5 lockplates in position between the retaining plates. Use IAE 1R18080 Drift drift to move the lockplates and retaining plates around the disk until they touch. Measure the total clearance (dimension X) between a lockplate and a retaining plate.

NOTE

If the last lockplate overlaps a retaining plate go to Step.Install a lockplate in to IAE 1R19813 Filing fixture filing fixture 1 off and use a file to remove metal. The minimum permitted width (dimension Y) of the stage 5 lockplate after filing is 0.297 in. (7.54 mm).

NOTE

Remove metal from the minimum number of lockplates.Remove metal from the edge opposite the extraction slot.

If it is necessary to remove metal from a lockplate to get the correct plate clearance do the steps that follow:

Install the lockplates in position.

NOTE

The lockplates must be in line with a blade root.You must make sure that if Repair, VRS6630 TASK 72-41-11-300-023 (REPAIR-023) is done, the lockplate is fitted centrally over any area(s) of material removed.

Install HPC Rotor Blades (72-41-15,01-725) stage 5 lockplates 3 off in to the grooves of the blades and the disk.

CAUTION

YOU MUST USE THE CORRECT ANVILS AND PLIERS FOR EACH STAGE WHEN LOCKING THE LOCKPLATES. IF YOU DO NOT USE THE CORRECT TOOLS YOU CAN DAMAGE THE LOCKPLATES.

CAUTION

LOCKPLATES THAT ARE DAMAGED IN ANY WAY DURING INSTALLATION, FOR EXAMPLE: OVER BENT, TWISTED OR NICKED SHOULD BE REPLACED WITH NEW PARTS. CORRECT ENGAGEMENT OF THE LOCKPLATES IS ESSENTIAL.Install IAE 1R18070 Front anvil front anvil 1 off and IAE 1R18069 Rear anvil rear anvil 1 off in to IAE 1R18082 Pliers pliers 1 off.

Install IAE 1R18245 Adapter adapter 1 off between the pressure control valve and IAE 1R18083 Hydraulic tool hydraulic tool 1 off.

Lock the stage 5 lockplates in position.

SUBTASK 72-41-00-440-242 Install the Replacement Stage 5 Blades in the Dummy Rotor

Use a brush to apply CoMat 03-398 METAL SPRAYING STOPPING-OFFCOMPOUND to protect the stage 5 rotor airfoils. Apply the material to approximately two thirds of the blade airfoil length when measured from the blade tips.

Grind the tips of the replacement stage 5 blades installed in the dummy HP compressor rotor using the procedures given in TASK 72-41-10-440-004-C00.

NOTE

The de-mineralized water must have a conductivity of 20 micro siemens.Use de-mineralized water and a cloth or brush to remove CoMat 03-398 METAL SPRAYING STOPPING-OFFCOMPOUND from the blade airfoils.

Remove the temporary surface protection from the rotor blade airfoils.

Remove the stage 5 blades from the dummy rotor, refer to the procedure in Step.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON temporary marker or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON temporary marker to identify the blades.

Make sure that the new blades are marked with their positions 1 to 64 in the disk.

SUBTASK 72-41-00-324-011 Grind the Tips of the Replacement Stage 5 Blades

Refer to Figure.

NOTE

This will allow the program to produce an acceptable pattern satisfactorily.Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON temporary marker or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON temporary marker to identify the blades in an initial light-heavy-light sequence ready for assembly.

Weigh and record the mass of each blade in its sequence in the stage. Refer to Step.

SUBTASK 72-41-00-440-243 Weigh the Removed Stage 5 Blades

Refer to Figure.

Record the results of the initial sequence from Step in the blade distribution program VX45 or alternative method IAE 1R19842 Blade distribution computer program X45 to calculate vector C.

Record the results of vector B in the blade distribution program VX45 or alternative method IAE 1R19842 Blade distribution computer program X45, refer to Step.

Record the results.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON temporary marker or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON temporary marker to identify the blades in the new sequence determined in step D.

Correlate the stage 5 blades.

SUBTASK 72-41-00-440-244 Do a Balance Patternation for the Replacement Stage 5 Blades

Apply CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMEL to the mating surfaces of the retaining plates.

Install one of the plates into the two grooves.

NOTE

You must make sure that if Repair VRS6630, TASK 72-41-11-300-023 (REPAIR-023) is done, the retaining plate is fitted centrally over any area(s) of material removed.Use IAE 1R18080 Drift drift 1 off to move the retaining plate around the disk in to the next blade groove.

Install the stage 5 retaining plates.

Install the three stage 5 lockplates in position between the retaining plates. Use IAE 1R18080 Drift drift to move the lockplates and retaining plates around the disk until they touch. Measure the total clearance (dimension X) between a lockplate and a retaining plate.

NOTE

If the last lockplate overlaps a retaining plate go to Step.Install a lockplate in to IAE 1R19813 Filing fixture filing fixture 1 off and use a file to remove metal. The minimum permitted width (dimension Y) of the stage 5 lockplate after filing is 0.297 in. (7.54 mm).

NOTE

Remove metal from the minimum number of lockplates.Remove metal from the edge opposite the extraction slot.

If it is necessary to remove metal from a lockplate to get the correct plate clearance do the steps that follow:

Apply CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMEL to the mating surfaces of the disk and the lockplates.

NOTE

The lockplates must be in line with a blade root.

You must make sure that if Repair VRS6630, TASK 72-41-11-300-023 (REPAIR-023) is done, the lockplate is fitted centrally over any area(s) of material removed.

Install the lockplates in position.

Install HPC Rotor Blades (72-41-15,01-725) stage 5 lockplates 3 off in to the grooves of the blades and the disk.

CAUTION

YOU MUST USE THE CORRECT ANVILS AND PLIERS FOR EACH STAGE WHEN LOCKING THE LOCKPLATES. IF YOU DO NOT USE THE CORRECT TOOLS YOU CAN DAMAGE THE LOCKPLATES.

CAUTION

LOCKPLATES THAT ARE DAMAGED IN ANY WAY DURING INSTALLATION, FOR EXAMPLE: OVER BENT, TWISTED OR NICKED SHOULD BE REPLACED WITH NEW PARTS. CORRECT ENGAGEMENT OF THE LOCKPLATES IS ESSENTIAL.Install IAE 1R18070 Front anvil front anvil 1 off and IAE 1R18069 Rear anvil rear anvil 1 off in to IAE 1R18082 Pliers pliers 1 off.

Install IAE 1R18245 Adapter adapter 1 off between the pressure control valve and IAE 1R18083 Hydraulic tool hydraulic tool 1 off.

Lock the stage 5 lockplates in position.

SUBTASK 72-41-00-440-245 Install the Replacement Stage 5 Blades in the HP Compressor Rotor

NOTE

It is recommended that one of the locking blades is used as the correlation position as a start point for the No. 1 position.Start from this No.1 blade slot and number the blades in a clockwise direction when you look from the rear.It is recommended that the same direction is used throughout all procedures.Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON temporary marker or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON temporary marker to temporarily mark the stage 6 disk rim and adjacent blade. Use this correlation mark as a start point and mark each of the stage 6 blades with a number from 1 to 79.

Correlate the stage 6 blades.

SUBTASK 72-41-00-040-214 Correlate the Stage 6 HP Compressor Blades

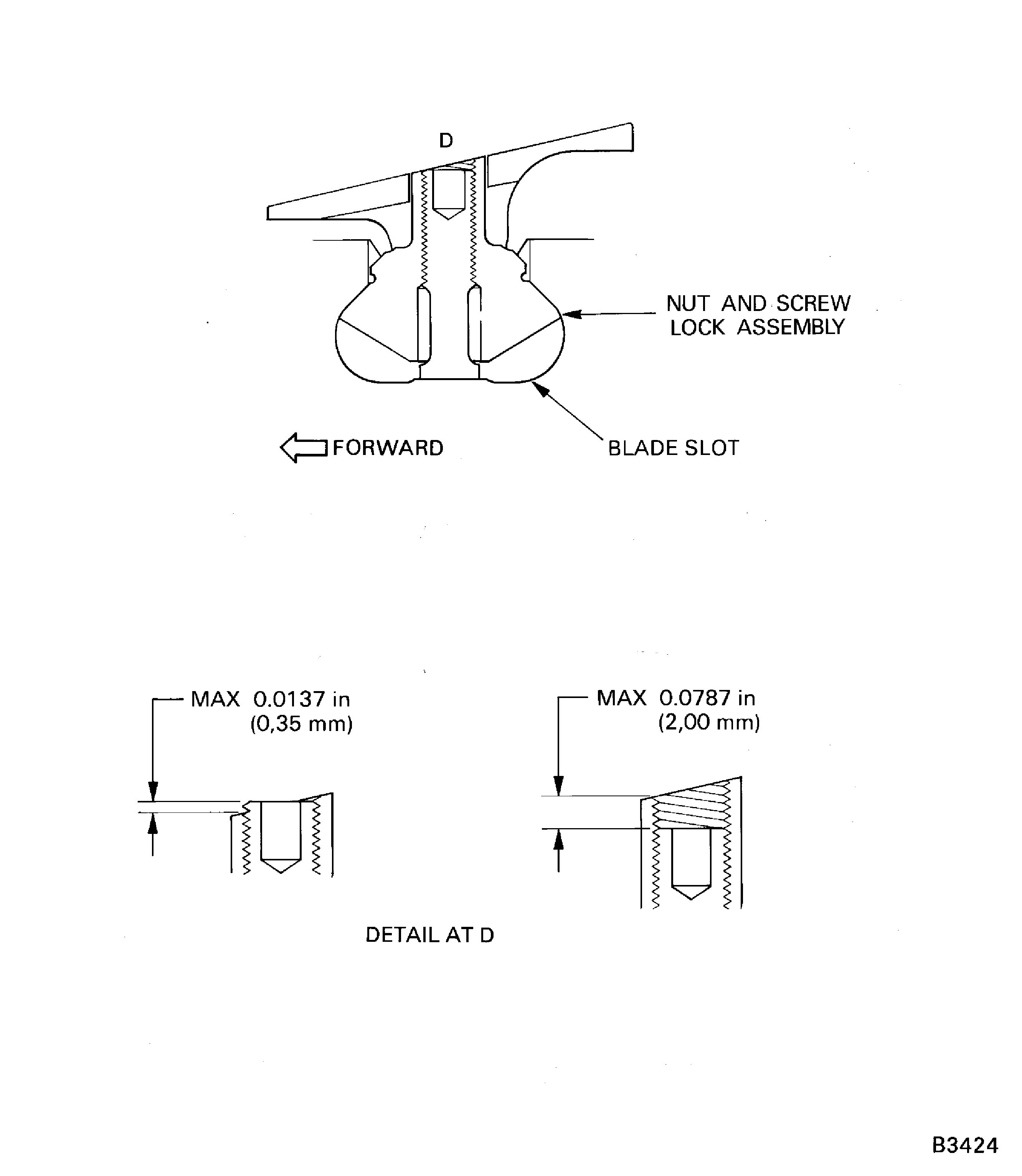

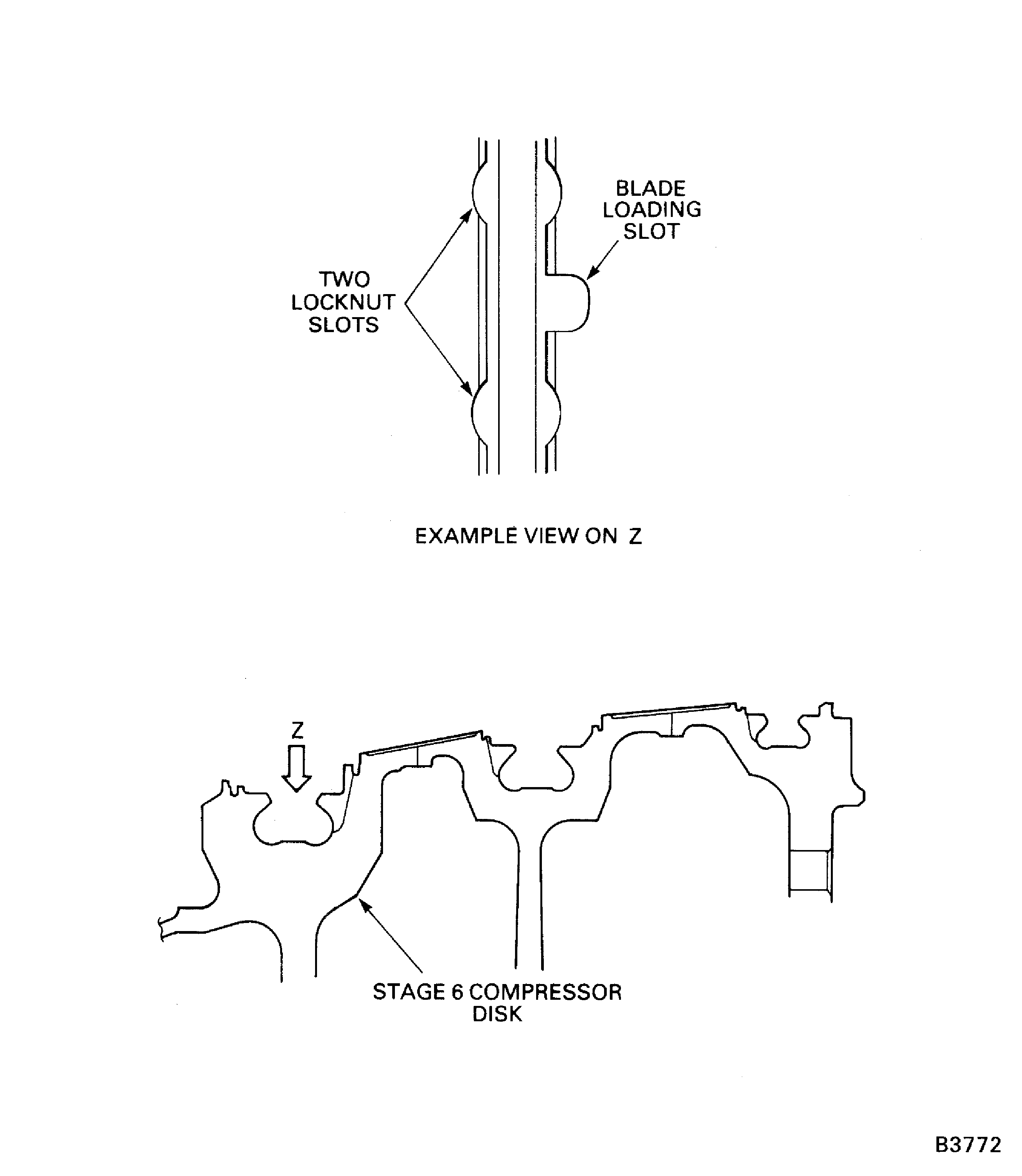

With IAE 1R18590 Socket end 1 off release the two nut and screw lock assemblies.

With IAE 1R18097 Drift 1 off move the blades around the disk until a blade can be removed through the loading slot.

Do Step again, to remove each blade and the two nut and screw lock assemblies, until all the blades have been removed.

NOTE

To drill out seized blade locknuts use the following tools: IAE 1R18911 Drill 1 off andIAE 1R18914 Setting gage 1 off.Each nut and screw lock assembly must be kept as a set.Correlate the nut and screw lock assemblies to their removed positions.Remove the blades from the stage 6 disk.

SUBTASK 72-41-00-040-215 Remove the Stage 6 HP Compressor Blades

Refer to TASK 72-41-15-200-000.

If it is necessary to discard a stage 6 nut and screw lock assembly then the replacement assembly must be matched weighed and correlated with the unsatisfactory assembly. Refer to Step.

Examine the removed stage 6 nut and screw lock assemblies HPC Rotor Blades (72-41-15,02-165).

SUBTASK 72-41-00-220-209 Examine the Stage 6 Nut and Screw lock assemblies

Weigh the stage 6 compressor blades (HPC Rotor Blades (72-41-15, 02-170), HPC Rotor Blades (72-41-15, 02-185), HPC Rotor Blades (72-41-15, 02-200), HPC Rotor Blades (72-41-15, 02-215) and HPC Rotor Blades (72-41-15, 02-217)).

NOTE

You only need to match weigh the assemblies if it requires replacement.Weigh the stage 6 nut and screw lock assembly HPC Rotor Blades (72-41-15, 02-165).

SUBTASK 72-41-00-440-246 Weigh the Removed Stage 6 Blades and Nut and Screw Lock Assemblies

Refer to Figure.

Put the resulting pattern of the stage 6 mass weights in to the blade distribution program VX45 or alternative method IAE 1R19842 Blade distribution computer program X45. The resultant residual unbalance will be a measurement in grams at an angle from the correlation datum point.

Record the residual unbalance, vector B. You must try to match the new set of blades with this target vector figure, refer to Step.

Determine the residual unbalance, distance A.

SUBTASK 72-41-00-440-247 Determine the Residual Unbalance of the Stage 6 Blades

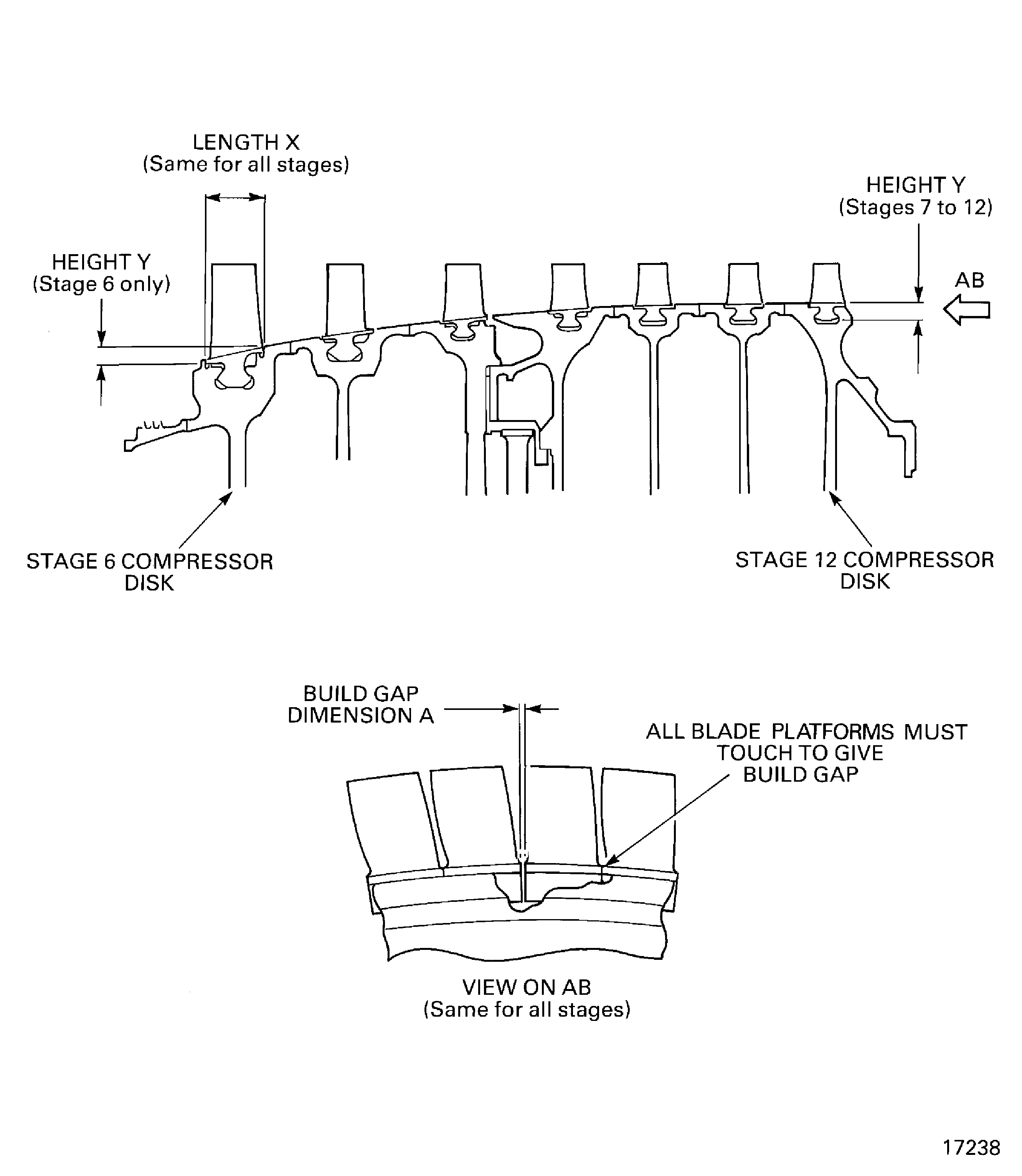

A selection of the 23 standard and the 23 undersize blades is used to get the correct platform build clearance.

A maximum of 23 undersize blades is permitted.

Install all of the standard blades in to the disk through the blade loading slot. Use IAE 1R18097 Drift 1 off positioned against the blade roots to move them around the disk in a counterclockwise direction when you look from the rear.

CAUTION

YOU MUST NOT USE THE DRIFT ON THE AIRFOIL SURFACES. IF YOU USE THE DRIFT ON THE AIRFOIL SUFACES YOU CAN CAUSE DAMAGE TO THE AIRFOIL SURFACES.Install the blades in to the stage 6 disk slot of the dummy rotor.

NOTE

Find the correct selection of stage 6 compressor blades.

A full set of stage 6 compressor blades includes the IPC Fig/item numbers that follow:

2 LH locking blades HPC Rotor Blades (72-41-15,02-170).

2 RH locking blades HPC Rotor Blades (72-41-15,02-185).

52 Standard blades HPC Rotor Blades (72-41-15,02-200).

23 Standard blades HPC Rotor Blades (72-41-15,02-215).

23 Undersize blades HPC Rotor Blades (72-41-15,02-217).

SUBTASK 72-41-00-440-248 Find the Correct Selection of Stage 6 Blades

Refer to Figure.

NOTE

Each nut and screw lock assembly must be kept as a set.

It is recommended that a dummy set of nut and screw lock assemblies are used for this part of the procedure and that these parts are not used again during subsequent compressor build operations.

It is not necessary to apply high temperature anti-seize compound to the threads of the nut and screw lock assemblies during this part of the procedure.

Make sure that there is no grit or unwanted material on the threads and surfaces and then assemble the jacking screw and locknut assemblies. Make sure the bottom end of the screws are below the surface of nuts.

Use IAE 1R18590 Socket end 1 off to torque the screws to between 4 and 5 lbfin (0.45 and 0.56 Nm) above the locking torque.

CAUTION

YOU MUST NOT USE THE DRIFT ON THE AIRFOIL SURFACES. IF YOU USE THE DRIFT ON THE AIRFOIL SUFACES YOU CAN CAUSE DAMAGE TO THE AIRFOIL SURFACES.NOTE

The nut and screwlock assemblies must be installed in the same positions as the removed assemblies. Refer to Step.Install the stage six standard and undersize blades which were selected in Step in to the disk in the identified sequence. Use IAE 1R18097 Drift 1 off to move the blades around the disk in a counterclockwise direction when you look from the rear.

SUBTASK 72-41-00-440-250 Install the Replacement Stage 6 Blades in the Dummy Rotor for Grinding Operations

Use a brush to apply CoMat 03-398 METAL SPRAYING STOPPING-OFFCOMPOUND to protect the stage 6 rotor airfoils. Apply the material to approximately two thirds of the blade airfoil length when measured from the blade tips.

Grind the tips of the replacement stage 6 blades installed in the dummy HP compressor rotor using the procedures given in TASK 72-41-10-440-004-C00.

NOTE

The de-mineralized water must have a conductivity of 20 micro siemens.Use de-mineralized water and a cloth or brush to remove CoMat 03-398 METAL SPRAYING STOPPING-OFFCOMPOUND from the blade airfoils.

Remove the temporary surface protection from the rotor blade airfoils.

Remove the stage 6 blades from the dummy rotor, refer to the procedure in Step.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON to identify the blades.

Make sure that the new blades are marked with their positions 1 to 79 in the disk.

SUBTASK 72-41-00-324-012 Grind the Tips of the Replacement Stage 6 Blades

Refer to Figure.

SUBTASK 72-41-00-440-251 Weigh the Removed Stage 6 Blades

Refer to Figure.

Record the results of the initial sequence (from Step) in the blade distribution program VX45 or alternative method IAE 1R19842 Blade distribution computer program X45 to calculate vector C.

Record the results of vector B in the blade distribution program VX45 or alternative method IAE 1R19842 Blade distribution computer program X45, refer to Step. Make sure that the position of the locking blades are fixed in the patternation sequence.

Record the results.

SUBTASK 72-41-00-440-252 Do a Balance Patternation for the Replacement Stage 6 Blades

Use CoMat 01-001 SOLVENT, DELETED or CoMat 01-002 SOLVENT, DELETED. and a cloth to clean the threads of the nut and screwlock assemblies removed in Step.

Use a brush to apply CoMat 10-070 ANTI-SEIZE COMPOUND to the threads of the stage 6 nut and screwlock assemblies.

WARNING

WHEN YOU USE CoMat 01-001 SOLVENT, DELETED OR CoMat 01-002 SOLVENT, DELETED. YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOUR CHANGES AND BECOMES TOXIC.Prepare the nut and screwlock assemblies.

Use IAE 1R18590 Socket end 1 off to torque the screws to between 4 and 5 lbfin (0.45 and 0.56 Nm) above the locking torque.

CAUTION

YOU MUST NOT USE THE DRIFT ON THE AIRFOIL SURFACES. IF YOU USE THE DRIFT ON THE AIRFOIL SUFACES YOU CAN CAUSE DAMAGE TO THE AIRFOIL SURFACES.NOTE

The nut and screwlock assemblies must be installed in the positions that they were removed from. Refer to Step.Install the stage six standard and undersize blades which were selected in Step in to the disk in the identified patternation sequence. Use IAE 1R18097 Drift 1 off to move the blades around the disk in a counterclockwise direction when you look from the rear.

Use IAE 1R18683 Caliper adapter 1 off to make sure that the jacking screws are correctly installed.

Measure the blade platform gaps.

SUBTASK 72-41-00-440-254 Install the Replacement Stage 6 Blades in the HP Compressor Rotor

Figure: Measure Blade Lockplate Clearance

Sheet 1

Figure: Install the Stage 3 Retaining Plates and Lockplates

Sheet 2

Figure: Examine the Clapper Abutment Faces

Sheet 3

Figure: Install the Stages 4 and 5 Retaining Plates and Lockplates

Sheet 1

Figure: Install the Stages 4 and 5 Retaining Plates and Lockplates

Sheet 2

Figure: Example of a Light-Heavy-Light Sequence

Example of a Light-Heavy-Light Sequence

Figure: Calculate the Static Unbalance

Calculate the Static Unbalance

Figure: Example of Stages 6 thru 12 Blade Loading Slot and Locknut Slots

Example of Stages 6 thru 12 Blade Loading Slot and Locknut Slots

Figure: Measure the Stages 6 Platform Build Clearance

Sheet 1

Figure: Measure the Stages 6 Platform Build Clearance

Sheet 2

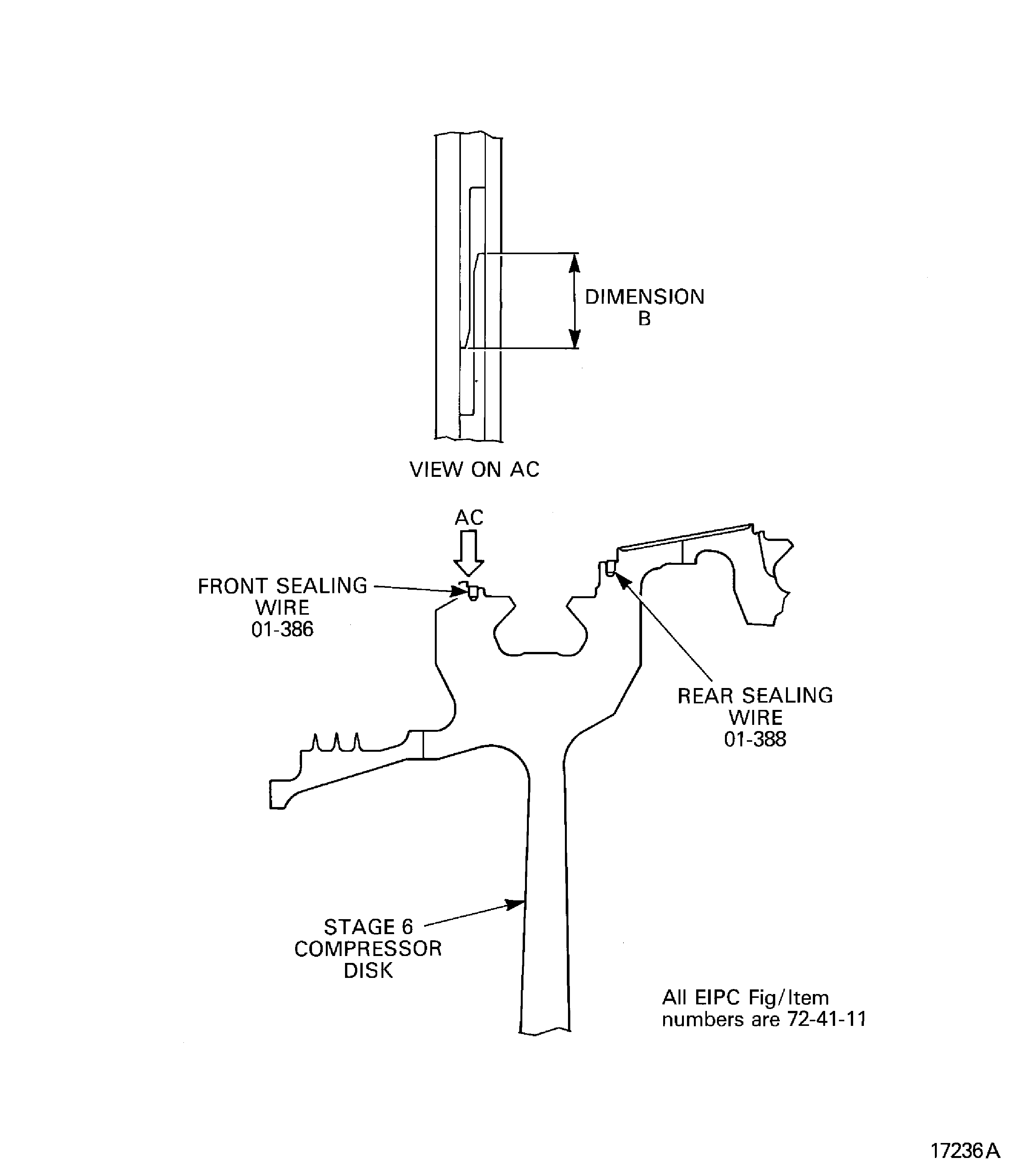

Figure: Measure the Stages 6 Sealing Wires Overlap

Measure the Stages 6 Sealing Wires Overlap

Figure: Install the Nut and Screw Lock Assemblies into the Stage HP Compressor Disk

Install the Nut and Screw Lock Assemblies into the Stage HP Compressor Disk