Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-35-25-300-001-C01 Replace The Cable Of The Electrical Harness, Repair-001 (VRS7002)

General

This TASK details the procedure for the replacement of the electrical cable.

Refer to Repair, VRS7002 SPM TASK 70-35-25-300-001 (REPAIR-001) for the following:

Effectivity

Equipment and materials

General

All illustrations/Figs

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 08-013 COLD CURING SILICONE COMPOUND | X222X | CoMat 08-013 | 75 ml | Silicoset 152, optional for BiFi connectors (point 8 of the procedure) |

| CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) | LOCAL | CoMat 02-148 | Optional for 90deg backshell (point 8 of the procedure) |

Spares

NONESafety Requirements

NONEProcedure

Refer to TASK 70-35-25-300-001-A01.

Loosen the backshell the connector or receptacle which is connected to the damaged cable.

SUBTASK 70-35-25-350-018 Loosen the Backshell

Use a clean blunt-edge tool.

CAUTION

BE CAREFUL NOT TO DAMAGE THE INSULATION OF CABLES WHEN REMOVING THE SEALANT FROM CONNECTORRemove all the sealant from the connector to completely uncover all cables and connector's surface.

SUBTASK 70-35-25-350-062 Remove the Sealant from the BiFi Connectors of EEC Core Harness And Voltage Divider Harness Assembly

NOTE

This subtask to be used only if following conditions applied:If repairing BIFI CONNECTOR (4008VC or 4009VC) of EEC Core Harness And Voltage Divider Harness Assembly (6A8171 or 6A8172) please check if the connector is filled with sealant and if there is a mark VRS9906/A on the identification sleeve of the harness adjacent to the connector. If so, use blunt-edge tool to remove the sealant.Use a clean blunt-edge tool.

CAUTION

BE CAREFUL NOT TO DAMAGE THE INSULATION OF CABLES WHEN REMOVING THE ANTI-CHAFING TAPE FROM CONNECTORRemove all the anti-chafing tape from the connector to completely uncover all cables.

SUBTASK 70-35-25-350-063 Remove the Anti-chafing Tape from the 90deg Backshells

NOTE

This subtask to be used only if following conditions applied:If repairing connector with 90deg backshell please check if the wires in the connector are wrapped by anti-chafing tape and if there is a mark VRS9907/A or VRS9908/A on the identification sleeve of the harness adjacent to the connector. If so, use blunt-edge tool to remove the anti-chafing tape.Refer to SPM TASK 70-35-25-300-001-A01.

Pull out the cable from the connectors or receptacle.

SUBTASK 70-35-25-350-019 Remove the Damaged Cable

NOTE

The dimensions for the length of the cable can be found in the Component Maintenance Manual. Electrical Harnesses and Cables Chapter 92-90.Refer to Figure.

Refer to SPM TASK 70-35-25-300-001-A01.

Install the contact pin and/or socket.

SUBTASK 70-35-25-350-020 Install the Contact Pin and/or Socket on the New Cable

Refer to SPM TASK 70-35-25-300-001-A01. If necessary remove all the contact pin(s) or socket(s) from the connector or receptacle with the cables and reinstall all the contact pin(s) or socket(s) into the connector or receptacle from the center to the outside.

Install the contact pin(s) and socket(s) into the connector or receptacle.

SUBTASK 70-35-25-350-021 Install the Contact Pin(s) and/or Socket(s) into the Connector or Receptacle

Refer to SPM TASK 70-35-25-300-001-B01.

NOTE

If repairing BIFI CONNECTOR (4008VC or 4009VC) of EEC Core Harness And Voltage Divider Harness Assembly (6A8171 or 6A8172) and if the connector before repair was filled with sealant and marked VRS9906/A on the identification sleeve of the harness adjacent to the connector please perform TASK 71-52-43-300-006 EEC Core Harness And Voltage Divider Harness Assembly - ADDING SEALANT TO BIFI CONNECTORS TO AVOID MOISTURE INGRESS, REPAIR-006 (VRS9906) before continue the assembly of electrical connector.NOTE

If you find the repairing connector with 90deg backshell and also before you do repair to the connector, if it has anti-chafing tape applied and marked VRS9907/A or VRS9908/A on the identification sleeve of the harness adjacent to the connector. You must do TASK 71-51-41-300-009 THE 90DEG BACKSHELL ANTI CHAFING TAPE REPAIR - WRAPPING TAPE AROUND WIRES INSIDE 90DEG BACKSHELL, REPAIR-009 (VRS9907) or TASK 71-52-43-300-008 THE 90DEG BACKSHELL ANTI CHAFING TAPE REPAIR - WRAPPING TAPE AROUND WIRES INSIDE 90DEG BACKSHELL, REPAIR-008 (VRS9908) accordingly before you do with the assembly of electrical connector.

Install the backshell.

SUBTASK 70-35-25-350-022 Install the Backshell

Refer to Figure.

Refer to SPM TASK 70-35-25-300-001-H01.

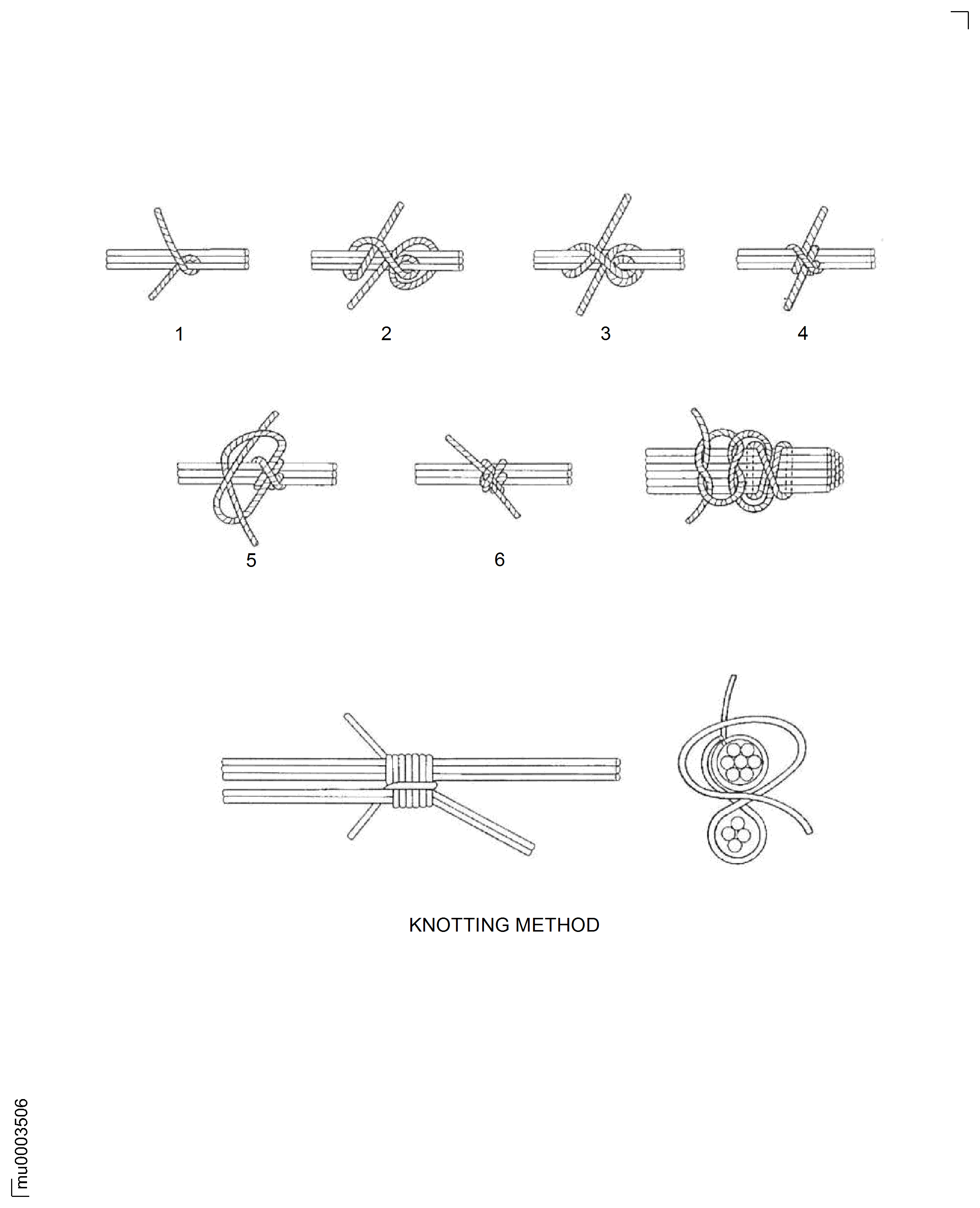

Install the harness ties.

SUBTASK 70-35-25-350-023 Install the Harness Ties

Refer to SPM TASK 70-35-25-300-001-D01.

Install the terminal(s) as necessary.

SUBTASK 70-35-25-350-024 Install the Terminal(s)

Refer to Figure.

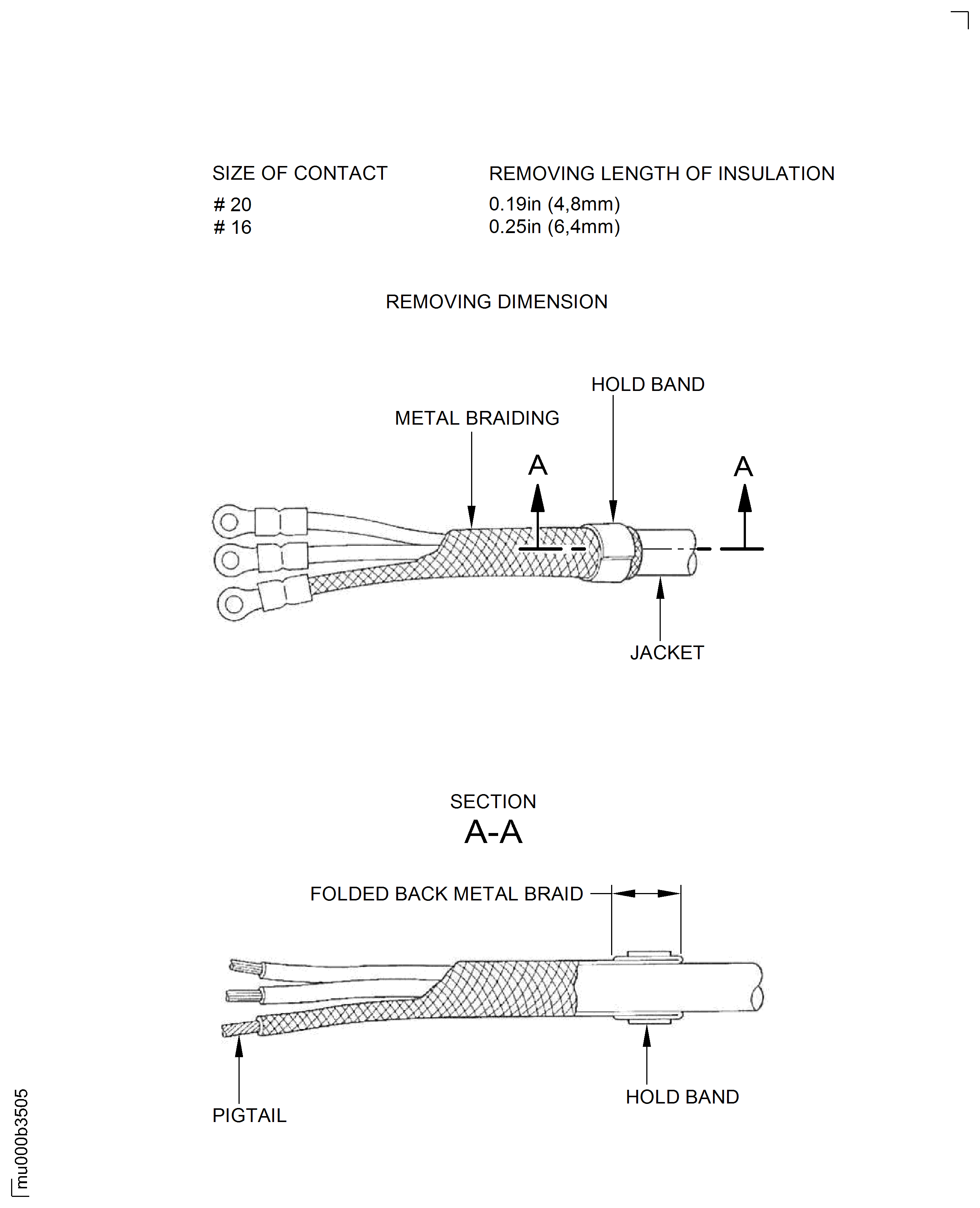

SUBTASK 70-35-25-350-025 Create the Pigtail (for earth) from the Metal Braiding

Refer to SPM TASK 70-35-25-300-001-F01.

Install the sleeve marker and the protective sleeve.

SUBTASK 70-35-25-350-026 Install the Sleeve Marker and the Protective Sleeve

Use permanent marker.

Make a mark VRS7002/C on the identification sleeve of the harness adjacent to the part number.

SUBTASK 70-35-25-350-053 Identify the Repair

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions