Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-32-450-002 LPC/Intermediate Case Module Components - Install The Relay Box, Installation-009

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-039 ENGINE OIL, unless other lubricants are referred to in the procedure.

Do not remove the special plastic caps from the electrical connectors and receptacles until immediately before they are connected. This will give protection from unwanted fluids or materials.

During the installation procedure make sure that the harnesses are held temporarily along their different lengths. This is to prevent too much strain on the harnesses, cables and electrical connectors.

For lockwire data and procedures refer to the SPM TASK 70-42-05-400-501.

For the data on the electrical connectors refer to the SPM TASK 70-43-00-400-501 and TASK 70-43-01-400-501.

For the torque tightening procedures, refer to the SPM TASK 70-41-00-400-501 and TASK 70-41-01-400-501.

Special torque data and assembly tolerances are included in this procedure.

Special torque data is identified with the symbol * after the torque value.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-002 SOLVENT, DELETED. | 0AM53 | CoMat 01-002 | ||

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-159 LACING TAPE | LOCAL | CoMat 02-159 | ||

| CoMat 10-039 ENGINE OIL | LOCAL | CoMat 10-039 | ||

| CoMat 06-086 TIES | 18992 | CoMat 06-086 |

Spares

NONESafety Requirements

NONEProcedure

WARNING

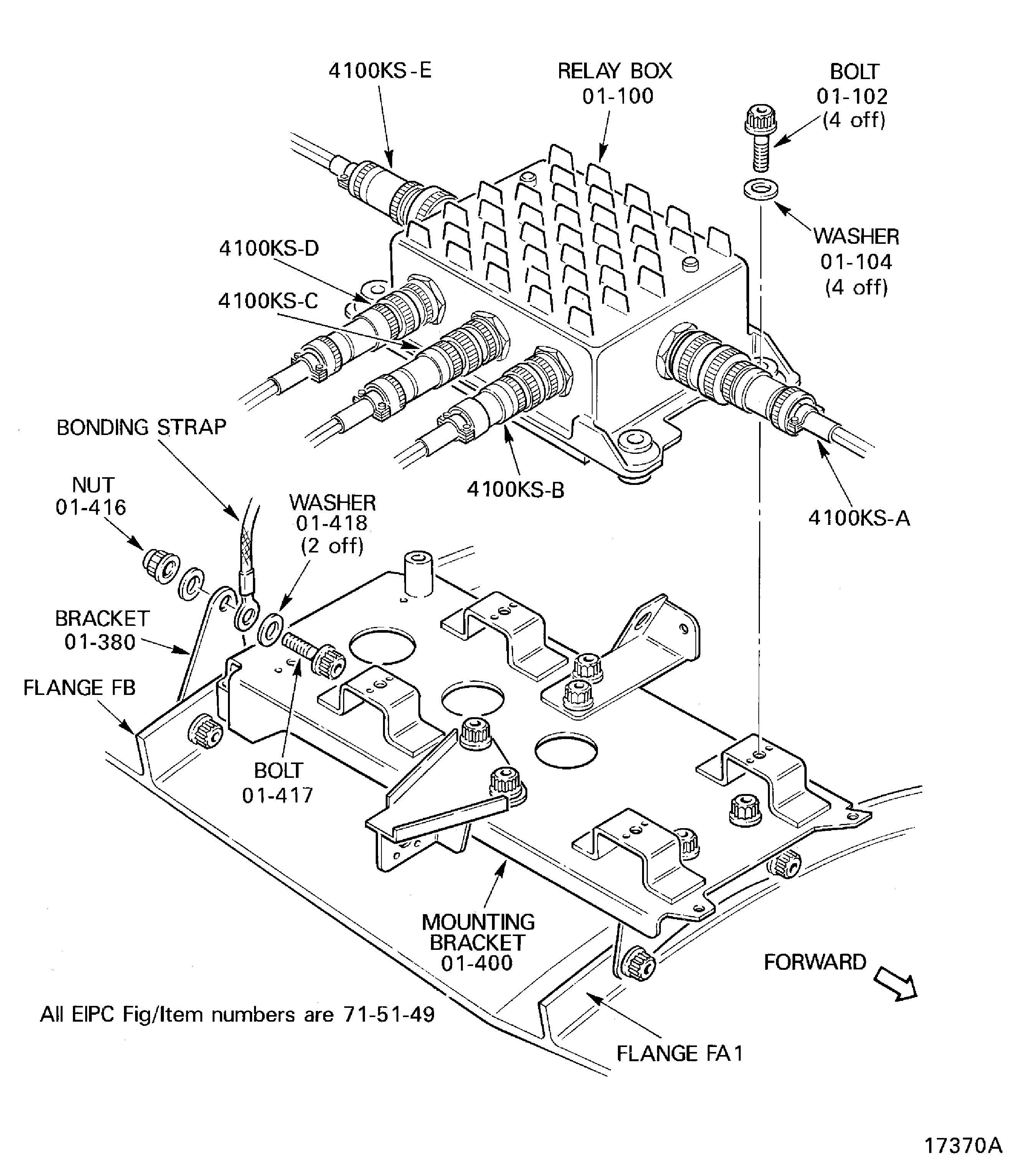

YOU MUST NOT PUT ELECTRICAL POWER THROUGH THE IGNITION SYSTEM UNTIL ALL THE WORK IS COMPLETED.YOU MUST NOT TOUCH THE IGNITION SYSTEM HIGH TENSION (HT) COMPONENTS WHEN THE ELECTRICAL POWER IS PUT THROUGH THE IGNITION SYSTEM. THE DISCHARGE CURRENT IS DANGEROUSLY HIGH.Install the relay box on the mounting bracket Ignition Relay Box (71-51-49, 01-400) pads with the four bolts and the four washers Ignition Relay Box (71-51-49, 01-102 and Ignition Relay Box 01-104). Torque the bolts to 36 to 45 lbf.in (4 to 5 Nm.).

WARNING

WHEN YOU USE COMAT 01-002 INHIBITED AND STABILIZED TRICHLOROETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NO GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the bonding strap connector and its mating face on the bracket Ignition Relay Box (71-51-49, 01-380) with CoMat 01-002 SOLVENT, DELETED..

Attach the bonding strap to the bracket with the bolt Ignition Relay Box (71-51-49, 01-417), the two washers Ignition Relay Box (71-51-49, 01-418) and the nut Ignition Relay Box (71-51-49, 01-416). Torque the nut to 85 to 105 lbf.in (10 to 12 Nm).

If the bonding strap impedance check is not satisfactory, do Step again. Make sure the bonding strap is not damaged and is installed correctly.

Install the bonding strap on flange FB.

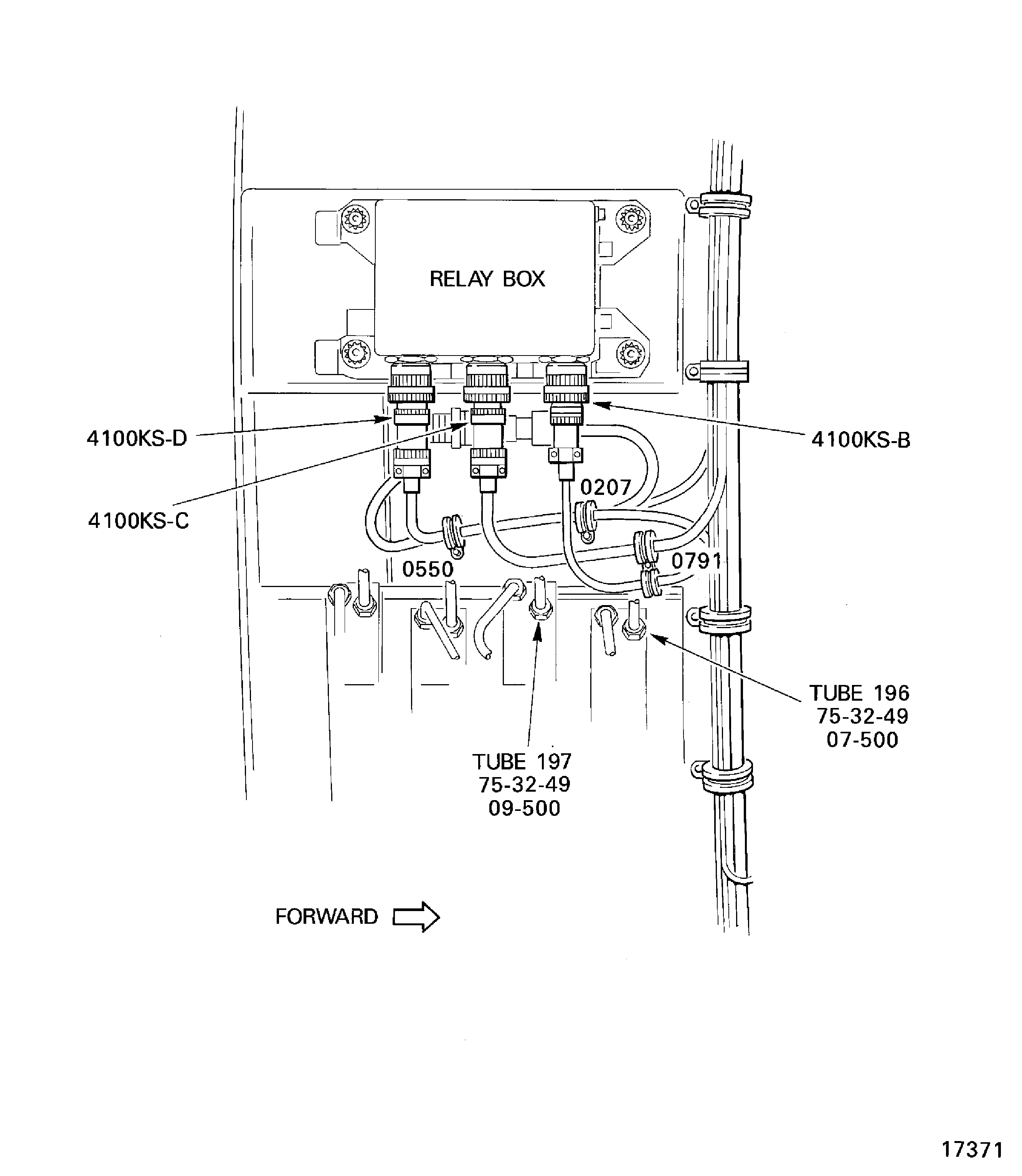

Remove the CoMat 06-086 TIES which attach the electrical harness/connectors 4100KS-B, 4100KS-C and 4100KS-D to the primary harness bundle. Connect each electrical connector to the relay box receptacle. Torque the connectors to 18* lbf.in (2.0 Nm).

Remove the CoMat 06-086 TIES which attach the electrical connectors 4100KS-A and 4100KS-E to the primary harness bundle and the mounting bracket. Connect each electrical connector to the relay box receptacles. Torque the connectors to 21* lbf.in (2.4 Nm).

Connect the electrical connectors.

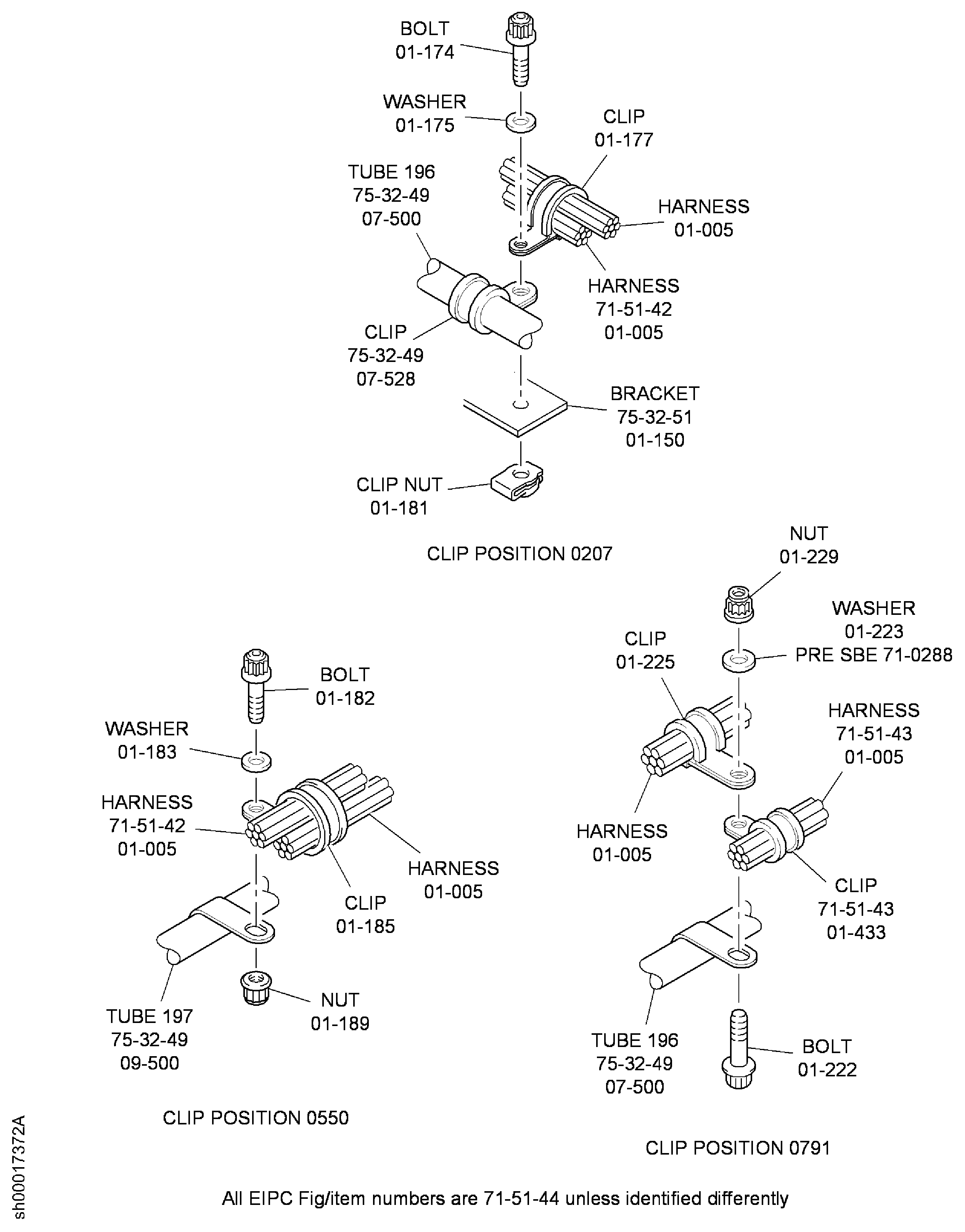

Attach the electrical harness together with CoMat 02-159 LACING TAPE. Refer to TASK 72-00-32-420-004.

SUBTASK 72-00-32-450-051 Install the Relay Box (71-51-49,01-100)

Refer to Figure.

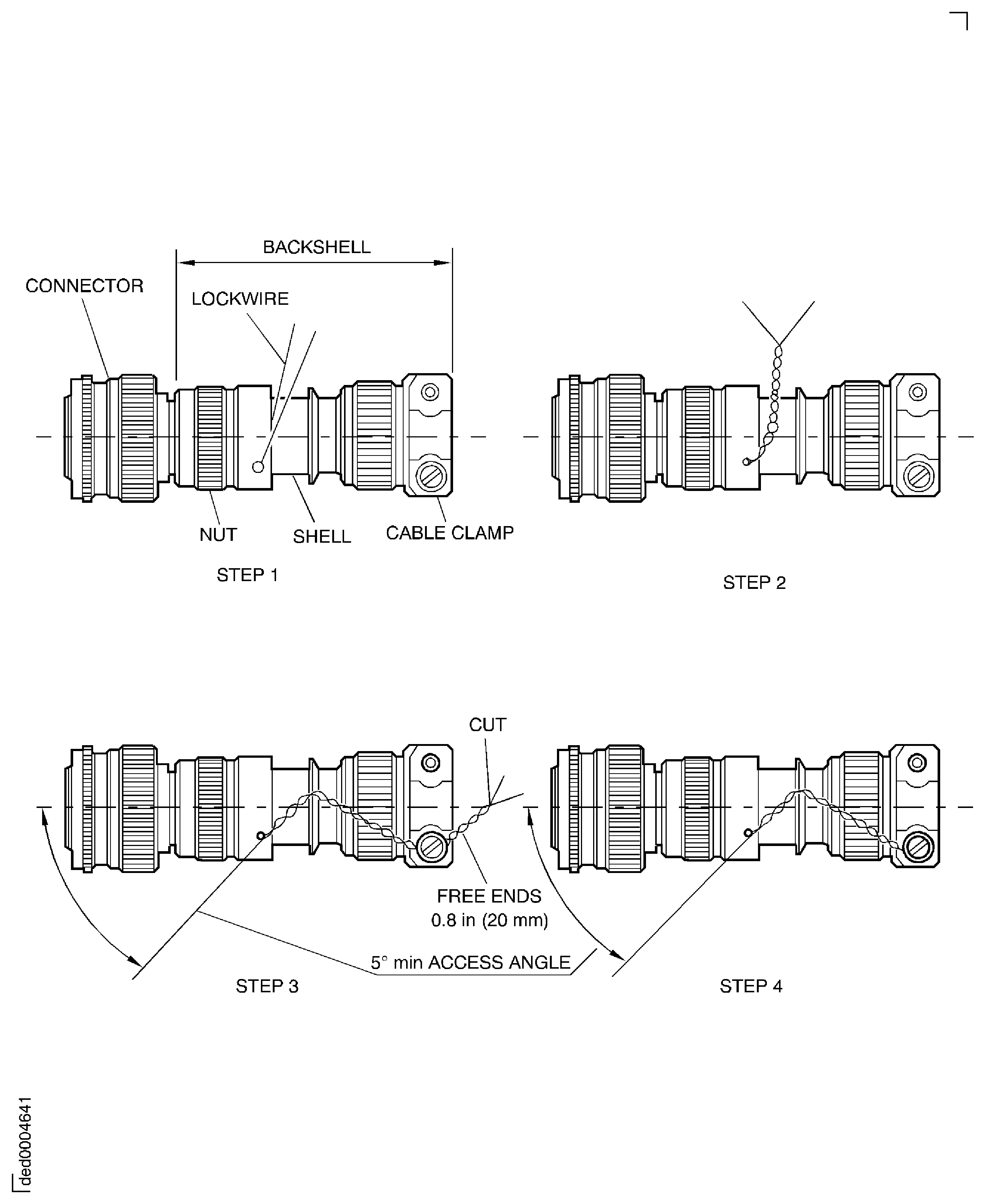

Make sure that all the applicable backshells and cable clamps are safetied with CoMat 02-126 LOCKWIRE. Refer to the SPM TASK 70-42-05-400-501.

SUBTASK 72-00-32-210- Visually Inspect the Electrical Backshells and Cable Clamps

Figure: Install the Relay Box

Sheet 1

Figure: Install the Relay Box

Sheet 2

Figure: Install the Relay Box

Sheet 3

Figure: Visually Inspect the Backshells and Cable Clamps

Visually Inspect the Backshells and Cable Clamps