Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-41-300-005 HP Compressor Rotor Blade(s) - Hand Cropping of Replacement Blade, Repair-005 (VRS6523)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

HPC Rotor Blades (72-41-15, 01-200) | 6A3513 |

HPC Rotor Blades (72-41-15, 01-200) | 6A3938 |

Deleted | Deleted |

Deleted | Deleted |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 01-200) | 6A8353 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 01-200) | 6A8688 |

HPC Rotor Blades (72-41-15, 01-500) | 6A3333 |

HPC Rotor Blades (72-41-15, 01-500) | 6A3635 |

HPC Rotor Blades (72-41-15, 01-500) | 6A3939 |

HPC Rotor Blades (72-41-15, 01-500) | 6A4254 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 01-500) | 6A7635 |

HPC Rotor Blades (72-41-15, 01-500) | 6A8738 |

HPC Rotor Blades (72-41-15, 01-800) | 6A3335 |

HPC Rotor Blades (72-41-15, 01-800) | 6A3637 |

HPC Rotor Blades (72-41-15, 01-800) | 6A3941 |

HPC Rotor Blades (72-41-15, 01-800) | 6A4198 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 01-800) | 6A8449 |

HPC Rotor Blades (72-41-15, 01-800) | 6A8451 |

HPC Rotor Blades (72-41-15, 01-800) | 6B1346 |

HPC Rotor Blades (72-41-15, 02-170) | 6A3338 |

HPC Rotor Blades (72-41-15, 02-170) | 6A4902 |

HPC Rotor Blades (72-41-15, 02-170) | 6A5586 |

HPC Rotor Blades (72-41-15, 02-170) | 6A7406 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-170) | 6A8322 |

HPC Rotor Blades (72-41-15, 02-170) | 6A8463 |

HPC Rotor Blades (72-41-15, 02-170) | 6A8797 |

HPC Rotor Blades (72-41-15, 02-185) | 6A3339 |

HPC Rotor Blades (72-41-15, 02-185) | 6A4903 |

HPC Rotor Blades (72-41-15, 02-185) | 6A5587 |

HPC Rotor Blades (72-41-15, 02-185) | 6A7407 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-185) | 6A8323 |

HPC Rotor Blades (72-41-15, 02-185) | 6A8464 |

HPC Rotor Blades (72-41-15, 02-185) | 6A8798 |

HPC Rotor Blades (72-41-15, 02-200) | 6A3340C01 |

HPC Rotor Blades (72-41-15, 02-200) | 6A4904C01 |

HPC Rotor Blades (72-41-15, 02-200) | 6A5583C01 |

HPC Rotor Blades (72-41-15, 02-200) | 6A7405C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-200) | 6A8320 |

HPC Rotor Blades (72-41-15, 02-200) | 6A8461 |

HPC Rotor Blades (72-41-15, 02-200) | 6A8732 |

HPC Rotor Blades (72-41-15, 02-215) | 6A3340C01 |

HPC Rotor Blades(72-41-15,02-215) | 6A4904C01 |

HPC Rotor Blades (72-41-15, 02-215) | 6A5583C01 |

HPC Rotor Blades (72-41-15, 02-215) | 6A7405C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-215) | 6A8320 |

HPC Rotor Blades (72-41-15, 02-215) | 6A8461 |

HPC Rotor Blades (72-41-15, 02-215) | 6A8732 |

HPC Rotor Blades (72-41-15, 02-217) | 6A3340C02 |

HPC Rotor Blades (72-41-15, 02-217) | 6A4904C02 |

HPC Rotor Blades (72-41-15, 02-217) | 6A5583C02 |

HPC Rotor Blades (72-41-15, 02-217) | 6A7405C02 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-217) | 6A8321 |

HPC Rotor Blades (72-41-15, 02-217) | 6A8462 |

HPC Rotor Blades (72-41-15, 02-217) | 6A8733 |

HPC Rotor Blades (72-41-15, 02-270) | 6A3246 |

HPC Rotor Blades (72-41-15, 02-270) | 6A4302 |

HPC Rotor Blades (72-41-15, 02-270) | 6A4905 |

HPC Rotor Blades (72-41-15, 02-270) | 6A5588 |

HPC Rotor Blades (72-41-15, 02-270) | 6A6462 |

HPC Rotor Blades (72-41-15, 02-270) | 6A6493 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-270) | 6A8314 |

HPC Rotor Blades (72-41-15, 02-270) | 6A8743 |

HPC Rotor Blades (72-41-15, 02-285) | 6A3247 |

HPC Rotor Blades (72-41-15, 02-285) | 6A4906 |

HPC Rotor Blades (72-41-15, 02-285) | 6A5589 |

HPC Rotor Blades (72-41-15, 02-285) | 6A6463 |

HPC Rotor Blades (72-41-15, 02-285) | 6A6494 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-285) | 6A8315 |

HPC Rotor Blades (72-41-15, 02-285) | 6A8744 |

HPC Rotor Blades (72-41-15, 02-300) | 6A3245C01 |

HPC Rotor Blades (72-41-15, 02-300) | 6A4907C01 |

HPC Rotor Blades (72-41-15, 02-300) | 6A5584C01 |

HPC Rotor Blades (72-41-15, 02-300) | 6A6469C01 |

HPC Rotor Blades (72-41-15, 02-300) | 6A6492C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-300) | 6A8312 |

HPC Rotor Blades (72-41-15, 02-300) | 6A8741 |

HPC Rotor Blades (72-41-15, 02-315) | 6A3245C01 |

HPC Rotor Blades (72-41-15, 02-315) | 6A4907C01 |

HPC Rotor Blades (72-41-15, 02-315) | 6A5584C01 |

HPC Rotor Blades (72-41-15, 02-315) | 6A6469C01 |

HPC Rotor Blades (72-41-15, 02-315) | 6A6492C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-315) | 6A8312 |

HPC Rotor Blades (72-41-15, 02-315) | 6A8741 |

HPC Rotor Blades (72-41-15, 02-317) | 6A3245C02 |

HPC Rotor Blades (72-41-15, 02-317) | 6A4907C02 |

HPC Rotor Blades (72-41-15, 02-317) | 6A5584C02 |

HPC Rotor Blades (72-41-15, 02-317) | 6A6469C02 |

HPC Rotor Blades (72-41-15, 02-317) | 6A6492C02 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-317) | 6A8313 |

HPC Rotor Blades (72-41-15, 02-317) | 6A8742 |

HPC Rotor Blades (72-41-15, 02-370) | 6A3249 |

HPC Rotor Blades (72-41-15, 02-370) | 6A4908 |

HPC Rotor Blades (72-41-15, 02-370) | 6A5590 |

HPC Rotor Blades (72-41-15, 02-370) | 6A6464 |

HPC Rotor Blades (72-41-15, 02-370) | 6A6496 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-370) | 6A8742 |

HPC Rotor Blades (72-41-15, 02-385) | 6A3250 |

HPC Rotor Blades (72-41-15, 02-385) | 6A4307 |

HPC Rotor Blades (72-41-15, 02-385) | 6A4909 |

HPC Rotor Blades (72-41-15, 02-385) | 6A5591 |

HPC Rotor Blades (72-41-15, 02-385) | 6A6465 |

HPC Rotor Blades (72-41-15, 02-385) | 6A6497 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-385) | 6A8748 |

HPC Rotor Blades (72-41-15, 02-400) | 6A3248C01 |

HPC Rotor Blades (72-41-15, 02-400) | 6A4910C01 |

HPC Rotor Blades (72-41-15, 02-400) | 6A5585C01 |

HPC Rotor Blades (72-41-15, 02-400) | 6A6470C01 |

HPC Rotor Blades (72-41-15, 02-400) | 6A6495C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-400) | 6A8745 |

HPC Rotor Blades (72-41-15, 02-415) | 6A3248C01 |

HPC Rotor Blades (72-41-15, 02-415) | 6A4910C01 |

HPC Rotor Blades (72-41-15, 02-415) | 6A5585C01 |

HPC Rotor Blades (72-41-15, 02-415) | 6A6470C01 |

HPC Rotor Blades (72-41-15, 02-415) | 6A6495C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-415) | 6A8745 |

HPC Rotor Blades (72-41-15, 02-417) | 6A3248C02 |

HPC Rotor Blades (72-41-15, 02-417) | 6A4910C02 |

HPC Rotor Blades (72-41-15, 02-417) | 6A5585C02 |

HPC Rotor Blades (72-41-15, 02-417) | 6A6470C02 |

HPC Rotor Blades (72-41-15, 02-417) | 6A6495C02 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-417) | 6A8746 |

HPC Rotor Blades (72-41-15, 02-470) | 6A3252 |

HPC Rotor Blades (72-41-15, 02-470) | 6A4366 |

HPC Rotor Blades (72-41-15, 02-470) | 6A4420 |

HPC Rotor Blades (72-41-15, 02-470) | 6A4726 |

HPC Rotor Blades (72-41-15, 02-470) | 6A6566 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-470) | 6A8751 |

HPC Rotor Blades (72-41-15, 02-485) | 6A3253 |

HPC Rotor Blades (72-41-15, 02-485) | 6A4367 |

HPC Rotor Blades (72-41-15, 02-485) | 6A4846 |

HPC Rotor Blades (72-41-15, 02-485) | 6A5637 |

HPC Rotor Blades (72-41-15, 02-485) | 6A5638 |

HPC Rotor Blades (72-41-15, 02-485) | 6A5645 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-485) | 6A8752 |

HPC Rotor Blades (72-41-15, 02-500) | 6A3251C01 |

HPC Rotor Blades (72-41-15, 02-500) | 6A4211C01 |

HPC Rotor Blades (72-41-15, 02-500) | 6A4365C01 |

HPC Rotor Blades (72-41-15, 02-500) | 6A4419C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-500) | 6A8749 |

HPC Rotor Blades (72-41-15, 02-515) | 6A3251C01 |

HPC Rotor Blades (72-41-15, 02-515) | 6A4211C01 |

HPC Rotor Blades (72-41-15, 02-515) | 6A4365C01 |

HPC Rotor Blades (72-41-15, 02-515) | 6A4419C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-515) | 6A8749 |

HPC Rotor Blades (72-41-15, 02-517) | 6A3251C02 |

HPC Rotor Blades (72-41-15, 02-517) | 6A4211C02 |

HPC Rotor Blades (72-41-15, 02-517) | 6A4365C02 |

HPC Rotor Blades (72-41-15, 02-517) | 6A4419C02 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-517) | 6A8750 |

HPC Rotor Blades (72-41-15, 02-570) | 6A3255 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-570) | 6A4727 |

HPC Rotor Blades (72-41-15, 02-570) | 6A5639 |

HPC Rotor Blades (72-41-15, 02-570) | 6A6563 |

HPC Rotor Blades (72-41-15, 02-570) | 6A6567 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-570) | 6A8755 |

HPC Rotor Blades (72-41-15, 02-585) | 6A3256 |

HPC Rotor Blades (72-41-15, 02-585) | 6A4221 |

HPC Rotor Blades (72-41-15, 02-585) | 6A5640 |

HPC Rotor Blades (72-41-15, 02-585) | 6A5646 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-585) | 6A8756 |

HPC Rotor Blades (72-41-15, 02-600) | 6A3254C01 |

HPC Rotor Blades (72-41-15, 02-600) | 6A4222C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-600) | 6A8753 |

HPC Rotor Blades (72-41-15, 02-615) | 6A3254C01 |

HPC Rotor Blades (72-41-15, 02-615) | 6A4222C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-615) | 6A8753 |

HPC Rotor Blades (72-41-15, 02-617) | 6A3254C02 |

HPC Rotor Blades (72-41-15, 02-617) | 6A4222C02 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-617) | 6A8754 |

HPC Rotor Blades (72-41-15, 02-670) | 6A3258 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-670) | 6A4728 |

HPC Rotor Blades (72-41-15, 02-670) | 6A5641 |

HPC Rotor Blades (72-41-15, 02-670) | 6A6564 |

HPC Rotor Blades (72-41-15, 02-670) | 6A6568 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-670) | 6A8759 |

HPC Rotor Blades (72-41-15, 02-685) | 6A3259 |

HPC Rotor Blades (72-41-15, 02-685) | 6A4253 |

HPC Rotor Blades (72-41-15, 02-685) | 6A5642 |

HPC Rotor Blades (72-41-15, 02-685) | 6A5647 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-685) | 6A8760 |

HPC Rotor Blades (72-41-15, 02-700) | 6A3257C01 |

HPC Rotor Blades (72-41-15, 02-700) | 6A4251C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-700) | 6A8757 |

HPC Rotor Blades (72-41-15, 02-715) | 6A3257C01 |

HPC Rotor Blades (72-41-15, 02-715) | 6A4251C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-715) | 6A8757 |

HPC Rotor Blades (72-41-15, 02-717) | 6A3257C02 |

HPC Rotor Blades (72-41-15, 02-717) | 6A4251C02 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-717) | 6A8758 |

HPC Rotor Blades (72-41-15, 02-770) | 6A3261 |

HPC Rotor Blades (72-41-15, 02-770) | 6A4729 |

HPC Rotor Blades (72-41-15, 02-770) | 6A5643 |

HPC Rotor Blades (72-41-15, 02-770) | 6A5947 |

HPC Rotor Blades (72-41-15, 02-770) | 6A6565 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-770) | 6A8763 |

HPC Rotor Blades (72-41-15, 02-785) | 6A3262 |

HPC Rotor Blades (72-41-15, 02-785) | 6A4206 |

HPC Rotor Blades (72-41-15, 02-785) | 6A5644 |

HPC Rotor Blades (72-41-15, 02-785) | 6A5648 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-785) | 6A8764 |

HPC Rotor Blades (72-41-15, 02-800) | 6A3260C01 |

HPC Rotor Blades (72-41-15, 02-800) | 6A4207C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-800) | 6A8761 |

HPC Rotor Blades (72-41-15, 02-815) | 6A3260C01 |

HPC Rotor Blades (72-41-15, 02-815) | 6A4207C01 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-815) | 6A8761 |

HPC Rotor Blades (72-41-15, 02-817) | 6A3260C02 |

HPC Rotor Blades (72-41-15, 02-817) | 6A4207C02 |

Deleted | Deleted |

HPC Rotor Blades (72-41-15, 02-817) | 6A8761 |

Material of component

PART IDENT | MATERIAL |

|---|---|

HP compressor rotor blade(s) stage 3 to stage 8 | Titanium alloy |

HP compressor rotor blade(s) stage 9 to stage 12 | Nickel alloy |

General

This repair must only be done when the instruction to do so is given in 72-00-41 Inspection/Check.

This TASK gives the procedure to hand crop replacement HP compressor rotor blade.

As each rotor blade is removed, its circumferential location in the assembly must be recorded.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Hand held mechanical clutters | LOCAL | Hand held mechanical clutters | ||

| Hand metal file | LOCAL | Hand metal file | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Precision mass weighing equipment | LOCAL | Precision mass weighing equipment | ||

| Soft jaw fixture | LOCAL | Soft jaw fixture | ||

| Surface measuring equipment | LOCAL | Surface measuring equipment | ||

| Vibrating Marking Pencil | LOCAL | Vibrating Marking Pencil | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-096 MARKER PEN | X111X | CoMat 02-096 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | 1E1X8 | CoMat 05-020 | ||

| CoMat 05-082 WATERPROOF SILICON CARBIDE | 1E1X8 | CoMat 05-082 | ||

| CoMat 05-127 ABRASIVE PAD | LOCAL | CoMat 05-127 | ||

| CoMat 05-140 ABRASIVE STONE SILICON CARBIDE | LOCAL | CoMat 05-140 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | X222X | CoMat 06-063 |

Spares

NONESafety Requirements

WARNING

Procedure

Refer to Figure.

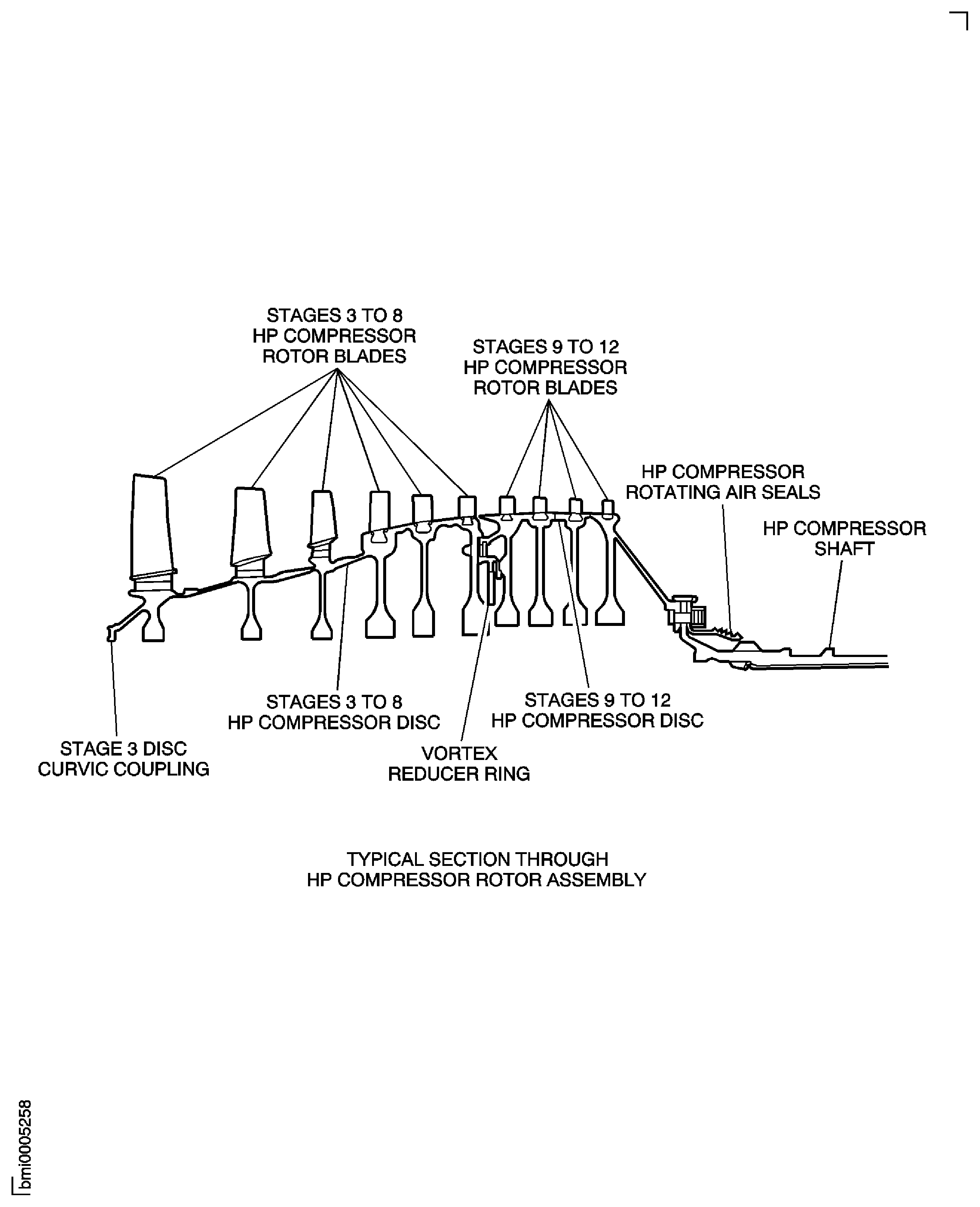

SUBTASK 72-00-41-350-028 Examine the Rotor Assembly

For A1 model HP compressor rotor assembly, refer to TASK 72-41-10-040-001-A00.

For A5 model HP compressor rotor assembly, refer to TASK 72-41-10-040-001-B00.

Remove the damaged blade.

SUBTASK 72-00-41-350-029 Remove the Damaged Rotor Blade(s)

Find the damaged blade.

Remove the nearest adjacent serviceable blade.

For A1 model HP compressor rotor assembly refer to TASK 72-41-10-040-001-A00.

For A5 model HP compressor rotor assembly refer to TASK 72-41-10-040-001-B00.

Remove the nearest serviceable blade.

Refer to TASK 72-41-15-100-000.

Clean the nearest serviceable blade.

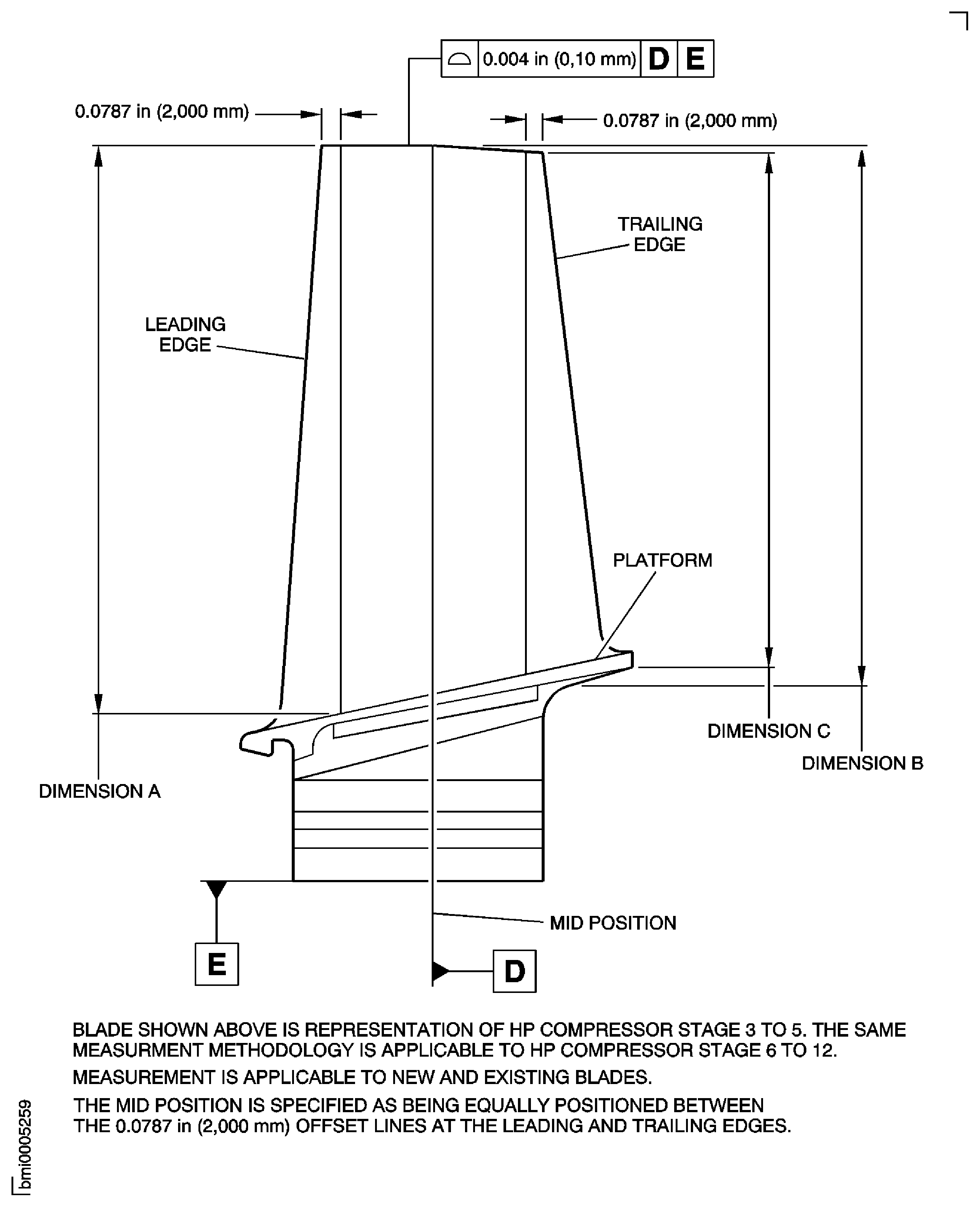

Measure the blade at the three positions shown in Figure.

Record the measurements.

Use Workshop inspection equipment 1 off.

Measure the nearest serviceable blade.

Refer to TASK 72-41-10-440-000.

Install the removed the serviceable blade again.

SUBTASK 72-00-41-350-030 Remove, Clean, Measure and Re-install the Nearest Serviceable Rotor Blade

NOTE

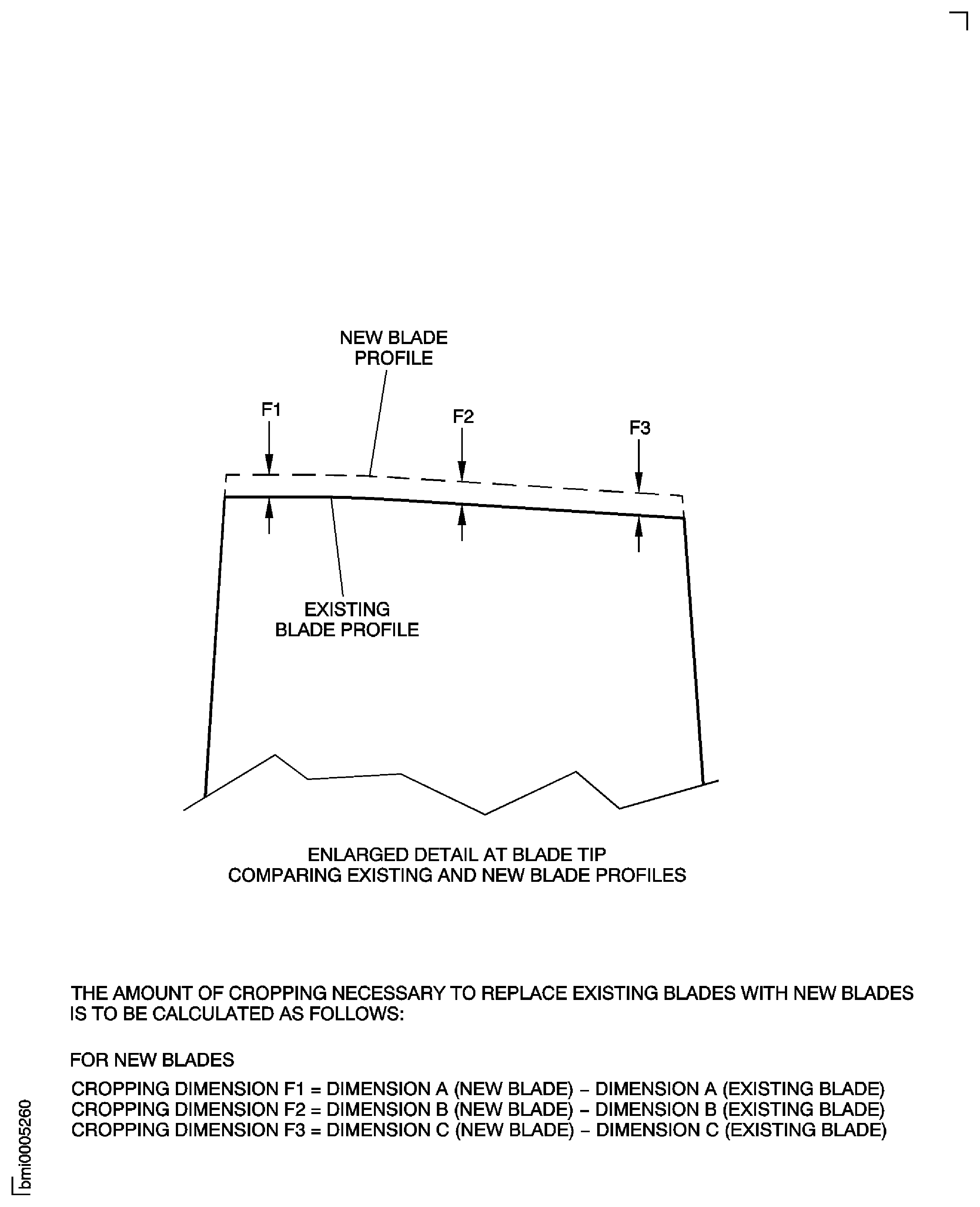

When you select a replacement blade choose the one that is lightly heavier than the rejected blade. This is for the removal of material from the blade tip during the blade cropping process.After the blade cropping process, the weight of the finished blade must be in plus or minus 0.5 gram of the original blade. If the cropped replacement blade is not in plus or minus 0.5 gram of the original blade, a new blade must be selected and the cropping process must be done again. This repair is limited to one blade only per HP compressor assembly without rebalancing. Balance check is necessary when more than one blade is replaced in this procedure.Measure the blade at three positions as shown in Figure.

Record the measurements.

Use Workshop inspection equipment 1 off.

Measure the replacement blade(s).

SUBTASK 72-00-41-220-071 Measure the Replacement New Blade(s)

Mark the area to be cropped from the tip on the new blade.

Measure the blade at three positions as shown in Figure.

Make sure the mark is in 0.002 in. (0.05 mm) of the necessary distance from the blade platform.

Use Workshop inspection equipment 1 off.

Mark out the replacement new blade.

SUBTASK 72-00-41-220-074 Mark-out the Replacement New Blade(s)

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE STONES AND ABRASIVE PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - APPLY GENTLE PRESSURE AND KEEP THE TOOL SPEED AS LOW AS POSSIBLE TO PREVENT BUILD UP OF HEAT. USE TECHNIQUES WHICH WILL LET FOR PROGRESSIVE WEAR OF THE DRESSING MEDIA TO GIVE A CONTINUALLY FRESH CUTTING SURFACE TO THE WORK PIECE.

CAUTION

TITANIUM COMPONENT - DO NOT DWELL ON ONE AREA OF THE COMPONENT.

CAUTION

TITANIUM COMPONENT - DRESS WHERE POSSIBLE, IN A CIRCULAR MOTION, TAKING LIGHT CUTS TO PREVENT OVERHEATING.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU REMOVE MATERIAL, BLEND AND POLISH TO MAKE SMOOTH, THAT NO SPARKS ARE PRODUCED.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT MUST BE REJECTED.Hand crop the tip of the blade.

Make sure the tip is dressed in the direction from the leading edge tip to the trailing edge tip.

If necessary, use mechanical hand clutters, smooth hand metal file and/or CoMat 05-140 ABRASIVE STONE SILICON CARBIDE.

Make sure you keep the dimensional limits set in Step.

Remove tip material by cropping.

Blend and polish the replacement blade tip.

Make sure the tip is dressed in the direction from the leading edge tip to the trailing edge tip.

Use CoMat 05-020 WATERPROOF SILICON CARBIDE, CoMat 05-082 WATERPROOF SILICON CARBIDE and CoMat 05-127 ABRASIVE PAD.

Make sure you keep the dimensional limits set in Step.

Blend and polish the replacement new blade tip.

SUBTASK 72-00-41-350-031 Crop the Replacement New Blade

Refer to the SPM TASK 70-11-39-300-503, SUBTASK 70-11-39-300-001.

Do a local swab etch of the dressed area.

SUBTASK 72-00-41-220-072 Swab Etch the Cropped Area

Measure the blade length at three positions as shown in Figure.

Make sure the blade length is in 0.002 in. (0.05 mm) of the adjacent serviceable blade length measured.

Use Workshop inspection equipment 1 off.

Dimensionally examine the replacement new blade.

SUBTASK 72-00-41-220-073 Examine the Replacement New Blade

Refer to the SPM TASK 70-09-00-400-501.

Use Vibrating Marking Pencil 1 off.

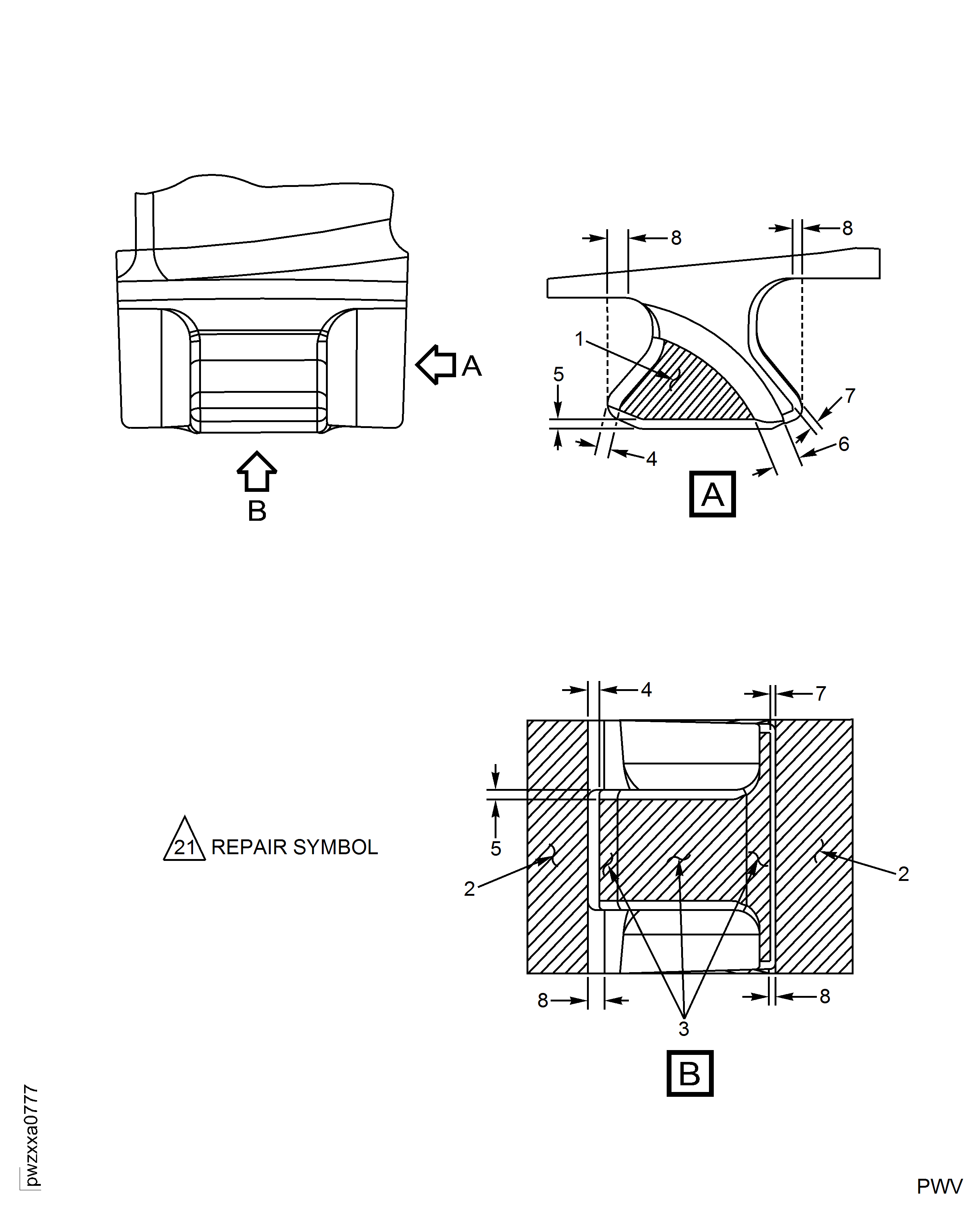

Mark the number 21 inside a triangle using the vibration peen method.

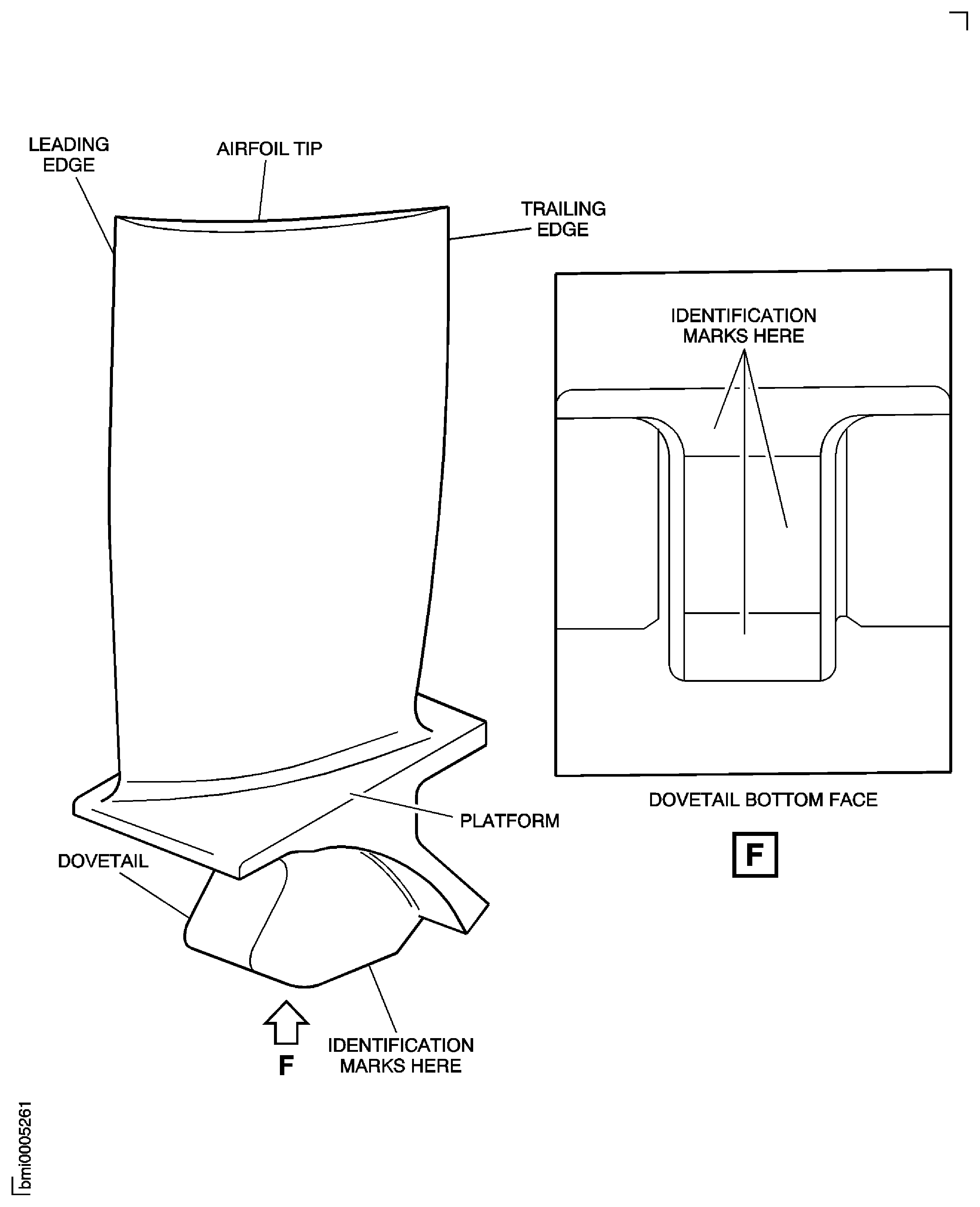

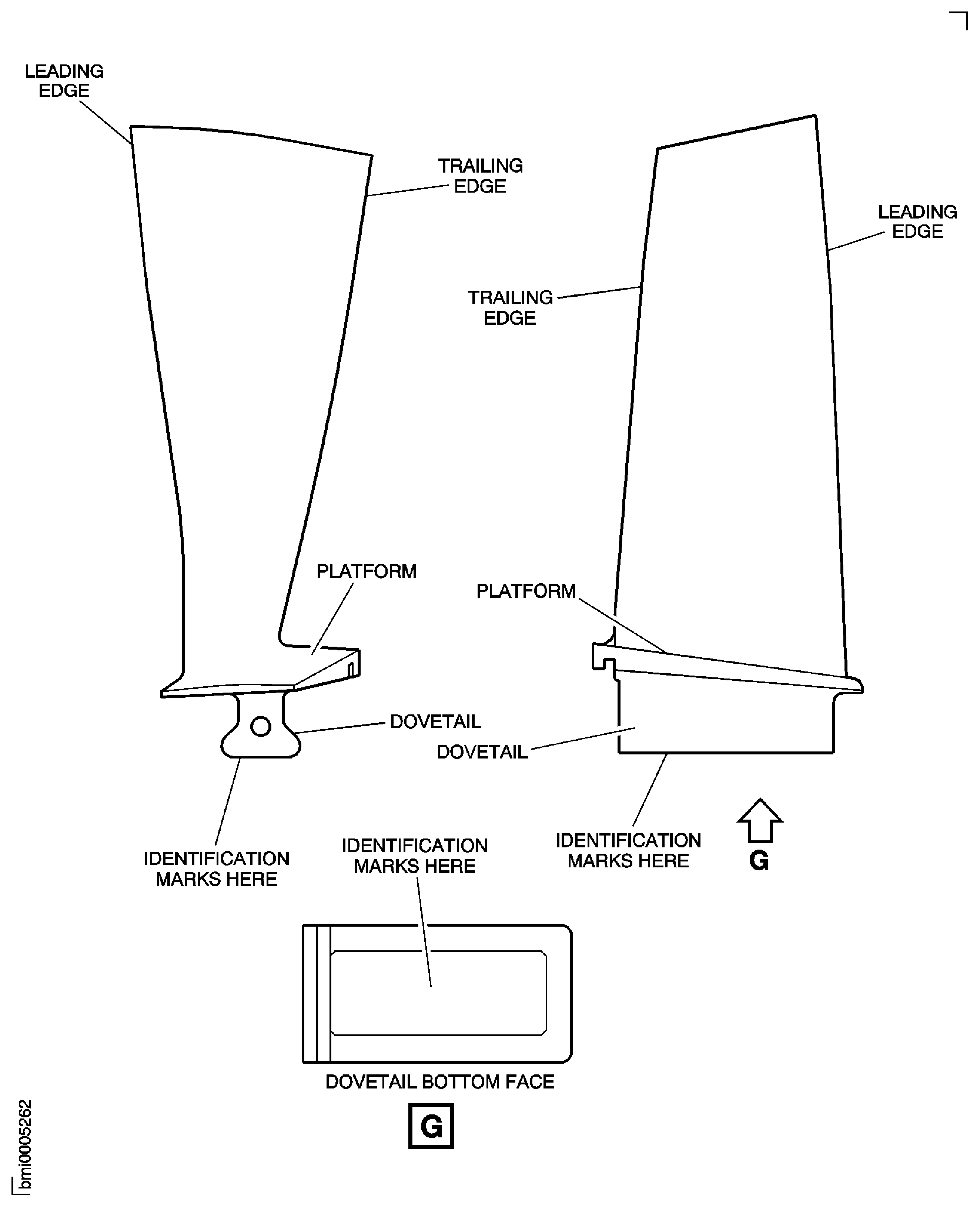

Mark the repair symbol at one of the indicated location(s) on the HP Compressor Rotor Blade(s).

SUBTASK 72-00-41-350-032 Identify the Replacement New Blade

Refer to TASK 72-41-10-440-000.

NOTE

After the blade cropping process, the weight of the finished blade must be in plus or minus 0.5 gram of the original blade. If the cropped replacement blade is not in plus or minus 0.5 gram of the original blade, a new blade must be selected and the cropping process must be done again. This repair is limited to one blade only per HP compressor assembly without rebalancing. Balance check is necessary when more than one blade is replaced in this procedure.The reference blade(s) used for measurement purpose must be installed again in their original positions in the assembly.Install the new replacement blade in the original blade set.

SUBTASK 72-00-41-420-059 Install the Replacement new Blade

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: HP Compressor Stage 6 To 8 Rotor Blades - Repair Details And Dimensions

HP Compressor Stage 6 To 8 Rotor Blades - Repair Details And Dimensions

Figure: HP Compressor Stage 3 To 5 Rotor Blades - Repair Details And Dimensions

HP Compressor Stage 3 To 5 Rotor Blades - Repair Details And Dimensions

Figure: HP Compressor Stage 9 To 12 Rotor Blades - Repair Marking Zones

HP Compressor Stage 9 To 12 Rotor Blades - Repair Marking Zones