Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-00-430-001 LPC/Intermediate Case Module - Install The Fan Frame And Fitting Parts (Fan Frame Assembly), Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

The No. 1 strut, which is the top position strut of the fan frame assembly, is identified by the five pressure tubes on the No. 1 strut leading edge.

This TASK gives the procedure to install the fan frame assembly. The subsequent TASKS give the procedure to assemble the LP compressor/intermediate case module.

TASK 72-32-00-430-002 Install the center bearing housing, the PTO sealing plate, the oil feed adapter, the main oil distributor and the oil feed tube.

TASK 72-32-00-430-003 Install the NO. 3 bearing, internal gearbox and support assembly.

TASK 72-32-00-430-004 Install the No. 2 and No. 3 bearing oil feed tubes, the NF electrical harness and the rear seal drain tube.

TASK 72-32-00-430-005 Install the No. 1 bearing support assembly.

TASK 72-32-00-430-006 Install the LP shaft, No. 1 and No. 2 bearing assembly.

TASK 72-32-00-430-007 Install the seal support, the front bearing compartment front air seal assembly, the No. 1 bearing compartment air tubes and the No. 1 bearing compartment scavenge oil tube.

TASK 72-32-00-430-008 Install the LP compressor bleed duct, the booster stage bleed valve and actuating mechanism and the right and left rod assemblies.

TASK 72-32-00-430-009 Install the LP compressor stage 2.5 vanes and the rear fairing.

TASK 72-32-00-430-010 Install the LP compressor stage 1.5, 2 and 2.5 assembly.

TASK 72-32-00-430-011 Install the fan case, the oil seal tube, the No. 1, 2, 3 bearing scavenge tube, the hot vent tube, the brush seal and the PTO shaft.

TASK 72-32-00-430-012 Install the fan case liner panels, the panel rubber seals, the fan exit guide vanes and the acoustic linings.

TASK 72-32-00-430-013 Install the fan outlet inner vane assembly.

TASK 72-32-00-430-014 Install the front fairings, the No. 1 and No. 6 strut fairing panels, the fan exit pressure boss and the block.

TASK 72-32-00-430-015 Move the LP compressor/intermediate case module from the turnover stand to the storage stand.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1J12311 Turnover stand | 0AM53 | IAE 1J12311 | 1 | |

| IAE 1J12317 Turnover adapter | 0AM53 | IAE 1J12317 | 1 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

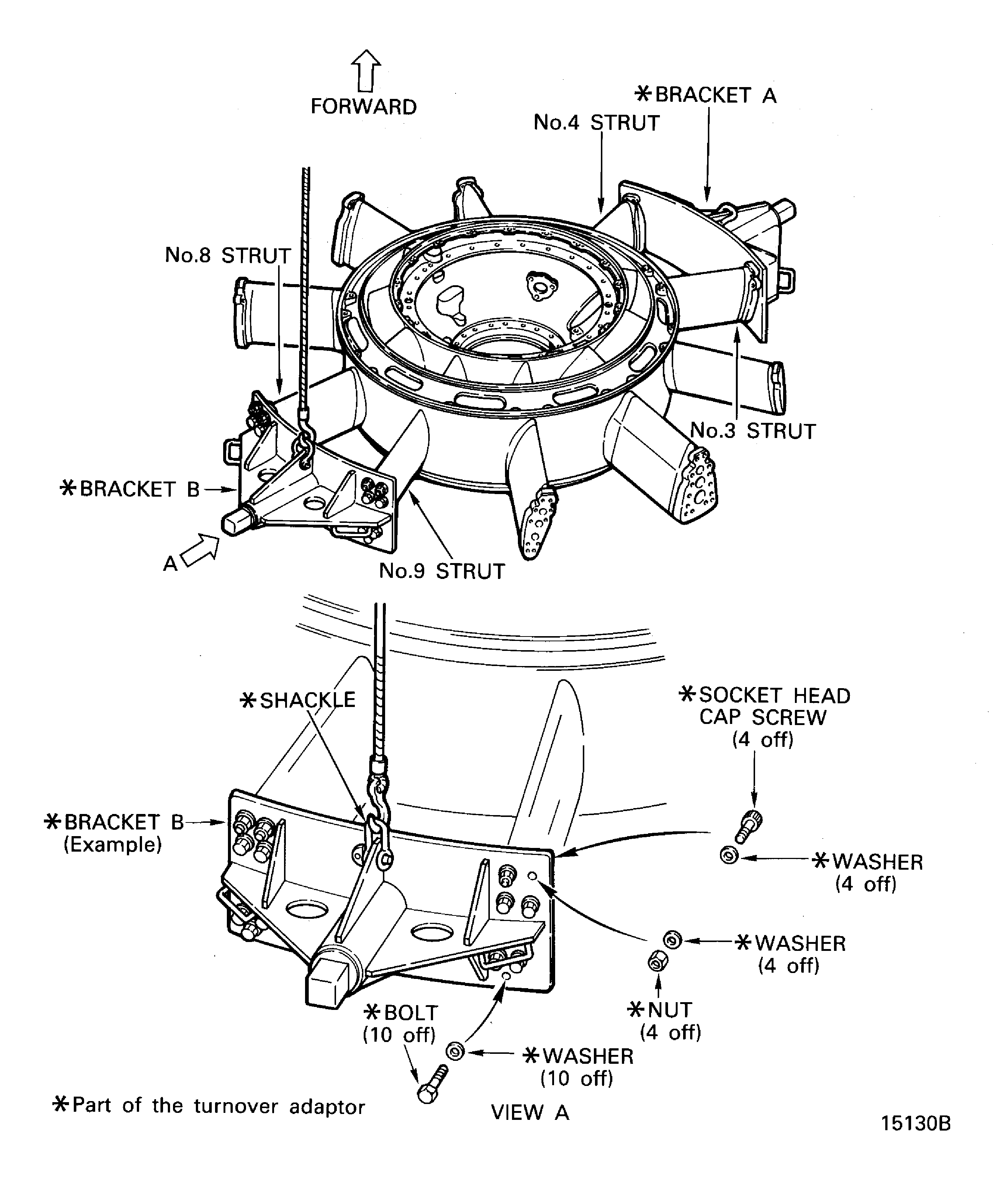

Attach a hoist to the shackle of the bracket B (part of IAE 1J12317 Turnover adapter 1 off).

Install the bracket A (part of IAE 1J12317 Turnover adapter 1 off) to the fan frame assembly.

SUBTASK 72-32-00-430-085 Install the Brackets A and B to the Fan Frame Assembly

Refer to Figure.

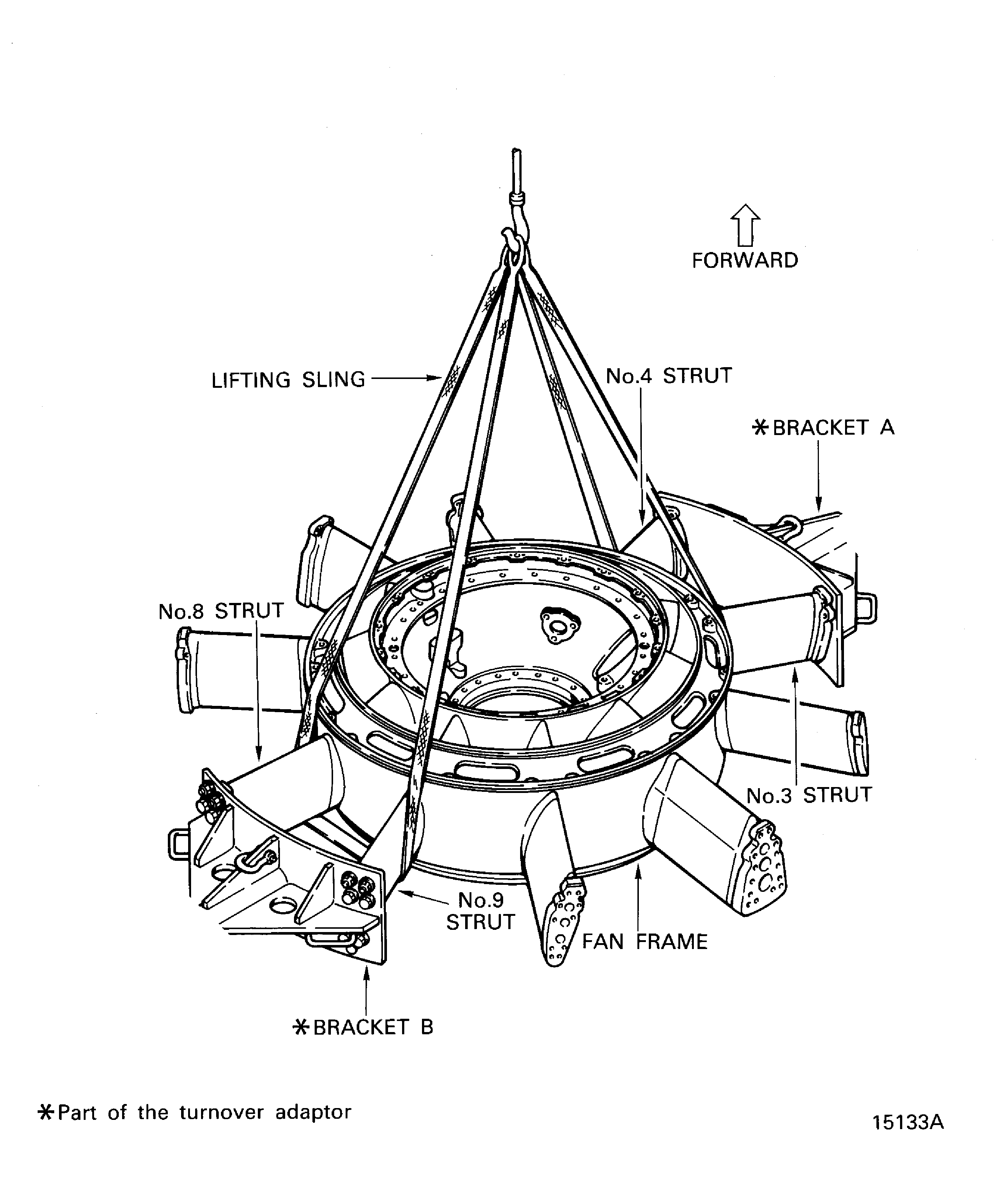

SUBTASK 72-32-00-430-086 Install the lifting Slings to the Fan Frame Assembly

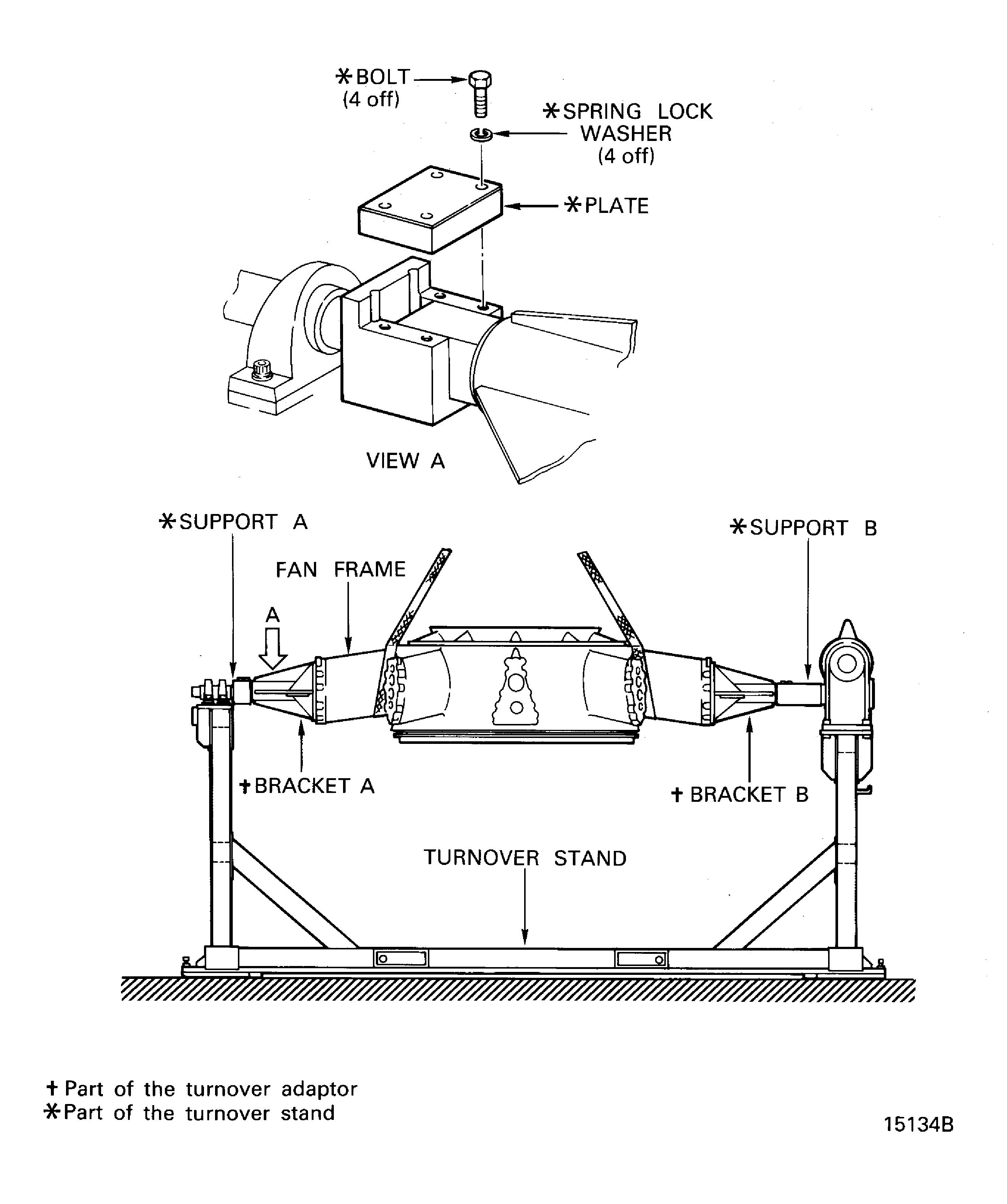

Move the fan frame assembly adjacent to the supports A and B (part of IAE 1J12311 Turnover stand 1 off).

SUBTASK 72-32-00-430-087 Install the Fan Frame Assembly to the Turnover Stand

Refer to Figure.

SUBTASK 72-32-00-430-088 Remove the Two Lifting Slings from the Fan Frame Assembly

Refer to Figure.

SUBTASK 72-32-00-430-089 Turn the Fan Frame Assembly Horizontal with the No. 6 Strut Up

Figure: Install the brackets A and B to the fan frame assembly

Install the brackets A and B to the fan frame assembly

Figure: Install the band slings to the fan frame assembly

Install the band slings to the fan frame assembly

Figure: Install the fan frame assembly to the turnover stand

Install the fan frame assembly to the turnover stand

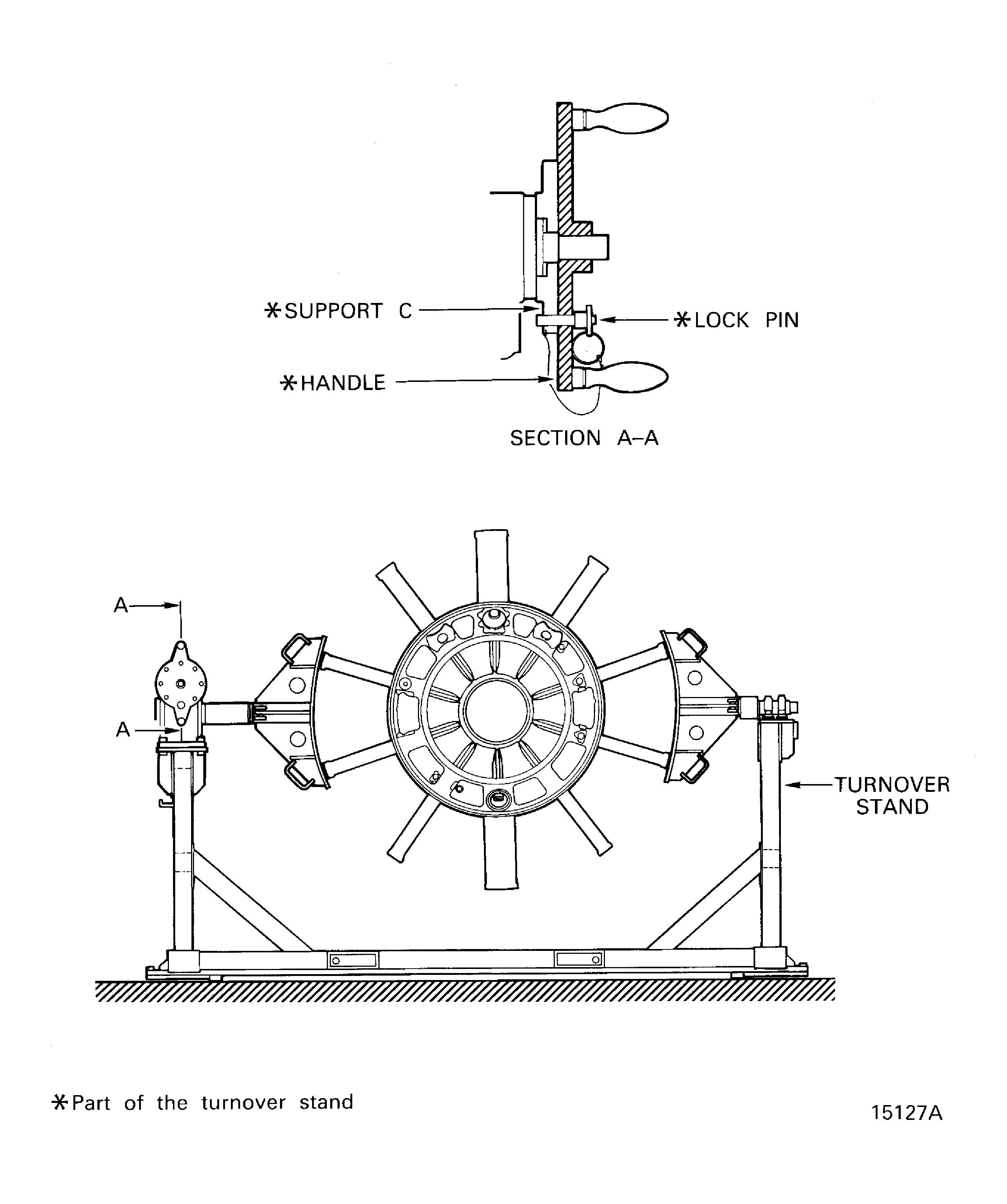

Figure: Install the lock pin in to position to lock the handle of the turnover stand

Install the lock pin in to position to lock the handle of the turnover stand