Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-86-300-008 Intermediate Structure Rear Fairing - Repair The Cracks On The Pads, Repair-008 (VRS1982)

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

Rear fairing assembly | Resin impregnated carbon fiber fabric |

General

Price and availability - none

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard equipment | LOCAL | Standard equipment | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-017 GARNET PAPER, 60 GRIT | LOCAL | CoMat 05-017 | ||

| CoMat 05-079 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-079 | ||

| CoMat 05-080 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-080 | ||

| CoMat 06-073 INK, METAL MARKING | 88303 | CoMat 06-073 | ||

| CoMat 08-015 RESIN | LOCAL | CoMat 08-015 | ||

| CoMat 08-016 HARDENER | LOCAL | CoMat 08-016 | ||

| CoMat 08-058 DRY CARBON FIBRE FABRIC | IAE79 | CoMat 08-058 | ||

| CoMat 08-059 DRY CARBON FIBRE FABRIC | IAE79 | CoMat 08-059 | ||

| CoMat 08-153 CARBON FIBER CLOTH | IE485 | CoMat 08-153 |

Spares

NONESafety Requirements

NONEProcedure

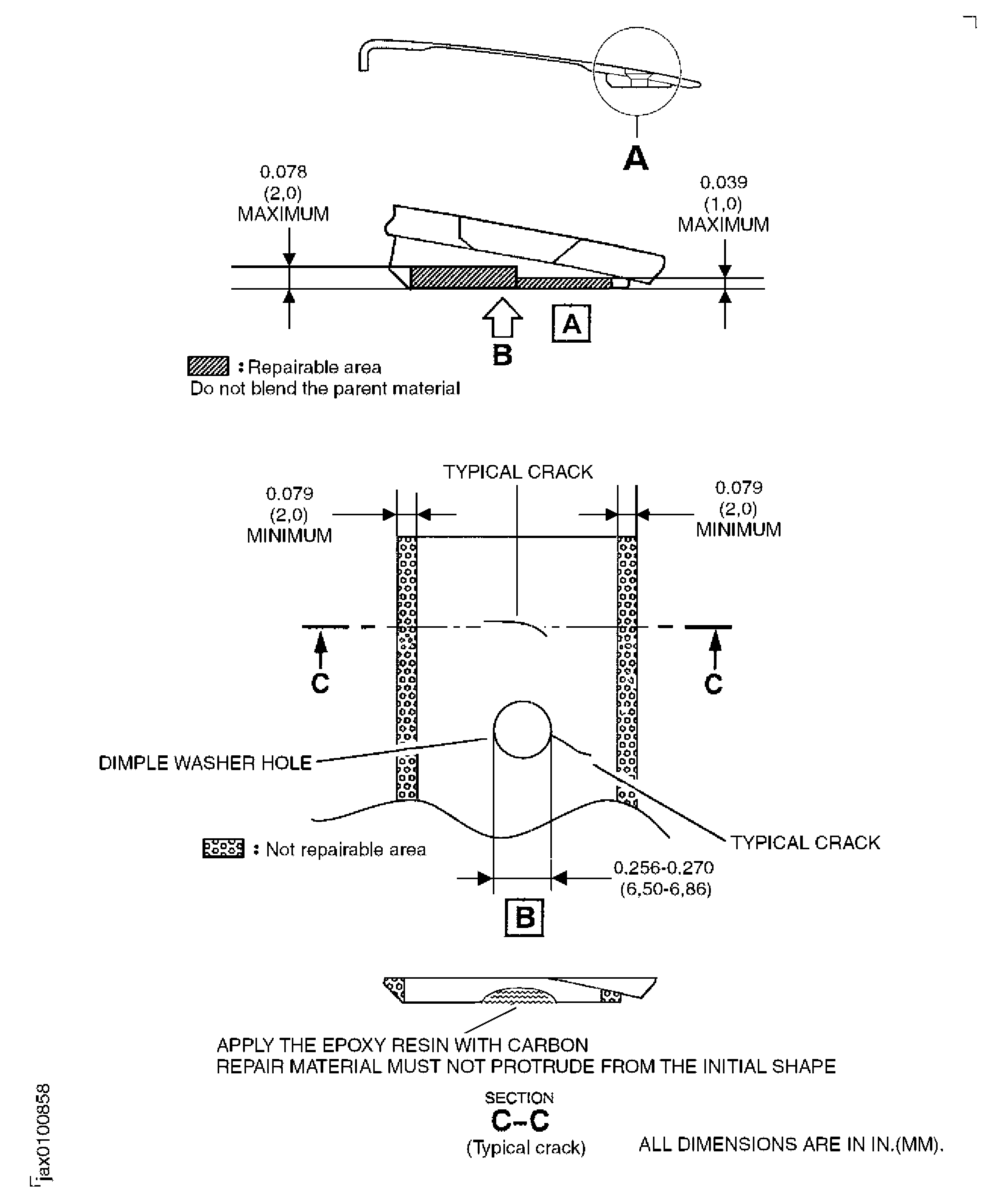

Refer to Figure.

Refer to the SPM TASK 70-11-26-300-503. Use CoMat 01-124 ISOPROPYL ALCOHOL. Use lint free cloth.

Clean the area to be repaired.

Use portable grinding equipment. Maximum blend limit is given in Figure.

Make smooth the edges of the blended area.

If the crack cannot be removed within the repairable limits, the pad must be removed and replaced in accordance with VRS1983, TASK 72-32-86-300-009.

NOTE

Keep the material removal to the minimum necessary to remove the crack.Remove the cracks on pads.

Do Step again.

SUBTASK 72-32-86-350-063 Remove the Cracks on the Pads

Refer to Figure.

SUBTASK 72-32-86-220-093 Examine the Blended Area

Refer to Figure.

Use CoMat 08-015 RESIN and CoMat 08-016 HARDENER.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-004.

Add CoMat 08-058 DRY CARBON FIBRE FABRIC or CoMat 08-059 DRY CARBON FIBRE FABRIC or CoMat 08-153 CARBON FIBER CLOTH, which is cut into fine strips, to the epoxy resin.

WARNING

DURING THE OPERATION, WEAR PROTECTIVE GLOVES AND GOGGLES.

WARNING

MAKE SURE THAT THERE IS SUFFICIENT VENTILATION DURING THE OPERATION.Make up the epoxy resin.

SUBTASK 72-32-86-380-054 Apply Epoxy Resin to the Repaired Area

Refer to Figure.

Use CoMat 05-079 WATERPROOF SILICON CARBIDE or CoMat 05-080 WATERPROOF SILICON CARBIDE and/or fine file.

The repaired area must be the same contour and surface finish as the initial pad.

Remove excess resin to make smooth surface.

SUBTASK 72-32-86-380-055 Cure the Repaired Area

Refer to Figure.

Refer to TASK 72-32-86-200-000 (INSPECTION-000).

Make sure that the repaired area is the same contour and surface finish as the initial pad.

Visually examine the repaired area.

SUBTASK 72-32-86-220-094 Examine the Repaired Area of the Rear Fairing Assembly

Refer to the SPM TASK 70-09-00-400-501.

Mark VRS1982 with white ink adjacent to the part number.

SUBTASK 72-32-86-350-064 Mark the Repair Number on the Rear Fairing Assembly

Figure: Repair Details and Dimensions

Repair Details and Dimensions