Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

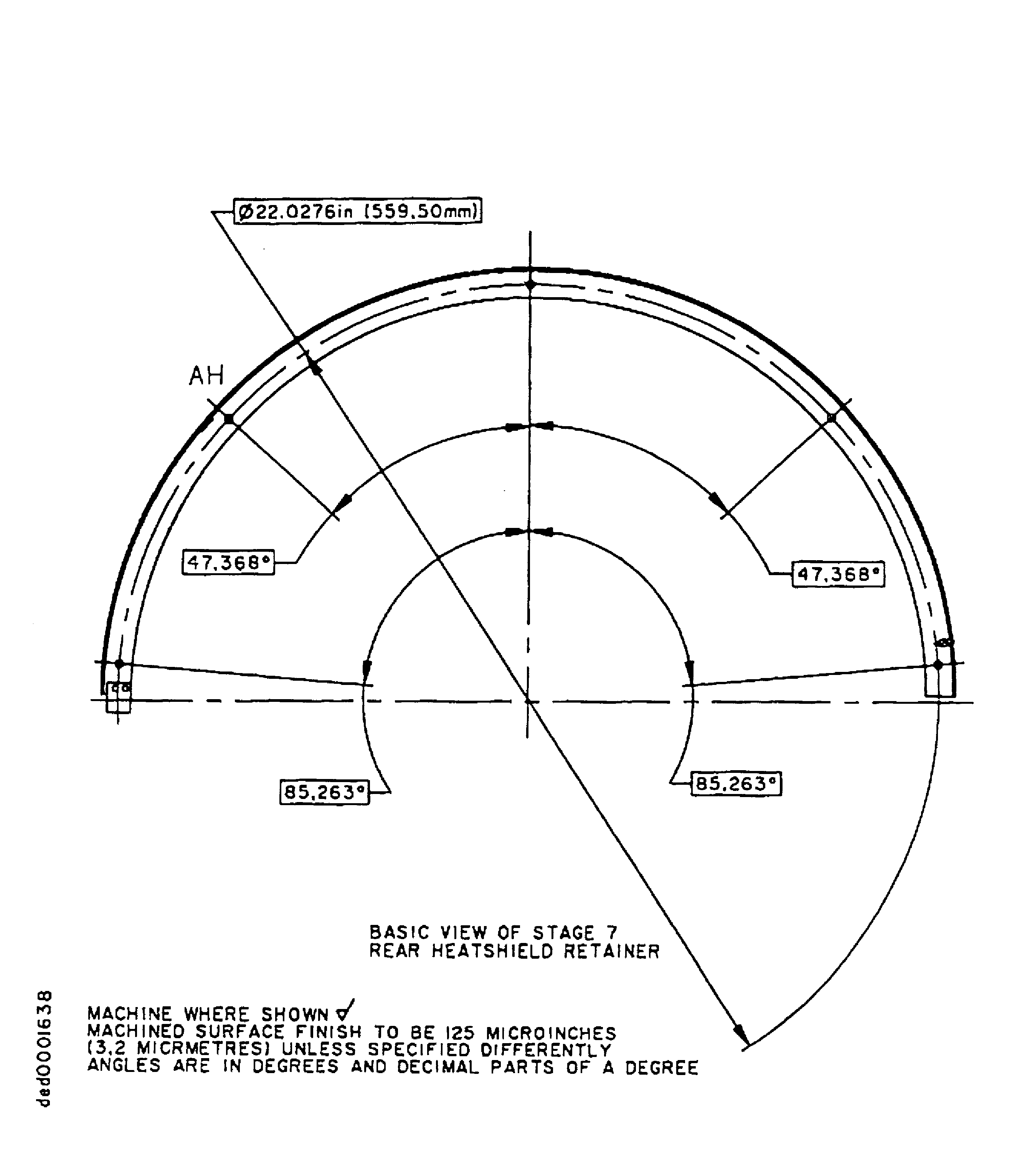

TASK 72-41-21-300-090 HPC Heatshield Retainers - Weld Repair The HPC Stage 7 Rear Heatshield Retainer Damaged/Worn Location Hole(s), Repair-090 (VRS6633)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor Rear Heatshield Retainer, Stage 7 | EAK or EBL EAE | Modified 12 percent Chromium steel 11.5 percent Chromium, 3 percent Nickel, 1.75 percent Molybdenum and 1.5 percent Cobalt |

General

This Repair must only be done when the instruction to do so is given in TASK TASK 72-41-21-200-000 (INSPECTION-000).

This Repair allows worn/damaged location hole(s) in the HP Compressor Rear Heatshield Retainer, Stage 7, to be repaired by weld.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and Availability

Refer to International Aero Engines.

Related repairs

HP Compressor Rear Heatshield Retainer, Stage 7 - Replace the surface protection, refer to TASK 72-41-21-300-073 (VRS6309).

HP Compressor Rear Heatshield Retainer, Stage 7 - Replace loose or damaged rivets and/or a damaged plate, refer to TASK 72-41-21-300-069 (VRS6308).

NOTE

Equivalent materials or equipment can be used.

More equipment and materials necessary to do this Repair are in the TASKS given below:

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Abrasive blast equipment | LOCAL | Abrasive blast equipment | ||

| Dry blast equipment | LOCAL | Dry blast equipment | ||

| Brush | LOCAL | Brush | Vacuum assisted | |

| Welding equipment | LOCAL | Welding equipment | Argonarc | |

| Heat treatment equipment | LOCAL | Heat treatment equipment | ||

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Drilling machine | LOCAL | Drilling machine | ||

| Boring machine | LOCAL | Boring machine | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 03-181 WELDING WIRE 12% Cr. STEEL | LOCAL | CoMat 03-181 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | LOCAL | CoMat 05-003 | ||

| CoMat 05-106 ABRASIVE STONE | K6835 | CoMat 05-106 | ||

| CoMat 05-110 EMERY POLISHING PAPER | 0AM53 | CoMat 05-110 | ||

| CoMat 05-111 EMERY POLISHING PAPER | 06565 | CoMat 05-111 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Repair, VRS6308 TASK 72-41-21-300-069 (REPAIR-069).

Remove the heatshield end plate, as necessary.

SUBTASK 72-41-21-350-184 Remove Heatshield End Plate

Refer to the SPM TASK 70-35-03-300-501.

Remove no more material than is necessary.

Remove damage to depth.

Use standard workshop equipment.

Remove the damage from the location hole(s), as necessary.

SUBTASK 72-41-21-350-185-A00 Remove Damage from the HP Compressor Rear Heatshield Retainer, Stage 7, Assembly A

Refer to the SPM TASK 70-35-03-300-501.

Remove no more material than is necessary.

Remove damage to depth.

Use standard workshop equipment.

Remove the damage from the location hole(s), as necessary.

SUBTASK 72-41-21-350-185-B00 Remove Damage from the HP Compressor Rear Heatshield Retainer Stage 7, Assembly B

Refer to the SPM TASK 70-35-03-300-501.

Remove no more material than is necessary.

Remove damage to depth.

Use standard workshop equipment.

Remove the damage from the location hole(s), as necessary.

SUBTASK 72-41-21-350-185-C00 Remove Damage from the HP Compressor Rear Heatshield Retainer Stage 7, Assembly C

Refer to the SPM TASK 70-11-39-300-503, SUBTASK 70-11-39-300-001 and SUBTASK 70-11-39-300-002.

Use chemical cleaning equipment.

Swab etch the repaired area(s).

SUBTASK 72-41-21-110-184 Cold Ferric Chloride Etch

Refer to the SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY), with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test of the repaired area(s).

SUBTASK 72-41-21-230-206 Do a Crack Test

Refer to the SPM TASK 70-11-03-300-503 or TASK 70-11-26-300-503.

Use chemical cleaning equipment.

Chemically clean the HP Compressor Rear Heatshield Retainer, Stage 7.

SUBTASK 72-41-21-110-185 Chemically Clean

Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE, with abrasive blast equipment.

Abrasive blast the areas to be repaired.

SUBTASK 72-41-21-120-082 Prepare the Part for Repair

CAUTION

SURFACES FOR REPAIR MUST BE FULLY CLEANED AND NOT TOUCHED BY HAND.

CAUTION

CLEAN COTTON OR POLYTHENE GLOVES MUST BE WORN.Refer to TASK 70-31-02-310-501-001 and SPM TASK 70-31-02-310-501-008.

Use CoMat 03-181 WELDING WIRE 12% Cr. STEEL, with argonarc welding equipment.

Apply sufficient weld, to allow the location hole(s) to be be machined to the diamensions given.

Weld build-up the weld/damage location hole(s).

SUBTASK 72-41-21-310-051-A00 Weld Build-Up Worn/Damaged Location Hole(s) in the HP Compressor Rear Heatshield Retainer, Stage 7, Assembly A

CAUTION

DO NOT ALLOW TOO MUCH HEAT TO BE APPLIED DURING THE WELD OPERATION.Refer to TASK 70-31-02-310-501-001 and SPM TASK 70-31-02-310-501-008.

Use CoMat 03-181 WELDING WIRE 12% Cr. STEEL, with argonarc welding equipment.

Apply sufficient weld, to allow the location hole(s) to be be machined to the diamensions given.

Weld build-up the weld/damage location hole(s).

SUBTASK 72-41-21-310-051-B00 Weld Build-Up Worn/Damaged Location Hole(s) in the HP Compressor Rear Heatshield Retainer, Stage 7, Assembly B

CAUTION

DO NOT ALLOW TOO MUCH HEAT TO BE APPLIED DURING THE WELD OPERATION.Refer to TASK 70-31-02-310-501-001 and SPM TASK 70-31-02-310-501-008.

Use CoMat 03-181 WELDING WIRE 12% Cr. STEEL, with argonarc welding equipment.

Apply sufficient weld, to allow the location hole(s) to be be machined to the diamensions given.

Weld build-up the weld/damage location hole(s).

SUBTASK 72-41-21-310-051-C00 Weld Build-Up Worn/Damaged Location Hole(s) in the HP Compressor Rear Heatshield Retainer, Stage 7, Assembly C

CAUTION

DO NOT ALLOW TOO MUCH HEAT TO BE APPLIED DURING THE WELD OPERATION.Refer to the SPM TASK 70-31-02-310-501-001.

Use heat treatment equipment.

Heat-Treat data

Heat to a temperature of 1202 deg F (650 deg C) for 30 minutes.

Cool down to room temperature in air or argon.

Heat-treat the heatshield retainer, in a vacuum or controlled atmosphere.

SUBTASK 72-41-21-370-051 Heat-Treat the HP Compressor Rear Heatshield Retainer, Stage 7

Refer to the SPM TASK 70-11-03-300-503 or SPM TASK 70-11-26-300-503.

Use chemical cleaning equipment.

Chemically clean the HP Compresor Rear Heatshield Retainer, Stage 7.

SUBTASK 72-41-21-110-186 Chemically Clean

Refer to TASK 70-11-39-300-503,SUBTASK 70-11-39-300-001 and SUBTASK 70-11-39-300-002.

Use chemical cleaning equipment.

Swab etch the repaired area(s).

SUBTASK 72-41-21-110-187 Cold Ferric Chloride Etch

Refer to the SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY), with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test of the repaired location hole(s).

SUBTASK 72-41-21-230-207 Do a Crack Test

Do Step again.

If the location hole(s) are more than the given limits.

SUBTASK 72-41-21-220-505-A00 Examine the Location Hole(s), Assembly A

Do Step again.

If the location hole(s) are more than the given limits.

SUBTASK 72-41-21-220-505-B00 Examine the Location Hole(s), Assembly B

Do Step again.

If the location hole(s) are more than the given limits.

SUBTASK 72-41-21-220-505-C00 Examine the Location Hole(s), Assembly C

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibro-engraving equipment.

Make a mark VRS6633 adjacent to the part number.

SUBTASK 72-41-21-350-187 Identify the Repair

Refer to VRS6308, TASK 72-41-21-300-069 (REPAIR-069).

Replace the heatshield end plate, as necessary.

SUBTASK 72-41-21-350-188 Replace the Heatshield End Plate

Refer to VRS6309,TASK 72-41-21-300-073 (REPAIR-073).

Replace the surface protection.

SUBTASK 72-41-21-380- Replace the Surface Protection

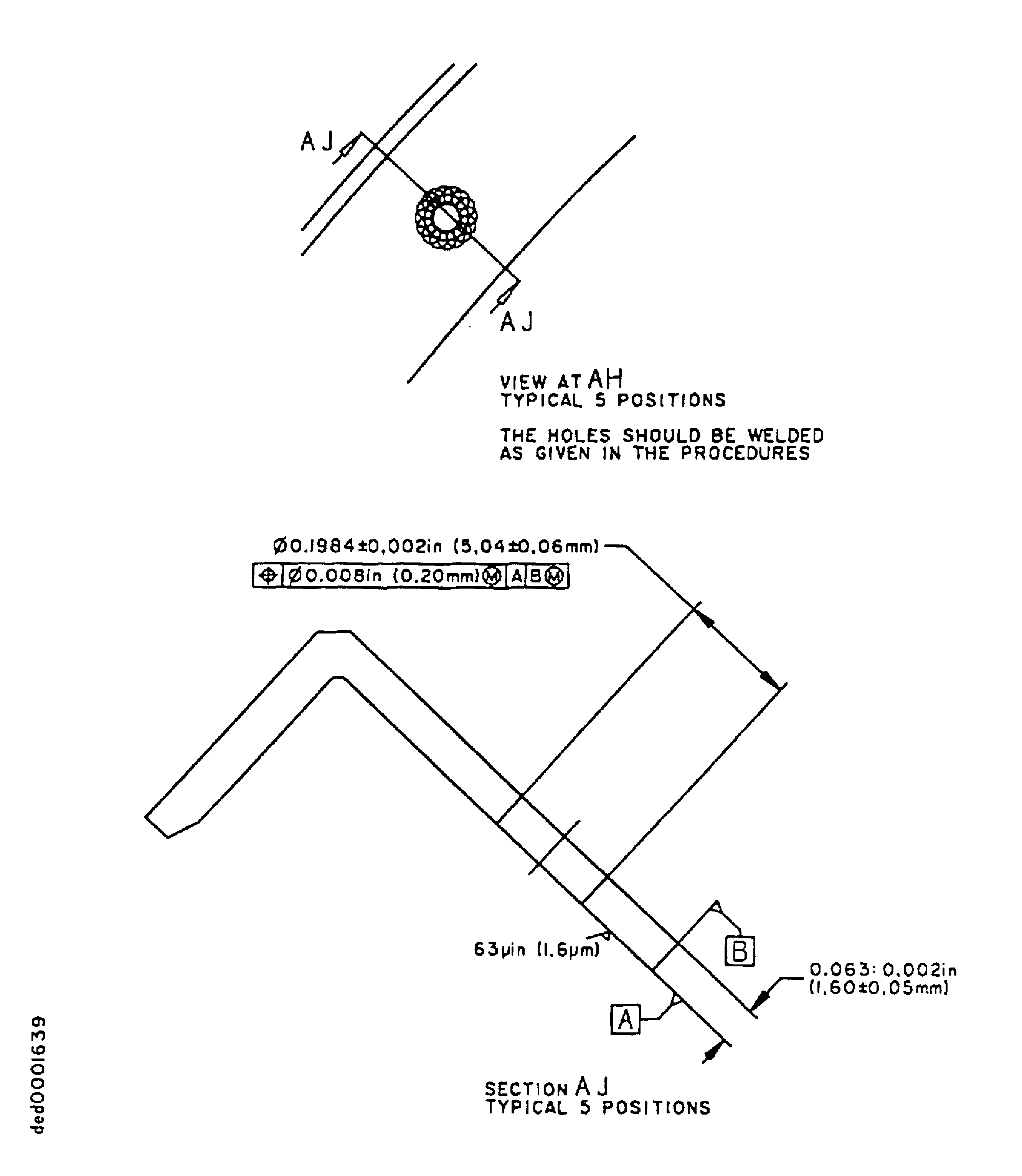

Figure: Repair details and diamensions, Assembly A

Repair details and diamensions, Assembly A

Figure: Repair details and diamensions, Assembly A

Repair details and diamensions, Assembly A

Figure: Repair details and diamensions, Assembly A

Repair details and diamensions, Assembly A

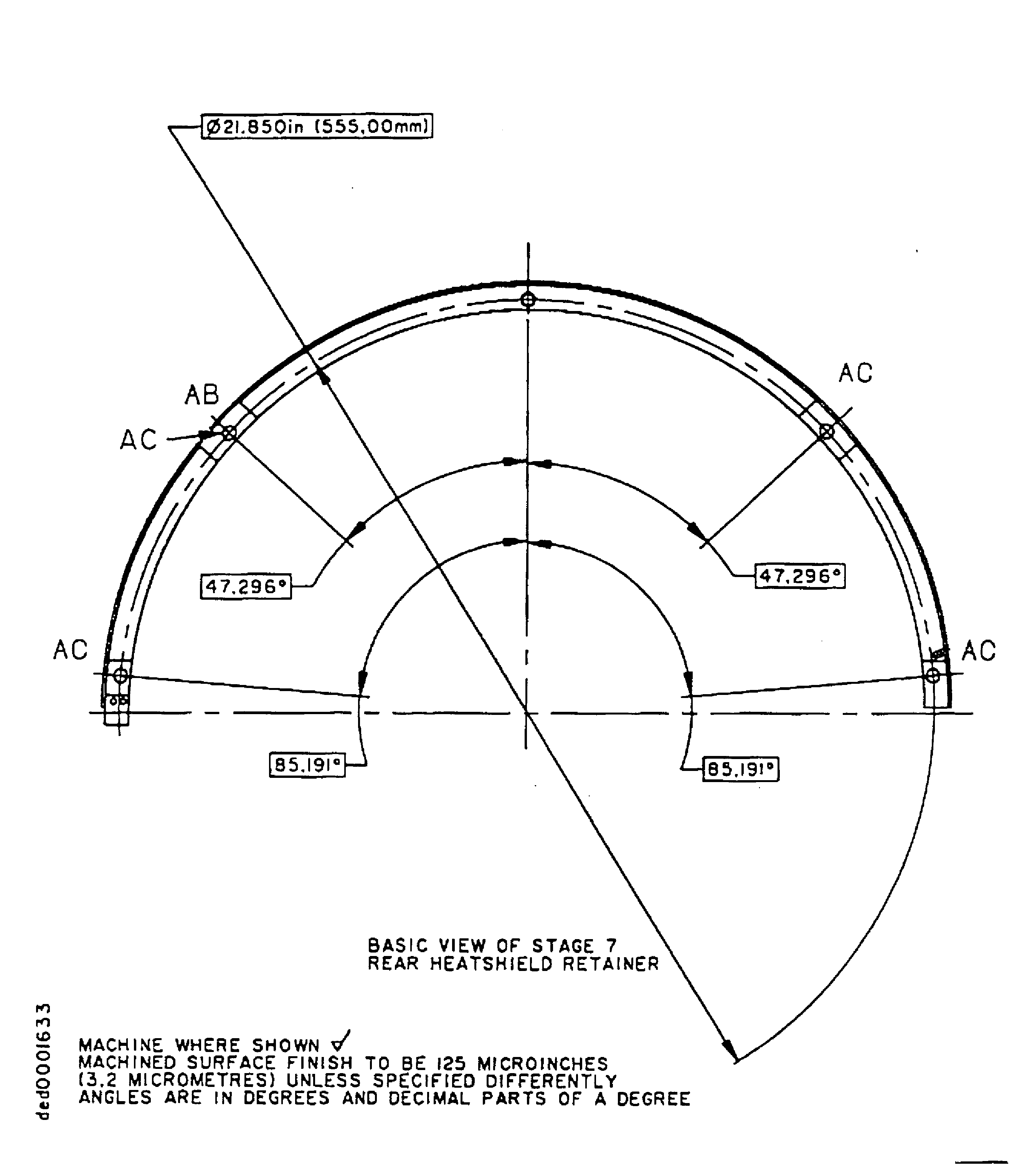

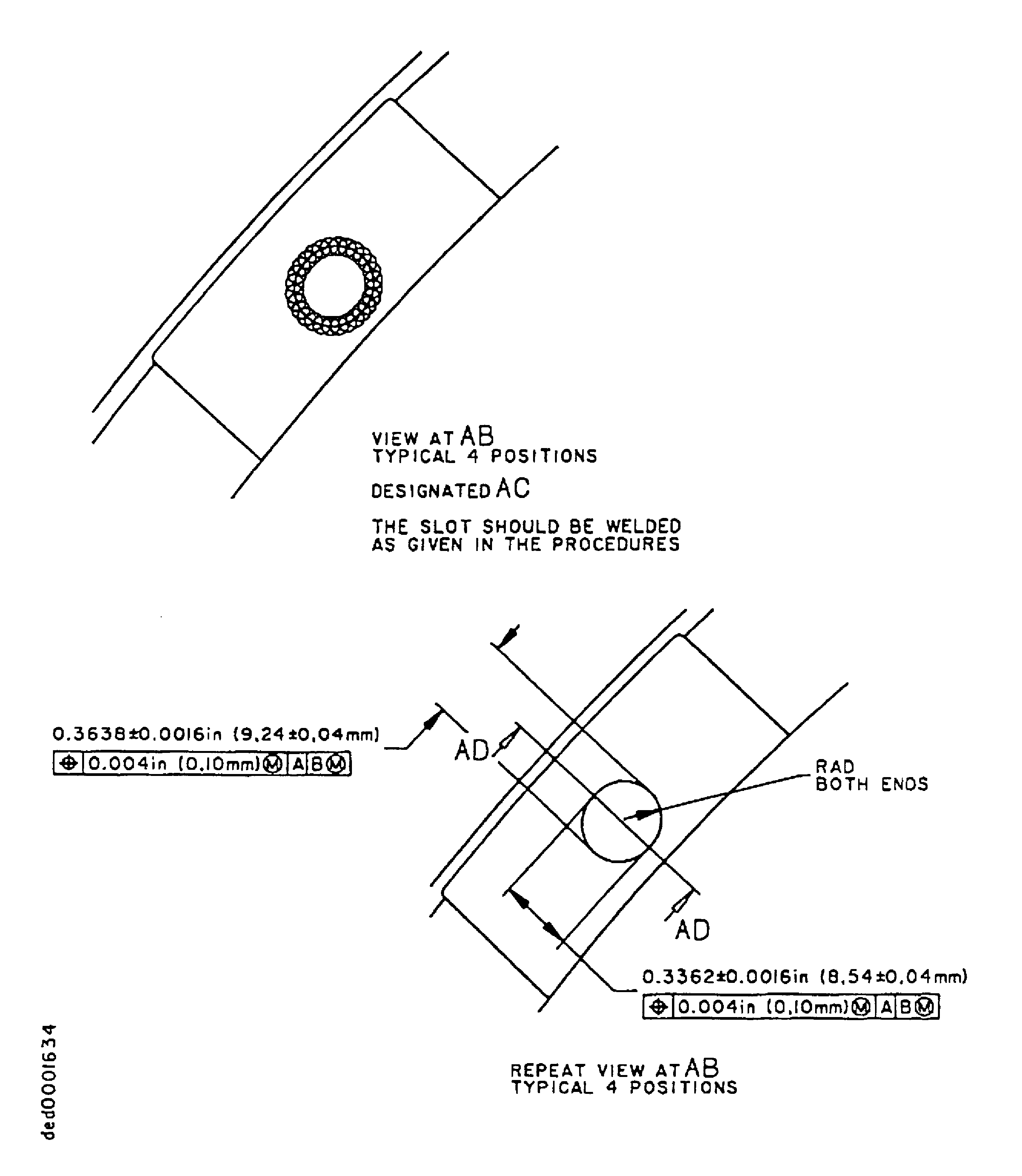

Figure: Repair details and diamensions, Assembly B

Repair details and diamensions, Assembly B

Figure: Repair details and diamensions, Assembly B

Repair details and diamensions, Assembly B

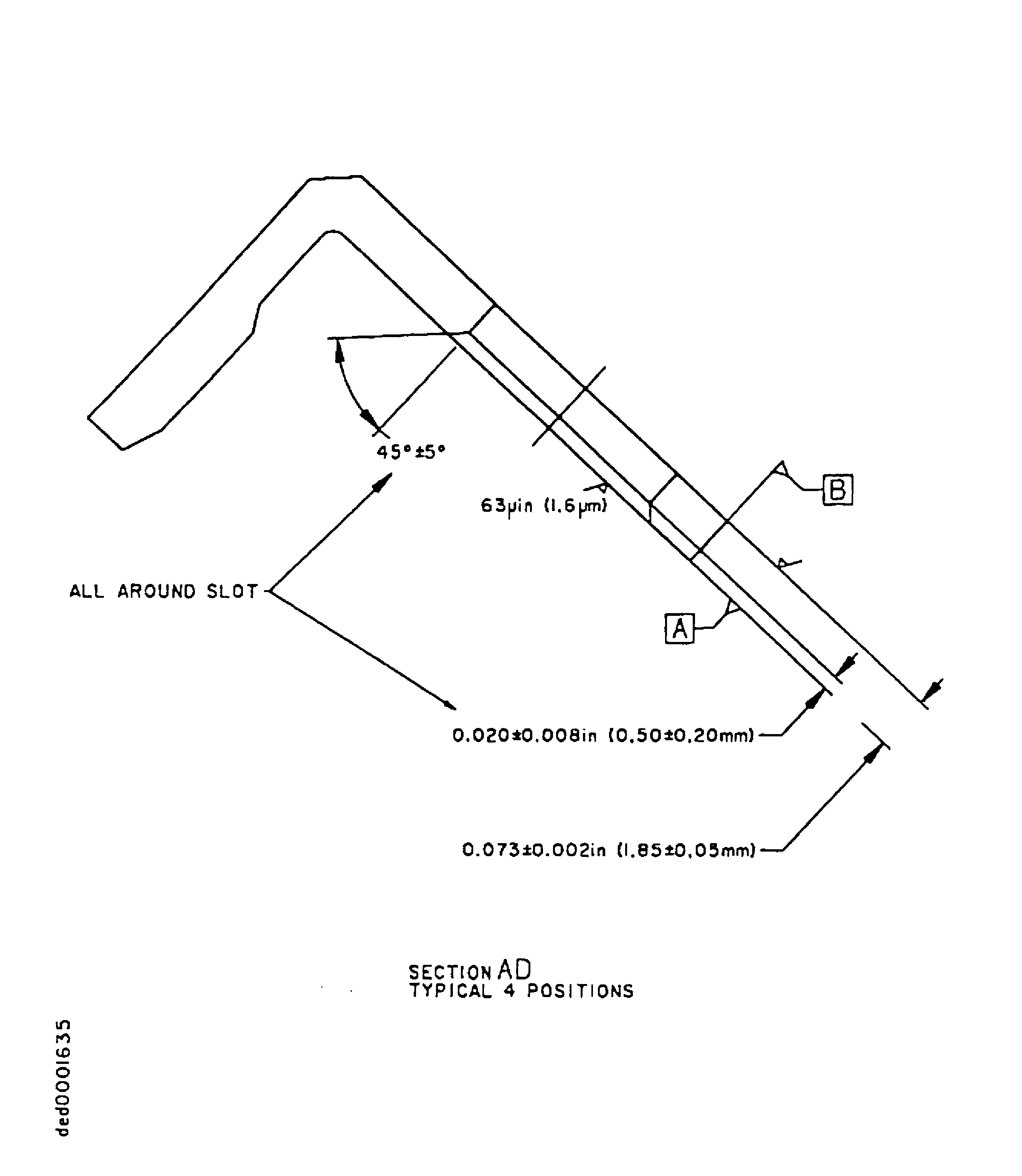

Figure: Repair details and diamensions, Assembly C

Repair details and diamensions, Assembly C

Figure: Repair details and diamensions, Assembly C

Repair details and diamensions, Assembly C