Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-22-300-022 HP Compressor Stages 6 To 11 Stator Vanes - Glass/Ceramic Bead Peen To Restore Airfoil Surface Condition, Repair-022 (VRS6210)

Effectivity

FIG./ITEM | PART NO. | ASSEMBLY |

|---|---|---|

01-350 | 6A4231 | A |

01-350 | 6A7424 | AA |

01-350 | 6A7481 | A |

01-350 | 6A8767 | B |

01-400 | 6A4230C01 | A |

01-400 | 6A7423C01 | AA |

01-400 | 6A7482C01 | A |

01-400 | 6A8765 | B |

01-448 | 6A4230C01 | A |

01-448 | 6A7423C01 | AA |

01-448 | 6A7482C01 | A |

01-448 | 6A8765 | B |

01-450 | 6A4230C02 | A |

01-450 | 6A7423C02 | AA |

01-450 | 6A7482C02 | A |

01-450 | 6A8766 | B |

02-150 | 6A4215 | D |

02-150 | 6A7426 | DD |

02-150 | 6A7483 | D |

02-350 | 6A3266 | C |

02-350 | 6A4216 | D |

02-350 | 6A7427 | DD |

02-350 | 6A7484 | D |

02-350 | 6A8770 | E |

02-400 | 6A3265C01 | C |

02-400 | 6A4213C01 | D |

02-400 | 6A7425C01 | DD |

02-400 | 6A7485C01 | D |

02-400 | 6A8768 | E |

02-448 | 6A3265C01 | C |

02-448 | 6A4213C01 | D |

02-448 | 6A7425C01 | DD |

02-448 | 6A7485C01 | D |

02-448 | 6A8768 | E |

02-450 | 6A3265C02 | C |

02-450 | 6A4213C02 | D |

02-450 | 6A7425C02 | DD |

02-450 | 6A7485C02 | D |

02-450 | 6A8769 | E |

03-150 | 6A3409 | F |

03-150 | 6A4250 | FF |

03-150 | 6A7486 | F |

03-200 | 6A3407 | F |

03-200 | 6A4246 | FF |

03-200 | 6A7487 | F |

03-200 | 6A8774 | G |

03-250 | 6A3408 | F |

03-250 | 6A4248 | FF |

03-250 | 6A7488 | F |

03-250 | 6A8775 | G |

03-350 | 6A3410 | F |

03-350 | 6A4249 | FF |

03-350 | 6A7489 | F |

03-350 | 6A8776 | G |

03-400 | 6A3267C01 | F |

03-400 | 6A4245C01 | FF |

03-400 | 6A7490C01 | F |

03-400 | 6A8772 | G |

03-448 | 6A3267C01 | F |

03-448 | 6A4245C01 | FF |

03-448 | 6A7490C01 | F |

03-448 | 6A8772 | G |

03-450 | 6A3267C02 | F |

03-450 | 6A4245C02 | FF |

03-450 | 6A7490C02 | F |

03-450 | 6A8773 | G |

04-200 | 6A3411 | H |

04-200 | 6A4226 | HH |

04-200 | 6A7491 | H |

04-200 | 6A8780 | J |

04-250 | 6A3412 | H |

04-250 | 6A4227 | HH |

04-250 | 6A7492 | H |

04-250 | 6A8781 | J |

04-350 | 6A3475 | H |

04-350 | 6A4228 | HH |

04-350 | 6A7493 | H |

04-350 | 6A8782 | J |

04-400 | 6A3271C01 | H |

04-400 | 6A4229C01 | HH |

04-400 | 6A7494C01 | H |

04-400 | 6A8778 | J |

04-448 | 6A3271C01 | H |

04-448 | 6A4229C01 | HH |

04-448 | 6A7494C01 | H |

04-448 | 6A8778 | J |

04-450 | 6A3271C02 | H |

04-450 | 6A4229C02 | HH |

04-450 | 6A7494C02 | H |

04-450 | 6A8779 | J |

05-350 | 6A3276 | K |

05-350 | 6A4224 | L |

05-350 | 6A7429 | LL |

05-350 | 6A7495 | L |

05-350 | 6A8786 | M |

05-355 | 6A4225 | L |

05-355 | 6A7430 | LL |

05-355 | 6A7496 | L |

05-355 | 6A8785 | M |

05-400 | 6A3275C01 | K |

05-400 | 6A4223C01 | L |

05-400 | 6A7428C01 | LL |

05-400 | 6A7497C01 | L |

05-400 | 6A8783 | M |

05-448 | 6A3275C01 | K |

05-448 | 6A4223C01 | L |

05-448 | 6A7428C01 | LL |

05-448 | 6A7497C01 | L |

05-448 | 6A8783 | M |

05-450 | 6A3275C02 | K |

05-450 | 6A4223C02 | L |

05-450 | 6A7428C02 | LL |

05-450 | 6A7497C02 | L |

05-450 | 6A8784 | M |

06-150 | 6A3415 | N |

06-150 | 6A4241 | NN |

06-150 | 6A7498 | N |

06-200 | 6A3413 | N |

06-200 | 6A4238 | NN |

06-200 | 6A7499 | N |

06-200 | 6A8789 | P |

06-250 | 6A3414 | N |

06-250 | 6A4239 | NN |

06-250 | 6A7500 | N |

06-250 | 6A8790 | P |

06-350 | 6A3416 | N |

06-350 | 6A4240 | NN |

06-350 | 6A7501 | N |

06-350 | 6A8791 | P |

06-400 | 6A3277C01 | N |

06-400 | 6A4237C01 | NN |

06-400 | 6A7502C01 | N |

06-400 | 6A8787 | P |

06-448 | 6A3277C01 | N |

06-448 | 6A4237C01 | NN |

06-448 | 6A7502C01 | N |

06-448 | 6A8787 | P |

06-450 | 6A3277C02 | N |

06-450 | 6A4237C02 | NN |

06-450 | 6A7502C02 | N |

06-450 | 6A8788 | P |

Material of component

PART IDENT | MATERIAL |

|---|---|

HP Compressor Stator Vanes, Stages 6 to 11 | Heat Resisting Alloy |

General

This TASK gives the procedure to glass/ceramic bead peen the HP Compressor Stator Vanes, Stage 6 to 11.

The vanes must have all other repairs completed and be serviceable, refer to relevant inspection procedures (identified by the applicable part number) located in section 72-41-22.

The vanes can only have the glass/ceramic bead peening operation completed on them three times.

This repair can be done again to the HP Compressor Stator Vanes if the part is within the repairable limits as given in vibro-polishing repairs (VRS6499, VRS6080, VRS6081, VRS6082, VRS6083 and VRS6084).

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the Standard Practices Manual (SPM).

Price and Availability.

Refer to International Aero Engines (IAE).

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Abrasive blast equipment | LOCAL | Abrasive blast equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Glass/Ceramic bead peening equipment | LOCAL | Glass/Ceramic bead peening equipment | ||

| Surface measuring equipment | LOCAL | Surface measuring equipment | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-293 GLASS BEADS | LOCAL | CoMat 01-293 | ||

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF | LOCAL | CoMat 02-003 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | LOCAL | CoMat 05-003 | ||

| CoMat 05-184 CERAMIC BEADS | IE460 | CoMat 05-184 |

Spares

NONESafety Requirements

NONEProcedure

For Assembly A, AA and B, refer to Figure. For Assembly C, refer to Figure. For Assembly D, DD and E, refer to Figure. For Assembly F, FF and G, refer to Figure. For Assembly H, HH and J, refer to Figure. For Assembly K, refer to Figure. For Assembly L, LL and M, refer to Figure. For Assembly N, NN and P, refer to Figure.

Continue with the repair.

If there is no previous marking of this repair:

Continue with the repair.

If only the code symbol 2 or 2/1 is marked:

For Assembly AA, DD, FF, HH, LL and NN, the glass/ceramic bead peening operation in Step cannot be performed on the part.

For Assembly A, C, D, F, H, K, L and N, reject the part.

If 2/2 is marked:

Check previous glass/ceramic bead peening repair identity markings, to make sure that the part can be repaired.

NOTE

Assemblies B, E, G, J, M and P are not glass/ceramic bead peened.NOTE

Glass/Ceramic bead peening is optional for AA, DD, FF, HH, LL and NN.

For Assembly A, AA, C, D, DD, F, FF, H, HH, K, L, LL, N and NN visually examine the roots of the HP Compressor Stages 6 to 11 Stator Vanes.

Reject, if the vane is super polished beyond the limits.

Inspect the vanes to make sure that the part is within the repairable limits as given in the repairs (VRS6499, VRS6080, VRS6081, VRS6082, VRS6083 and VRS6084).

Examine the vanes to make sure all necessary repairs have been completed.

SUBTASK 72-41-22-220-144 Make sure the HP Compressor Stages 6 to 11 Stator Vanes can be repaired

Refer to SPM TASK 70-11-03-300-503.

Chemically clean the vanes.

SUBTASK 72-41-22-110-069 Clean the HP Compressor Stages 6 to 11 Stator Vanes

For Assembly A, AA and B, refer to Figure. For Assembly C, refer to Figure. For Assembly D, DD and E, refer to Figure. For Assembly F, FF and G, refer to Figure. For Assembly H, HH and J, refer to Figure. For Assembly K, refer to Figure. For Assembly L, LL and M, refer to Figure. For Assembly N, NN and P, refer to Figure.

Continue from Step.

If surface finish not within the limits:

Check for surface finish of 40 micro in to 80 micro in. (1.0 microns to 2.0 microns) has to be recorded. Use Surface measuring equipment.

Examine the surface finish of the vanes.

SUBTASK 72-41-22-220-167 Examine the HP Compressor Stages 6 to 11 Stator Vanes

For Assembly A, AA and B, refer to Figure. For Assembly C, refer to Figure. For Assembly D, DD and E, refer to Figure. For Assembly F, FF and G, refer to Figure. For Assembly H, HH and J, refer to Figure. For Assembly K, refer to Figure. For Assembly L, LL and M, refer to Figure. For Assembly N, NN and P, refer to Figure.

Apply masking tape to the vane root.

Refer to SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-001.

Dry abrasive blast the vane airfoil to remove dressing or etch marks.

Remove the masking tape.

SUBTASK 72-41-22-120-056 Dry Abrasive Blast the HP Compressor Stages 6 to 11 Stator Vanes to Remove Dressing or Etch Marks

For Assembly A, AA and B, refer to Figure. For Assembly C, refer to Figure. For Assembly D, DD and E, refer to Figure. For Assembly F, FF and G, refer to Figure. For Assembly H, HH and J, refer to Figure. For Assembly K, refer to Figure. For Assembly L, LL and M, refer to Figure. For Assembly N, NN and P, refer to Figure.

Refer to SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-001.

Make sure that all dressing marks are removed.

Visually examine the vane airfoil.

A surface finish of 40 micro in. to 80 micro in. (1.0 microns to 2.0 microns) has to be achieved.

Make sure that the subsequent centreline average (CLA) quality of finish is achieved.

Repeat the Step.

If surface finish not achieved.

Continue with the repair.

If surface finish achieved.

Examine the surface finish of the vanes.

SUBTASK 72-41-22-220-145 Examine the HP Compressor Stages 6 to 11 Stator Vanes

For Assembly A and AA, refer to Figure. For Assembly C, refer to Figure. For Assembly D and DD, refer to Figure. For Assembly F and FF , refer to Figure. For Assembly H and HH, refer to Figure. For Assembly K, refer to Figure. For Assembly L and LL, refer to Figure. For Assembly N and NN, refer to Figure.

Apply the adhesive tape to the vane root and areas not to be glass/ceramic bead peened.

Refer to SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-002.

Use CoMat 01-293 GLASS BEADS or CoMat 05-184 CERAMIC BEADS to achieve an intensity of 7N - 11N.

Glass/Ceramic bead peen the vane airfoil, to restore surface condition.

Remove masking tape.

SUBTASK 72-41-22-380-060 Restore the Airfoil Surface Condition (for Assembly A, AA, C, D, DD, F, FF, H, HH, K, L, LL, N and NN)

NOTE

Glass/Ceramic bead peening is optional for AA, DD, FF, HH, LL and NN.Refer to Figure.

Refer to repair, VRS6499 TASK 72-41-22-300-025 (REPAIR-025).

Stage 6 stator vanes.

Refer to repair, VRS6080 TASK 72-41-22-300-002 (REPAIR-002).

Stage 7 stator vanes.

Refer to repair, VRS6081 TASK 72-41-22-300-006 (REPAIR-006).

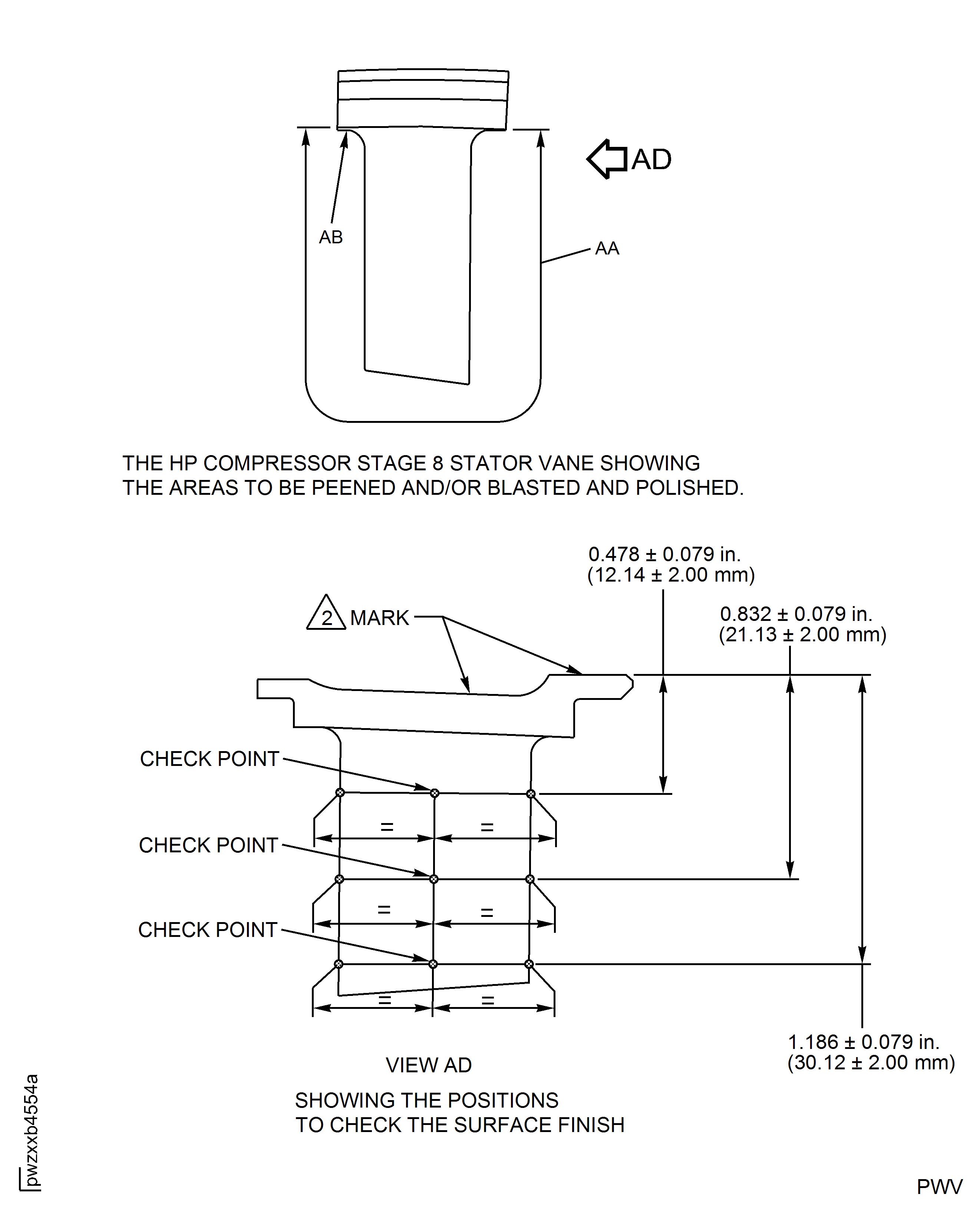

Stage 8 stator vanes.

Refer to repair, VRS6082 TASK 72-41-22-300-010 (REPAIR-010).

Stage 9 stator vanes.

Refer to repair, VRS6083 TASK 72-41-22-300-014 (REPAIR-014).

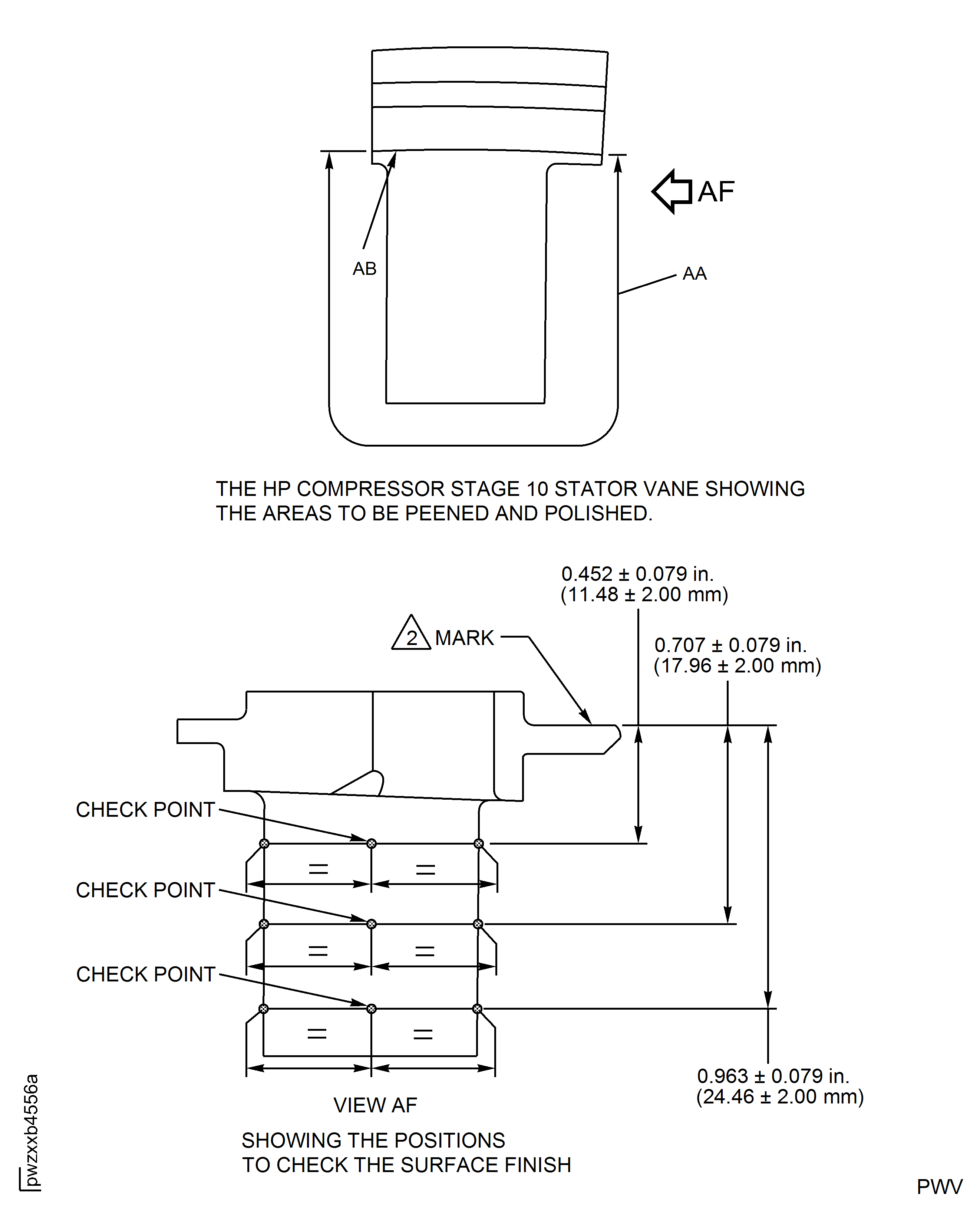

Stage 10 stator vanes.

Refer to repair, VRS6084 TASK 72-41-22-300-018 (REPAIR-018).

Stage 11 stator vanes.

SUBTASK 72-41-22-380-061 Vibro-Polish the HP Compressor Stages 6 to 11 Stator Vanes Airfoil

For Assembly A, AA and B, refer to Figure. For Assembly C, refer to Figure. For Assembly D, DD and E, refer to Figure. For Assembly F, FF and G, refer to Figure. For Assembly H, HH and J, refer to Figure. For Assembly K, refer to Figure. For Assembly L, LL and M, refer to Figure. For Assembly N, NN and P, refer to Figure.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

New repair identification marking is not required.

If glass/ceramic bead peeing has not been carried out on the part.

Vibro-engrave the code symbol 2.

If there is no previous marking of this repair.

Vibro-engrave suffix /1 adjacent to the code symbol.

If code symbol 2 and no suffix is vibro-engraved on the part.

Strike through the suffix /1 using a single line and vibro-engraving suffix /2.

NOTE

The HP Compressor Stages 6 to 11 Stator Vanes can only be glass/ceramic bead peened three times to this repair.

If code symbol 2 and suffix /1 is vibro-engraved on the part.

If glass/ceramic bead peening is carried out on the part.

Make a mark adjacent to the part number as follows

SUBTASK 72-41-22-350-081 Identify the Repair

CAUTION

DO NOT VIBRO-ENGRAVE ON THE VANE AIRFOIL OR LOCATION FACES.

Figure: HP Compressor Stages 6 to 11 Stator Vanes (All Assemblies) - Repair Details and Dimensions

HP Compressor Stages 6 to 11 Stator Vanes (All Assemblies) - Repair Details and Dimensions

Figure: HP Compressor Stage 6 Stator Vanes (Assembly A, AA and B) - Repair Details and Dimensions

HP Compressor Stage 6 Stator Vanes (Assembly A, AA and B) - Repair Details and Dimensions

Figure: HP Compressor Stage 7 Stator Vanes (Assembly C) - Repair Details and Dimensions

HP Compressor Stage 7 Stator Vanes (Assembly C) - Repair Details and Dimensions

Figure: HP Compressor Stage 7 Stator Vanes (Assembly D, DD and E) - Repair Details and Dimensions

HP Compressor Stage 7 Stator Vanes (Assembly D, DD and E) - Repair Details and Dimensions

Figure: HP Compressor Stage 8 Stator Vanes (Assembly F, FF and G) - Repair Details and Dimensions

HP Compressor Stage 8 Stator Vanes (Assembly F, FF and G) - Repair Details and Dimensions

Figure: HP Compressor Stage 9 Stator Vanes (Assembly H, HH and J) - Repair Details and Dimensions

HP Compressor Stage 9 Stator Vanes (Assembly H, HH and J) - Repair Details and Dimensions

Figure: HP Compressor Stage 10 Stator Vanes (Assembly K) - Repair Details and Dimensions

HP Compressor Stage 10 Stator Vanes (Assembly K) - Repair Details and Dimensions

Figure: HP Compressor Stage 10 Stator Vanes (Assembly L, LL and M) - Repair Details and Dimensions

HP Compressor Stage 10 Stator Vanes (Assembly L, LL and M) - Repair Details and Dimensions

Figure: HP Compressor Stage 11 Stator Vanes (Assembly N, NN and P) - Repair Details and Dimensions

HP Compressor Stage 11 Stator Vanes (Assembly N, NN and P) - Repair Details and Dimensions