Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-31-300-023 HPC Front Case Assembly - Repair The Stage 4 And Stage 6 Anti-Rotation Pin Stop Hole By Welding, Repair-023 (VRS3861)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HPC Front Case Assembly | - | AMS 4928 (Ti-6Al-4V Titanium alloy) |

General

This repair must only be done when the instruction to do so is given in 72-41-31, Inspection-002.

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the necessary cleaning and inspection procedures are done before this repair. | |

| Remove all details by the applicable repairs. | |

| Remove all coatings by the applicable repairs. |

Support Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-195 WELDING WIRE TITANIUM | LOCAL | CoMat 03-195 |

Spares

NONESafety Requirements

NONEProcedure

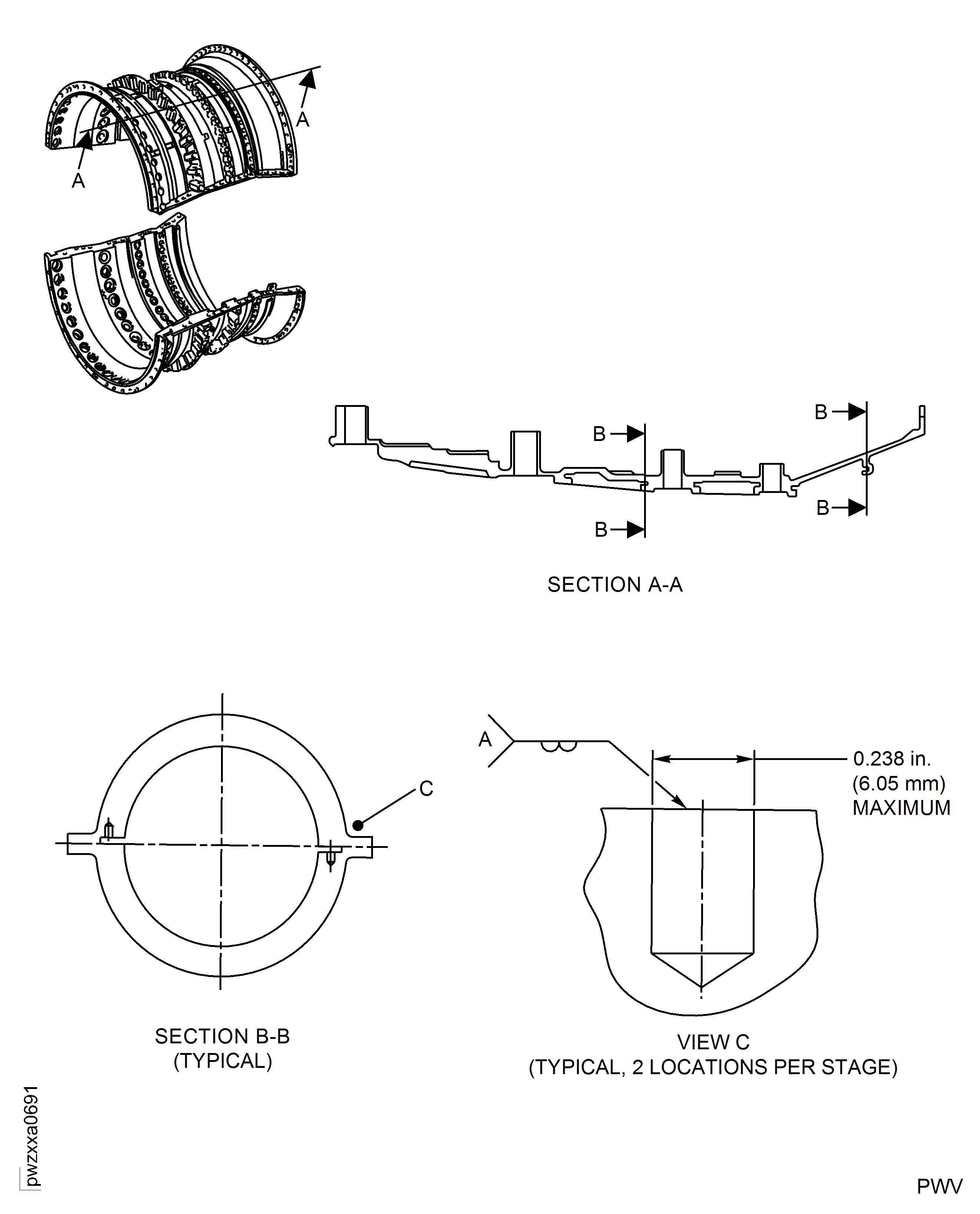

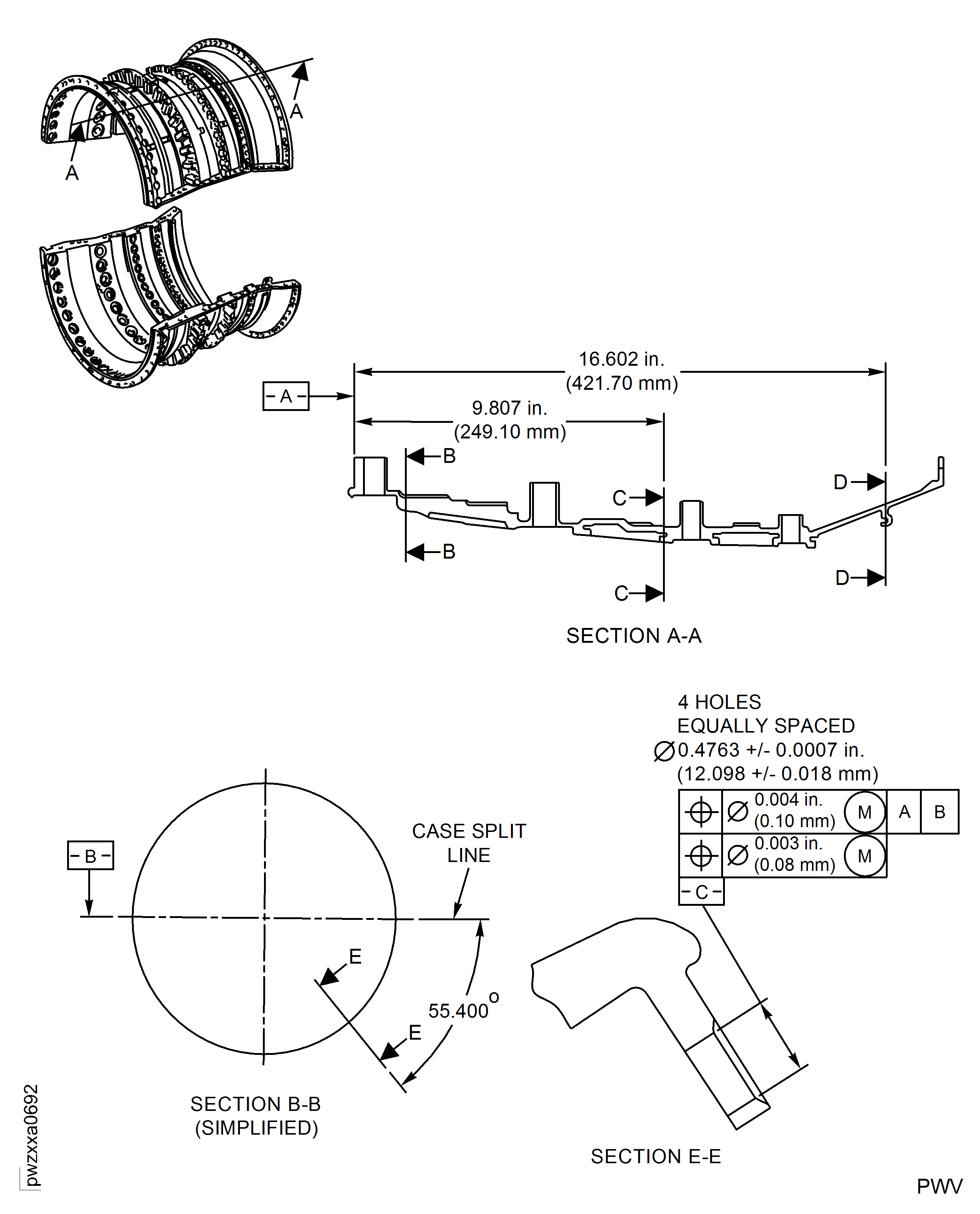

Refer to Figure.

Refer to SPM TASK 70-31-13-310-501.

Use an austenitic stainless steel wire brush or silicon carbide abrasive to remove oxides from the repair area and prepare it for weld.

Refer to SPM TASK 70-11-26-300-503.

Clean the repair area.

SUBTASK 72-41-31-350-131 Prepare the Repair Area(s) for Welding

Refer to Figure.

Refer to SPM TASK 70-31-13-310-501.

Apply sufficient weld to allow machining of the anti-rotation stop pin hole(s) back to required OEM dimensions.

Use clamps and chills to minimize the risk of distortion.

Weld build-up the Stage 4 and/or Stage 6 anti-rotation stop pin hole(s) by manual gas tungsten arc welding by IAE 16-66.

SUBTASK 72-41-31-310-005 Weld the Anti-Rotation Pin Hole(s)

Refer to SPM TASK 70-11-06-300-503.

SUBTASK 72-41-31-110-142 Clean the Case

Refer to SPM TASK 70-37-17-370-501.

Do a local heat treat of the welded area(s) in air or argon.

SUBTASK 72-41-31-370-001 Do a Local Heat Treat

Refer to SPM TASK 70-31-13-310-501.

Do a visual inspection of the welded area(s).

SUBTASK 72-41-31-310-006 Visually Examine the Welded Area(s)

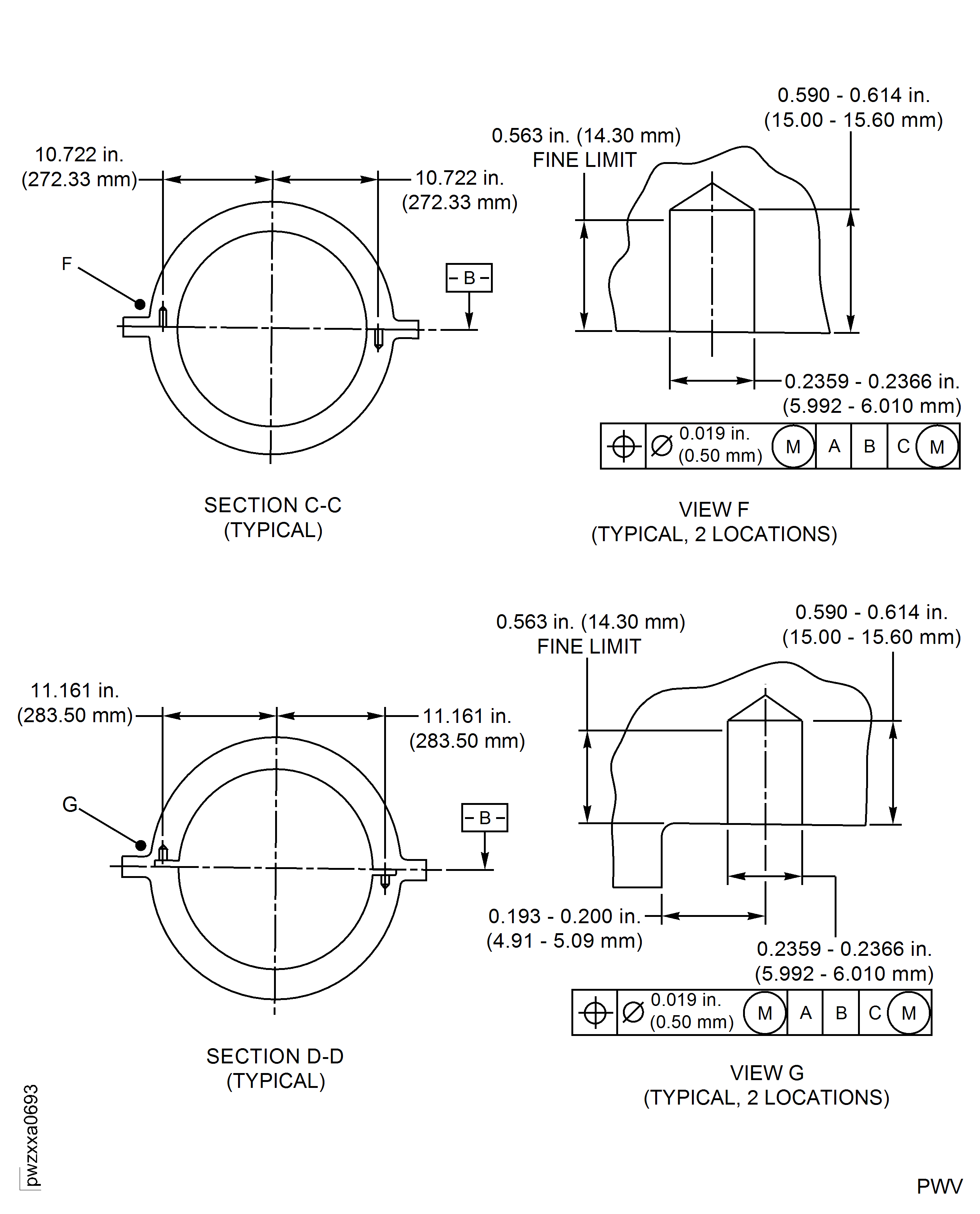

Refer to Figure.

No mismatch is allowed between repaired and non-repaired areas.

SUBTASK 72-41-31-320-008 Finish Machine the Repaired Area(s)

Refer to SPM TASK 70-11-08-300-503.

SUBTASK 72-41-31-110-143 Clean and Swab Etch the Repair Area(s)

Use high sensitivity penetrant.

Cracks are not permitted.

Refer to SPM TASK 70-23-05-230-501.

SUBTASK 72-41-31-230-164 Do a Local Crack Test on the Welded Area(s)

Refer to Figure.

SUBTASK 72-41-31-220-297 Visually and Dimensionally Examine the Repaired Area(s)

Refer to Repair, VRS6624 TASK 72-41-31-300-026 (REPAIR-026).

SUBTASK 72-41-31-350-132 Re-Install the Anti-Rotation Stop Pin(s)

Refer to SPM TASK 70-09-00-400-501.

Vibration peen "VRS3861" adjacent to the part number.

SUBTASK 72-41-31-350-133 Identify the Repair

Figure: Repair Location, Stage 4 And Stage 6 Anti-Rotation Pin Stop Holes

Repair Location, Stage 4 And Stage 6 Anti-Rotation Pin Stop Holes

Figure: Finish Requirements

Finish Requirements

Finish Requirements

Requirements After Job Completion

Follow-On Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Re-apply coatings by the applicable repairs. | |

| Re-install all details by the applicable repairs. |