Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-31-300-031 HPC Stage 6 Rotor Path Segment - Replace The Lining, Repair-031 (VRS6670)

Material of component

PART IDENT | MATERIAL |

HP compressor stage 6 rotor path ring | Corrosion resistant steel |

General

This is a source demonstrated repair that can only be accomplished by IAE approved vendors.

The vendor is self-provisioning for the coating material.

Price and Availability

Refer to International Aero Engines

Related Repairs

HP Compressor Stage 7 Rotor Path Ring - Replace the Rotor Path Lining, refer to VRS6671, TASK 72-41-21-300-091 (REPAIR-091).

HP Compressor Stage 8 Rotor Path Ring - Replace the Rotor Path Lining, refer to VRS6663, TASK 72-41-21-300-092 (REPAIR-092).

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Abrasive Blast Equipment | LOCAL | Abrasive Blast Equipment | ||

| Air grinder | LOCAL | Air grinder | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Dial indicator | LOCAL | Dial indicator | ||

| Hardness Tester | LOCAL | Hardness Tester | ||

| Lathe | LOCAL | Lathe | ||

| Metal spray equipment | LOCAL | Metal spray equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Bottle | LOCAL | Bottle | Polythene | |

| Rotary burr | LOCAL | Rotary burr | ||

| Standard Workshop Equipment | LOCAL | Standard Workshop Equipment | ||

| Water-jet machine | LOCAL | Water-jet machine | Ultra high pressure | |

| Vibrating Marking Pencil | LOCAL | Vibrating Marking Pencil | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-025 NITRIC ACID HNO3, TECHNICAL GRADE | LOCAL | CoMat 01-025 | ||

| CoMat 01-041 ALKALINE RUST REMOVER | LOCAL | CoMat 01-041 | ||

| CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) | 07512 | CoMat 02-198 | ||

| CoMat 03-036 METAL SPRAYING WIRE, Ni,Al | LOCAL | CoMat 03-036 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | 00BB6 | CoMat 03-038 | ||

| CoMat 03-057 ALUMINIUM ALLOY/POLYESTERCOMPOSITE | LOCAL | CoMat 03-057 | ||

| CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) | 33870 | CoMat 03-089 | ||

| CoMat 03-090 METAL SPRAYING POWDER Ni/Al (95/5) | X111X | CoMat 03-090 | ||

| CoMat 03-457 METAL SPRAY POWDER | 39918 | CoMat 03-457 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | X222X | CoMat 06-063 |

Spares

NONESafety Requirements

NONEProcedure

The source demonstration requirements of this repair means that the facility not authorised to accomplish this repair either utilise the Authorised Repair Vendors listed below, or contact the IAE Repair Services Group to determine if a qualification program can be initiated at their facility.

IAE International Aero Engines AG

400 Main Street

M/S 121-10

East Hartford CT 06118

U.S.A.

Attn: Manager Technical Services

Authorised Repair Vendors for repair VRS6670 are listed below:

ROLLS-ROYCE AERO REPAIR AND OVERHAUL

East Kilbride

Glasgow

G74 4PY

SCOTLAND

MTU MAINTENANCE ZHUHAI

1 Tianke Road

Free Trade Zone

Zhuhai, Guangdong

519030

P.R. CHINA

MTU MAINTENANCE HANNOVER Gmbh

Muenchner Str.31

30855 Langenhagan

GERMANY

IHI CORPORATION

229 Tonogaya Mizuho-Machi

Nishitama-Gun

Tokyo 190-12

JAPAN

LUFTHANSA TECHNIK AG

HAM WR 420

PO Box 63 03 00

D-22313 Hamburg-Airport

GERMANY

PRATT AND WHITNEY COLUMBUS ENGINE CENTER

8801 Macon Road

M/S 906-05

Columbus

GA31908

USA

PRATT AND WHITNEY AIR NEW ZEALAND SERVICES

PO Box 14005

634 Memorial Avenue

Christchurch International Airport

Christchurch 8053

NEW ZEALAND

Rolls-Royce Inchinnan

Inchinnan Drive

Inchinnan Business Park

Inchinnan, PA4 9AF

Scotland

Asian Compressor Technology Services Co., Ltd.

1, Industrial 3rd Rd., Kuanyin Industrial Park, Kuanyin Dist.,

Taoyuan City

Taiwan 32853

MTU Aero Engines AG

Dachauer Strasse 665

80995 Muenchen

Germany

The designation by IAE of an Authorised Repair Vendor indicates that the Repair Vendor has demonstrated the necessary capability to enable it to carry out the listed repair work. However, IAE makes no warranties or representations concerning the qualifications or quality standards of the Repair Vendors to carry out the repair work and accepts no responsibility whatsoever for the work that may be carried out by a Repair Vendor other than when IAE is listed as the Repair Vendor. Authorised Repair Vendors do not act as agents or representatives of IAE.

Repair Facilities

Refer to the SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-003.

Use CoMat 01-041 ALKALINE RUST REMOVER with chemical cleaning equipment.

Chemically remove the abradable lining.

SUBTASK 72-41-31-330-061 Chemically Remove the Abradable Lining

Refer to the SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-002.

Use CoMat 01-025 NITRIC ACID HNO3, TECHNICAL GRADE with chemical cleaning equipment.

Put the assembly into the nitric acid and keep below the surface.

Stripping is complete when gassing stops.

Remove assembly from the acid immediately after gassing stops.

Chemically remove the bond coat.

SUBTASK 72-41-31-330-062 Chemically Remove the Bond Coat

Refer to the SPM TASK 70-15-01-160-501.

Use an ultra high pressure water-jet machine.

Make sure that the abradable lining and old bond coat are removed.

Remove the abradable lining.

SUBTASK 72-41-31-330-064 Remove the Abradable Lining by Ultra High Pressure Water-Jet

Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE with abrasive blast equipment.

Make sure the old bond coat and abradable lining have been removed.

Abrasive blast to remove the bond coat that remains.

SUBTASK 72-41-31-120-065 Abrasive Blast to Remove the Remaining Bond Coat

Refer to the SPM TASK 70-23-05-230-501.

Use CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test on the repair area(s).

SUBTASK 72-41-31-230-128 Do a Local Crack Test

Use CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) or locally made fixture.

Seal the areas not to be sprayed.

SUBTASK 72-41-31-350-113 Seal the Areas Not to be Sprayed

Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE with abrasive blast equipment.

Abrasive blast.

SUBTASK 72-41-31-120-066 Abrasive Blast the Areas to be Sprayed

CAUTION

DO NOT TOUCH THE SURFACE, WHICH IS CLEANED FOR REPAIR. YOU MUST NOT DO THIS TO PREVENT THE CONTAMINATION.

CAUTION

DO NOT DWELL IN ANY ONE AREA, USE CONTINUOUS MOTION. YOU MUST PREVENT THE EXTENDED DURATION OF ABRASIVE BLASTING. IF YOU DO NOT DO THIS, IT CAN CAUSE DETERIORATION OF THE PREPARED SURFACE CONDITION.Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-025 or SUBTASK 70-34-01-340-010.

For powder feed plasma spray gun, use CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5), CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) or CoMat 03-090 METAL SPRAYING POWDER Ni/Al (95/5).

Alternatively for the wire feed combustion spraying, use CoMat 03-036 METAL SPRAYING WIRE, Ni,Al.

Pre heat the seal ring to 221 deg F to 257 deg F (105 deg C to 125 deg C).

Use metal spray equipment.

Apply bond coat to a test piece.

Apply the bond coat.

Refer to the SPM TASK 70-34-01-340-501.

Use CoMat 03-457 METAL SPRAY POWDER with metal spray equipment.

Spray sufficient thickness to let it for machining.

Also spray a test piece to check the spray hardness.

Apply abradable lining to a test piece to check the spray hardness.

Apply the abradable lining.

SUBTASK 72-41-31-340-059 Apply the Abradable Lining to the Repaired Part and Test Piece

Refer to the SPM TASK 70-34-01-340-501.

Visually examine the sprayed coating on the ring.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-004.

Use hardness testing equipment.

Average hardness must be 45 to 70 R15Y, outer limits 35 minimum, 80 maximum.

If the hardness value is outside these limits, reject the assembly and do the repair again.

Test the hardness of the sprayed coating on the test piece.

SUBTASK 72-41-31-220-272 Examine the Stage 6 Rotor Path Lining

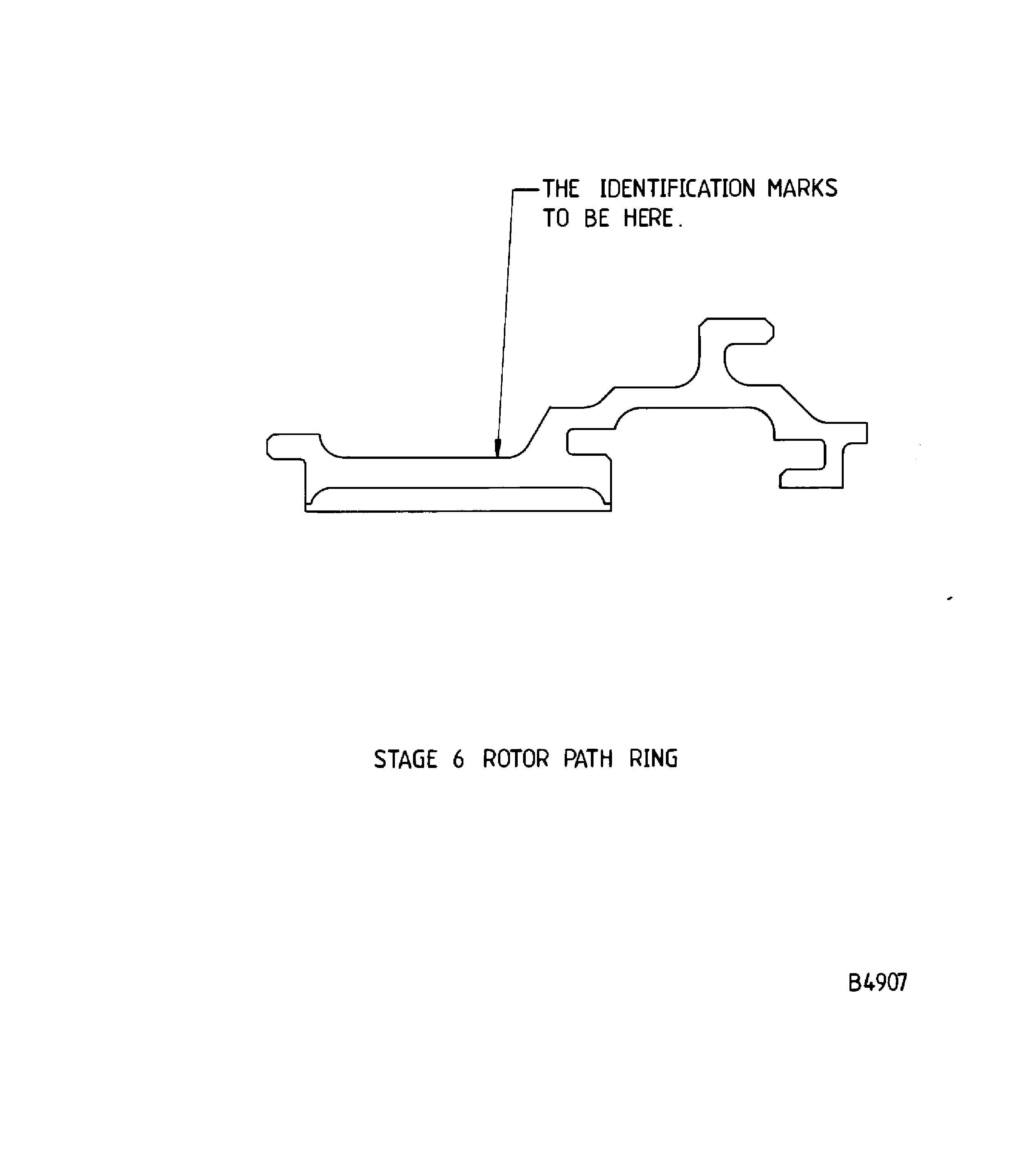

Refer to Figure.

SUBTASK 72-41-31-330-063 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

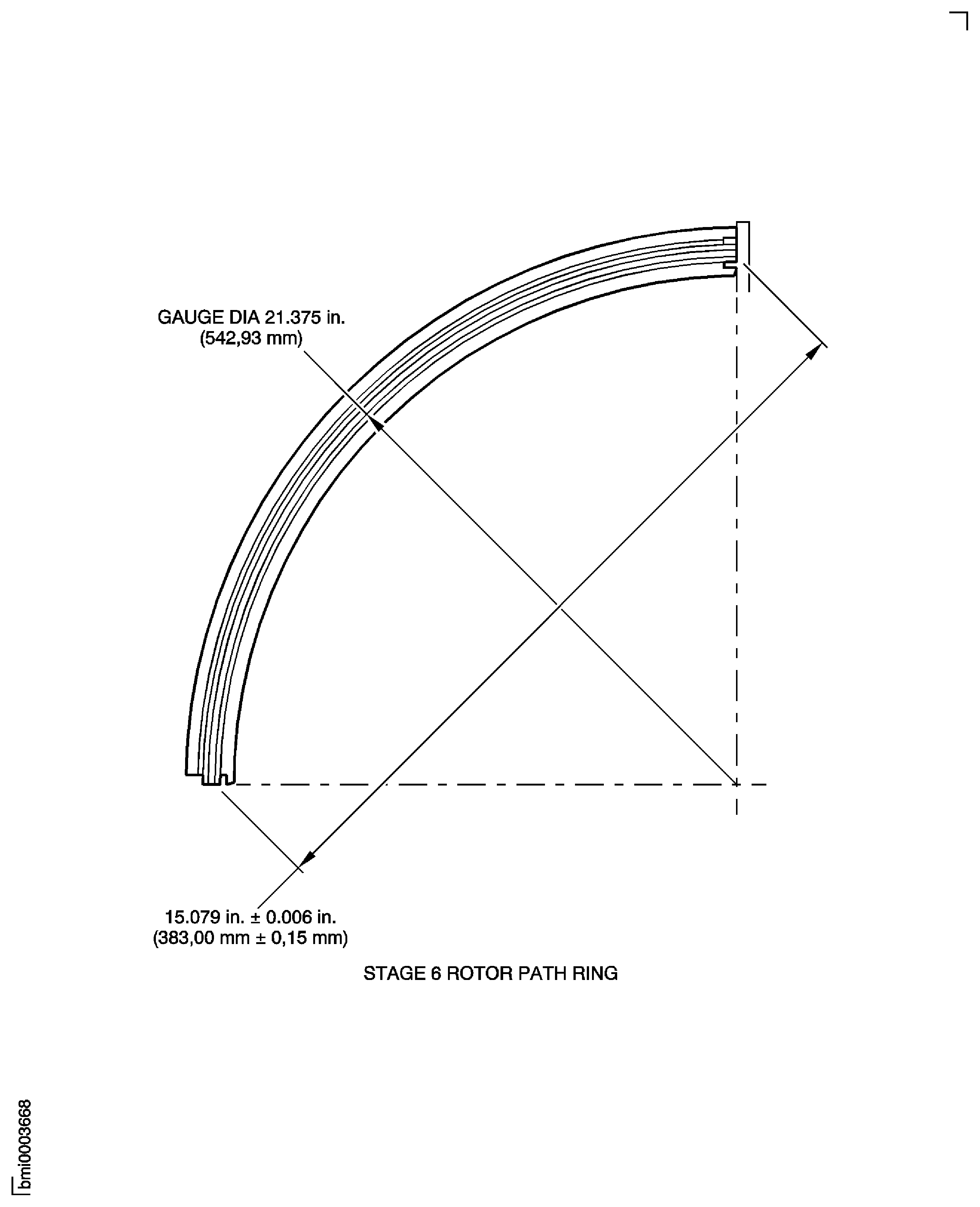

Figure: Repair Details and Dimensions

Repair Details and Dimensions

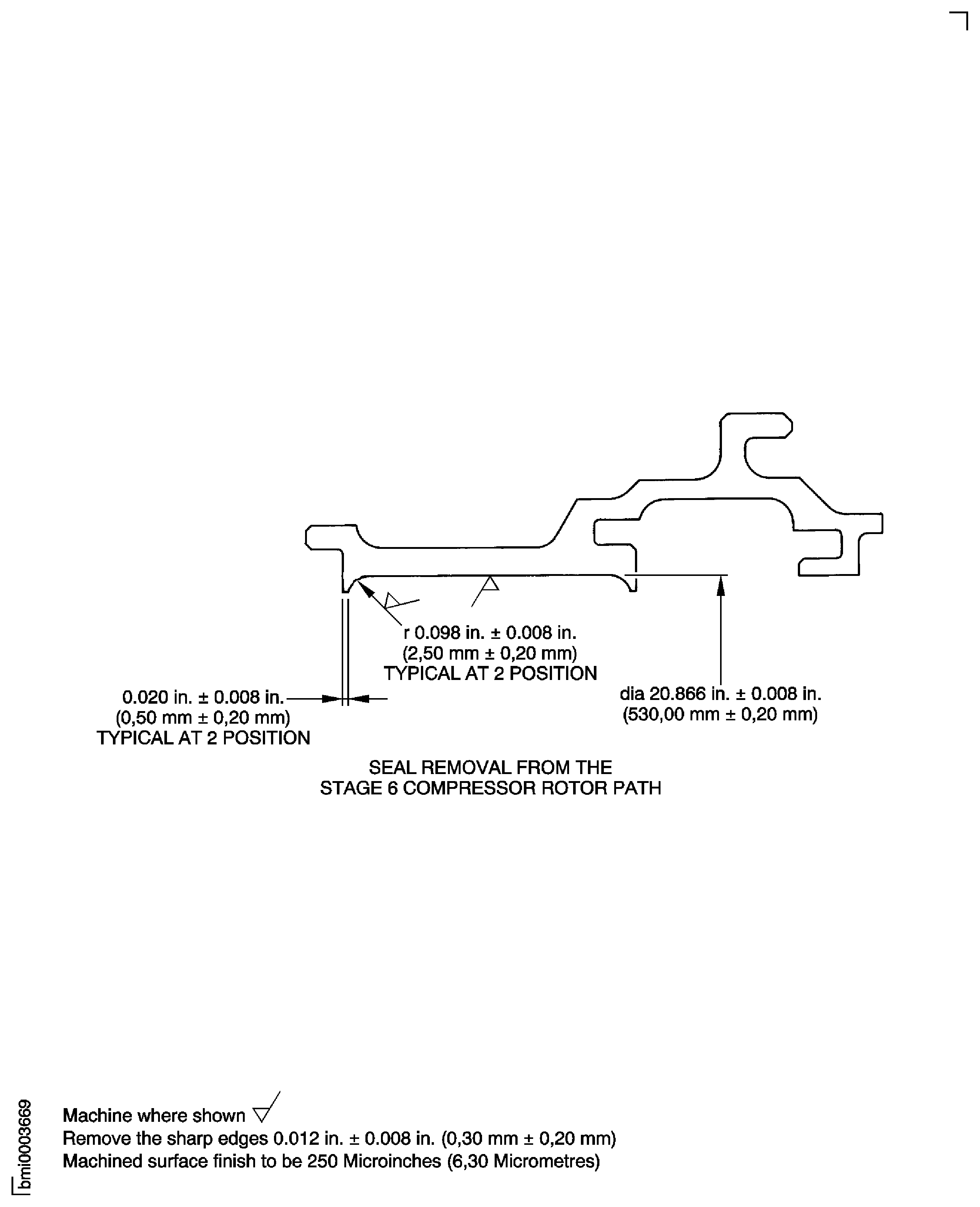

Figure: Repair Details and Dimensions

Repair Details and Dimensions

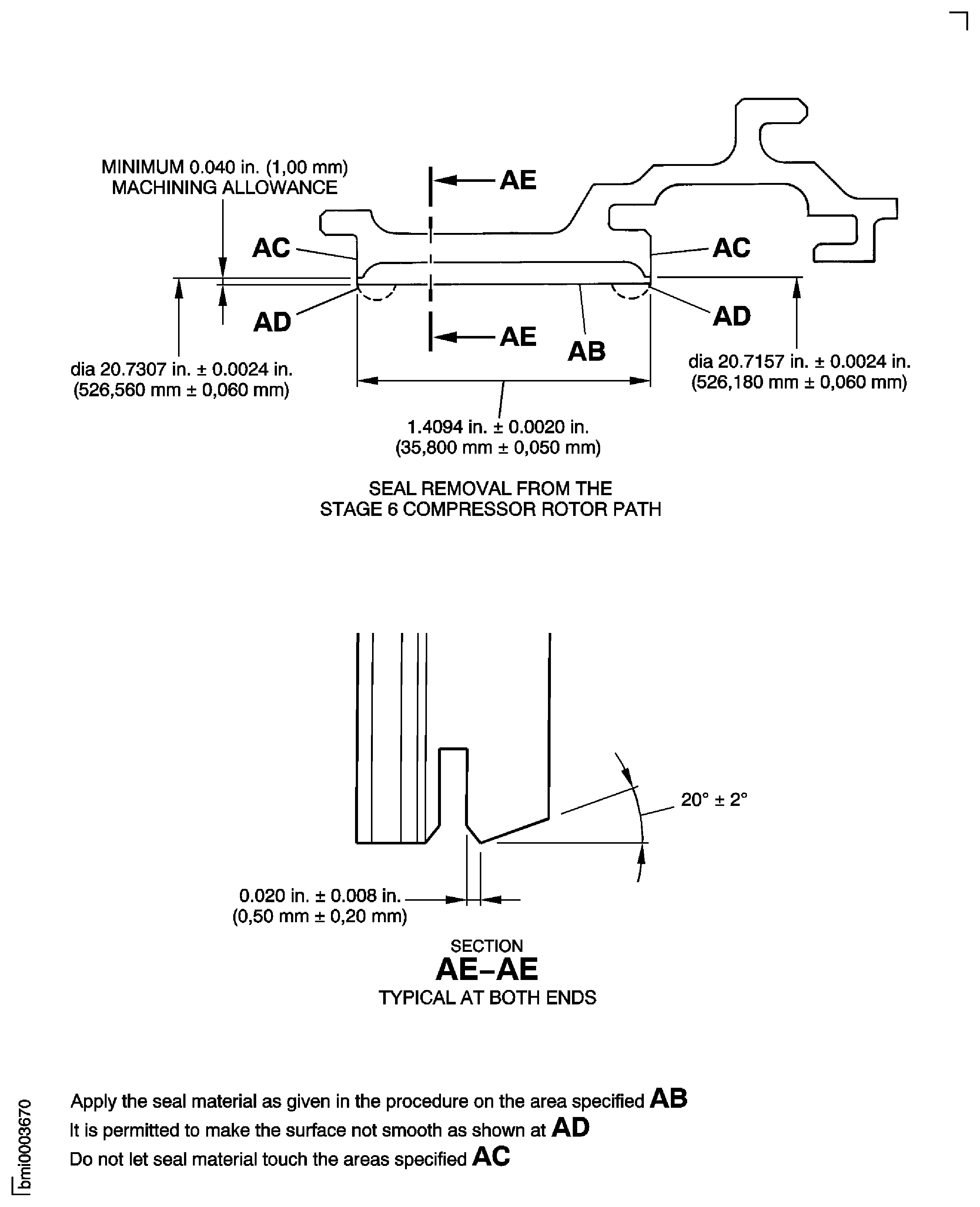

Figure: Repair Details and Dimensions

Repair Details and Dimensions