Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

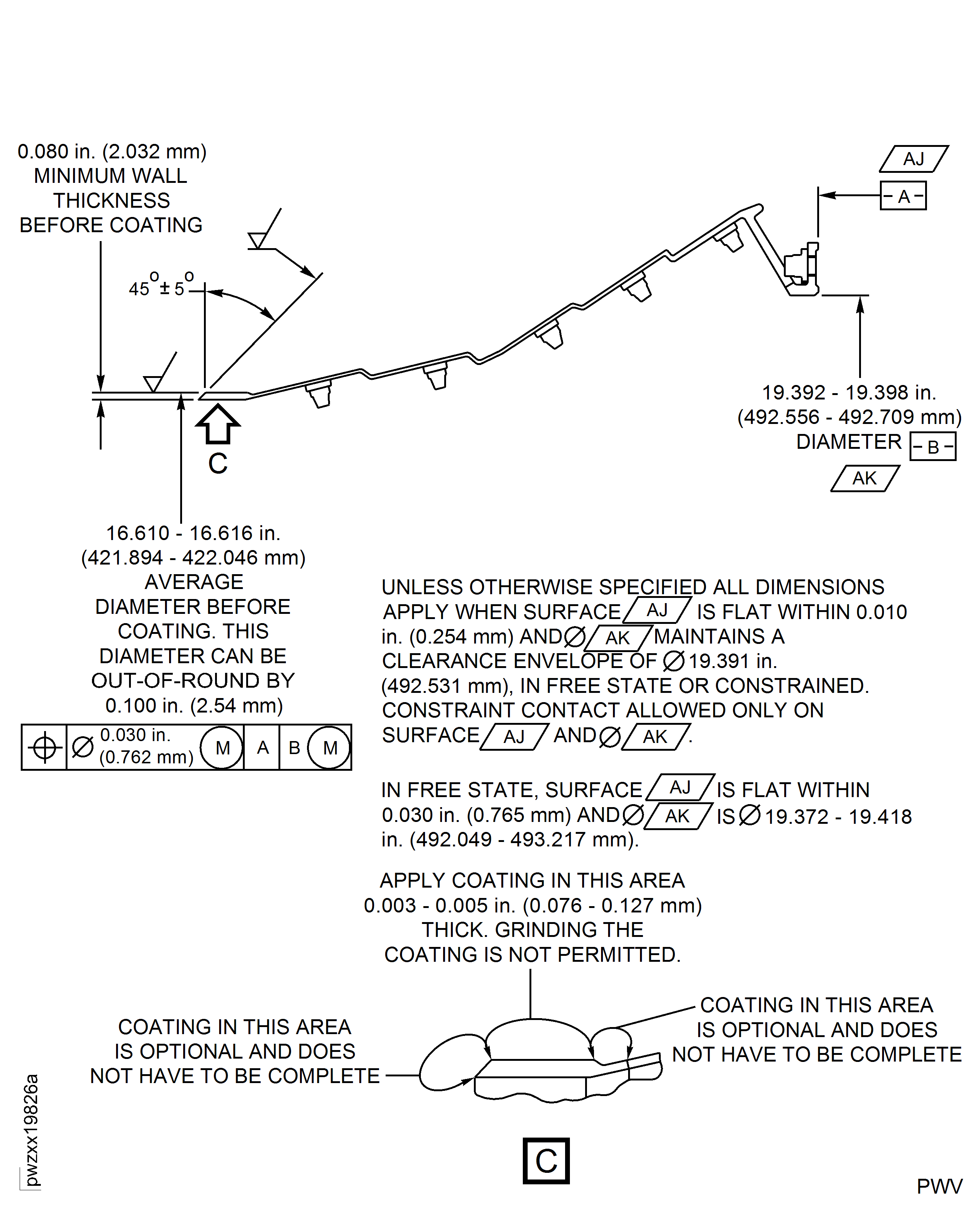

TASK 72-44-30-300-007 Inner Combustion Chamber Liner - Repair The Plasma Coat On The Front Outside Diameter Seal, Repair-007 (VRS3169)

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

Combustion Chamber - Inner Liner | - | Wrought non-hardable nickel |

base alloy |

General

The practices and processes referred to in the procedure by the TASK number are in SPM.

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before this repair. | |

| If you use chemical removal procedure, all details must be removed by the given repairs: | TASK 72-44-30-300-001 |

| TASK 72-44-30-300-003 |

Support Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Make sure all details are removed.

Apply a mask or maskants to all the areas that are not removed by SPM TASK 70-38-24-300-503.

Remove the coat that is on the part by the chemical removal procedure. Refer to SPM TASK 70-33-90-300-503.

Remove the coat that is on the part by high pressure water jet. Refer to SPM TASK 70-15-01-160-501.

Remove the coat that is on the part by one or more of the procedures that follow:

SUBTASK 72-44-30-350-066 Remove the Remaining Plasma Coat from the Front Outside Diameter Seal on the Combustion Chamber Inner Liner

Clean the part by SPM TASK 70-11-03-300-503.

SUBTASK 72-44-30-110-073 Clean the Combustion Chamber Inner Liner

Do a fluorescent penetrant inspection of the repair area by SPM TASK 70-23-03-230-501.

Do a fluorescent penetrant inspection of the repair area by SPM TASK 70-23-08-230-501.

Do a fluorescent penetrant inspection of the repair area by one of the methods that follow. Refer to Figure.

SUBTASK 72-44-30-230-074 Fluorescent Penetrant Inspect the Repair Area

Do a dimensional inspection of the repair area. Refer to Figure.

SUBTASK 72-44-30-220-106 Examine the Front Outside Diameter Seal on the Combustion Chamber Inner Liner

Refer to SPM TASK 70-34-18-380-501 and Figure.

Grit blast out of the repair area shown is not permitted. Use masks or maskants.

Prepare the surface for coating.

SUBTASK 72-44-30-380-005 Prepare the Surface of the Front Outside Diameter Seal

Coat out of the repair area is not permitted. Apply a mask or maskants.

Grind operation is not permitted to remove coat.

Coat the front outer diameter seal by IAE 53-5. Refer to SPM TASK 70-34-03-340-501 and Figure.

Deleted.

SUBTASK 72-44-30-340-053 Apply Plasma Coating to the Front Outside Diameter Seal of the Combustion Chamber Inner Liner

Refer to Figure.

Examine the coat after repair. Refer to SPM TASK 70-34-03-340-501.

SUBTASK 72-44-30-220-078 Examine the Plasma Coating on the Front Outside Diameter Seal on the Combustion Chamber Inner Liner

Deleted.

Use vibration peen procedure to mark VRS3169 adjacent to the part number. Refer to SPM TASK 70-09-00-400-501.

SUBTASK 72-44-30-350-067 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Requirements After Job Completion

Follow-On Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| If removed, all details must be installed by the given repairs: | TASK 72-44-30-300-001 |

| TASK 72-44-30-300-003 |