Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

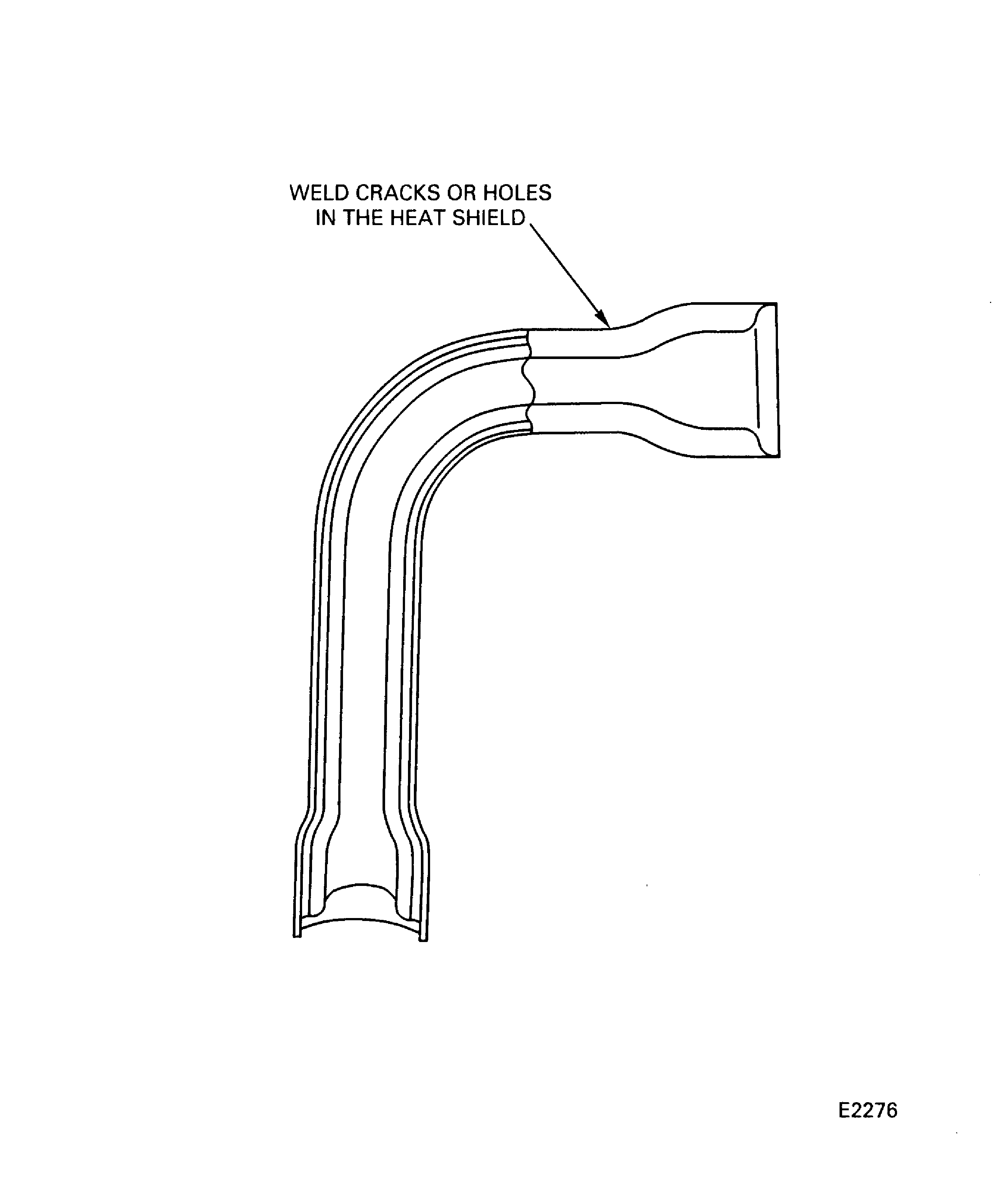

TASK 72-50-53-300-037 No. 5 Bearing Pressure Tube Heat Shields - Weld Repair, Repair-037 (VRS3333)

Material of component

RR | ||

|---|---|---|

DESCRIPTION | SYMBOL | MATERIAL |

No. 5 bearing pressure tube | - | AMS 5510 stainless steel |

heat shield | ||

General

Price and availability - refer to IAE

The practices and processes referred to in this procedure by TASK numbers are in the SPM.

Part number with more REACh (Registration, Evaluation, Authorization, and Restriction of Chemicals) information are listed below:

2A2229-01

Refer to How To Use (Engine Manual) Substances of Very High Concern and Safe Use Information.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Silicon carbide wheel | LOCAL | Silicon carbide wheel | ||

| Welding equipment | LOCAL | Welding equipment |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-11-01-300-503, SPM TASK 70-11-13-300-503, SPM TASK 70-11-16-300-503, SPM TASK 70-11-26-300-503 or SPM TASK 70-11-03-300-503.

Clean the heat shield.

SUBTASK 72-50-53-110-097 Clean the No. 5 Bearing Pressure Tube Heat Shield

Refer to Figure.

There is no maximum length or quantity for cracks.

Cracks in welds must be fully routed out.

Cracks in the sheet metal do not have to be routed out.

Rout out cracks in the welds.

Refer to the SPM TASK 70-31-13-310-501.

Weld the cracks by the manual gas tungsten arc method.

SUBTASK 72-50-53-310-059 Weld Repair the No. 5 Bearing Pressure Tube Heat Shield

Refer to the SPM TASK 70-31-13-310-501 for size limits. The area you machine to remove damage can be any shape. The area must be in a 2.000 in. (50.800 mm) diameter circle.

Inner and outer corner radii must be 0.250 in. (6.350 mm) or larger.

Machine to remove rough edges or distortion around holes.

Refer to the SPM TASK 70-31-13-310-501.

Weld the patch in position.

SUBTASK 72-50-53-310-060 Weld Patches on Holes in the No. 5 Bearing Pressure Tube Heat Shield

Refer to TASK 72-50-53-200-000 (INSPECTION-000).

Inspect the heat shield after weld repair.

SUBTASK 72-50-53-220-173 Examine the No. 5 Bearing Pressure Tube Heat Shield after Weld Repair

Figure: Weld repair the No. 5 bearing pressure tube heat shield

Weld repair the No. 5 bearing pressure tube heat shield