Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 73-13-41-300-011 Fuel Nozzle And Support Assembly - Replace The Fuel Inlet Fitting And Insert, Repair-011 (VRS3590)

Effectivity

FIG/ITEM | PART NO. |

01-020 | 2A1637 |

01-020 | 2A1637-001 |

01-020 | 2A2250 |

01-020 | 2A2250-001 |

01-020 | 2A3448 |

01-020 | 2A3448-001 |

01-020 | 2A3453 |

01-020 | 2A3453-001 |

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Braze oven | LOCAL | Braze oven |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-114 BRAZE FILLER METAL 82Au-18Ni | 0AM53 | CoMat 03-114 | ||

| CoMat 03-286 WELDING WIRE | LOCAL | CoMat 03-286 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Repair, VRS3458 (Repair-002) TASK 73-13-41-300-002.

Remove fuel strainer element and metering plug.

Clean by Cleaning-000 TASK 73-13-41-100-200 and Examine by Inspection-000 TASK 73-13-41-200-400.

Make sure the cleaning and inspections for this repair have been done before you do this repair.

SUBTASK 73-13-41-350-064 Prerequisites

Use Comat 10-069 calibration fluid or water.

Back flush the support assembly to remove debris from the fuel passage

SUBTASK 73-13-41-350-065 Remove Debris from Support Assembly Fuel Passage

Clean by Cleaning-003 TASK 73-13-41-100-203.

Ultrasonic clean the support

SUBTASK 73-13-41-130-053 Clean the Support

Refer to SPM TASK 70-23-05-230-501.

No cracks permitted.

Do a fluorescent penetrant inspection of the machined area of the support

SUBTASK 73-13-41-230-063 Do a Fluorescent Penetrant Inspection of the Support

Refer to SPM TASK 70-11-03-300-503.

Clean the support, replacement fuel inlet fitting and insert

SUBTASK 73-13-41-110-064 Clean the Support, Replacement Fuel Inlet Fitting and Insert

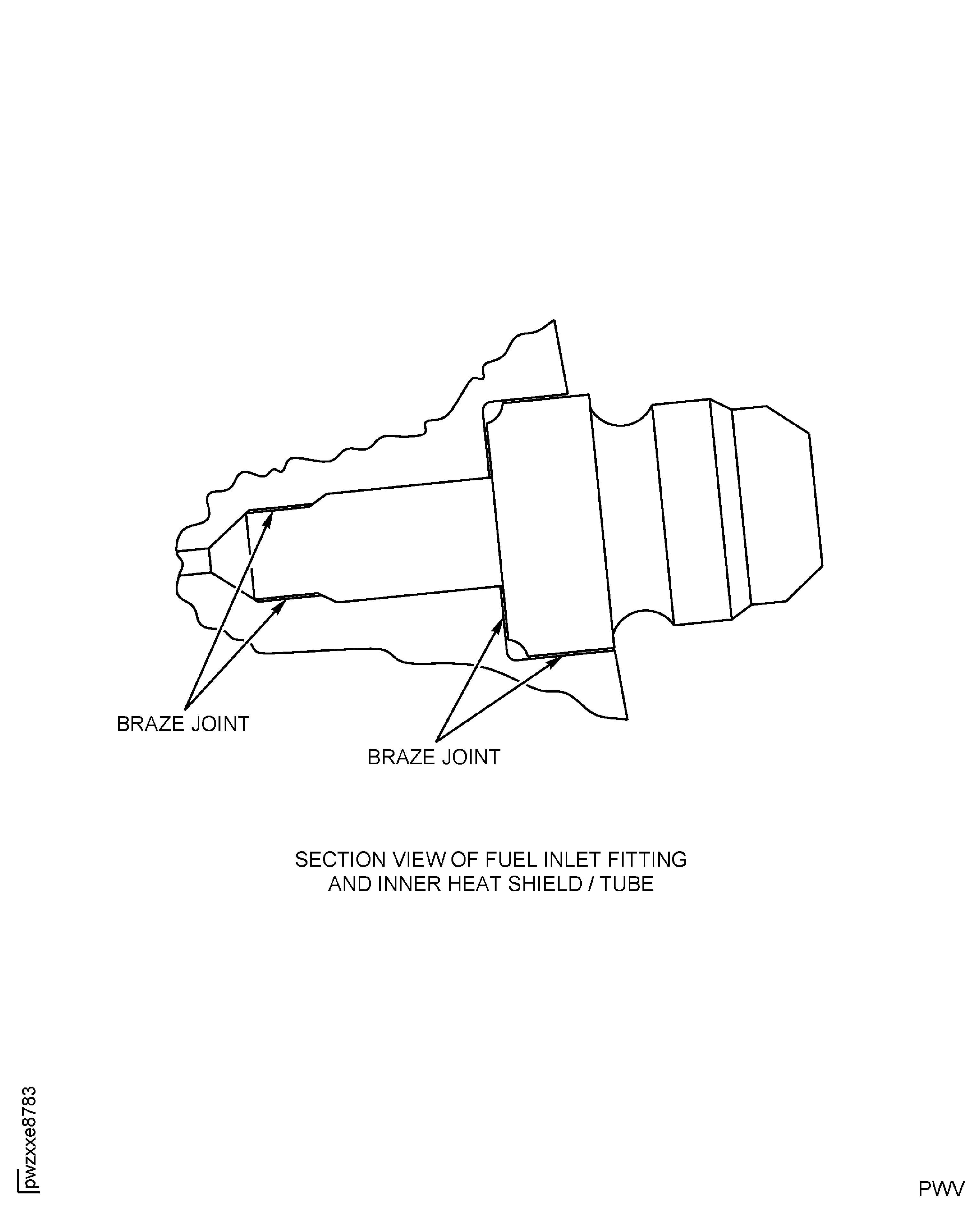

Prepare, install and braze the replacement fuel inlet fitting

Refer to SPM TASK 70-31-14-310-501.

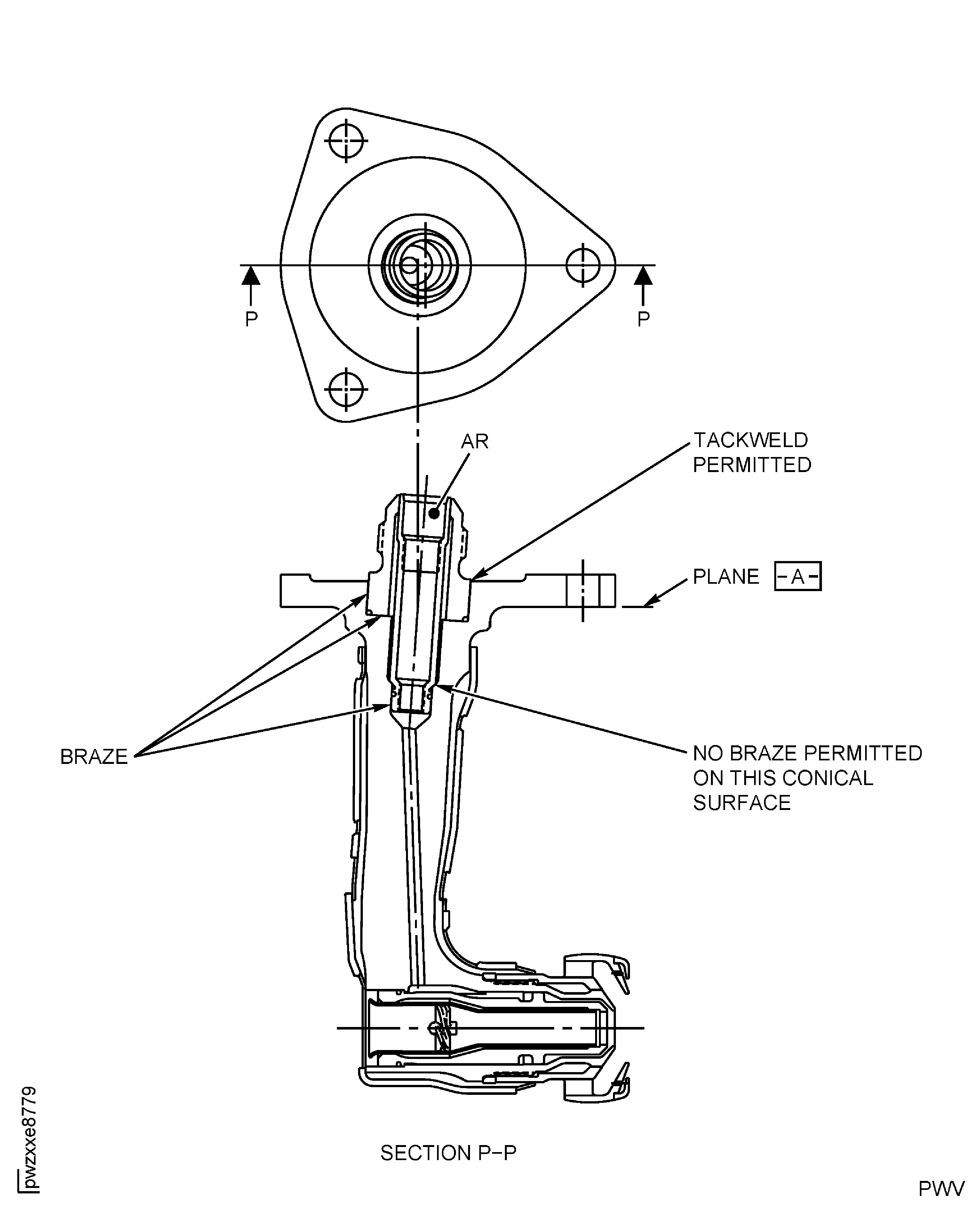

NOTE

Track welding the fuel inlet fitting to the support is permitted. Track welding the insert to the fuel is permitted but must be removed at final assembly. Use CoMat 03-286 WELDING WIRE.

SUBTASK 73-13-41-350-066 Prepare, Install and Braze the Replacement Inlet Fuel Fitting

A complete line of braze must be visible at the outer end of the joint. Too much braze in the fillet at the external end of the joint is acceptable.

Too much braze on other areas of the support or fitting OD beyond the fillet is acceptable, if it is firmly bonded, smooth in appearance, not located on a mating surface and is not more than 0.015 in. (0.38 mm) high.

Too much braze on the conical seat is not acceptable. Refer to repair, VRS3257 (Repair-004) TASK 73-13-41-300-004 Signs of too much braze removal is acceptable, if parent material is not removed.

Do a visual inspection of the braze joint.

SUBTASK 73-13-41-210-001 Do an Inspection of the Braze Joint

CAUTION

FUEL NOZZLE SUPPORT ASSEMBLY CONTAINS ADDITIONAL CoMat 03-114 BRAZE FILLER METAL 82Au-18Ni BRAZE JOINTS AT THE INNER HEAT SHIELD, INNER AIR SWIRLER AND CENTER BODY. BRAZE PROCESS CONDUCTED BY SPM TASK 70-31-14-310-501 PROCESS WINDOW MUST ENSURE MINIMAL BRAZE FLOW AT THE EXISTING BRAZE JOINTS. WHEN YOU DO A VISUAL INSPECTION OF THE JOINTS, THE JOINTS MUST SHOW 100 PERCENT LINE OF BRAZE AT THE OUTER END OF THE JOINT.Area of braze coverage must not be less than 80 percent of the mating portions of assembly.

A complete braze fillet must be present for 360 degrees at the exposed edge of the braze joint. This braze fillet must be free of any voids.

NOTE

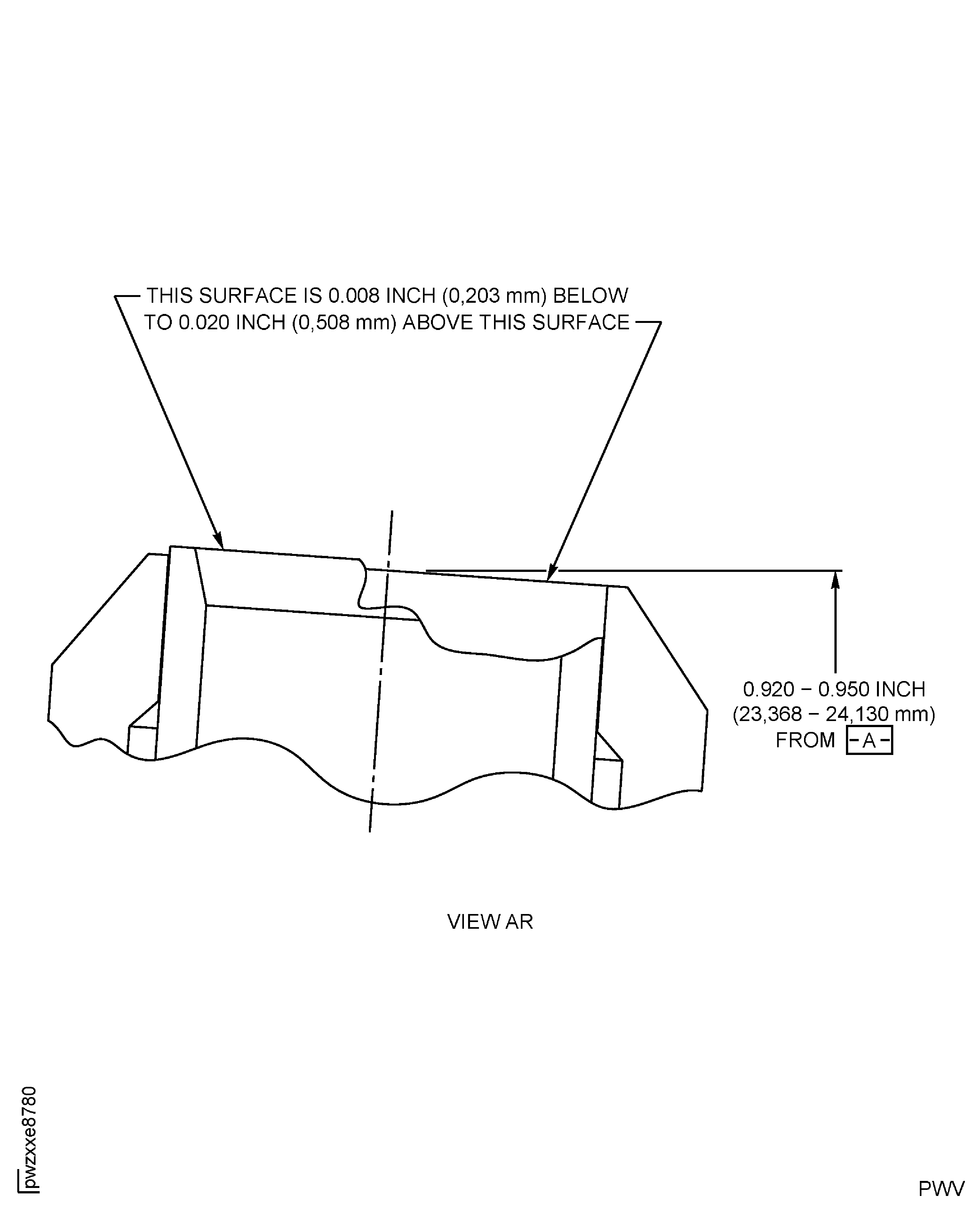

Single exposure technique shows tangential braze lines which are criteria for judging braze flow within the joint. Refer to Figure.NOTE

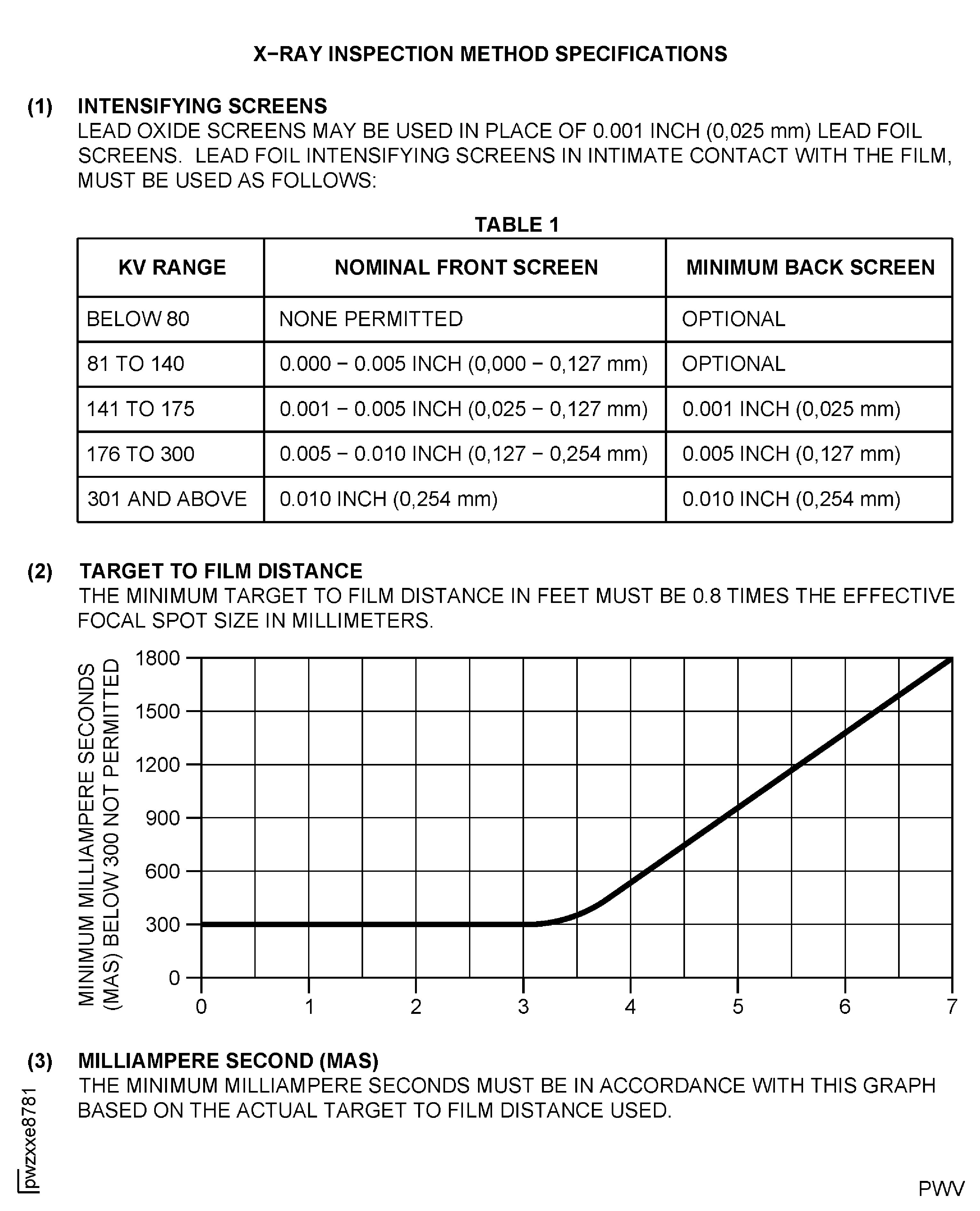

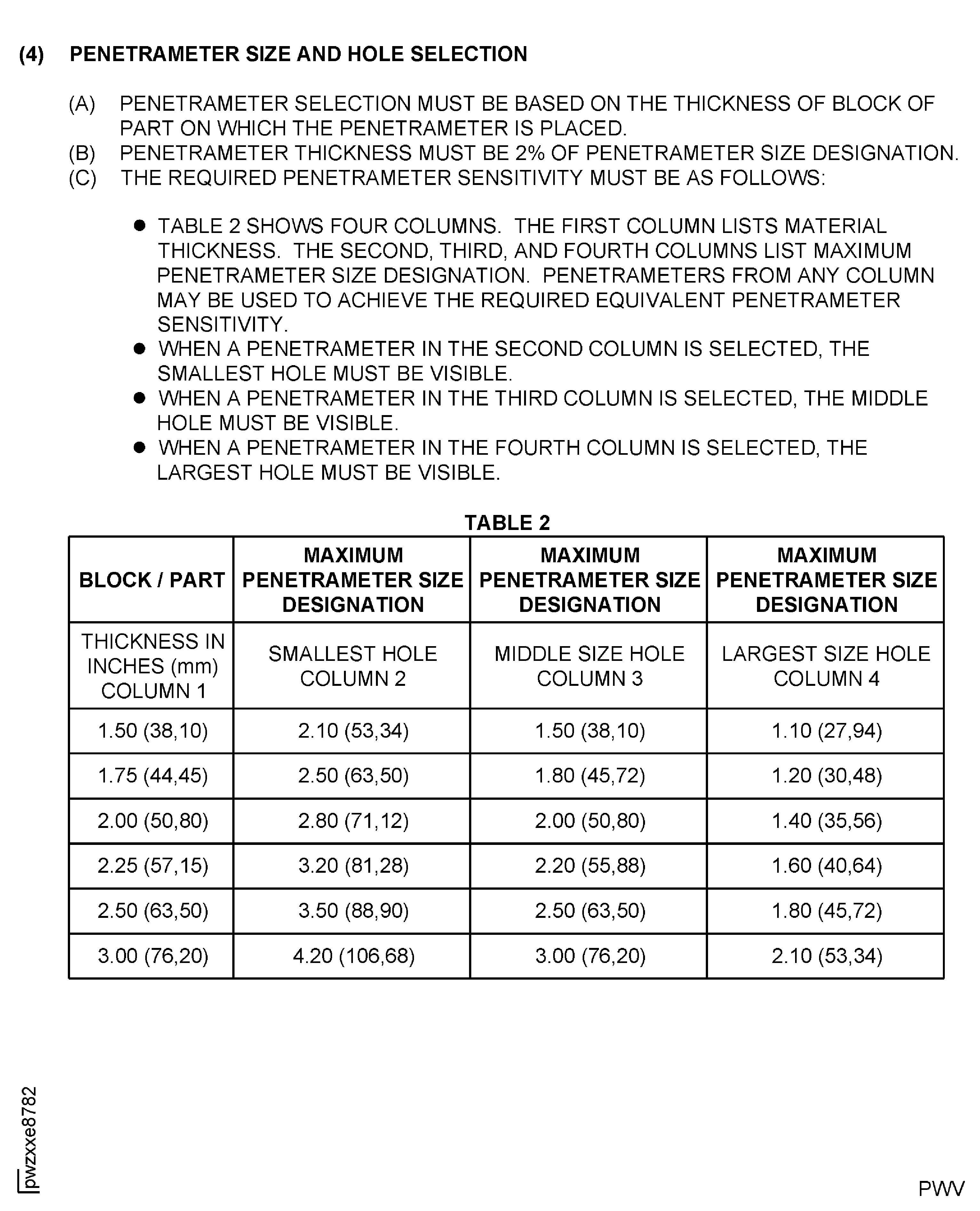

X-ray machine procedures can be obtained from the machine manufacturer. The necessary X-ray machine settings must be developed with the machine manufacturer's parameters and by the X-ray inspection method specifications as stated in Table 1 and Table 2 in Figure and Figure. Refer to SPM TASK 70-26-00-260-501.

Do an X-ray examination of the braze bond.

SUBTASK 73-13-41-260-001 Do an X-Ray Inspection of the Braze Bond

Use Comat 10-069 calibration fluid or water.

Back flush the support assembly

SUBTASK 73-13-41-110-065 Back Flush Support Assembly

Test by Testing-001 TASK 73-13-41-700-201.

No leaks permitted.

Do a leak test with nitrogen.

SUBTASK 73-13-41-350-067 Do a Leak Test

Repair by VRS3458 (Repair-002) TASK 73-13-41-300-002.

Install metering plug and fuel strainer

Examine by Inspection-000 TASK 73-13-41-200-400.

Test by Testing-001 TASK 73-13-41-700-201.

Storage by Storage-001 TASK 73-13-41-550-001.

Make sure all of the applicable inspection, testing and storage requirements are completed and acceptable.

SUBTASK 73-13-41-350-068 Postrequisites

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

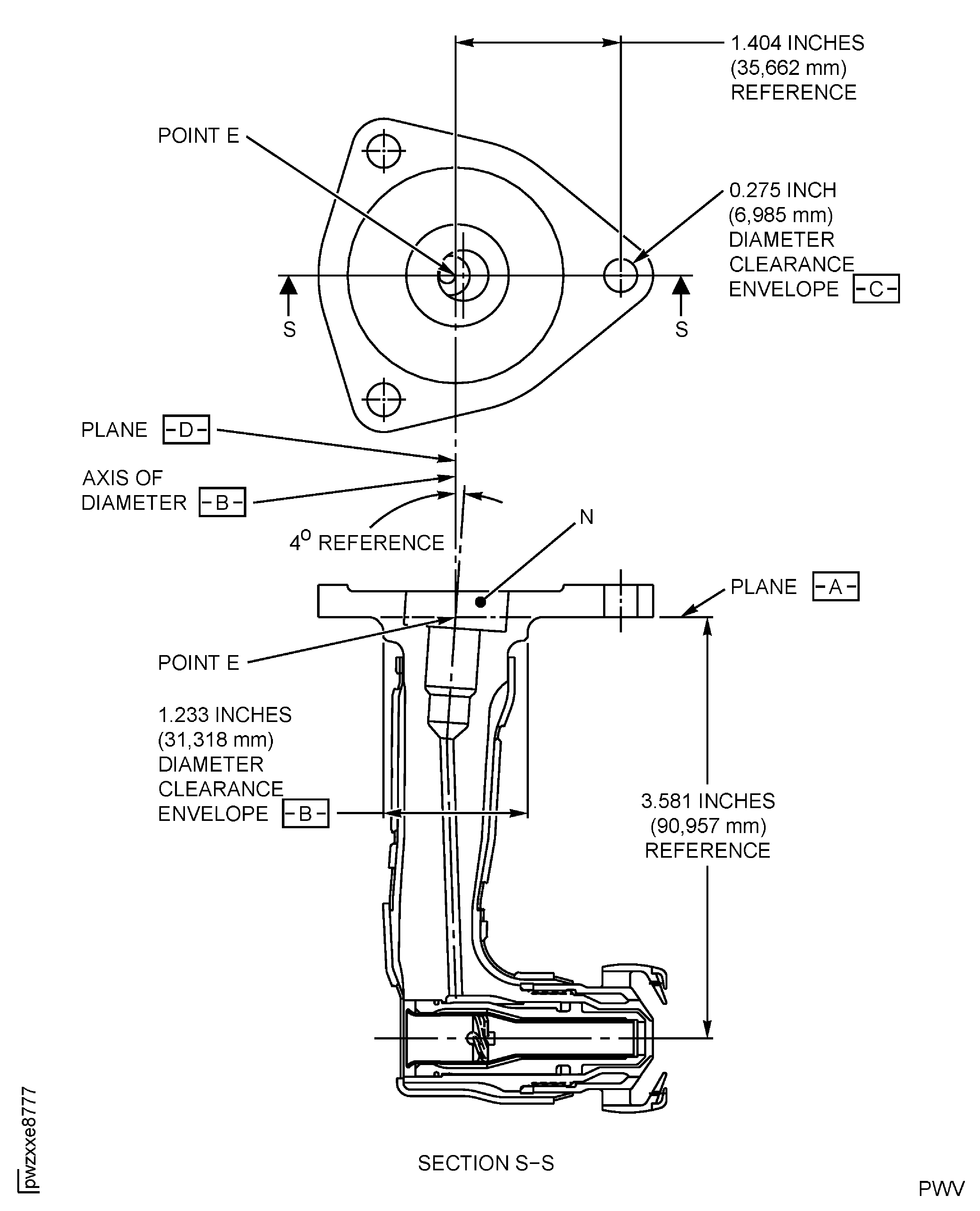

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

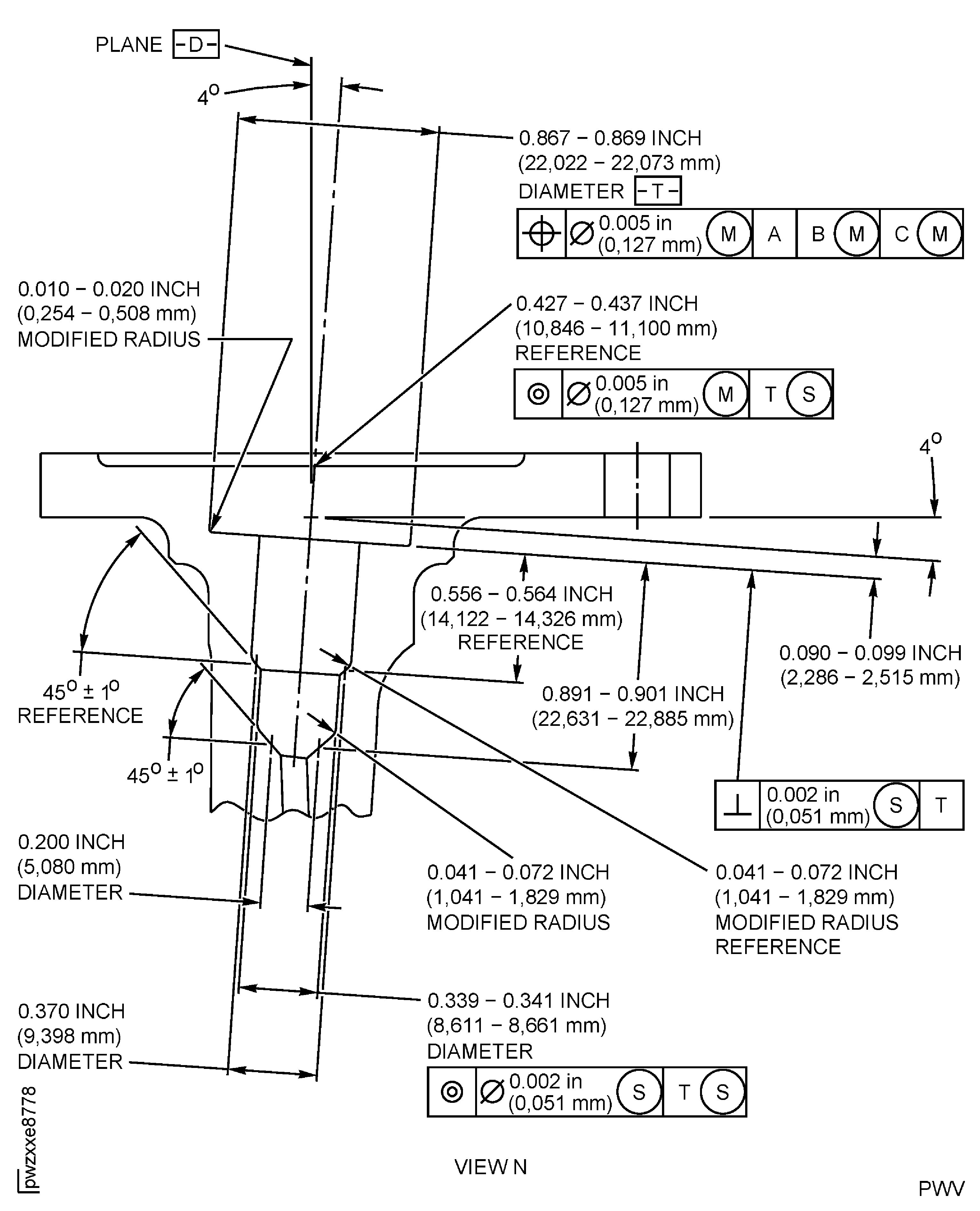

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions