Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-00-100-001-A00 Engine General - Clean The Engine Gas Path For Performance Improvement, Cleaning-001

General

This TASK gives the procedure to clean the engine gas path for improved performance.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Portable water source | LOCAL | Portable water source | (pressure of 40 psi to 50 psi (275 kPa to 345 kPa), refer to potable water quality specifications in SPM V2500-00-70-10-00-00A-250A-D.) | |

| Hoses and nozzles | LOCAL | Hoses and nozzles | (waterflow capacity of approximately 5 to 10 U.S. gallons (20 to 40 liters)) | |

| Plugs or covers for the disconnectedtubes | LOCAL | Plugs or covers for the disconnected tubes | ||

| Tank and Pump | LOCAL | Tank and Pump | ||

| IAE 4J12031 Spray ring | 0AM53 | IAE 4J12031 | 1 | (Alternate to IAE 4J12034) |

| IAE 4J12034 Water wash tube | 0AM53 | IAE 4J12034 | 1 | (Alternate to IAE 4J12031) |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-007 ETHYL ALCOHOL C2H5OH (DENATURED) | LOCAL | CoMat 01-007 | ||

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 |

Spares

NONESafety Requirements

WARNING

Procedure

Refer to SPM TASK 70-11-48-110-501 makeup of cleaning solutions for the makeup of Solution Code 181 Engine Gas Path Cleaning Solution.

Water for engine gas path cleaning must agree with the Potable Water Quality Specifications in SPM TASK 70-10-00-100-501.

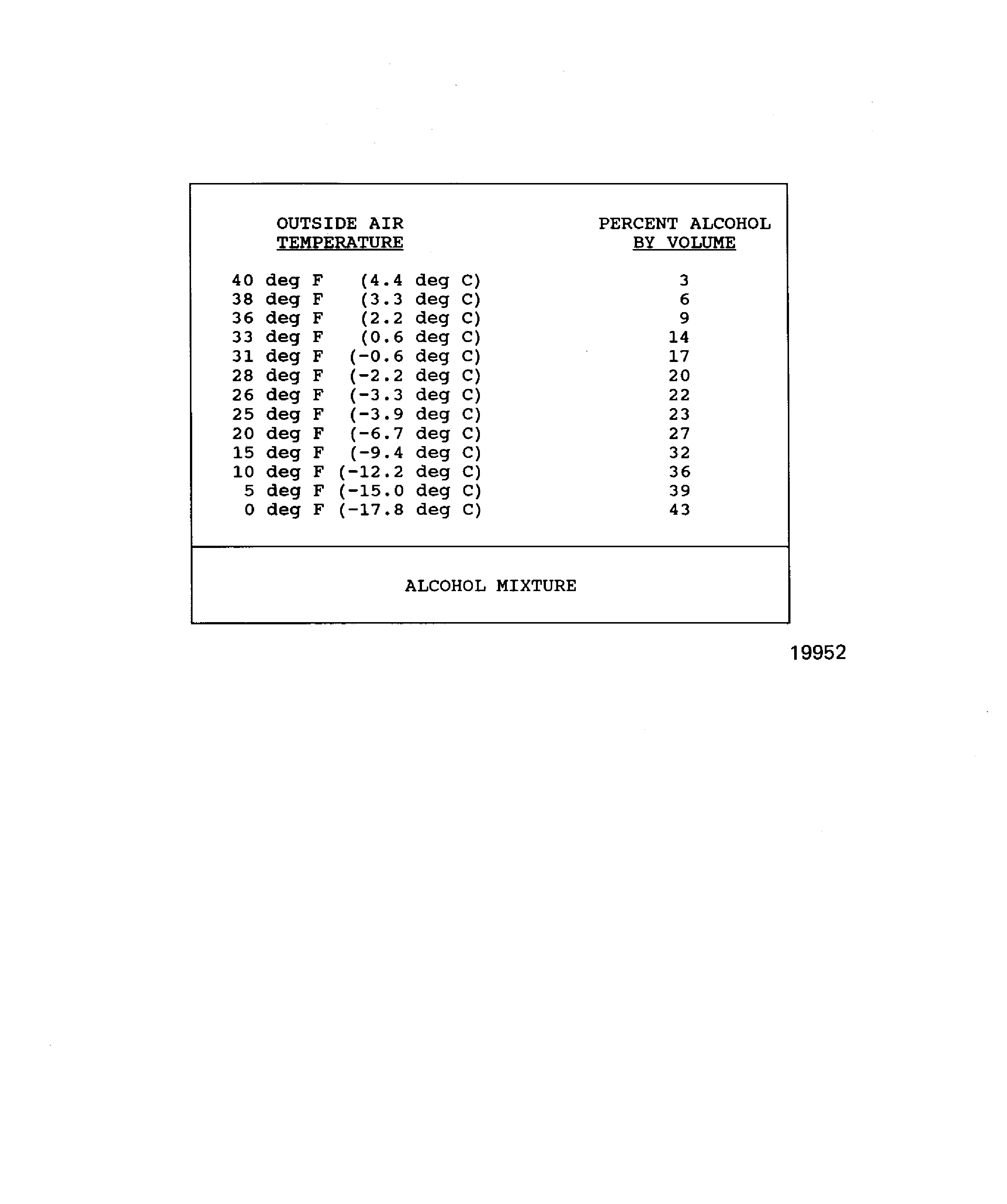

If the ambient temperature is 41.9 deg F (5.5 deg C) or less, use water mixed with CoMat 01-007 ETHYL ALCOHOL C2H5OH (DENATURED) or CoMat 01-124 ISOPROPYL ALCOHOL at the applicable ratio to prevent icing. Refer to Figure.

SUBTASK 72-00-00-110-056 Makeup of Engine Gas Path Cleaning Solution

CAUTION

DO NOT USE A DETERGENT WASH ON ENGINES WITH GAS PATHS THAT WERE EXPOSED TO DRY POWDER FIRE EXTINGUISHING AGENTS. THESE AGENTS ARE NOT WATER SOLUBLE. WATER WASHING WILL CAUSE THESE MATERIALS TO CAKE AND STICK ON ENGINE PARTS.

CAUTION

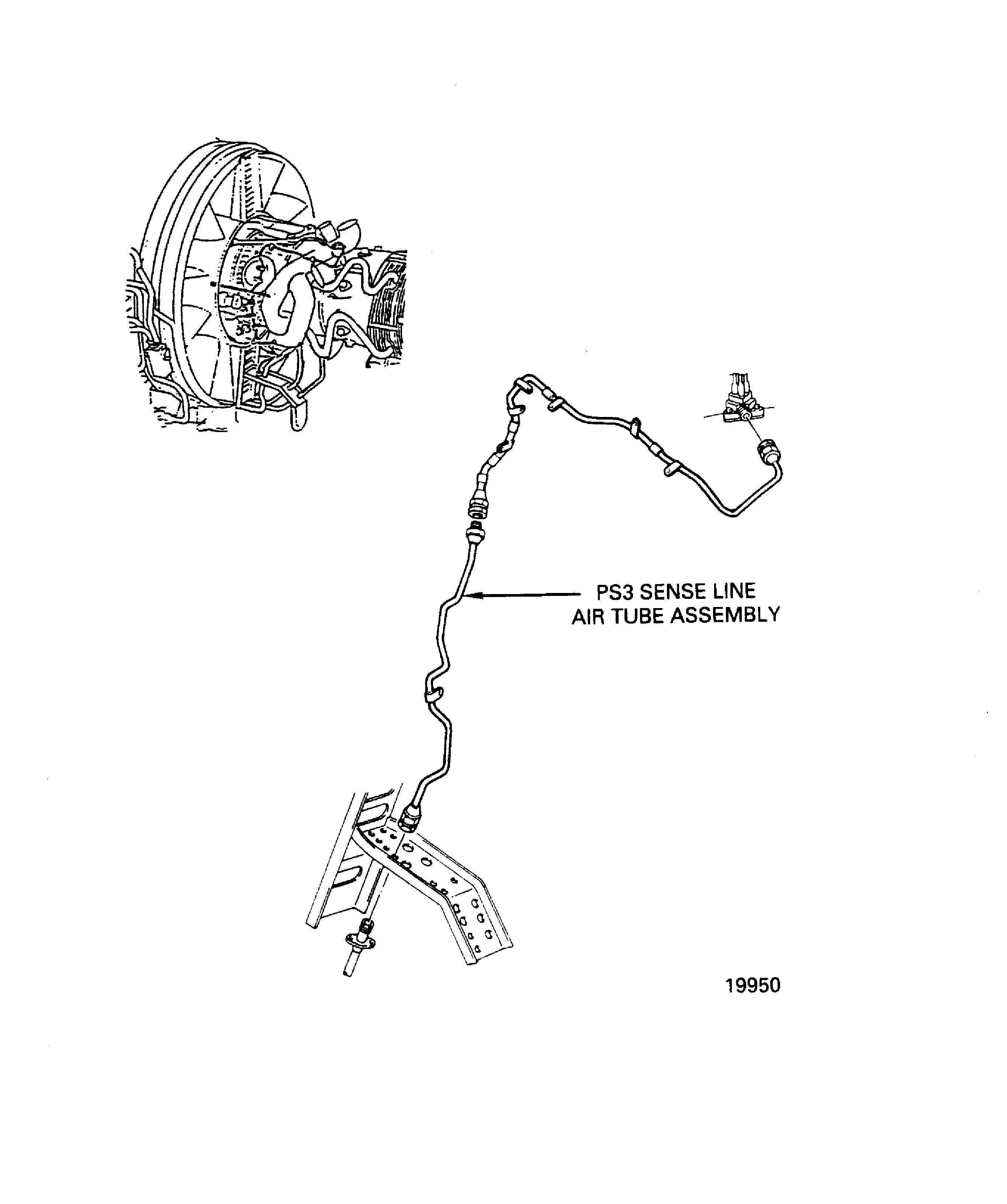

THE ENGINE EGT MUST BE BELOW 150 DEG F (65.6 DEG C) TO PREVENT ENGINE DAMAGE.Disconnect the PS3 sensing tube from the autostart probe. Install a plug. Refer to Figure.

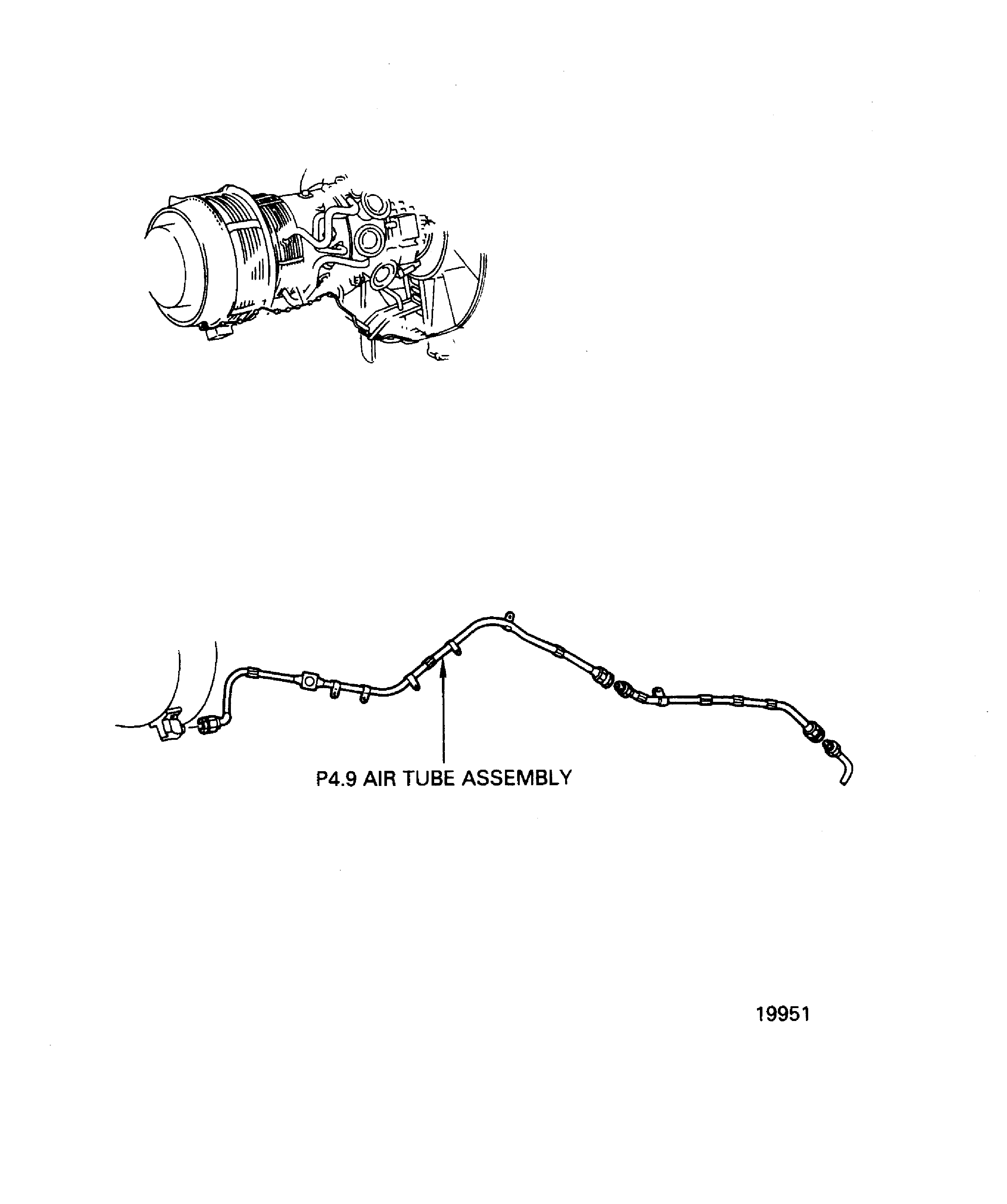

Disconnect the Air-to-P4.9 EEC tube at the fitting on the bottom of the turbine exhaust case. Install a plug. Refer to Figure.

Connect one end of the long hose to the spray ring assembly and the other end to a pressure pump for the Portable water source.

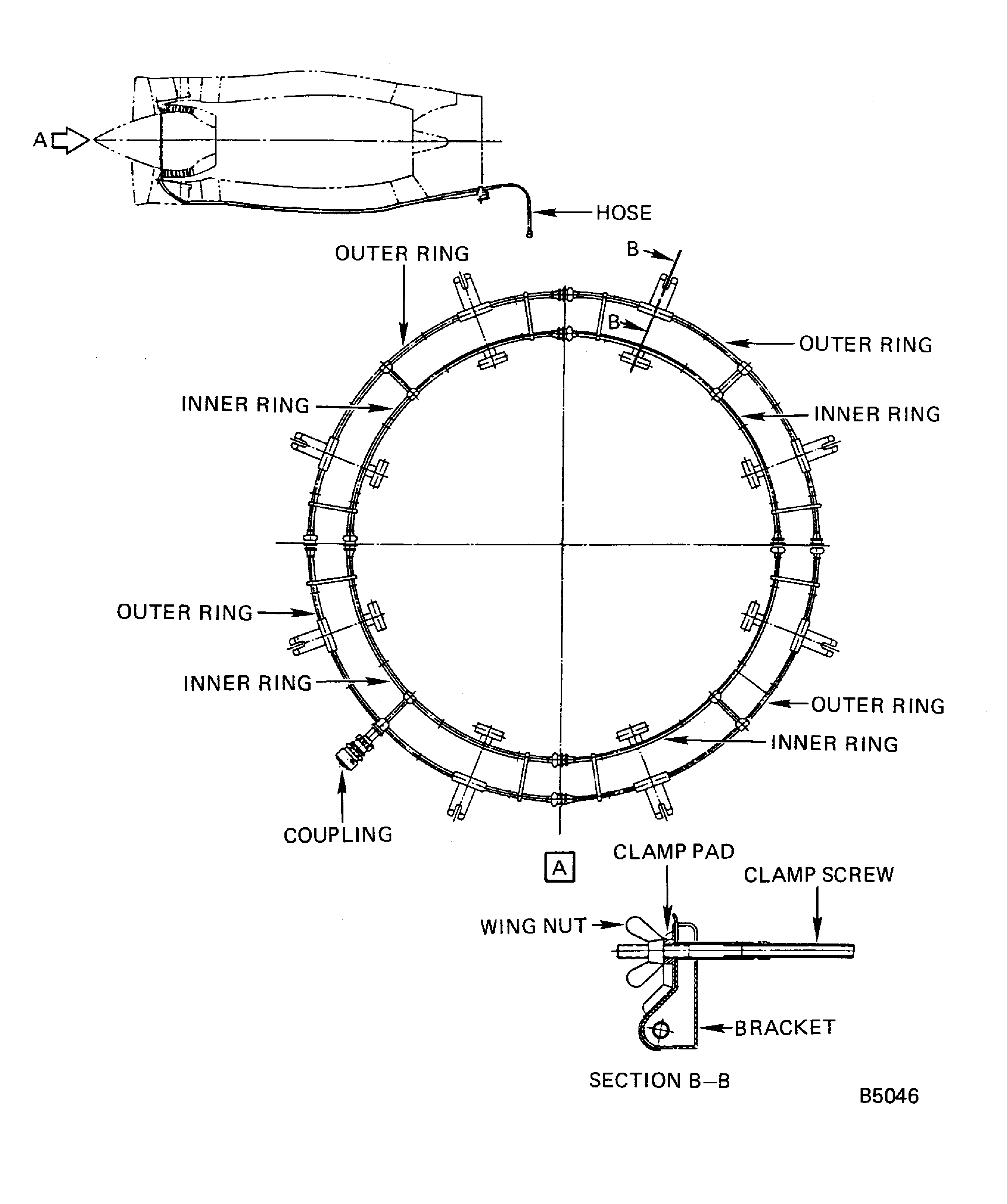

Install the IAE 4J12031 Spray ring 1 off as follows. Refer to Figure.

Install the IAE 4J12034 Water wash tube 1 off as follows. Refer to Figure.

Install the IAE 4J12031 Spray ring 1 off or the IAE 4J12034 Water wash tube 1 off.

If the ambient temperature is below 40 deg F (4.4 deg C), use the applicable potable water/alcohol mixture as an alternative to plain potable water in the solution to prevent ice. Refer to Step.

Prepare 20 US gal to 30 US gal (80 l to 120 l) of Solution Code 181 Engine Gas Path Cleaning Solution. Refer to Step.

Disconnect the variable stator vane actuator from the crankshaft and manually set the stator vanes to full open and fit rigging pin. Refer to TASK 72-00-40-050-001 (REMOVAL-011).

Let the engine soak for 30 minutes minimum after each third wash-and-soak procedure cycle to let the starter become cool.

Let the engine soak for 10 minutes minimum after all other wash-and-soak procedure cycles.

Stop motoring the engine.

Do the subsequent wash-and-soak procedure two times/cycles and let the engine soak for 10 minutes minimum between the wash-and-soak procedure cycles:

After each second (2nd) wash-and-soak procedure cycle, let the engine soak for 30 minutes to let the starter become cool.

If the solution that comes out of the tailpipe continues to look dirty, an added wash-and-soak procedure cycle will help to increase the benefit of the gas path wash. Operators are permitted to do the wash-and-soak procedure again at their discretion.

Motor the engine with the starter until N2 is at 2000 RPM minimum.

While you motor the engine, spray 10 gal to 15 gal (40 l to 60 l) of the potable water or potable water/alcohol mixture in two minutes into the low pressure compressor.

Stop motoring the engine.

Exchange the detergent source for one that has a similar amount of potable water or portable water/alcohol mixture (refer to Step and Figure). Do the subsequent rinse procedure two times/cycles and let the engine drain for 10 minutes minimum between the rinse procedure cycles:

Clean the blades by SPM TASK 70-11-03-300-503 SUBTASK 70-11-03-300-002 Aqueous Spray or Wipe (with Rinsing) Method.

Aqueous Degreaser Solution Procedure.

Clean the blades with Solution Code 181 Engine Gas Path Cleaning Solution and a clean cloth.

Rinse the blades thoroughly with potable water.

Engine Gas Path Cleaner Solution Procedure.

Use one of the procedures in the subsequent list to clean the LPC 1st Stage (fan) Blades:

Motor the engine with the starter for approximately 30 seconds to remove water.

Disconnect the P2.5 at the EEC and purge the line. Remove all the plugs and the rigging pin, purge and connect all the lines and connect the variable stator vane actuator control rod. Refer to TASK 72-00-40-450-001 (INSTALLATION-011).

Remove the IAE 4J12031 Spray ring or IAE 4J12034 Water wash tube.

If the water content is above 800 parts per million (ppm) by weight or by volume , drain the engine oil system. Refer to TASK 71-00-00-600-003 (SERVICING-003). Fill the system with new oil. Refer to TASK 71-00-00-600-002 (SERVICING-002).

Set the ignition circuit breakers again and start the engine. Refer to TASK 71-00-00-700-053-A01, 71-00-00-700-B01 (TESTING-000 CONFIG-001 and CONFIG-002) or TASK 71-00-00-700-053-A02, 71-00-00-700-B02 (TESTING-000, CONFIG-001 and CONFIG-002). Operate the engine at a power setting that is sufficient to keep the oil temperature at a minimum of 220 deg F (104.5 deg C) for no less than 10 minutes. If the minimum oil temperature cannot be reached, it is necessary to do an oil check for water content.

SUBTASK 72-00-00-110-053 Clean the Engine Gas Path

Figure: Alcohol and water mixture ratio

Alcohol and water mixture ratio

Figure: Remove the PS3 sense line air tube assembly

Remove the PS3 sense line air tube assembly

Figure: Remove the P4.9 air tube assembly

Remove the P4.9 air tube assembly

Figure: Install the IAE 4J12031 Spray Ring

Install the IAE 4J12031 Spray Ring

Figure: Install the IAE 4J12034 water wash tube

Install the IAE 4J12034 water wash tube