Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-32-00-430-010-A00 LPC/Intermediate Case Module - Install The LPC Booster Stage Assembly, Assembly-010

General

This TASK gives the procedure to install the LP Compressor Booster Assembly. For other parts of the LP Compressor/Intermediate Case Module, refer to TASK 72-32-00-430-000 (ASSEMBLY-000).

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-410-501.

To identify, lubricate and install seal rings, refer to the SPM TASK 70-64-02-640-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

The abbreviation Intf shows an interference or tight fit. This causes REJECT IF MORE THAN to become REJECT IF LESS THAN. The abbreviation Clear shows a clearance fit.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

The No. 1 Strut, which is the top position Strut of the Fan Frame Assembly, is identified by the five pressure tubes on the No. 1 Strut leading edge.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1J12457 Measuring stretch | 0AM53 | IAE 1J12457 | 1 | |

| IAE 1J12507 Guide pin | 0AM53 | IAE 1J12507 | 1 | |

| IAE 1J13109 0AM53 heater | 0AM53 | IAE 1J13109 | 1 | |

| IAE 1J13103 Vertical sling | 0AM53 | IAE 1J13103 | 1 | |

| IAE 6F10027 Heater control unit | 0AM53 | IAE 6F10027 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE | LOCAL | CoMat 04-004 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

CAUTION

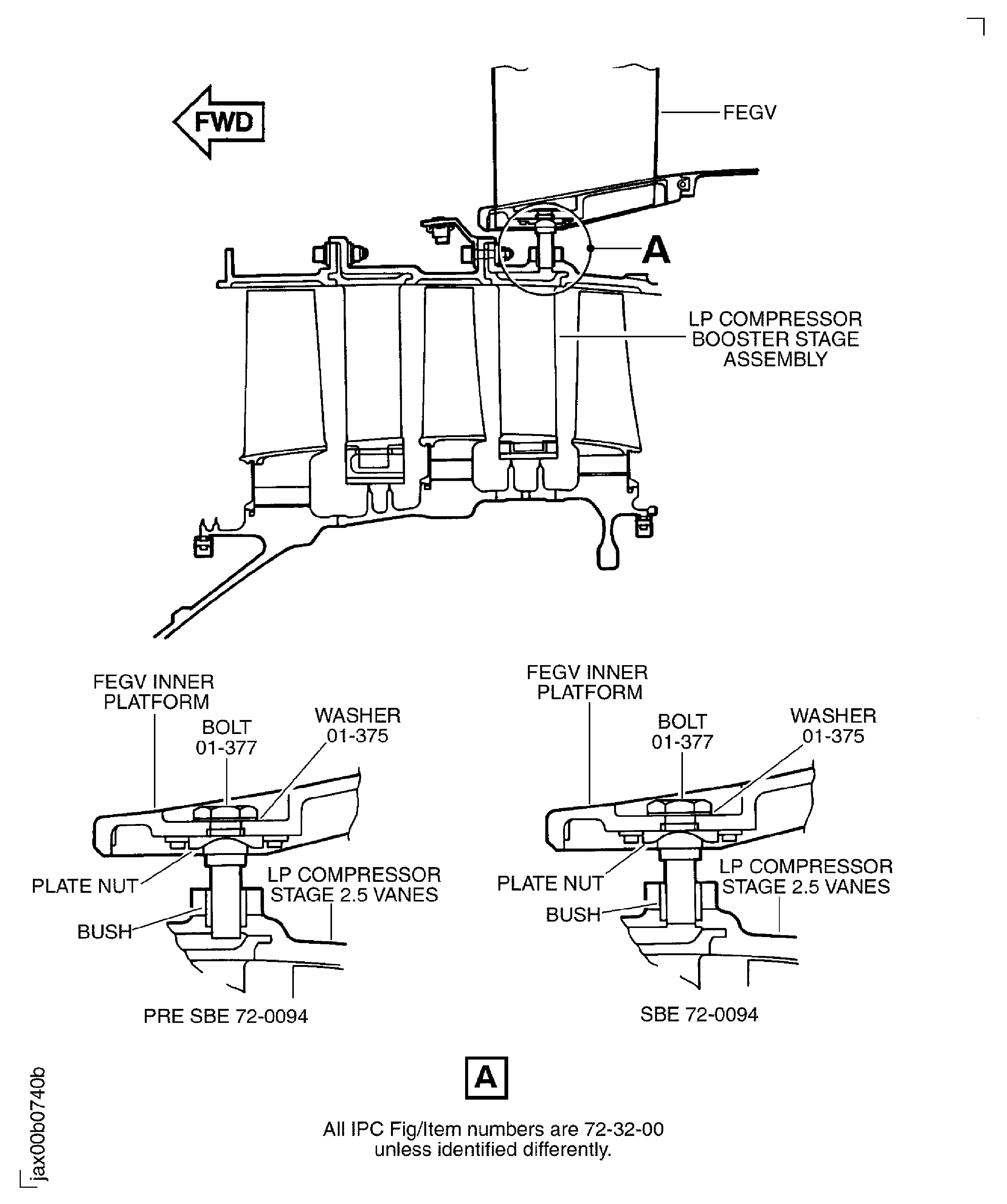

THE BOLTS (01-377) MUST BE REMOVED BEFORE YOU INSTALL THE LP COMPRESSOR BOOSTER STAGE ASSEMBLY. THE BOLTS CAN TOUCH THE ASSEMBLY AND CAUSE DAMAGE TO IT.Remove the FEGV's if they are installed. Refer to TASK 72-32-00-030-004 (Disassembly-004).

Turn the Fan Frame Assembly vertical with the front end up. Refer toTASK 72-32-00-430-009-A00 (ASSEMBLY-009).

SUBTASK 72-32-00-430-187-A00 Prepare the Fan Frame Assembly (Pre SBE 72-0094)

Refer to Figure.

Make sure that the Fan Frame Assembly is installed vertically with the front end up, on the turnover stand. Refer to TASK 72-32-00-430-009-A00 (ASSEMBLY-009).

SUBTASK 72-32-00-430-187-B00 Prepare the Fan Frame Assembly (SBE 72-0094)

SBE 72-0094: Shorter FEGV platform bolts.

Refer to Figure.

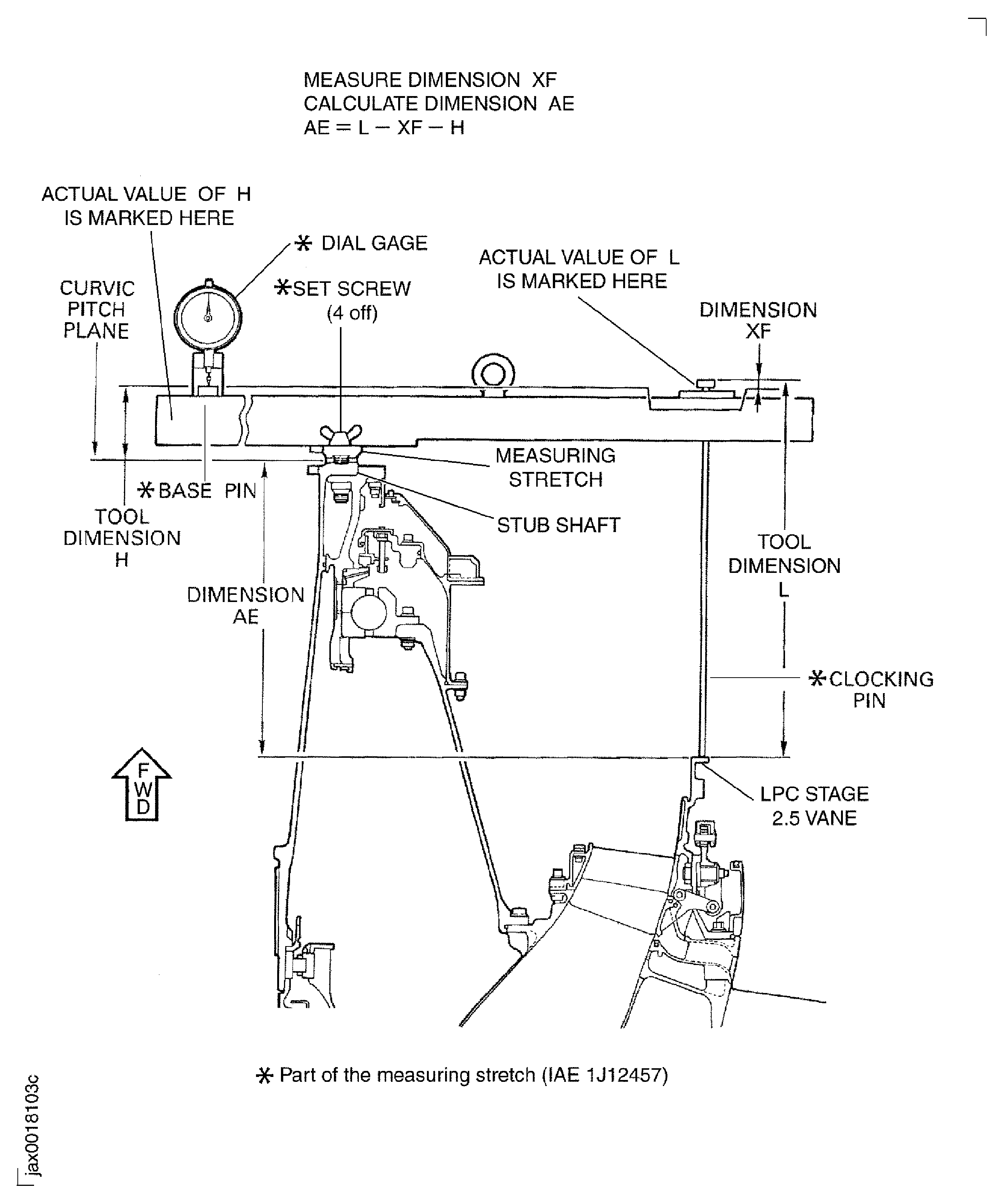

Clean the mating faces of the stub shaft and the measuring stretch with a clean lint free cloth made moist with CoMat 01-124 ISOPROPYL ALCOHOL.

Install IAE 1J12457 Measuring stretch 1 off onto the stub shaft.

SUBTASK 72-32-00-430-131-A00 Measure the Interface Dimensions for the Installation of the LP Compressor Booster Stage Assembly (Pre SBE 72-0391)

Refer to Figure.

Clean the mating faces of the stub shaft and the measuring stretch with a clean lint free cloth made moist with CoMat 01-124 ISOPROPYL ALCOHOL.

Install IAE 1J12457 Measuring stretch 1 off onto the stub shaft.

SUBTASK 72-32-00-430-131-B00 Measure the Interface Dimensions for the Installation of the LP Compressor Booster Stage Assembly (SBE 72-0391)

SBE 72-0391: New separate type No. 1 Bearing Support Assembly.

Refer to Figure.

Reference dimensions at location 0108. If required use the data written as a NOTE in TASK 72-32-81-200-000 (INSPECTION-000) and TASK 72-32-51-200-000 (INSPECTION-000).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

Location 0108

LP Compressor Booster Stage Disk Assembly "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 DISC (72-32-81, 01-200), Front Location Bore

Rotor Center Shaft ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-100), Front Location Diameter

Disk Bore

11.8051

Intf

11.8032

0.0012

Shaft Diameter

11.8074

0.0042

11.8063

Intf

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

Location 0108

LP Compressor Booster Stage Disk Assembly "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 DISC (72-32-81, 01-200), Front Location Bore

Rotor Center Shaft ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-100), Front Location Diameter

Disk Bore

299.852

Intf

299.800

0.026

Shaft Diameter

299.910

0.110

299.878

Intf

SUBTASK 72-32-00-220-087 Reference Fits and Clearances of the LP Compressor Booster Stage Disk and the Rotor Center Shaft at Location 0108

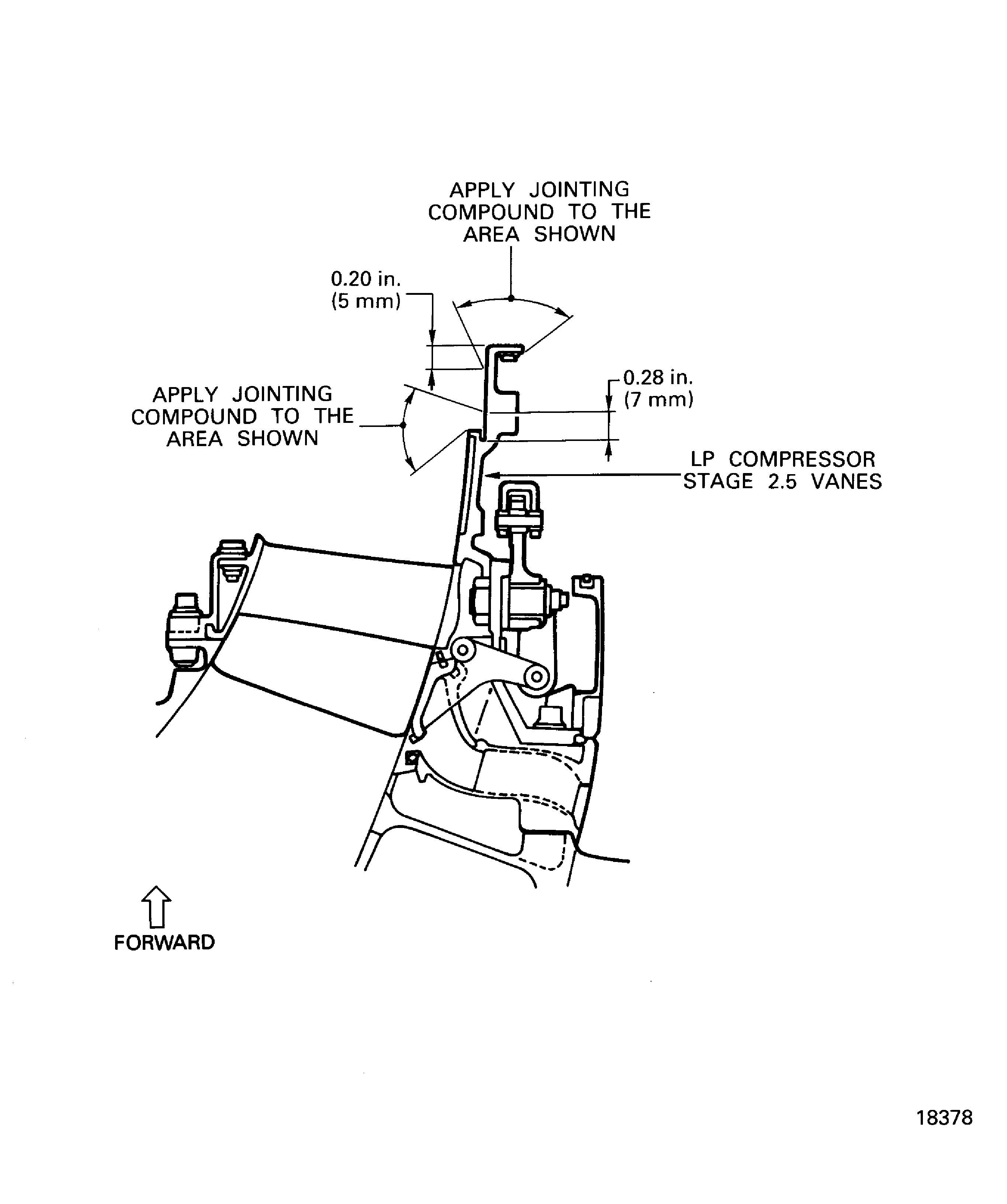

Refer to Figure.

Use a clean cloth made moist with CoMat 01-124 ISOPROPYL ALCOHOL to clean the mating faces.

Apply CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to the mating faces with a soft brush.

NOTE

Do not get the jointing compound to the threaded holes of the clinch nuts on the Stage 2.5 Vanes.Install the LP Compressor Booster Stage Assembly to the Stage 2.5 Vanes before the jointing compound becomes dry.

SUBTASK 72-32-00-430-132 Apply Jointing Compound to the Mating Faces on the LP Compressor Stage 2.5 Vanes (Stage 2.5 Vanes)

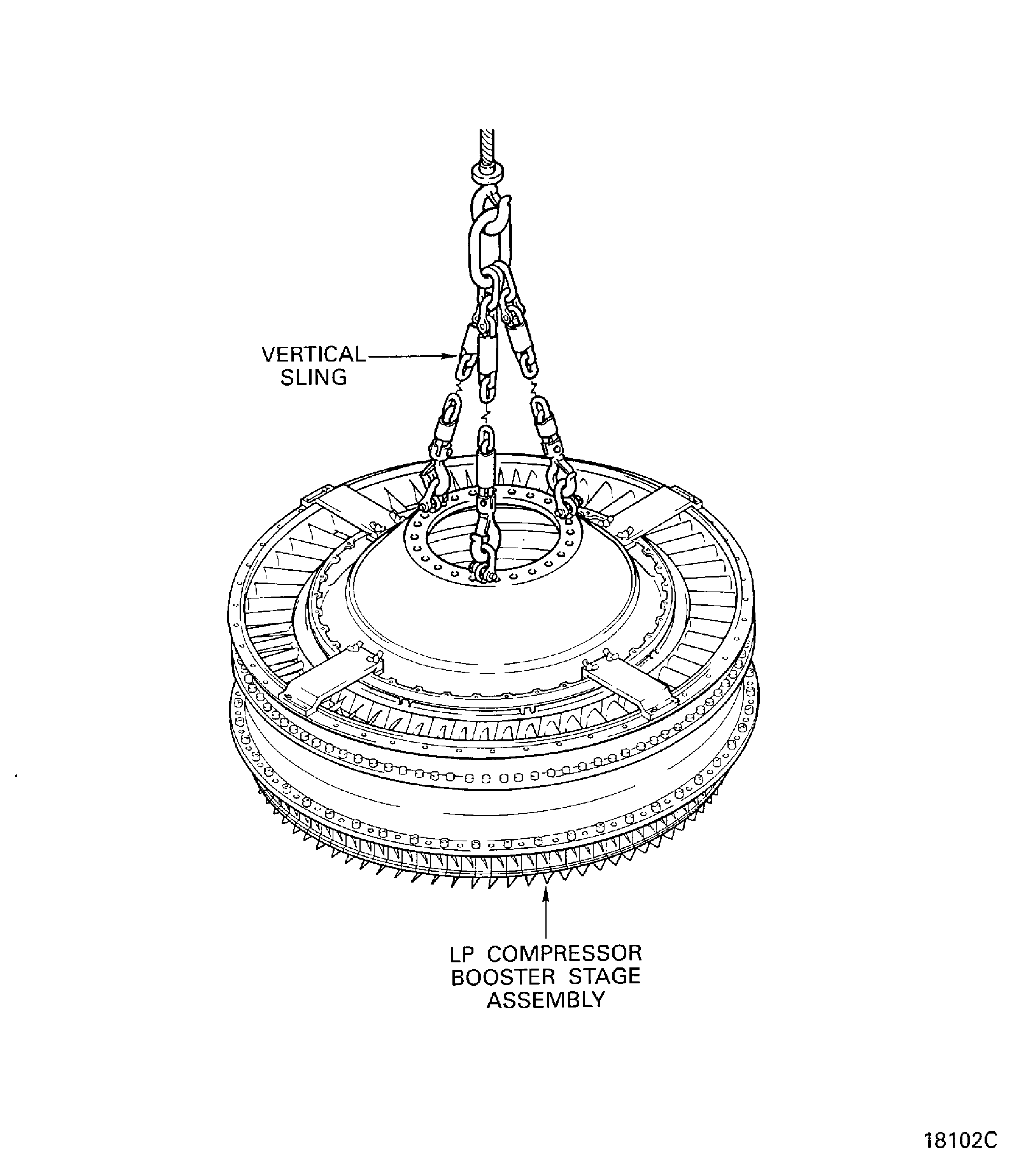

Install IAE 1J13103 Vertical sling 1 off onto the disk front flange of the LPC Assembly, Figure.

NOTE

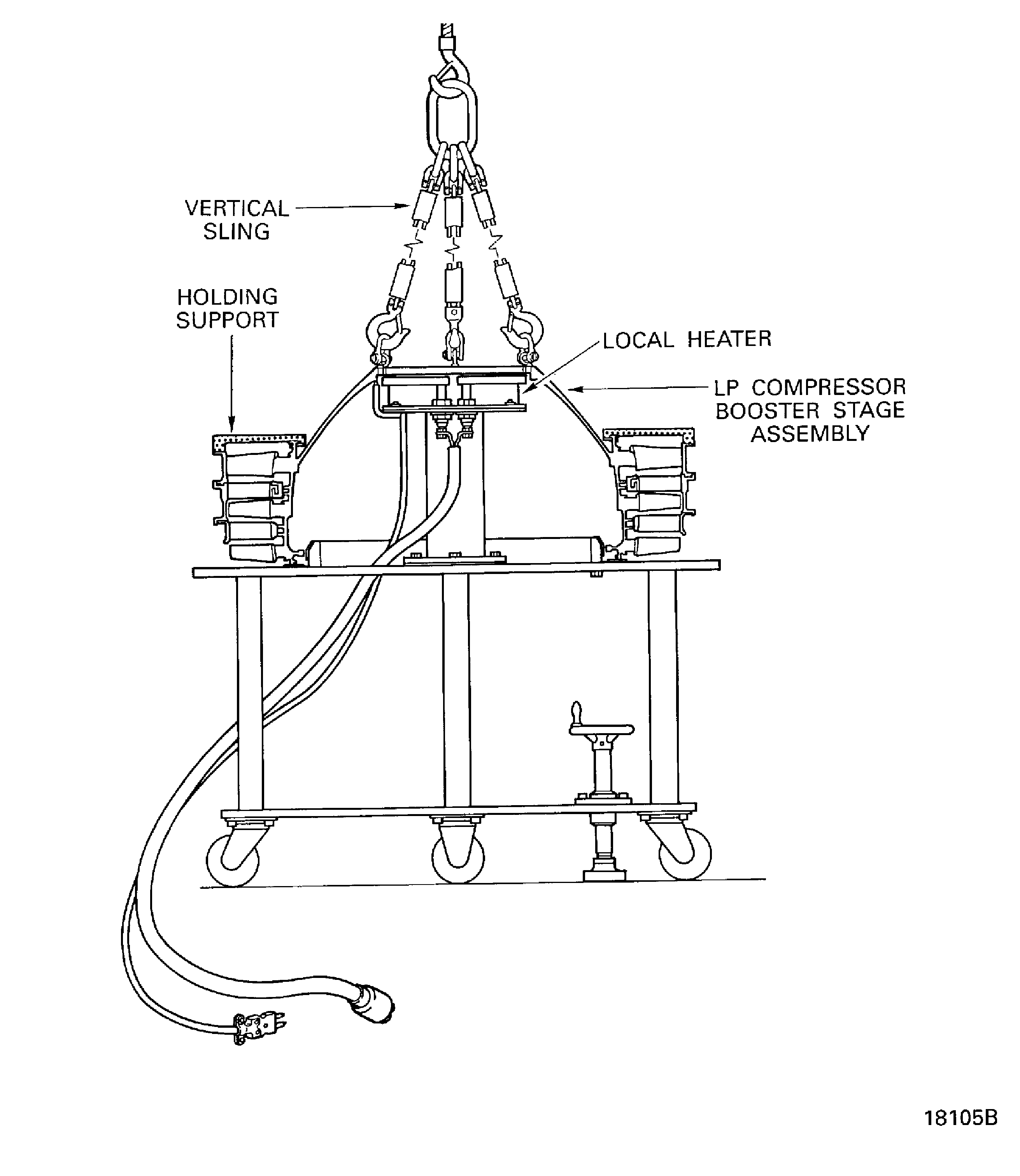

The LPC Assembly is installed on the storage stand in TASK 72-32-80-440-001-A00 (ASSEMBLY-001) and TASK 72-32-80-440-001-B00 (ASSEMBLY-001).Move the LPC Assembly from the storage stand to IAE 1J13109 0AM53 heater 1 off, Figure.

Connect the cables of the local heater to IAE 6F10027 Heater control unit 1 off.

SUBTASK 72-32-00-430-133 Prepare the LP Compressor Booster Stage Assembly (LPC Assembly) for Installation of It to the Rotor Center Shaft and the Stage 2.5 Vanes

Increase the temperature of the disk front flange of the LPC Assembly to 248 deg F (120 deg C) with the local heater, Figure.

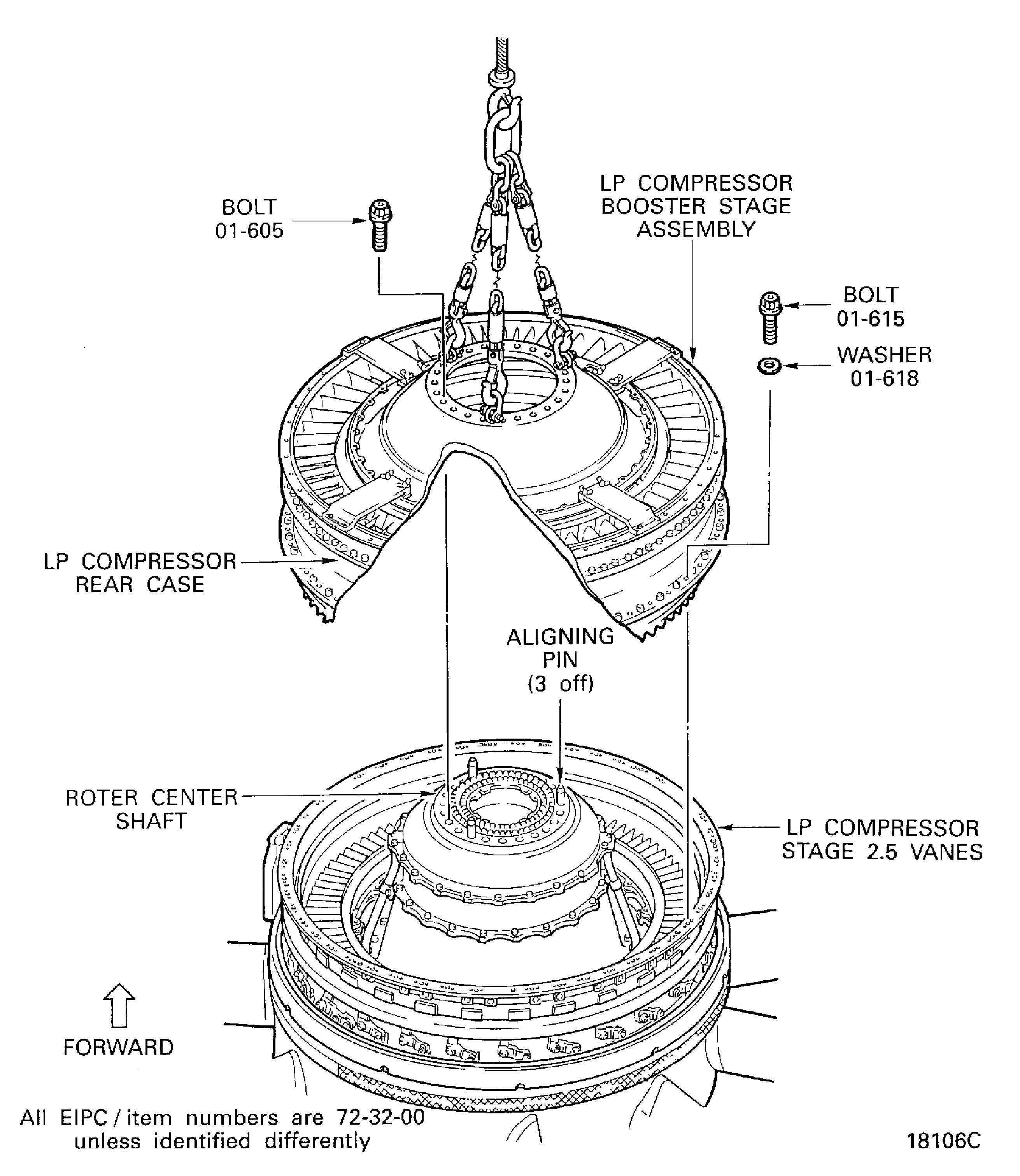

Install the three aligning pins (part of IAE 1J12507 Guide pin 1 off) into three of the 24 nuts of the Rotor Center Shaft. The three aligning pins must be installed at 120 degrees apart from each other.

Attach the LPC Assembly with the 24 bolts ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-605). Tighten the bolts lightly.

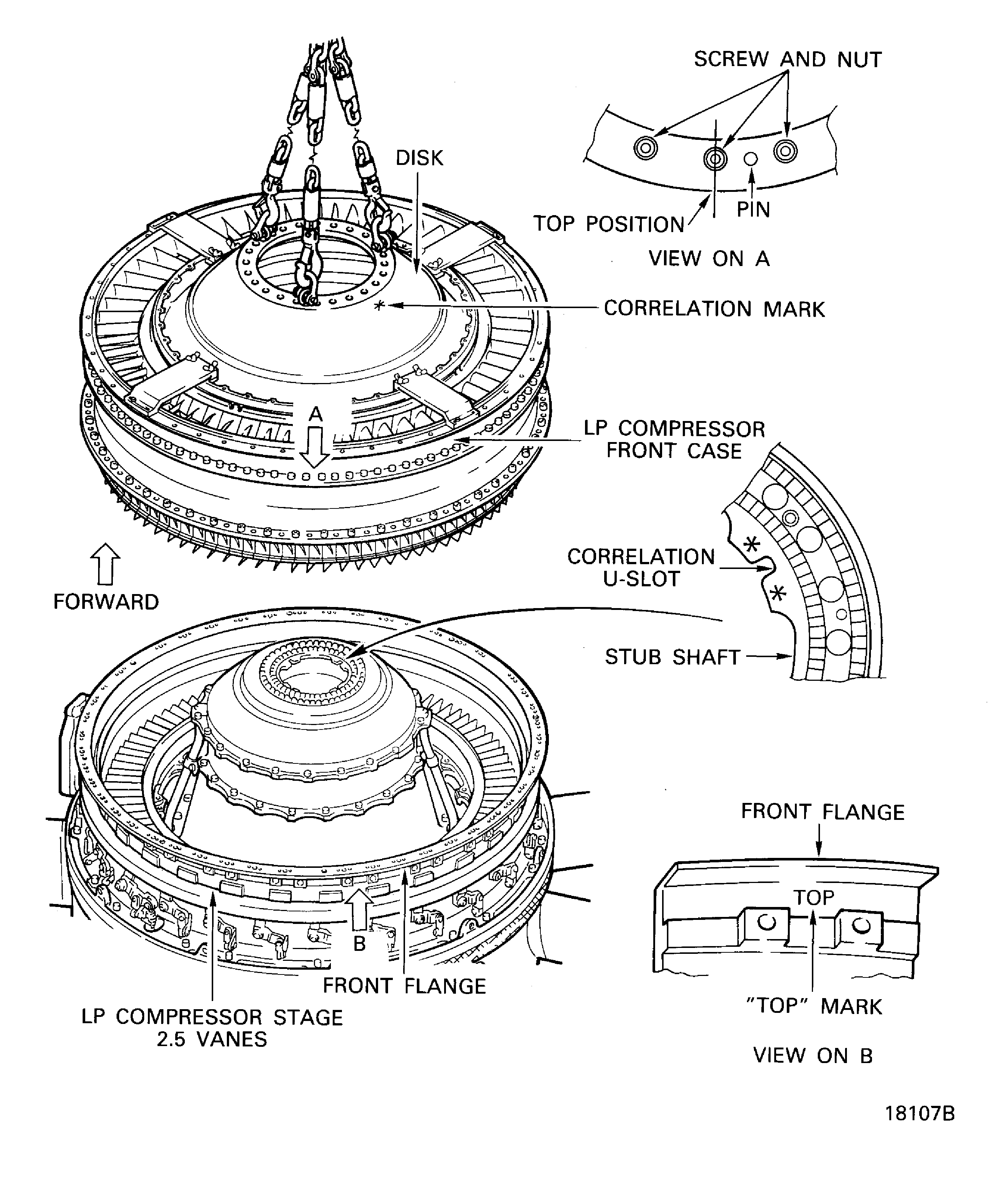

Remove the three eye bolts of the vertical sling, Figure.

Remove the four holding supports from the LPC Assembly, Figure.

NOTE

The holding supports are installed to the LPC Assembly in TASK 72-32-80-440-001-A00 (ASSEMBLY-001) and TASK 72-32-80-440-001-B00 (ASSEMBLY-001).Align the TOP mark of the LP Compressor front case with the TOP mark of the Stage 2.5 Vanes, Figure.

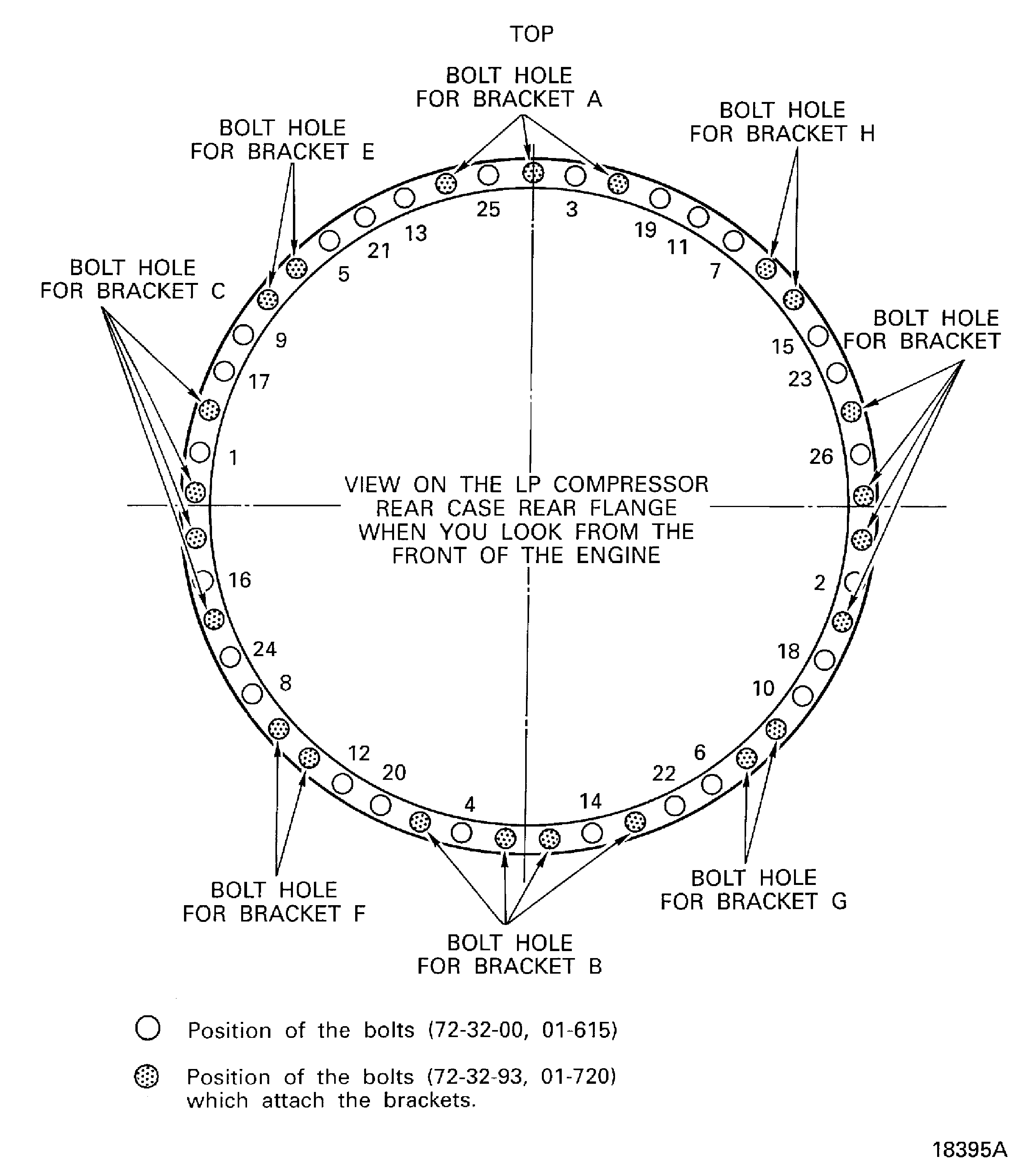

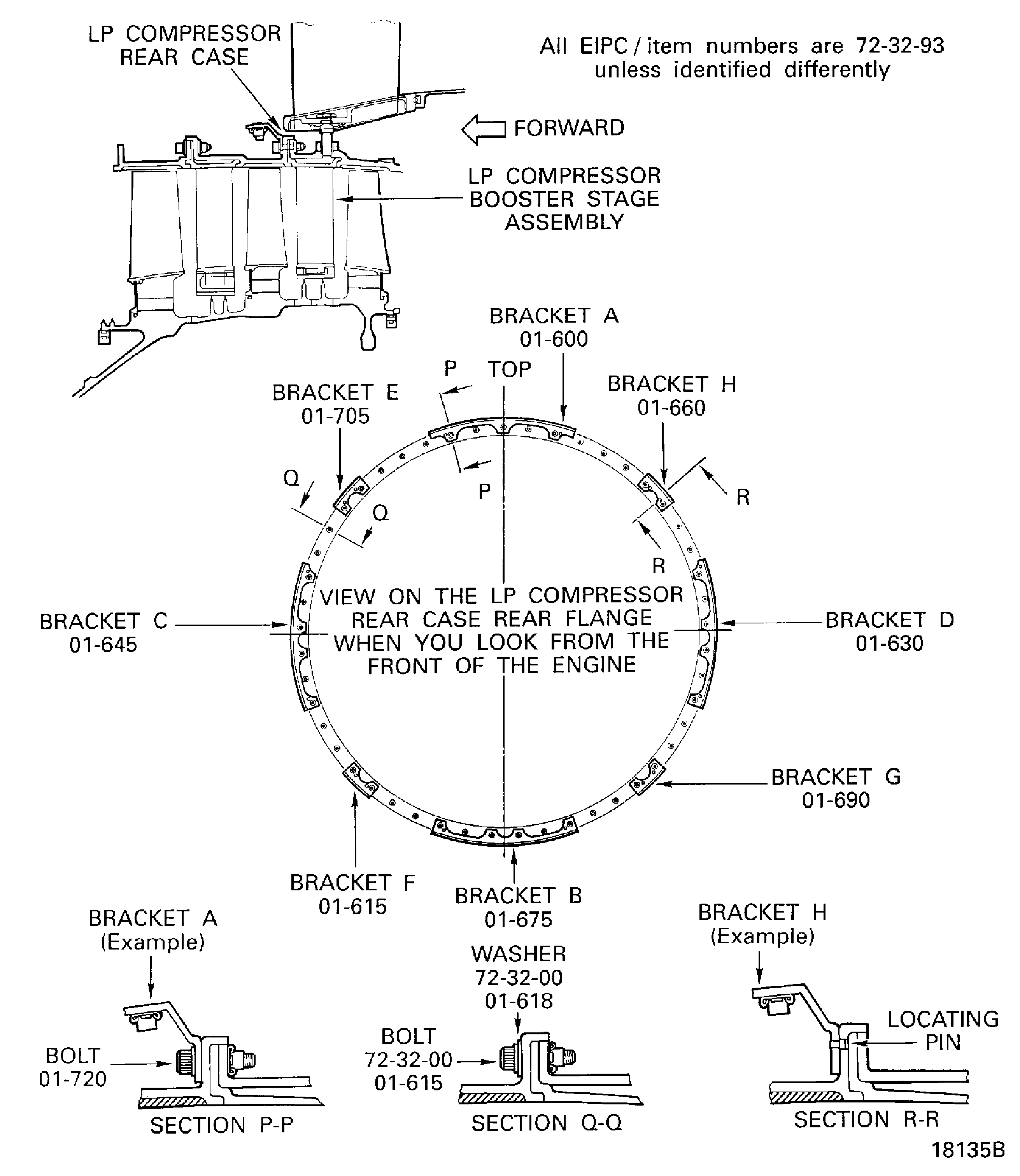

Attach the rear case to the Stage 2.5 Vanes with the 26 bolts ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-615) and washers ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-618), Figure, Figure and Figure.

NOTE

Do not install the bolts V2500-A5-72-32-93-01A-941A-D (72-32-93, 01-720) and the brackets A, B, C, D, E, F, G and H in this TASK. The bolts and the brackets are installed inTASK 72-32-00-430-012-A00 (ASSEMBLY-012).

Attach the LP Compressor rear case to the Stage 2.5 Vanes.

When the LPC Assembly becomes cool, loosen the 24 bolts ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-605) fully.

Torque the 24 bolts ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-605) to between 180 lbfin and 220 lbfin (20.00 Nm and 25.00 Nm).

NOTE

Hold the LP Compressor Disk Assembly to prevent the rotation of it while you apply the torque to each bolt.Torque the 26 bolts ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-615) to between 36 lbfin and 45 lbfin (4.00 Nm to 5.00 Nm), Figure and Figure.

SUBTASK 72-32-00-430-134 Install the LP Compressor Booster Stage Assembly (LPC Assembly) to the Rotor Center Shaft and the LP Compressor Stage 2.5 Vanes (Stage 2.5 Vane)

Figure: Make Sure that the FEGVs are Removed

Make Sure that the FEGVs are Removed

Figure: Measure the Interface Dimensions for the Installation of the LP Compressor Booster Stage Assembly

Measure the Interface Dimensions for the Installation of the LP Compressor Booster Stage Assembly

Figure: Reference Fits and Clearances of the LP Compressor Booster Stage Disk and the Rotor Center Shaft at Location 0108

Reference Fits and Clearances of the LP Compressor Booster Stage Disk and the Rotor Center Shaft at Location 0108

Figure: Apply Jointing Compound to the Mating Faces on the LP Compressor Stage 2.5 Vanes

Apply Jointing Compound to the Mating Faces on the LP Compressor Stage 2.5 Vanes

Figure: Install the Vertical Sling onto the LP Compressor Booster Stage Assembly

Install the Vertical Sling onto the LP Compressor Booster Stage Assembly

Figure: Install the LP Compressor Booster Stage Assembly onto the Local Heater

Install the LP Compressor Booster Stage Assembly onto the Local Heater

Figure: Install the LP Compressor Booster Stage Assembly onto the Rotor Center Shaft and the LP Compressor Stage 2.5 Vanes

Sheet 1

Figure: Install the LP Compressor Booster Stage Assembly onto the Rotor Center Shaft and the LP Compressor Stage 2.5 Vanes

Sheet 2

Figure: Remove the Holding Supports from the LP Compressor Booster Stage Assembly

Remove the Holding Supports from the LP Compressor Booster Stage Assembly

Figure: Position of the Bolts (72-32-00,01-615) and Torque Sequence

Sheet 1

Figure: Position of the Bolts (72-32-00,01-615) and Torque Sequence

Sheet 2