Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-32-80-440-001-A00 LPC Assembly - Assemble The LPC Cases And Vanes To The Rotor Assembly, Assembly-001

General

This TASK gives the procedure to assemble the LP compressor booster stage assembly.

There are two types of the vertical sling in this TASK

- If you use IAE 1J13203 LPC Vertical sling (method 1), select the method 1.

- If you use IAE 1J12213 LPC Vertical sling, select the method 2.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

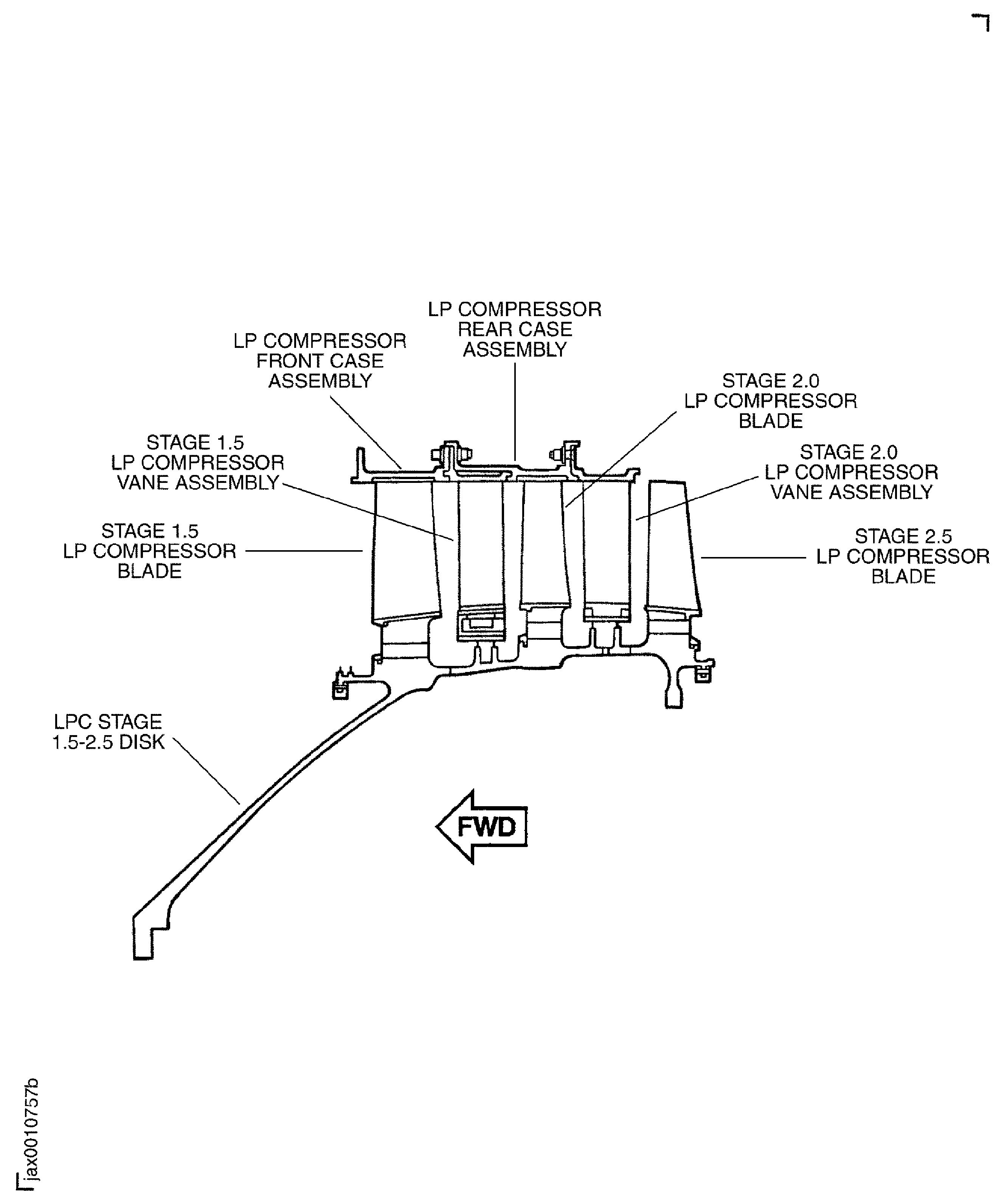

Refer to Figure for the sectional view of an LP compressor (booster) stage assembly.

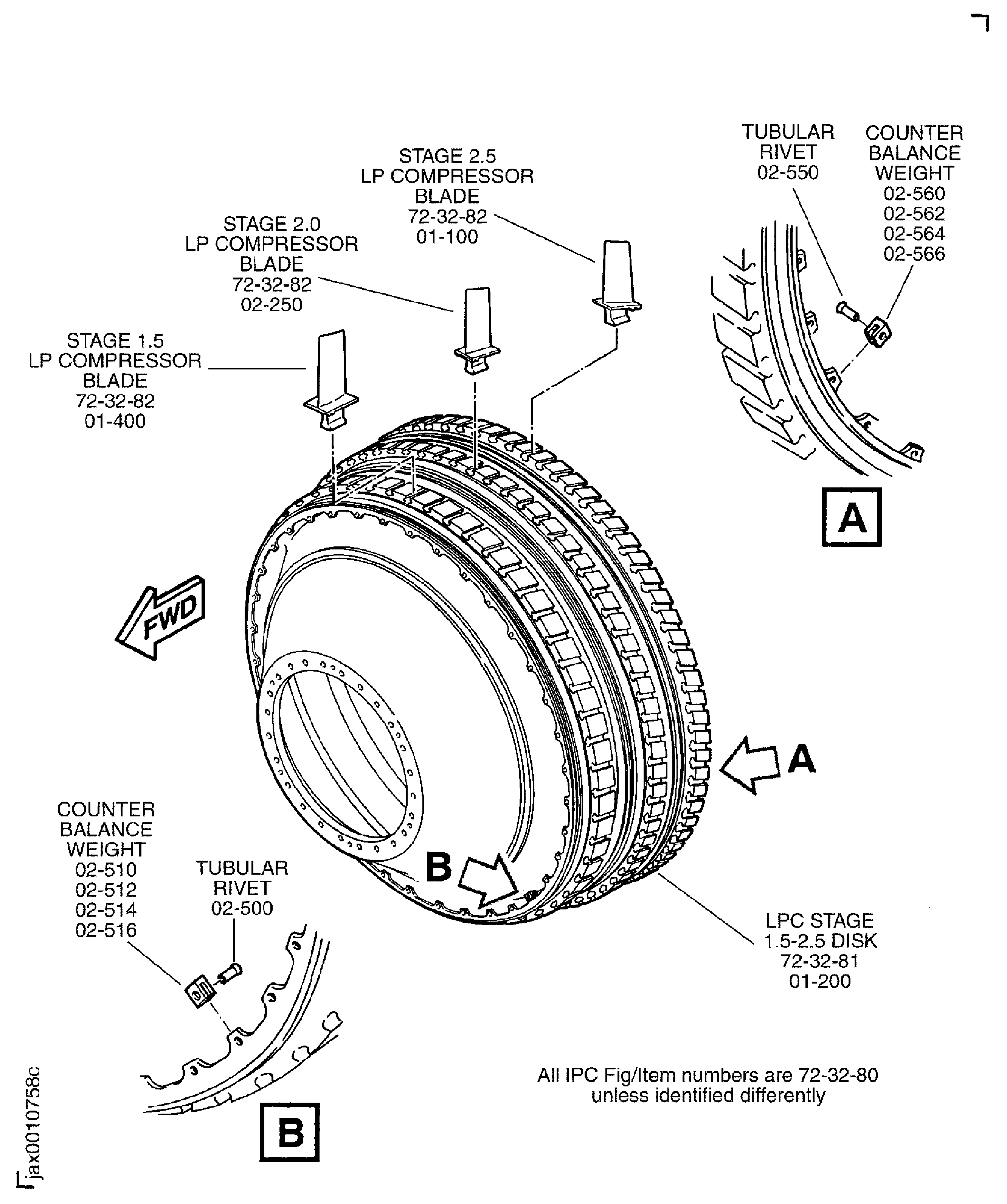

Refer to Figure for the view of the LP compressor stage 1.5, 2 and 2.5 disk and blades.

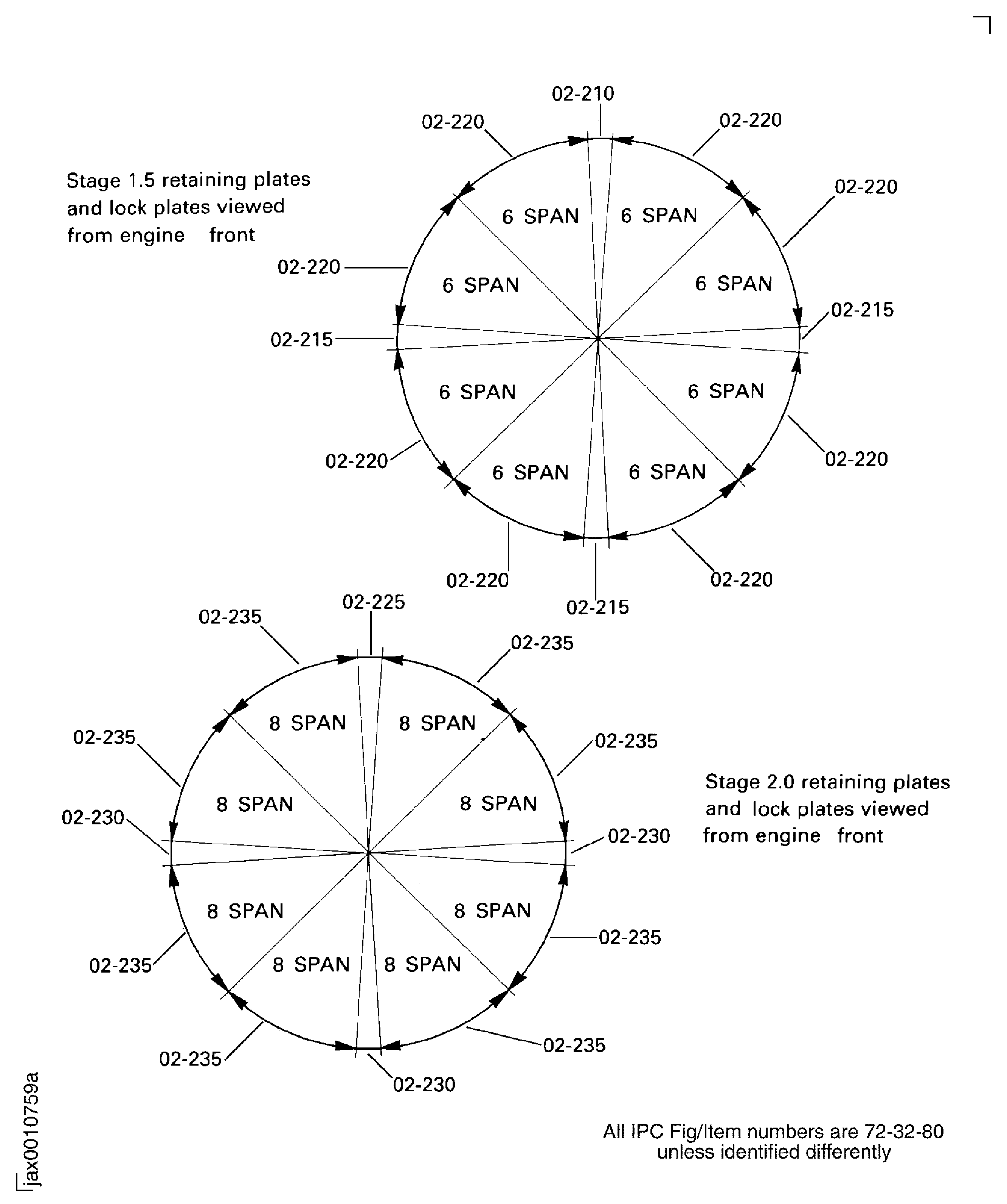

Refer to Figure for positions of the stage 1.5 and 2 retaining plates and locknuts.

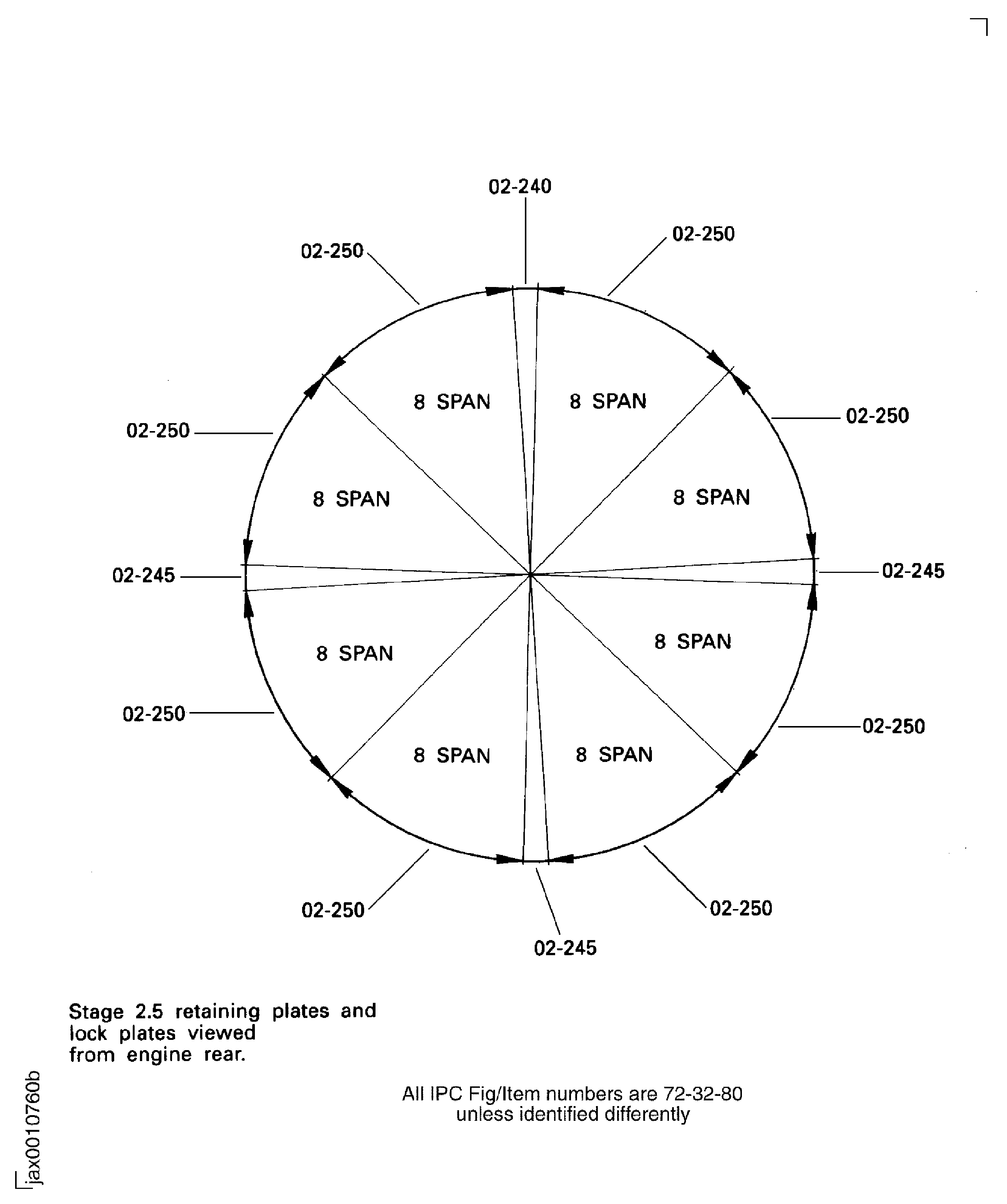

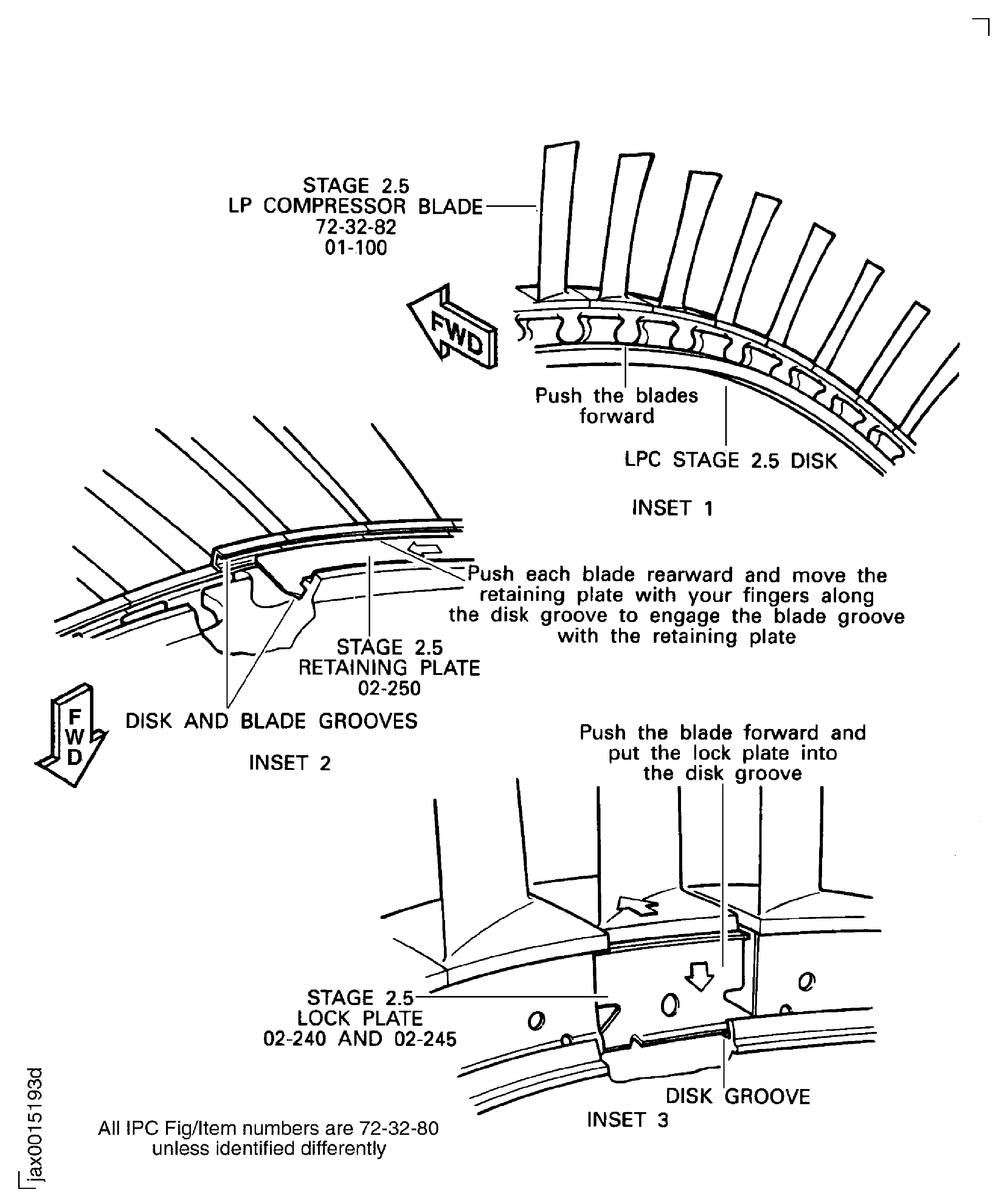

Refer to Figure.or positions of the stage 2.5 retaining plates and lockplates.

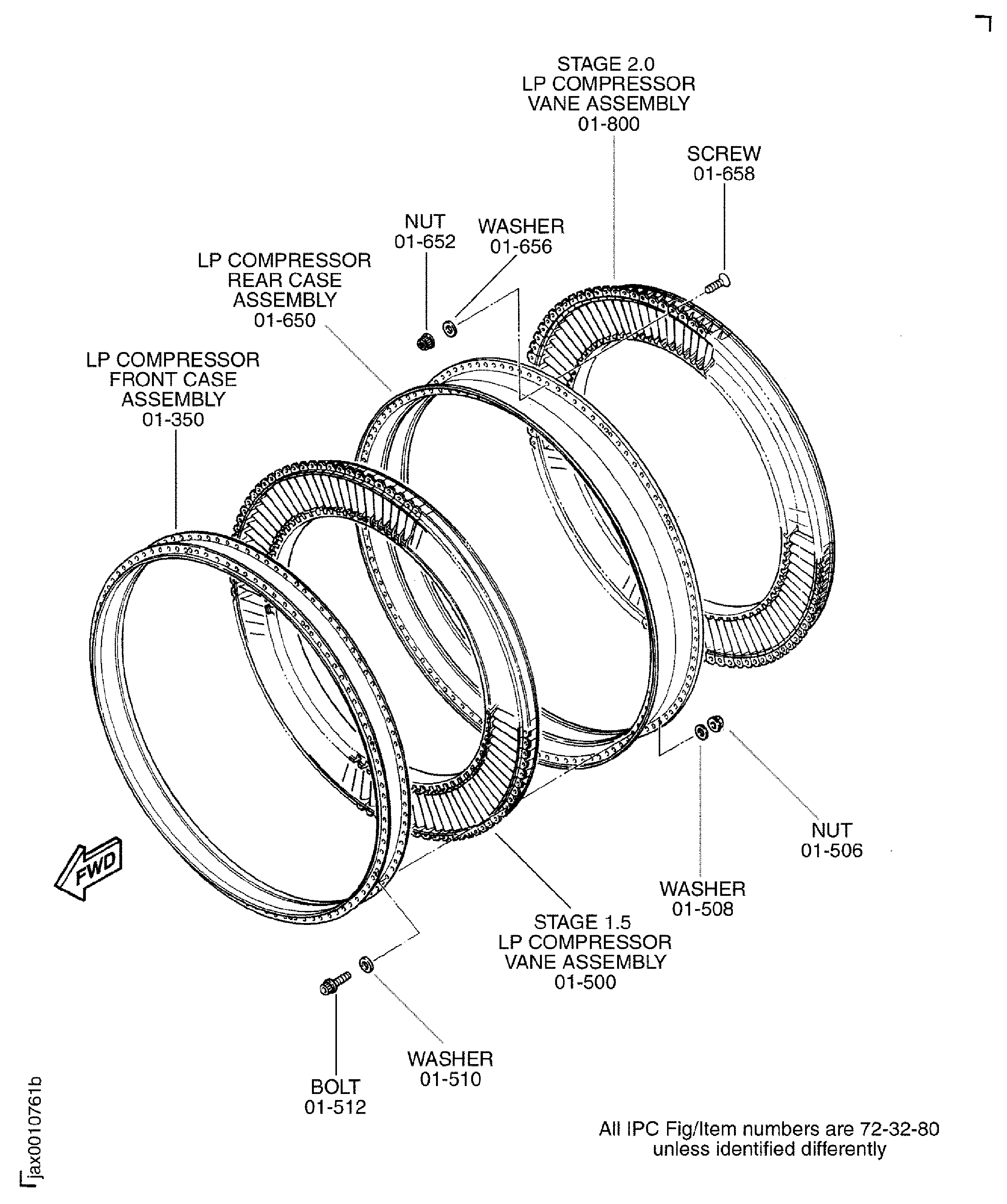

Refer to Figure.or a view of the LP compressor stage 1.5 and 2 vanes.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Dynamic balancing machine | LOCAL | Schenck HL-5U | or equivalent | |

| IAE 1J12213 LPC Vertical sling | 0AM53 | IAE 1J12213 | 1 | |

| IAE 1J12399 Handling sling | 0AM53 | IAE 1J12399 | 1 | |

| IAE 1J13107 Holding support | 0AM53 | IAE 1J13107 | 1 | |

| IAE 1J13109 0AM53 heater | 0AM53 | IAE 1J13109 | 1 | |

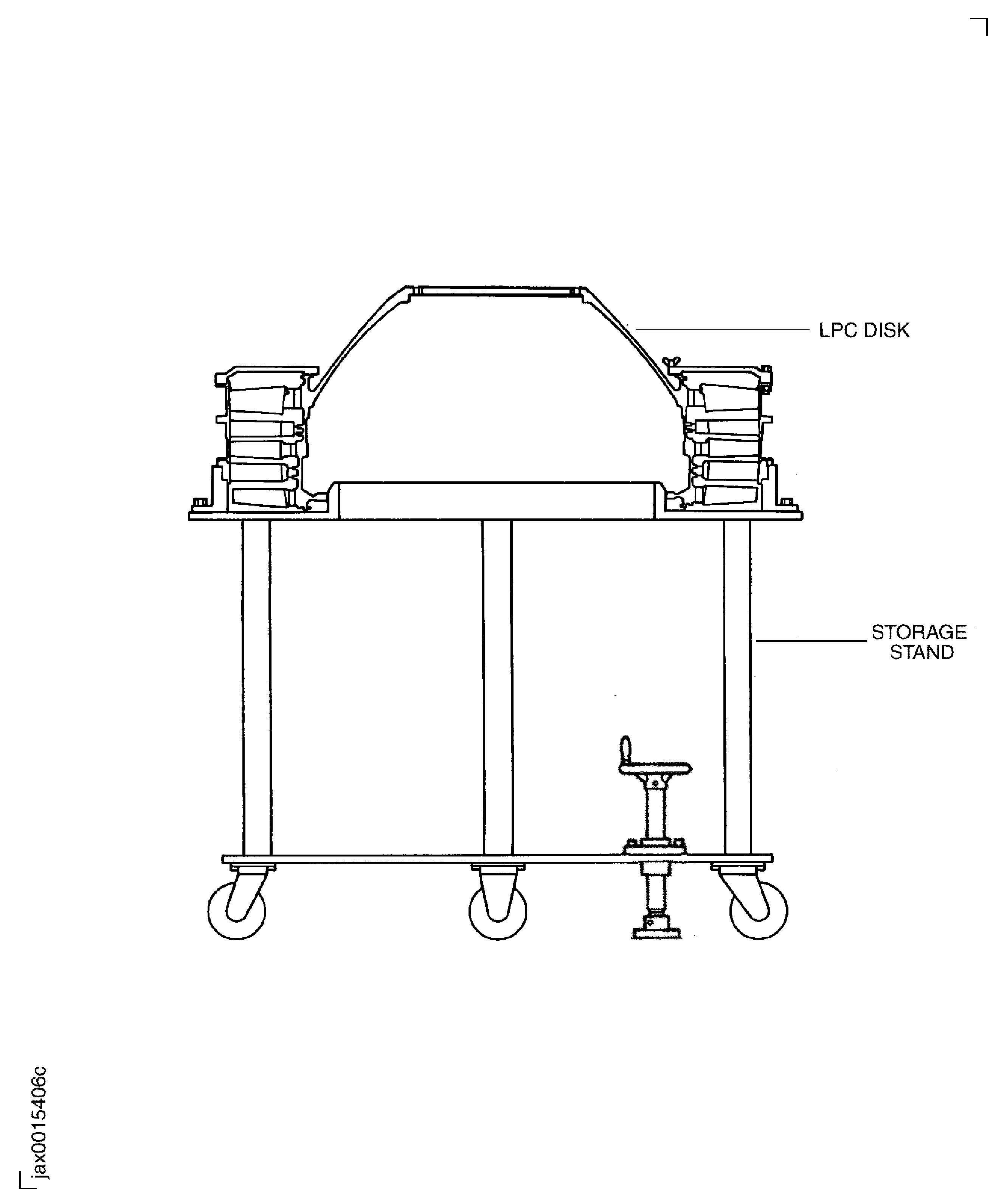

| IAE 1J13111 LPC storage stand | 0AM53 | IAE 1J13111 | 1 | |

| IAE 1J13103 Vertical sling | 0AM53 | IAE 1J13103 | 1 | |

| IAE 1J13203 LPC Vertical sling (method 1) | 0AM53 | IAE 1J13203 | 1 | |

| IAE 1J13204 Vertical work stand | 0AM53 | IAE 1J13204 | 1 | |

| IAE 1J13205 Balance arbor | 0AM53 | IAE 1J13205 | 1 | |

| IAE 1J13206 Horizontal work stand | 0AM53 | IAE 1J13206 | 1 | |

| IAE 1J13207 Balance cover and fixture | 0AM53 | IAE 1J13207 | 1 | |

| IAE 1J13208 Transport stand | 0AM53 | IAE 1J13208 | 1 | |

| IAE 1J12188 Puller bolt | 0AM53 | IAE 1J12188 | 1 | |

| IAE 1J12507 Guide pin | 0AM53 | IAE 1J12507 | 1 | |

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 1 | |

| IAE 1J13209 Riveter | 0AM53 | IAE 1J13209 | 1 | |

| IAE 1J13210 LPC holding block | 0AM53 | IAE 1J13210 | 1 | |

| IAE 6F10027 Heater control unit | 0AM53 | IAE 6F10027 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE | LOCAL | CoMat 04-004 | ||

| CoMat 06-069 MARKER | IE207 | CoMat 06-069 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

Safety Requirements

NONEProcedure

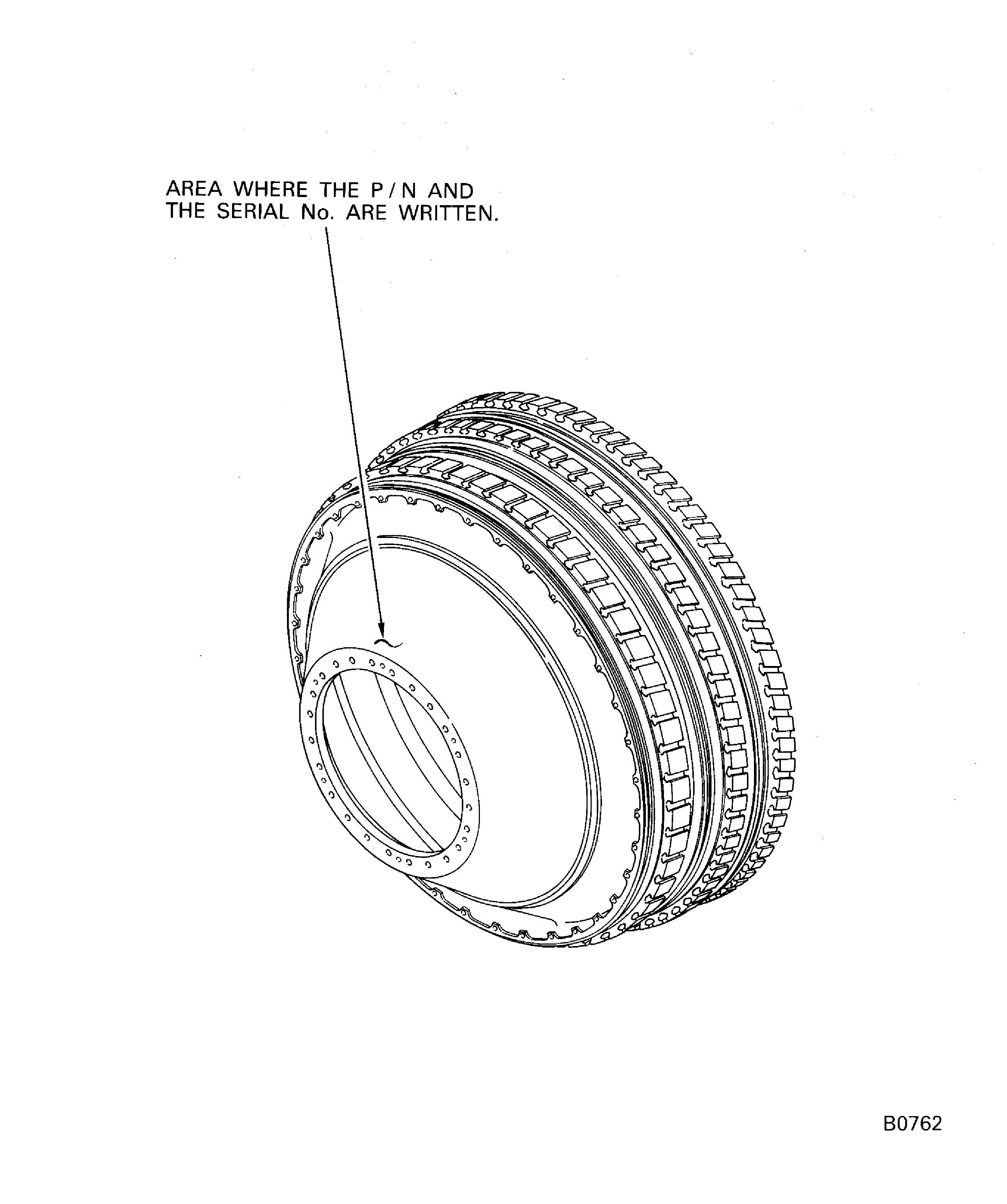

Refer to Figure.

Write the sub-module number and serial number on the specified area with electrochemical etching. Refer to the SPM TASK 70-09-00-400-501 for mark procedure.

If the sub-module number and serial number are not written, write them on the specified area on the LP compressor booster stage assembly.

SUBTASK 72-32-80-440-094 Identify the LP Compressor Booster Stage Assembly (Sub-Module)

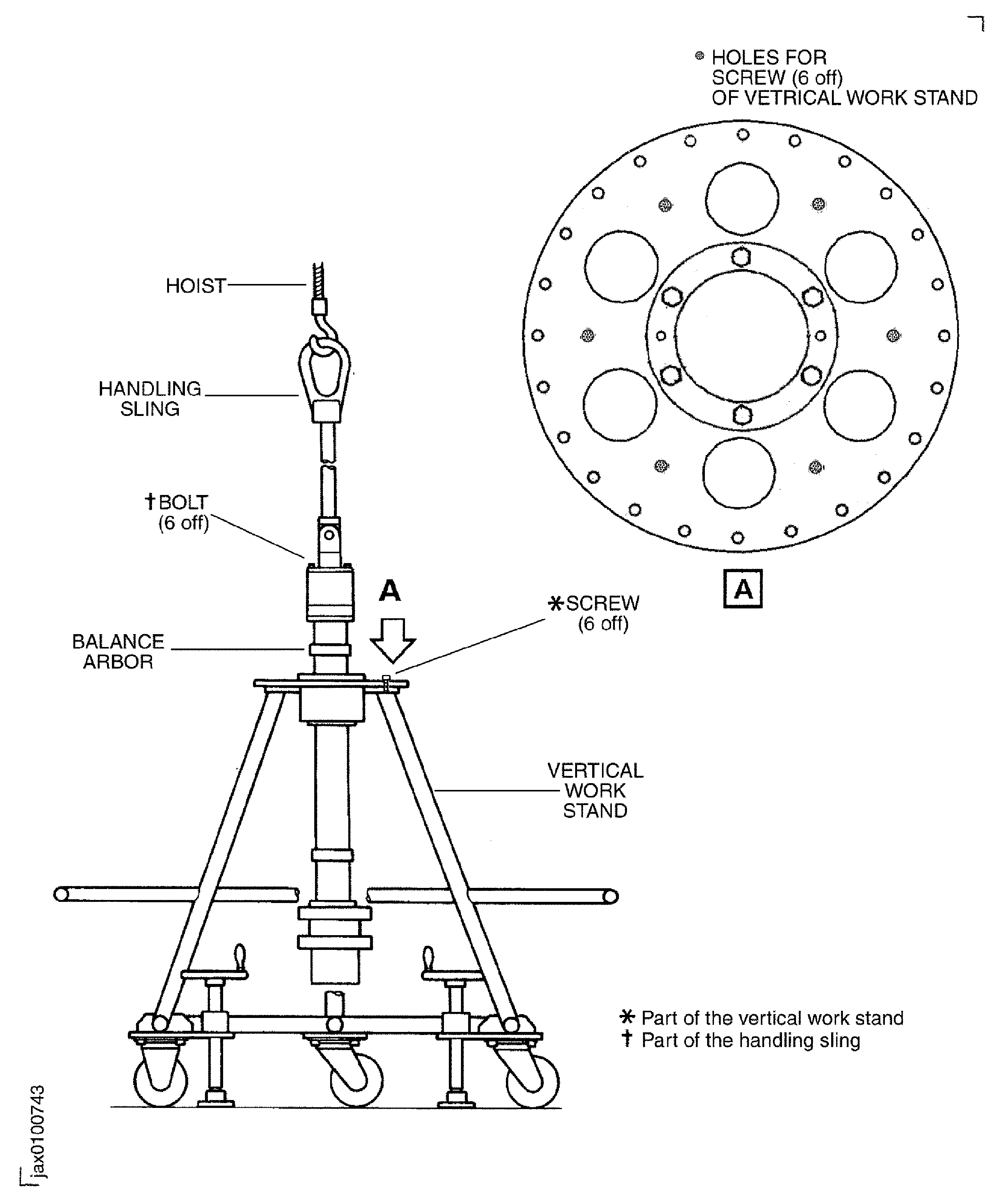

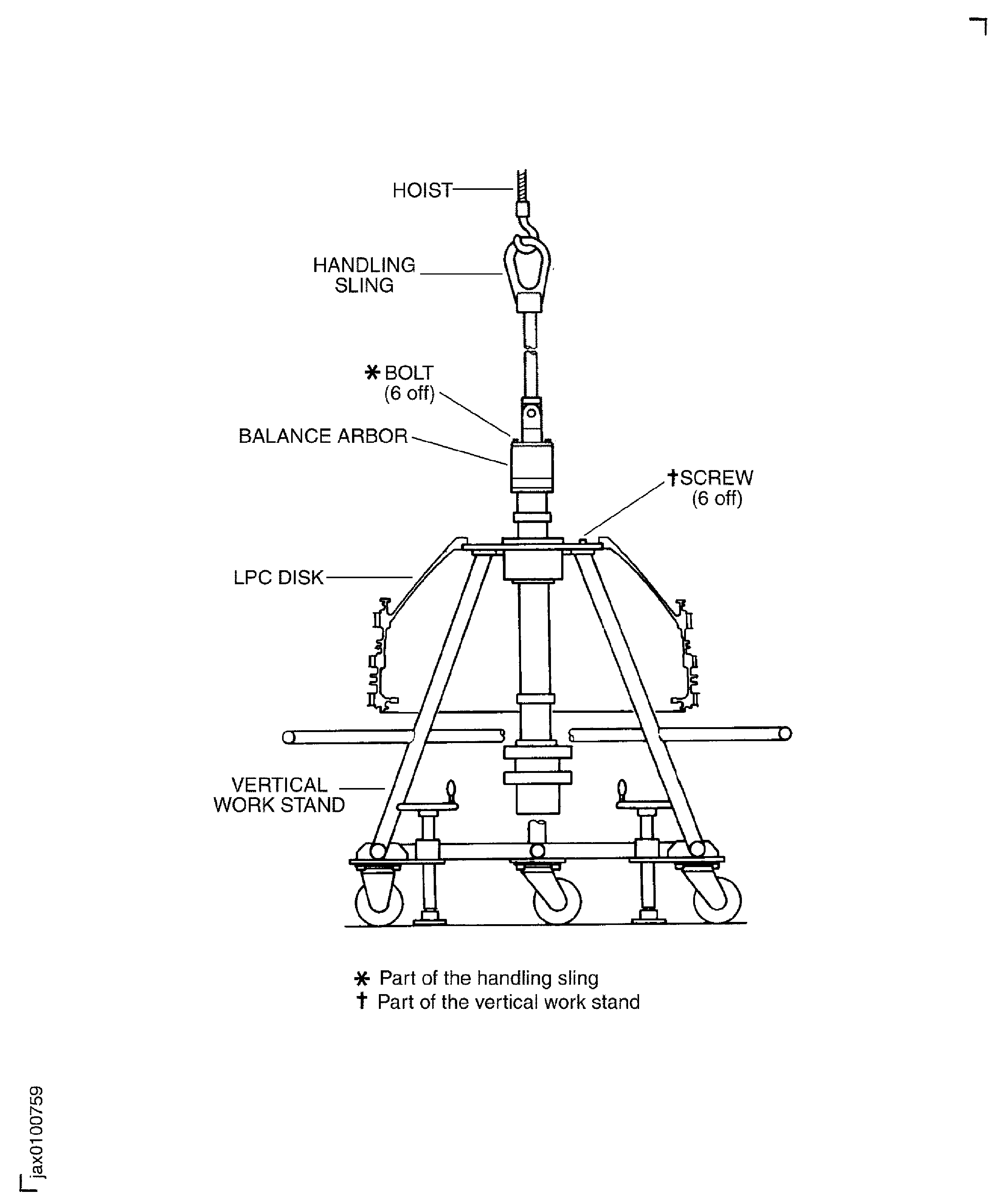

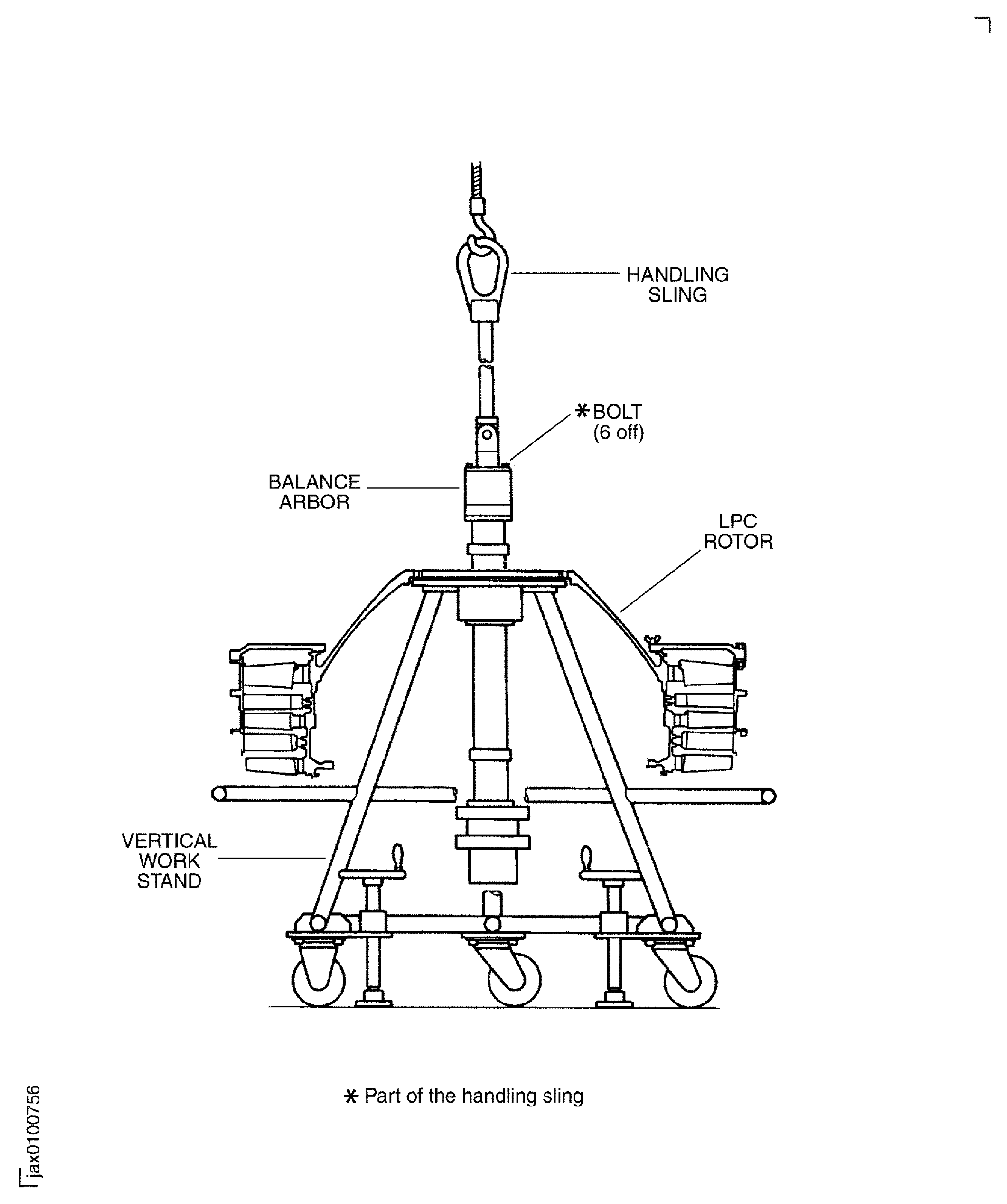

Move IAE 1J13204 Vertical work stand 1 off, IAE 1J13205 Balance arbor 1 off and IAE 1J12399 Handling sling 1 off to the work area.

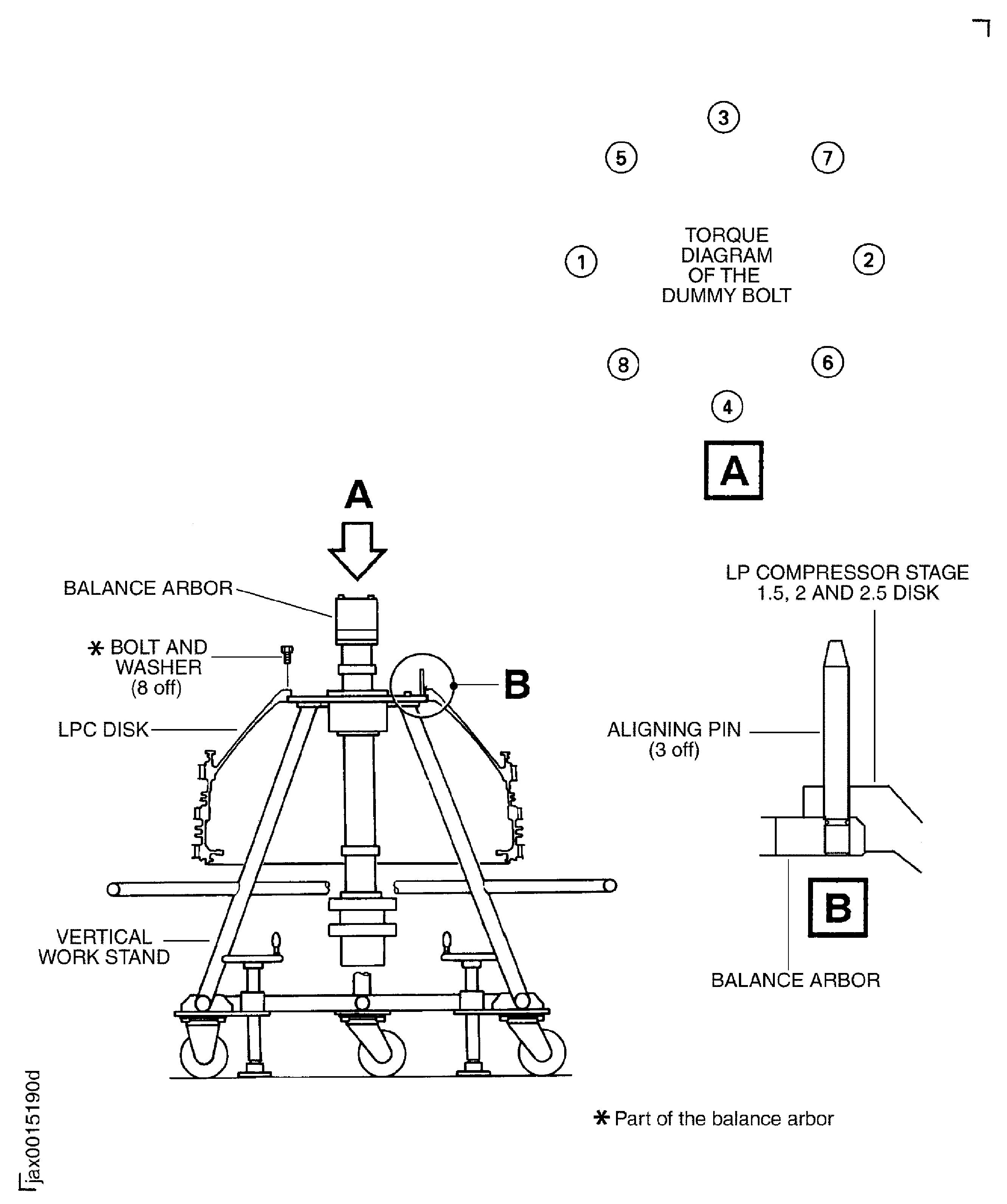

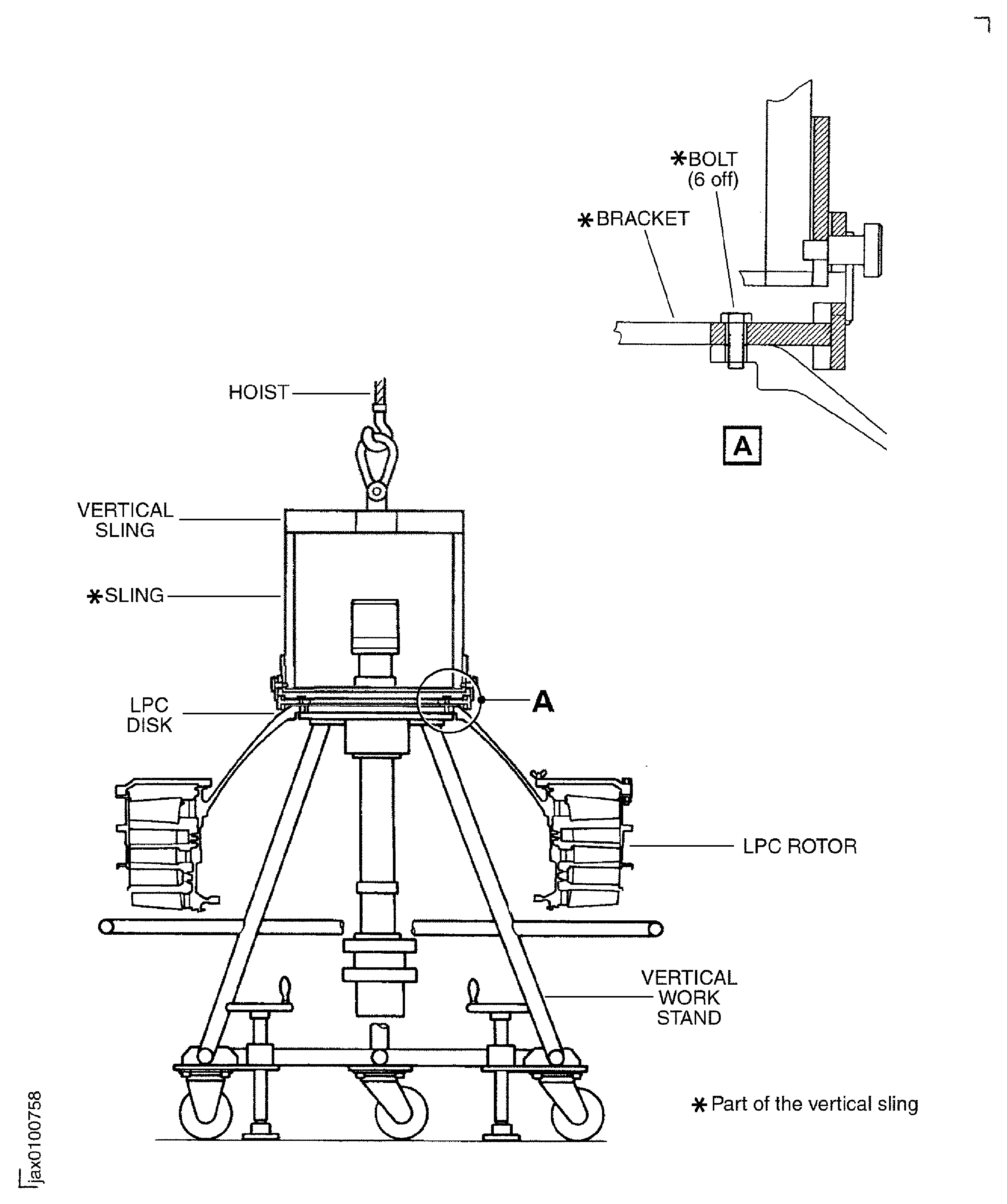

SUBTASK 72-32-80-440-051 Preparation for the Installation of the LP Compressor Stage 1.5, 2 and 2.5 Disk (LPC Disk) (72-32-81,01-200) on to Balance Arbor

Move IAE 1J13203 LPC Vertical sling (method 1) 1 off or 1J12213 LPC vertical sling 1 off and the IAE 1J13109 0AM53 heater 1 off and the LPC disk on the storage stand to the work area.

Method 1: Install the LPC vertical sling (IAE 1J13203 LPC Vertical sling (method 1)) to the LPC disk.

Method 2: Install the LPC vertical sling (IAE 1J12213 LPC Vertical sling) to the LPC disk.

Install the three aligning pins (part of IAE 1J12507 Guide pin 1 off) in to three of the 24 screw holes in the flange of the balance arbor. The three aligning pins must be installed approximately 120 degrees apart from each other.

Method 1: Install the LPC disk on to the balance arbor immediately.

Install the three aligning pins (part of IAE 1J12507 Guide pin 1 off) in to three of the 24 screw holes in the flange of the balance arbor. The three aligning pins must be installed approximately 120 degrees apart from each other.

Method 2: Install the LPC disk on to the balance arbor immediately.

SUBTASK 72-32-80-440-052 Install the LPC Disk on to the Balance Arbor

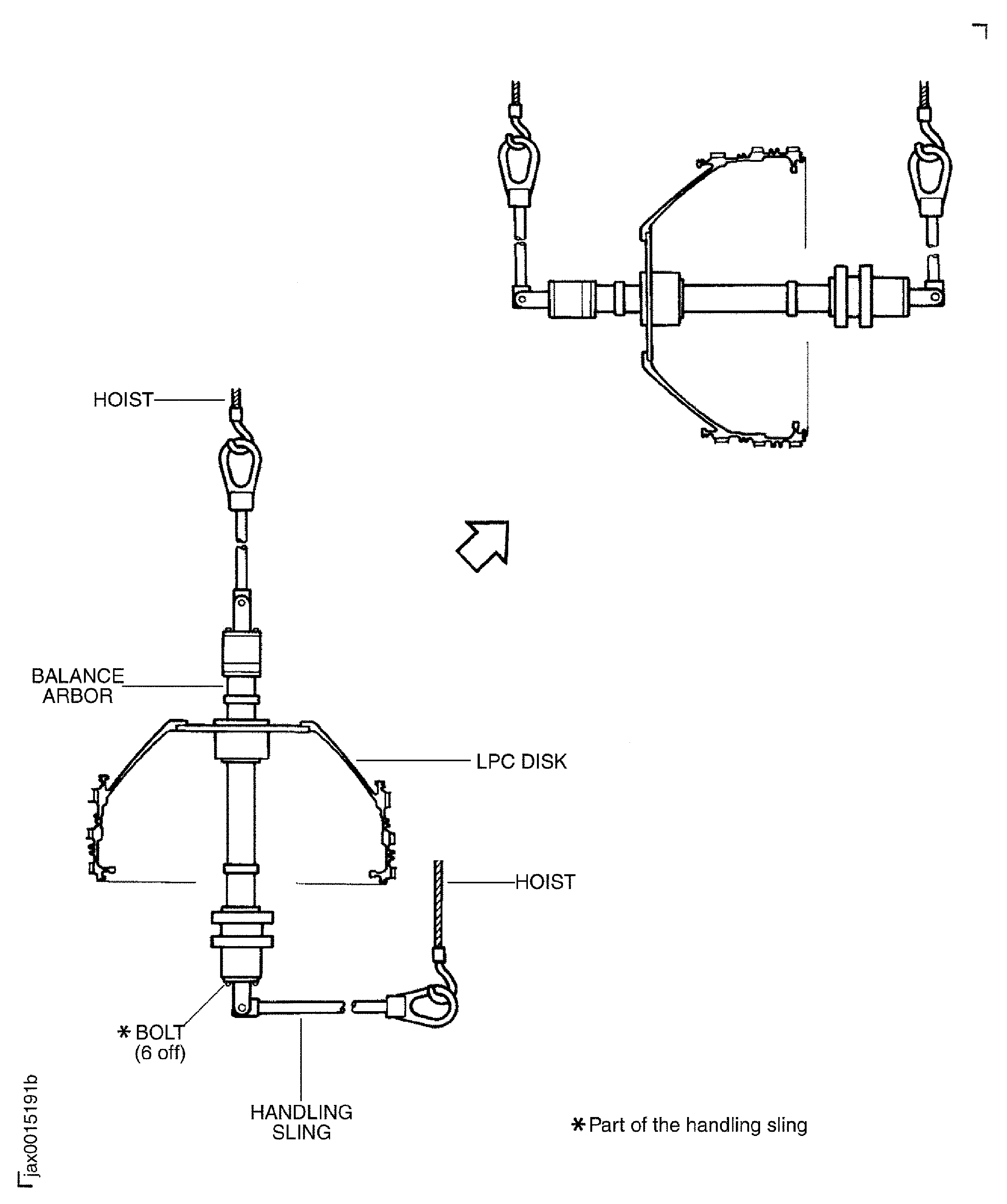

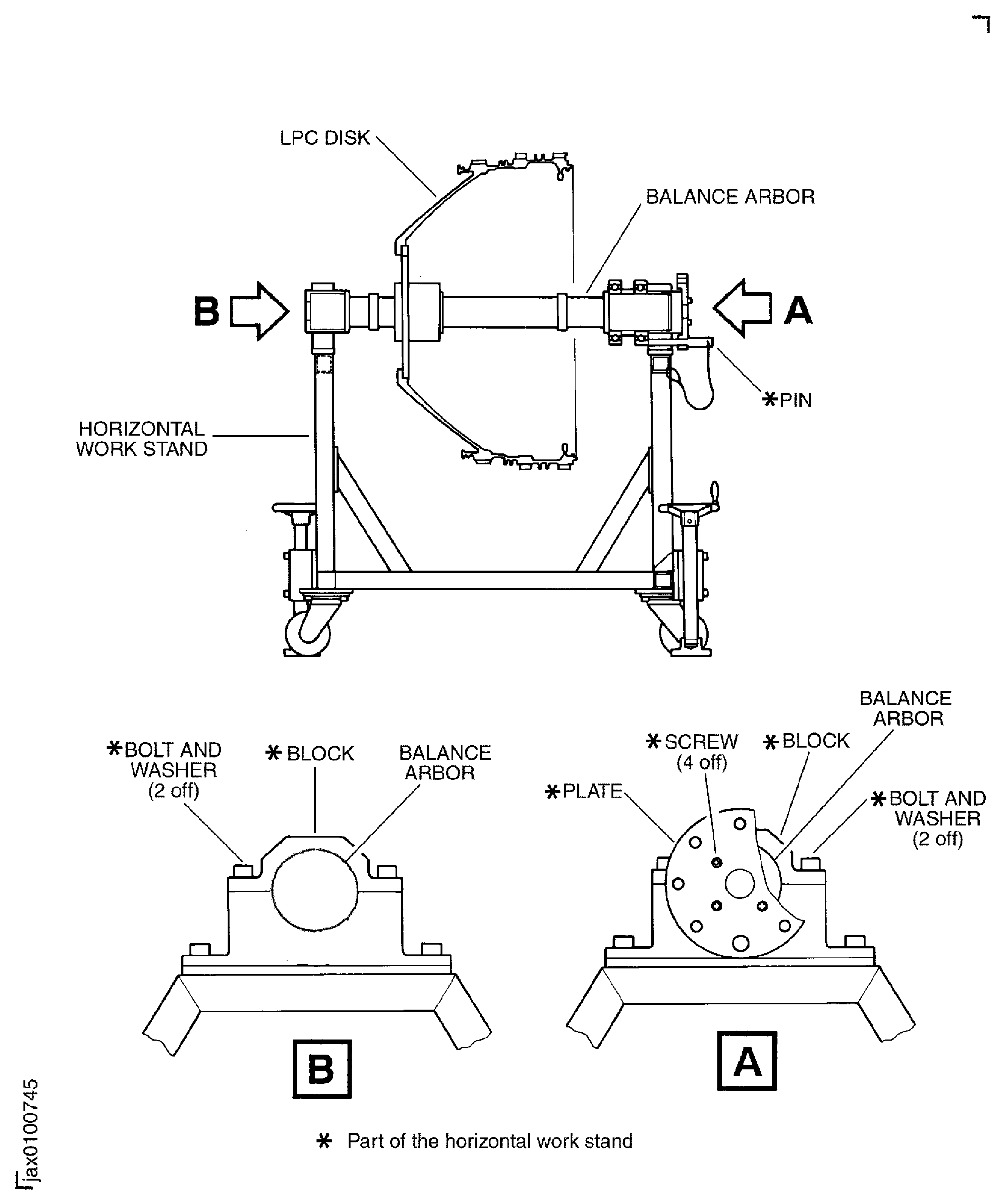

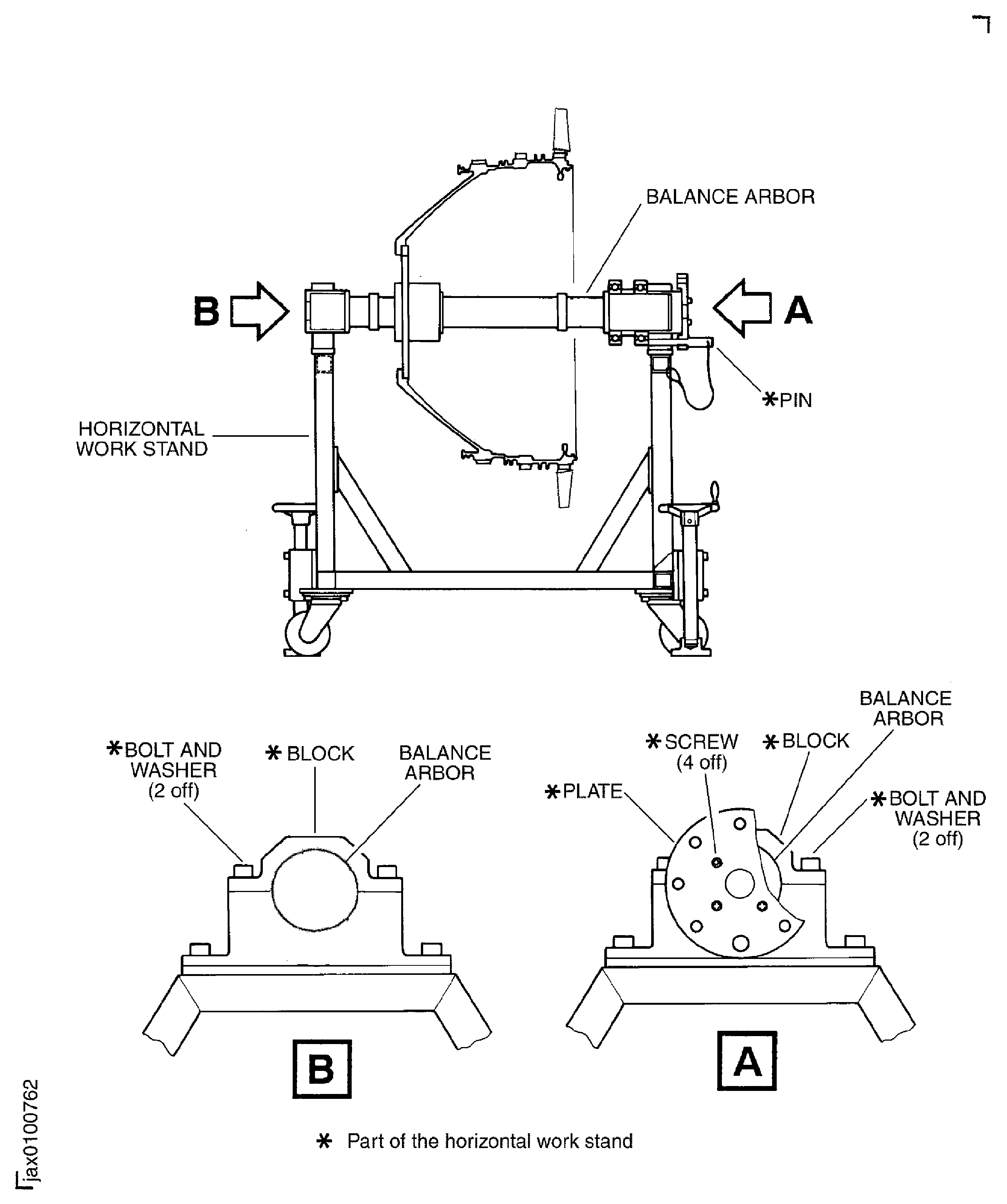

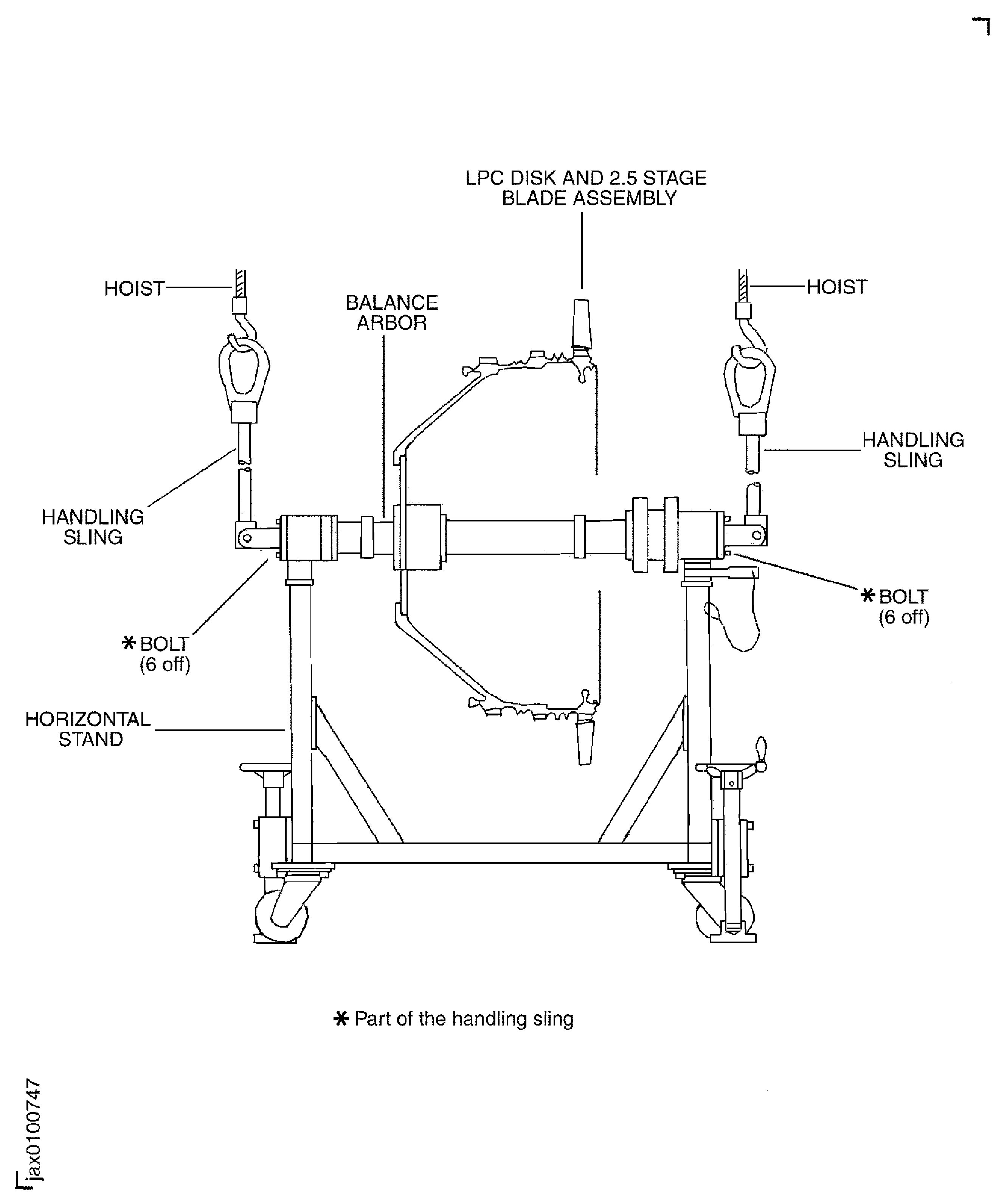

Move IAE 1J13206 Horizontal work stand 1 off to the work area.

SUBTASK 72-32-80-440-053 Turn the LPC Disk and the Balance Arbor Assembly from the Vertical to the Horizontal for the Stage 2.5 LP Compressor Blades (Stage 2.5 Blade) Assembly

NOTE

If computer calculated assembly sequence is available, it is better than the heavy-light-heavy sequence.Write the weight and the identification code on the blade convex airfoil surface with CoMat 06-069 MARKER.

SUBTASK 72-32-80-440-054 Weigh the Stage 1.5 LP Compressor Blades (Stage 1.5 Blades) (72-32-82,01-400), the Stage 2 LP Compressor Blades (Stage 2.0 Blades) (72-32-82,01-250) and the Stage 2.5 Blades (72-32-82,01-100)

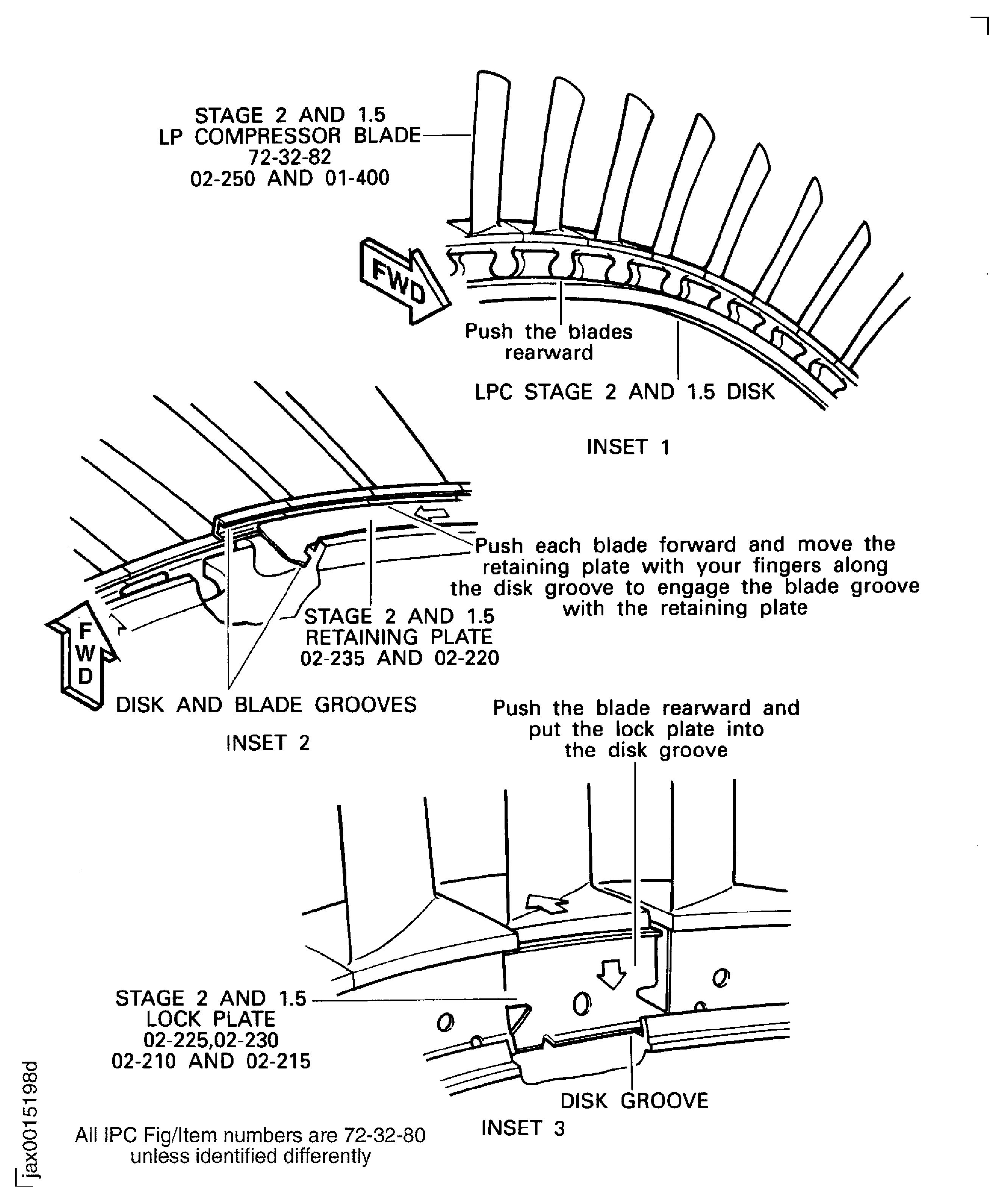

Install the stage 2.5 blades to the disk in the sequence found in Step. Start from the No. 1 blade slot and install the blades in a counterclockwise direction when you look from the rear. The identification number of the No. 1 slot is on the top of the disk tang.

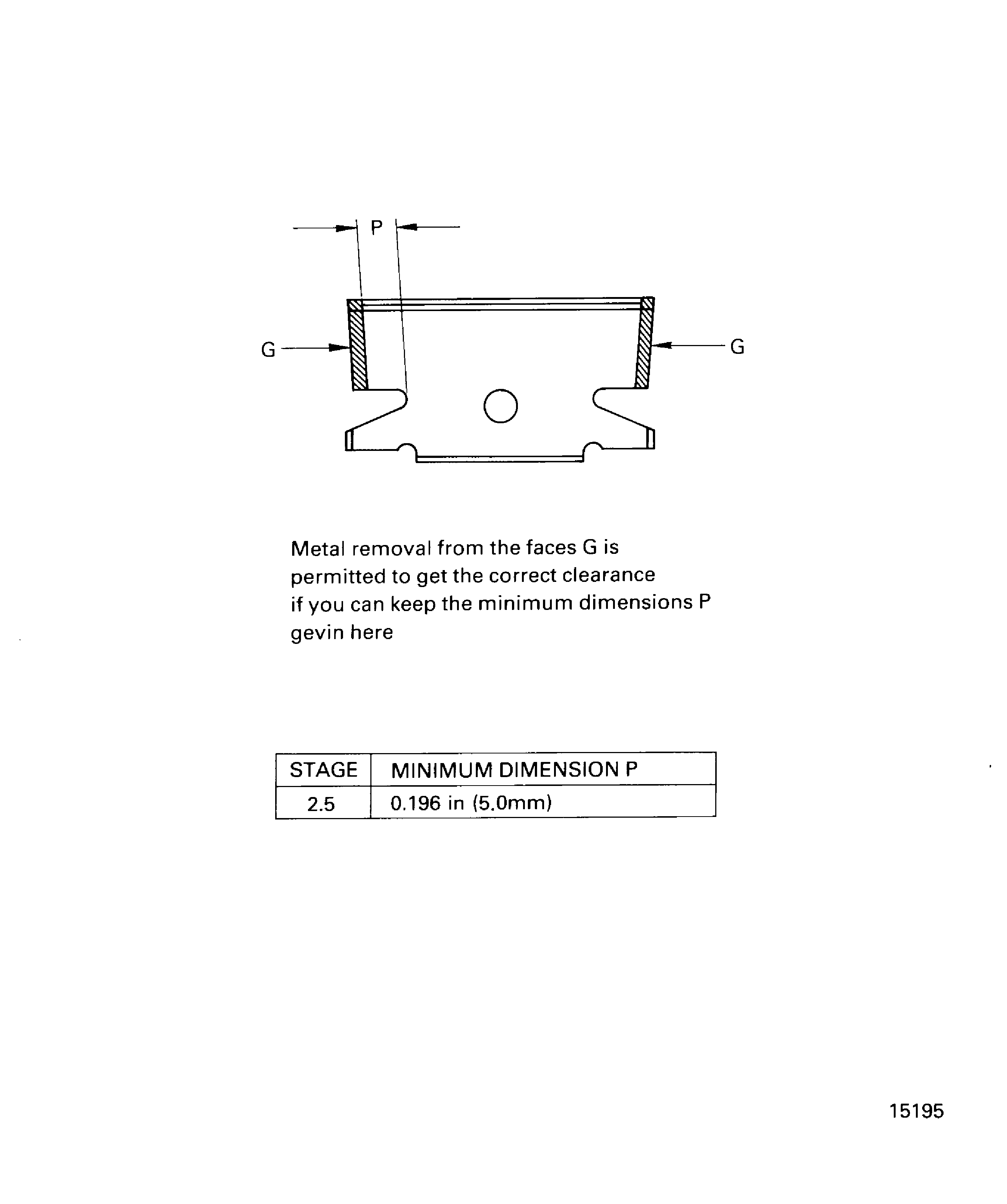

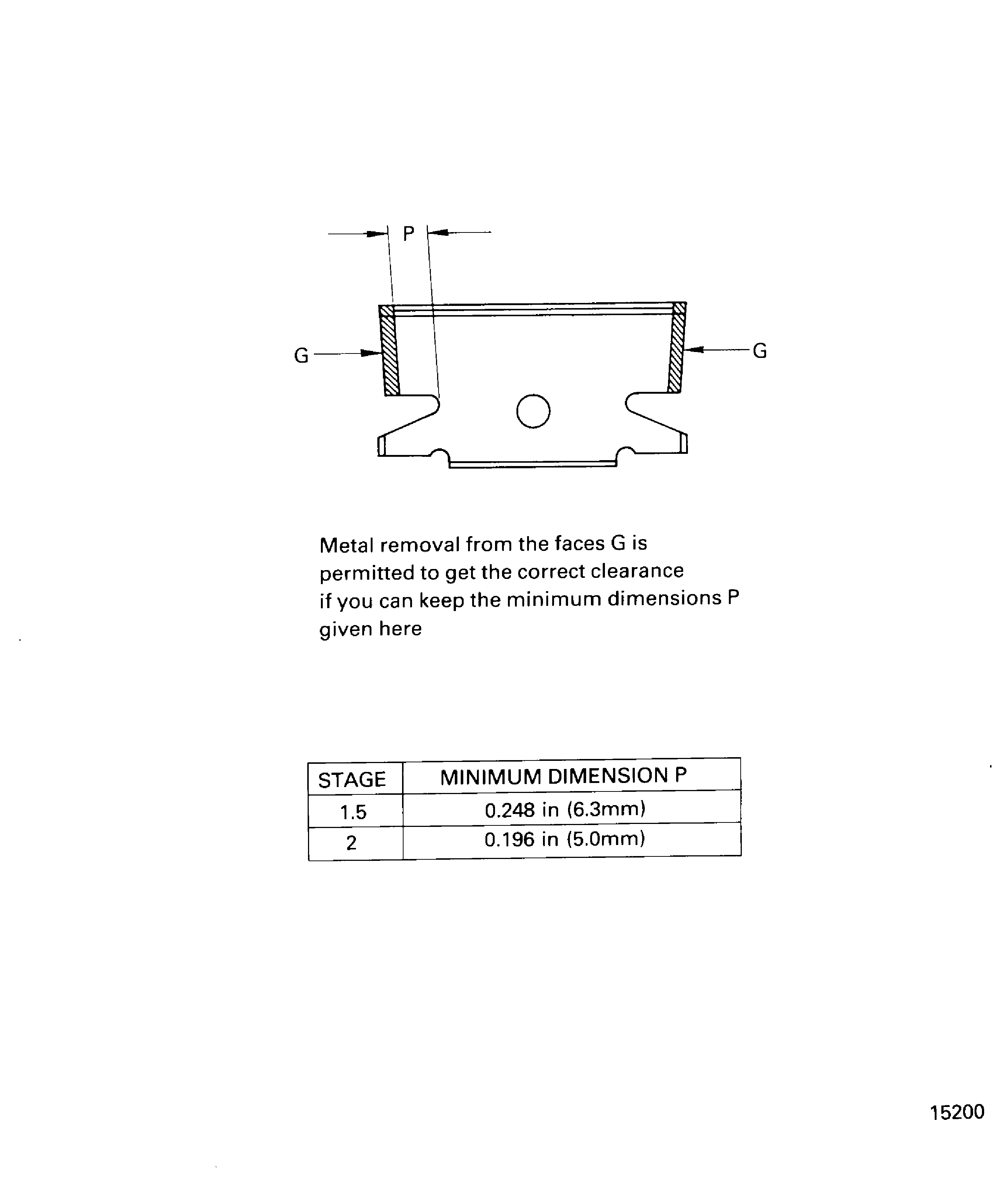

Install the eight stage 2.5 8 span retaining plates "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-250) between the two grooves on the stage 2.5 blades and disk.

Install a new "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-245) stage 2.5 single span lock plates 3 off in to the grooves of the blades and the disk.

Install a new "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80,02-240) stage 2.5 single span adjusting lock plate 1 off in to the grooves of the blades and the disk. The adjusting lock plate is between the two stage 2.5 8 span retaining plates and 180 degrees apart from the first lock plate.

Bend the tabs on the three single span lock plates and on the adjusting lock plate with a pair of pliers. Make sure that the tabs are correctly bent, Figure, Inset 5.

SUBTASK 72-32-80-440-055 Install the Stage 2.5 Blades to the LPC Disk

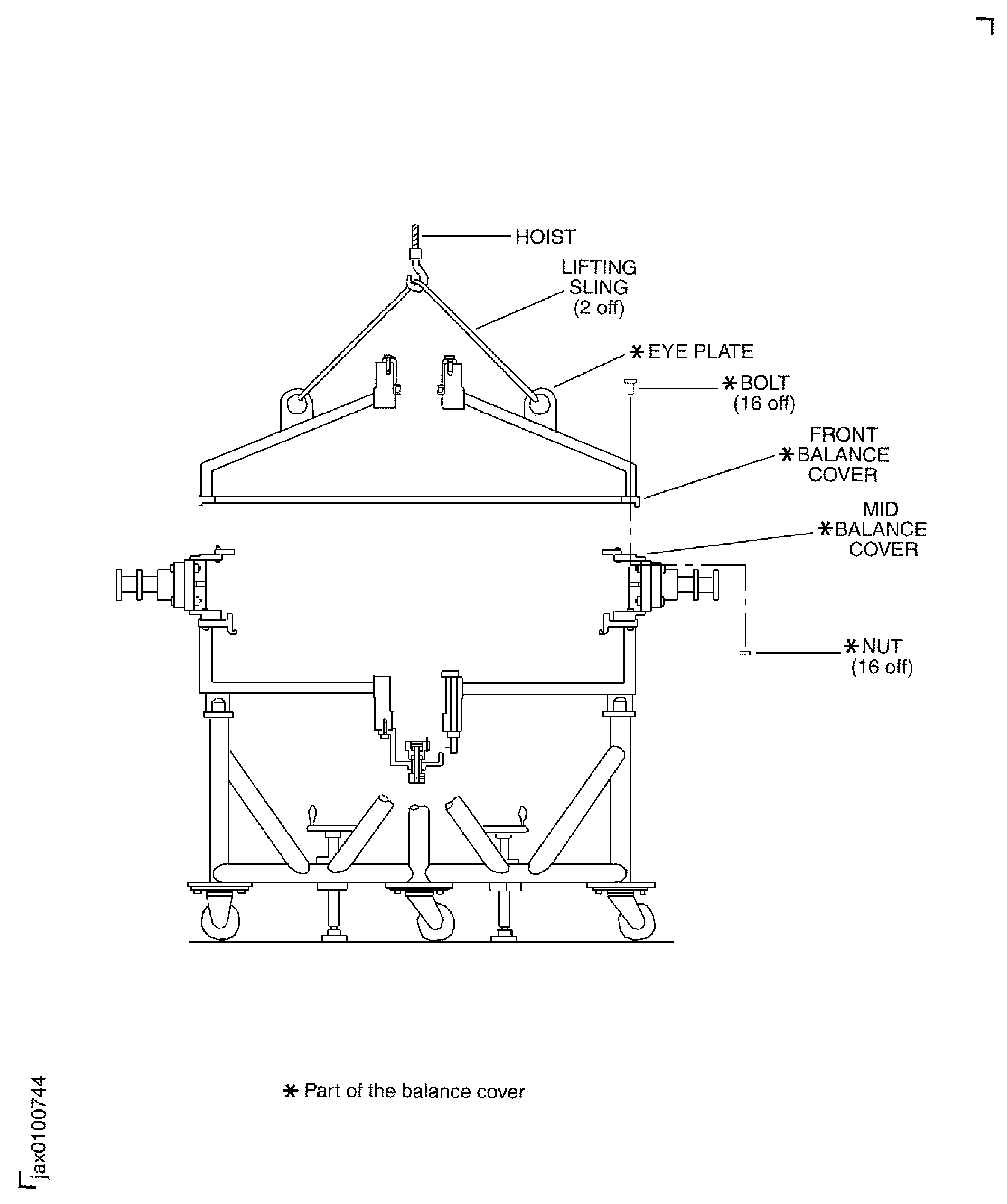

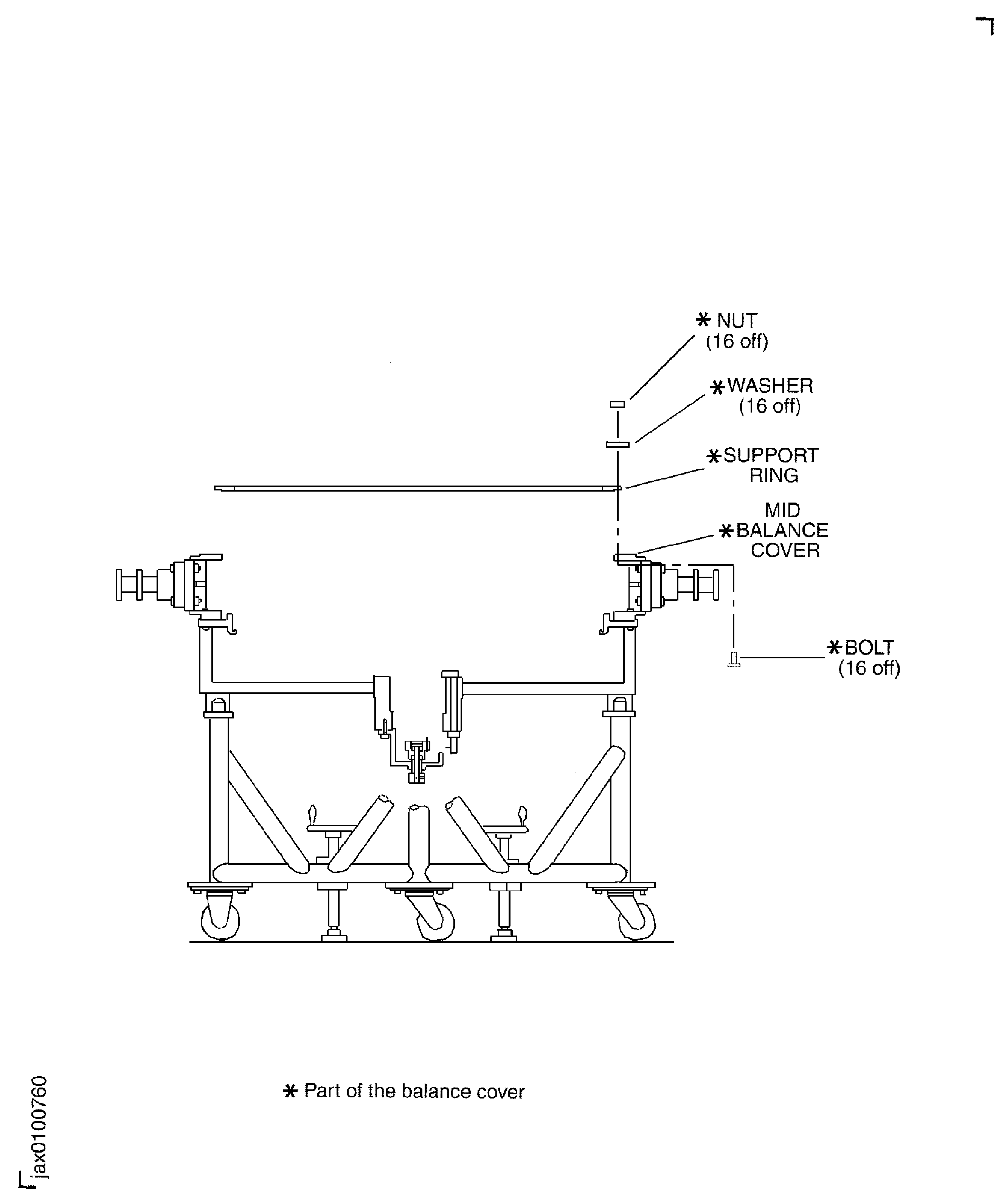

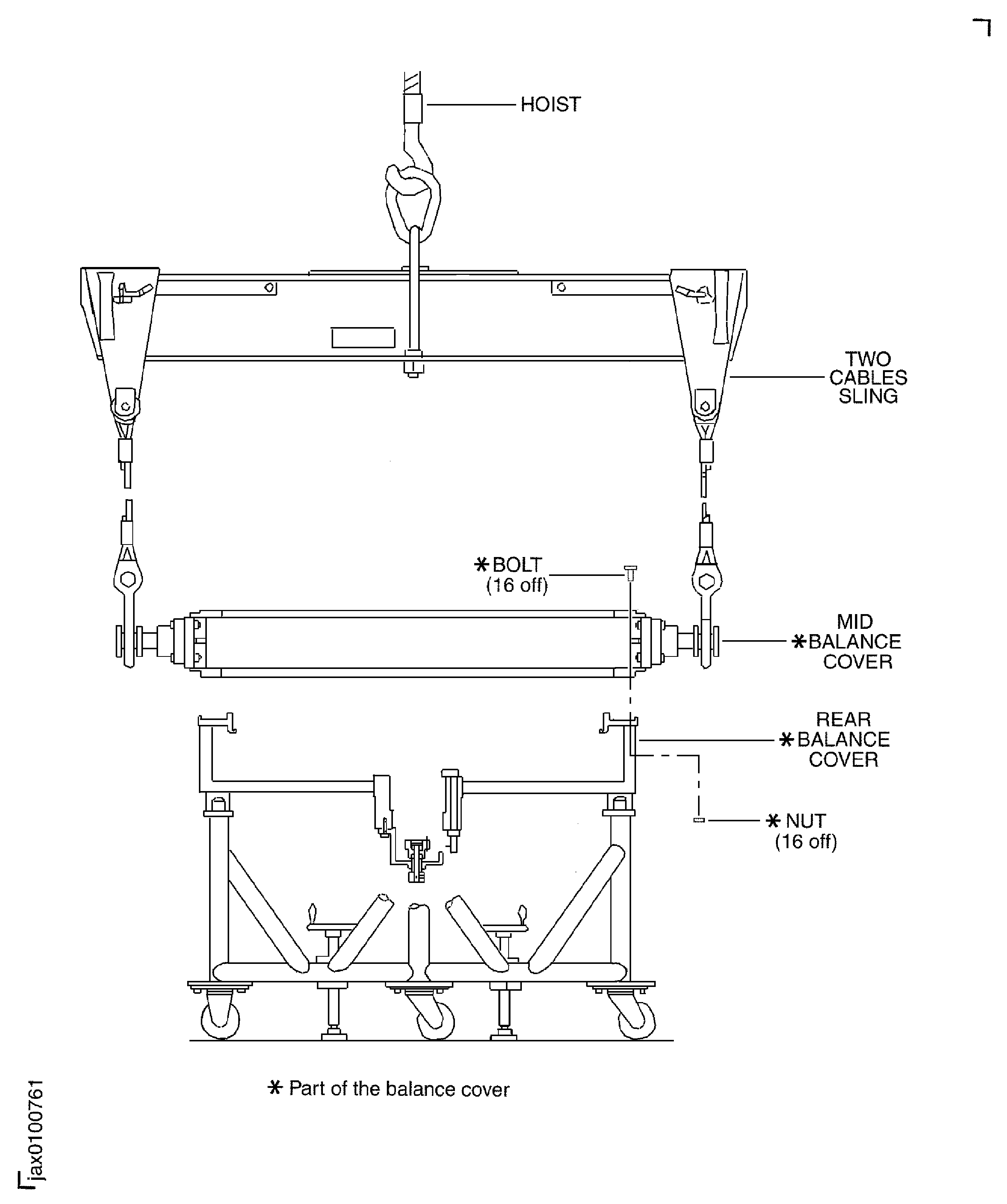

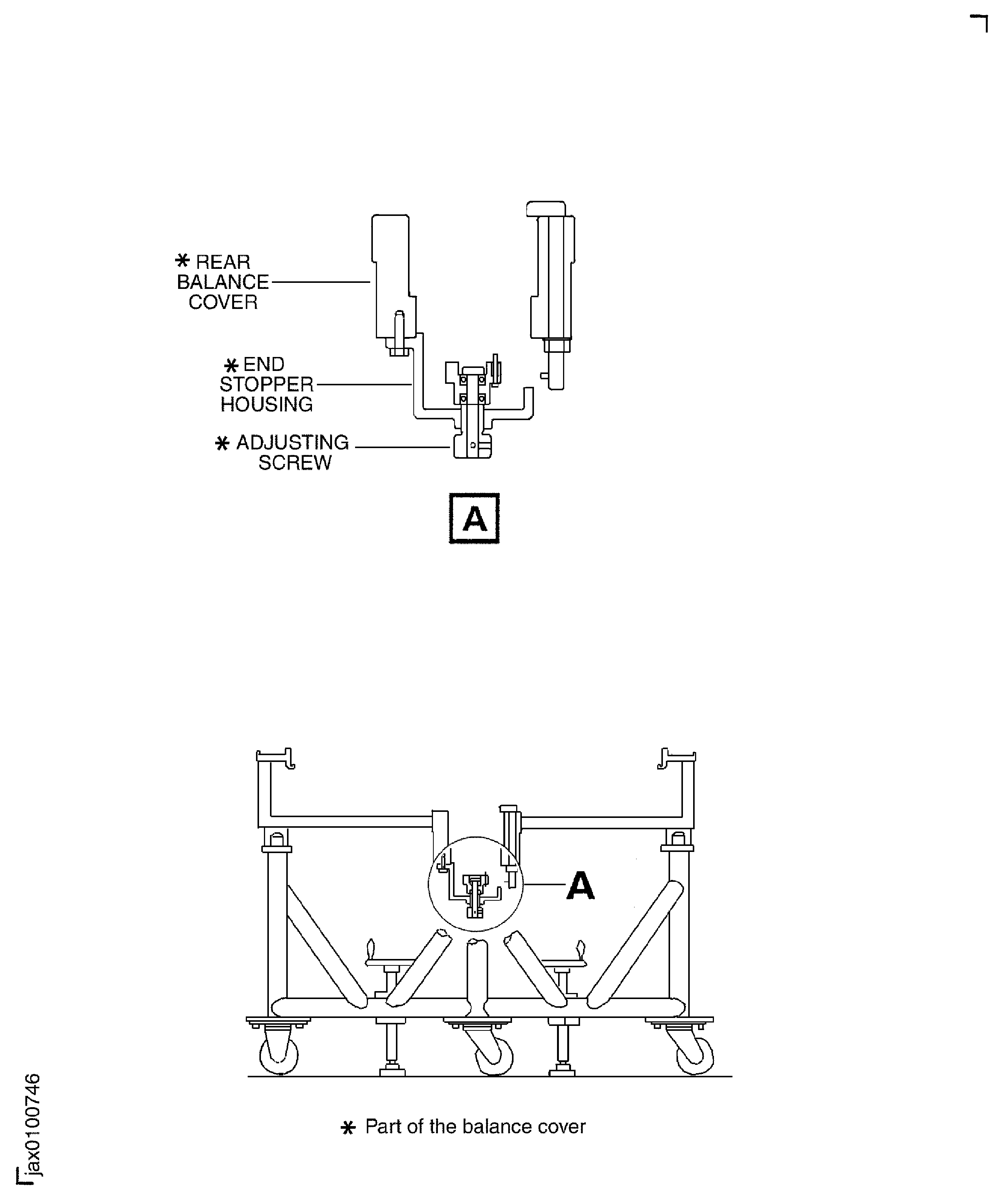

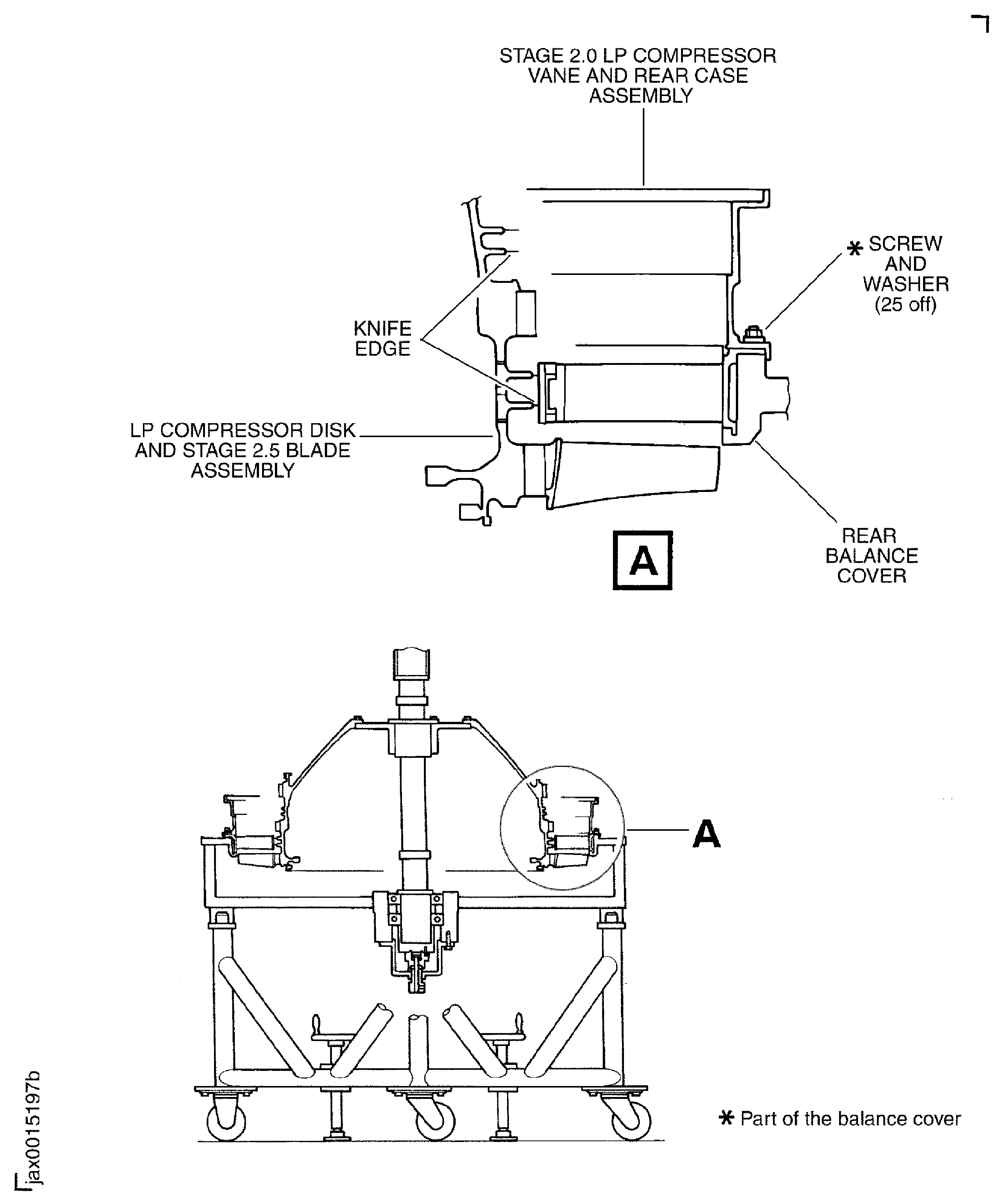

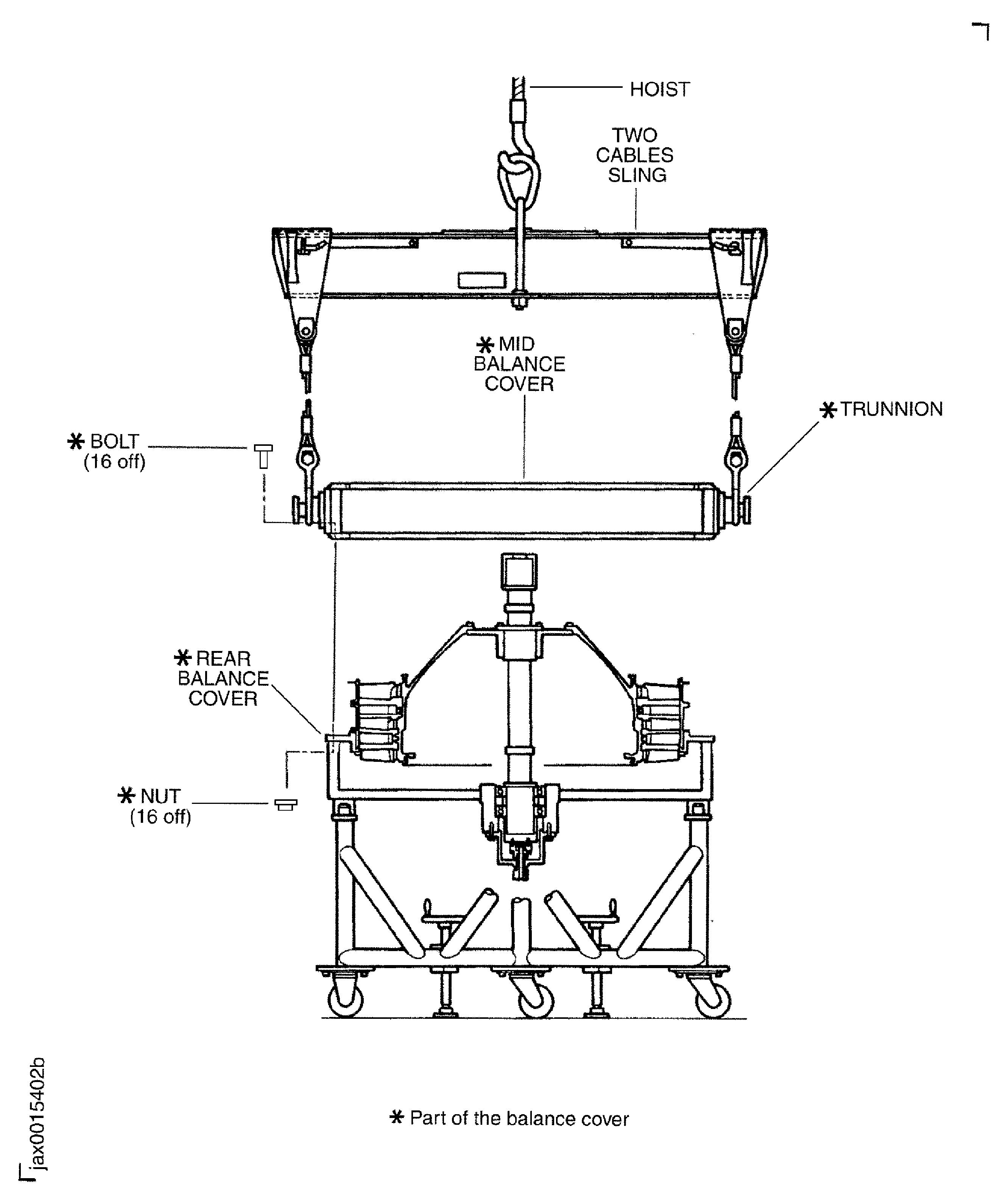

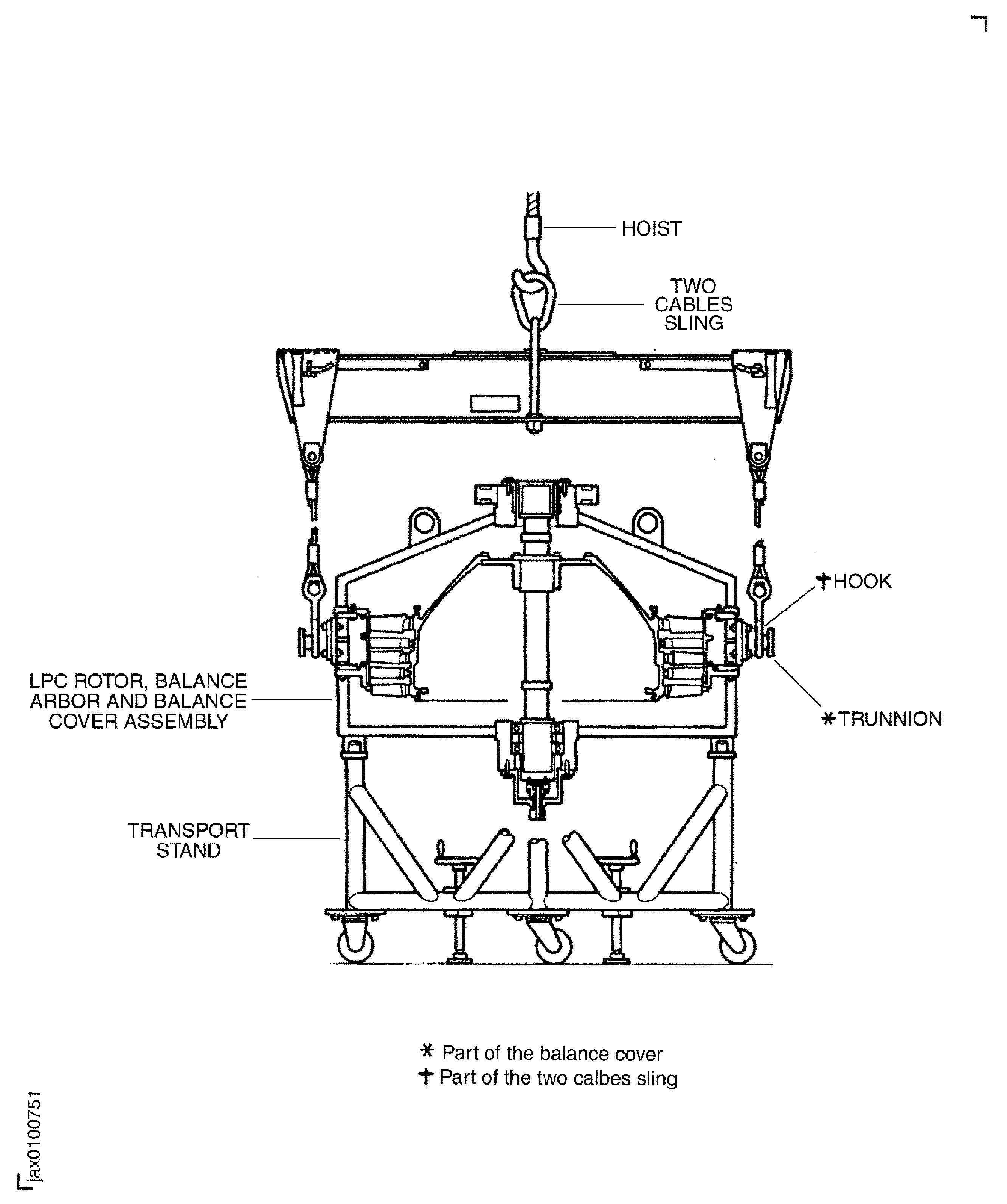

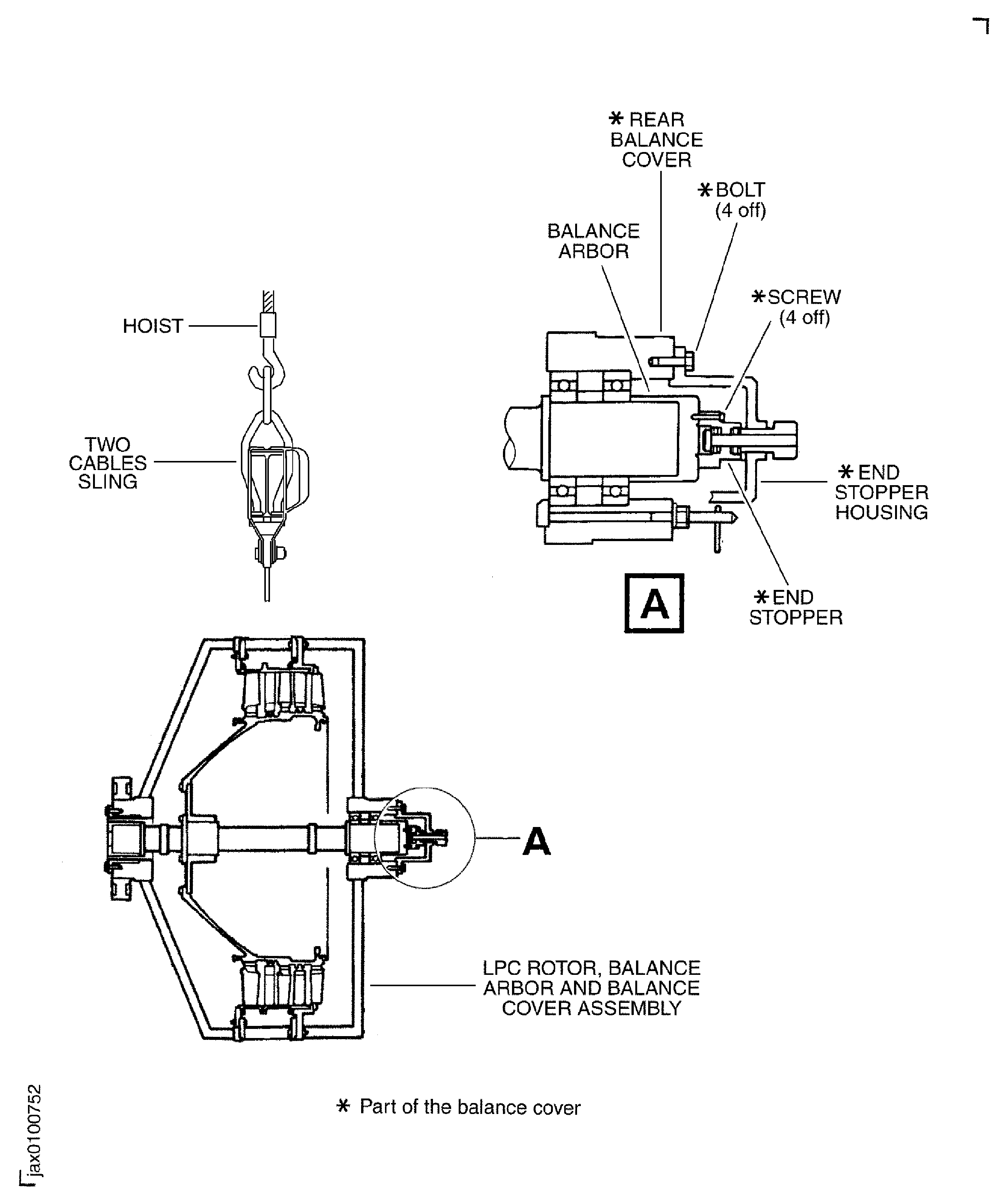

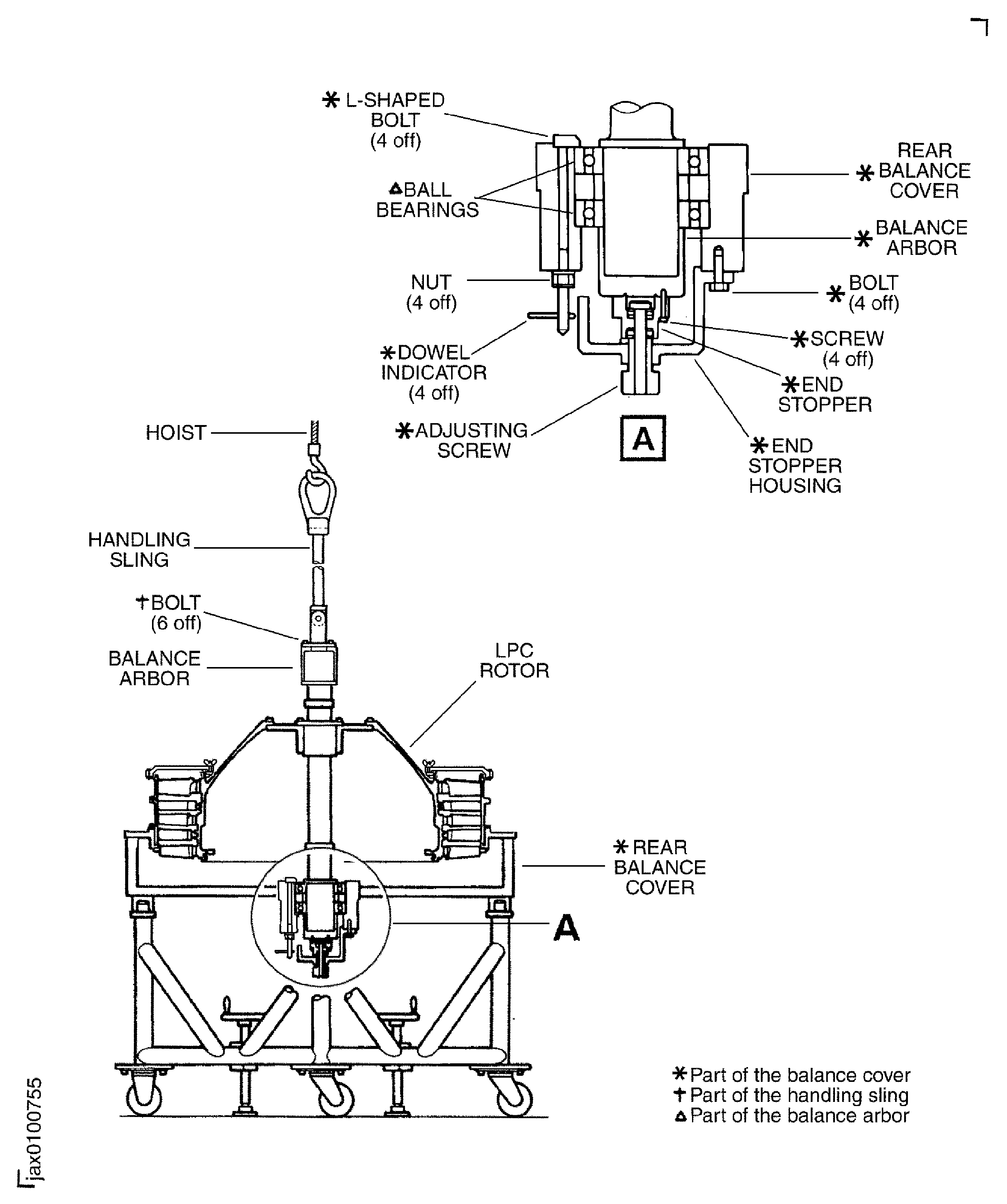

Move IAE 1J13208 Transport stand 1 off and IAE 1J13207 Balance cover and fixture 1 off to the work area.

Install IAE 1F10052 Two cables sling 1 off to the mid balance cover.

Remove the mid balance cover from the rear balance cover (part of the balance cover and fixture).

Make sure the dowel indicator (part of the balance cover and fixture) of the four L-shaped bolts (part of the balance cover and fixture) in the rear balance cover point to the inside diameter of the rear balance cover. When the dowel indicator points to the outside diameter the L-shaped bolt lock the axial movement of the ball bearing.

Move the LPC disk, stage 2.5 blade and arbor assembly from the horizontal stand to the transport stand.

SUBTASK 72-32-80-440-056 Turn the LPC Disk, 2.5 Stage Blades and Arbor Assembly to the Vertical and Install in to the Balance Cover and Fixture

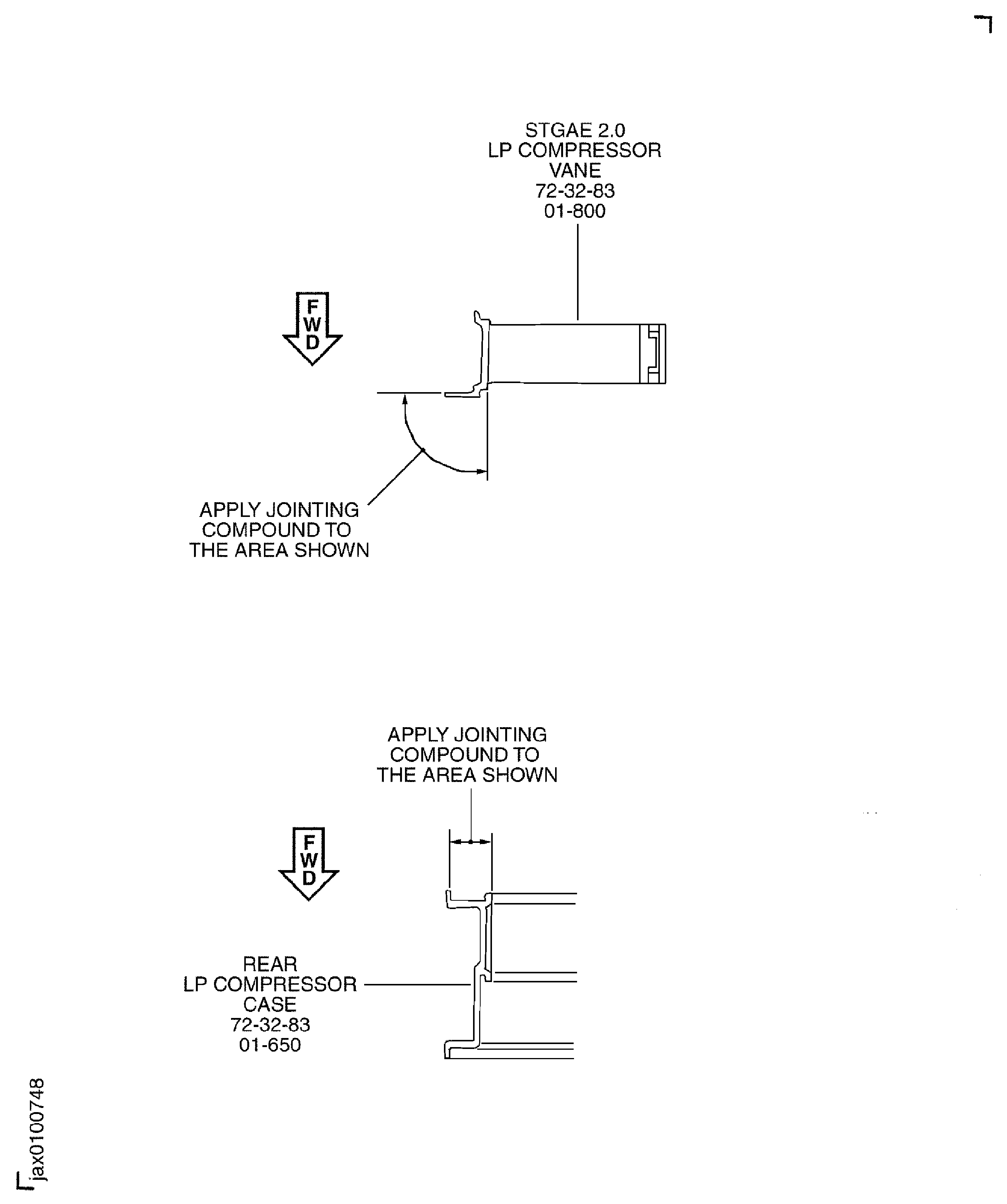

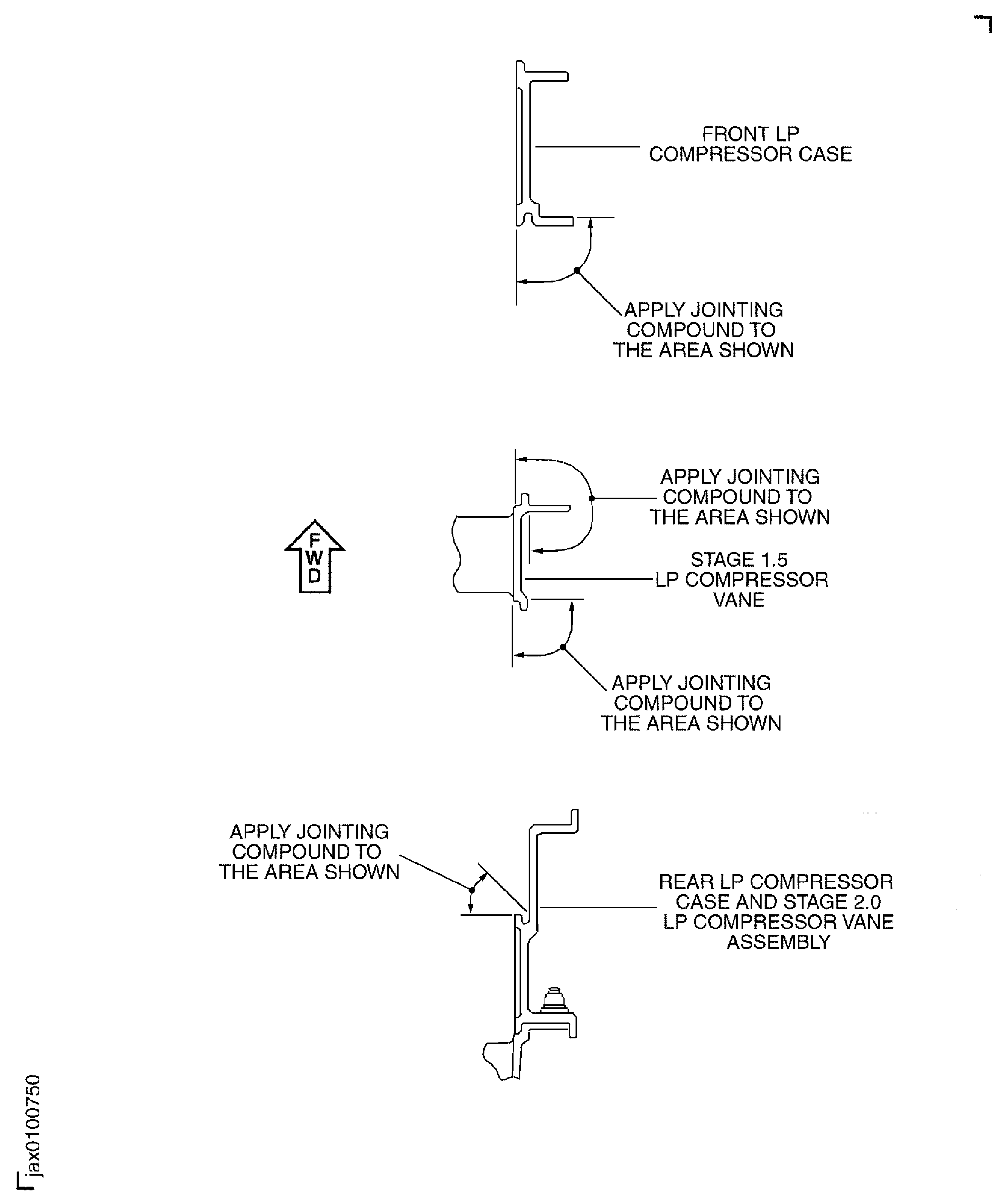

Clean the mating faces of the stage 2.0 vane and the rear case with CoMat 01-124 ISOPROPYL ALCOHOL.

Apply CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE on to the mating faces of the stage 2.0 vane and the rear case.

Apply the jointing compound on to the mating faces of the stage 2.0 vane and the rear case.

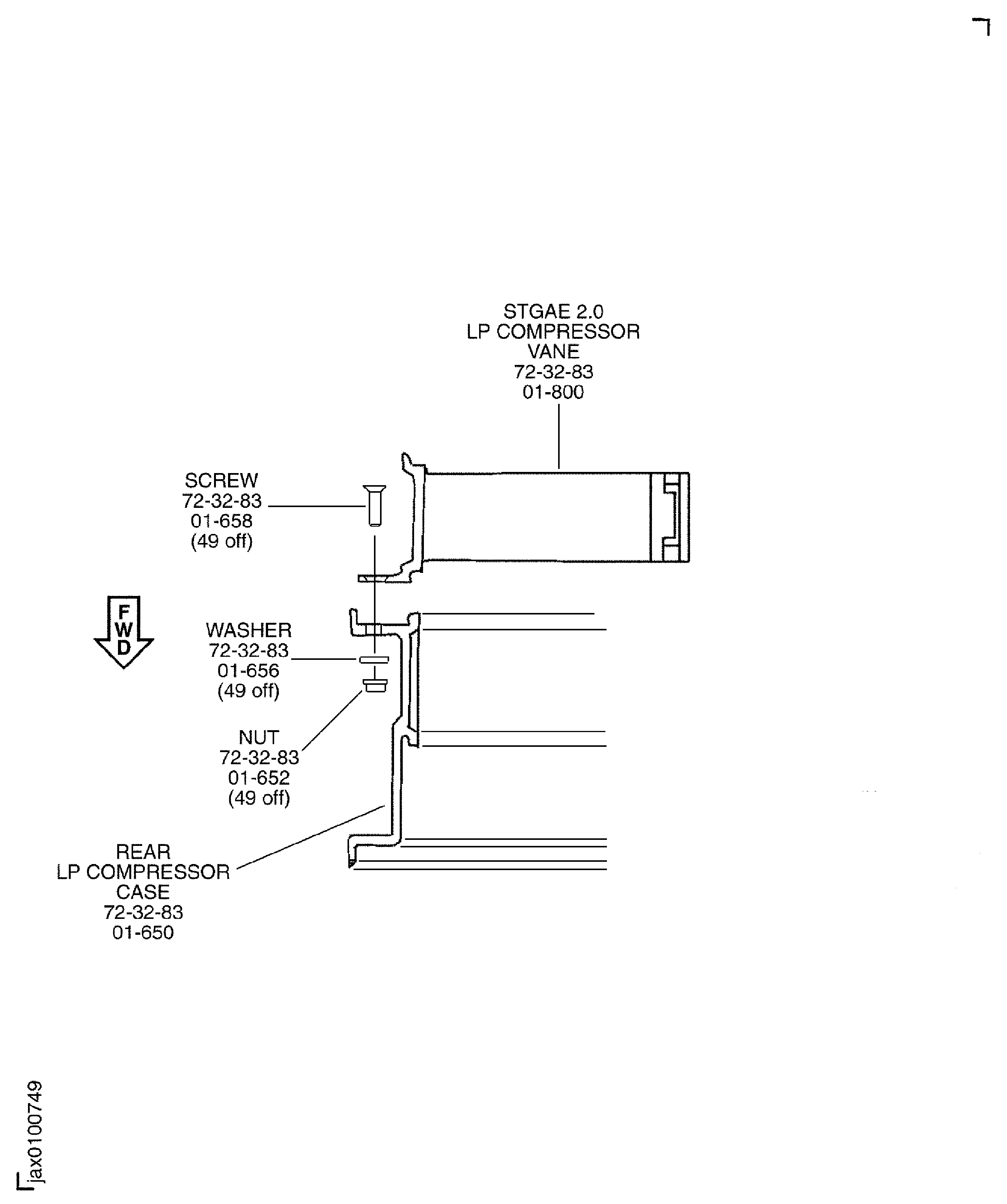

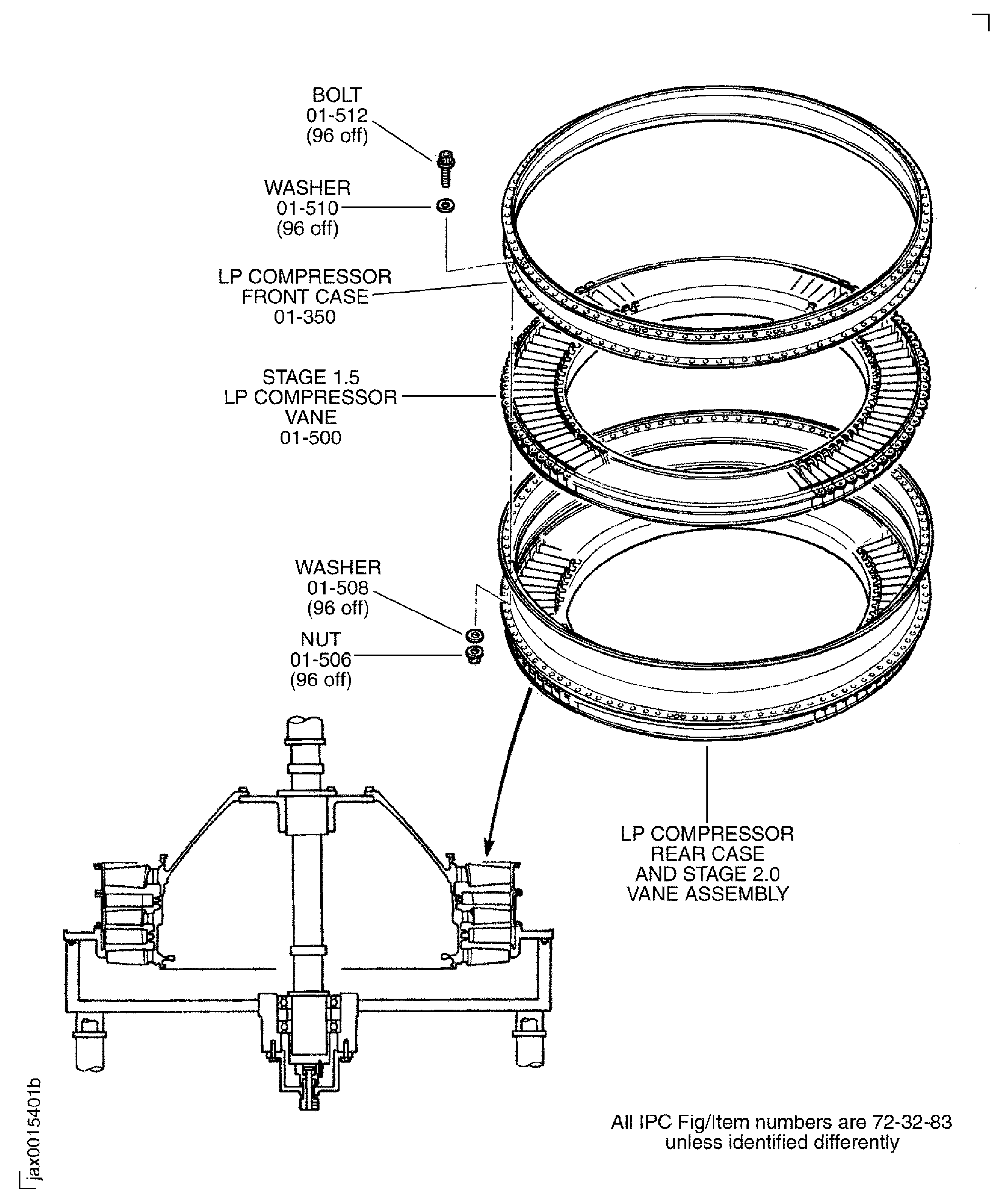

Install the stage 2.0 vane to the rear case with 49 screws ENGINE-LP COMPRESSOR STAGE 1.5 AND 2 VANES (72-32-83, 01-658), washers ENGINE-LP COMPRESSOR STAGE 1.5 AND 2 VANES (72-32-83, 01-656) and nuts ENGINE-LP COMPRESSOR STAGE 1.5 AND 2 VANES (72-32-83, 01-652).

SUBTASK 72-32-80-440-057 Install the Stage 2.0 LP Compressor Vane (Stage 2.0 Vane) (72-32-83,01-800) in to the LP Compressor Rear Case (Rear Case) (72-32-83,01-650)

Install the stage 2.0 blades to the disk in the sequence found in the Step. Start from the No. 1 blade slot and install the blades in a counterclockwise direction when you look from the rear. The identification number of the No. 1 slot is on the top of the disk tang.

Install the eight stage 2.0 8 span retaining plates "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-235) between the two grooves on the stage 2.0 blades and disk.

Install a new "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-230) stage 2.0 single span lock plates 3 off in to the grooves of the blades and the disk.

Install a new "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-225) stage 2.0 single span adjusting lock plate 1 off in to the grooves of the blades and the disk. The adjusting lock plate is between the two stage 2.0 8 span retaining plates and 180 degrees apart from the first lock plate.

Bend the tabs on the three single span lock plates and on the adjusting lock plate with a pair of pliers. Make sure that the tabs are correctly bent, Figure, Inset 5.

SUBTASK 72-32-80-440-059 Install the Stage 2.0 Blades to the LPC Disk and Safety with the Retaining Plates

Clean the mating faces of the stage 1.5 vane, the front case and the rear case with CoMat 01-124 ISOPROPYL ALCOHOL.

Apply CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE on to the mating faces of the stage 1.5 vane, the front case and the rear case. Dry in the air for five minutes.

Apply the jointing compound on to the mating faces of the stage 1.5 vane, the front case and the rear case.

Install the front case and the stage 1.5 vane to the rear case with the 96 bolts ENGINE-LP COMPRESSOR STAGE 1.5 AND 2 VANES (72-32-83, 01-512), washers ENGINE-LP COMPRESSOR STAGE 1.5 AND 2 VANES (72-32-83, 01-508), washers ENGINE-LP COMPRESSOR STAGE 1.5 AND 2 VANES (72-32-83, 01-510) and nuts ENGINE-LP COMPRESSOR STAGE 1.5 AND 2 VANES (72-32-83, 01-506).

SUBTASK 72-32-80-440-060 Install the Stage 1.5 LP Compressor Vane (Stage 1.5 Vane) (72-32-83,01-500) and the LP Compressor Front Case (Front Case) (72-32-83,01-350) on to the LP Compressor Rear Case (Rear Case) and the Stage 2.0 Vane Assembly

Install the stage 1.5 blades to the LPC disk in the sequence found in the Step. Start from the No. 1 blade slot and install the blades in a counterclockwise direction when you look from the rear. The identification number of the No. 1 slot is on the top of the disk tang.

Install the eight stage 1.5 6 span retaining plates "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-220) between the two grooves on the stage 1.5 blades and disk.

Install a new "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-215) stage 1.5 single span lock plates 3 off in to the grooves of the blades and the disk.

Install a new "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-210) stage 1.5 single span adjusting lock plate 1 off in to the grooves of the blades and the disk. The adjusting lock plate is between the two stage 1.5 6 span retaining plates and 180 degrees apart from the first lock plate.

Bend the tabs on the three single span lock plates and on the adjusting lock plate with a pair of pliers. Make sure that the tabs are correctly bent, Figure, Inset 5.

SUBTASK 72-32-80-440-061 Install the Stage 1.5 Blades to the LPC Disk and Safety with the Retaining Plates

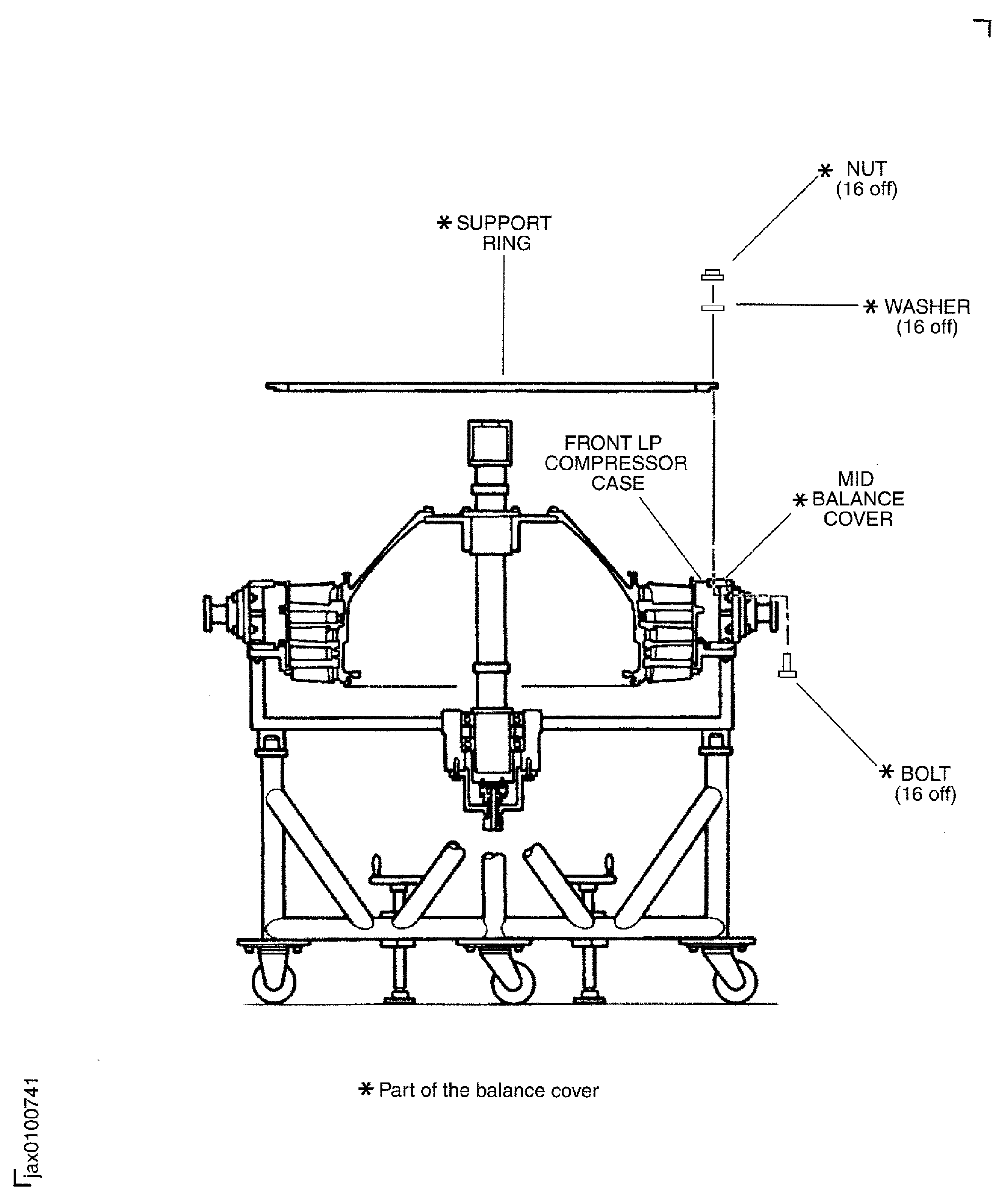

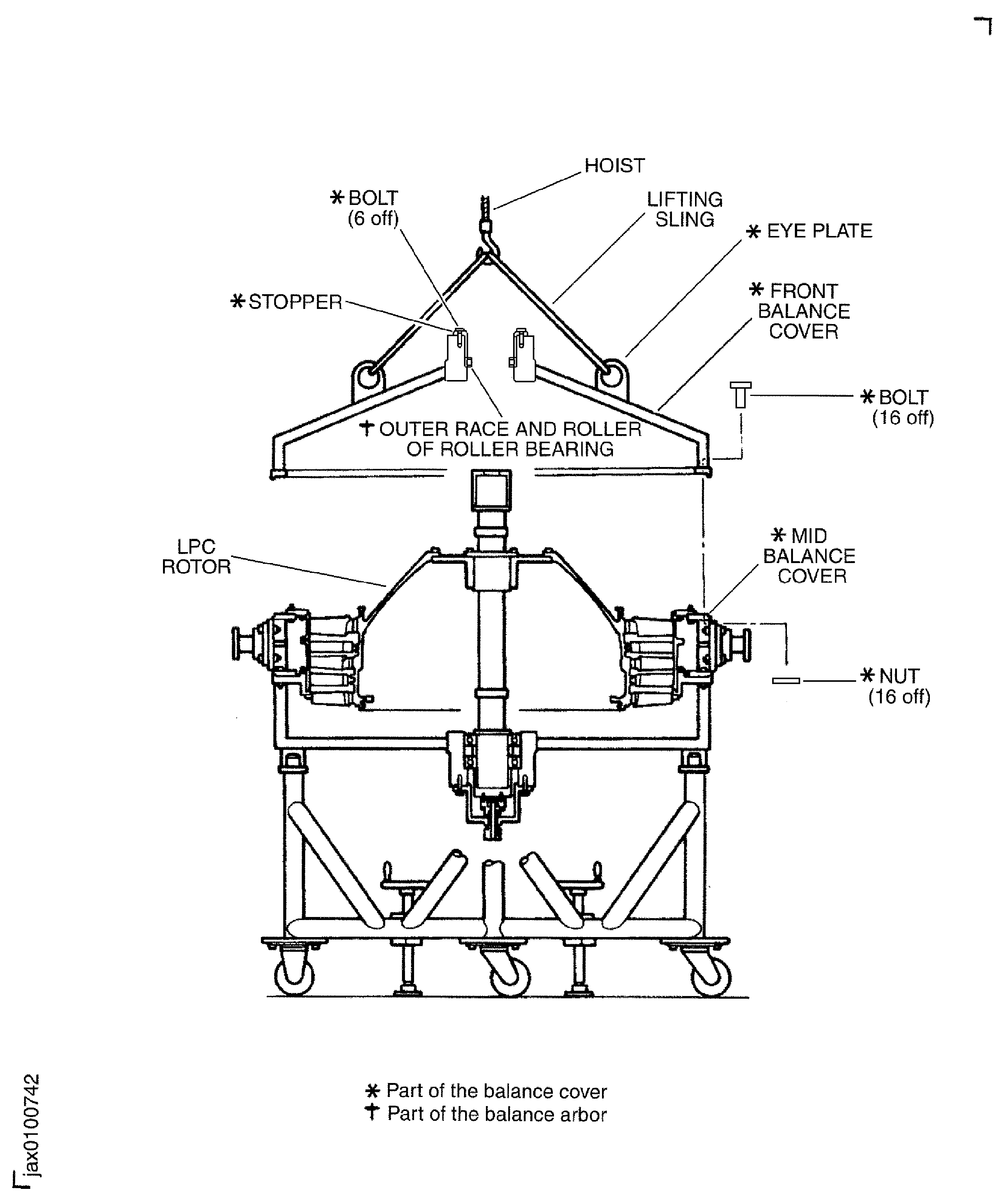

SUBTASK 72-32-80-440-062 Install the Mid and Front Balance Cover on to the Rear Balance Cover

NOTE

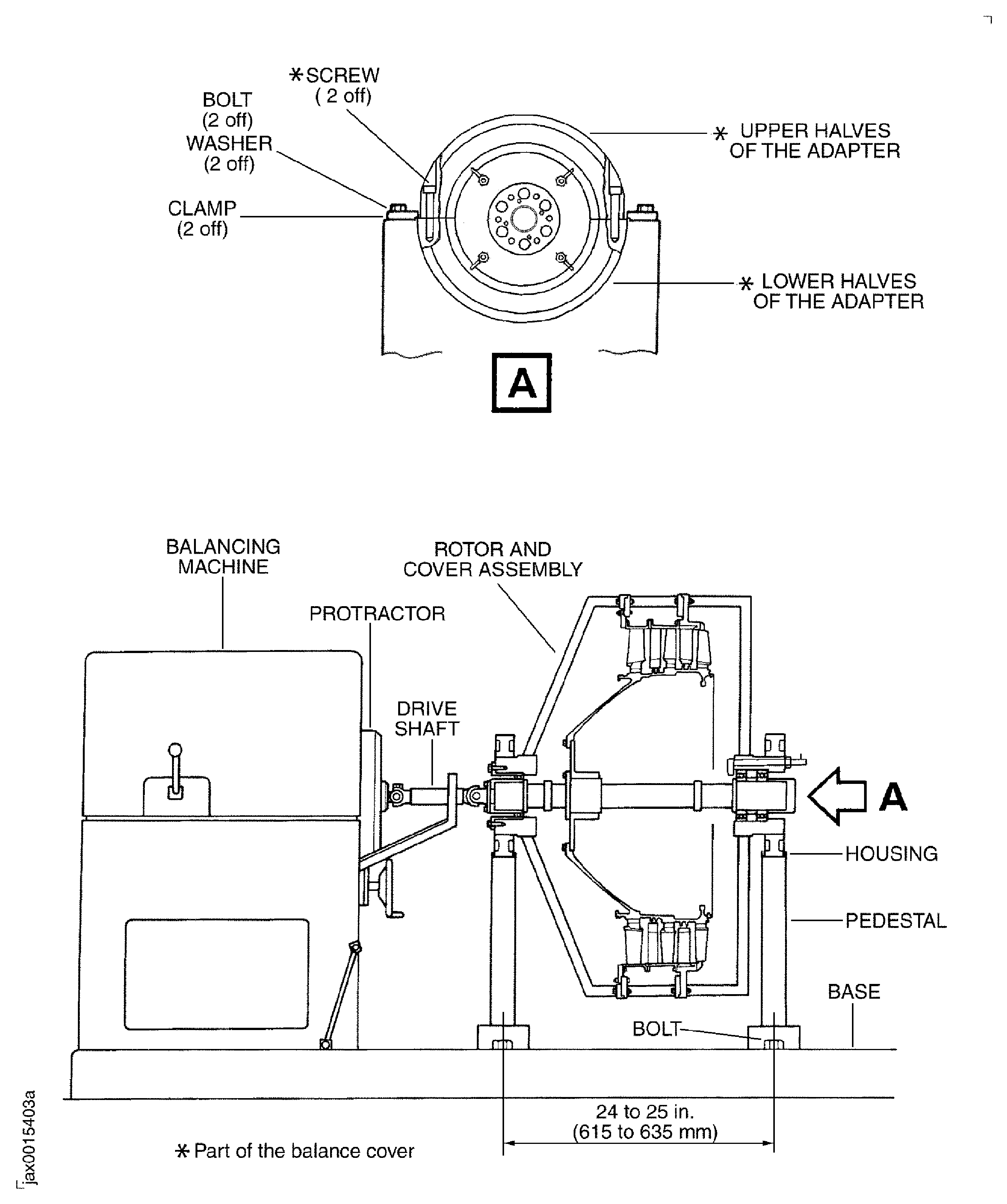

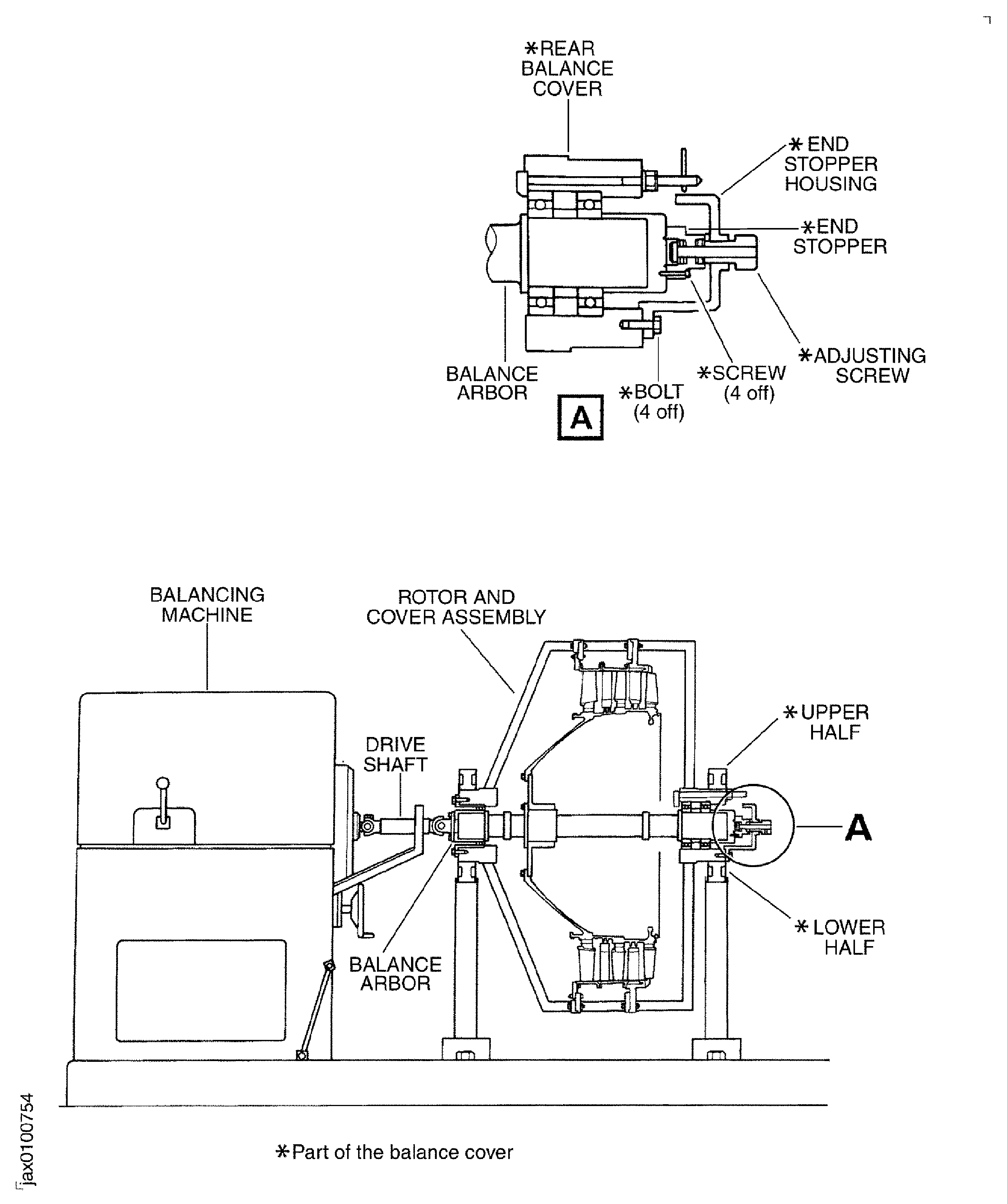

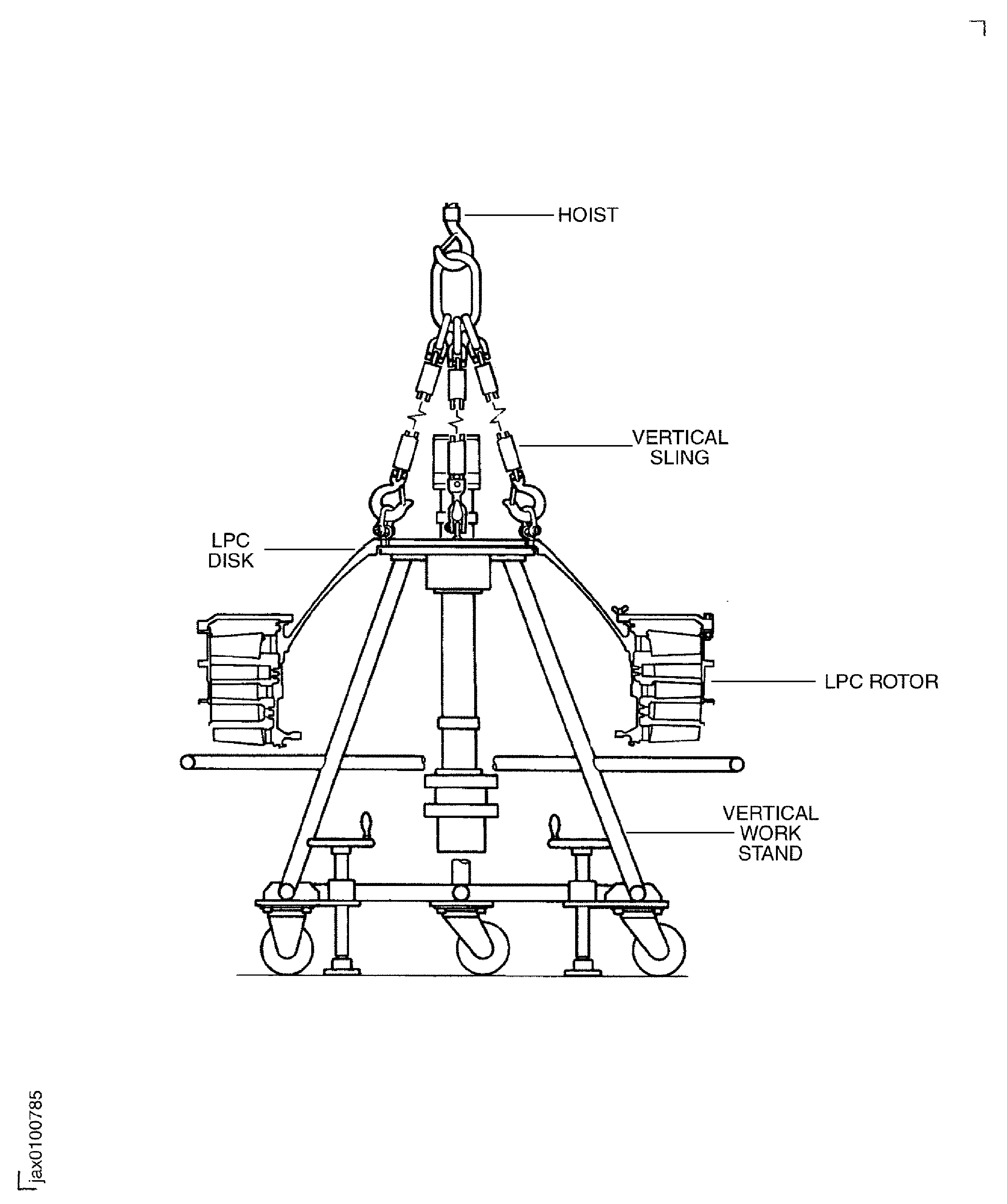

Balancing tools in this TASK are applicable to a SCHENCK HL5 U horizontal balancing machine and bearing housing.Balancing must be operated at a speed between 700 to 900 rpm to agree with the gear ratios available.The direction of rotation is clockwise when you look from the rear.Move the LPC rotor and balance cover assembly on the transport stand to the balance area.

SUBTASK 72-32-80-440-063 Install the LPC Rotor, Balance Arbor and Balance Cover Assembly (LPC Rotor and Balance Cover Assembly) on to the Balancing Machine

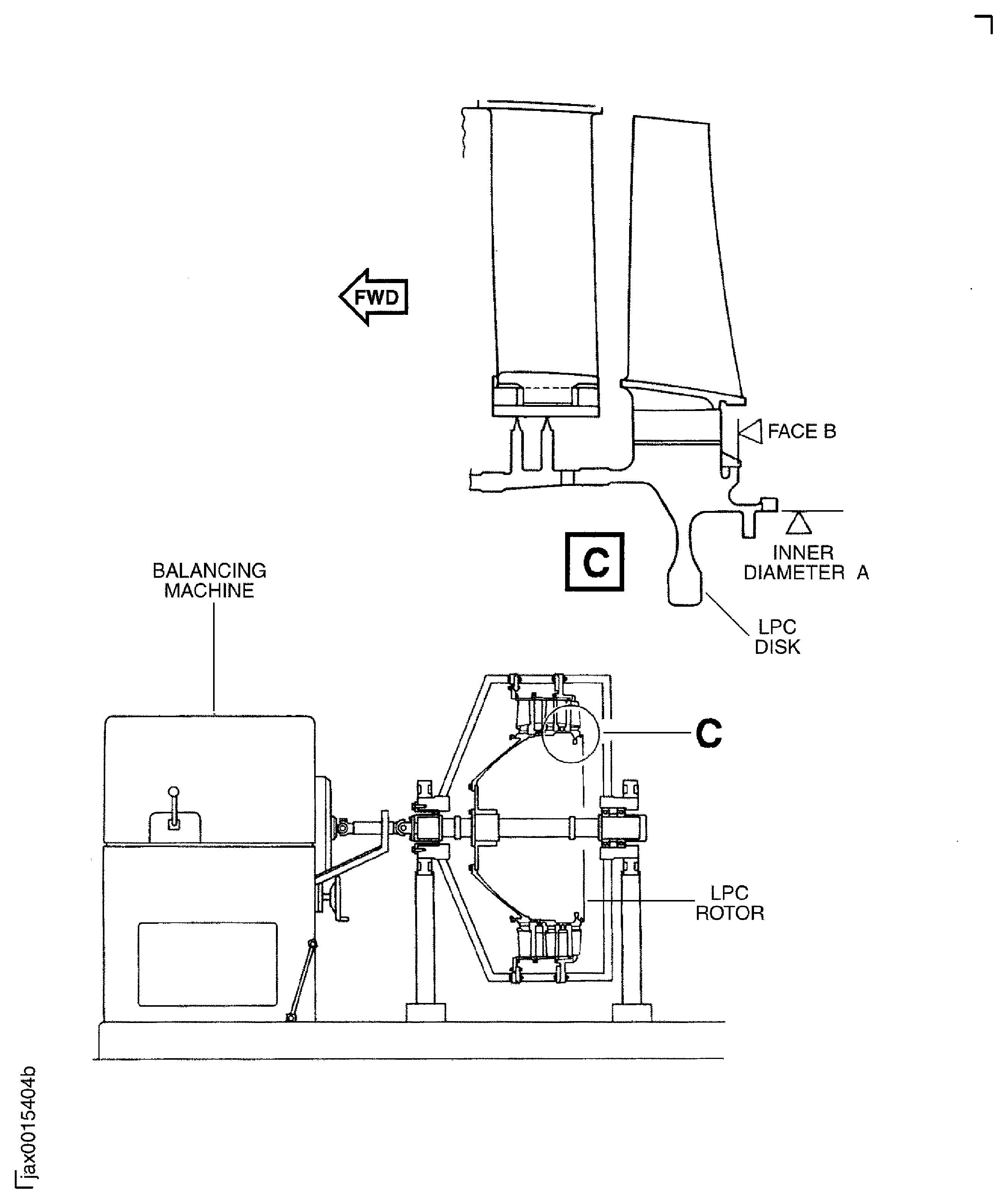

Refer to Figure.

SUBTASK 72-32-80-220-051 Examine the Runout of the LPC Rotor

Refer to Figure.

SUBTASK 72-32-80-440-064 Examine the Initial Unbalance of the LPC Rotor

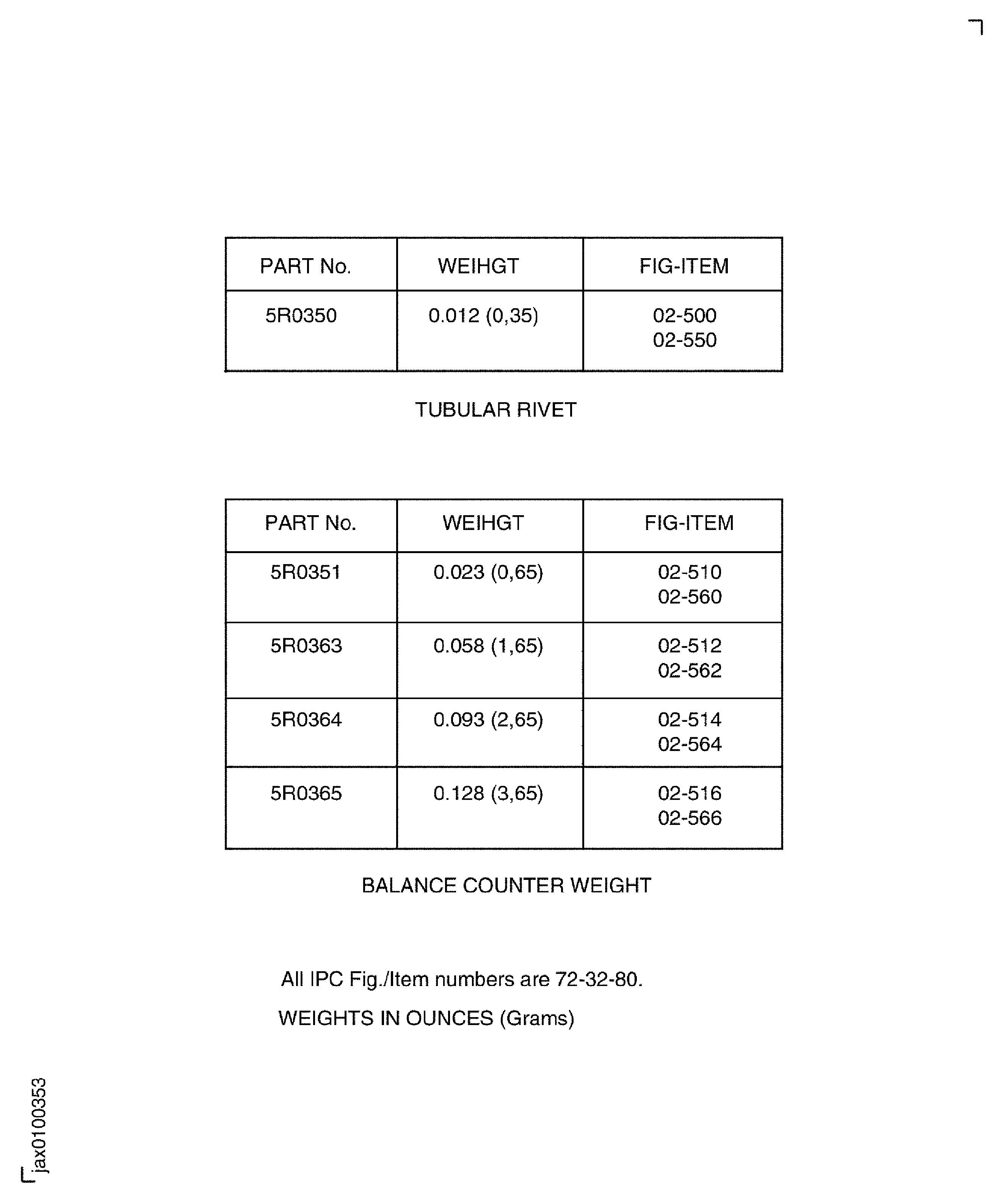

Prepare the balance counter weight "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-510), "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-512), "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY(72-32-80, 02-514), "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-516), "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-560), "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-562), "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-564) and "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-566) and the tubular rivet "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-500) and "ENGINE-LP COMPRESSOR STAGE 1.5,2 AND 2.5 ASSY (72-32-80, 02-550).

NOTE

You can attach more than two balance counter weights if required.Install the balance counter weights and safety them with the tubular rivets. Use IAE 1J13209 Riveter 1 off. Refer to SPM TASK 70-39-03-390-501 for rivet installation.

Do the unbalance correction in the subsequent steps.

SUBTASK 72-32-80-440-065 Correct the Unbalance of the LP Compressor Rotor

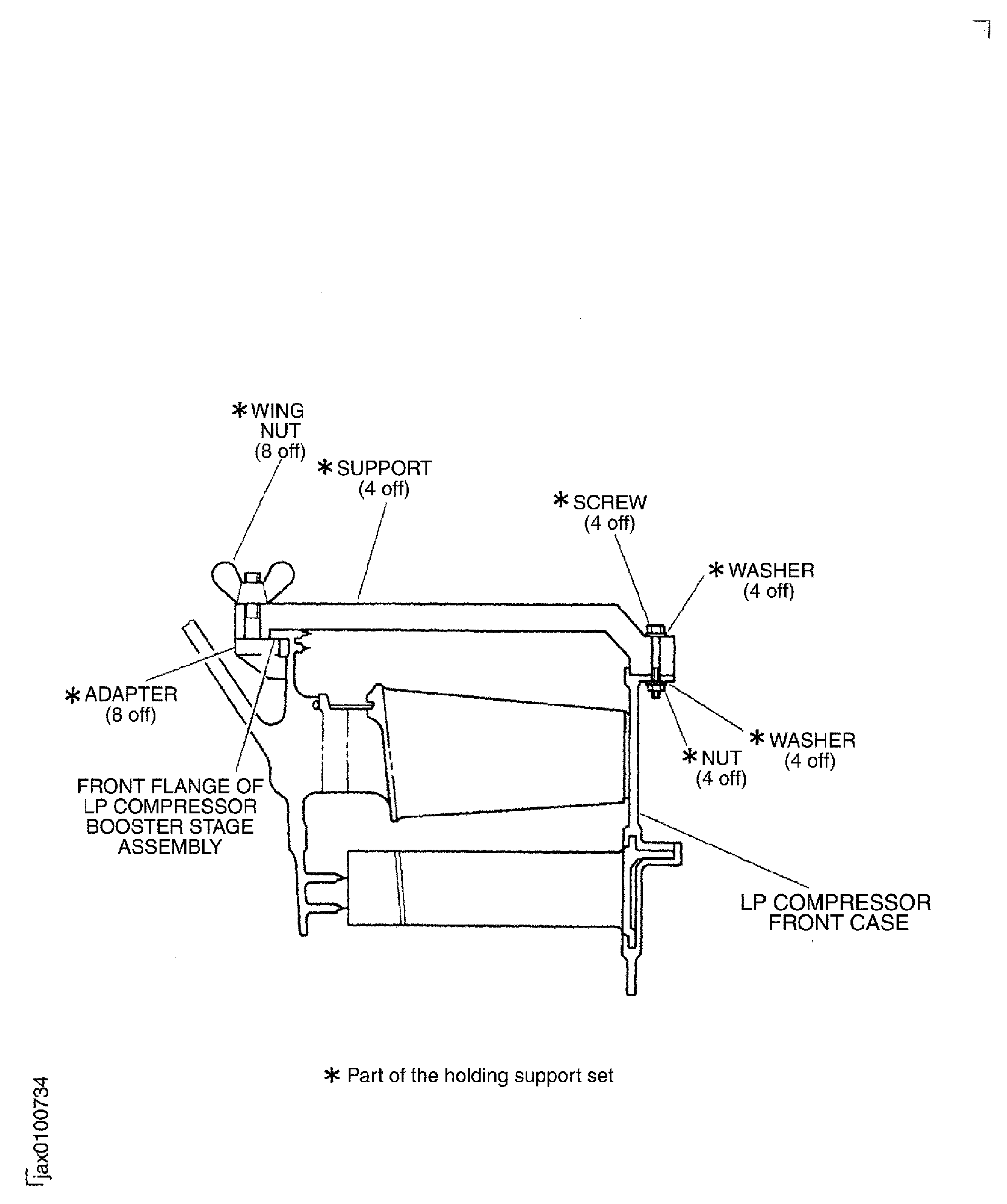

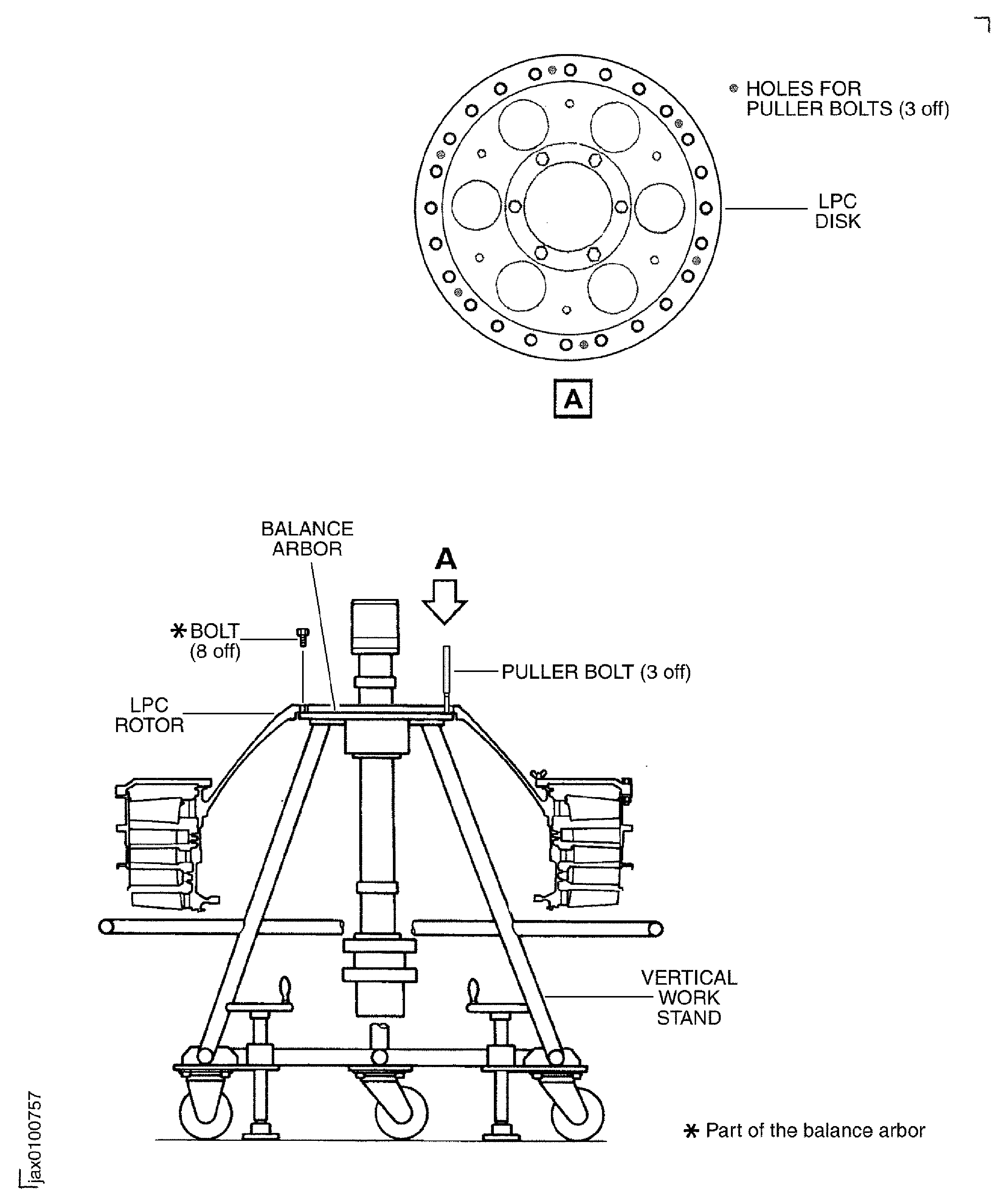

Install IAE 1J13107 Holding support 1 off to the front case and stage 1.5 LPC disk front flange.

SUBTASK 72-32-80-440-067 Remove the LPC Rotor from the Balance Cover and Fixture

Install three puller bolts (part of IAE 1J12188 Puller bolt 1 off) in to the three threaded holes out of six threaded holes in the LPC disk front flange. The three puller bolts must be installed approximately 120 degrees apart from each other.

Method 1: Install the vertical sling (IAE 1J13103 Vertical sling) to the LPC disk.

Method 2: Install the vertical sling (IAE 1J12213 LPC Vertical sling) to the LPC disk.

Slowly lower the LPC rotor on to IAE 1J13111 LPC storage stand the storage stand 1 off.

Method 1: Remove the vertical sling (IAE 1J13103 Vertical sling) from the LPC disk.

Method 2: Remove the vertical sling (IAE 1J12213 LPC Vertical sling) from the LPC disk.

SUBTASK 72-32-80-440-068 Remove the LPC Rotor from the Balance Arbor

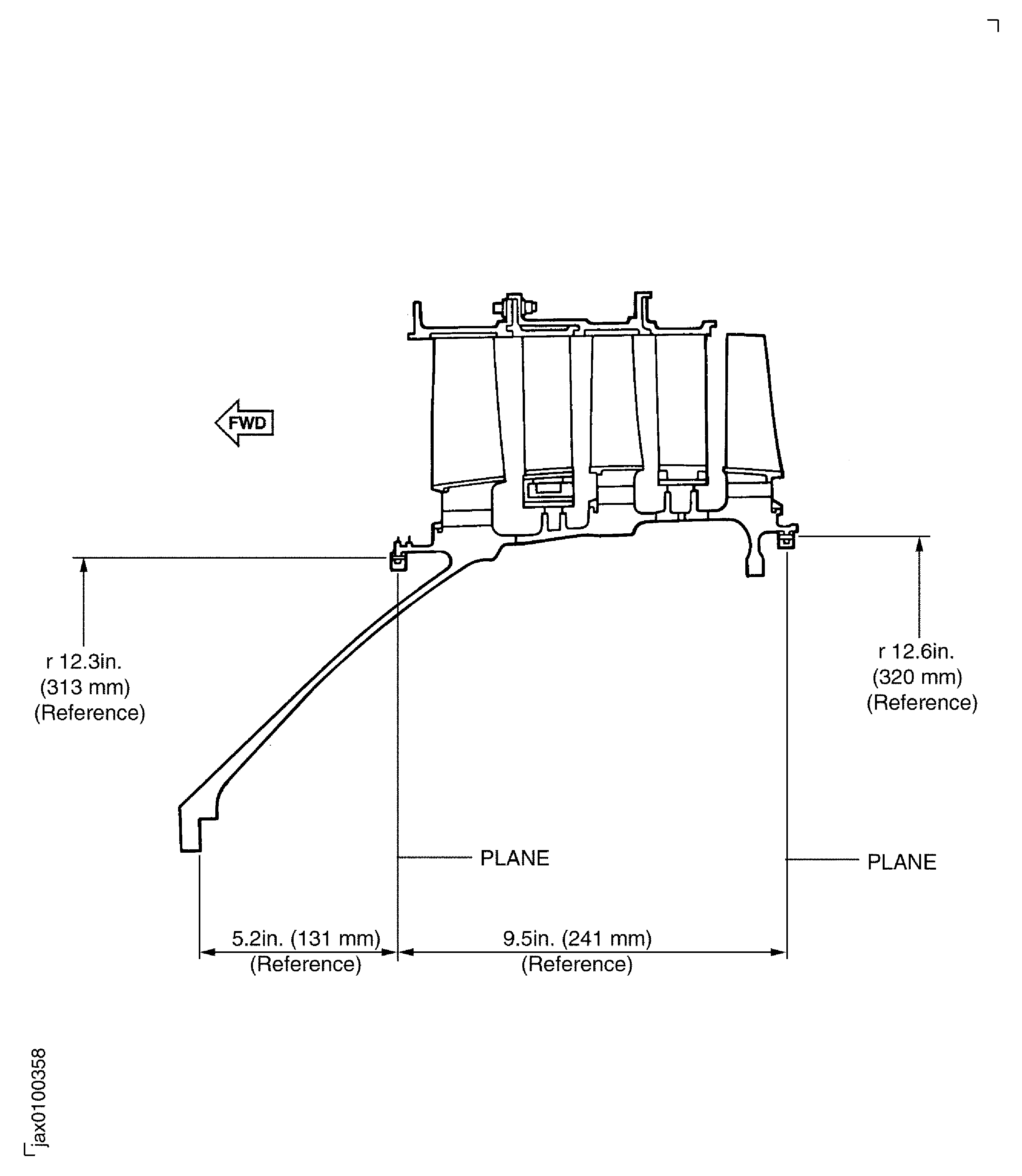

Figure: Sectional View of the LP Compressor Stage 1.5, 2 and 2.5 Assembly

Sectional View of the LP Compressor Stage 1.5, 2 and 2.5 Assembly

Figure: View of the LP Compressor Stage 1.5, 2 and 2.5 Disk and Blades

View of the LP Compressor Stage 1.5, 2 and 2.5 Disk and Blades

Figure: Positions of the Stage 1.5 and 2 Retaining Plates and Lockplates

Positions of the Stage 1.5 and 2 Retaining Plates and Lockplates

Figure: Positions of the Stage 2.5 Retaining Plates and Lockplates

Positions of the Stage 2.5 Retaining Plates and Lockplates

Figure: View of the LP Compressor Stage 1.5 and 2 Vanes

View of the LP Compressor Stage 1.5 and 2 Vanes

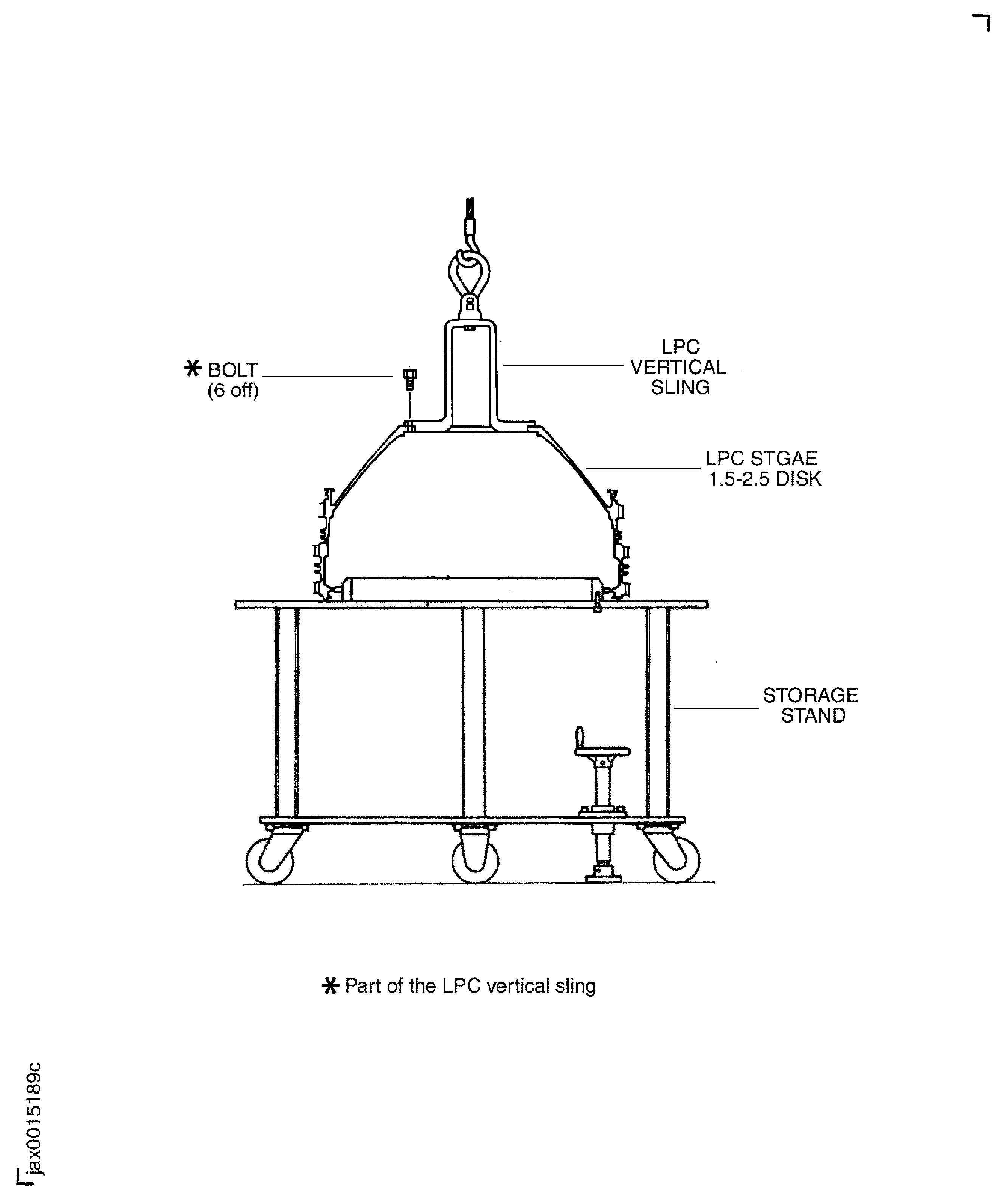

Figure: Preparation for the Installation of the LP Compressor Disk Assembly

Sheet 1

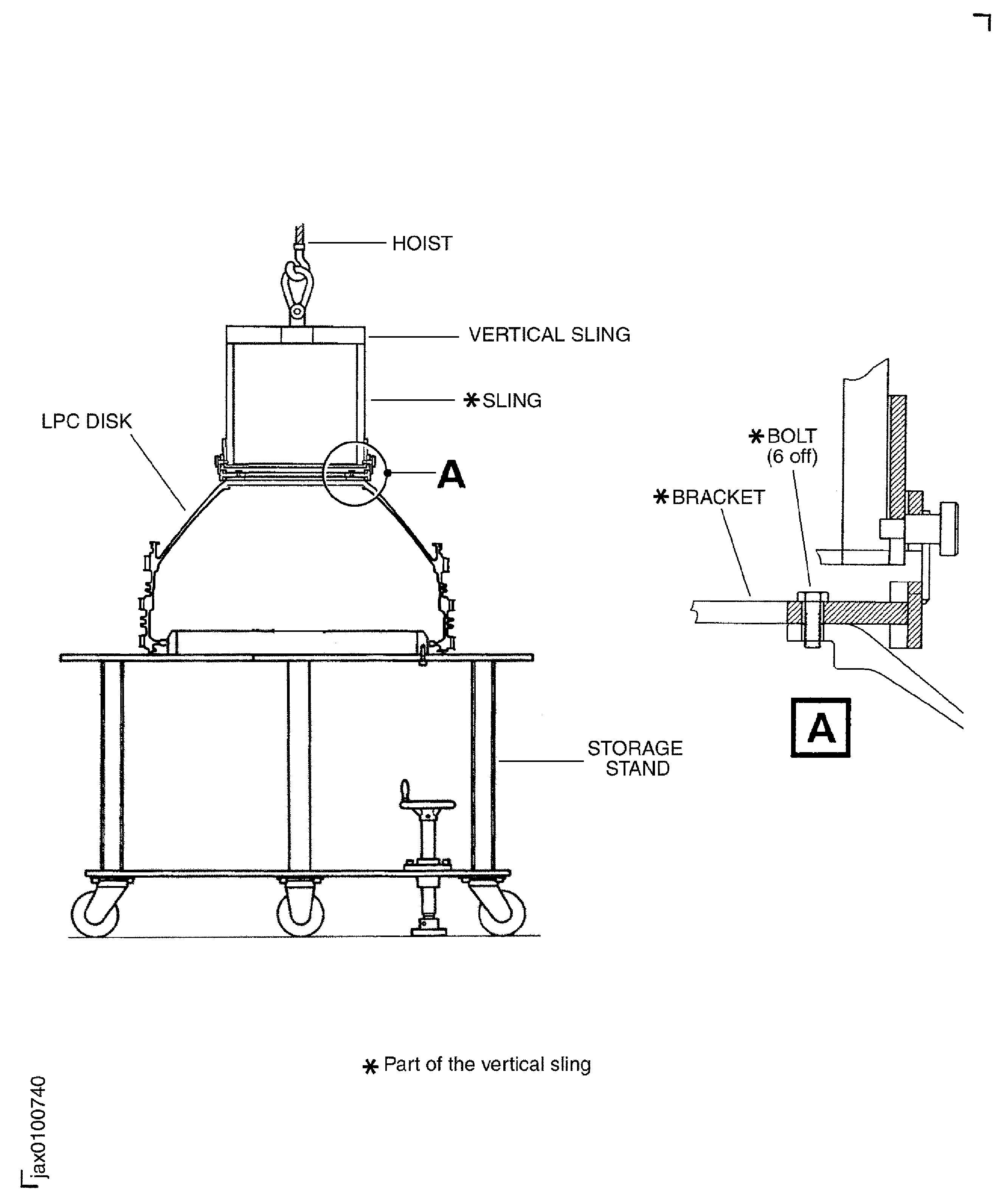

Figure: Preparation for the Installation of the LP Compressor Disk Assembly

Sheet 2

Figure: Method 1: Install the Vertical Sling to LP Compressor Disk Assembly

Sheet 1

Figure: Method 2: Install the Vertical Sling to LP Compressor Disk Assembly

Sheet 2

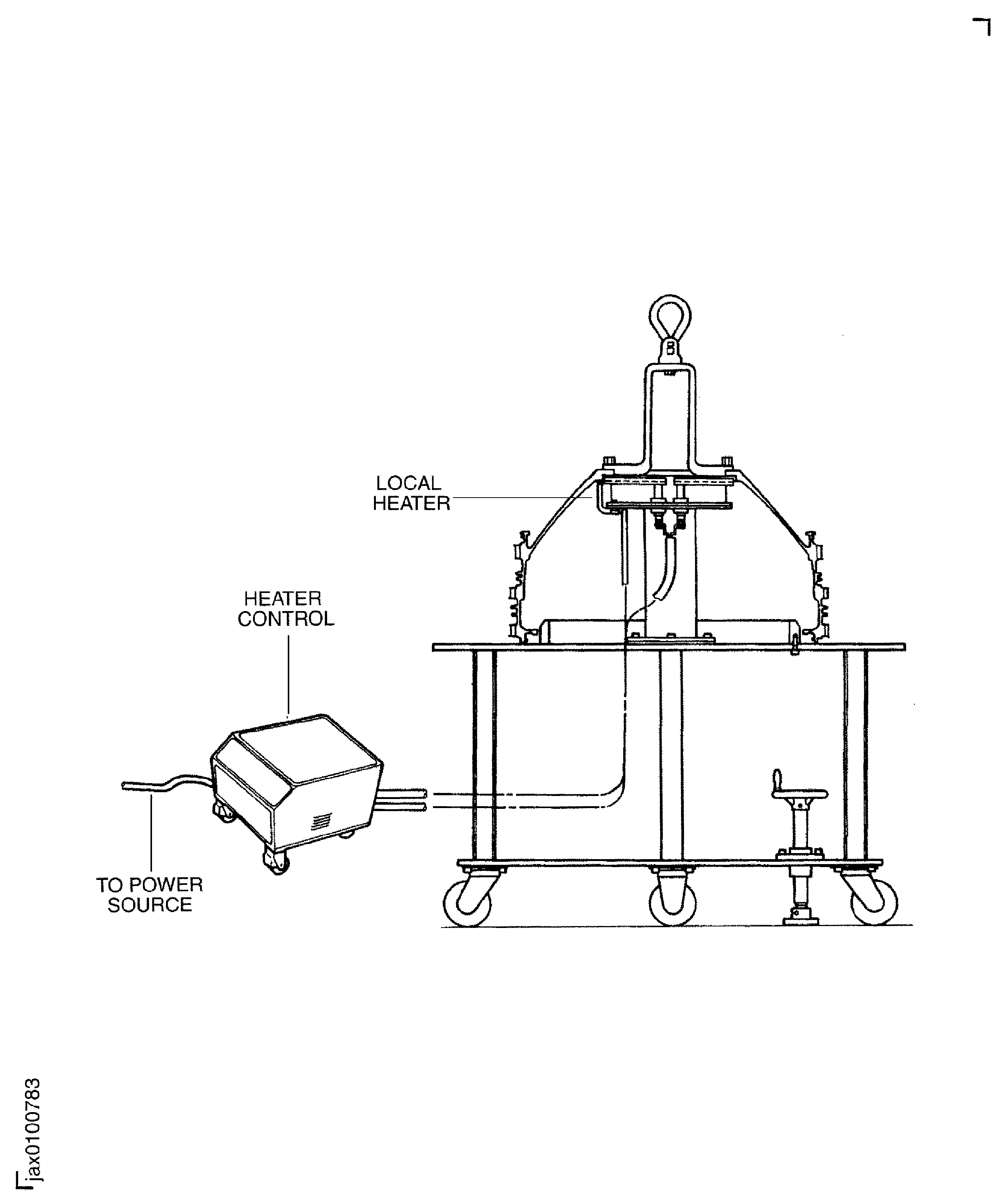

Figure: Method 1: Install the LP Compressor Disk Assembly on to the Heater

Sheet 3

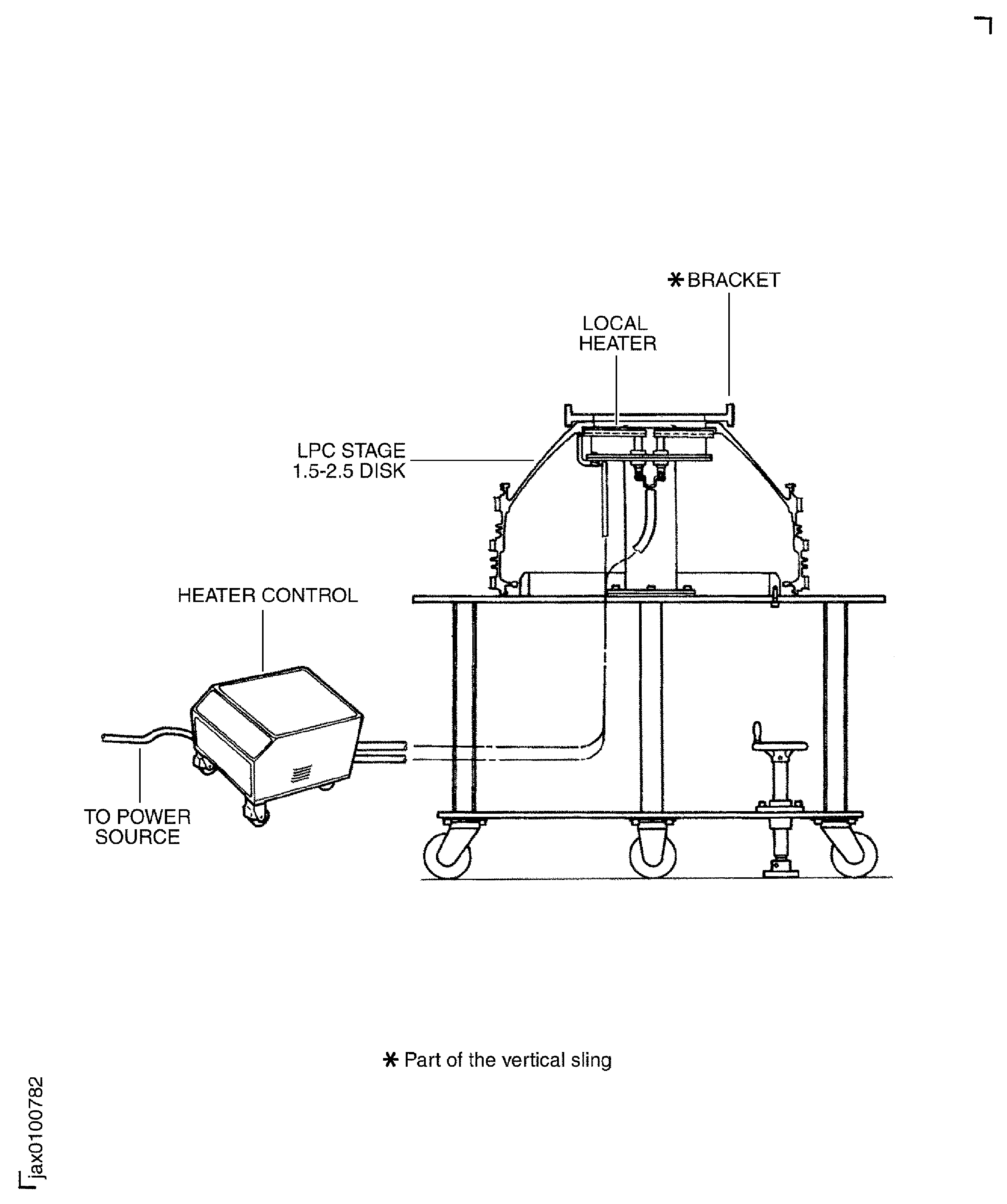

Figure: Method 2: Install the LP Compressor Disk Assembly on to the Heater

Sheet 4

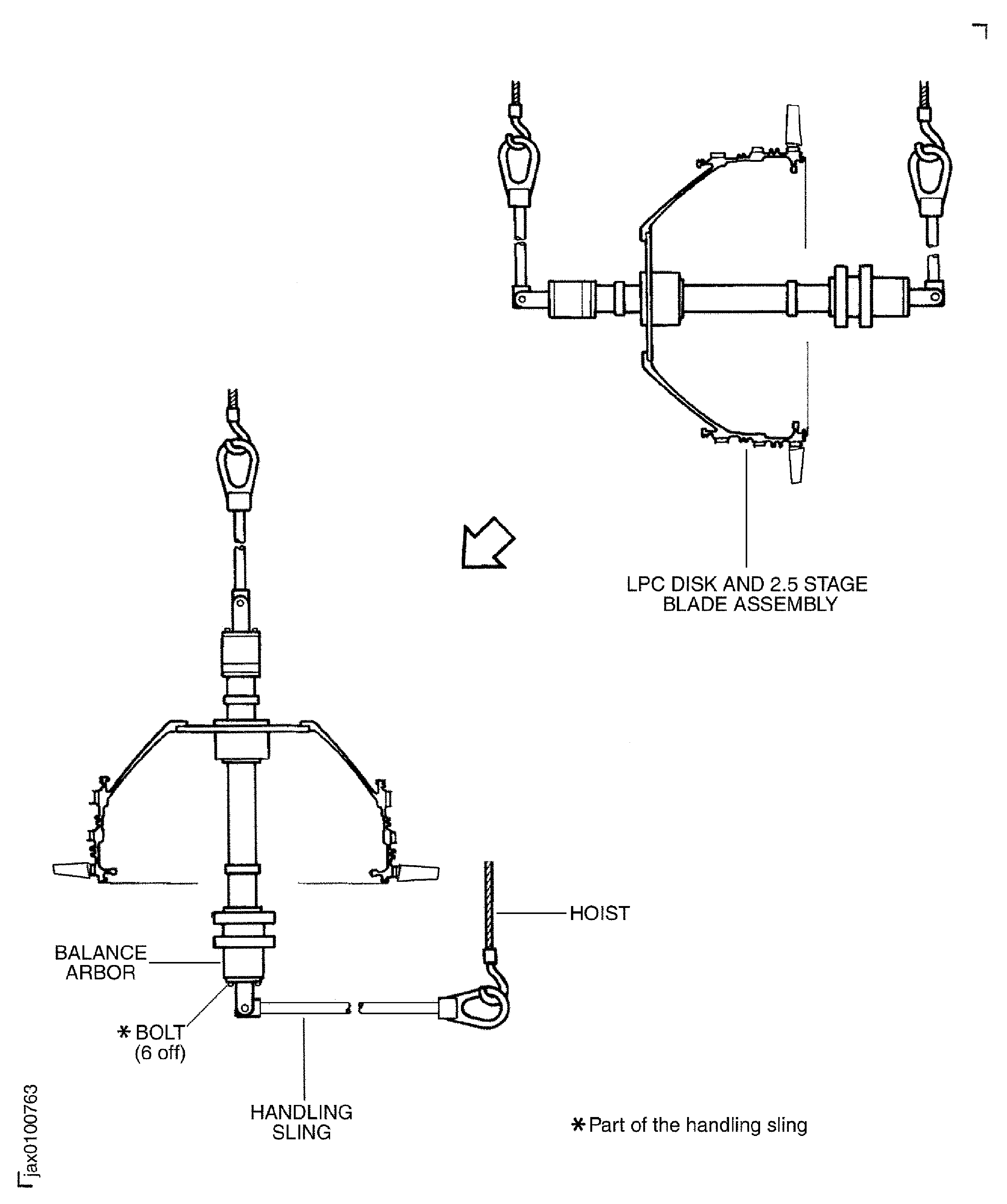

Figure: Install the LP Compressor Disk Assembly on to the Balance Arbor

Sheet 1

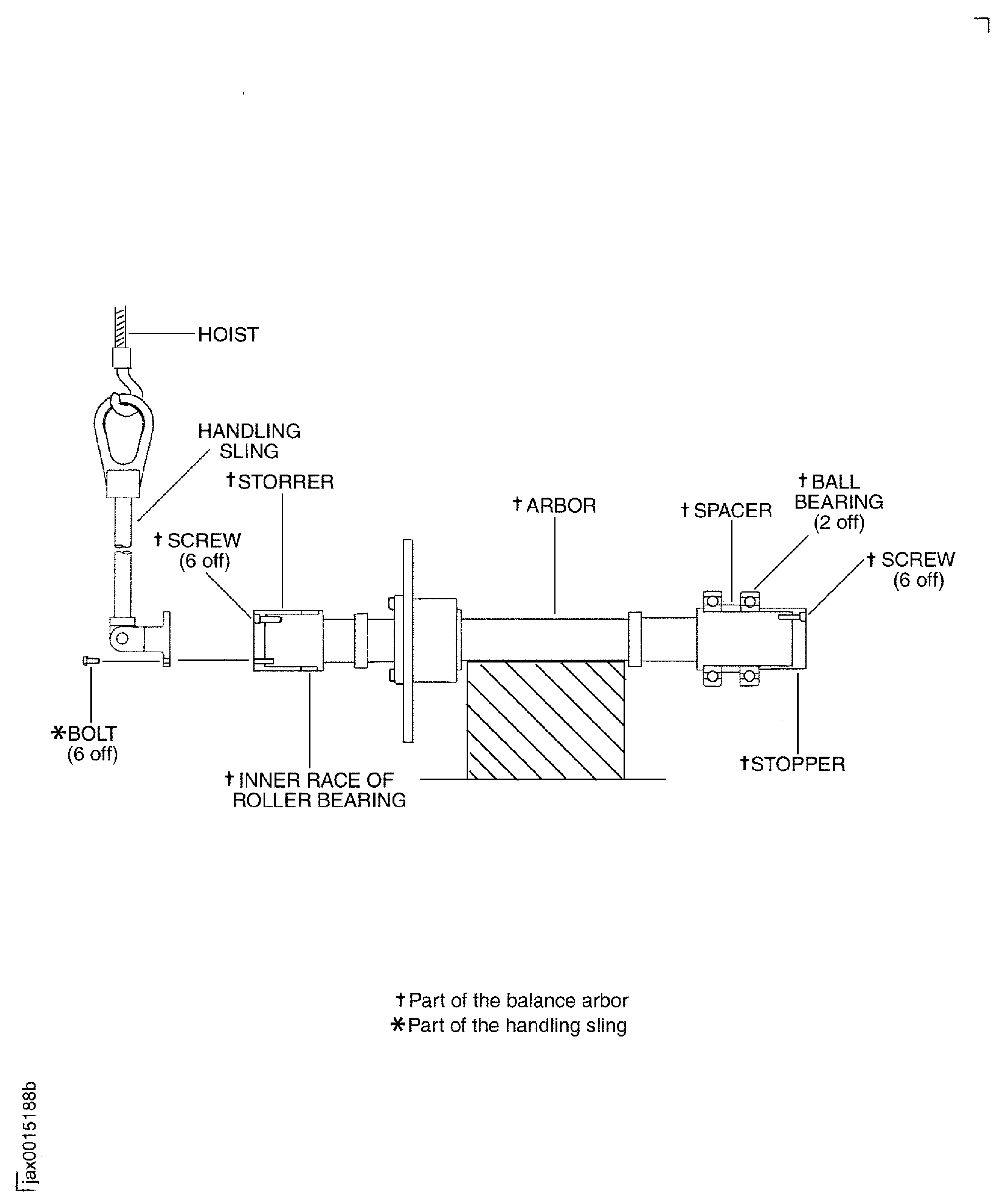

Figure: Install the Handling Sling on to the Balance Arbor

Sheet 2

Figure: Move the LPC Disk and Balance Arbor Assembly from Vertical Work Stand to the Horizontal Work Stand

Sheet 1

Figure: Move the LPC Disk and Balance Arbor Assembly from Vertical Work Stand to the Horizontal Work Stand

Sheet 2

Figure: The Sequence Diagram to Install the LP Compressor Blades

The Sequence Diagram to Install the LP Compressor Blades

Figure: Install the LP Compressor Stage 2.5 Blades to the Disk

Sheet 1

Figure: Install the LP Compressor Stage 2.5 Blades to the Disk

Sheet 2

Figure: Install the LP Compressor Stage 2.5 Blades to the Disk

Sheet 3

Figure: Remove the Front Balance Cover from the Mid Balance CoverF

Sheet 4

Figure: Remove the Support Ring from the Mid Balance Cover

Sheet 5

Figure: Remove the Mid Balance Cover from the Rear Balance Cover

Sheet 6

Figure: Move the LPC Disk, Stage 2.5 Blades and Arbor Assembly from the Horizontal Work Stand to the Balance Cover

Sheet 7

Figure: Install the two Handling Slings to the Balance Arbor

Sheet 8

Figure: Install the two Handling Slings to the Balance Arbor

Sheet 9

Figure: Move the LPC Disk, Stage 2.5 Blade and Arbor Assembly from the Horizontal Stand to the Transport Stand

Sheet 10

Figure: Move the LPC Disk, Stage 2.5 Blades and Arbor Assembly from the Horizontal Work Stand to the Balance Cover

Sheet 1

Figure: Apply the Jointing Compound on to the Mating Faces of the Stage 2.0 Vane and the Rear LP Compressor Case

Sheet 2

Figure: Install the Stage 2.0 LP Compressor Vane in to the Rear LP Compressor Case

Sheet 3

Figure: Install the Stage 2 LP Compressor Vane and Case Assembly on to the LPC Disk and Rear Balance Cover

Install the Stage 2 LP Compressor Vane and Case Assembly on to the LPC Disk and Rear Balance Cover

Figure: Install the LP Compressor Stage 2 Blades and the LP Compressor Stage 1.5 Blades to the Disk

Sheet 1

Figure: Install the LP Compressor Stage 2 Blades and the LP Compressor Stage 1.5 Blades to the Disk

Sheet 2

Figure: Install the LP Compressor Stage 2 and 1.5 Blades to the Disk

Sheet 3

Figure: Apply the Jointing Compound on to the Mating Faces of the Stage 1.5 Vane, the LP Compressor Front Case and the Rear LP Compressor Case

Sheet 4

Figure: Install the Stage 1.5 LP Compressor Vane and the Front LP Compressor Case on to the Rear LP Compressor Case and Stage 2.0 LP Compressor

Install the Stage 1.5 LP Compressor Vane and the Front LP Compressor Case on to the Rear LP Compressor Case and Stage 2.0 LP Compressor

Figure: Install the Mid Balance Cover on to the Rear Balance Cover

Sheet 1

Figure: Install the Support Ring on to the Mid Balance Cover and Front LP Compressor Case

Sheet 2

Figure: Install the Front Balance Cover on to the Mid Balance Cover

Sheet 3

Figure: Install the two Cables Sling on to the Trunnions

Sheet 4

Figure: Turn the LPC Rotor, Balance Arbor and Balance Cover Assembly from the Vertical to the Horizontal

Sheet 5

Figure: Install the LPC Rotor, Balance Arbor and Balance Cover Assembly to the Balancing Machine

Install the LPC Rotor, Balance Arbor and Balance Cover Assembly to the Balancing Machine

Figure: Set up for Run out Checks and Dynamic Balancing

Sheet 1

Figure: Examine the Initial Unbalance of the LPC Rotor

Sheet 2

Figure: Tubular Rivet and Balance Counter Weight

Sheet 3

Figure: Remove the LP Compressor Rotor from the Balancing Machine

Sheet 4

Figure: Install the Holding Supports

Sheet 1

Figure: Release the Ball Bearing from the Bear Balance Cover

Sheet 2

Figure: Install the LPC Rotor to the Vertical Work Stand

Sheet 3

Figure: Remove the LPC Rotor from the Balance Arbor

Sheet 4

Figure: Method 1: Install the Vertical Sling to the LPC Disk

Sheet 5

Figure: Method 2: Install the Vertical Sling to the LPC Disk

Sheet 6

Figure: Remove the LP Compressor Stage 1.5, 2 and 2.5 Assembly from the Balance Arbor

Remove the LP Compressor Stage 1.5, 2 and 2.5 Assembly from the Balance Arbor

Figure: Locations of the Sub-Module Serial Number and Sub-Module Number

Locations of the Sub-Module Serial Number and Sub-Module Number