Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-32-80-440-001-B00 LPC Assembly - Assemble The LPC Cases And Vanes To The Rotor Assembly, Assembly-001

General

This task gives the procedure to assemble the LP compressor booster stage assembly.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedure refer to the SPM and SPM TASK 70-41-01-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

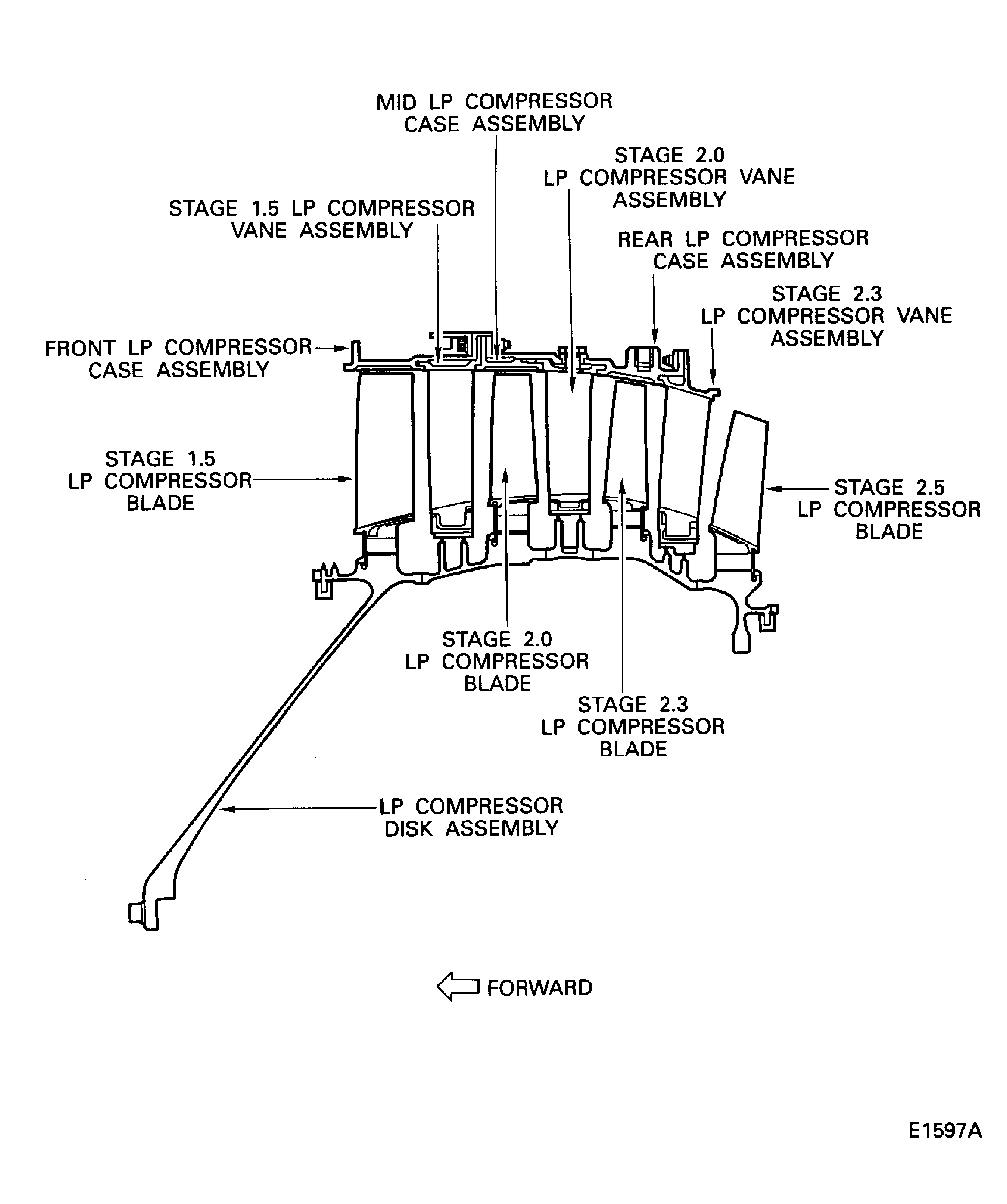

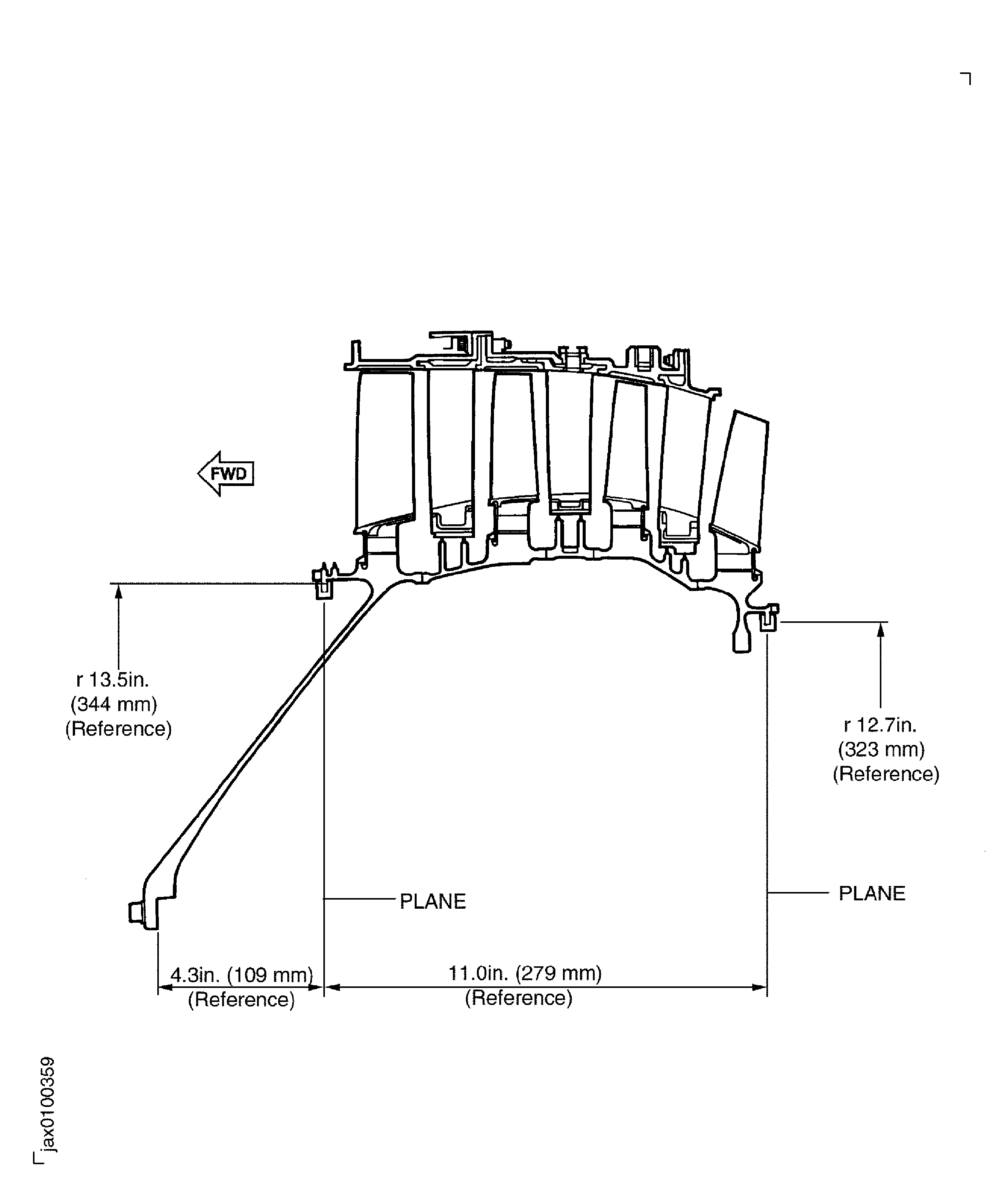

Refer to Figure for a sectional view of the LP compressor booster stage assembly.

Refer to Figure for a view of the LP compressor booster stage blades and disk.

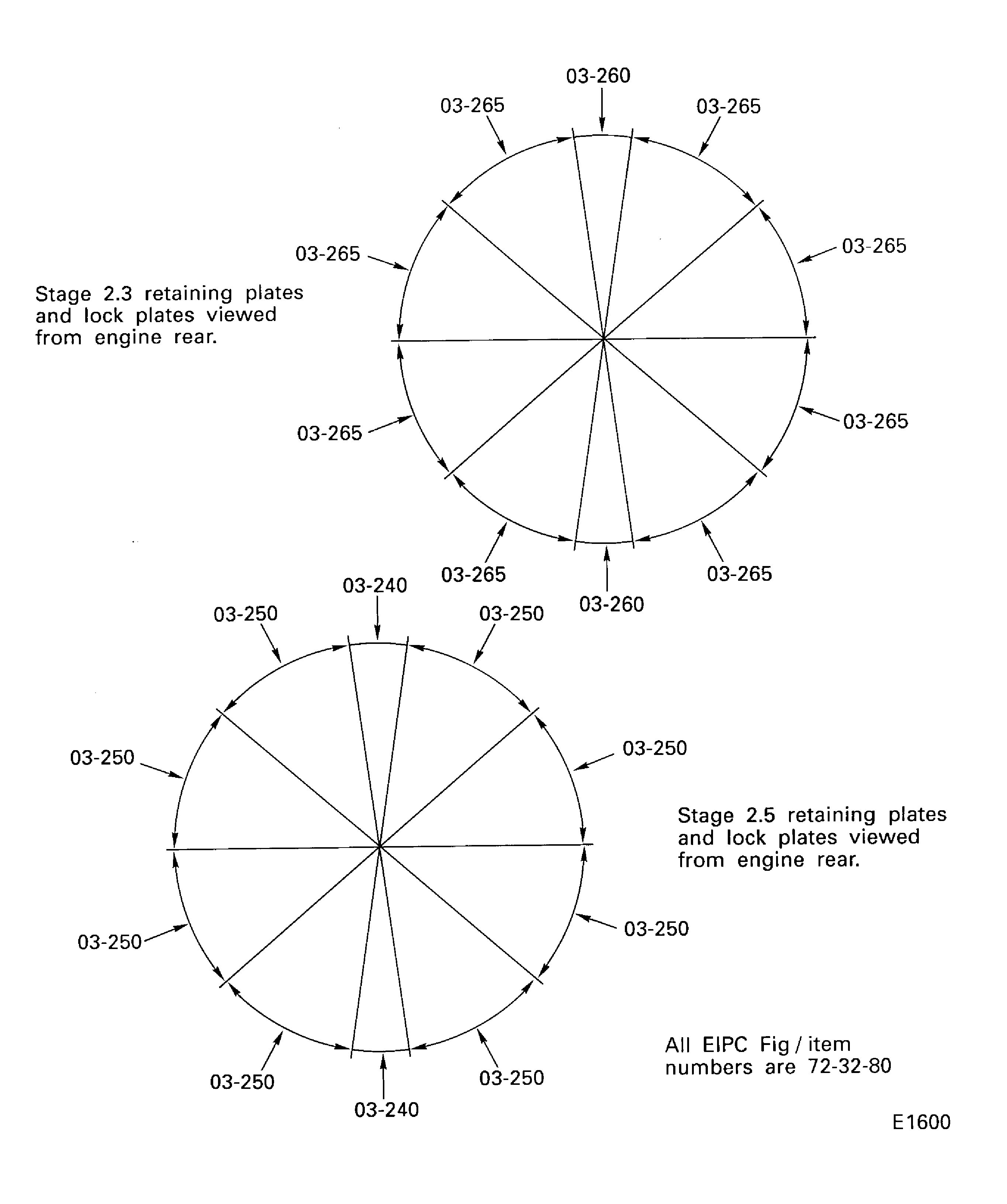

Refer to Figure for positions of the LP compressor booster stage blades retaining plates and lock plates.

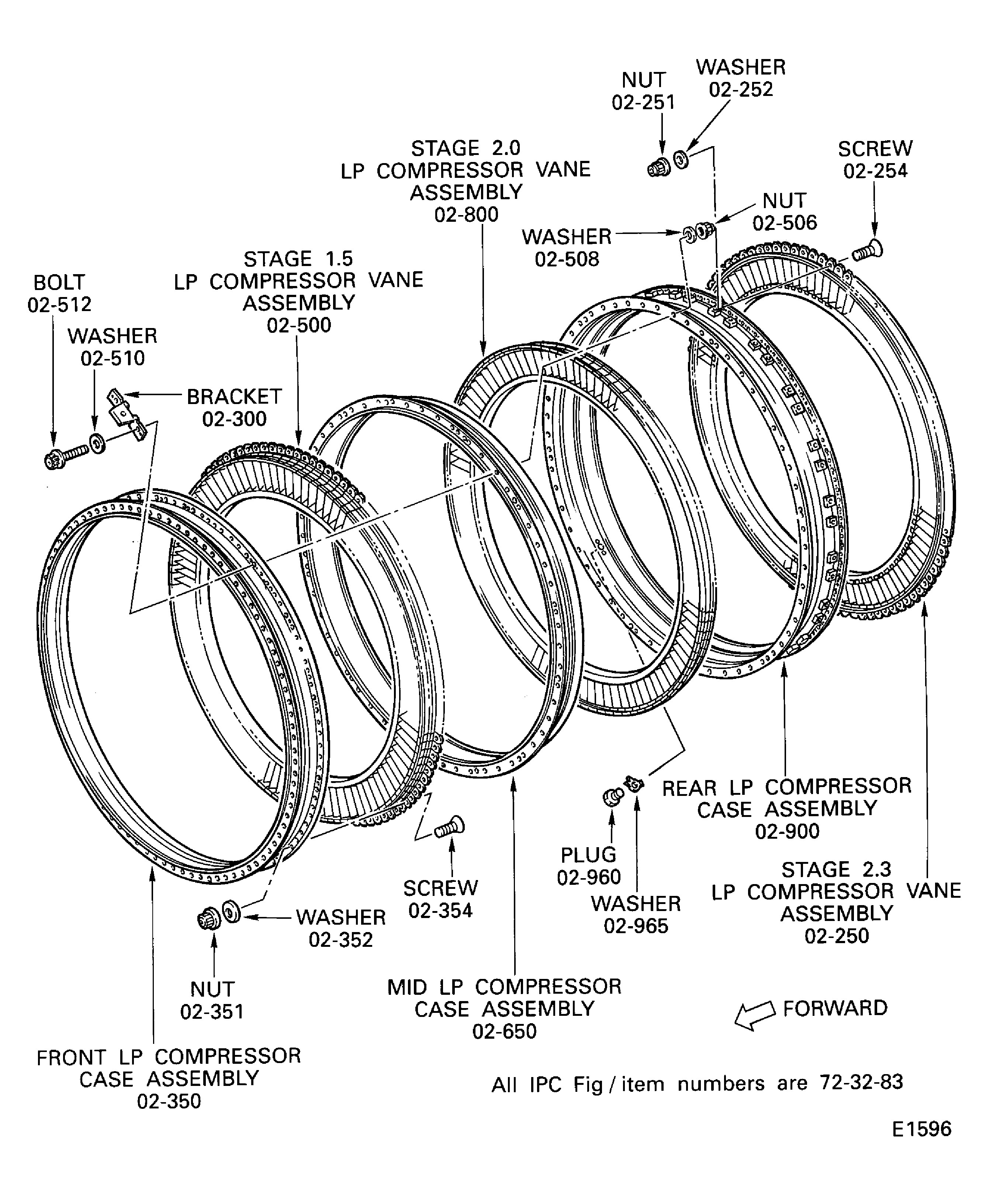

Refer to Figure for a view of the LP compressor booster stage vanes.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Dynamic balancing machine | LOCAL | Schenck HL-5U | or equivalent | |

| Dial caliper | LOCAL | Dial caliper | ||

| File | LOCAL | File | ||

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 1 | |

| IAE 1J12188 Puller bolt | 0AM53 | IAE 1J12188 | 1 | |

| IAE 1J12213 LPC Vertical sling | 0AM53 | IAE 1J12213 | 1 | |

| IAE 1J12399 Handling sling | 0AM53 | IAE 1J12399 | 1 | |

| IAE 1J12410 Transport stand | 0AM53 | IAE 1J12410 | 1 | |

| IAE 1J12505 0AM53 heater | 0AM53 | IAE 1J12505 | 1 | |

| IAE 1J12507 Guide pin | 0AM53 | IAE 1J12507 | 1 | |

| IAE 1J12532 Balance fixture | 0AM53 | IAE 1J12532 | 1 | |

| IAE 1J12533 Storage stand | 0AM53 | IAE 1J12533 | 1 | |

| IAE 1J12535 Balance adapter | 0AM53 | IAE 1J12535 | 1 | |

| IAE 1J12541 Holding support | 0AM53 | IAE 1J12541 | 1 | |

| IAE 1J12542 Long support | 0AM53 | IAE 1J12542 | ||

| IAE 1J12554 Storage stand | 0AM53 | IAE 1J12554 | 1 | |

| IAE 1J13100 Tab bender | 0AM53 | IAE 1J13100 | 1 | |

| IAE 1J13206 Horizontal work stand | 0AM53 | IAE 1J13206 | 1 | |

| IAE 1J13209 Riveter | 0AM53 | IAE 1J13209 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE | LOCAL | CoMat 04-004 | ||

| CoMat 06-069 MARKER | IE207 | CoMat 06-069 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| PLATE - LOCK | 0AM53 | 5R0152 | 2 | 72-32-80, 03-210 |

| PLATE - LOCK | 0AM53 | 5R0154 | 2 | 72-32-80, 03-225 |

| PLATE - LOCK | 0AM53 | 5R0158 | 2 | 72-32-80, 03-240 |

| PLATE - LOCK | 0AM53 | 5R0156 | 2 | 72-32-80, 03-260 |

| WASHER | 96906 | MS9581-12 | 1 | 72-32-83, 02-965 |

Safety Requirements

NONEProcedure

Refer to Figure.

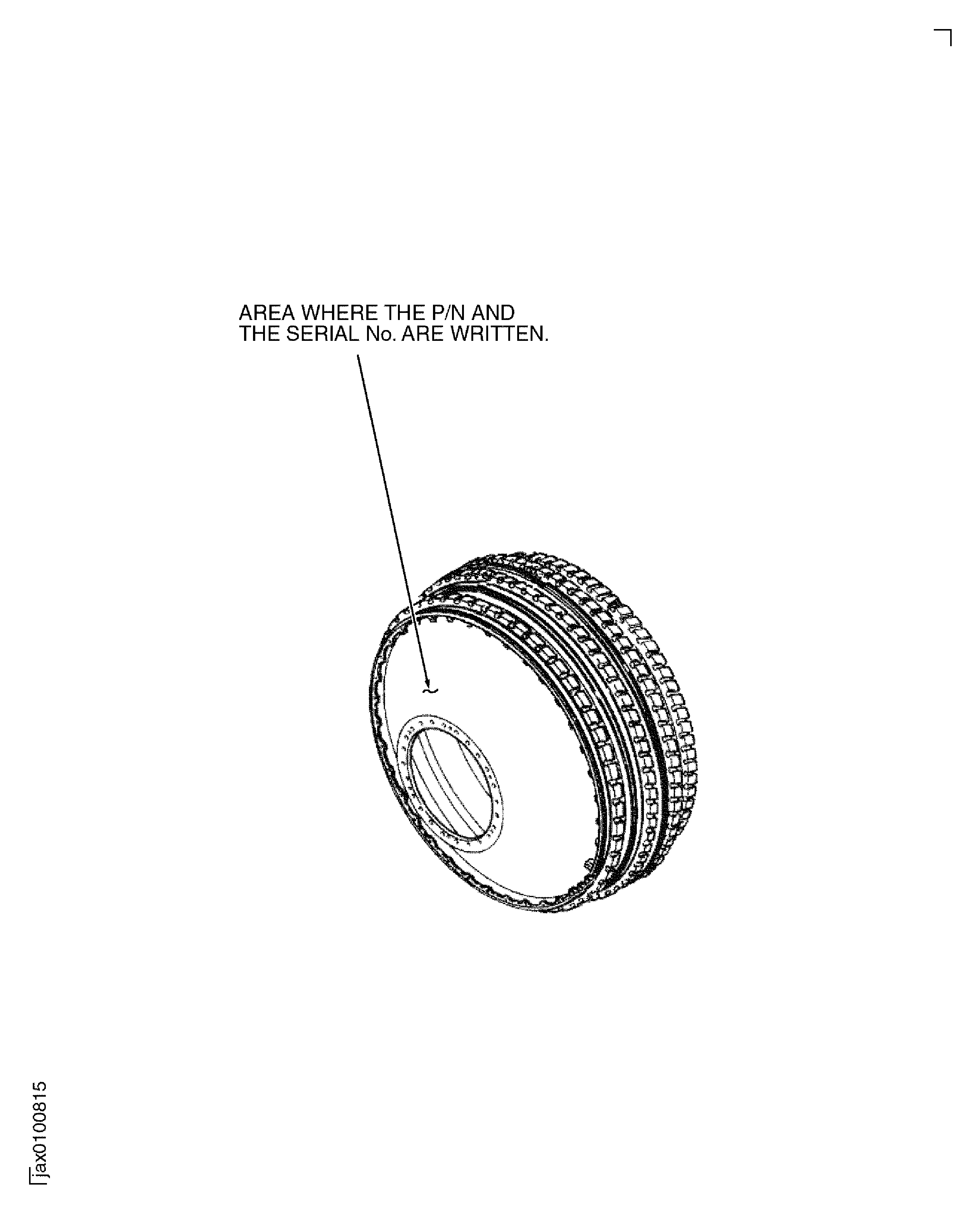

Write the sub-module number and serial number on the specified area with electrochemical etching. Refer to the SPM TASK 70-09-00-400-501 for mark procedure.

If the sub-module number and serial number are not written, write them on the specified area on the LP compressor booster stage assembly.

SUBTASK 72-32-80-440-095 Identify the LP Compressor Booster Stage Assembly (Sub-Module)

Refer to Figure.

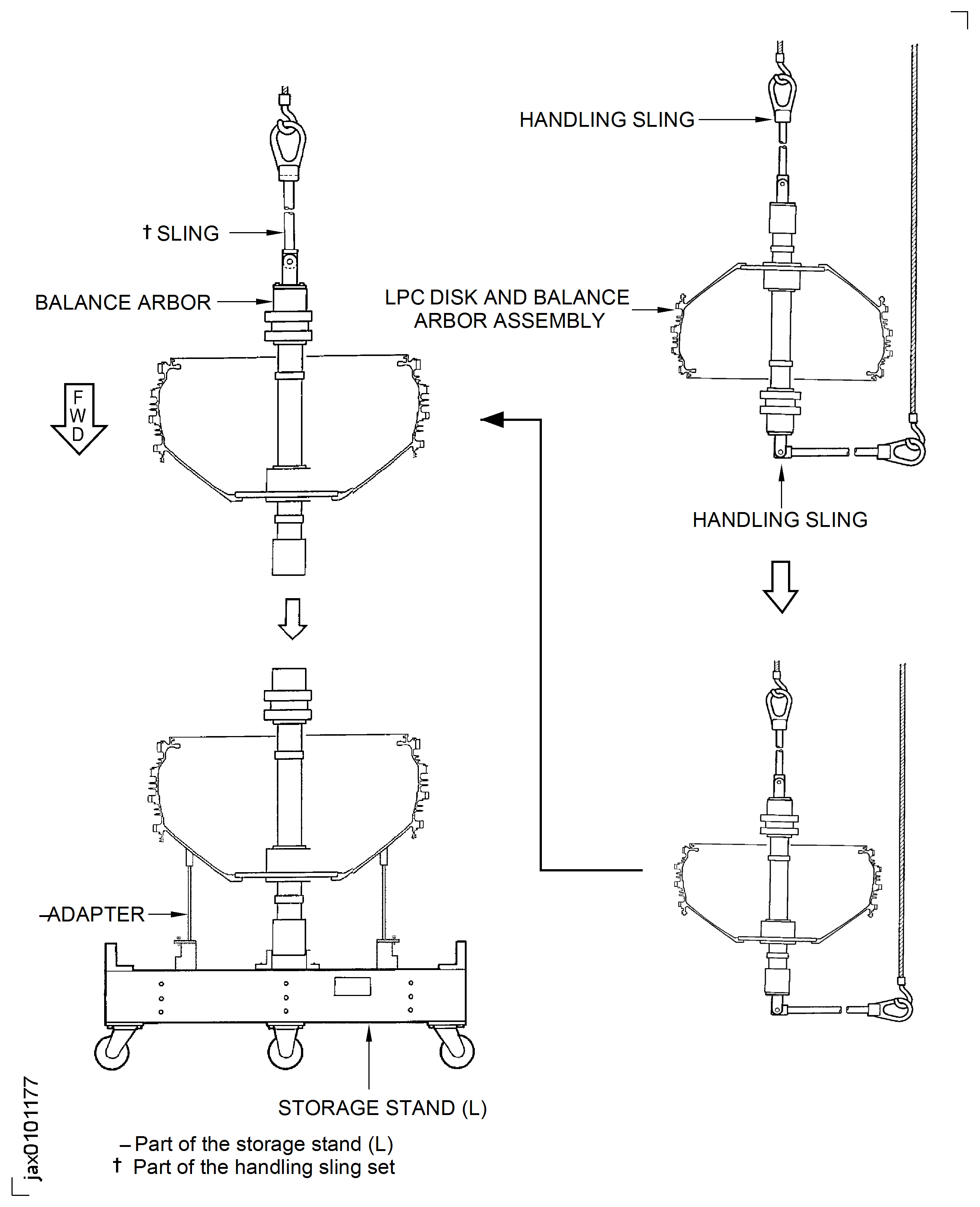

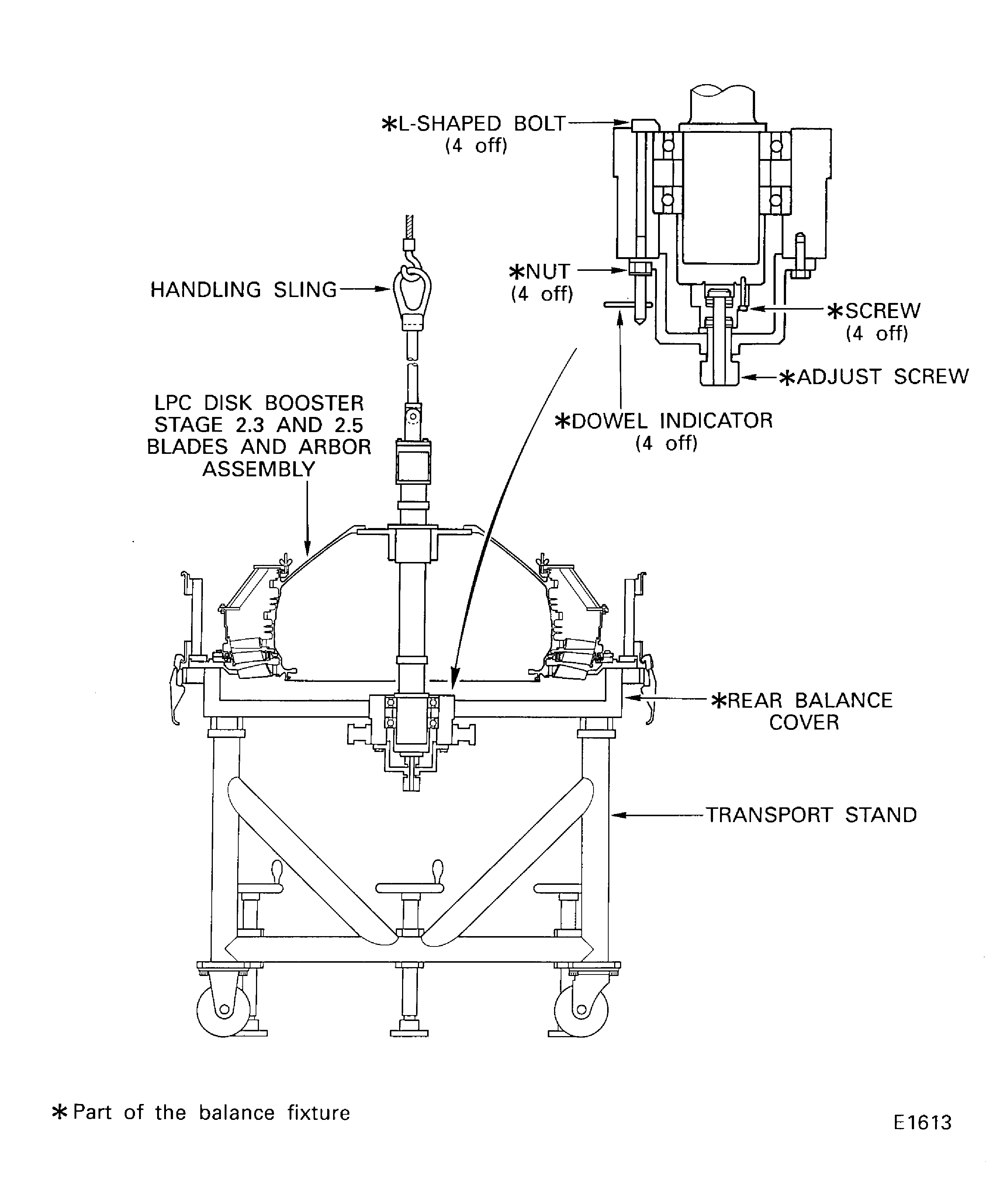

Move IAE 1J12410 Transport stand 1 off, IAE 1J12535 Balance adapter 1 off, IAE 1J12532 Balance fixture 1 off and IAE 1J12399 Handling sling 1 off to the work area.

SUBTASK 72-32-80-440-070 Preparation for the Installation of the LP Compressor Booster Stage Disk Assembly (72-32-81,02-200) on to the Balance Arbor

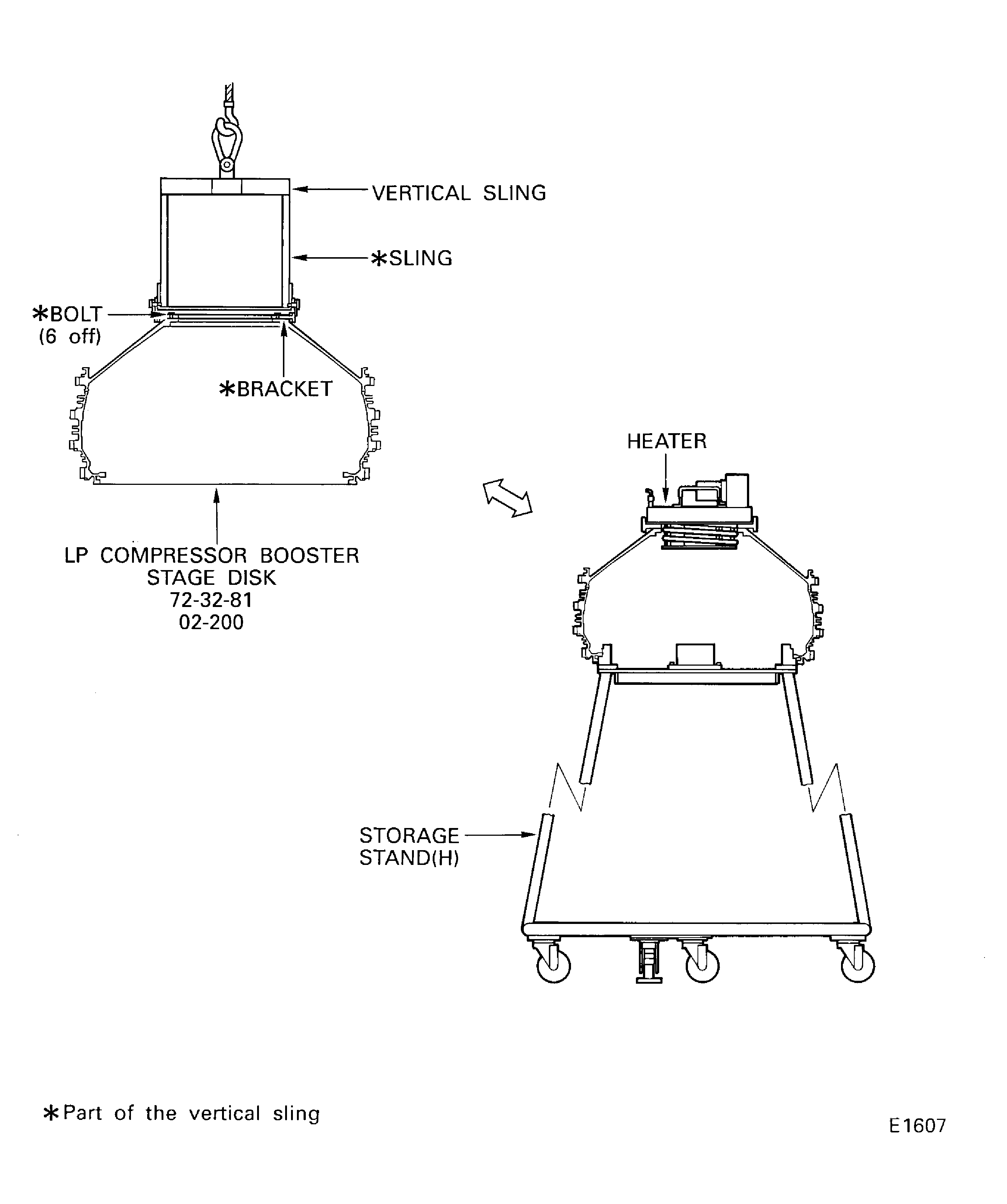

Move IAE 1J12213 LPC Vertical sling 1 off and IAE 1J12505 0AM53 heater 1 off to the work area.

Attach a hoist to the vertical sling and lift and move the disk on to the IAE 1J12554 Storage stand 1 off.

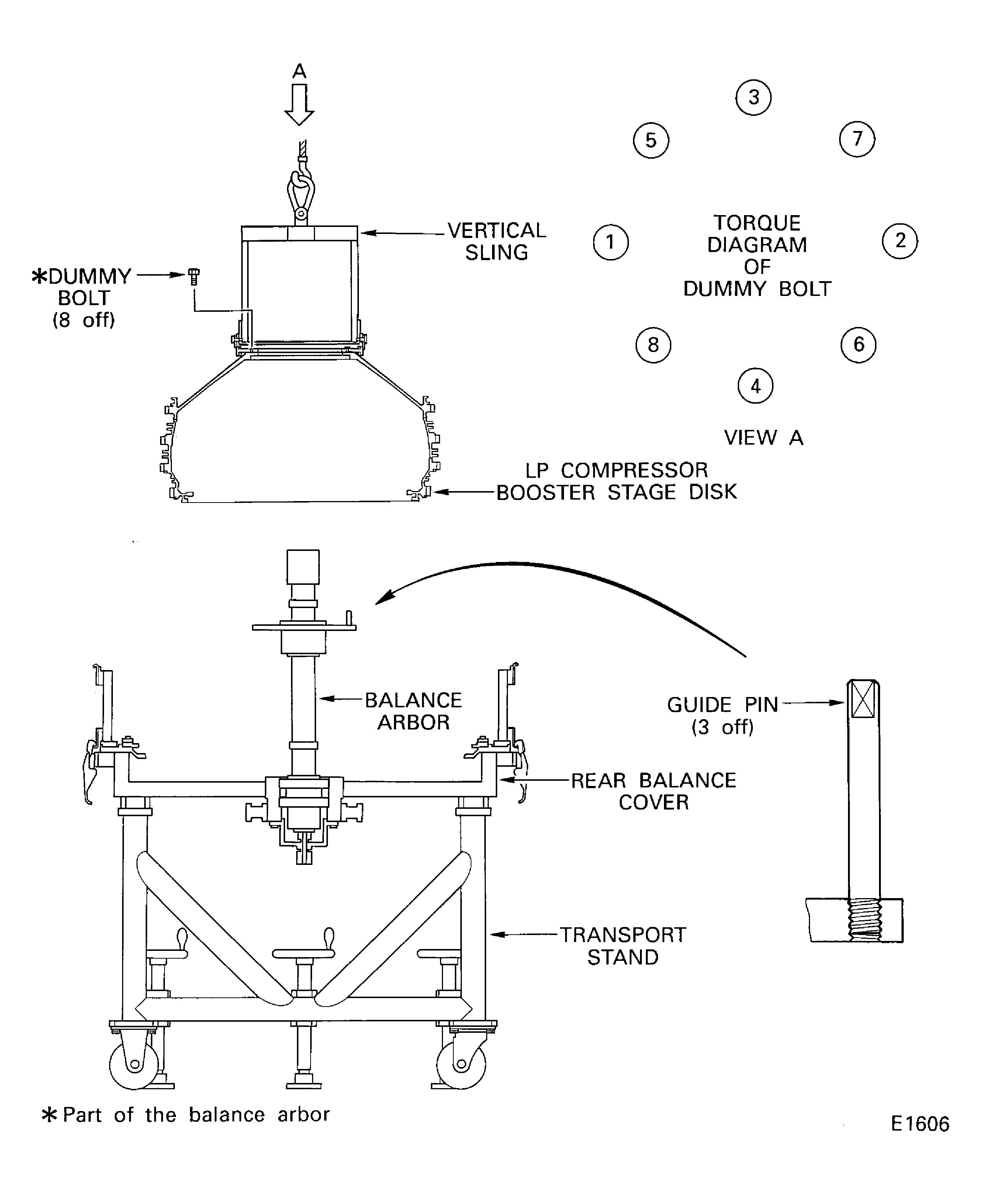

Install the three guide pins (part of IAE 1J12507 Guide pin 1 off) in to the three threaded holes in the flange of the balance arbor.

SUBTASK 72-32-80-440-071 Install the LP Compressor Booster Stage Disk on the Balance Arbor

Refer to Figure.

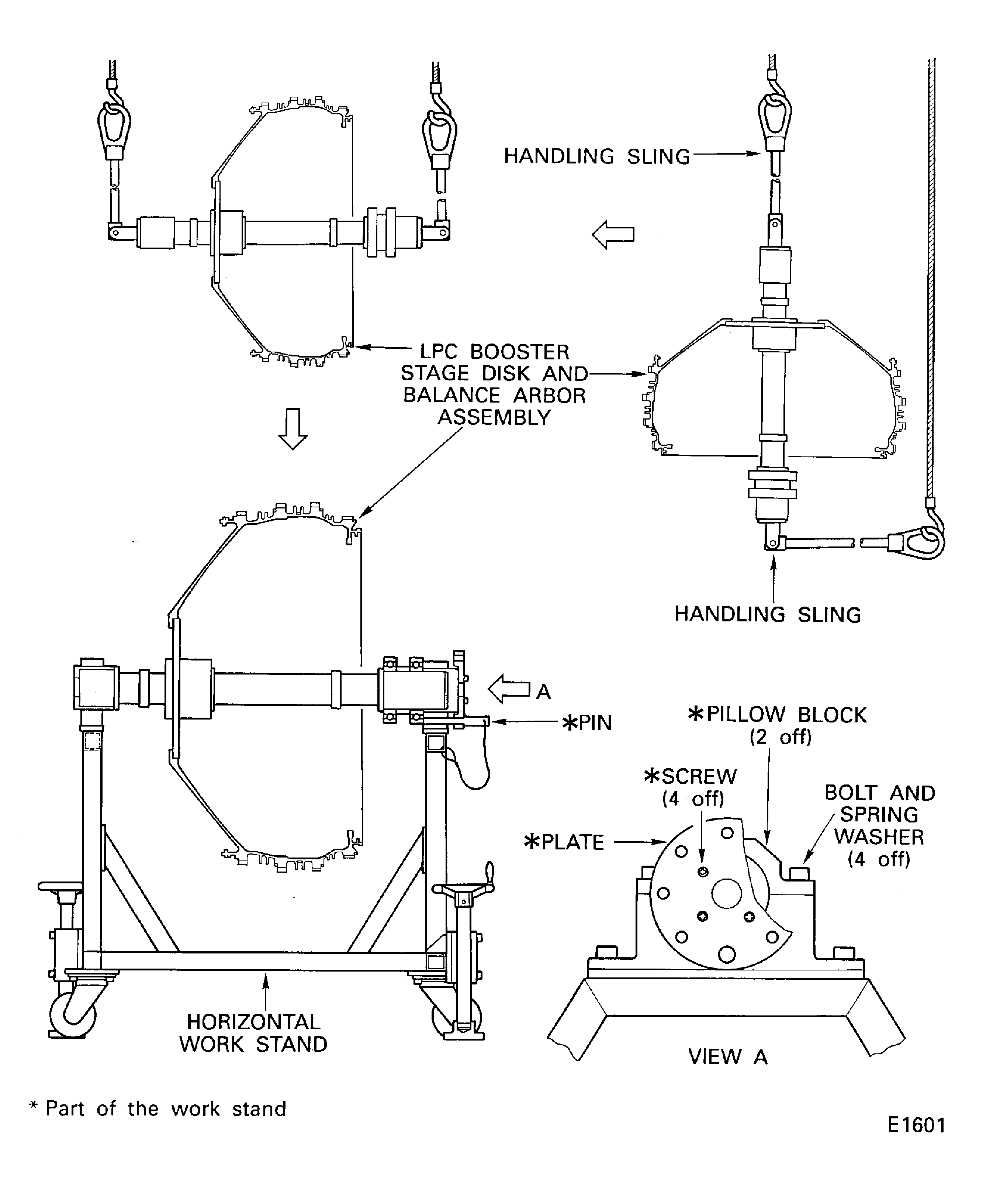

Move the handling sling and the IAE 1J13206 Horizontal work stand 1 off to the work area.

SUBTASK 72-32-80-440-072 Turn the LPC Disk and Balance Arbor Assembly from Vertical to the Horizontal

NOTE

If you use IAE 1J13206 Horizontal work stand to install the stage 2.3 blades to the disk, do this step.Refer to Figure.

Move the IAE 1J12399 Handling sling and the IAE 1J12533 Storage stand 1 off to the work area.

Install the IAE 1J12399 Handling sling on to the top end of the balance arbor and safety the sling with the six bolts of the sling.

Attach a hoist to the sling and lift slowly until the balance arbor is clear of the transport stand.

Attach another IAE 1J12399 Handling sling on to the bottom end of the balance arbor and safety it with the six bolts of the sling.

Attach another hoist to the bottom sling and lift the hoist and turn over the LPC disk and balance arbor assembly with the rear end up.

Remove the sling from the front end of the balance arbor.

Install the adapter (part of the storage stand (L)) on to the storage stand (L). Safety the adapter with the 12 screws.

Slowly lower and put the LPC disk and balance arbor assembly on to the storage stand (L).

Remove the sling from the rear end of the disk.

SUBTASK 72-32-80-440-097 Put the LPC Disk and Balance Arbor Assembly on to the Storage Stand (L)

NOTE

If you use IAE 1J12533 Storage stand to install the stage 2.3 blades to the disk, do this step.Refer to Figure.

NOTE

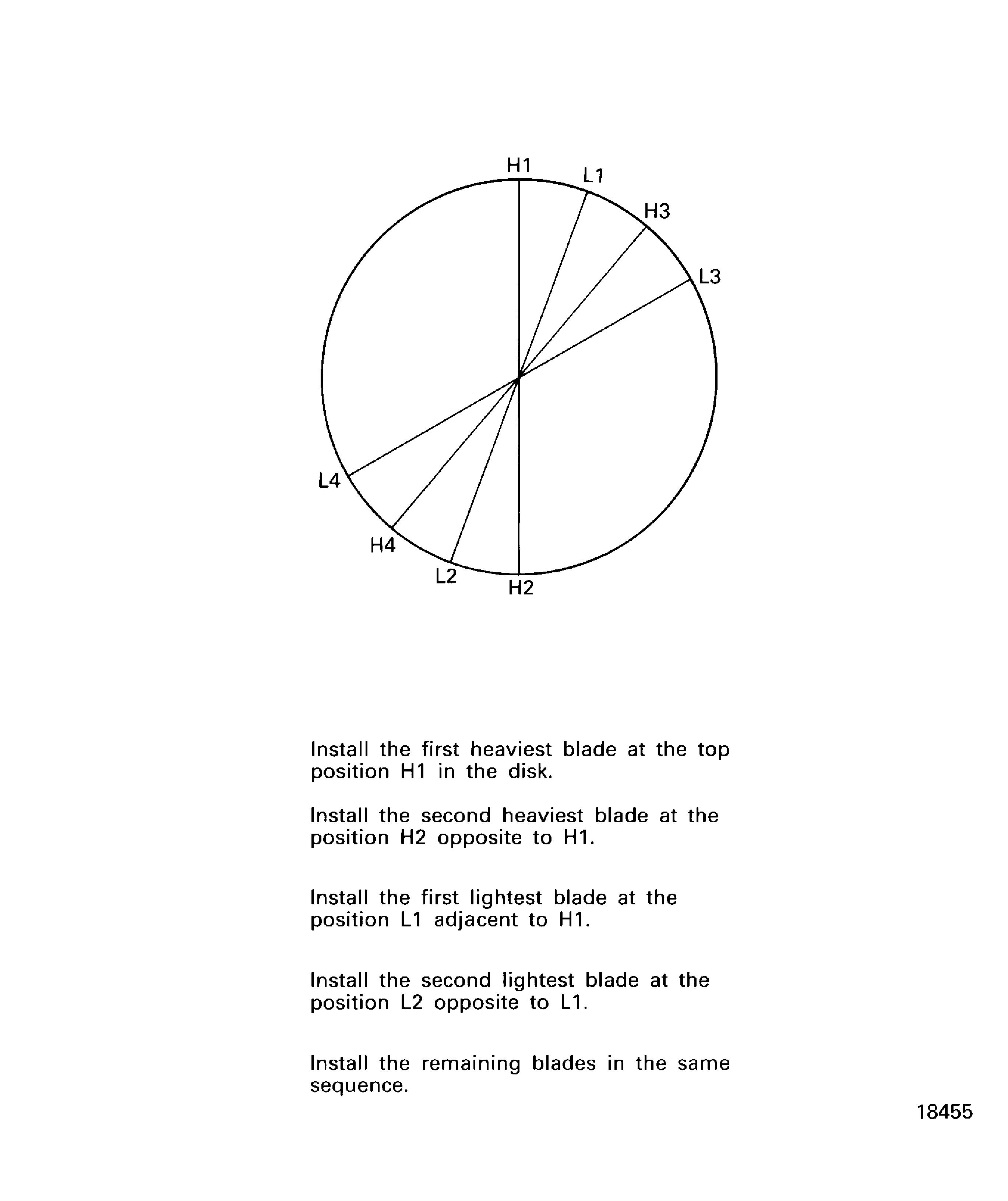

If computer calculated assembly sequence is available, it is better than the heavy-light-heavy sequence.Write the weight and the identification code on the blade convex airfoil surface with CoMat 06-069 MARKER.

SUBTASK 72-32-80-440-073 Weigh the Stage 1.5 Blades (72-32-82, 02-400), the Stage 2 Blades (72-32-82, 02-250), the Stage 2.3 Blades (72-32-83, 02-550) and the Stage 2.5 Blades (72-32-82, 02-100)

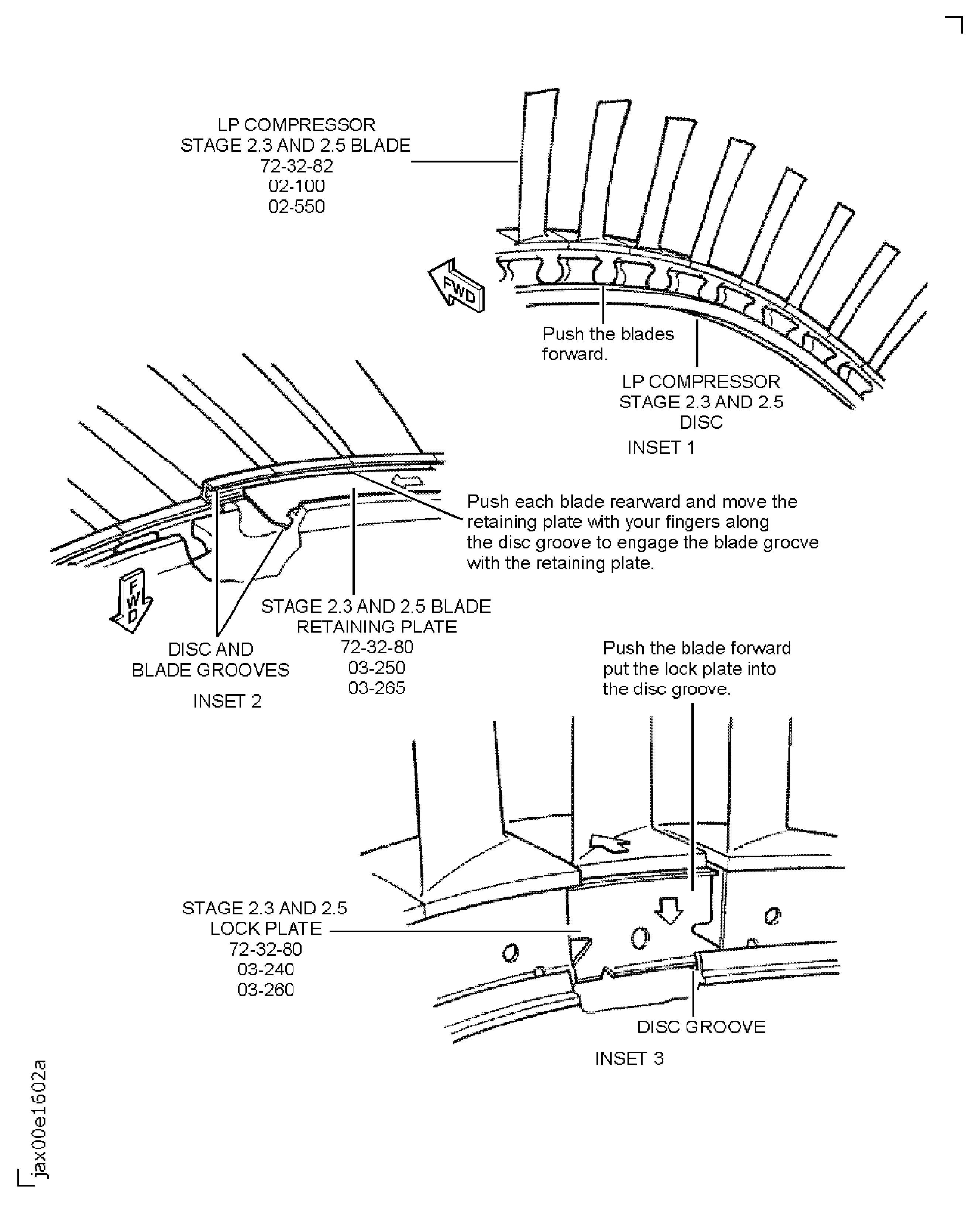

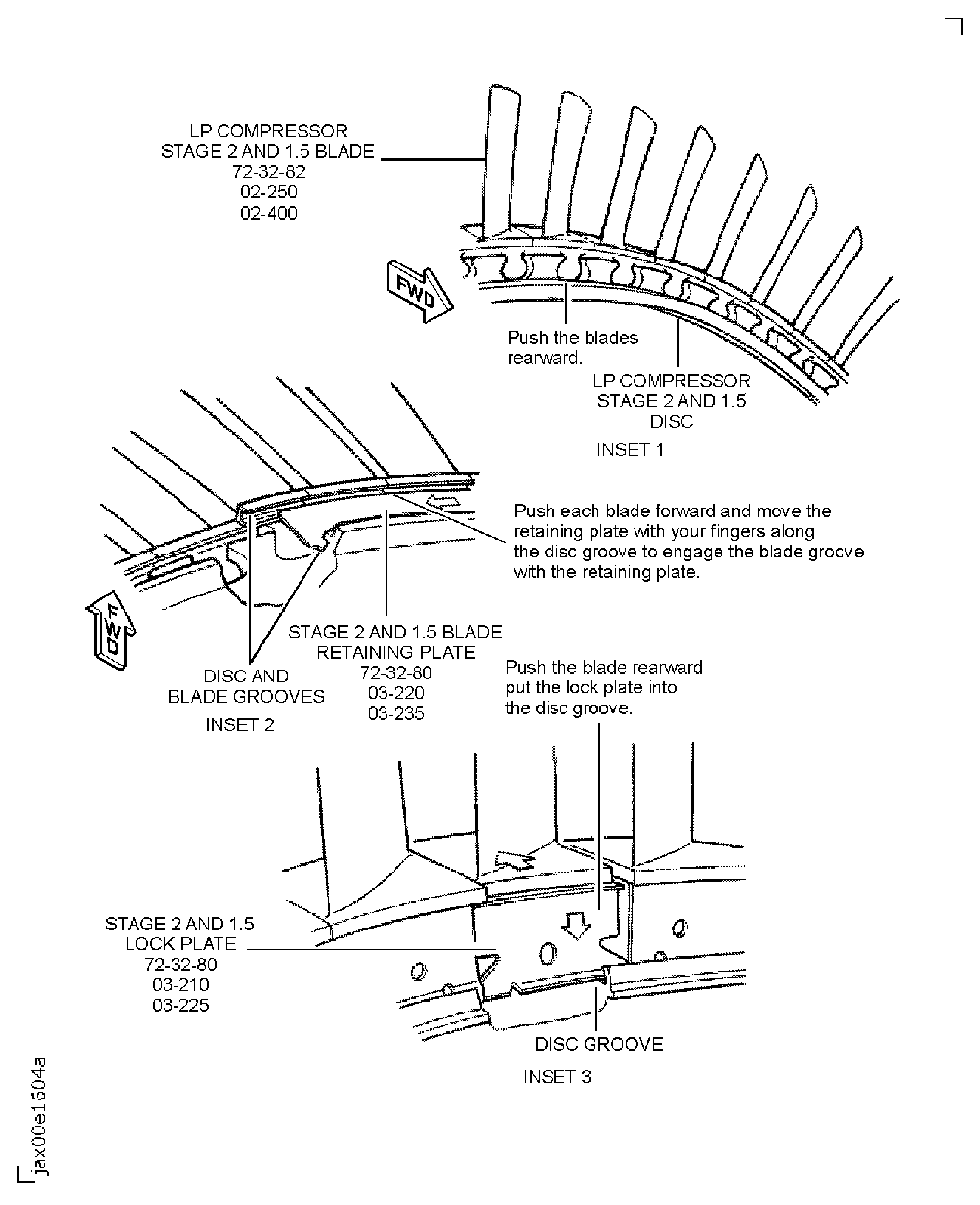

Install the stage 2.3 blades to the disc in the sequence given in Step. Start from the No. 1 blade slot and install the blades in a counterclockwise direction when you look from the rear. The identification number of the No. 1 slot is on the top of the disc tang.

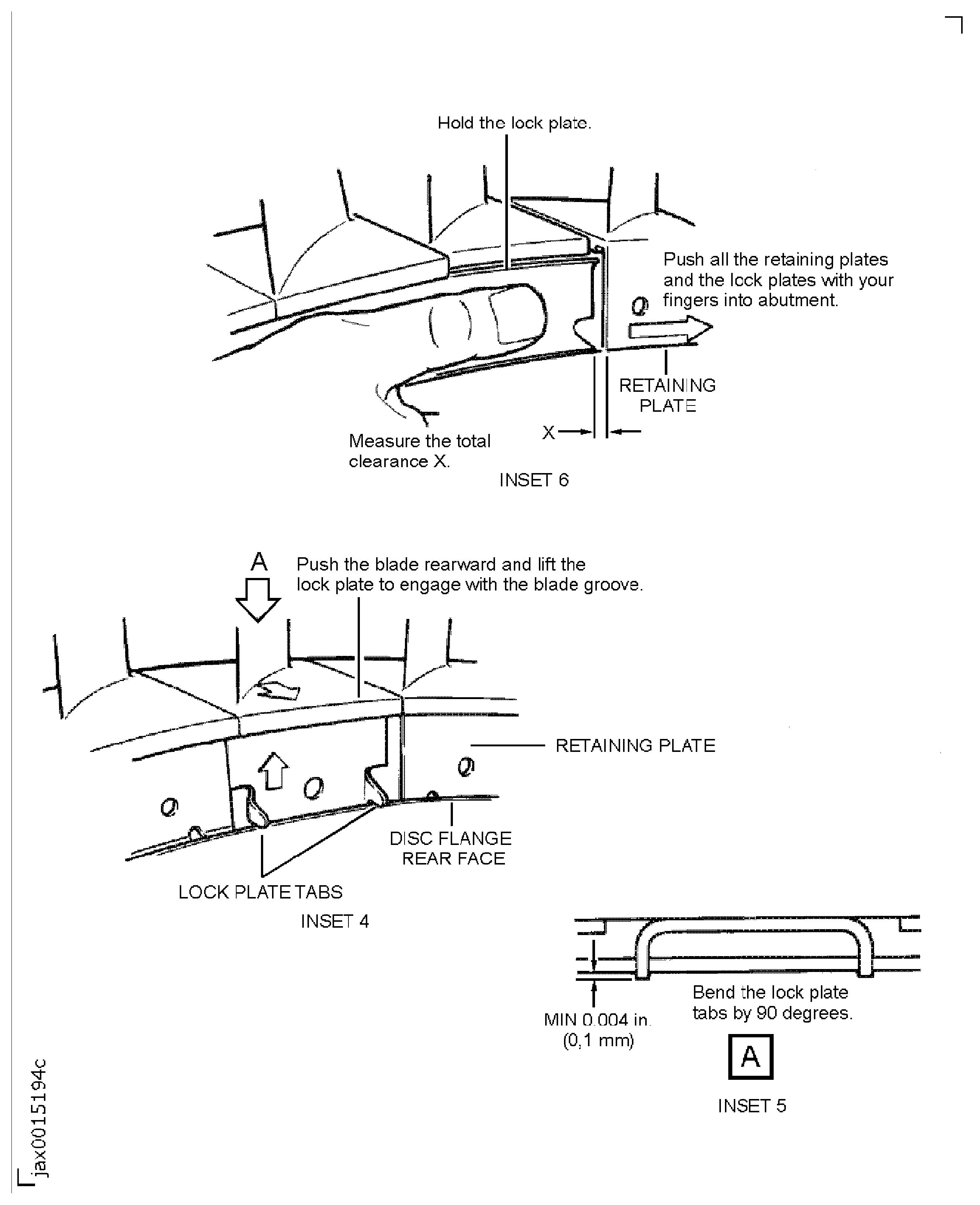

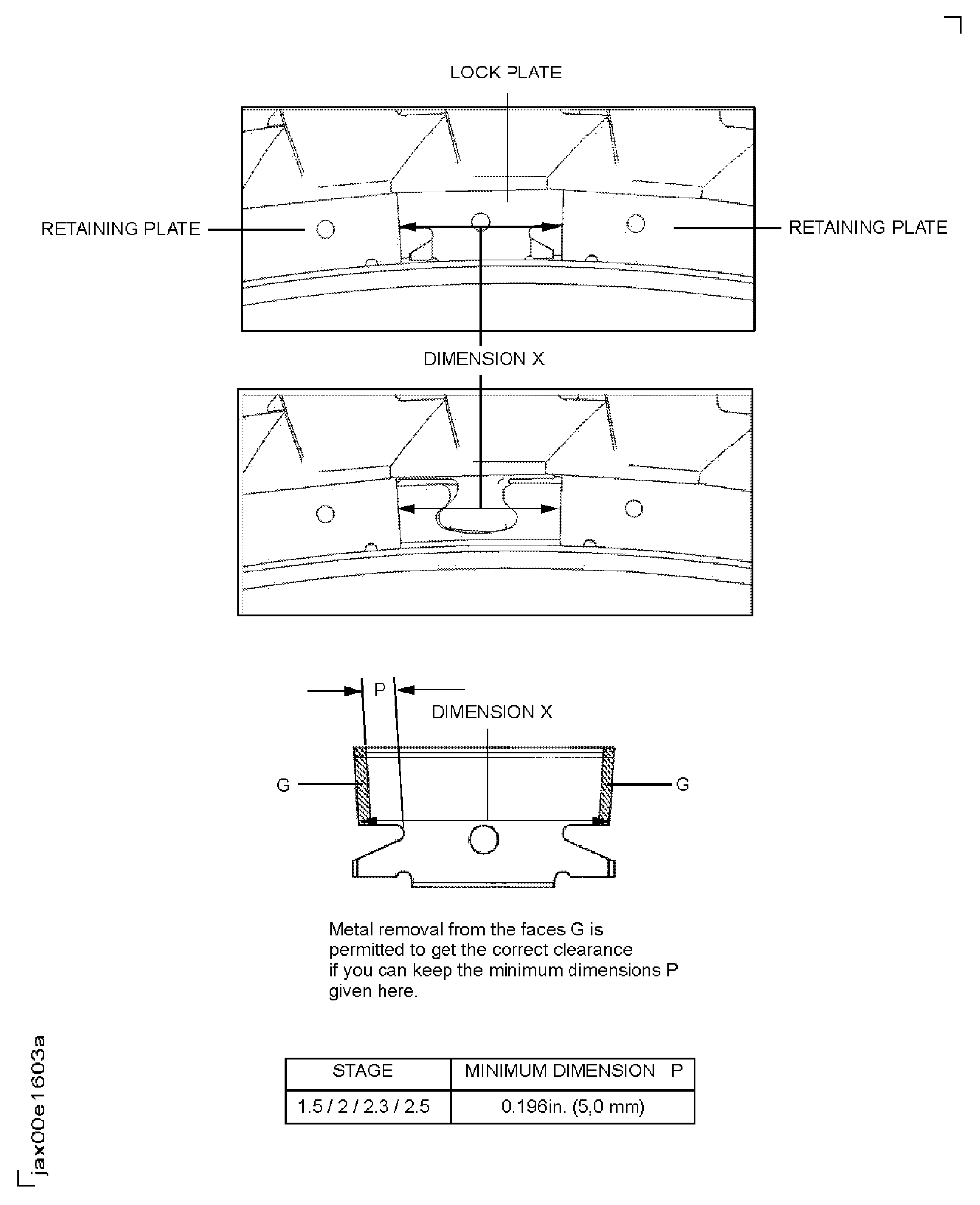

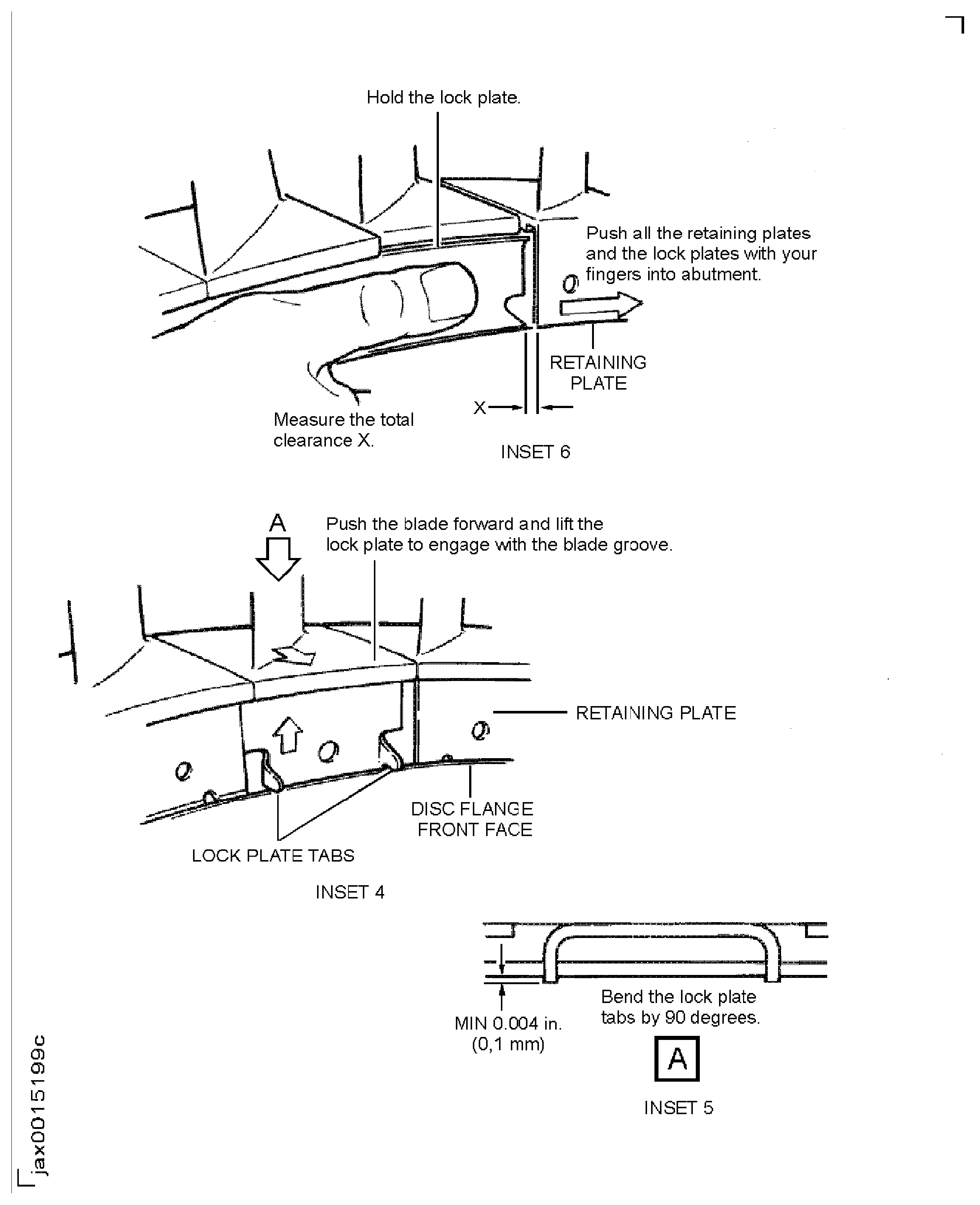

Remove metal from the lock plate in parallel with surface G with a file to get the specified clearance. Refer to Figure.

If it is necessary to remove metal from a lock plate to get the correct plate clearance do the steps that follow:

Measure the clearance between two retaining plates after collecting all the circular clearance.

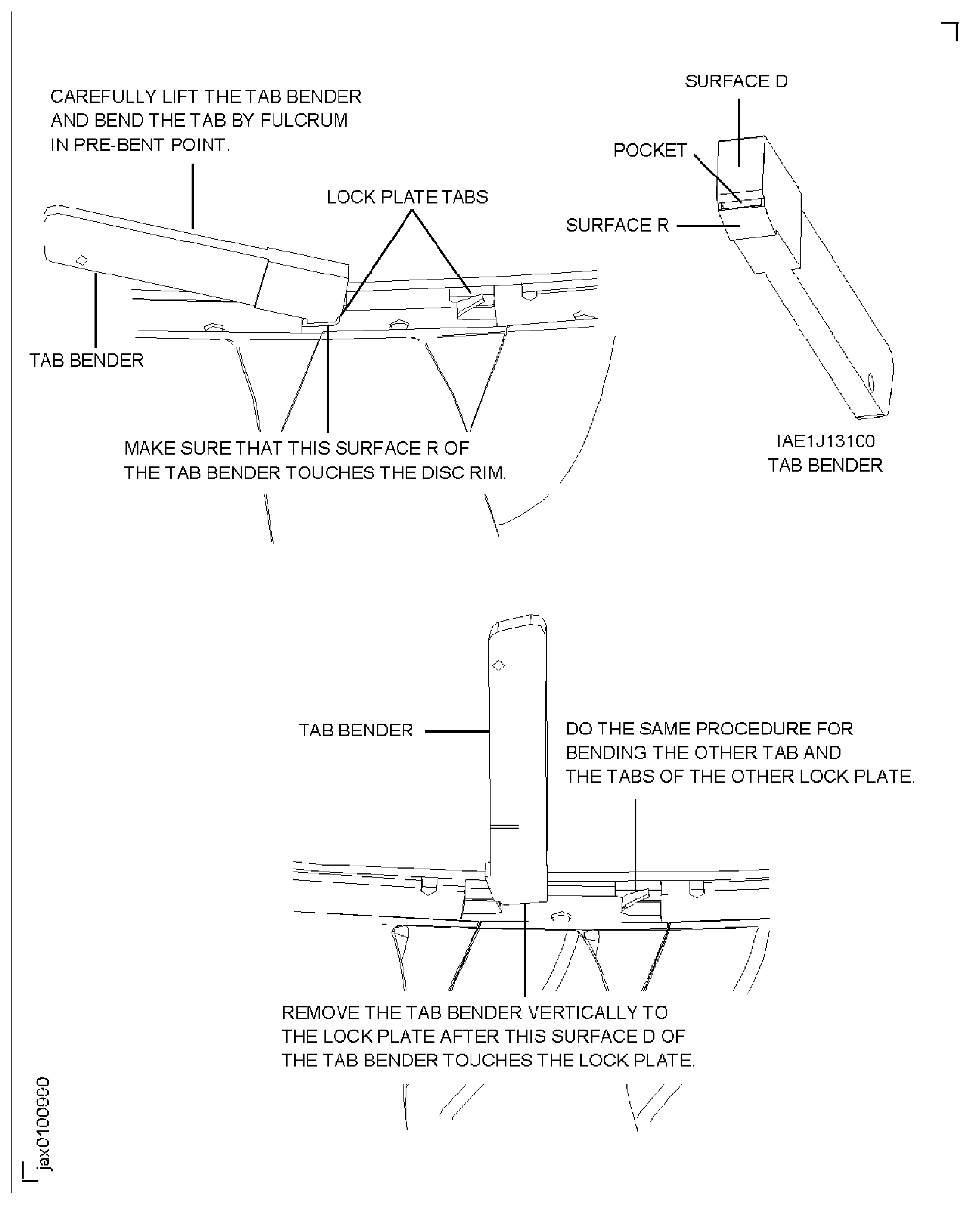

Put the tab into the pocket of IAE 1J13100 Tab bender 1 off correctly and make sure that the surface R of the tab bender touches the rim of the LPC disc.

Make sure that the tab is correctly bent, Figure, inset 5.

CAUTION

OBEY THE FOLLOWING PROCEDURE WITH IAE 1J13100 Tab bender 1 OFF FOR BENDING THE LOCK PLATE TABS. IF YOU DO NOT OBEY IT, THE LOCK PLATES AND THE BLADES CAN COME OFF DURING FLIGHT. IT CAN CAUSE DAMAGE TO THE LP COMPRESSOR BOOSTER STAGE ASSEMBLY.Bend the tabs on the two lock plates.

CAUTION

MAKE SURE THE RETAINING PLATES AND LOCK PLATES ARE INSTALLED INTO THE GROOVES OF THE BLADES. IF THEY ARE NOT INSTALLED PROPERLY, BLADES CAN COME OFF DURING FLIGHT. IT CAN CAUSE DAMAGE TO THE LP COMPRESSOR BOOSTER STAGE ASSEMBLY.Check the blades and make sure that the retaining plates and lock plates are properly installed into the grooves of the blades.

SUBTASK 72-32-80-440-074 Install the Stage 2.3 Blades to the Disc

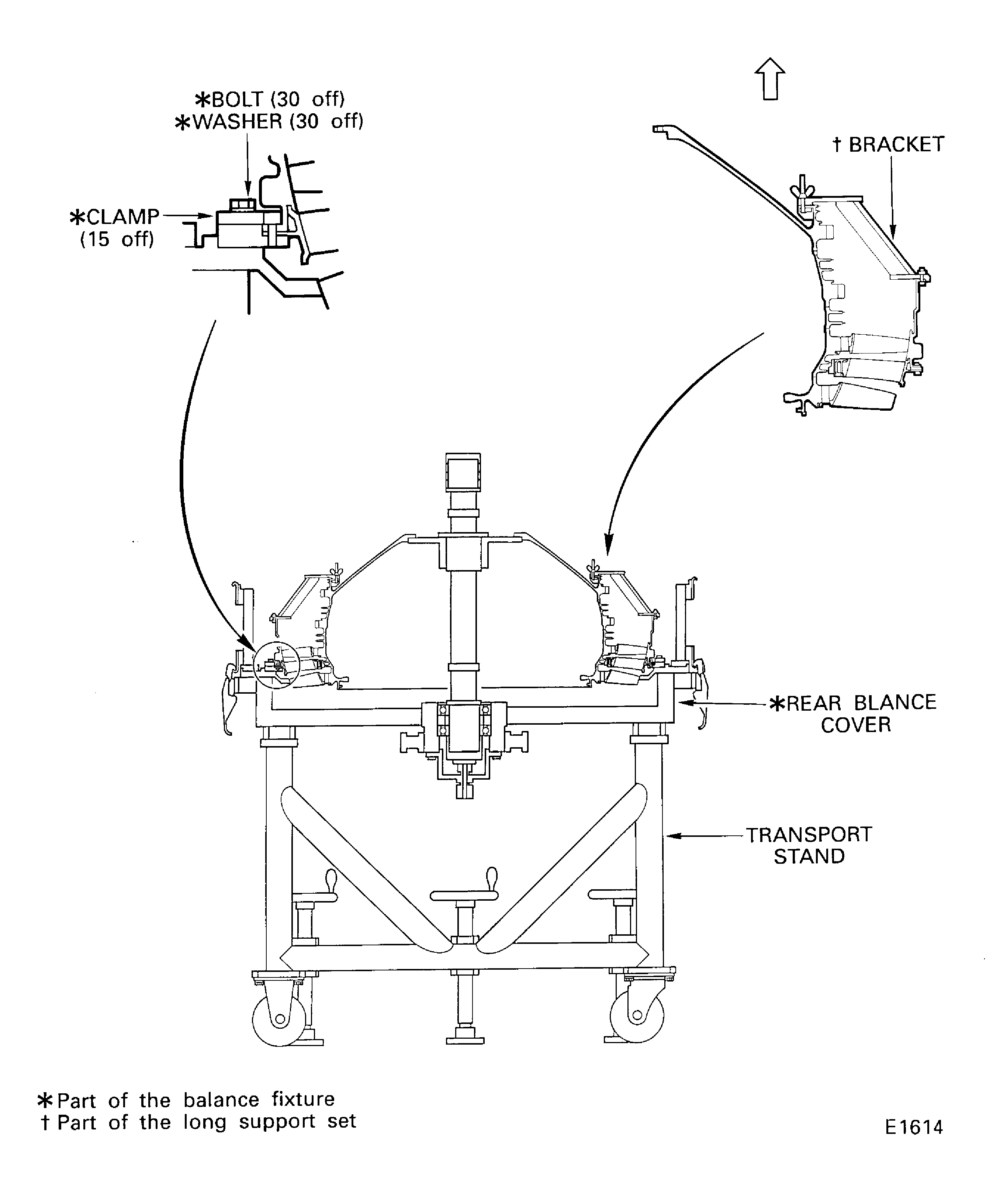

Refer to Figure.

Install IAE 1J12542 Long support 1 off to the disk.

SUBTASK 72-32-80-440-075 Install the Brackets on to the Disk

Remove the four blocks (part of IAE 1J12533 Storage stand 1 off) from the storage stand (L).

SUBTASK 72-32-80-440-076 Put the LPC Disk and Balance Arbor Assembly on to the Storage Stand (L)

NOTE

If the LPC disk and balance arbor assembly is already put on to the IAE 1J12533 Storage stand, this step is not necessary.Refer to Figure.

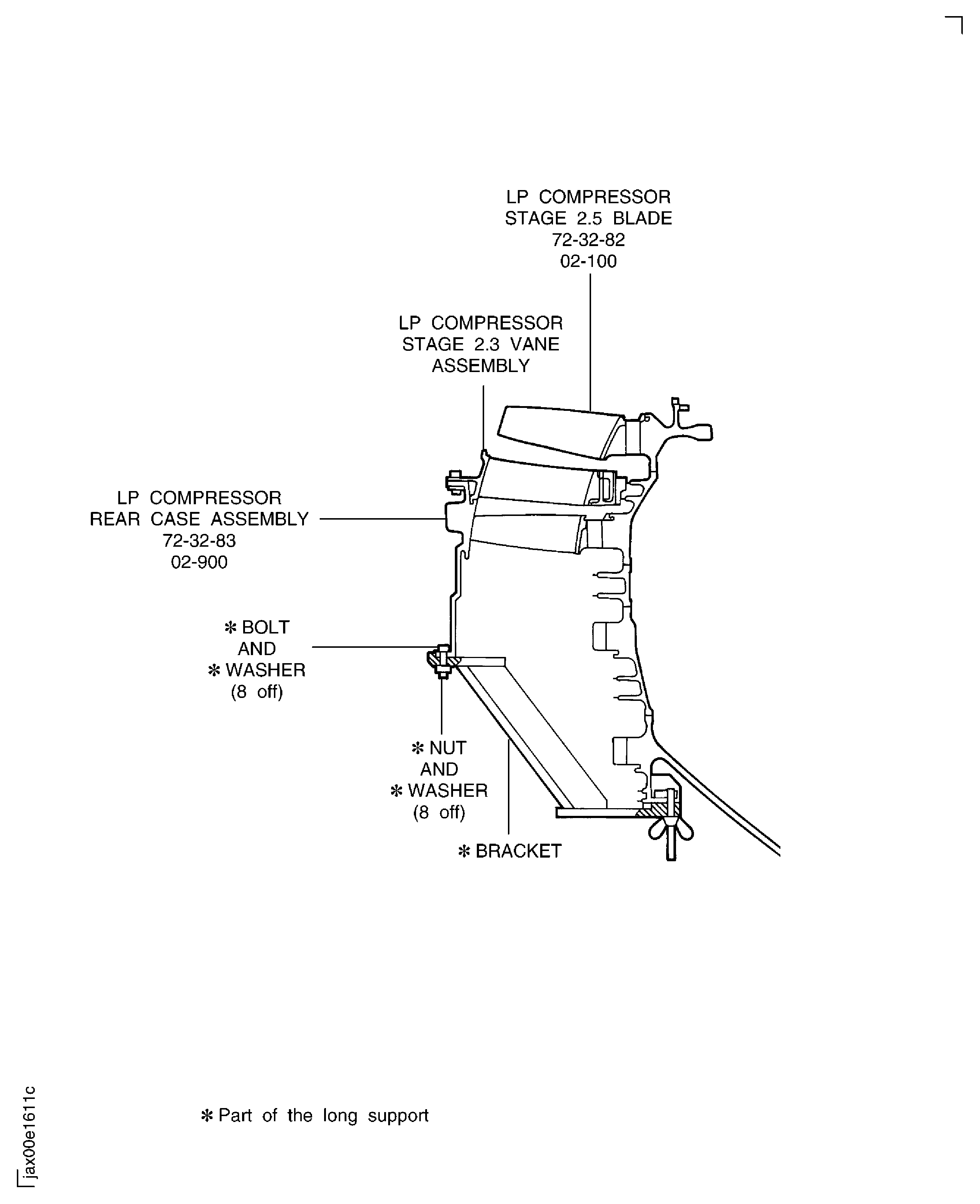

Clean the mating faces of the stage 2.3 vane assembly and the LP compressor rear case assembly with CoMat 01-124 ISOPROPYL ALCOHOL.

Apply CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE on to the mating faces of the stage 2.3 vane assembly and the LP compressor rear case assembly.

Apply the joint compound on to the mating faces of the stage 2.3 vane assembly and the LP compressor rear case assembly.

Install the 62 countersunk head screws V2500-A5-72-32-83-02A-941A-D (72-32-83, 02-254), washers V2500-A5-72-32-83-02A-941A-D (72-32-83, 02-252) and nuts V2500-A5-72-32-83-02A-941A-D (72-32-83, 02-251) through the conical holes of the stage 2.3 vane assembly. Torque the nuts to 36 to 45 lbfin (4.00 to 5.00 Nm).

SUBTASK 72-32-80-440-077 Install the Stage 2.3 LP Compressor Vane Assembly (72-32-83, 02-250) in to the LP Compressor Rear Case Assembly (72-32-83, 02-900)

Install the stage 2.5 blades to the disc in the sequence given in the Step. Start from the No. 1 blade slot and install the blades in the counterclockwise direction when you look from the rear. The identification number of the No. 1 slot is on the top of the disc tang.

Remove metal from the lock plate in parallel with surface G with a file to get the specified clearance. Refer to Figure.

If it is necessary to remove metal from a lock plate to get the correct plate clearance do the steps that follow:

Measure the clearance between two retaining plates after collecting all the circular clearance.

Put the tab into the pocket of IAE 1J13100 Tab bender 1 off correctly and make sure that the surface R of the tab bender touches the rim of the LPC disc.

Make sure that the tab is correctly bent, Figure, inset 5.

CAUTION

OBEY THE FOLLOWING PROCEDURE WITH IAE 1J13100 Tab bender 1 OFF FOR BENDING THE LOCK PLATE TABS. IF YOU DO NOT OBEY IT, THE LOCK PLATES AND THE BLADES CAN COME OFF DURING FLIGHT. IT CAN CAUSE DAMAGE TO THE LP COMPRESSOR BOOSTER STAGE ASSEMBLY.Bend the tabs on the two lock plates.

CAUTION

MAKE SURE THE RETAINING PLATES AND LOCK PLATES ARE INSTALLED INTO THE GROOVES OF THE BLADES. IF THEY ARE NOT INSTALLED PROPERLY, BLADES CAN COME OFF DURING FLIGHT. IT CAN CAUSE DAMAGE TO THE LP COMPRESSOR BOOSTER STAGE ASSEMBLY.Check the blades and make sure that the retaining plates and lock plates are properly installed into the grooves of the blades.

SUBTASK 72-32-80-440-079 Install the Stage 2.5 Blades to the Disc and Safety with the Retaining Plates

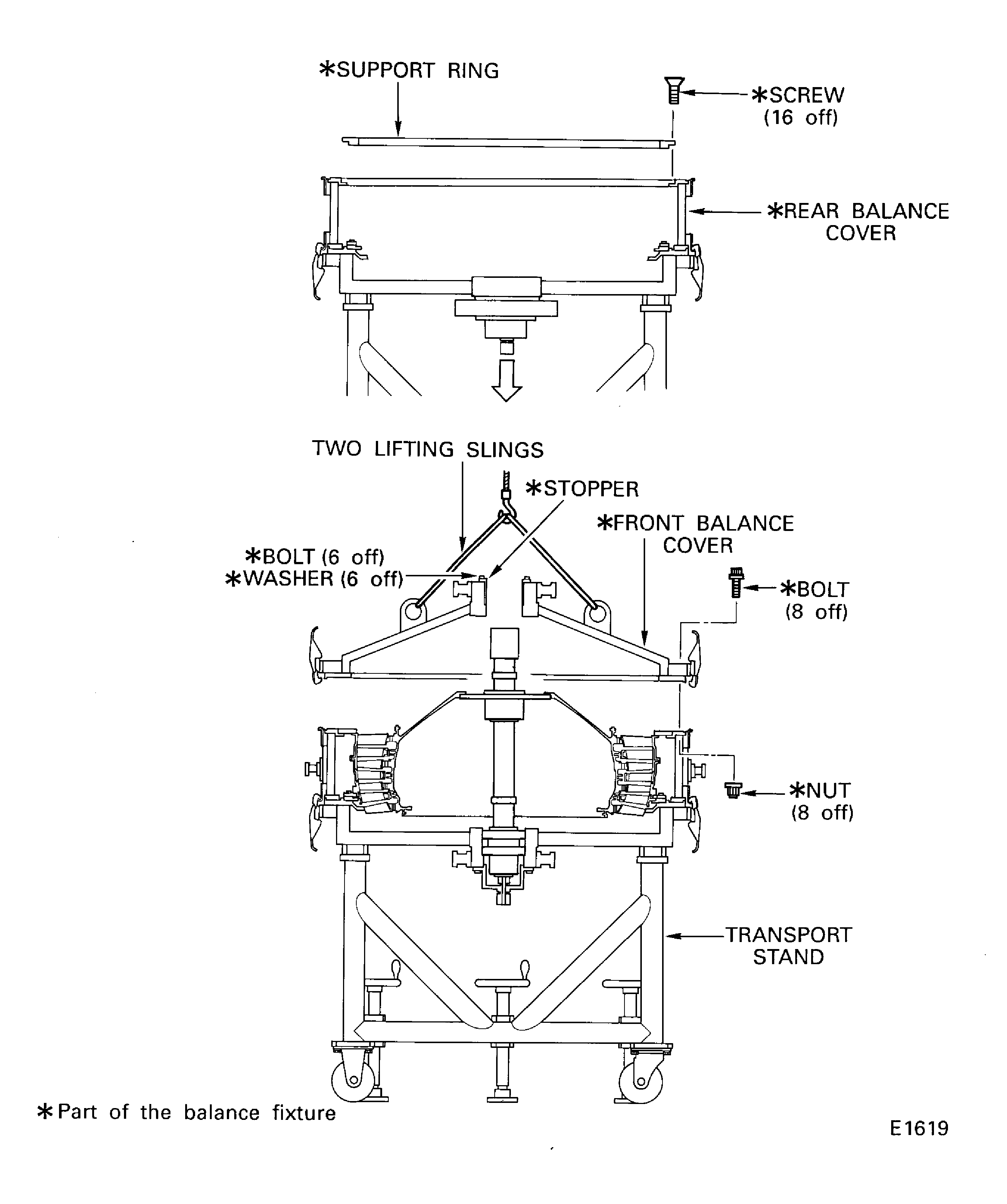

Move IAE 1J12410 Transport stand 1 off and IAE 1J12532 Balance fixture 1 off to the work area.

NOTE

Make sure the stage 2.5 blades do not touch the rear balance cover.NOTE

Make sure the dowel pointer of the four L-shaped bolts in the rear balance cover point to the inside diameter of the rear balance cover. When the dowel pointer points to the outside diameter the L-shaped bolts lock the axial movement of the ball bearing.Lower the adjusting screw in the end stopper housing at the bottom of the rear balance cover.

SUBTASK 72-32-80-440-081 Install the Disk, Stage 2.3 Blades and Balance Arbor Assembly onto the Balance Fixture

Refer to Figure.

Clean the mating faces of the stage 2.0 vane assembly and the mid case assembly with CoMat 01-124 ISOPROPYL ALCOHOL.

Apply CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE on to the mating faces of the stage 2.0 vane assembly and the mid case assembly. Dry for five minutes.

Apply the joint compound on the mating faces of the stage 2.0 vane assembly and the mid case assembly.

SUBTASK 72-32-80-440-096 Install the LP Compressor Mid Case Assembly (72-32-83, 02-650) to the Stage 2.0 LP Compressor Vane Assembly (72-32-83, 02-800)

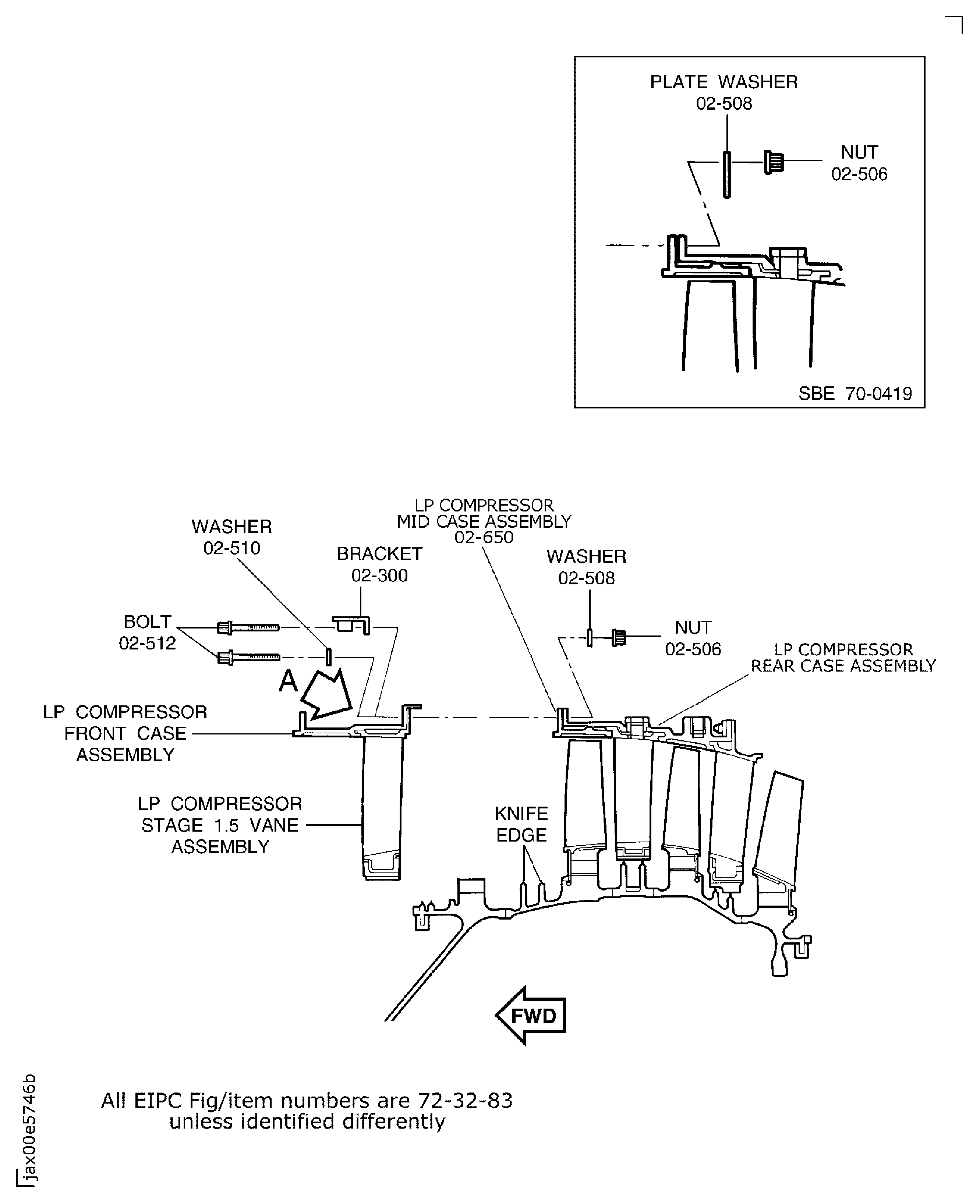

Refer to Figure.

Clean the mating faces between the stage 2.0 LP compressor vane and mid case assembly and the LP compressor rear case assembly with CoMat 01-124 ISOPROPYL ALCOHOL and apply CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE on to the faces and dry for five minutes.

Safety the stage 2.0 vane and mid case assembly to the rear case assembly with the plug V2500-A5-72-32-82-02A-941A-D (72-32-82, 02-960) and washer V2500-A5-72-32-83-02A-941A-D (72-32-83, 02-965). Torque the plug to 102 to 111 lbfin (11.50 to 12.50 Nm) and bend the tab of the washers. Refer to the SPM TASK 70-42-03-400-501 for tab washer installation.

SUBTASK 72-32-80-440-082 Install the Stage 2.0 LP Compressor Vane and LP Compressor Mid Case Assembly in to the LP Compressor Rear Case Assembly

Install the stage 2.0 blades to the disc in the sequence given in the Step. Start from the No. 1 blade slot and install the blades in the counterclockwise direction when you look from the rear. The identification number of the No. 1 slot is on the top of the disc tang.

Remove metal from the lock plate in parallel with surface G with a file to get the specified clearance. Refer to Figure.

If it is necessary to remove metal from a lock plate to get the correct plate clearance do the steps that follow:

Measure the clearance between two retaining plates after collecting all the circular clearance.

Put the tab into the pocket of IAE 1J13100 Tab bender 1 off correctly and make sure that the surface R of the tab bender touches the rim of the LPC disc.

Make sure that the tab is correctly bent, Figure, inset 5.

CAUTION

OBEY THE FOLLOWING PROCEDURE WITH IAE 1J13100 Tab bender 1 OFF FOR BENDING THE LOCK PLATE TABS. IF YOU DO NOT OBEY IT, THE LOCK PLATES AND THE BLADES CAN COME OFF DURING FLIGHT. IT CAN CAUSE DAMAGE TO THE LP COMPRESSOR BOOSTER STAGE ASSEMBLY.Bend the tabs on the two lock plates.

CAUTION

MAKE SURE THE RETAINING PLATES AND LOCK PLATES ARE INSTALLED INTO THE GROOVES OF THE BLADES. IF THEY ARE NOT INSTALLED PROPERLY, BLADES CAN COME OFF DURING FLIGHT. IT CAN CAUSE DAMAGE TO THE LP COMPRESSOR BOOSTER STAGE ASSEMBLY.Check the blades and make sure that the retaining plates and lock plates are properly installed into the grooves of the blades.

SUBTASK 72-32-80-440-083 Install the Stage 2.0 Blades to the Disc and Safety with the Retaining Plates

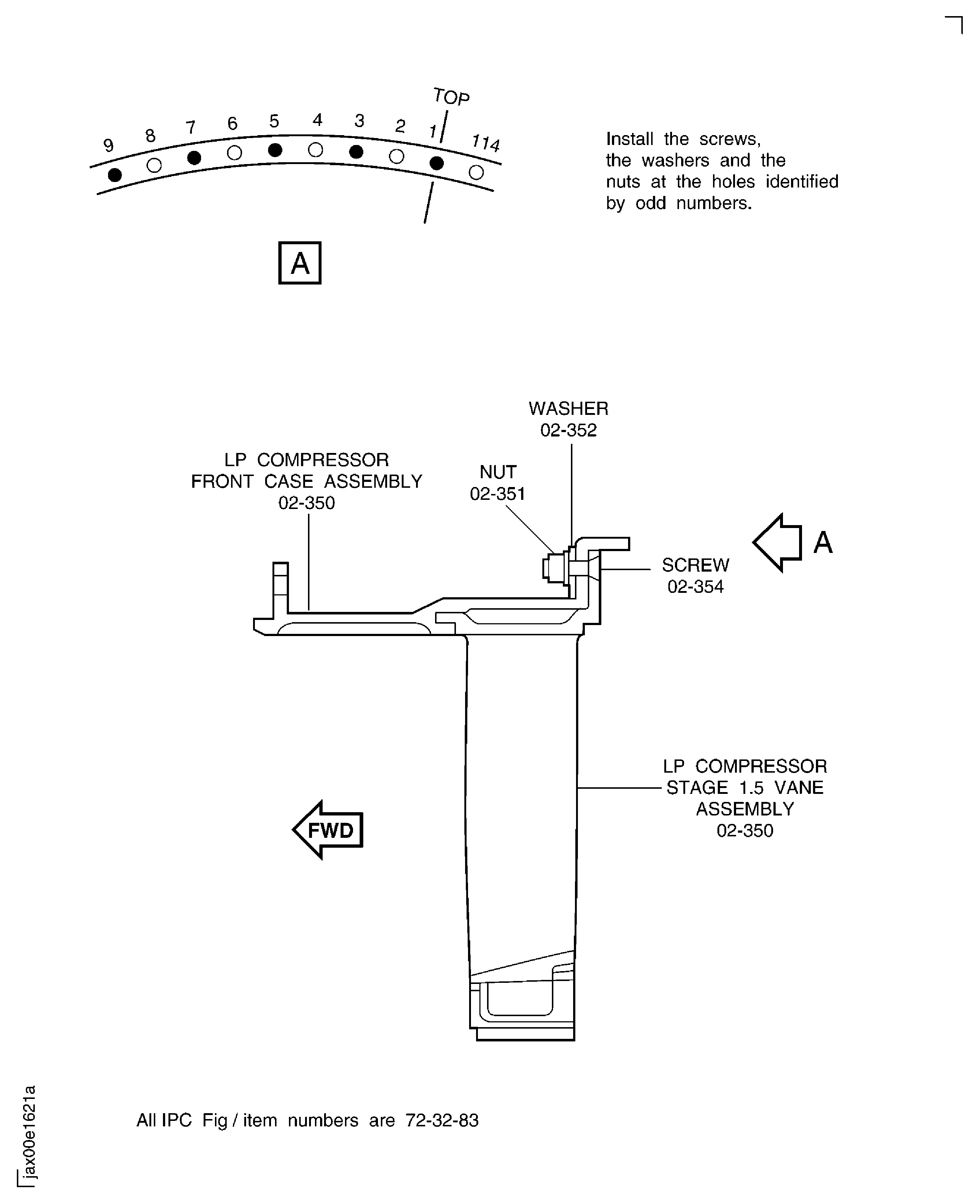

Refer to Figure.

Clean the mating faces of the stage 1.5 vane, the LP compressor front case assembly with CoMat 01-124 ISOPROPYL ALCOHOL.

Apply CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE on to the mating faces of the stage 1.5 vane and the LP compressor front case assembly. Dry for five minutes.

Apply the joint compound on to the mating faces of the stage 1.5 vane and the LP compressor front case assembly.

SUBTASK 72-32-80-440-084 Install the Stage 1.5 Vane (72-32-83, 02-500) in to LP Compressor Front Case Assembly (72-32-83, 02-350)

Clean the mating faces of the stage 1.5 vane, the LP compressor front case assembly and the LP compressor mid case assembly with CoMat 01-124 ISOPROPYL ALCOHOL.

Apply CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE on to the mating faces of the stage 1.5 vane, the LP compressor front case assembly and the LP compressor mid case assembly. Dry for five minutes.

Apply the joint compound on to the mating faces of the stage 1.5 vane, the LP compressor front case assembly and the LP compressor mid case assembly.

Pre SBE 70-0419: Safety the brackets and the LP compressor front case assembly with the 57 bolts V2500-A5-72-32-83-02A-941A-D (72-32-83, 02-512), the 29 washers V2500-A5-72-32-83-02A-941A-D (72-32-83, 02-510), the 57 washers V2500-A5-72-32-83-02A-941A-D (72-32-83, 02-508) and the 57 nuts V2500-A5-72-32-83-02A-941A-D (72-32-83, 02-506). Torque the nuts to 36 to 45 lbfin. (4 to 5 Nm).

NOTE

Install the 29 washers V2500-A5-72-32-83-02A-941A-D (72-32-83, 02-510) at the bolt holes at which the brackets are not installed.SBE 70-0419: Safety the brackets and the LP compressor front case assembly with the 57 bolts V2500-A5-72-32-83-02A-941A-D (72-32-83, 02-512), the 29 washers V2500-A5-72-32-83-02A-941A-D (72-32-83, 02-510), the 19 washers V2500-A5-72-32-83-02A-941A-D (72-32-83, 02-508) and the 57 nuts V2500-A5-72-32-83-02A-941A-D (72-32-83, 02-506). Torque the nuts to 36 to 45 lbfin. (4 to 5 Nm).

SUBTASK 72-32-80-440-085 Install the Stage 1.5 Vane and LP Compressor Front Case Assembly to the LP Compressor Mid Case Assembly

Install the stage 1.5 blades to the disc in the sequence given in the Step. Start from the No. 1 blade slot and install the blades in the counterclockwise direction when you look from the rear. The identification number of the No. 1 slot is on the top of the disc tang.

Remove metal from the lock plate in parallel with surface G with a file to get the specified clearance. Refer to Figure.

If it is necessary to remove metal from a lock plate to get the correct plate clearance do the steps that follow:

Measure the clearance between two retaining plates after collecting all the circular clearance.

Put the tab into the pocket of IAE 1J13100 Tab bender 1 off correctly and make sure that the surface R of the tab bender touches the rim of the LPC disc.

Make sure that the tab is correctly bent, Figure, inset 5.

CAUTION

OBEY THE FOLLOWING PROCEDURE WITH IAE 1J13100 Tab bender 1 OFF FOR BENDING THE LOCK PLATE TABS. IF YOU DO NOT OBEY IT, THE LOCK PLATES AND THE BLADES CAN COME OFF DURING FLIGHT. IT CAN CAUSE DAMAGE TO THE LP COMPRESSOR BOOSTER STAGE ASSEMBLY.Bend the tabs on the two lock plates.

CAUTION

MAKE SURE THE RETAINING PLATES AND LOCK PLATES ARE INSTALLED INTO THE GROOVES OF THE BLADES. IF THEY ARE NOT INSTALLED PROPERLY, BLADES CAN COME OFF DURING FLIGHT. IT CAN CAUSE DAMAGE TO THE LP COMPRESSOR BOOSTER STAGE ASSEMBLY.Check the blades and make sure that the retaining plates and lock plates are properly installed into the grooves of the blades.

SUBTASK 72-32-80-440-086 Install the Stage 1.5 Blades to the Disc and Safety with the Retaining Plates

Refer to Figure.

NOTE

Make sure that the support ring inner diameter align with the spigot of the 1.5 casing front flange.NOTE

Make sure that there are no clearances between the mating faces of the two flanges on the support ring and rear balance cover.Install the support ring on to the rear balance cover and LP compressor case assembly.

SUBTASK 72-32-80-440-087 Install the Mid and Front Balance Cover on to the Rear Balance Cover

Refer to Figure.

NOTE

Balancing tools in this TASK are applicable to a SCHENCK HL-5U dynamic balancing machine and bearing housing.NOTE

Balancer must be operated at a speed between 700 and 900 rpm to agree with the gear ratios available.NOTE

The direction of rotation is clockwise when you look from the rear.Move the LPC rotor balance arbor and balance cover assembly on the transport stand to the balance area.

InstallIAE 1F10052 Two cables sling 1 off on to the trunnions on the rear balancing cover.

SUBTASK 72-32-80-440-088 Install the LP Compressor Rotor on to the Balancing Machine

Refer to Figure.

SUBTASK 72-32-80-220-056 Examine the Runout of the Rotor

Refer to Figure.

SUBTASK 72-32-80-440-089 Examine the Initial Unbalance of the Rotor

Install the balance counter weights and safety them with the tubular rivets. UseIAE 1J13209 Riveter 1 off. Refer to the SPM TASK 70-39-03-390-501 for rivet installation.

Do the unbalance correction in the subsequent steps.

SUBTASK 72-32-80-440-090 Correct the Unbalance of the LP Compressor Rotor

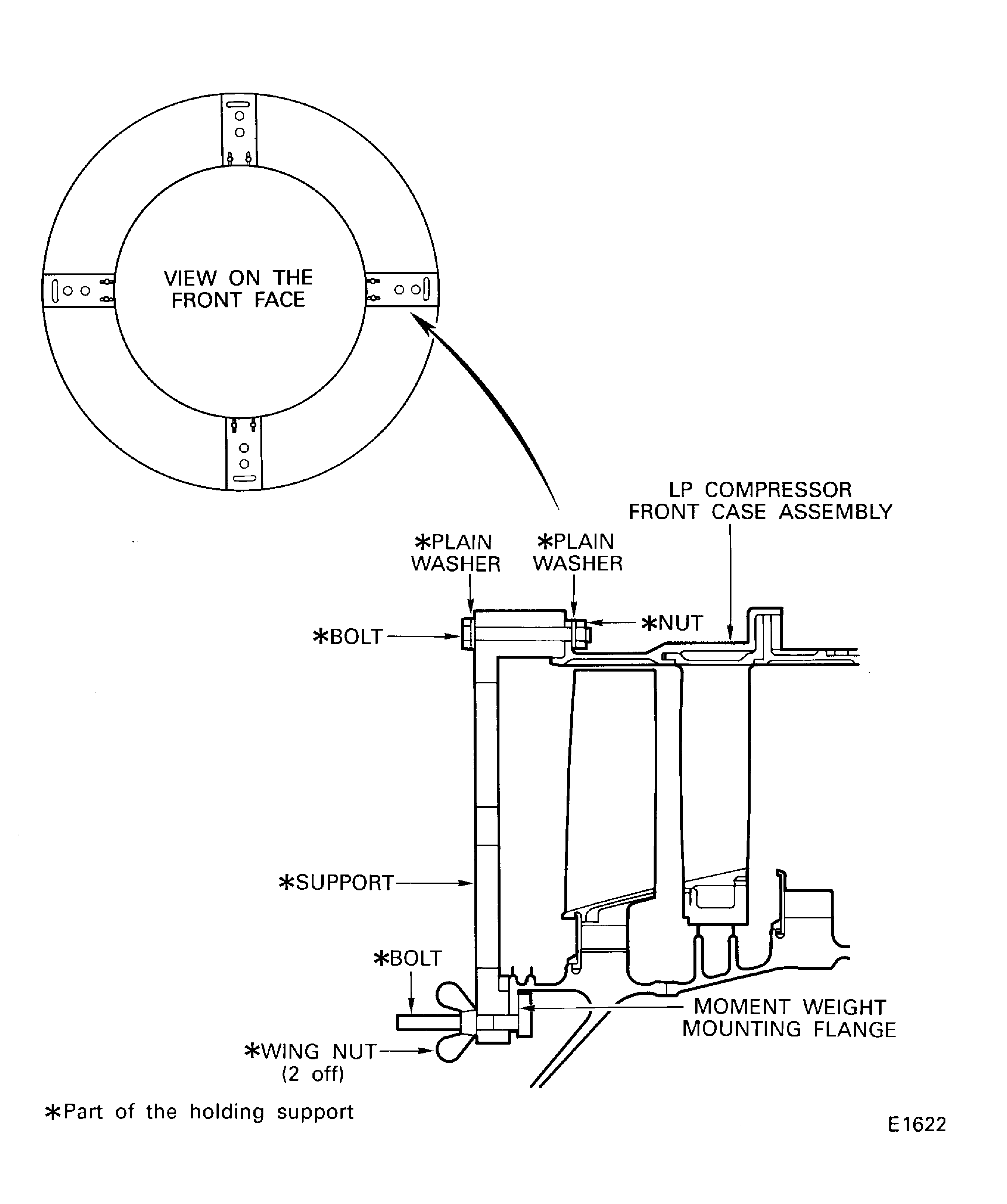

InstallIAE 1J12541 Holding support 1 off to the stage 1.5 casing and stage 1.5 blade front flange.

Install the three puller bolts (part of IAE 1J12188 Puller bolt 1 off) in to three of the six threaded holes on the LP compressor booster stage disk inner flange.

SUBTASK 72-32-80-440-092 Remove the LP Compressor from the Balance Cover

Figure: Sectional View of the LP Compressor Booster Stage Assembly

Sectional View of the LP Compressor Booster Stage Assembly

Figure: View of the LP Compressor Booster Stage Blades and Disk

View of the LP Compressor Booster Stage Blades and Disk

Figure: Positions of the LP Compressor Booster Stage Blades Retaining Plates and Lock Plates

Sheet 1

Figure: Positions of the LP Compressor Booster Stage Blades Retaining Plates and Lock Plates

Sheet 2

Figure: View of the LP Compressor Booster Stage Vanes

View of the LP Compressor Booster Stage Vanes

Figure: Install the Balance Adapter to the Transport Stand and Balance Fixture

Install the Balance Adapter to the Transport Stand and Balance Fixture

Figure: Put the Heater on to the LP Compressor Booster Stage Disk

Put the Heater on to the LP Compressor Booster Stage Disk

Figure: Install the LP Compressor Booster Stage Disk on to the Balance Arbor

Install the LP Compressor Booster Stage Disk on to the Balance Arbor

Figure: Move the LP Compressor Booster Stage Disk and Balance Adapter Assembly from the Transport Stand to the Horizontal Work Stand

Move the LP Compressor Booster Stage Disk and Balance Adapter Assembly from the Transport Stand to the Horizontal Work Stand

Figure: The Sequence Diagram to Install the LP Compressor Booster Stage Blades

The Sequence Diagram to Install the LP Compressor Booster Stage Blades

Figure: Install the LP Compressor Booster Stage Blades to the Disk

Sheet 1

Figure: Install the LP Compressor Booster Stage Blades to the Disk

Sheet 2

Figure: Install the LP Compressor Booster Stage Blades to the Disk

Sheet 3

Figure: Install the LP Compressor Booster Stage Blades to the Disk

Sheet 4

Figure: Install the Holding Support

Install the Holding Support

Figure: Put the LP Compressor Booster Stage Disk and Balance Arbor Assembly on to the Storage Stand (L)

Sheet 1

Figure: Install the LP Compressor Stage 2.3 Vane Assembly onto LP Compressor Rear Case Assembly

Sheet 2

Figure: Install the LP Compressor Stage 2.3 Vanes, the LP Compressor Rear Case, and the Stage 2.5 Compressor Blades Assembly on to the Disk

Install the LP Compressor Stage 2.3 Vanes, the LP Compressor Rear Case, and the Stage 2.5 Compressor Blades Assembly on to the Disk

Figure: Install the LP Compressor Disk, the 2.3 and 2.5 Stage Blades and the Balance Arbor Assembly on to the Balance Fixture

Sheet 1

Figure: Install the LP Compressor Disk, the 2.3 and 2.5 Stage Blades and the Balance Arbor Assembly on to the Balance Fixture

Sheet 2

Figure: Install the LP Compressor Stage 2 and 1.5 Blades to the Disk

Sheet 1

Figure: Install the LP Compressor Stage 2 and 1.5 Blades to the Disk

Sheet 2

Figure: Install the LP Compressor Stage 1.5 Vane in to the LP Compressor Front Case

Install the LP Compressor Stage 1.5 Vane in to the LP Compressor Front Case

Figure: Install the LP Compressor Stage 1.5 Vanes, LP Compressor Front Case and the LP Compressor Mid Case Assembly on to the LP Compressor Rear Case

Sheet 1

Figure: Install the LP Compressor Stage 1.5 Vanes, LP Compressor Front Case and the LP Compressor Mid Case Assembly on to the LP Compressor Rear Case

Sheet 2

Figure: Install the Front Balance Cover on to the Rear Balance Cover

Install the Front Balance Cover on to the Rear Balance Cover

Figure: Install and Remove the LP Compressor Booster Stage Assembly to the Balancing Machine

Install and Remove the LP Compressor Booster Stage Assembly to the Balancing Machine

Figure: Set up for Run Out Checks and Dynamic Balancing

Sheet 1

Figure: Balance Correction Planes

Sheet 2

Figure: Tubular Rivet and Balance Counter Weight

Sheet 3

Figure: Install the Holding Support

Install the Holding Support

Figure: Move the LP Compressor Booster Stage Assembly From the Transport Stand to the Storage Stand (L)

Move the LP Compressor Booster Stage Assembly From the Transport Stand to the Storage Stand (L)

Figure: Locations of the Sub-Module Serial Number and Sub-Module Number

Locations of the Sub-Module Serial Number and Sub-Module Number

Figure: Put The LP Compressor Booster Stage Disk And Balance Arbor Assembly On To The Storage Stand (L)

Put The LP Compressor Booster Stage Disk And Balance Arbor Assembly On To The Storage Stand (L)