Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-50-420-003-C00 LPT Module - Install The Turbine Exhaust Case (TEC) (Horizontal) - Method 2, Installation-004

General

Transportation covers/blanks must be removed immediately before installation of the components.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Special torque data is identified by the * symbol after the torque value.

Assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK 70-64-02-640-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to SPM TASK 70-38-21-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Electronic balance crane | LOCAL | Electronic balance crane | ||

| IAE 1F10016 Mechanical wrench | 0AM53 | IAE 1F10016 | 1 | |

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1F10033 Hydraulic installation pusher | 0AM53 | IAE 1F10033 | 1 | |

| IAE 1F10034 Hydraulic installation pusher | 0AM53 | IAE 1F10034 | 1 | |

| IAE 1F10038 Torque wrench | 0AM53 | IAE 1F10038 | 1 | |

| IAE 1F10039 Anti-torque adapter | 0AM53 | IAE 1F10039 | 1 | |

| IAE 1F10040 Anchor wrench plate | 0AM53 | IAE 1F10040 | 1 | |

| IAE 1F10051 Two cable sling | 0AM53 | IAE 1F10051 | 1 | |

| IAE 1F10073 remove/installation fixture | 0AM53 | IAE 1F10073 | 1 | |

| IAE 1F10075 Support pedestal | 0AM53 | IAE 1F10075 | 2 | |

| IAE 1F10076 Locking collar | 0AM53 | IAE 1F10076 | 1 | |

| IAE 1F10178 Storage and Turnover adapter | 0AM53 | IAE 1F10178 | 1 | |

| IAE 6F01029 Pneumatic cart | 0AM53 | IAE 6F01029 | 1 | |

| IAE 6F10030 Vacuum test cart | 0AM53 | IAE 6F10030 | 1 | |

| IAE 1J12244 Sizing sleeve | 0AM53 | IAE 1J12244 | 1 | |

| IAE 1J12263 Seal slider | 0AM53 | IAE 1J12263 | 1 | |

| IAE 1J12523 Seal slider | 0AM53 | IAE 1J12523 | ||

| IAE 1M14143 Support fixture | 0AM53 | IAE 1M14143 | 1 | |

| IAE 1M14461 Supporting fixture | LOCAL | IAE 1M14461 | ||

| IAE 1P16354 Vacuum Test Adapter | 0AM53 | IAE 1P16354 | 1 | |

| IAE 1P16374 Wrench support | 0AM53 | IAE 1P16374 | 1 | |

| IAE 1P16377 Guide support | 0AM53 | IAE 1P16377 | 1 | |

| IAE 1P14041 Drier | 0AM53 | IAE 1P14041 | 1 | |

| IAE 1P17523 Blank-off Plate | 0AM53 | IAE 1P17523 | 1 | |

| IAE 1P17041 Drier | 0AM53 | IAE 1P17041 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 07-038 AIR DRYING ENAMEL | k3504 | CoMat 07-038 | ||

| CoMat 10-045 LEAK CHECK FLUID, BUBBLES-TYPE | 03530 | CoMat 10-045 | ||

| CoMat 10-045A LEAK CHECK FLUID, BUBBLES-TYPE | LOCAL | CoMat 10-045A | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 | ||

| CoMat 10-129 ANTI-SEIZE PASTE | 34568 | CoMat 10-129 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Sealing ring | 1 | |||

| Packing | 3 | |||

| Packing | 1 | |||

| Packing | 1 |

Safety Requirements

NONEProcedure

Examine the LP Turbine Module interface E-50/50. Refer to TASK 72-00-50-200-004 (INSPECTION-004).

SUBTASK 72-00-50-220-151 Examine the Module Interfaces

Refer to Figure.

Reference the clearance at location 2275. If required, use the data written as a note in TASK 72-50-53-200-000 (INSPECTION-000) and TASK 72-50-00-200-000 (INSPECTION-000).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2275

No. 5 Bearing Housing Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 21-350)

Stage 6 Inner Turbine Air Seal LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00, 01-240)

No. 5 Bearing Housing

5.5512

Clear

5.5551

0.0315

Stage 6 Inner Turbine Air Seal

5.5157

0.0394

5.5197

Clear

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2275

No. 5 Bearing Housing Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 21-350)

Stage 6 Inner Turbine Air Seal LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00, 01-240)

No. 5 Bearing Housing

141.000

Clear

141.099

0.800

Stage 6 Inner Turbine Air Seal

140.099

1.001

140.200

Clear

SUBTASK 72-00-50-220-153 Reference Fits and Clearances of the Stage 6 Inner Turbine Air Seal and the No.5 Bearing Housing at Location 2275

Refer to Figure.

Reference the interference at location 2277. If required, use the data written as a note in TASK 72-50-10-200-000 (INSPECTION-000) and TASK 72-50-53-200-000 (INSPECTION-000).

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2277

LP Turbine Case (72-50-10, 01-010)

Turbine Exhaust Case Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 21-020)

LP Turbine Case Diameter

38.6587

Intf

38.6480

Clear

38.6642

0.0000

38.6642

0.0244

Turbine Exhaust Case Bore

38.6524

0.0118

38.6524

0.0118

38.6587

Intf

38.6724

Intf

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2277

LP Turbine Case (72-50-10, 01-010)

Turbine Exhaust Case Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 21-020)

LP Turbine Case Diameter

981.931

Intf

981.66

Clear

982.070

0.000

982.07

0.62

Turbine Exhaust Case Bore

981.771

0.300

981.77

0.30

981.931

Intf

982.28

Intf

SUBTASK 72-00-50-220-154 Reference Fits and Clearances of the LP Turbine Case and the Tec at Location 2277

Refer to Figure.

Reference the interference at location 2271. If required, use the data written as a note in TASK 72-50-41-200-000 (INSPECTION-000) and TASK 72-50-52-200-000 (INSPECTION-000).

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2271

LP Turbine Shaft LPT Shaft And Related Parts (72-50-41, 01-200)

No. 5 Bearing ENGINE-NO.5 BEARING PLATE AND OIL DEFLECTOR (72-50-52, 20-060)

LP Turbine Shaft Diameter

3.6224

Intf

3.6228

0.0003

No. 5 Bearing Bore

3.6217

0.0011

3.6220

Intf

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2271

LP Turbine Shaft LPT Shaft And Related Parts (72-50-41, 01-200)

No. 5 Bearing ENGINE-NO.5 BEARING PLATE AND OIL DEFLECTOR (72-50-52, 20-060)

LP Turbine Shaft Diameter

92.0090

92.0191

Intf

0.0080

No. 5 Bearing Bore

91.9912

91.9988

0.0279

Intf

SUBTASK 72-00-50-220-155 Reference Fits and Clearances of the LP Shaft and the No. 5 Bearing at Location 2271

Refer to Figure.

Reference the clearance at location 2272. If required, use the data written as a note in TASK 72-50-41-200-000 (INSPECTION-000) and TASK 72-50-42-200-000 (INSPECTION-000).

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2272

LP Turbine Shaft LPT Shaft And Related Parts (72-50-41, 01-200)

No. 5 Bearing Seal Spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-120)

LP Turbine Shaft Diameter

3.7392

Clear

3.7398

0.0004

No. 5 Bearing Seal Spacer

3.7402

0.0019

3.7411

Clear

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2272

LP Turbine Shaft LPT Shaft And Related Parts (72-50-41, 01-200)

No. 5 Bearing Seal Spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-120)

LP Turbine Shaft Diameter

94.9757

Clear

94.9909

0.011

No. 5 Bearing Seal Spacer

95.0011

0.048

95.0239

Clear

SUBTASK 72-00-50-220-156 Reference Fits and Clearances of the LP Turbine Shaft and the No. 5 Bearing Seal Spacer at Location 2272

Refer to Figure.

Reference the clearance at location 2273. If required, use the data written as a note in TASK 72-50-41-200-000 (INSPECTION-000) and TASK 72-50-42-200-000 (INSPECTION-000).

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2273

LP Turbine Shaft LPT Shaft And Related Parts (72-50-41, 01-200)

No. 5 Bearing Seal Spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-160)

LP Turbine Shaft Diameter

3.739

Clear

3.740

0.008

No. 5 Bearing Seal Spacer

3.748

0.019

3.758

Clear

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2273

LP Turbine Shaft LPT Shaft And Related Parts(72-50-41, 01-200)

No. 5 Bearing Seal Spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-160)

LP Turbine Shaft Diameter

94.971

Clear

94.996

0.200

No. 5 Bearing Seal Spacer

95.200

0.480

95.450

Clear

SUBTASK 72-00-50-220-157-A00 Reference Fits and Clearances of the LP Turbine Shaft and the No. 5 Bearing Seal Spacer at Location 2273 (Pre SBE 72-0165)

Refer to Figure.

Reference the clearance at location 2273. If required, use the data written as a note in TASK 72-50-41-200-000 (INSPECTION-000) and TASK 72-50-42-200-000 (INSPECTION/CHECK-000).

Table 11. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2273

LP Turbine Shaft LPT Shaft And Related Parts (72-50-41, 01-200)

No. 5 Bearing Seal Spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-160)

LP Turbine Shaft Diameter

3.739

Clear

3.740

0.004

No. 5 Bearing Seal Spacer

3.744

0.006

3.745

Clear

Table 12. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2273

LP Turbine Shaft LPT Shaft And Related Parts (72-50-41, 01-200)

No. 5 Bearing Seal Spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-160)

LP Turbine Shaft Diameter

94.971

Clear

94.946

0.102

No. 5 Bearing Seal Spacer

95.098

0.152

95.123

Clear

SUBTASK 72-00-50-220-157-B00 Reference Fits and Clearances of the LP Turbine Shaft and the No. 5 Bearing Seal Spacer at Location 2273 (SBE 72-0165)

Refer to Figure.

Reference the clearance at location 2274. If required, use the data written as a note in TASK 72-50-42-200-000 (INSPECTION-000).

Table 13. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2274

No. 5 Bearing Seal Spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-120)

No. 5 Bearing Seal Spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-160)

No. 5 Bearing Seal Spacer

4.0645

Clear

4.0655

0.002

No. 5 Bearing Seal Spacer

4.0675

0.004

4.0685

Clear

Table 14. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2274

No. 5 Bearing Seal Spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-120)

No. 5 Bearing Seal Spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-160)

No. 5 Bearing Seal Spacer

103.238

Clear

103.264

0.051

No. 5 Bearing Seal Spacer

103.314

0.102

103.340

Clear

SUBTASK 72-00-50-220-158 Reference Fits and Clearances of the No. 5 Bearing Seal Spacers at Location 2274

Refer to Figure.

Reference the clearance at location 2283. If required, use the data written as a note in TASK 72-58-02-200-000 (INSPECTION-000) and TASK 72-50-53-200-000 (INSPECTION-000).

Table 15. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2283

No. 5 Bearing Nozzle NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-070)

Turbine Exhaust Case Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 21-300)

No. 5 Bearing Nozzle

0.534

Clear

0.536

0.002

Turbine Exhaust Case

0.538

0.008

0.542

Clear

Table 16. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2283

No. 5 Bearing Nozzle NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-070)

Turbine Exhaust Case Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 21-300)

No. 5 Bearing Nozzle

13.564

Clear

13.614

0.051

Turbine Exhaust Case

13.665

0.203

13.767

Clear

SUBTASK 72-00-50-220-159 Reference Fits and Clearances of the No. 5 Bearing Nozzle and the TEC at Location 2283

Refer to Figure.

Reference the clearance at location 2284. If required, use the data written as a note in TASK 72-58-02-200-000 (INSPECTION-000) and TASK 72-50-53-200-000 (INSPECTION-000).

Table 17. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2284

No. 5 Bearing Transfer Tube NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-030)

The Turbine Exhaust Case Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 21-300)

No. 5 Bearing Transfer Tube

0.359

Clear

0.361

0.017

Turbine Exhaust Case

0.378

0.023

0.382

Clear

Table 18. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2284

No. 5 Bearing Transfer Tube NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-030)

The Turbine Exhaust Case Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 21-300)

No. 5 Bearing Transfer Tube

9.119

Clear

9.169

0.432

Turbine Exhaust Case

9.601

0.584

9.703

Clear

SUBTASK 72-00-50-220-160 Reference Fits and Clearances of the No. 5 Bearing Transfer Tube and the TEC at Location 2284

Refer to Figure.

Reference the clearance at location 2285. If required, use the data written as a note in TASK 72-58-02-200-000 (INSPECTION-000).

Table 19. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2285

No. 5 Bearing Transfer Tube NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-030)

No. 5 Bearing Nozzle NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-070)

No. 5 Bearing Transfer Tube

0.359

Clear

0.361

0.017

No. 5 Bearing Nozzle

0.378

0.023

0.382

Clear

Table 20. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2285

No. 5 Bearing Transfer Tube NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-030)

No. 5 Bearing Nozzle NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-070)

No. 5 Bearing Transfer Tube

9.119

Clear

9.169

0.432

No. 5 Bearing Nozzle

9.601

0.584

9.703

Clear

SUBTASK 72-00-50-220-161 Reference Fits and Clearances of the No. 5 Bearing Transfer Tube and the No. 5 Bearing Nozzle at Location 2285

Refer to Figure.

Reference the clearance at location 2286. If required, use the data written as a note in TASK 72-58-02-200-000 (INSPECTION-000).

Table 21. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2286

No. 5 Bearing Transfer Tube NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-030)

No. 5 Bearing Nozzle NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-070)

No. 5 Bearing Transfer Tube

0.394

Clear

0.396

0.017

No. 5 Bearing Nozzle

0.413

0.023

0.417

Clear

Table 22. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2286

No. 5 Bearing Transfer Tube NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-030)

No. 5 Bearing Nozzle NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-070)

No. 5 Bearing Transfer Tube

10.008

Clear

10.058

0.432

No. 5 Bearing Nozzle

10.490

0.584

10.592

Clear

SUBTASK 72-00-50-220-162 Reference Fits and Clearances of the No. 5 Bearing Transfer Tube and the No. 5 Bearing Nozzle at Location 2286

Refer to Figure.

Reference the interference at location 3792. If required, use the data written as a note in TASK 72-50-32-200-000 (INSPECTION-000) and TASK 72-50-53-200-000 (INSPECTION-000).

Table 23. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 3792

Stage 7 LP Turbine Blade LPT Stage 3, 4, 5, 6, 7 Blades (72-50-32, 01-010)

Turbine Exhaust Case Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 21-300)

Stage 7 LP Turbine Blade

0.0740

Minimum

Turbine Exhaust Case

0.1770

Maximum

Table 24. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 3792

Stage 7 LP Turbine Blade LPT Stage 3, 4, 5, 6, 7 Blades (72-50-32, 01-010)

Turbine Exhaust Case Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 21-300)

Stage 7 LP Turbine Blade

1.879 Minimum

Turbine Exhaust Case

4.493 Maximum

SUBTASK 72-00-50-220-164 Reference Fits and Clearances of the Stage 7 LP Turbine Blade and the TEC at Location 3792

Refer to Figure.

CAUTION

MAKE SURE THE LID OF THE NO. 5 BEARING SEAL SPACER POINTS TOWARDS THE REAR.Install the No. 5 Bearing seal spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-160) to the rear end of the LP Turbine Shaft.

Lightly coat the No. 5 Bearing Carbon Seal ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-140) with CoMat 10-077 APPROVED ENGINE OILS.

Install the No. 5 Bearing seal spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-120) to the rear end of the LP Turbine Shaft.

Install the IAE 1F10033 Hydraulic installation pusher 1 off on the rear end of the LP Turbine Shaft. Attach the reaction adapter (part of the hydraulic installation pusher) to the rear thread of the LP Turbine Shaft.

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the coupler of the pusher.

SUBTASK 72-00-50-420-208-A00 Install the No. 5 Bearing Seal Spacers on to the LP Turbine Shaft (Pre SBE 72-0165)

Refer to Figure.

SBE 72-0165: Replace the No. 5 Bearing seal spacer with a spacer incorporating fool-proof installation features.

Install the No. 5 Bearing seal spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-160) to the rear end of the LP Turbine Shaft.

Lightly coat the No. 5 Bearing carbon seal ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-140) with a lint-free cloth made moist with CoMat 10-077 APPROVED ENGINE OILS.

Install the No. 5 Bearing seal spacer ENGINE-NO.5 BEARING ASSEMBLY AND SEAL (72-50-42, 20-120) to the rear end of the LP Turbine Shaft.

Install the IAE 1F10033 Hydraulic installation pusher 1 off on the rear end of the LP Turbine Shaft. Attach the reaction adapter (part of the hydraulic installation pusher) to the rear thread of the LP Turbine Shaft.

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the coupler of the pusher.

SUBTASK 72-00-50-420-208-B00 Install the No. 5 Bearing Seal and Spacers on to the LP Turbine Shaft (SBE 72-0165)

Refer to Figure.

Heat the inner race of the No. 5 Bearing ENGINE-NO.5 BEARING PLATE AND OIL DEFLECTOR (72-50-52, 20-060) to approximately 212 deg F (100 deg C).

Install the IAE 1F10034 Hydraulic installation pusher 1 off on the rear end of the LP Turbine Shaft. Attach the reaction adapter (part of the hydraulic installation pusher) to the rear thread of the LP Turbine Shaft.

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the coupler of the pusher.

SUBTASK 72-00-50-420-209-A00 Install the No. 5 Bearing Inner Race (Pre SBE 72-0165)

Refer to Figure.

SBE 72-0165: Replace the No. 5 Bearing seal spacer with a spacer incorporating fool-proof installation features.

Heat the inner race of the No. 5 Bearing ENGINE-NO.5 BEARING PLATE AND OIL DEFLECTOR (72-50-52, 20-060) to approximately 212 deg F (100 deg C).

Install the IAE 1F10034 Hydraulic installation pusher 1 off on the rear end of the LP Turbine Shaft. Attach the reaction adapter (part of the hydraulic installation pusher) to the rear thread of the LP Turbine Shaft.

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the coupler of the pusher.

SUBTASK 72-00-50-420-209-B00 Install the No. 5 Bearing Inner Race (SBE 72-0165)

Refer to Figure.

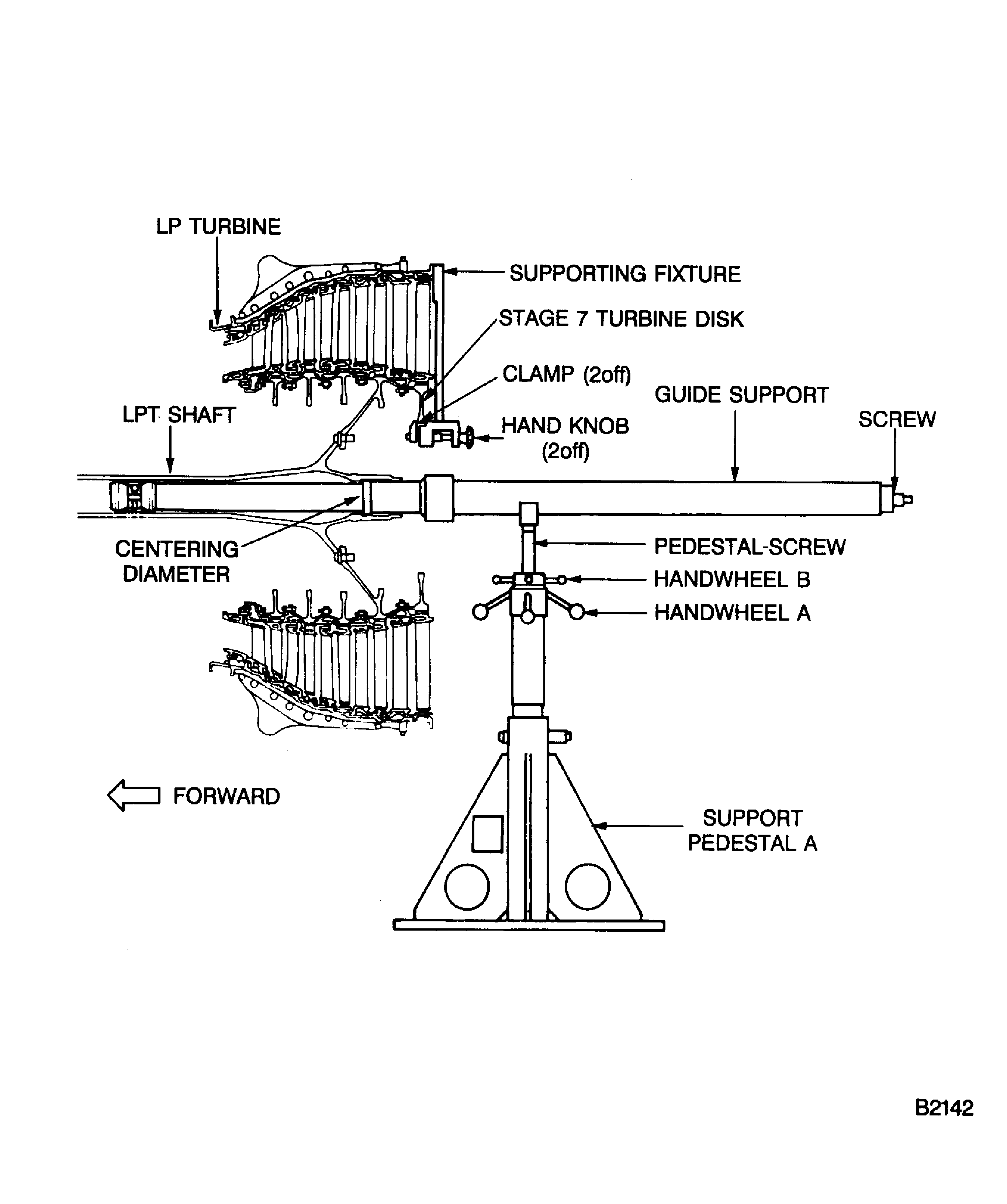

Install the IAE 1P16377 Guide support 1 off into the inner diameter of the LP Turbine Shaft. Use an applicable webbing sling.

Put the IAE 1F10075 Support pedestal 1 off below the guide support. Move the support pedestal A near to the rear flange of the LP Turbine Shaft.

SUBTASK 72-00-50-420-210 Install the Guide Support to the LP Turbine Shaft

Refer to Figure.

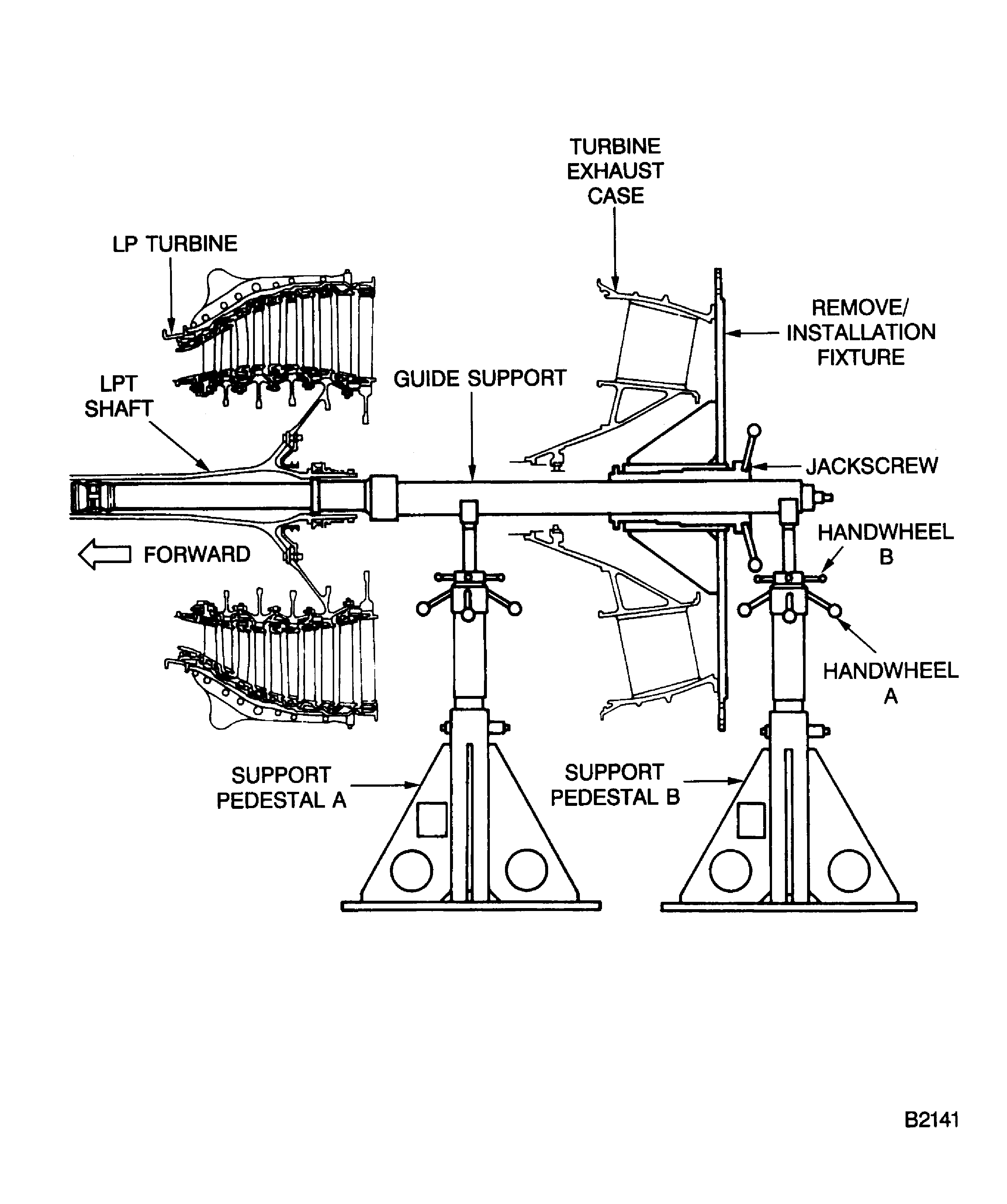

Attach hoist equipment to the upper supports of the IAE 1F10073 remove/installation fixture 1 off.

SUBTASK 72-00-50-420-211 Install the Remove/Installation Fixture to the TEC

Refer to Figure.

Attach electronic balance crane to hoist equipment. Attach the IAE 1F10051 Two cable sling 1 off to the electronic balance crane. Connect the two cables sling to the spools of the IAE 1F10073 remove/installation fixture 1 off.

Lift the Turbine Exhaust Case from the IAE 1F10178 Storage and Turnover adapter 1 off.

CAUTION

IN THE FOLLOWING STEPS, THE ELECTRONIC BALANCE CRANE MUST STAY AT APPROXIMATELY THE SAME WEIGHT.Lift the Turbine Exhaust Case and engage it to the IAE 1P16377 Guide support. Move the TEC forward.

Install the IAE 1F10075 Support pedestal 1 off behind the Turbine Exhaust Case to the rear end of the guide support. Refer to SUBTASK 72-00-50-420-141, step D.

SUBTASK 72-00-50-420-212 Install the TEC to the Guide support

Refer to Figure.

Release the two hand knobs that attach the two clamps (part of the IAE 1M14143 Support fixture or of the IAE 1M14461 Supporting fixture) 1 off to the Stage 7 Turbine Disk.

SUBTASK 72-00-50-420-213 Remove the Supporting Fixture

Refer to Figure.

Remove the IAE 1F10075 Support pedestal A 1 off.

Release the handwheel B of the IAE 1F10075 Support pedestal B 1 off. Turn the handwheel A until the electronic balance crane shows the initial weight. Refer to Step.

Turn the jackscrew (part of the remove/installation fixture) clockwise to the stop position. Lock the jackscrew in this position with the IAE 1F10076 Locking collar 1 off.

CAUTION

HOLD THE BOLTS IN THEIR POSITION WHEN YOU INSTALL THE NUTS ON TO THE BOLTS. DO NOT TURN THE BOLTS OR MAKE TO-AND-FRO MOVEMENTS. THE TURBINE EXHAUST CASE/LP CASE FLANGE AND/OR THE BOLTS CAN BE DAMAGED.

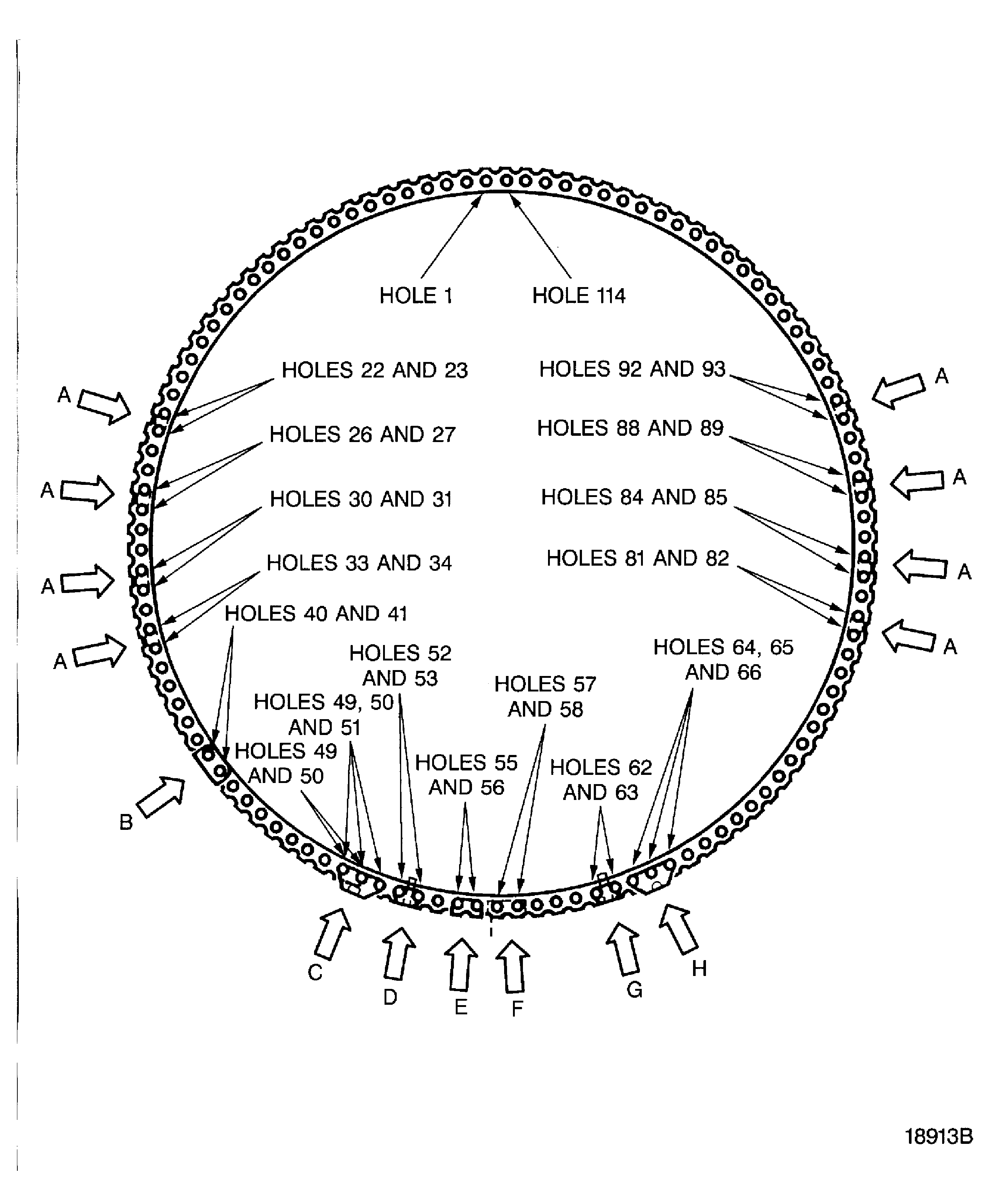

CAUTION

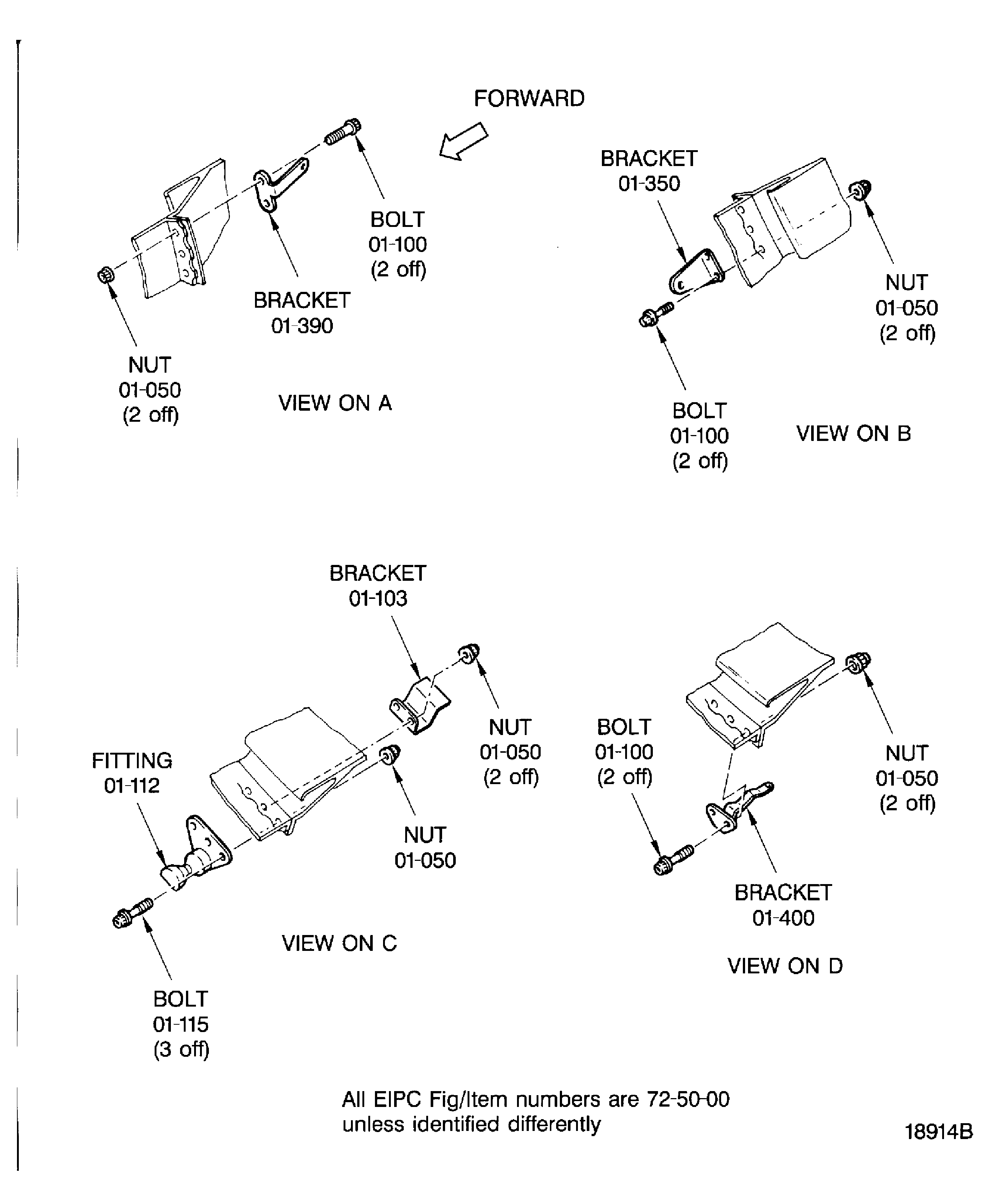

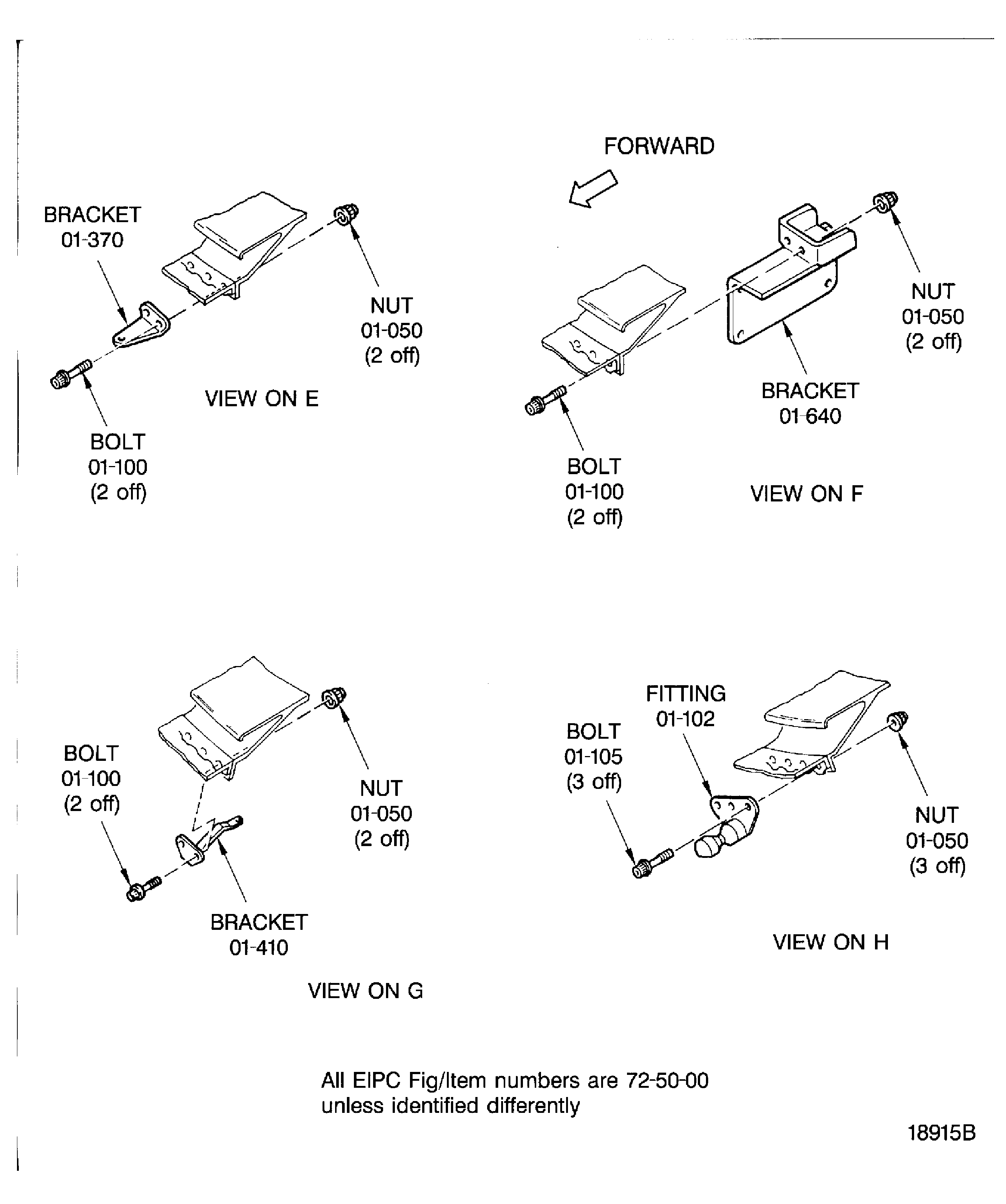

INCORRECT ASSEMBLY OF THE BOLT AND NUT CAN CAUSE OIL TUBE DAMAGE.Install the 16 brackets and attach the 114 bolts and nuts which lock the Turbine Exhaust Case to the LP Turbine Case. Refer to Figure.

SUBTASK 72-00-50-420-214 Install the TEC to the LP Turbine Case

Refer to Figure.

Attach the IAE 1P16374 Wrench support 1 off to the inner rear flange of the TEC.

Install the IAE 1F10038 Torque wrench 1 off through the wrench support. Engage the torque wrench with the rear lock nut.

Install the IAE 1F10039 Anti-torque adapter 1 off through the torque wrench. Lock the anti-torque adapter to the LP Turbine Shaft.

Install the IAE 1F10016 Mechanical wrench 1 off to the torque wrench. Attach the anti-torque adapter to the mechanical wrench with the IAE 1F10040 Anchor wrench plate 1 off.

Make a correlation mark between the IAE 1F10016 Mechanical wrench and the IAE 1F10038 Torque wrench.

Make a correlation mark between the IAE 1F10016 Mechanical wrench 1 off and the IAE 1F10038 Torque wrench 1 off.

If the correlation mark is within the limit, continue with Step.

SUBTASK 72-00-50-420-215 Install the Rear Lock Nut to the LP Turbine Shaft

Refer to Figure.

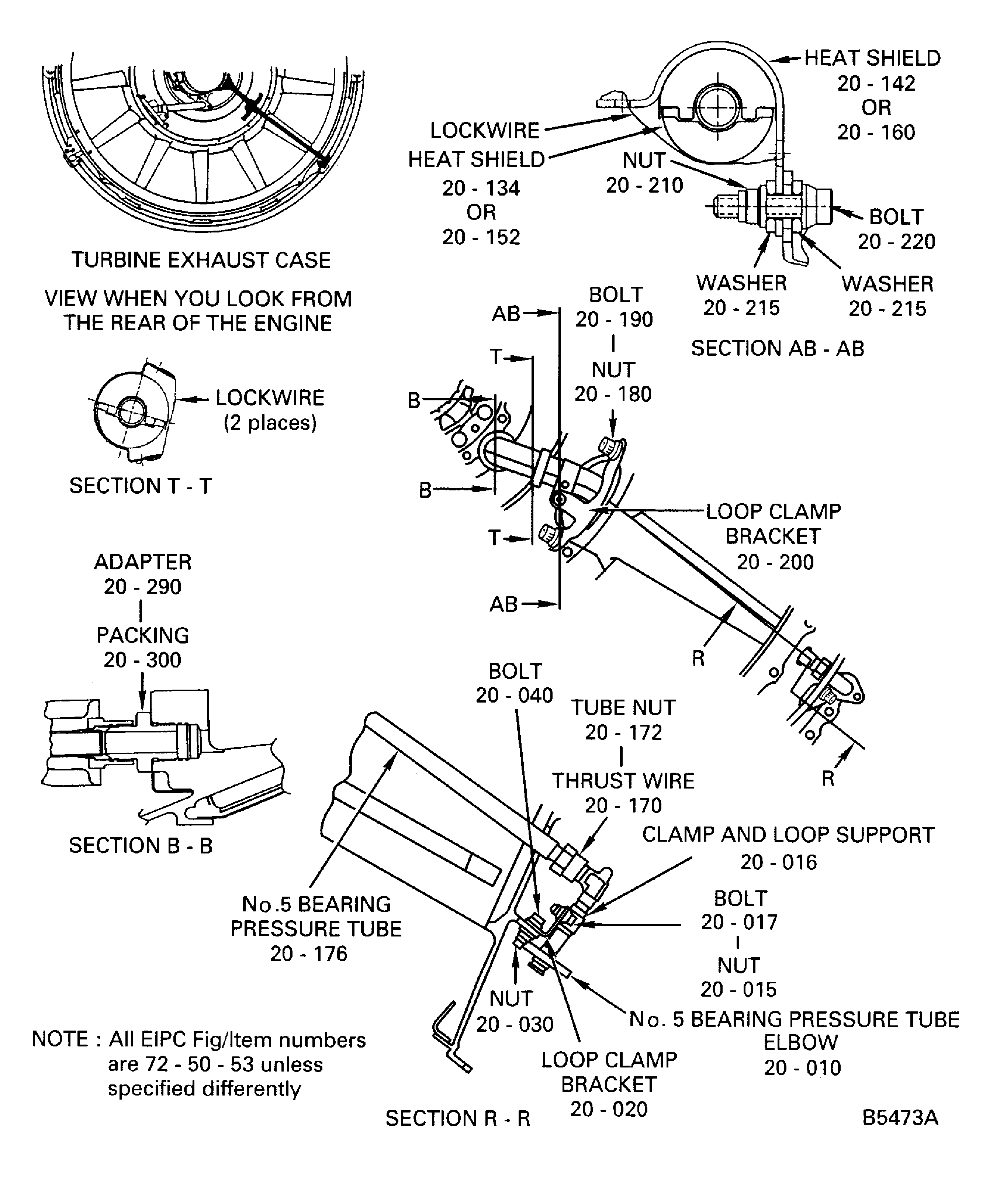

Attach the loop clamp bracket Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-020) to the external flange of the Turbine Exhaust Case with the two bolts Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-040) and two nuts Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-030).

Attach the No. 5 Bearing pressure tube Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-010) to the bracket. Install a nut Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-015) and bolt Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-017) to the clamp and support assembly Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-016).

Attach the No. 5 Bearing pressure tube Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-176) to the nipple.

Safety the nut with CoMat 02-141 LOCKWIRE.

Attach the loop clamp bracket Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-200) to the tube heat shield with two washers Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-215), nut Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-210) and bolt Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-220).

Attach the bracket to the inner support of the Turbine Exhaust Case with two bolts Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-190) and two nuts Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-180).

SUBTASK 72-00-50-420-216 Connect the No. 5 Bearing Pressure Tube Assembly

Refer to Figure.

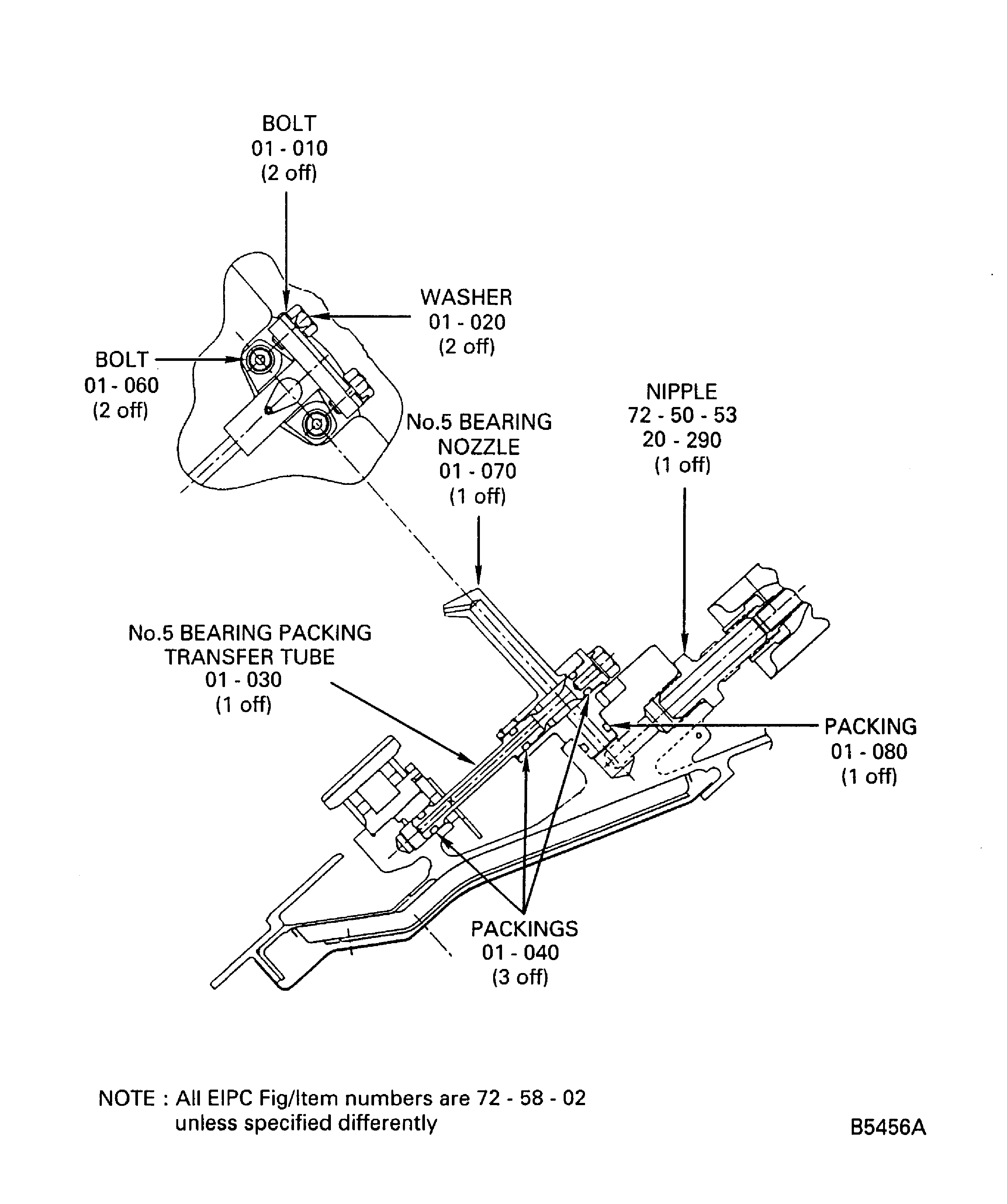

Install the new packings NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-040) and the No. 5 Bearing Packing Transfer Tube NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-030) into the No. 5 Bearing Nozzle NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-070).

Install the two washers NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-020) and the two bolts NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-010) to attach the transfer tube to the Bearing Nozzle.

Install a new packing NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-080) on the Bearing Nozzle.

Attach the Bearing Nozzle with two bolts NO.5 BEARING OIL JET AND FILTER (72-58-02, 01-060).

Install the nipple Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-290) and a new packing Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53, 20-300) Torque the nipple to 110 lbfin to 120 lbfin (12.43 Nm to 13.56 Nm).

SUBTASK 72-00-50-420-217 Install the No. 5 Bearing Nozzle

NOTE

Use of IAE 1J12263 Seal slider without IAE 1J12244 Sizing sleeve is not permitted.Put the blind cap LPT Shaft And Related Parts (72-50-41, 01-150) on to a work bench with the rear end down.

Install the IAE 1J12263 Seal slider 1 off on the blind cap.

Lubricate the new LPT Shaft And Related Parts (72-50-41, 01-160) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS.

Lubricate the outer diameter faces of the seal slider and the blind cap with CoMat 10-077 APPROVED ENGINE OILS.

Extend the sealing ring and install it to the blind cap as follows.

Put the IAE 1J12244 Sizing sleeve 1 off on to the work bench with the front end down.

Lubricate the inner diameter face of the sizing sleeve and the outer diameter of the sealing ring with CoMat 10-077 APPROVED ENGINE OILS.

CAUTION

DO NOT INSTALL THE BLIND CAP AND THE SEALING RING INTO THE LP TURBINE SHAFT BEFORE Step THE SEALING DIAMETER IS EXTENDED. THE LP TURBINE SHAFT BORE CAN CAUSE DAMAGE TO THE EXTENDED SEALING RING.Make the sealing ring diameter smaller as follows.

Install the blind cap on the LP Turbine Shaft. Use the IAE 1P17041 Drier driver 1 off.

Install the internal retaining ring LPT Shaft And Related Parts (72-50-41, 01-100).

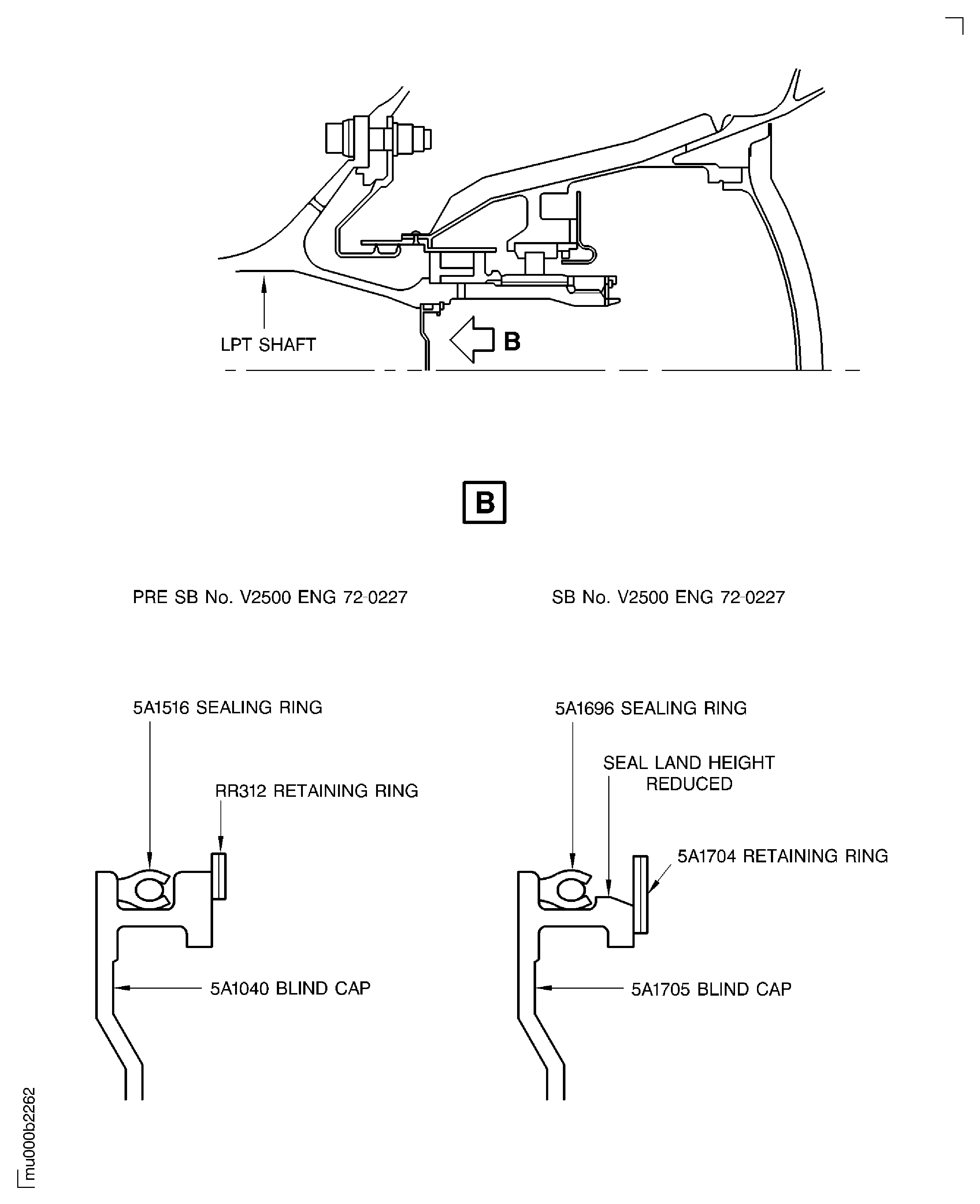

SUBTASK 72-00-50-420-218-A00 Install the Blind Cap to the LP Turbine Shaft (Pre SBE 72-0227)

SBE 72-0227: Provide a new blind cap with decreased seal land height.

Install the IAE 1J12523 Seal slider 1 off on the blind cap.

Lubricate the sealing ring with CoMat 10-077 APPROVED ENGINE OILS.

Lubricate the outer diameter faces of the seal slider and the blind cap with CoMat 10-077 APPROVED ENGINE OILS.

Install the new LPT Shaft And Related Parts (72-50-41, 01-160) sealing ring to the blind cap LPT Shaft And Related Parts (72-50-41, 01-150) as follows:

Install the blind cap to the LP Turbine Shaft. Use the IAE 1P17041 Drier 1 off.

CAUTION

DO NOT USE THE INTERNAL RETAINING RING P/N RR312 WITH THE BLIND CAP P/N 5A1705.Install the internal retaining ring LPT Shaft And Related Parts (72-50-41, 01-100).

SUBTASK 72-00-50-420-218-C00 Install the Blind Cap to the LP Turbine Shaft (SBE 72-0227)

Refer to Figure.

Install a new packing ENGINE-NO.5 BEARING COMPARTMENT COVER (72-58-01, 20-160) on to the No. 5 Bearing compartment cover ENGINE-NO.5 BEARING COMPARTMENT COVER (72-58-01, 20-120).

Install 13 work bolts to the compartment cover. Tighten the bolts.

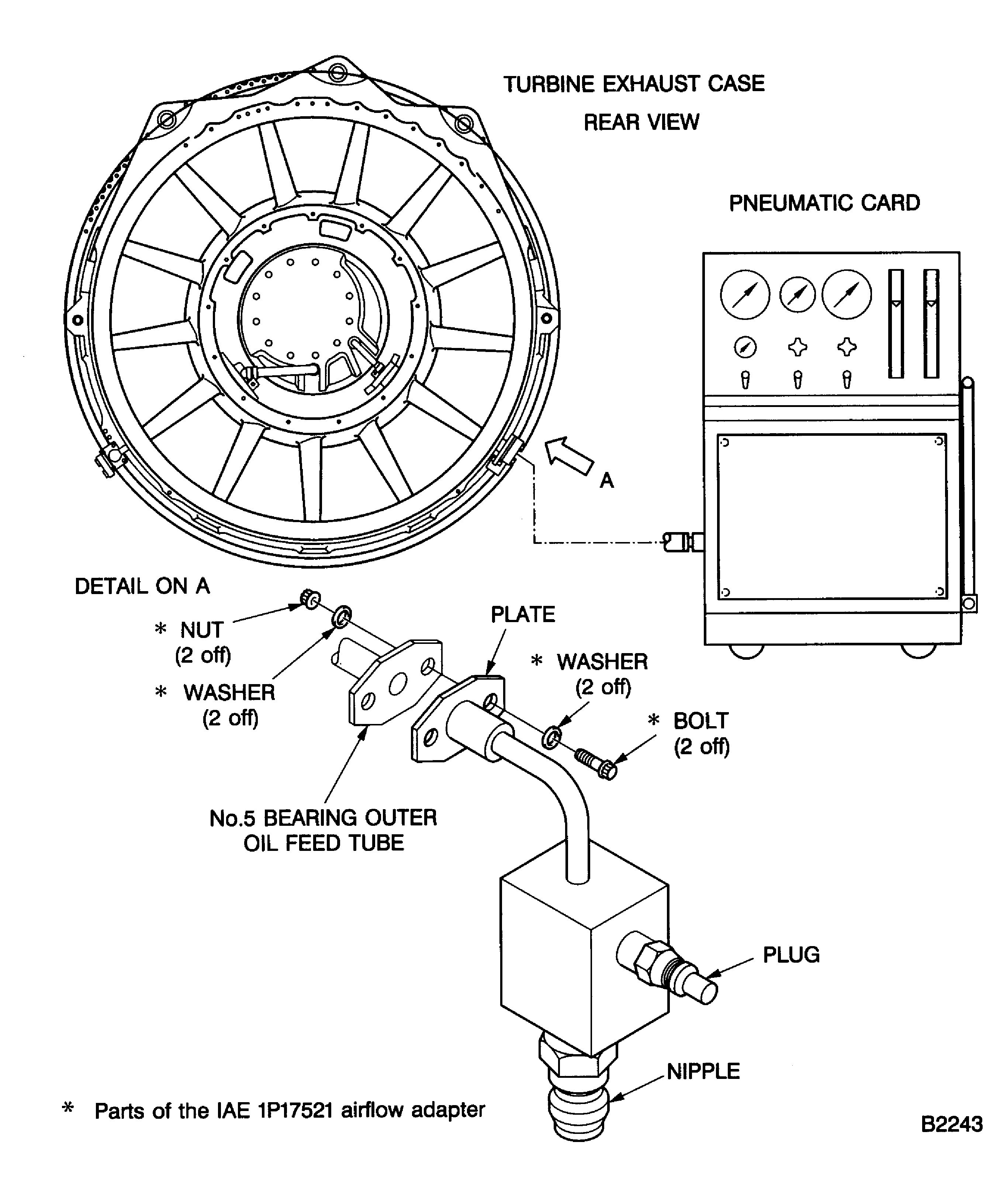

Install the IAE 1P17523 Blank-off Plate to the No. 5 Bearing outer oil feed tube. Refer to Figure.

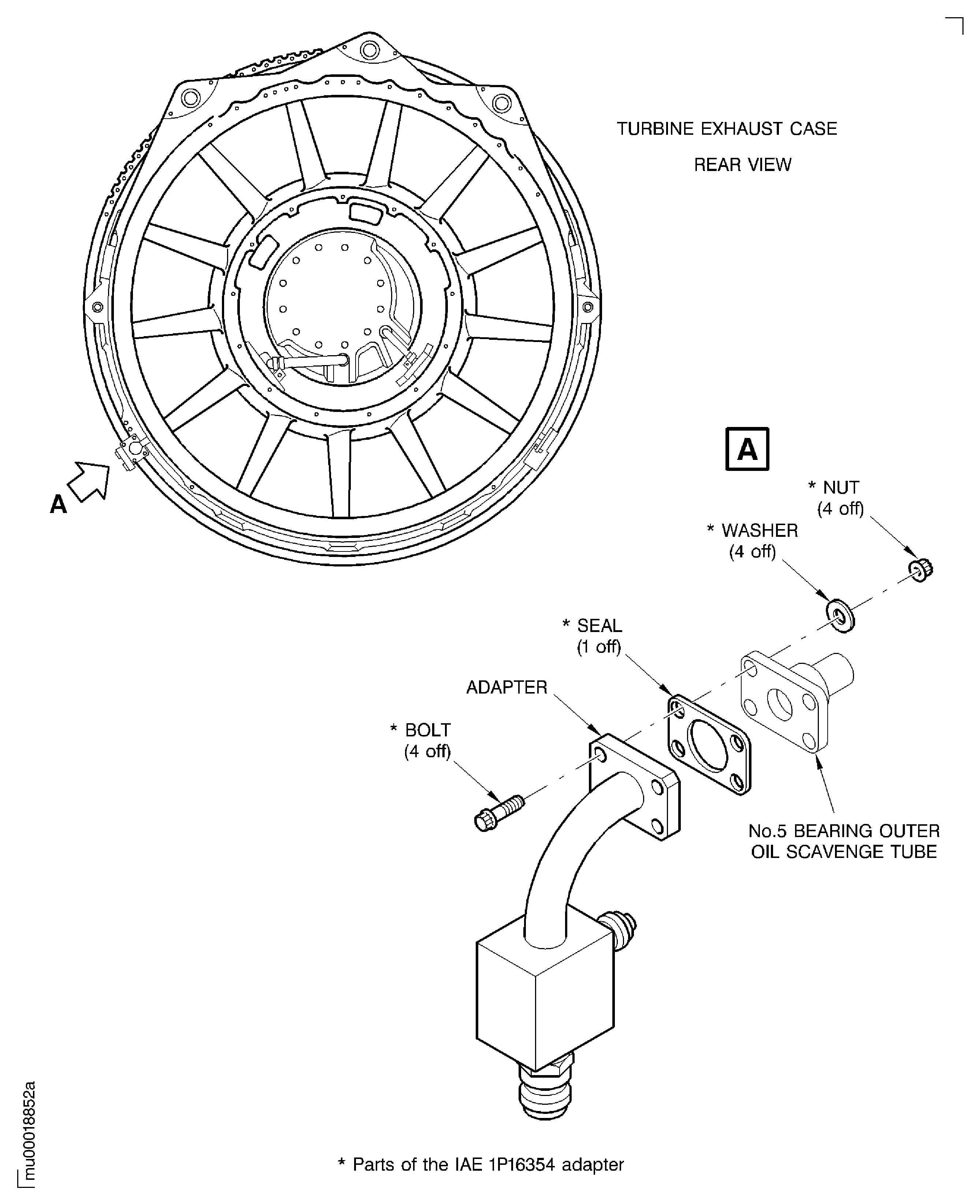

Install the IAE 1P16354 Vacuum Test Adapter to the No. 5 Bearing oil scavenge tube outlet with three bolts (part of the adapter). Tighten the bolts. Refer to Figure.

Attach the hose on the IAE 6F01029 Pneumatic cart to the adapter.

Control the air pressure to the adapter to 10 psig (68.95 kPa).

Apply CoMat 10-045 LEAK CHECK FLUID, BUBBLES-TYPE or CoMat 10-045A LEAK CHECK FLUID, BUBBLES-TYPE around the cover and oil tube interfaces to check for leaks. Replace the seal of any leaking interface with a new seal.

Do the leak test again.

Remove the 13 work bolts.

Do a leak check of the compartment cover and oil tubes.

Install the No. 5 Bearing shields ENGINE-NO.5 BEARING COMPARTMENT COVER (72-58-01, 20-100) and ENGINE-NO.5 BEARING COMPARTMENT COVER (72-58-01, 20-080) on the No. 5 Bearing compartment cover. Align the bolt holes.

Treat threads and underside of head of the bolts with CoMat 10-129 ANTI-SEIZE PASTE at assembly.

SUBTASK 72-00-50-420-219 Install the No. 5 Bearing Compartment Cover

WARNING

IF YOU DO NOT SECURE THE COMPARTMENT COVER DURING THE LEAK TEST THERE IS A RISK OF PERSONAL INJURY FROM THE RELEASED COVER.Lubricate the bolts, nuts and washers with CoMat 10-077 APPROVED ENGINE OILS.

Install the IAE 1P16354 Vacuum Test Adapter 1 off to the No. 5 Bearing outer oil scavenge tube, Figure.

Lubricate the bolts, nuts and washers with CoMat 10-077 APPROVED ENGINE OILS.

Install the IAE 1P17523 Blank-off Plate 1 off to the No. 5 Bearing outer oil feed tube, Figure.

SUBTASK 72-00-50-420-220 Install the Adapter and the Plate to the TEC

Refer to Figure.

Connect the hose of the IAE 6F10030 Vacuum test cart 1 off to the nipple of the IAE 1P16354 Vacuum Test Adapter 1 off.

Set the air pressure at the test port to -20 inHg (-508 mmHg gage). Based on the ambient pressure, refer to the table below for the vacuum pressure in psia.

Ambient Pressure of the Day (psia)

Vacuum Pressure (psia)

14.7

4.9

14.5

4.7

14.3

4.5

14.1

4.3

13.9

4.1

13.7

3.9

13.5

3.7

13.3

3.5

13.1

3.3

Vacuum pressure (psia) = Ambient pressure of the day (psia) - 9.8 psia

SUBTASK 72-00-50-420-221 Do an Evacuation Check for the No. 5 Bearing Compartment

Install the module dressings. Refer to TASK 72-00-50-420-005-B00 (INSTALLATION-007).

SUBTASK 72-00-50-420-223 Install the Module Dressings

Figure: Fits and Clearances at Interface N-50/10 and N-50/50

Fits and Clearances at Interface N-50/10 and N-50/50

Figure: Fits and Clearances at Interface N-50/10 and N-50/50

Fits and Clearances at Interface N-50/10 and N-50/50

Figure: Fits and Clearances of the No.5 Bearing and the TEC

Fits and Clearances of the No.5 Bearing and the TEC

Figure: Install the No.5 Bearing Seal Spacers and the Inner Race of the No.5 Bearing

Install the No.5 Bearing Seal Spacers and the Inner Race of the No.5 Bearing

Figure: Install the Guide Support to the LP Turbine Shaft

Install the Guide Support to the LP Turbine Shaft

Figure: Install the Remove/Installation Fixture

Install the Remove/Installation Fixture

Figure: Installation of the Bolts and Brackets at the Front Flange of the TEC

Installation of the Bolts and Brackets at the Front Flange of the TEC

Figure: Installation of the Bolts and Brackets at the Front Flange of the TEC

Installation of the Bolts and Brackets at the Front Flange of the TEC

Figure: Installation of the Bolts and Brackets at the Front Flange of the TEC

Installation of the Bolts and Brackets at the Front Flange of the TEC

Figure: Install the No. 5 Bearing Nozzle

Install the No. 5 Bearing Nozzle

Figure: Connect the No. 5 Bearing Pressure Tube Assembly

Connect the No. 5 Bearing Pressure Tube Assembly

Figure: Install the Turbine Shaft Rear Lock Nut

Install the Turbine Shaft Rear Lock Nut

Figure: Install the Blind Cap

Install the Blind Cap

Figure: Connect the No. 5 Bearing Pressure Tube Assembly

Connect the No. 5 Bearing Pressure Tube Assembly

Figure: Installation of the Adapter to No. 5 Bearing Outer Oil Scavenge Tube

Installation of the Adapter to No. 5 Bearing Outer Oil Scavenge Tube

Figure: Installation of the Plate to the No. 5 Bearing Outer Oil Feed Tube

Installation of the Plate to the No. 5 Bearing Outer Oil Feed Tube

Figure: Connect the Fitting of the Vacuum Test Cart to the Adapter

Connect the Fitting of the Vacuum Test Cart to the Adapter

Figure: Pre SBE 72-0227: Installation of the Sealing Ring onto the Blind Cap

Pre SBE 72-0227: Installation of the Sealing Ring onto the Blind Cap

Figure: SBE 72-0227: Installation of the Sealing Ring onto the Blind Cap

SBE 72-0227: Installation of the Sealing Ring onto the Blind Cap

Figure: Pre SBE 72-0227: Installation of the Sealing Ring into the Sizing Sleeve

Pre SBE 72-0227: Installation of the Sealing Ring into the Sizing Sleeve

Figure: Installed Condition of the Sealing Ring

Installed Condition of the Sealing Ring

Figure: Installation of the Sealing Ring on the Blind Cap Method 2

Installation of the Sealing Ring on the Blind Cap Method 2

Figure: Example of Incorrect Installation of the Sealing Rings on the Blind Cap

Example of Incorrect Installation of the Sealing Rings on the Blind Cap

Figure: Oil Jet Air Flow Check

Oil Jet Air Flow Check

Figure: Installation of Blind Cap and Retaining Ring

Installation of Blind Cap and Retaining Ring