Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-50-420-005-B00 LPT Module - Install The LPT Module Components, External Harnesses, And Tubes, Installation-007

General

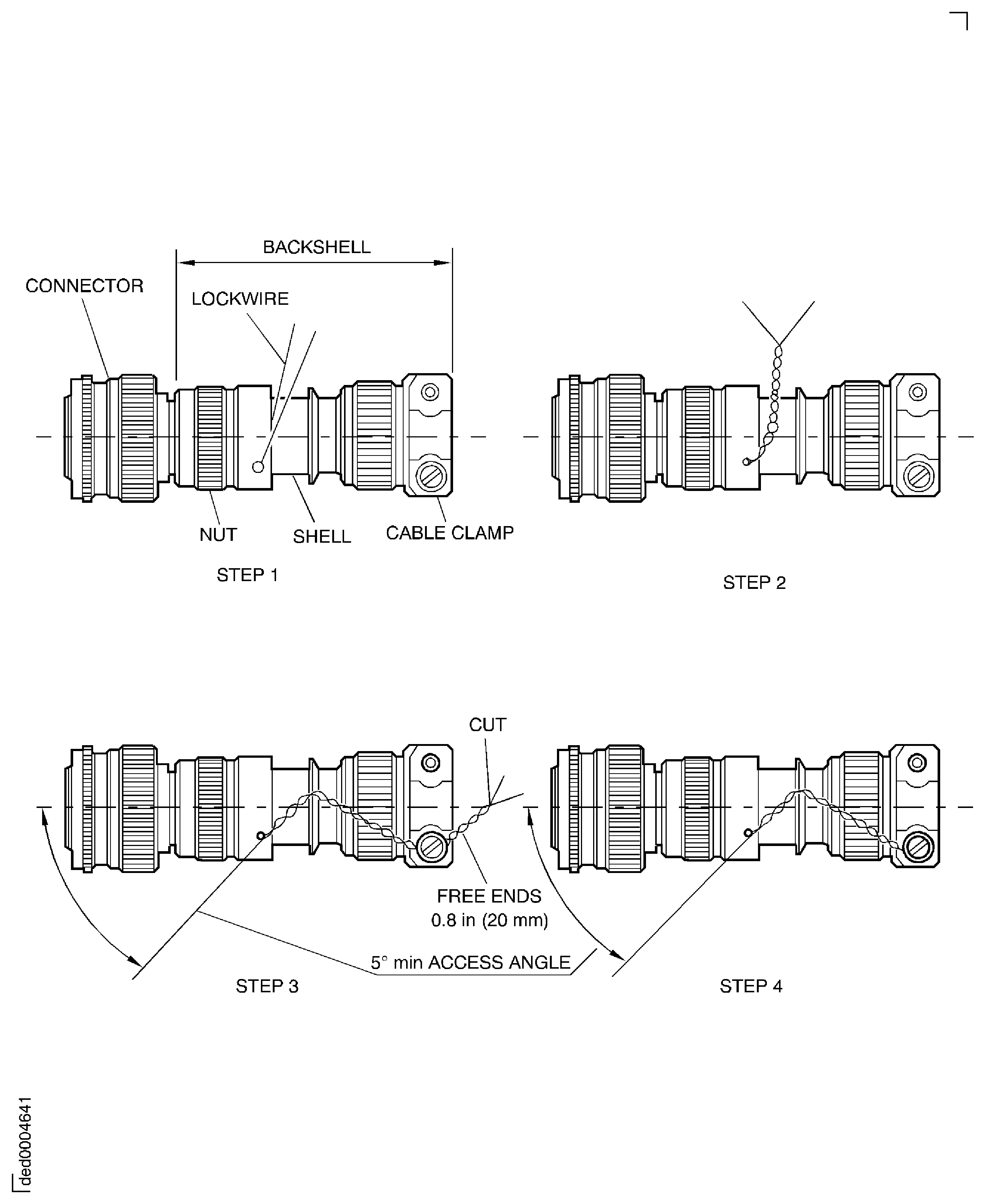

For lockwire data and procedures refer to the SPM TASK 70-42-05-400-501.

Transportation covers/blanks must be removed immediately before the installation of components and tubes.

Fig/item numbers in parentheses in the procedure agree with those used in the EIPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the EIPC.

For all parts identified in a different ATA Chapter/Section/Subject, the applicable ATA Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures refer to the SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is identified with the symbol * after the torque value.

Special assembly tolerances are included in this procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-129 ANTI-SEIZE PASTE A, pure Ni-special, unless other lubricants are referred to in the procedure.

Refer to the V2500 Illustrated Tool and Equipment Manual (ITEM), Pub.ref.ITE-V2500-1IA, for the illustrations of the special tools given in this procedure.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1M14117 Checking go/no-go gage | 0AM53 | IAE 1M14117 | 1 | |

| IAE 1M14118 Checking go/no-go gage | 0AM53 | IAE 1M14118 | 1 | |

| IAE 1M14121 Checking go/no-go gage | 0AM53 | IAE 1M14121 | 1 | |

| IAE 1M14122 Checking go/no-go gage | 0AM53 | IAE 1M14122 | 1 | |

| IAE 1N20015 Aft engine mount sling | 0AM53 | IAE 1N20015 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-119 LOCKWIRE | LOCAL | CoMat 02-119 | ||

| CoMat 02-126 LOCKWIRE | K6835 | CoMat 02-126 | ||

| CoMat 02-128 LOCKWIRE | LOCAL | CoMat 02-128 | ||

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 10-078 ANTISEIZE COMPOUND | LOCAL | CoMat 10-078 | ||

| CoMat 10-129A ANTI-SEIZE PASTE | 71984 | CoMat 10-129A | ||

| CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) | LOCAL | CoMat 02-148 | ||

| CoMat 10-129 ANTI-SEIZE PASTE | 34568 | CoMat 10-129 |

Spares

NONESafety Requirements

WARNING

Procedure

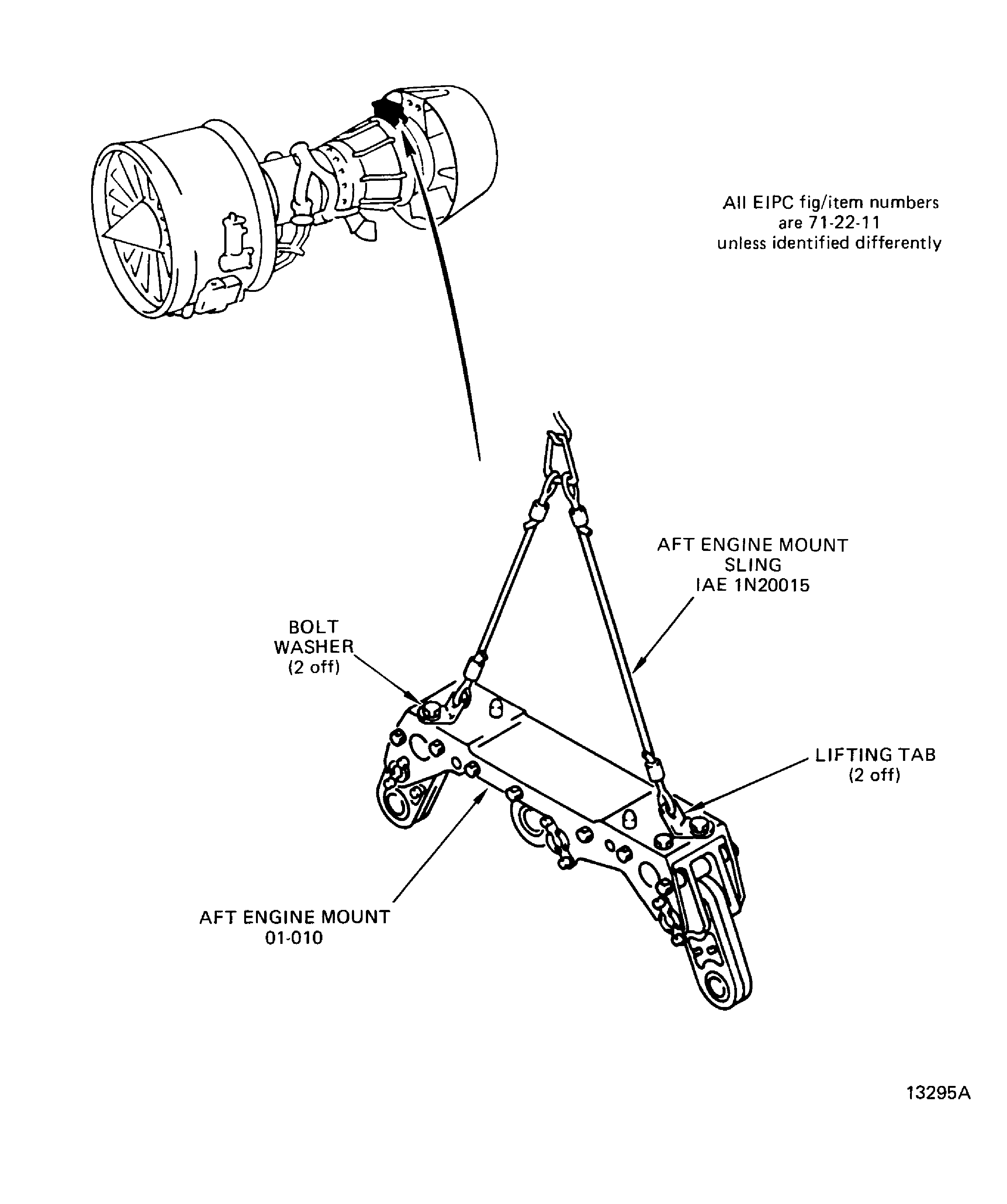

Attach IAE 1N20015 Aft engine mount sling 1 off to a hoist in position over the aft engine mount.

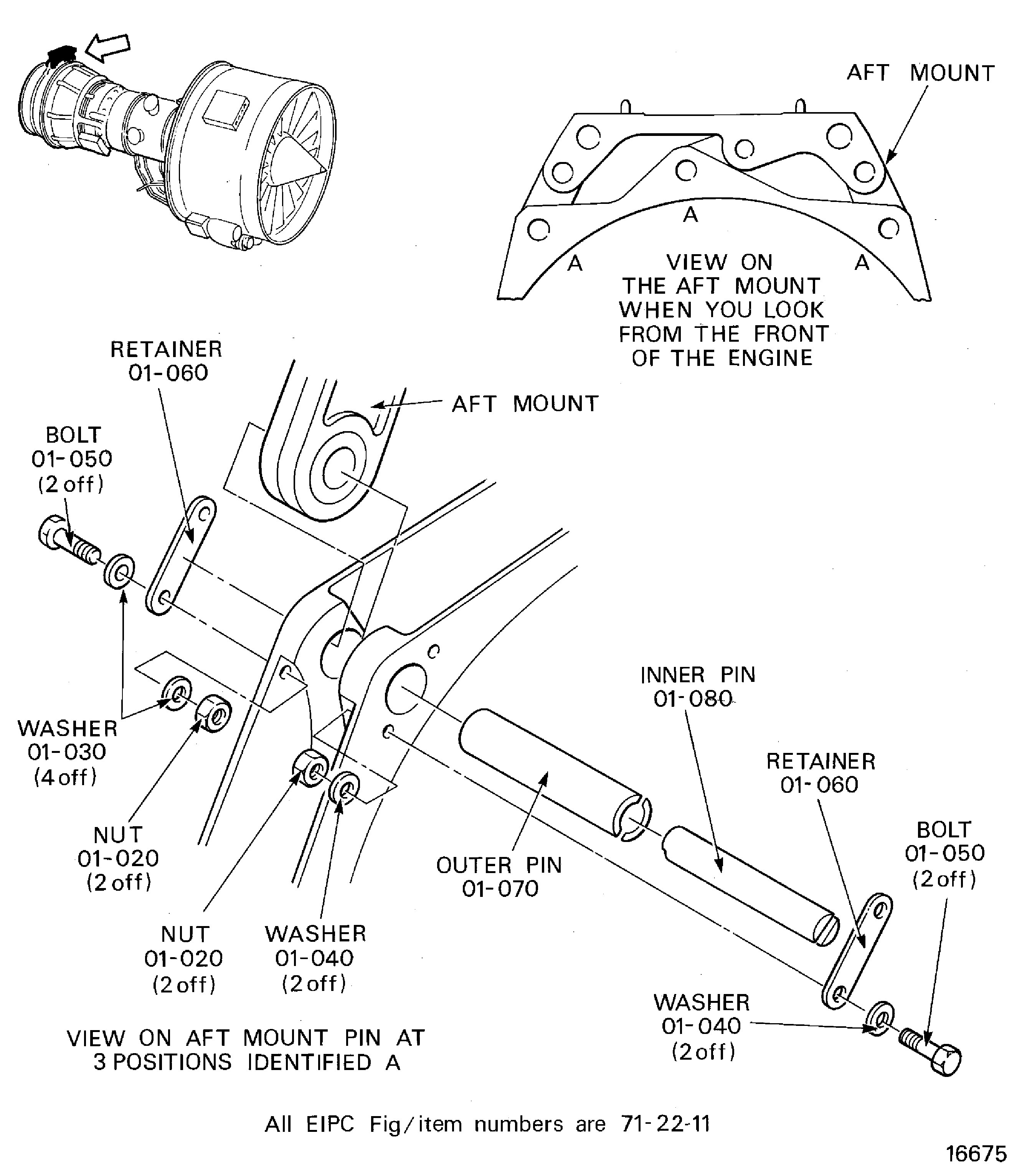

Apply CoMat 10-078 ANTISEIZE COMPOUND to the outside surface of the three outer pins POWER PLANT-AFT MOUNT (71-22-11, 01-070).

Install the three outer pins POWER PLANT-AFT MOUNT (71-22-11, 01-070) through the LP turbine case flange and in to the aft mount, at the three locations A.

Apply CoMat 10-078 ANTISEIZE COMPOUND to the outside surface of the three inner pins POWER PLANT-AFT MOUNT (71-22-11, 01-080).

Install the three inner pins POWER PLANT-AFT MOUNT (71-22-11, 01-080) in to the outer pins.

Install the six retainers POWER PLANT-AFT MOUNT (71-22-11, 01-060) in to the slots of the outer pin and inner pin.

Install the 12 bolts POWER PLANT-AFT MOUNT (71-22-11, 01-050), the 12 washers POWER PLANT-AFT MOUNT (71-22-11, 01-040), the 12 washers POWER PLANT-AFT MOUNT (71-22-11, 01-030) and the 12 nuts POWER PLANT-AFT MOUNT (71-22-11, 01-020).

SUBTASK 72-00-50-420-182 Install the Aft Mount

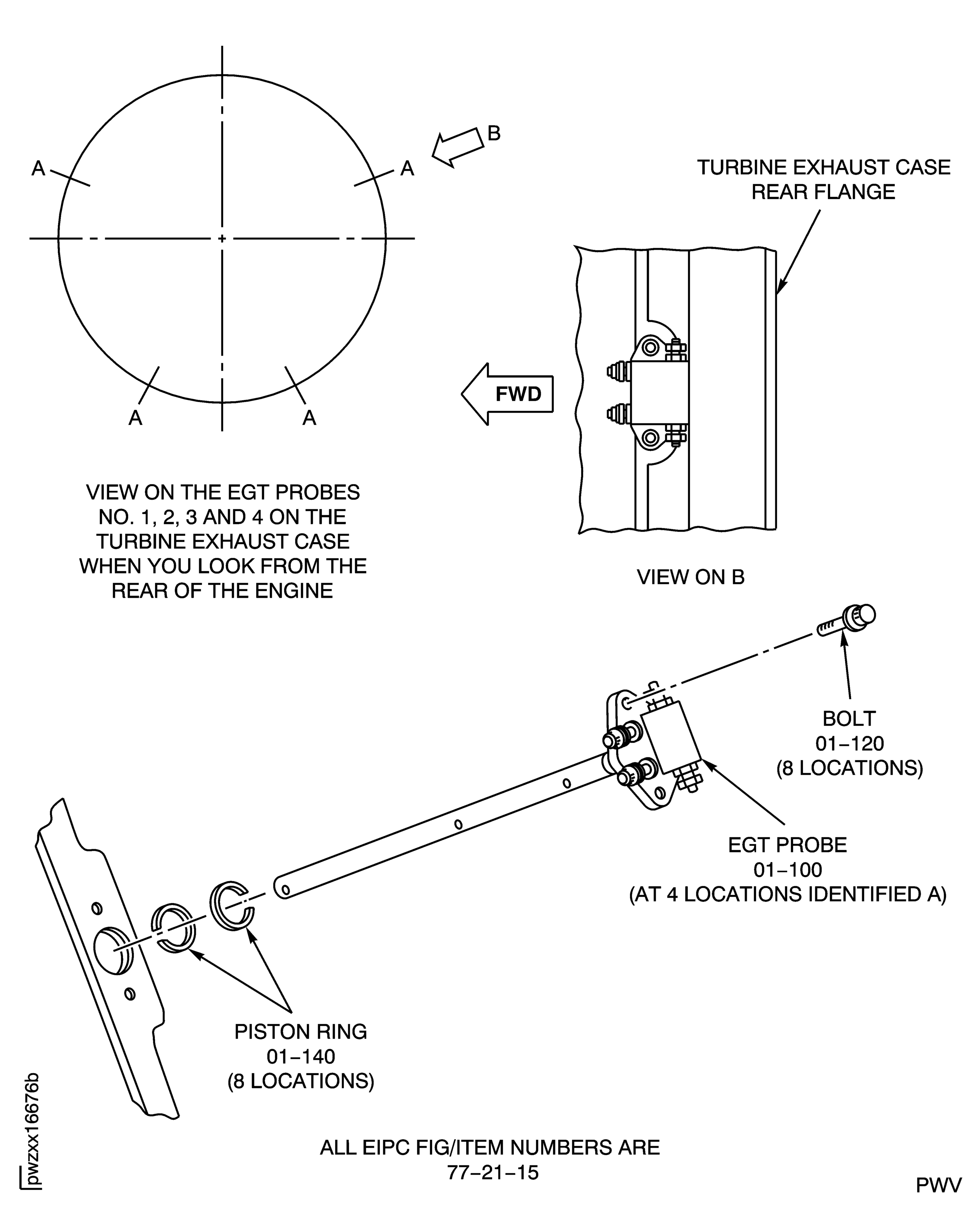

Install the two piston rings ENGINE INDICATING-EGT THERMOCOUPLE (77-21-15, 20-140) in to the grooves one of the four EGT probes ENGINE INDICATING-EGT THERMOCOUPLE (77-21-15, 20-100). Make sure that the spaces in each piston ring are 180 degrees apart.

Install the two bolts ENGINE INDICATING-EGT THERMOCOUPLE (77-21-15, 20-120) in to the turbine exhaust case through the EGT probe.

CAUTION

YOU MUST MAKE SURE THAT THE EGT THERMOCOUPLE BOLTS ARE CORRECTLY SAFETIED. INCORRECT SAFETYING OF THE BOLTS CAN RESULT IN LOOSE BOLTS AND SUBSEQUENT LOSS OF EGT INDICATION.

CAUTION

MAKE SURE THE SAFETY WIRE DOES NOT TOUCH THE THERMOCOUPLE STUDS OR THE EGT HARNESS LEADS. THIS CAN CAUSE ERRATIC OR UNRELIABLE EGT INDICATION.Safety the bolts with CoMat 02-141 LOCKWIRE.

NOTE

You must not use the EGT thermocouple probe terminals to attach the lockwire. Refer to the view which shows the method which is not acceptable and must not be used.Make sure the lockwire correctly safeties the eight EGT thermocouple bolts V2500-A5-77-21-15-01A-941A-D (77-21-15, 01-120). Refer to the view which shows the acceptable method to safety the bolts, Figure.

SUBTASK 72-00-50-420-183 Install the Exhaust Gas Thermocouple (EGT) Probes in to the Turbine Exhaust Case

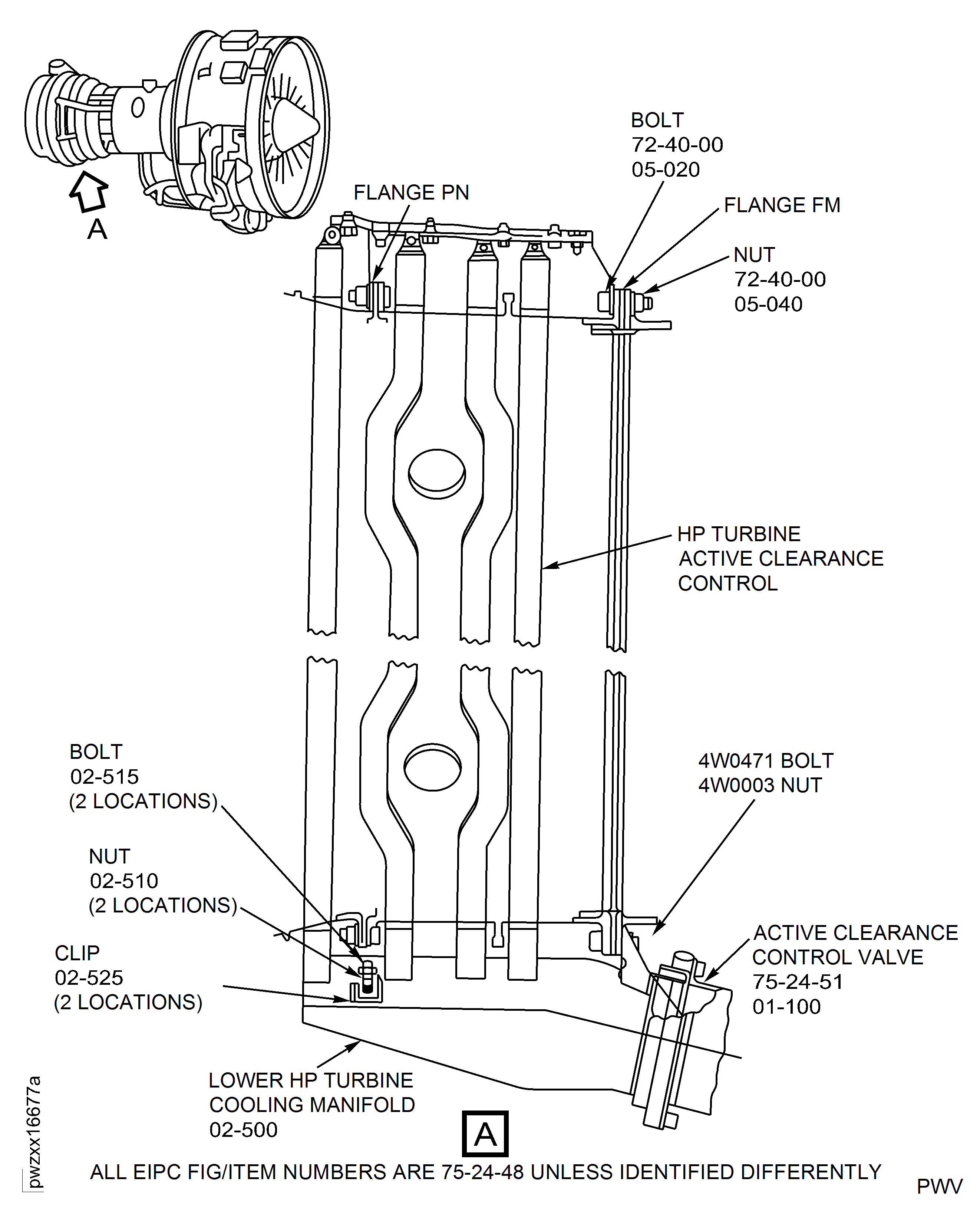

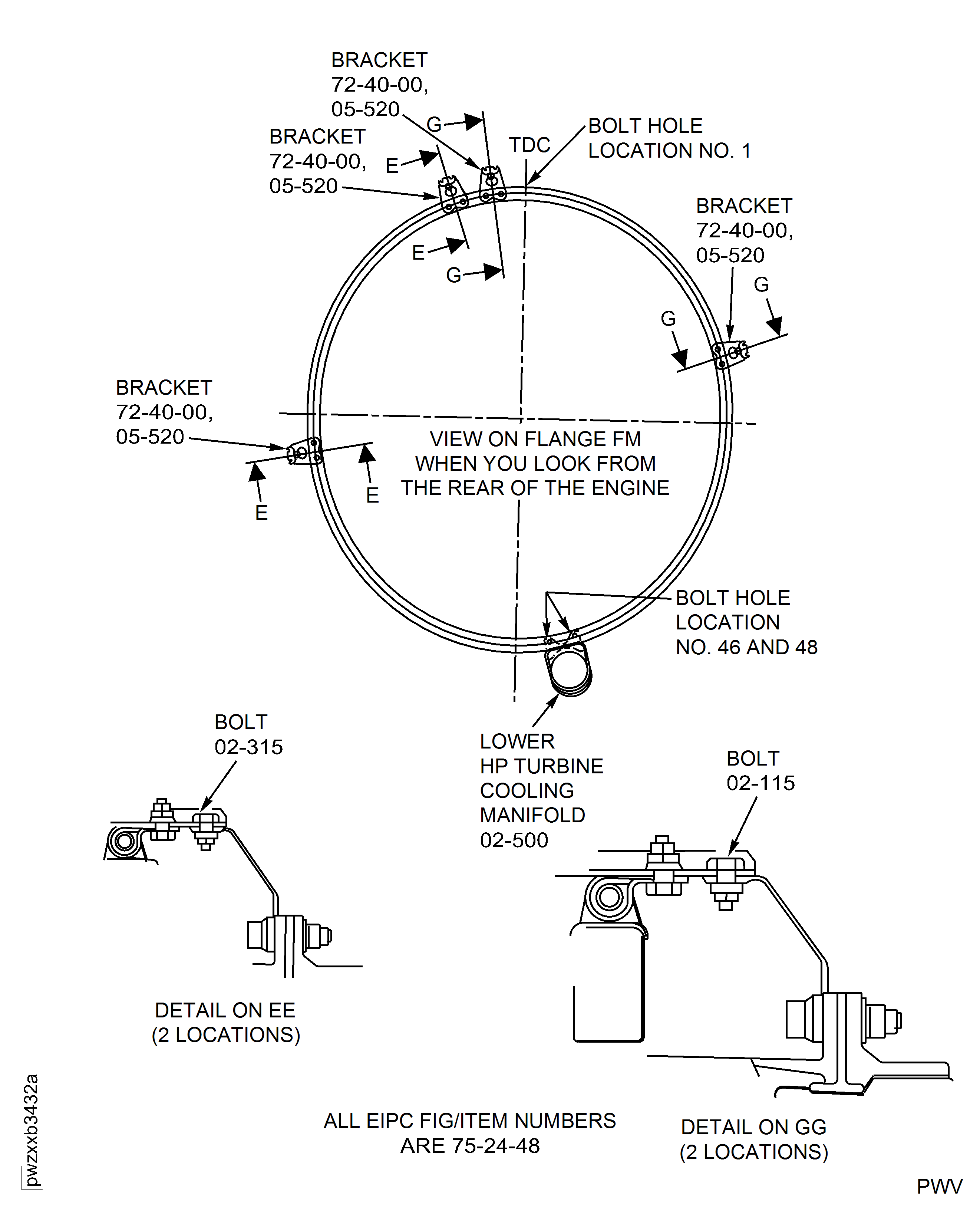

Remove the two bolts HPC Module - Attaching Parts (72-40-00, 05-020) and the two nuts HPC Module - Attaching Parts (72-40-00, 05-040) at the bolt hole Location numbers 46 and 48 on flange FM.

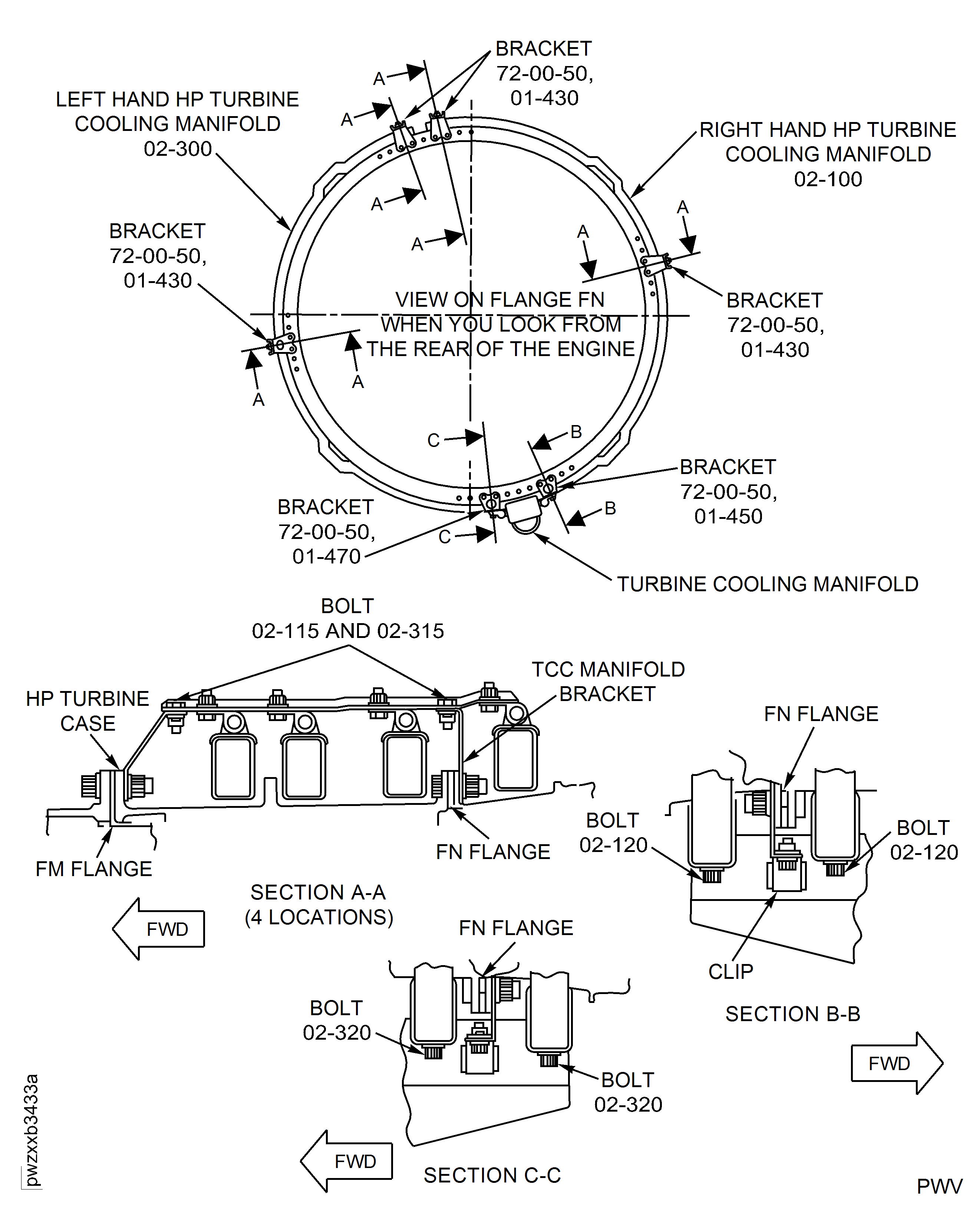

Install the two clips AIR-HP ACTIVE CLEARANCE CONTROL MANIFOLD (75-24-48, 02-525), and the two bolts AIR-HP ACTIVE CLEARANCE CONTROL MANIFOLD (75-24-48, 02-515) that attach the lower TCM to the brackets LP TURBINE (LPT) MODULE (72-00-50, 01-450) and LP TURBINE (LPT) MODULE (72-00-50, 01-470) on flange FN. Make sure that the lower TCM engages in the active clearance control valve. Torque the bolts to 36 to 40 lbfin. (4 to 5 Nm).

Install the lower TCM to the flange FM with the two bolts HPC Module - Attaching Parts (72-40-00, 05-020) and the two nuts HPC Module - Attaching Parts (72-40-00, 05-040). Torque the nuts to 180 to 200 lbfin. (20.34 to 22.59 Nm).

Install the lower turbine cooling manifold (TCM) AIR-HP ACTIVE CLEARANCE CONTROL MANIFOLD (75-24-48, 02-500).

Attach the left hand TCM to two of the brackets LP TURBINE (LPT) MODULE (72-00-50, 01-430) on the flange FN, with two of the four bolts AIR-HP ACTIVE CLEARANCE CONTROL MANIFOLD (75-24-48, 02-315). Torque the bolts to 36 to 45 lbfin. (4 to 5 Nm).

Attach the left hand TCM to two of the brackets HPC Module - Attaching Parts (72-40-00, 05-520) on the flange FM, with the other two bolts AIR-HP ACTIVE CLEARANCE CONTROL MANIFOLD (75-24-48, 02-315). Torque the bolts to 36 to 45 lbfin. (4 to 5 Nm).

Install the four bolts AIR-HP ACTIVE CLEARANCE CONTROL MANIFOLD (75-24-48, 02-320) to the lower TCM AIR-HP ACTIVE CLEARANCE CONTROL MANIFOLD (75-24-48, 02-500). Torque the bolts to 36 to 45 lbfin. (4 to 5 Nm).

Install the left hand turbine cooling manifold (TCM) AIR-HP ACTIVE CLEARANCE CONTROL MANIFOLD (75-24-48, 02-300).

Attach the right hand TCM to the other two brackets LP TURBINE (LPT) MODULE (72-00-50, 01-430) on the flange FN, with two of the four bolts AIR-HP ACTIVE CLEARANCE CONTROL MANIFOLD (75-24-48, 02-115). Torque the bolts to 36 to 45 lbfin. (4 to 5 Nm).

Attach the right hand TCM to the other two brackets HPC Module - Attaching Parts (72-40-00, 05-520) on the flange FM, with the other two bolts AIR-HP ACTIVE CLEARANCE CONTROL MANIFOLD (75-24-48, 02-115). Torque the bolts to 36 to 45 lbfin. (4 to 5 Nm).

Install the four bolts AIR-HP ACTIVE CLEARANCE CONTROL MANIFOLD (75-24-48, 02-120) to the lower TCM AIR-HP ACTIVE CLEARANCE CONTROL MANIFOLD (75-24-48, 02-500). Torque the bolts to 36 to 45 lbfin. (4 to 5 Nm).

Install the right hand turbine cooling manifold (TCM) AIR-HP ACTIVE CLEARANCE CONTROL MANIFOLD (75-24-48, 02-100).

SUBTASK 72-00-50-420-184 Install the HP Turbine Active Clearance Control Manifolds

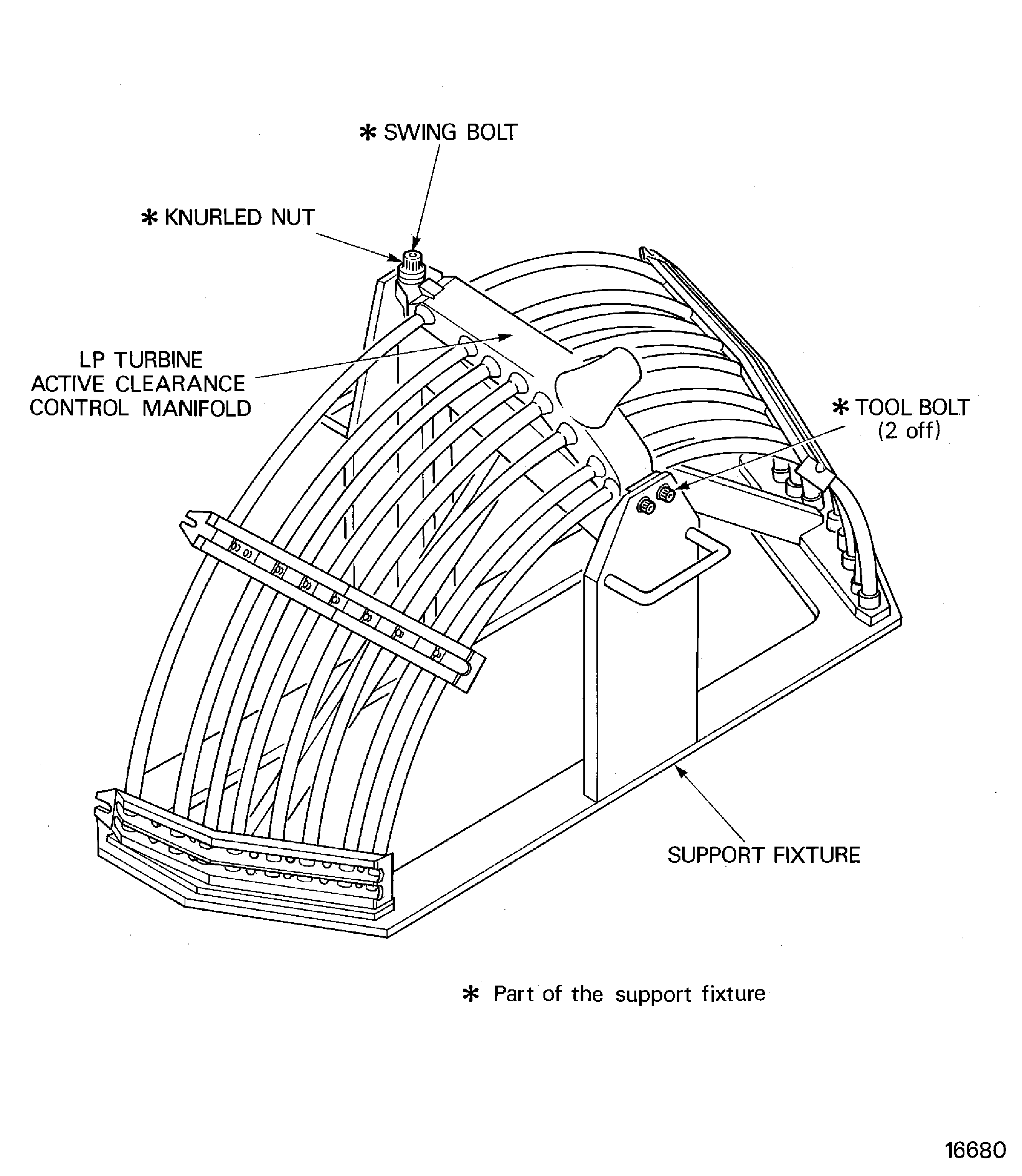

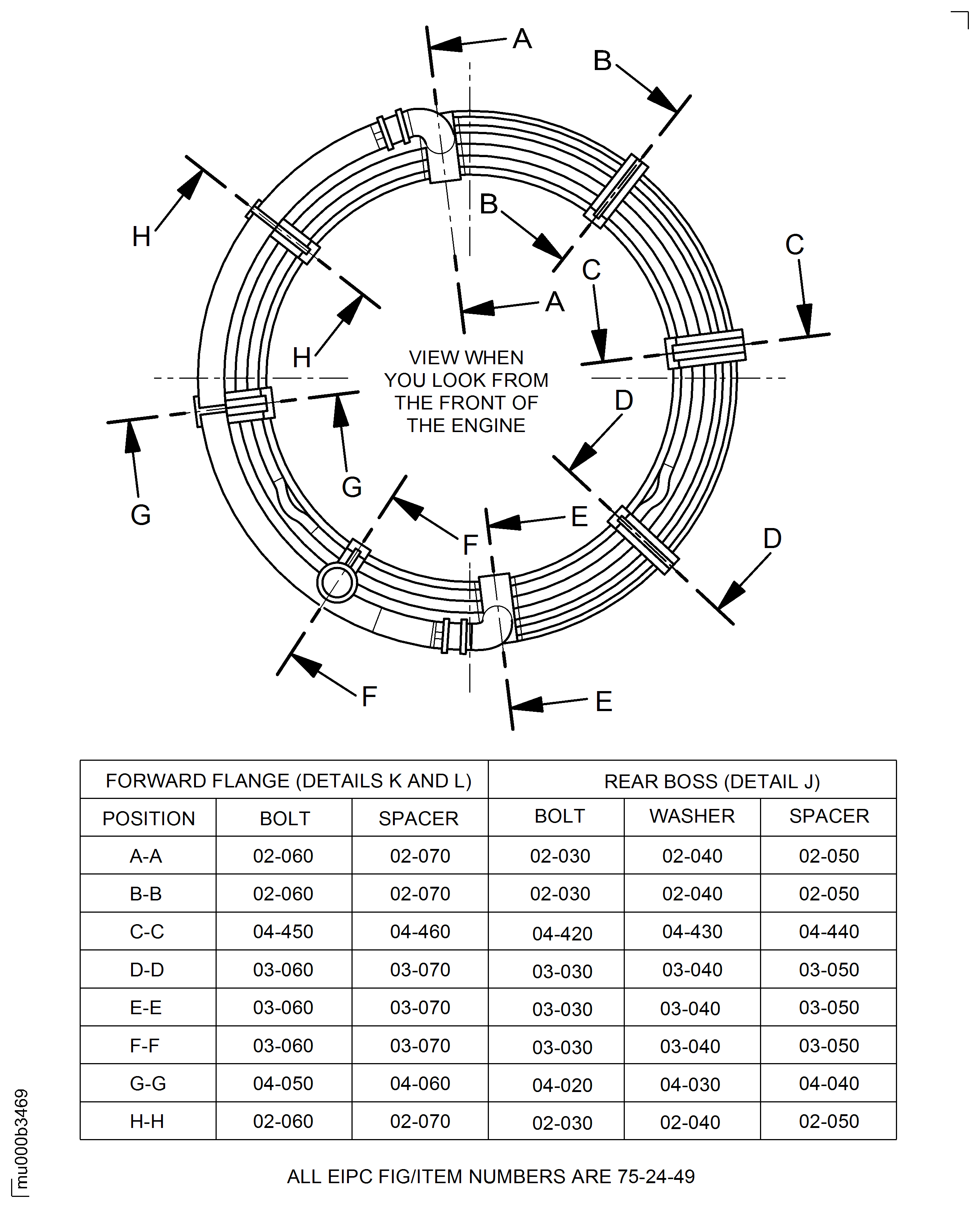

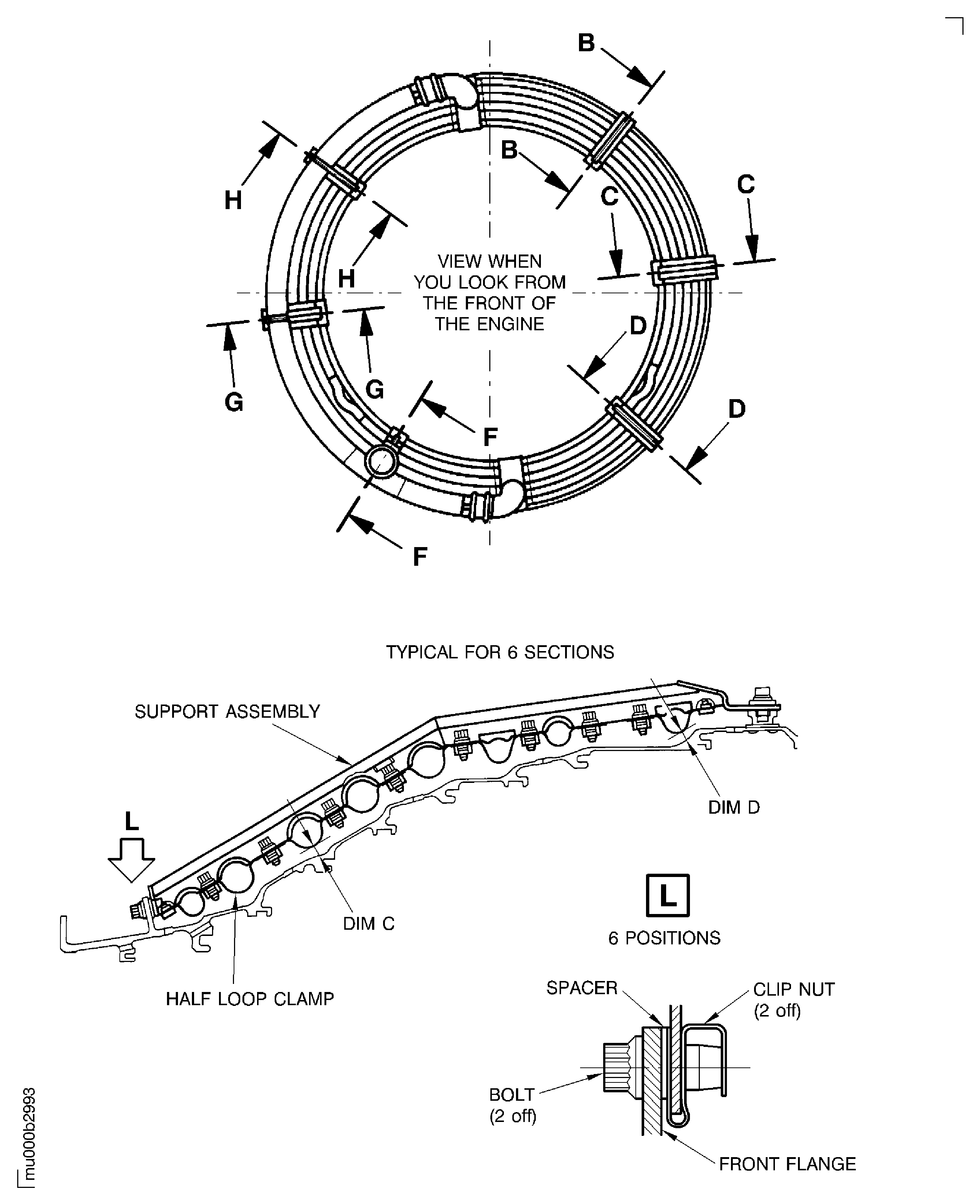

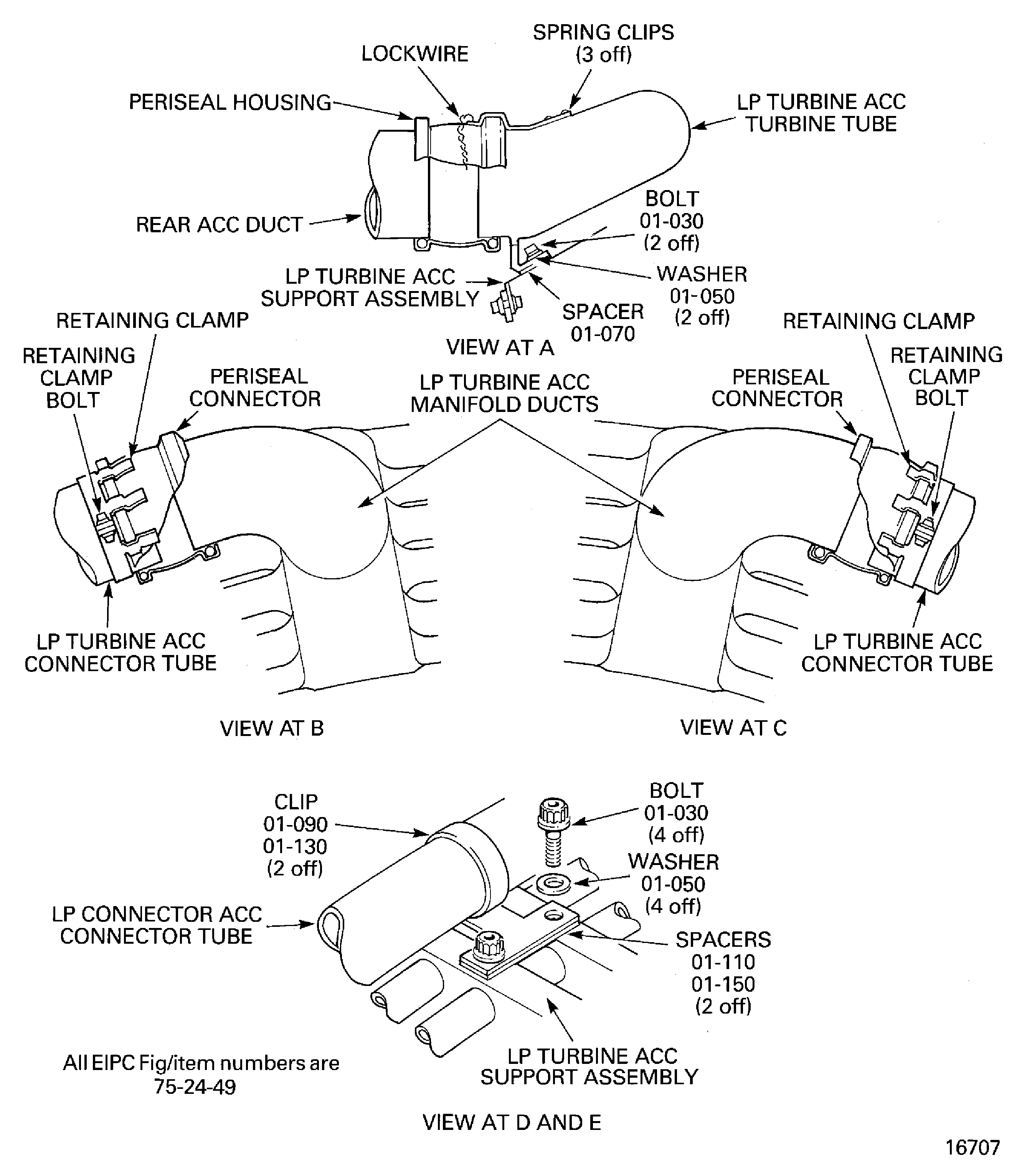

Remove the upper ACC manifold LPT ACC Air Ducts And Tubes (75-24-49, 02-010) from the support fixture.

Install the two bolts LPT ACC Air Ducts And Tubes (75-24-49, 02-060) and the spacers (max. two) with a small diameter LPT ACC Air Ducts And Tubes (75-24-49, 02-070) to the clip nuts equally at each of the three positions.

Assemble the joints on the front flange at positions A, B and H.

Install two spacers LPT ACC Air Ducts And Tubes (75-24-49, 02-050) between the rear boss and the support assembly at each of the three positions.

Install a bolt LPT ACC Air Ducts And Tubes (75-24-49, 02-030) and a washer LPT ACC Air Ducts And Tubes (75-24-49, 02-040) with two more spacers, at each of the three positions through the flange in to the rear boss and the other spacers. Loosely tighten the three bolts.

Assemble the joints on the rear boss at the positions A, B and H.

Remove the lower ACC manifold LPT ACC Air Ducts And Tubes (75-24-49, 03-010) from the support fixture.

Install the two bolts LPT ACC Air Ducts And Tubes (75-24-49, 03-060) and the spacers (max. two) with a small diameter LPT ACC Air Ducts And Tubes (75-24-49, 03-070) to the clip nuts equally at each of the three positions.

Assemble the joints on the front flange at positions D, E and F.

Install two spacers LPT ACC Air Ducts And Tubes (75-24-49, 03-050) between the rear boss and the support assembly at each of the three positions.

Install a bolt LPT ACC Air Ducts And Tubes (75-24-49, 03-030) and a washer LPT ACC Air Ducts And Tubes (75-24-49, 03-040) with two more spacers, at each of the three positions, through the flange in to the rear boss and spacers. Loosely tighten the three bolts.

Assemble the joints on the rear boss at the positions D, E and F.

Install the two bolts LPT ACC Air Ducts And Tubes (75-24-49, 04-450) and the spacers (max. two) with a small diameter LPT ACC Air Ducts And Tubes (75-24-49, 04-460) to the anchor nuts equally.

Assemble the joint at the front flange.

Install two spacers LPT ACC Air Ducts And Tubes (75-24-49, 04-440) between the rear boss and the support assembly.

Install a bolt LPT ACC Air Ducts And Tubes (75-24-49, 04-420) and a washer LPT ACC Air Ducts And Tubes (75-24-49, 04-430) with two more spacers through the flange in to the rear boss and the other spacers. Loosely tighten the bolt.

Assemble the joint at the rear boss.

Move the support assembly at position C in to position.

Install the two bolts LPT ACC Air Ducts And Tubes (75-24-49, 04-450) and the spacers (max. two) with a small diameter LPT ACC Air Ducts And Tubes (75-24-49, 04-460) to the anchor nuts equally.

Assemble the joint at the front flange.

Install two spacers LPT ACC Air Ducts And Tubes (75-24-49, 04-040) between the rear boss and the support assembly.

Install a bolt LPT ACC Air Ducts And Tubes (75-24-49, 04-020) and a washer LPT ACC Air Ducts And Tubes (75-24-49, 04-030) with two more spacers through the flange in to the rear boss and the other spacers. Loosely tighten the bolt.

Assemble the joint at the rear boss.

Move the support assembly at position G in to position.

The axial and radial clearances, between the LP Turbine case and the LP Turbine cooling air ducts at tubes No.3 and 8, are in relation to the LP Turbine case and the LP Turbine cooling air ducts assembly configuration.

The adjustment is correct if:

The go gage or the gage end of the checking gage, identified by the green area, can be put in between the LP Turbine case and the LP Turbine cooling air duct.

The no gage or the gage end of the checking gage, identified by the red area, can not be put in between the LP Turbine case and the LP Turbine cooling air duct.

Use the IAE 1M14121 Checking go/no-go gage 1 off for the tubes No. 3 and the IAE 1M14122 Checking go/no-go gage 1 off for tee tubes No. 8.

Examine the radial and axial clearances again and adjust them, if necessary. Use the above procedure.

NOTE

Adjust the upper and lower LP Turbine cooling air ducts.

SUBTASK 72-00-50-420-185 Install the LP Turbine Active Clearance Control (ACC) Manifolds

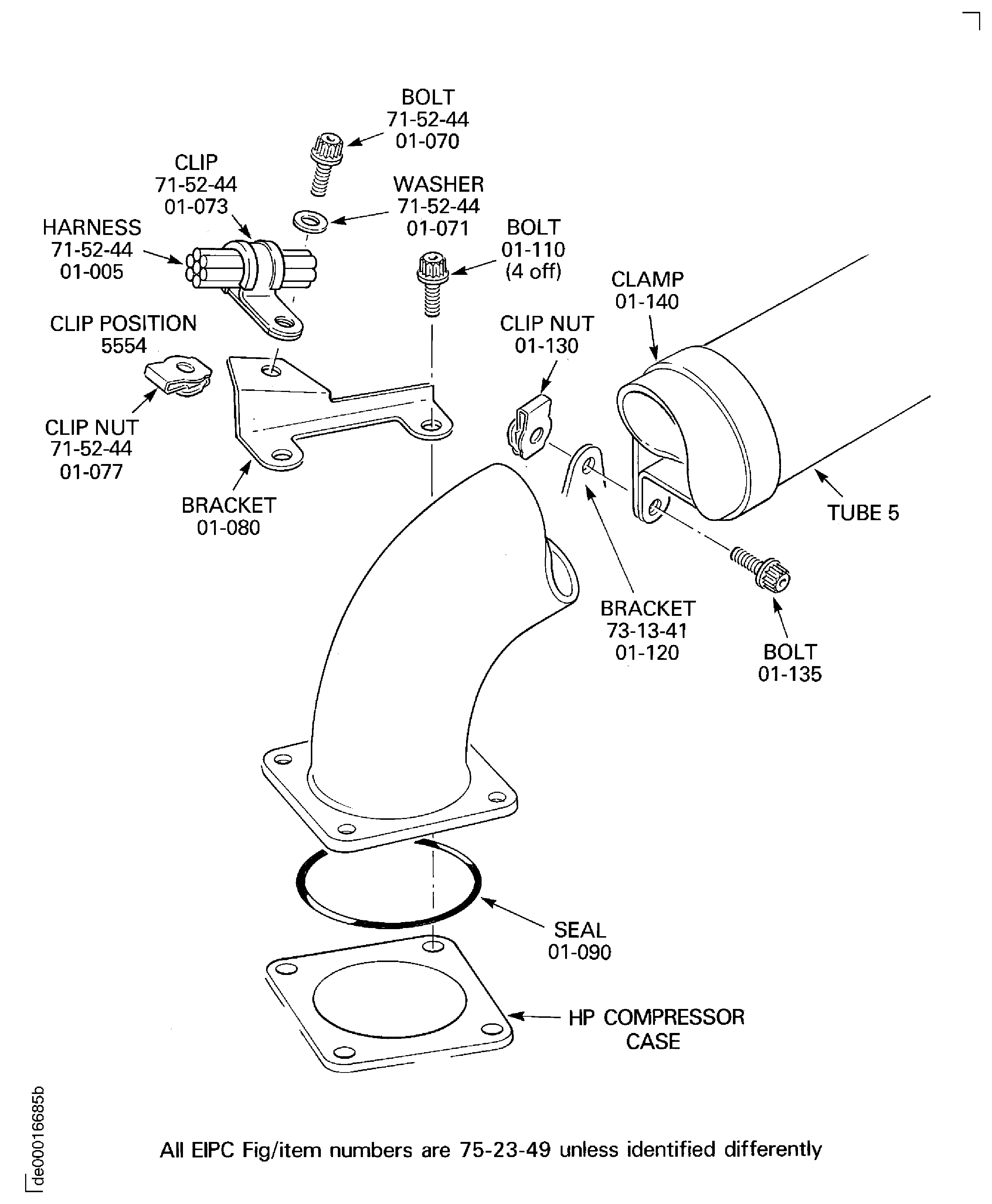

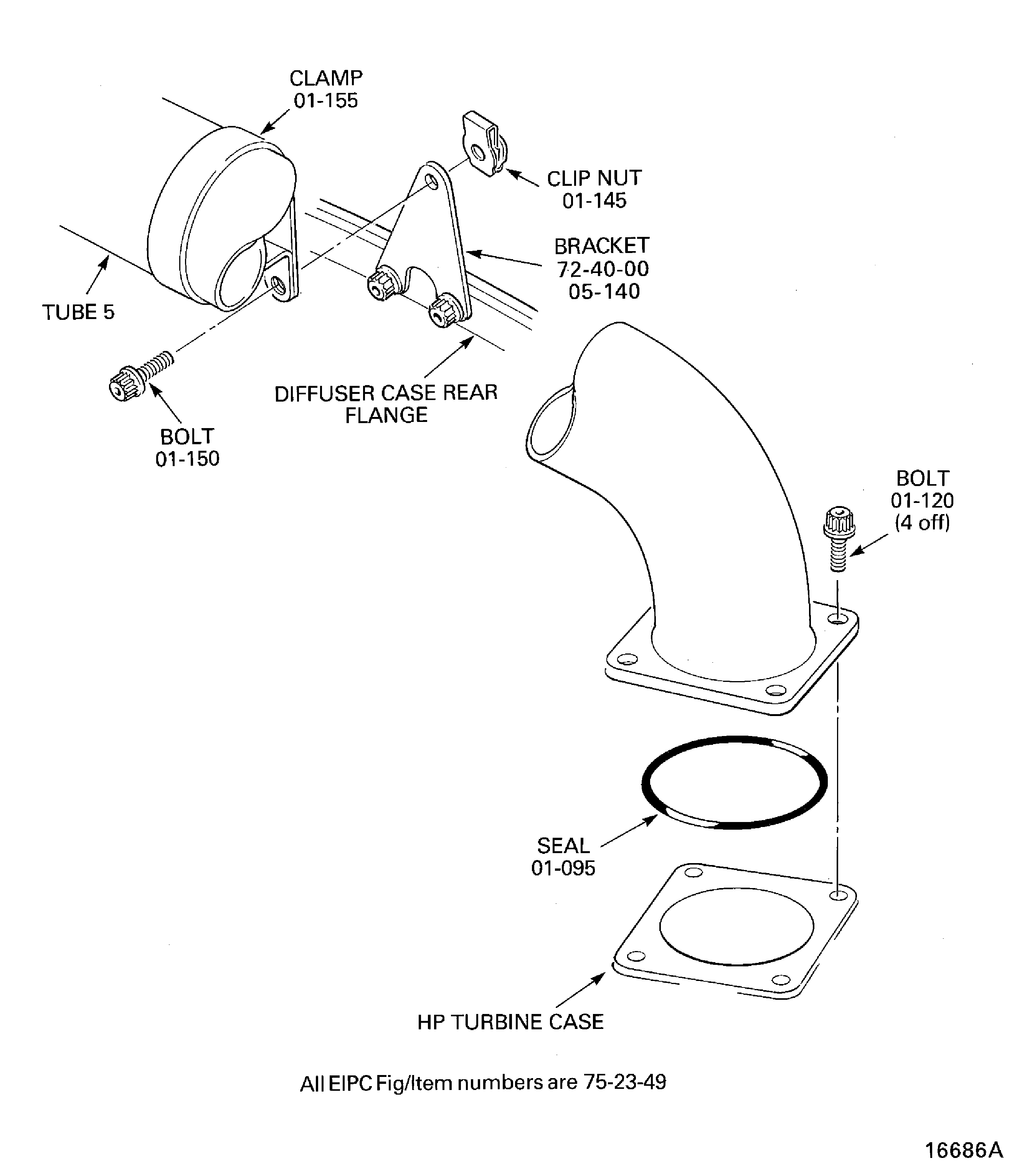

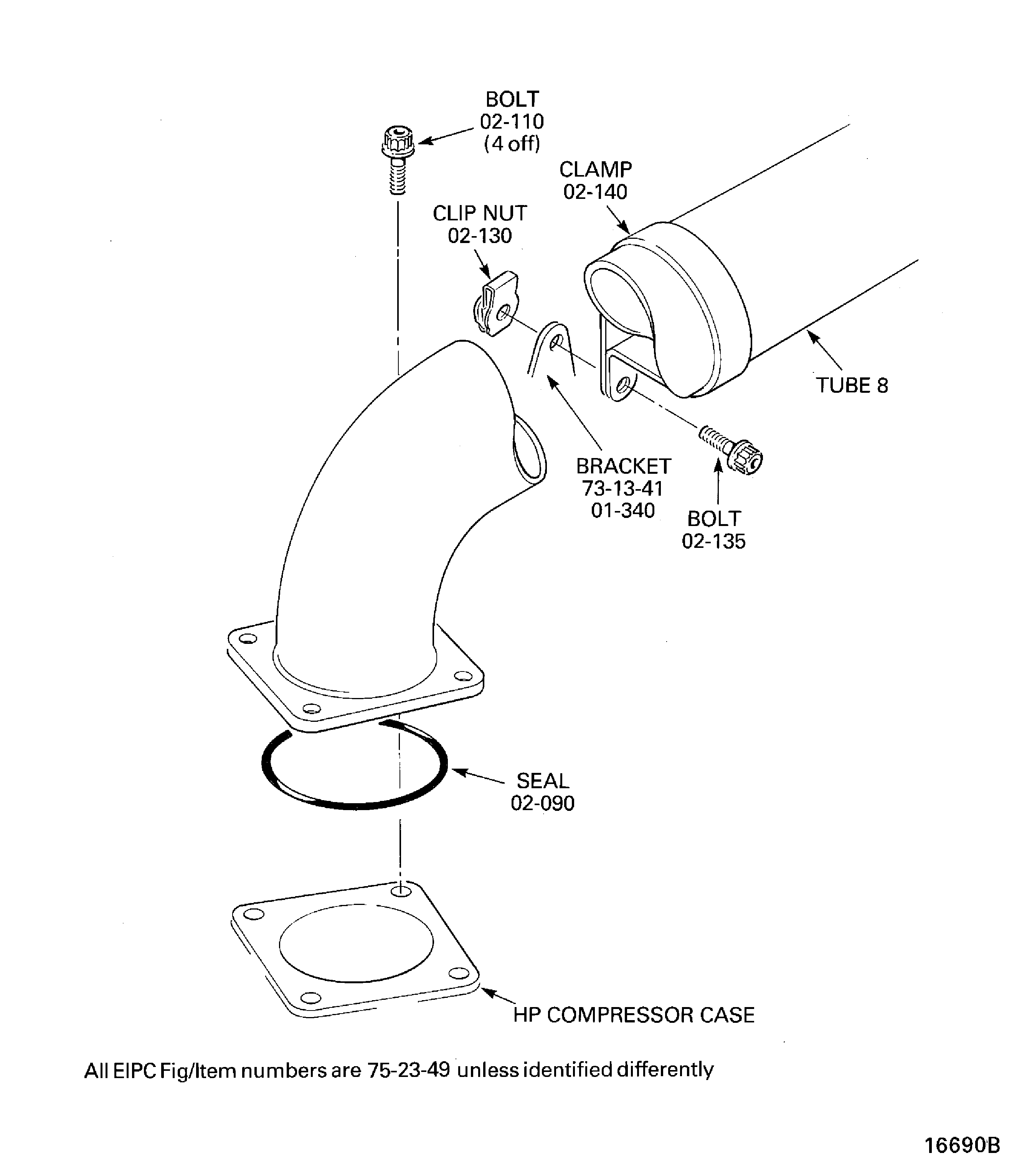

Install the metal C seal AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-095) 1 off, at the HP turbine case connection.

Install the metal C seal AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-090) 1 off in the forward tube connector.

Install the bracket AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-080) and the four bolts AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-110) at the HP compressor case connector flange. Torque the bolts to 180 to 220 lbfin. (20 to 25 Nm).

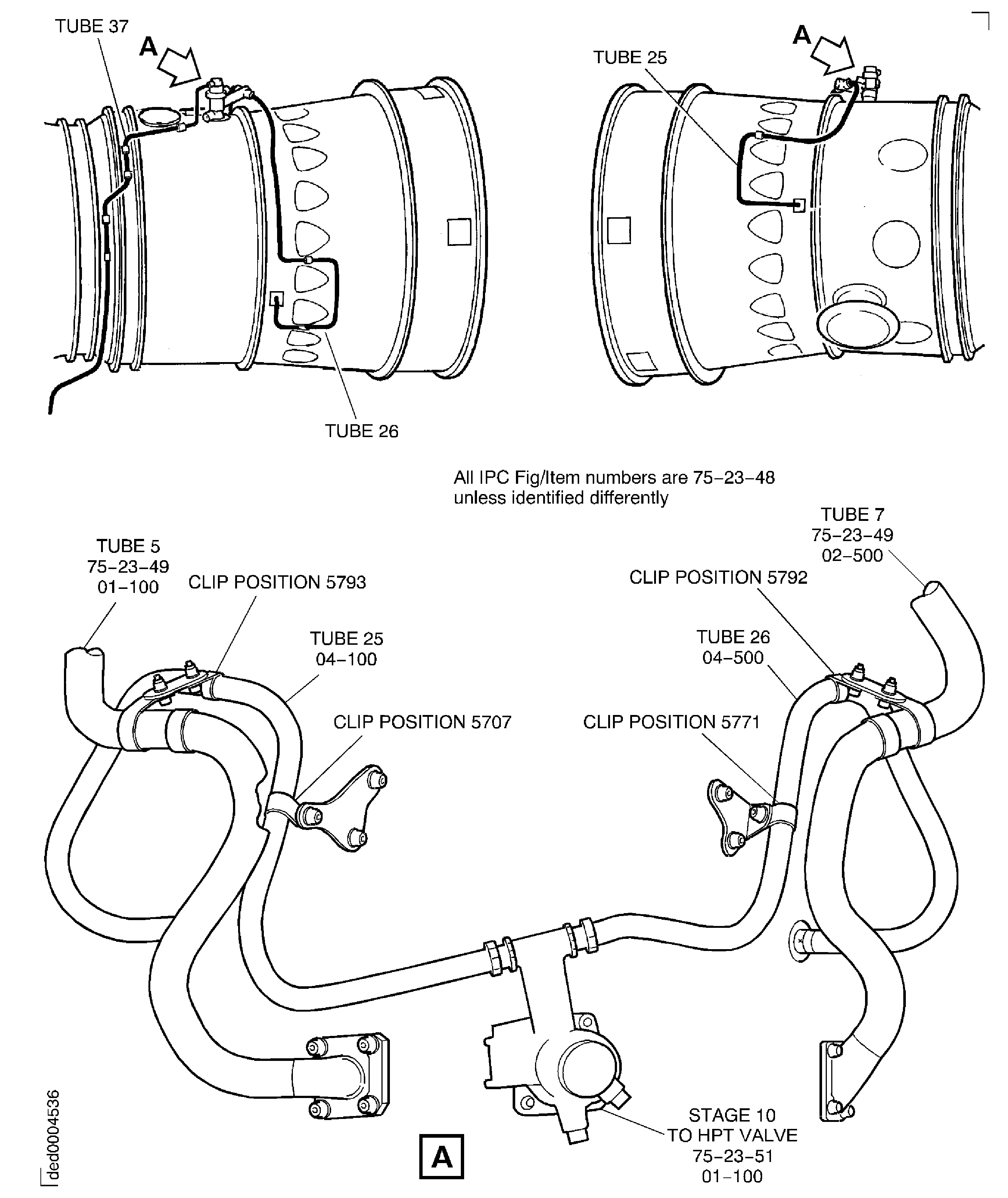

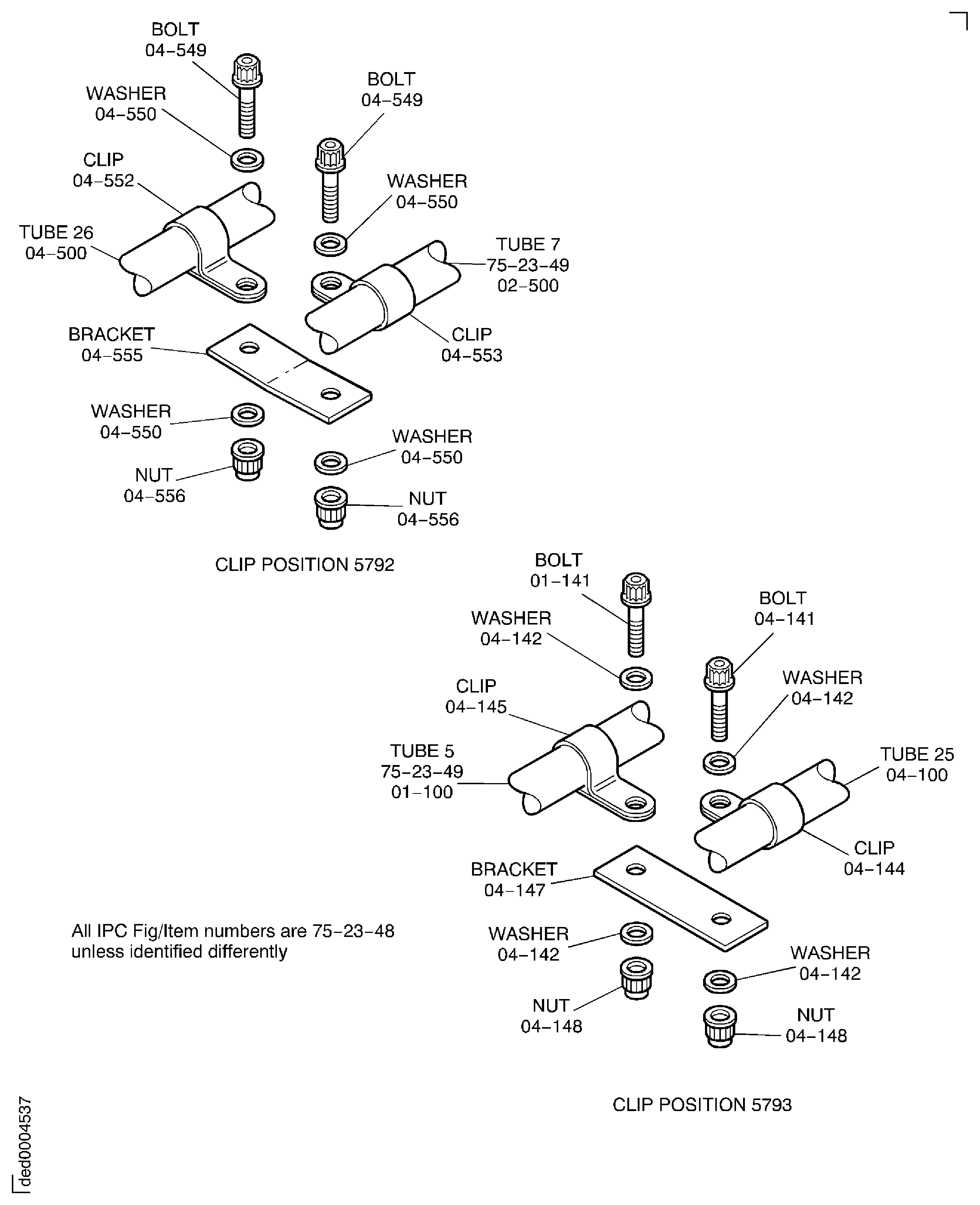

Install the clip, bolt, two washers and nut at the clip position 5793 to attach the tube 5 to the bracket Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 04-147). Torque the bolt to 36 to 45 lbfin. (4 to 5 Nm).

Install the clip, bolt, two washers and nut at the clip position 5793 to attach the tube 25 Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 04-100) to the bracket Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 04-147). Torque the bolt to 36 to 45 lbfin. (4 to 5 Nm).

Install the four bolts AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-120) at the HP turbine case connection flange. Torque the bolts to 180 lbfin. to 220 lbfin. (20 Nm to 25 Nm). Safety the bolts with CoMat 02-126 LOCKWIRE.

Put the clamp adjacent to the bracket Fuel Nozzle And Support Assembly (73-13-41, 01-120).

Install the bolt AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-135) and the clip nut AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-130). Torque the bolt to 36 to 45 lbfin. (4 to 5 Nm).

Install the clamp AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-140).

Put the clamp adjacent to the bracket HPC Module - Attaching Parts (72-40-00, 05-140).

Install the bolt AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-150) and the clip nut AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-145). Torque the bolt to 36 to 45 lbfin. (4 to 5 Nm).

Install the clamp AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-155).

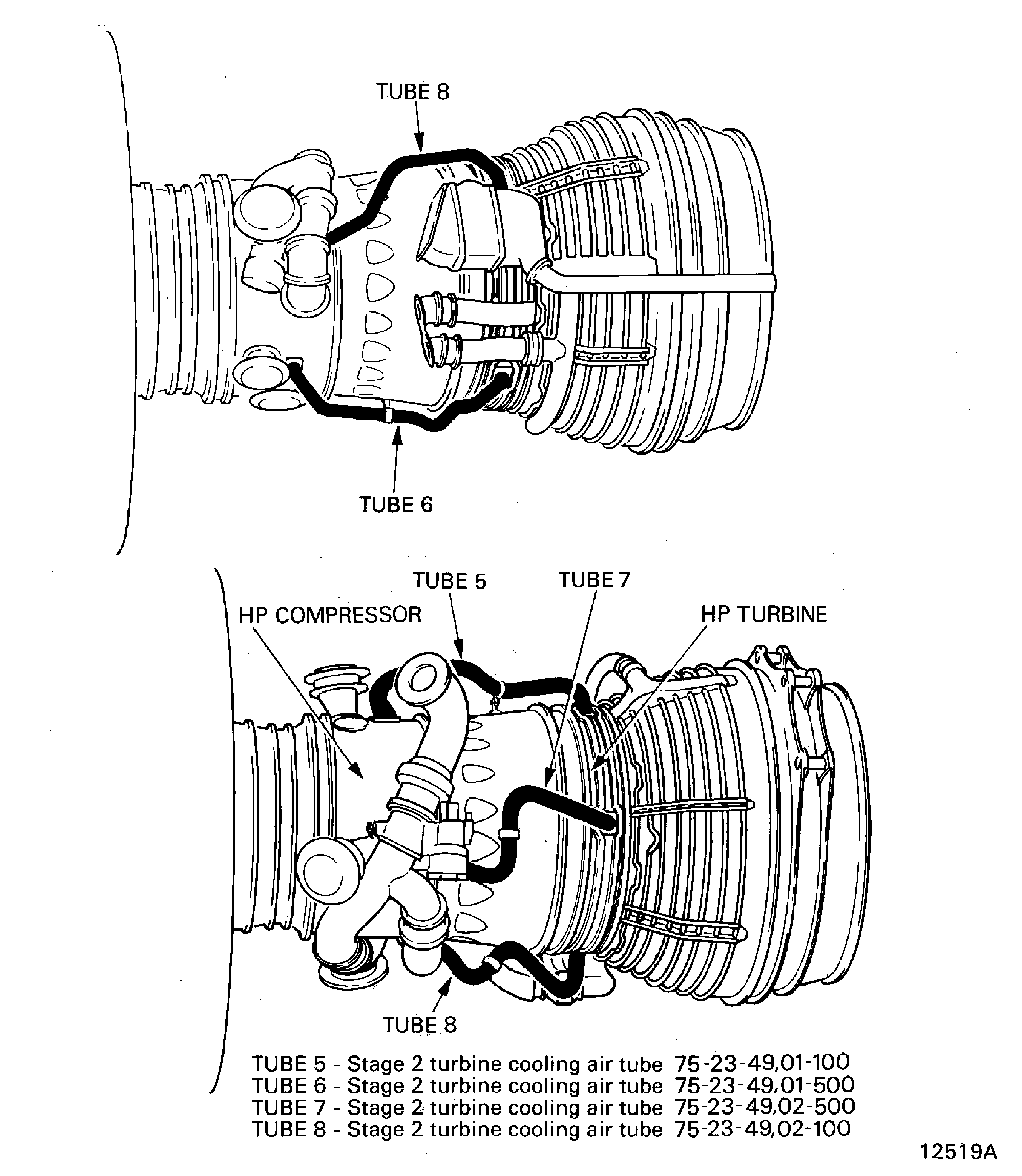

Install tube 5 AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-100).

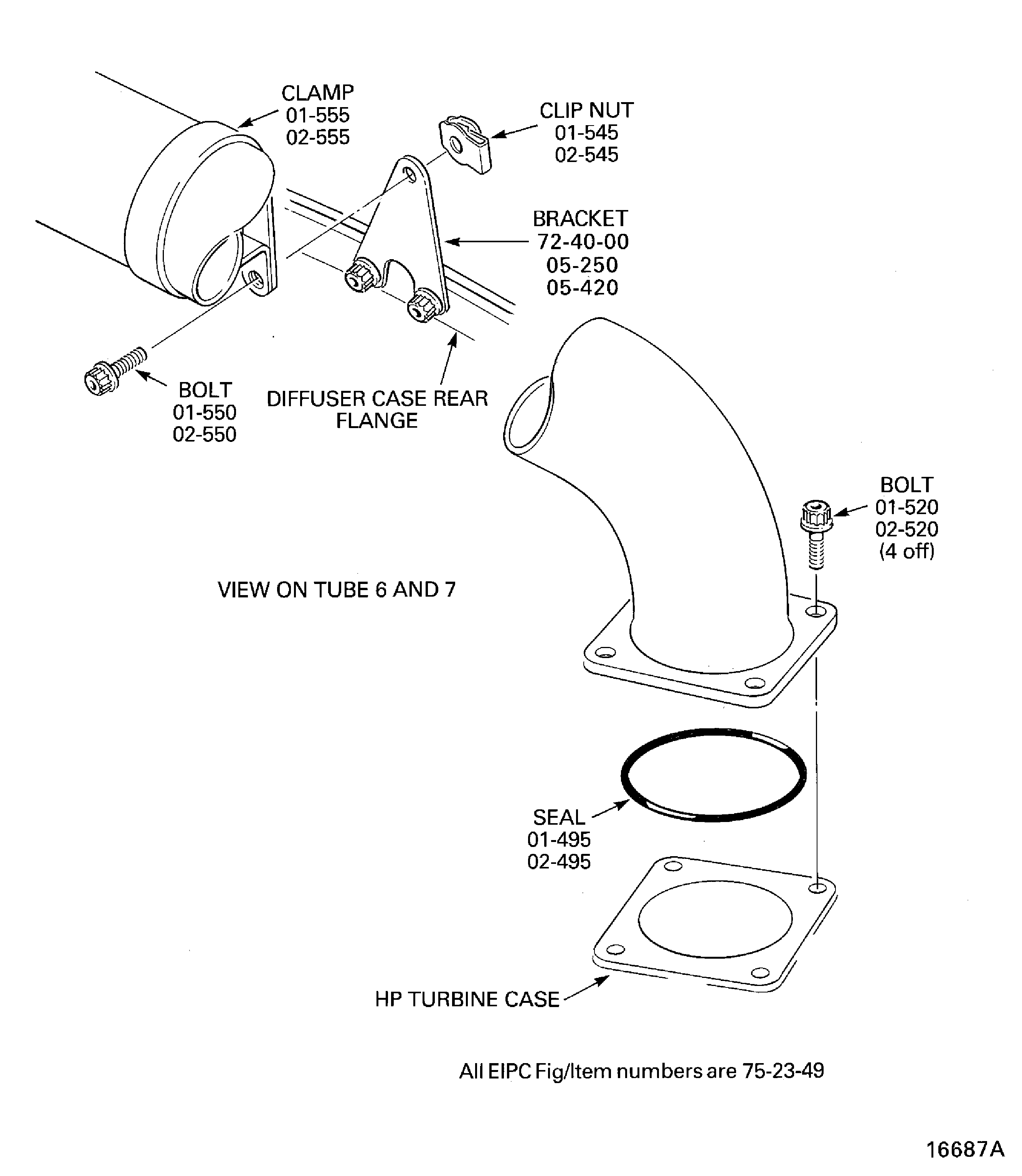

Install the metal C seal AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-495) 1 off at the HP turbine case connection.

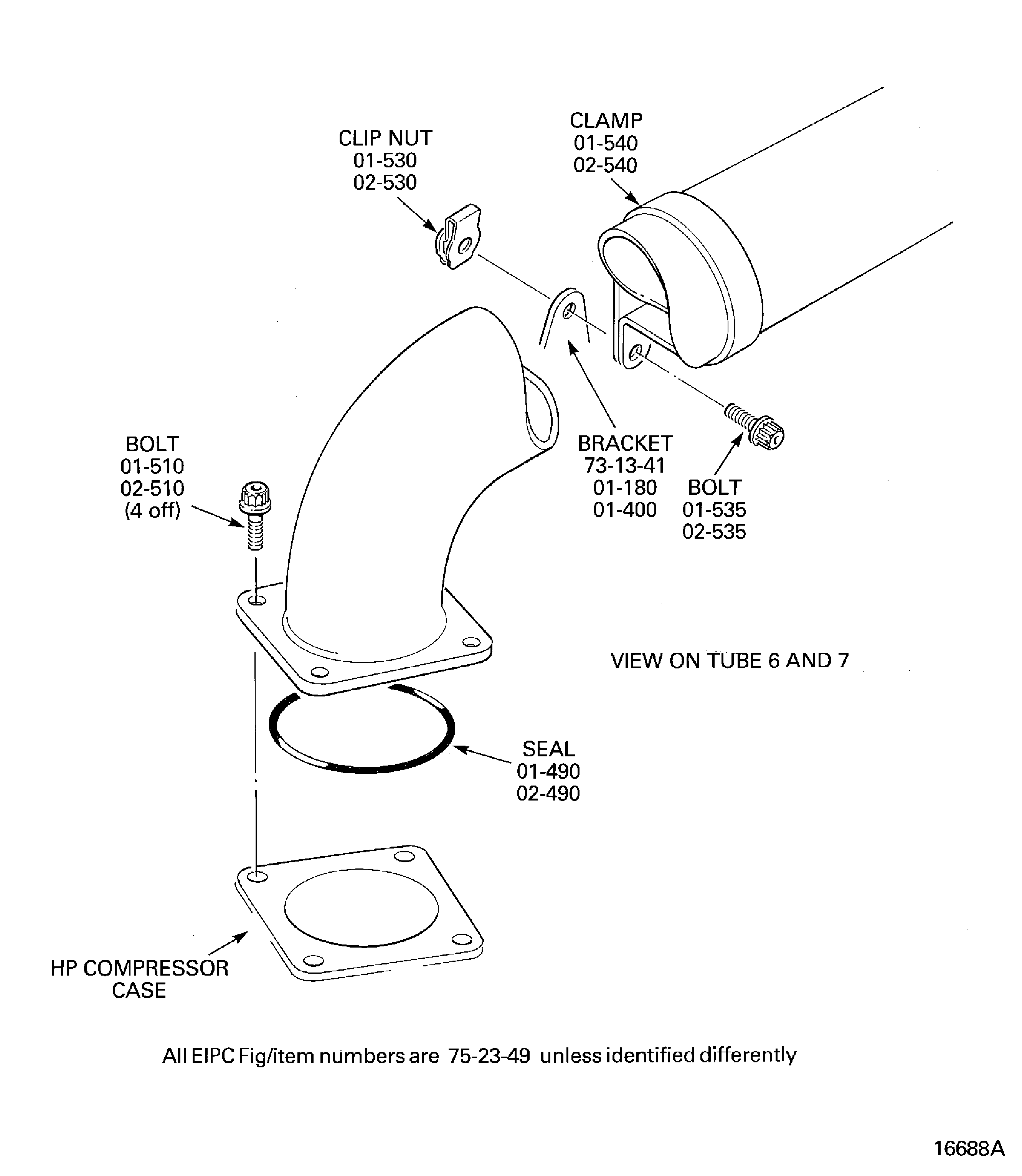

Install the metal C seal AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-490) 1 off in the forward tube connection.

Install the four bolts AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-510) at the HP compressor case connection flange. Torque the bolts to 180 to 220 lbfin. (20 to 25 Nm).

Install the four bolts AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-520) at the HP turbine case connector flange. Torque the bolts to 180 lbfin. to 220 lbfin. (20 Nm to 25 Nm). Safety the bolts with CoMat 02-126 LOCKWIRE.

Put the clamp adjacent to the bracket Fuel Nozzle And Support Assembly (73-13-41, 01-180).

Install the bolt AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-535) and the clip nut AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-530). Torque the bolt to 36 to 45 lbfin. (4 to 5 Nm).

Install the clamp AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-540).

Put the clamp adjacent to the bracket HPC Module - Attaching Parts (72-40-00, 05-520).

Install the bolt AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-550) and the clip nut AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-545). Torque the bolt to 36 to 45 lbfin. (4 to 5 Nm).

Install the clamp AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-555).

Install tube 6 AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-500).

Install the metal C seal AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-495) 1 off at the HP turbine case connection.

Install the metal C seal AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-490) 1 off in the forward tube connection.

Install the four bolts AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-510) at the HP compressor case connection. Torque the bolts to 180 to 220 lbfin. (20 to 25 Nm).

Install the four bolts AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-520) at the HP turbine case connection. Torque the bolts to 180 lbfin. to 220 lbfin. (20 Nm to 25 Nm). Safety the bolts with CoMat 02-126 LOCKWIRE.

Put the clamp adjacent to the bracket Fuel Nozzle And Support Assembly (73-13-41, 01-400).

Install the bolt AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-535) and the nut AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-530). Torque the nut to 36 to 45 lbfin. (4 to 5 Nm).

Install the clamp AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-540).

Put the clamp adjacent to the bracket HPC Module - Attaching Parts (72-40-00, 05-420).

Install the clamp AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-555).

Install the bolt AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-550) and the nut AIR-TURBINE COOLING AIR TUBES (75-23-49, 01-545). Torque the bolt to 36 to 45 lbfin. (4 to 5 Nm).

Install the clip, bolt, two washers and nut at the clip position 5792 to attach the tube 7 to the bracket Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 04-555). Torque the bolt to 36 to 45 lbfin. (4 to 5 Nm).

Install the clip, bolt, two washers and nut at the clip position 5792 to attach the tube 26 Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 04-500) to the bracket Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 04-555). Torque the bolt to 36 to 45 lbfin. (4 to 5 Nm).

Install tube 7 AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-500).

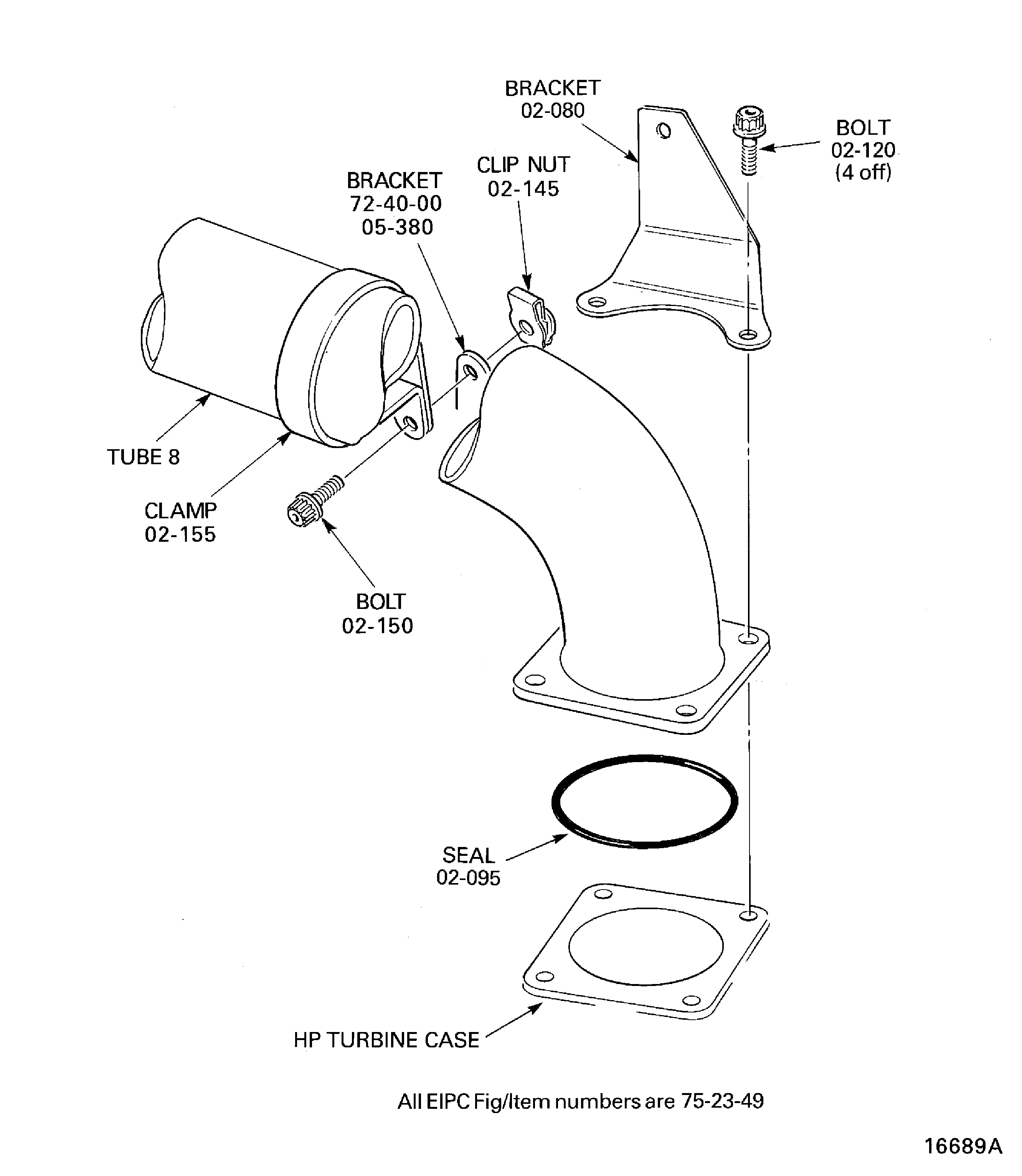

Install the metal C seal AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-095) 1 off, at the HP turbine case connection.

Install the metal C seal AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-090) 1 off in the forward tube connection.

Install the four bolts AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-110) at the HP compressor connector flange. Torque the bolts to 180 to 220 lbfin. (20 to 25 Nm).

Install the bracket AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-080) and the four bolts AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-120) at the HP turbine case connector flange. Torque the bolts to 180 lbfin. to 220 lbfin. (20 Nm to 25 Nm). Safety the bolts with CoMat 02-126 LOCKWIRE.

Put the clamp adjacent to the bracket Fuel Nozzle And Support Assembly (73-13-41, 01-340).

Install the bolt AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-135) and the clip nut AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-130). Torque the nut to 36 to 45 lbfin. (4 to 5 Nm).

Install the clamp AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-140).

Put the clamp adjacent to the bracket HPC Module - Attaching Parts (72-40-00, 05-380).

Install the bolt AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-150) and the clipnut AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-145). Torque the bolt to 36 to 45 lbfin. (4 to 5 Nm).

Install the clamp AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-155).

Install tube 8 AIR-TURBINE COOLING AIR TUBES (75-23-49, 02-100).

SUBTASK 72-00-50-420-186 Install the Tubes 5, 6, 7, 8, the Turbine Cooling Air Supply Tubes

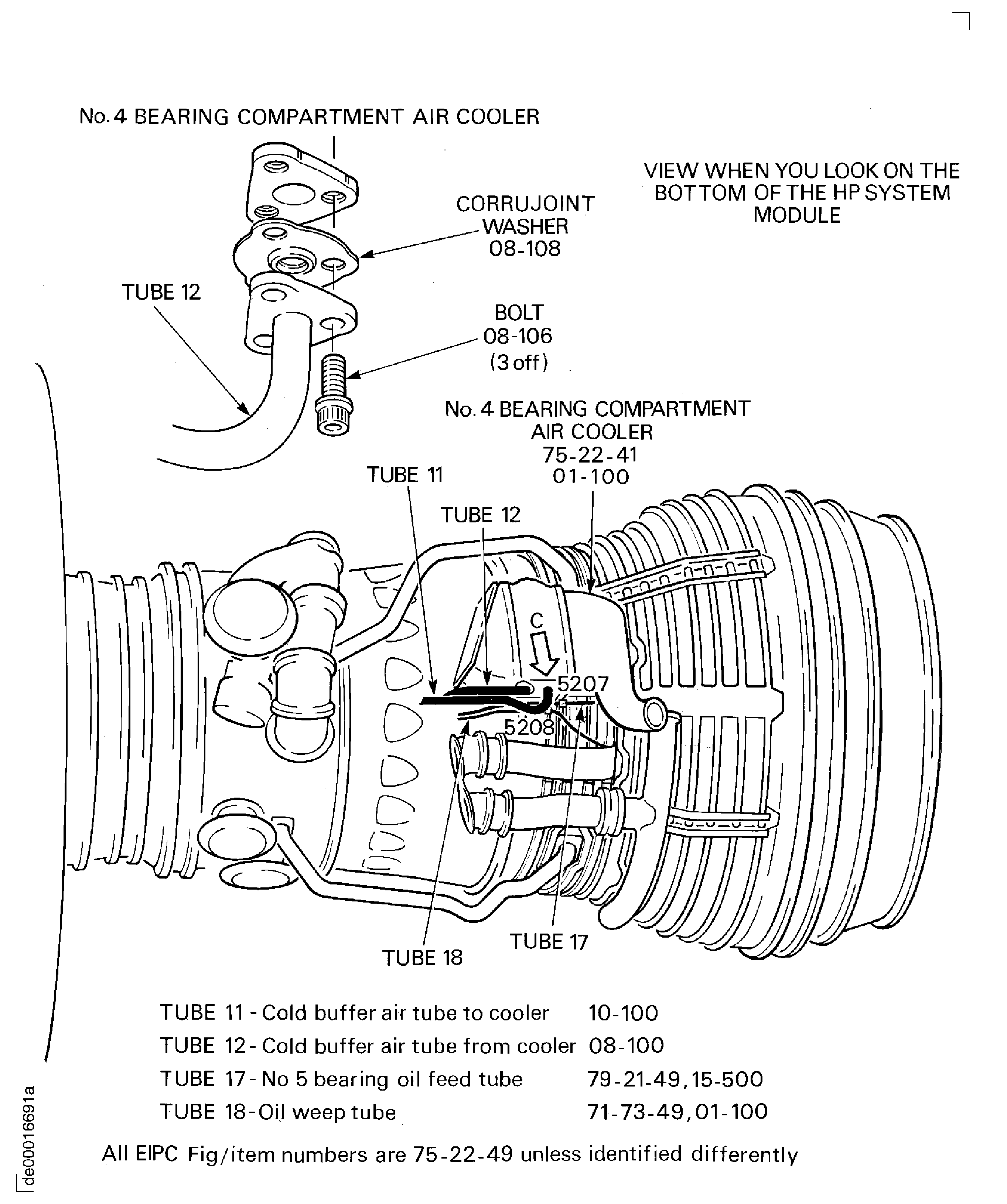

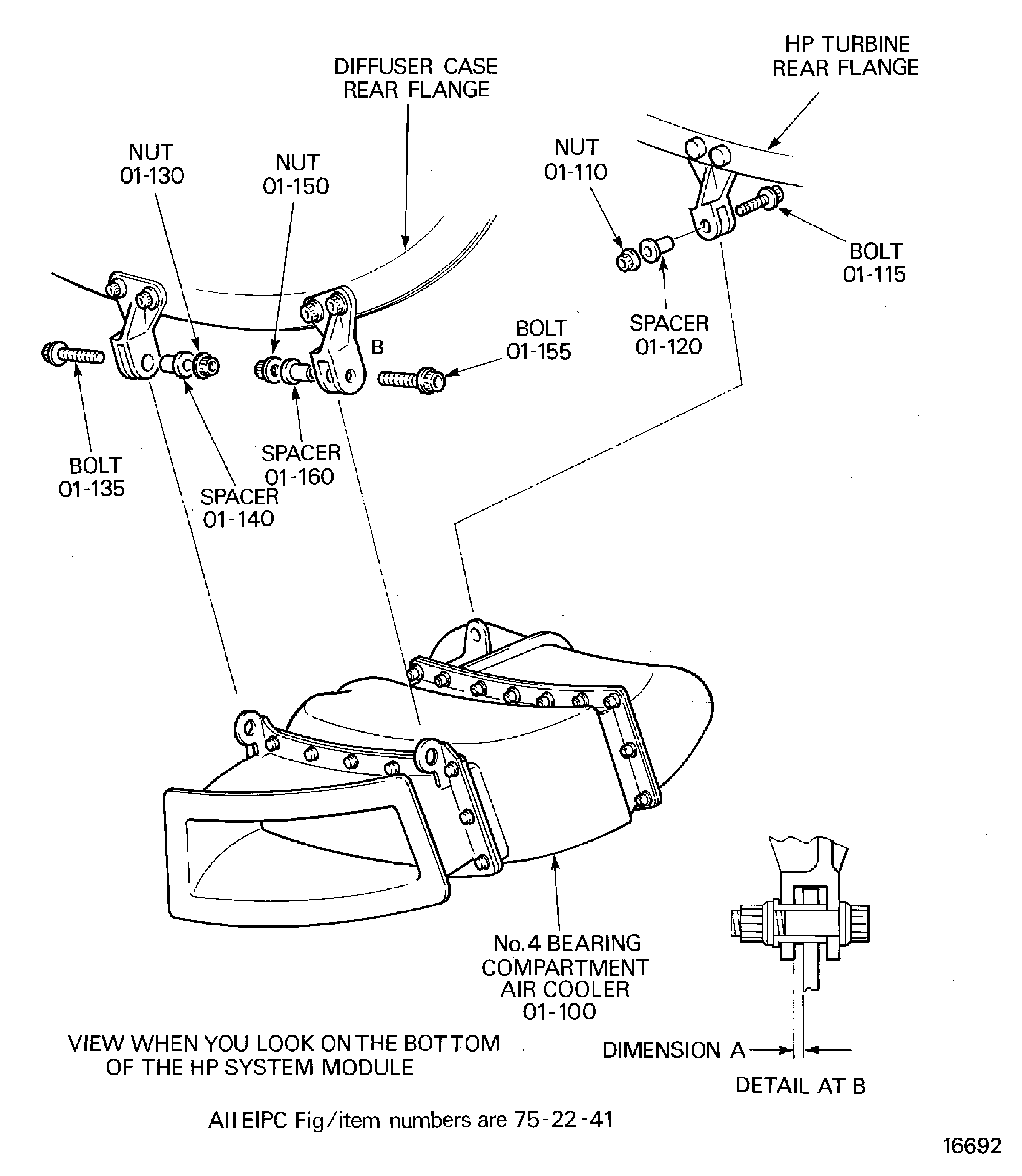

Put the number 4 bearing air cooler in to position and install the bolts No. 4 Bearing Compartment Cooler Air Ducts (75-22-41, 01-135) and No. 4 Bearing Compartment Cooler Air Ducts (75-22-41, 01-155) the spacers No. 4 Bearing Compartment Cooler Air Ducts (75-22-41, 01-140) and No. 4 Bearing Compartment Cooler Air Ducts (75-22-41, 01-160) and the nuts No. 4 Bearing Compartment Cooler Air Ducts (75-22-41, 01-130) and No. 4 Bearing Compartment Cooler Air Ducts (75-22-41, 01-150) in to the forward brackets HPC Module - Attaching Parts (72-40-00, 05-300) and HPC Module - Attaching Parts (72-40-00, 05-340) on diffuser case rear flange.

Install the bolt No. 4 Bearing Compartment Cooler Air Ducts (75-22-41, 01-115), the spacer No. 4 Bearing Compartment Cooler Air Ducts (75-22-41, 01-120) and the nut No. 4 Bearing Compartment Cooler Air Ducts (75-22-41, 01-110) at the rear bracket LP TURBINE (LPT) MODULE (72-00-50, 01-330) on HP turbine rear flange.

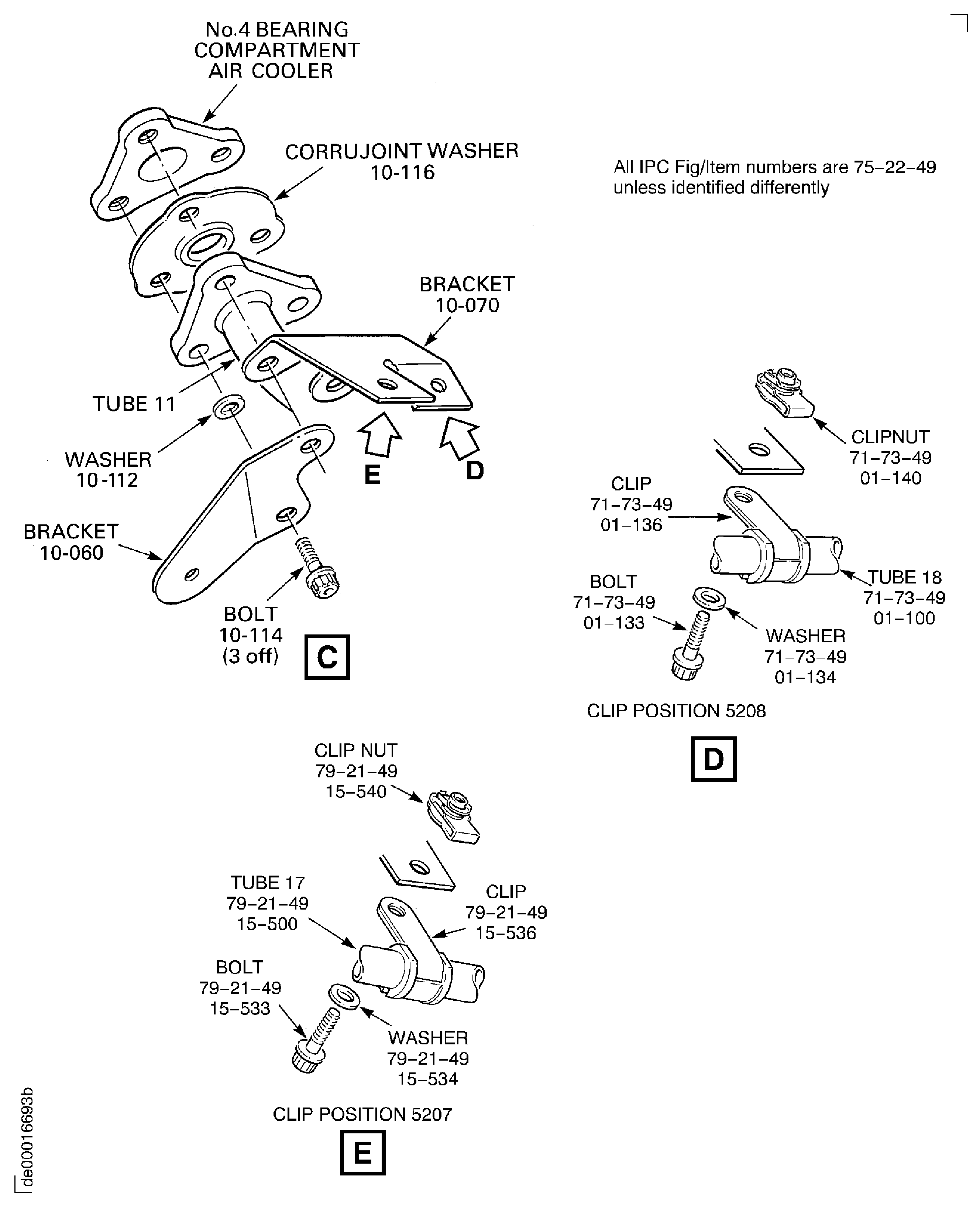

Install the new Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 08-108) corrujoint washer 1 off, between the tube 12 and the number 4 bearing compartment air cooler.

Install the three bolts Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 08-106).

Attach the tube 12 to the number 4 bearing compartment air cooler.

Install the new AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 10-116) corrujoint washer 1 off, between the tube 11 and the number 4 bearing compartment air cooler.

Install the three bolts AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 10-114), the washer AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 10-112) and the two brackets AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 10-060) and AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 10-070).

Attach the tube 11 to the number 4 bearing compartment air cooler.

SUBTASK 72-00-50-420-187 Install the Number 4 Bearing Compartment Air Cooler

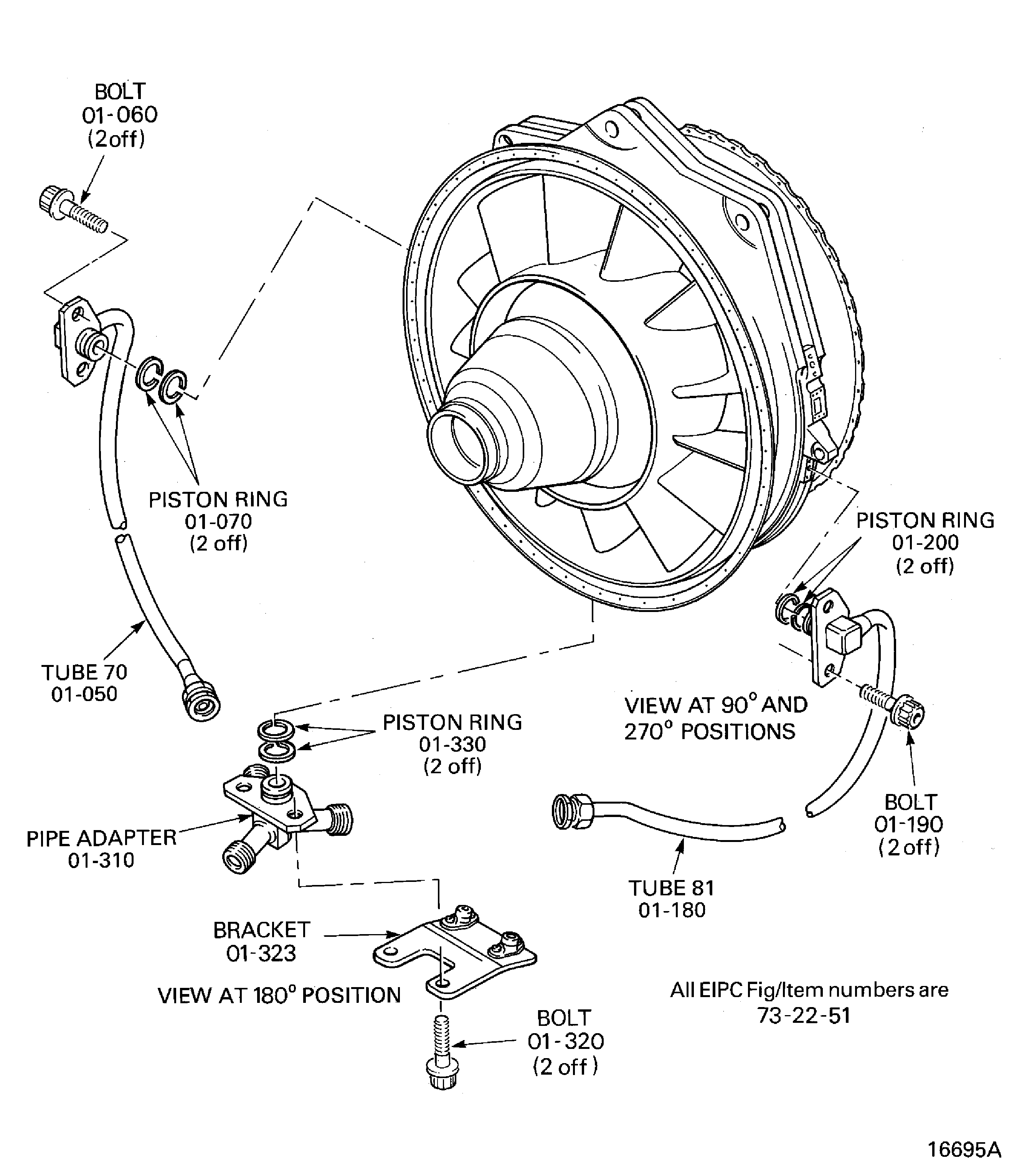

Put the piston rings ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 20-330) in position on the pipe adapter. Make sure that the space in each piston ring are 180 degrees apart.

Install the two bolts ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 20-320) and the bracket ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 20-323). Torque the bolts to 85 to 105 lbfin. (10 to 12 Nm).

Safety the bolts with CoMat 02-126 LOCKWIRE.

Install the pipe adapter ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 20-310).

Put the piston rings ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 20-070) in position on the tube 70. Make sure that the space in each piston ring are 180 degrees apart.

Install the two bolts ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 20-060) at the flange connection and torque to 85 to 105 lbfin. (10 to 12 Nm).

Safety the bolts and the pipe nut with CoMat 02-126 LOCKWIRE.

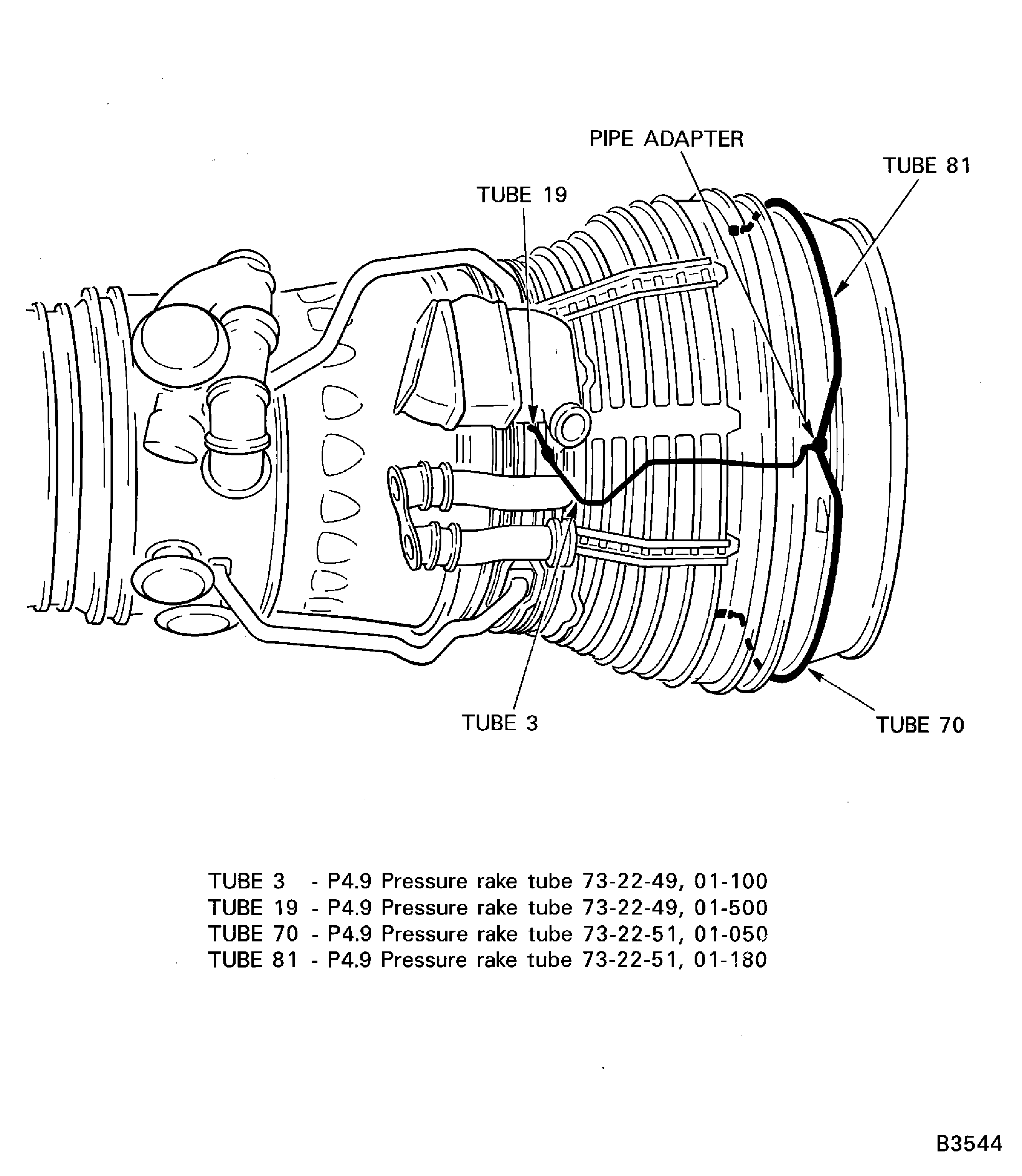

Install tube 70 RH pressure control manifold ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 20-050).

Put the piston rings ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 20-200) in to position on tube 81. Make sure that the space in each piston ring are 180 degrees apart.

Install the two bolts ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 20-190) at the flange connection and torque to 85 to 105 lbfin. (10 to 12 Nm).

Safety the bolts and the tube nut with CoMat 02-126 LOCKWIRE.

Install the tube 81 LH pressure control manifold ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 20-180).

Safety the tube nut with CoMat 02-126 LOCKWIRE.

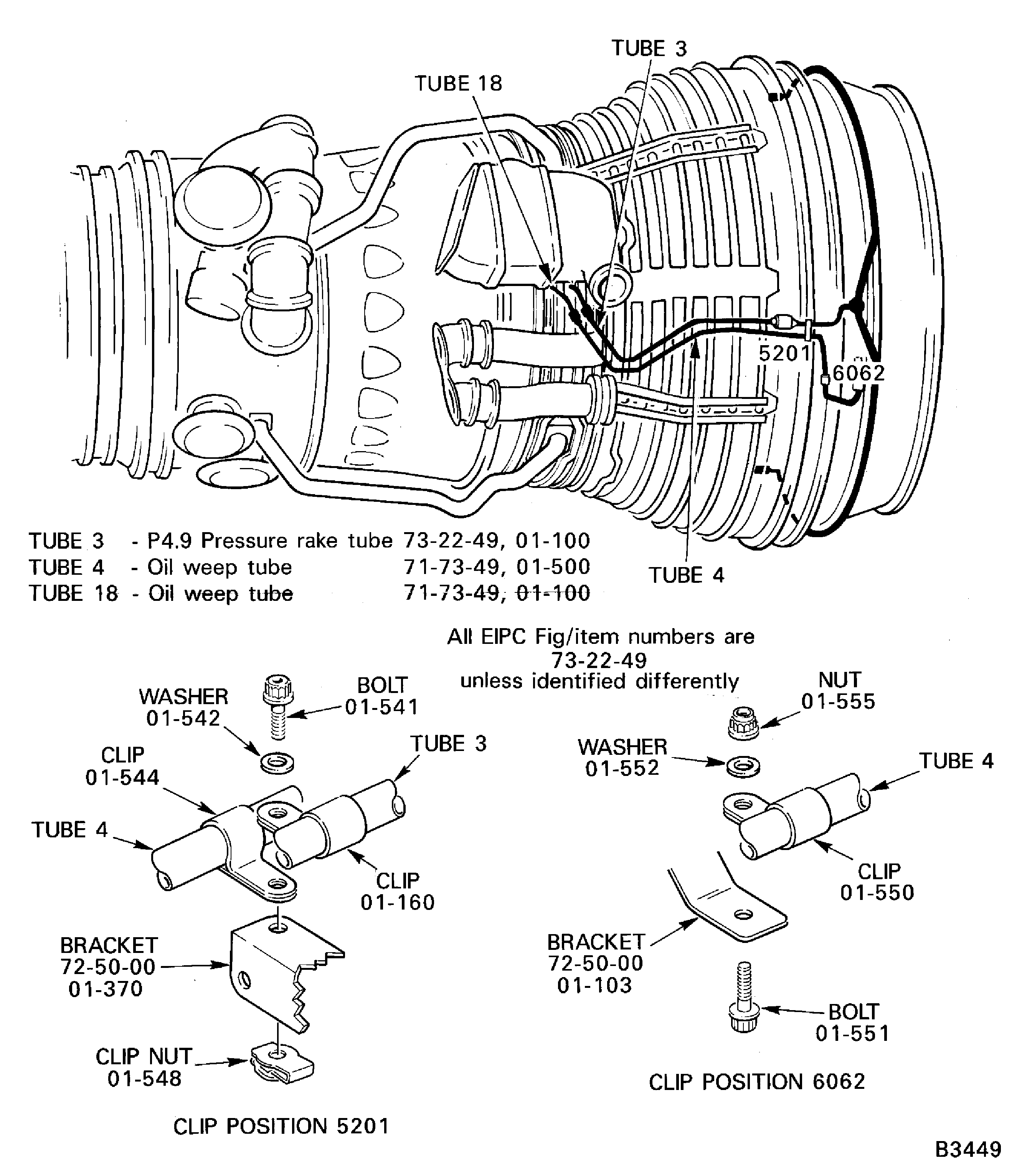

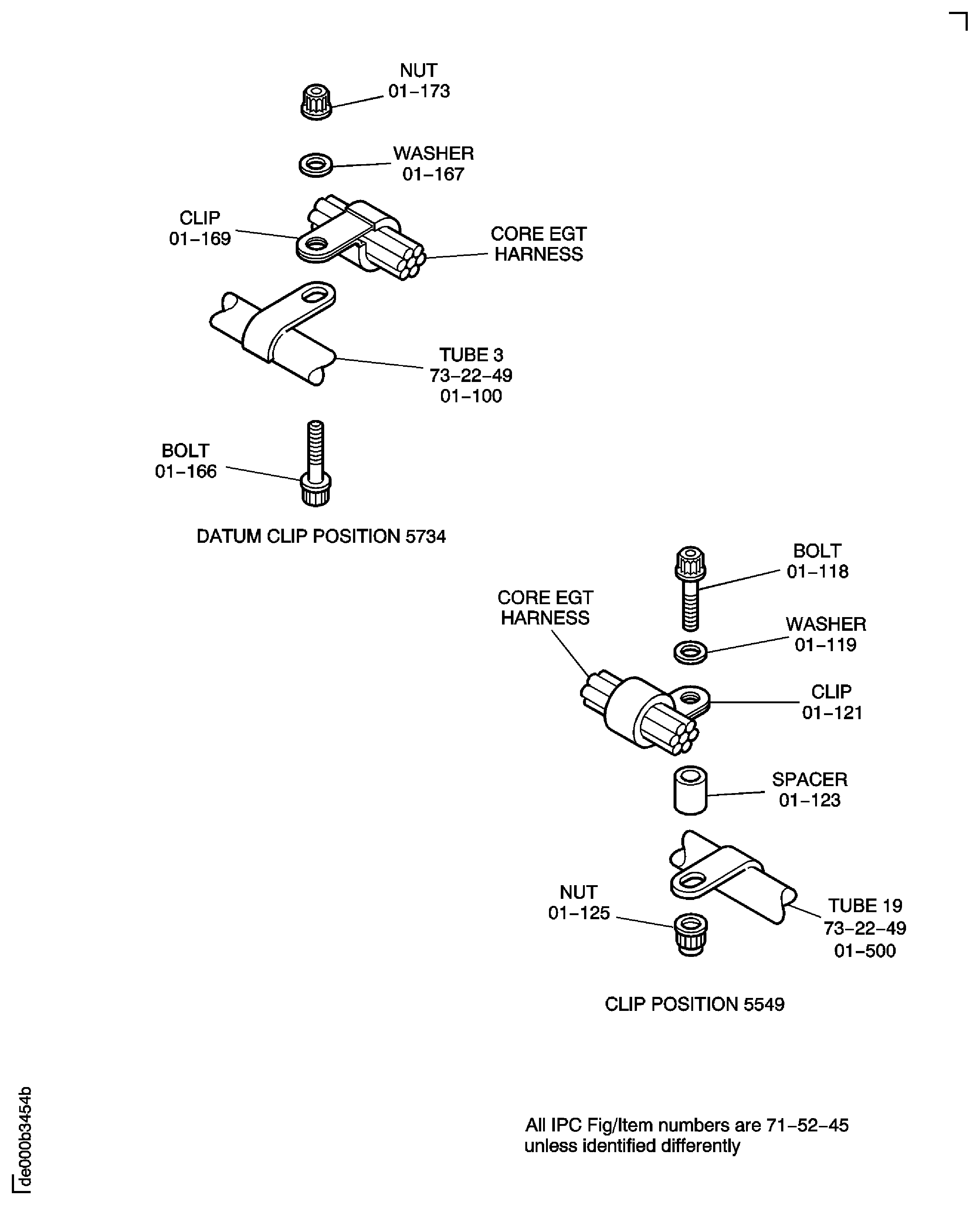

Install the tube 3, P4.9 EEC tube Fuel System Air Tubes (73-22-49, 01-100).

SUBTASK 72-00-50-420-188 Install the Tubes 70, 81 and 3, the P4.9 the Pressure Rake Tubes

Refer to Figure.

Put tube 4 No. 4 Bearing Compartment Weep Oil Tubes (71-73-49, 01-500) in position on the engine.

Torque the tube nuts to 159 to 177 lbfin. (18 to 20 Nm) and safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-50-420-189 Install the Tube 4, Number 4 Bearing Oil Weep Tube

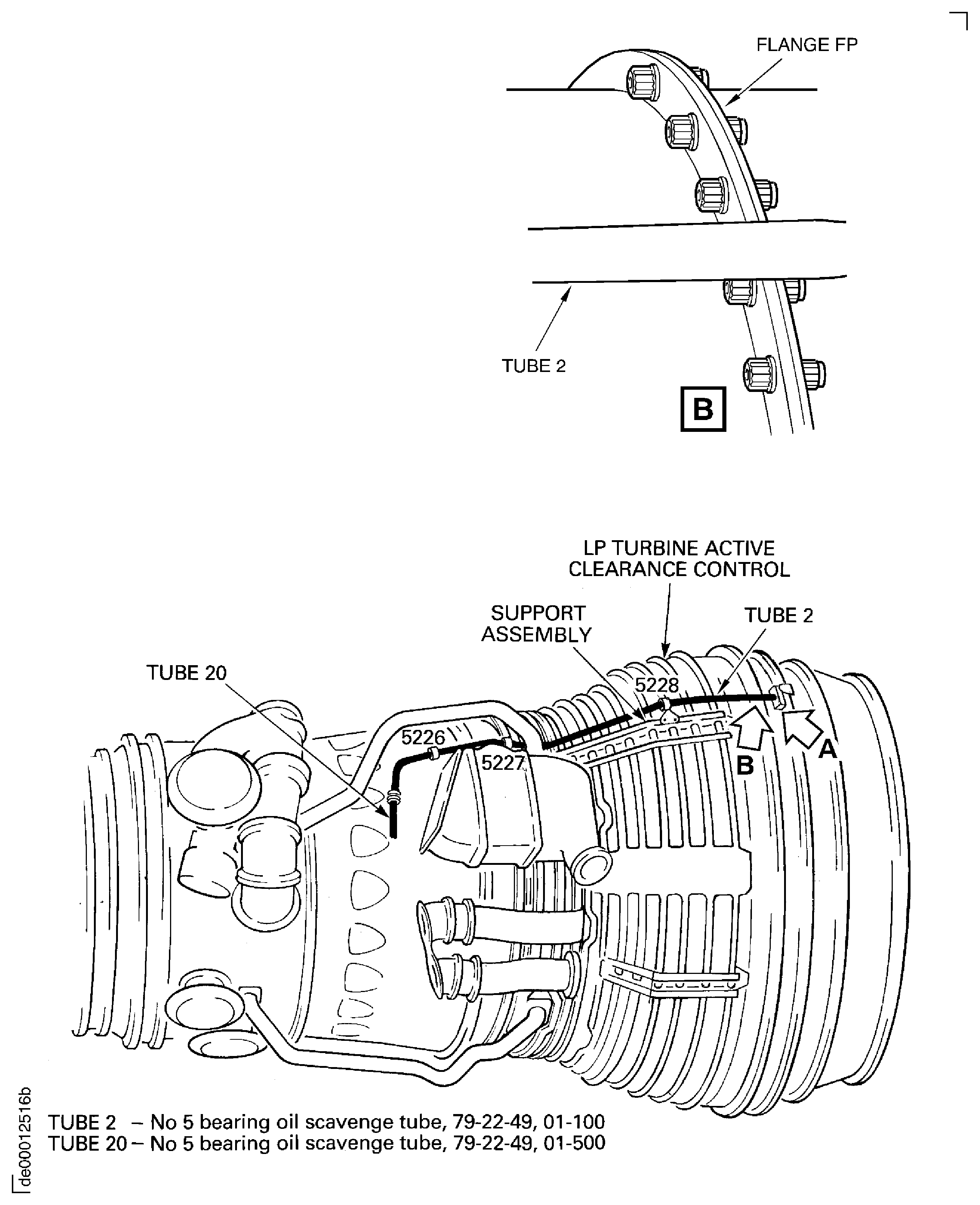

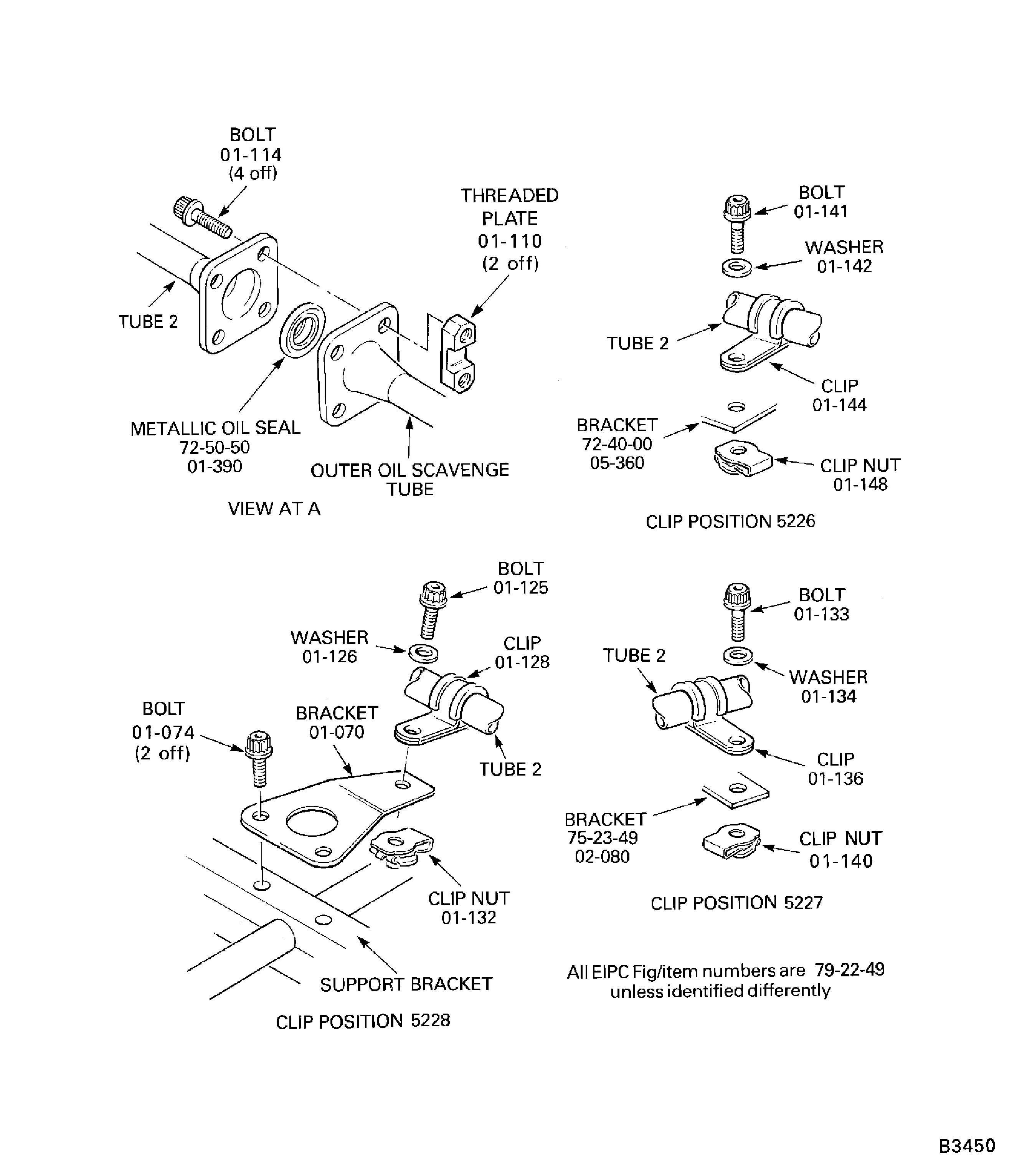

Attach the bracket Engine Scavenge Oil Tubes (79-22-49, 01-070) to the LP turbine active clearance control with the two bolts Engine Scavenge Oil Tubes (79-22-49, 01-074). Torque the bolts to 36 to 45 lbfin. (4.00 to 5.00 Nm).

Put the metallic oil seal Engine Scavenge Oil Tubes (79-22-49, 01-116) in to the correct position.

Install the four bolts Engine Scavenge Oil Tubes (79-22-49, 01-114) and the two threaded plates Engine Scavenge Oil Tubes (79-22-49, 01-110).

Safety the bolts with CoMat 02-119 LOCKWIRE.

Connect the tube 2 to the outer oil scavenge tube.

Torque the tube nut to 398 to 434 lbfin. (45 to 49 Nm) and safety with CoMat 02-126 LOCKWIRE.

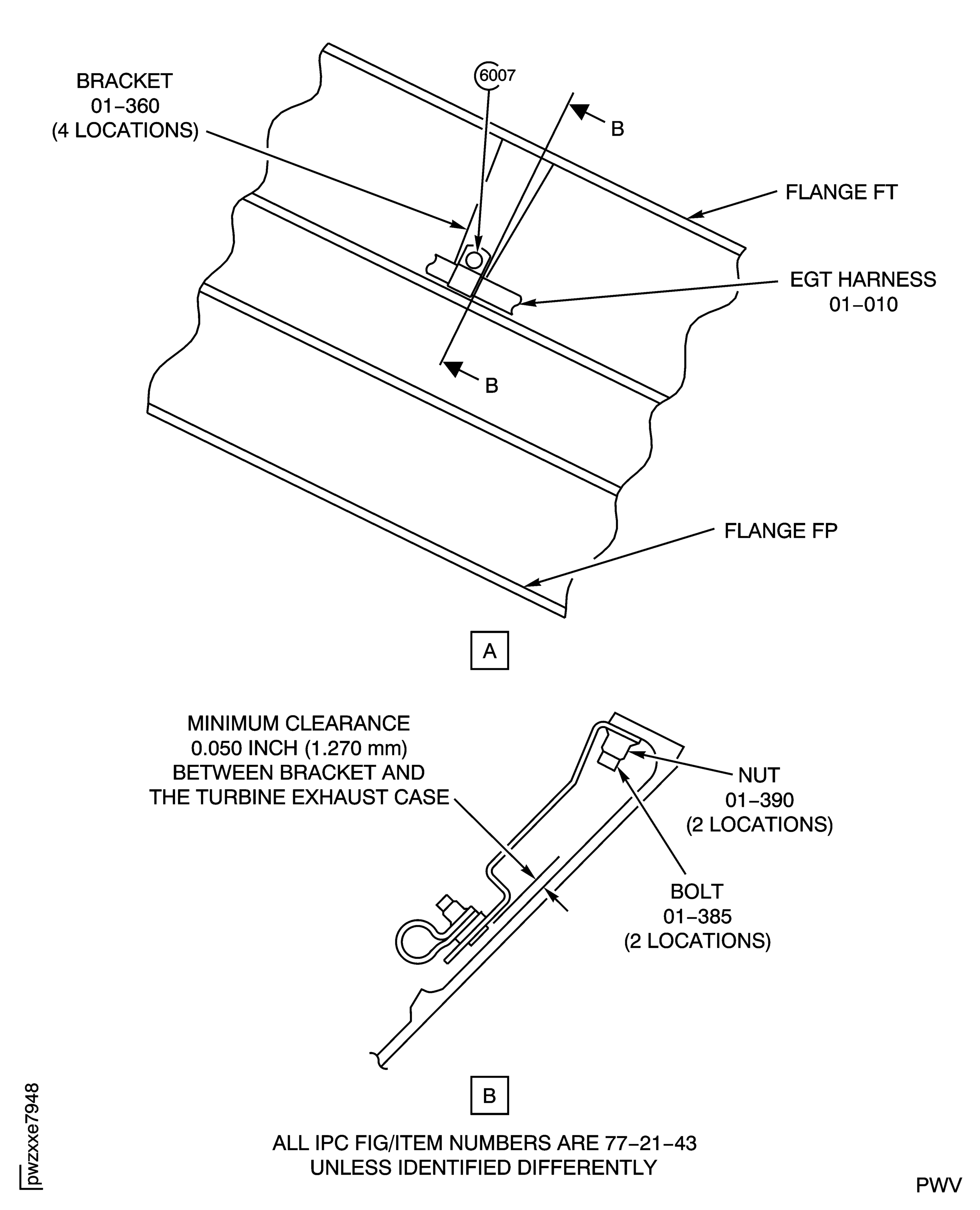

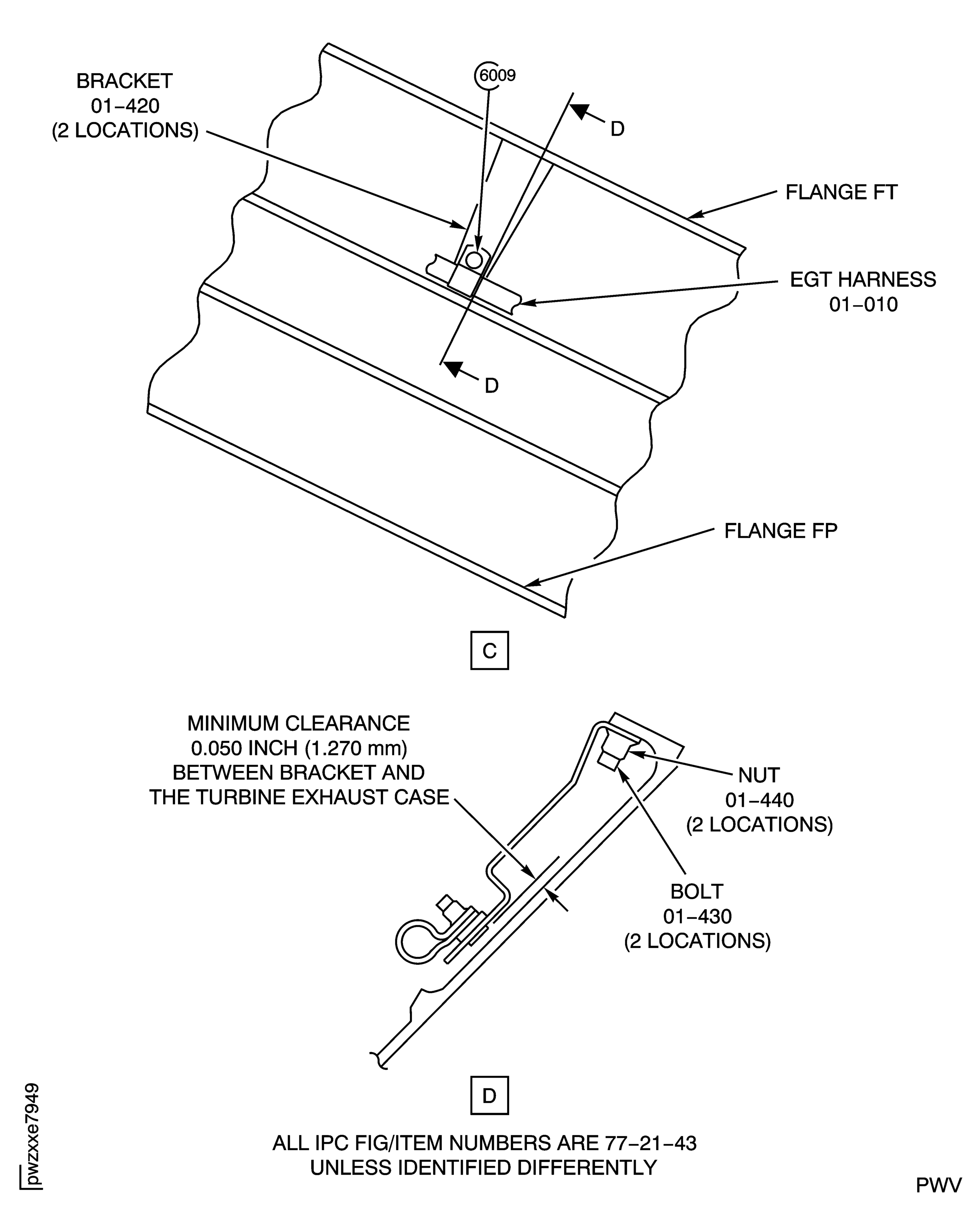

Do a check on the clearance between the tube 2 and the flange FP bolt. Make sure that there is a minimum clearance of 0.050 in. (1.27 mm), refer to Figure detail B.

SUBTASK 72-00-50-420-190 Install the tube 2, Number 5 Bearing Oil Scavenge Tube

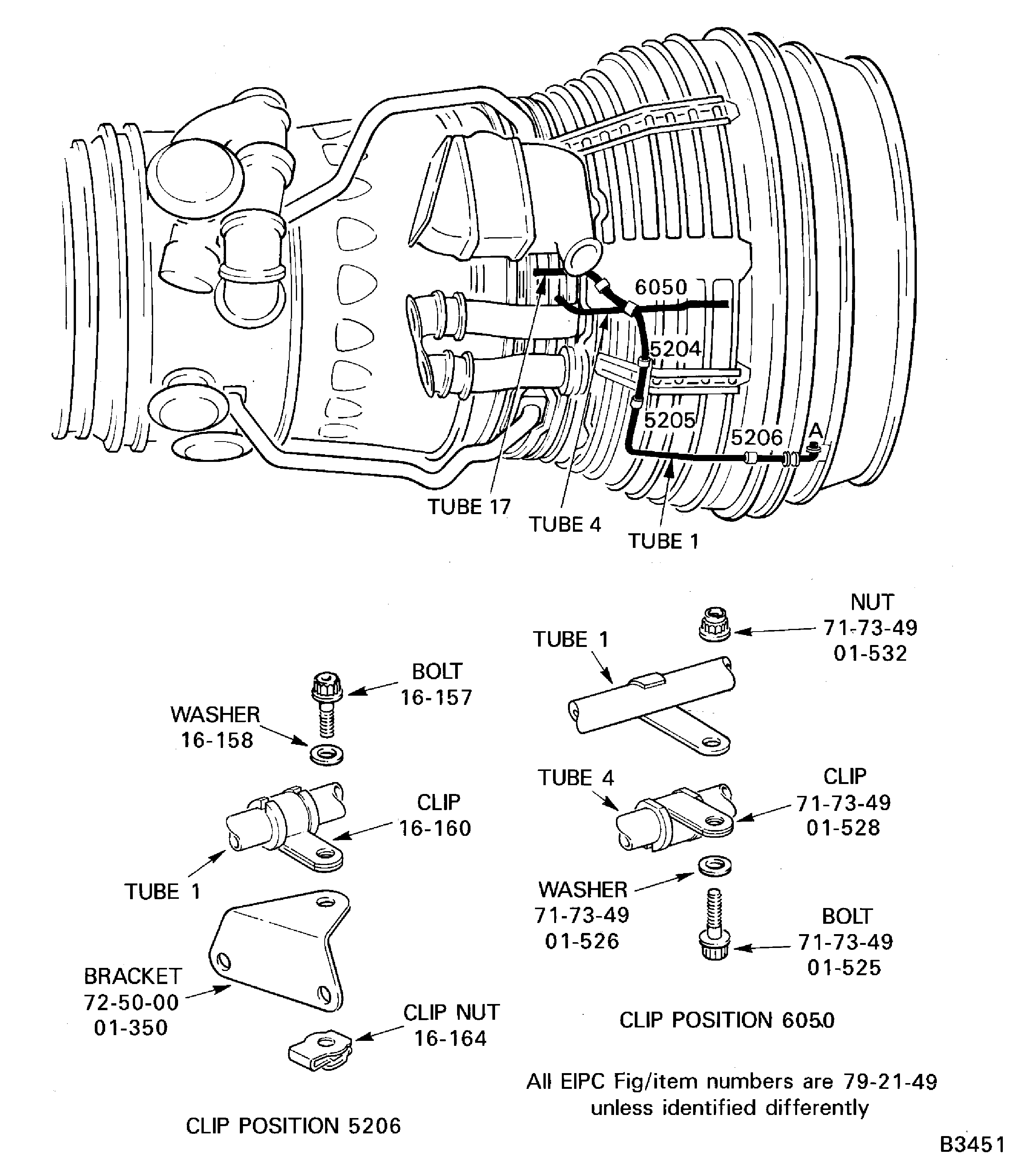

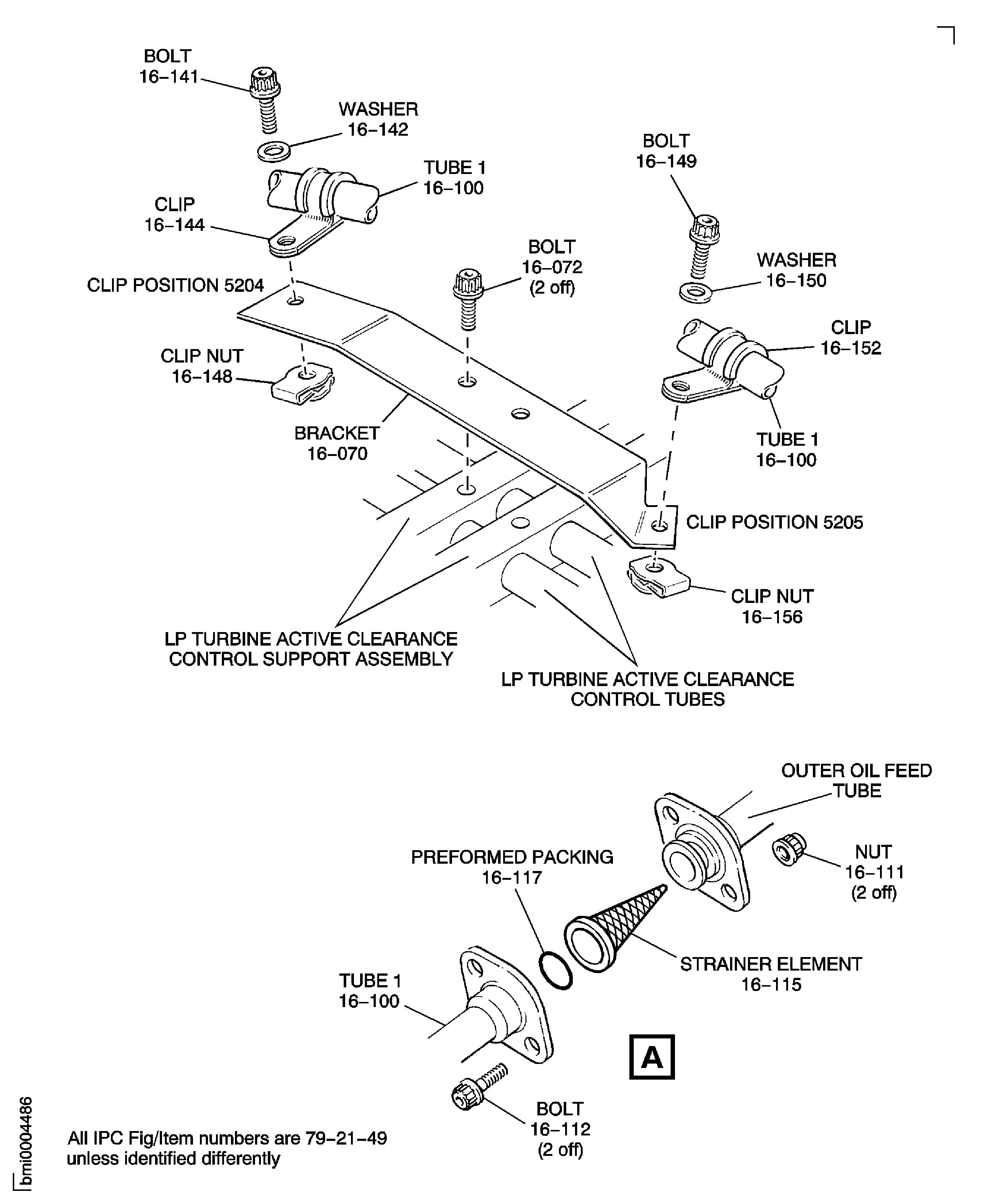

Attach the bracket OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 16-070) to the LP turbine active clearance control at the seven o'clock position, with the two bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 16-072). Torque the bolts to 36 to 45 lbfin. (4 to 5 Nm).

Put the strainer element OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 16-115) and the preformed packing OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 16-117) in the correct position.

Install the two bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 16-112) and the two nuts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 16-111).

Connect the tube 1 to the outer oil feed tube:

Torque the tube nut to 230 to 248 lbfin. (26 to 28 Nm) and safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-50-420-191 Install the Tube 1, Number 5 Bearing Oil Feed Tube

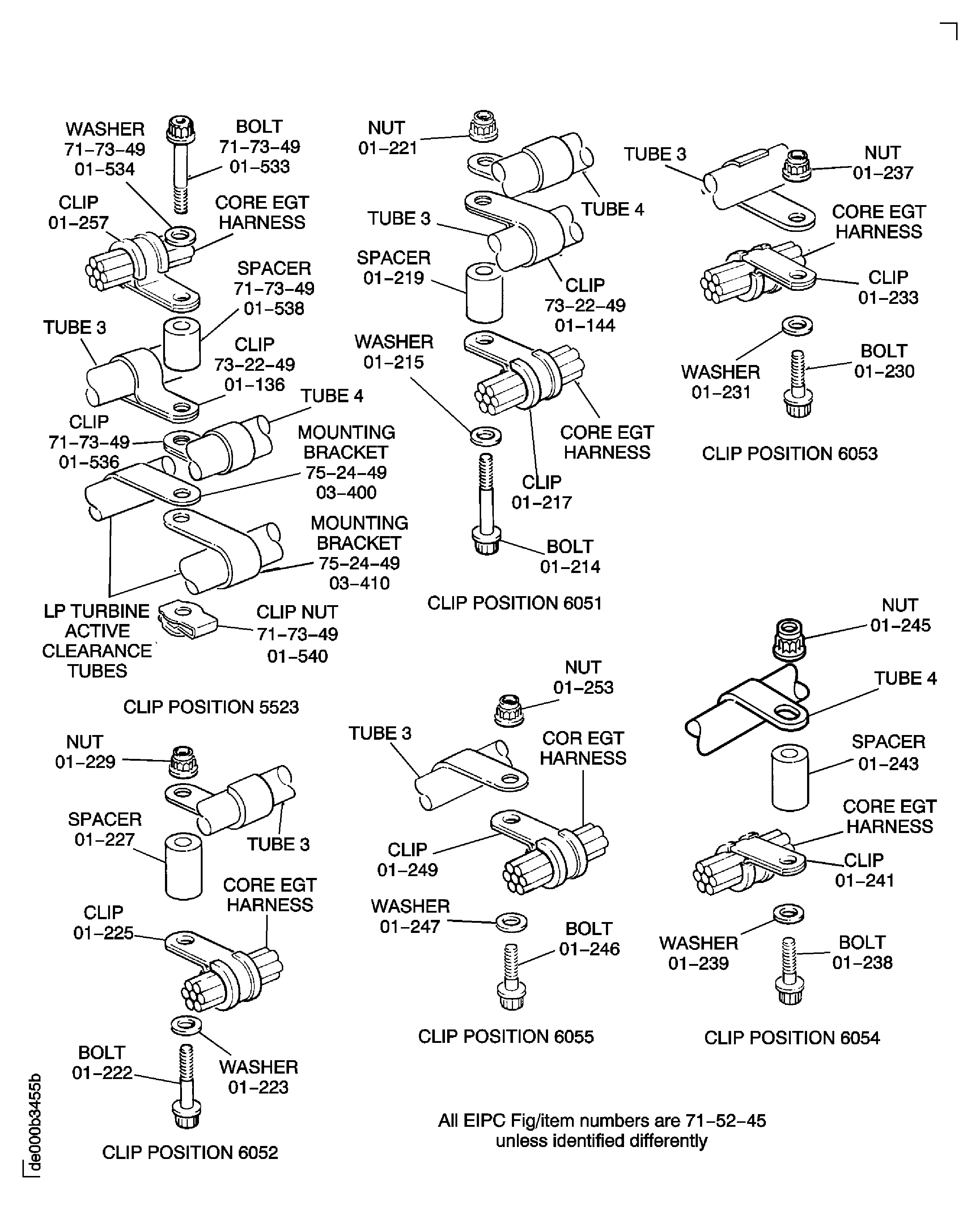

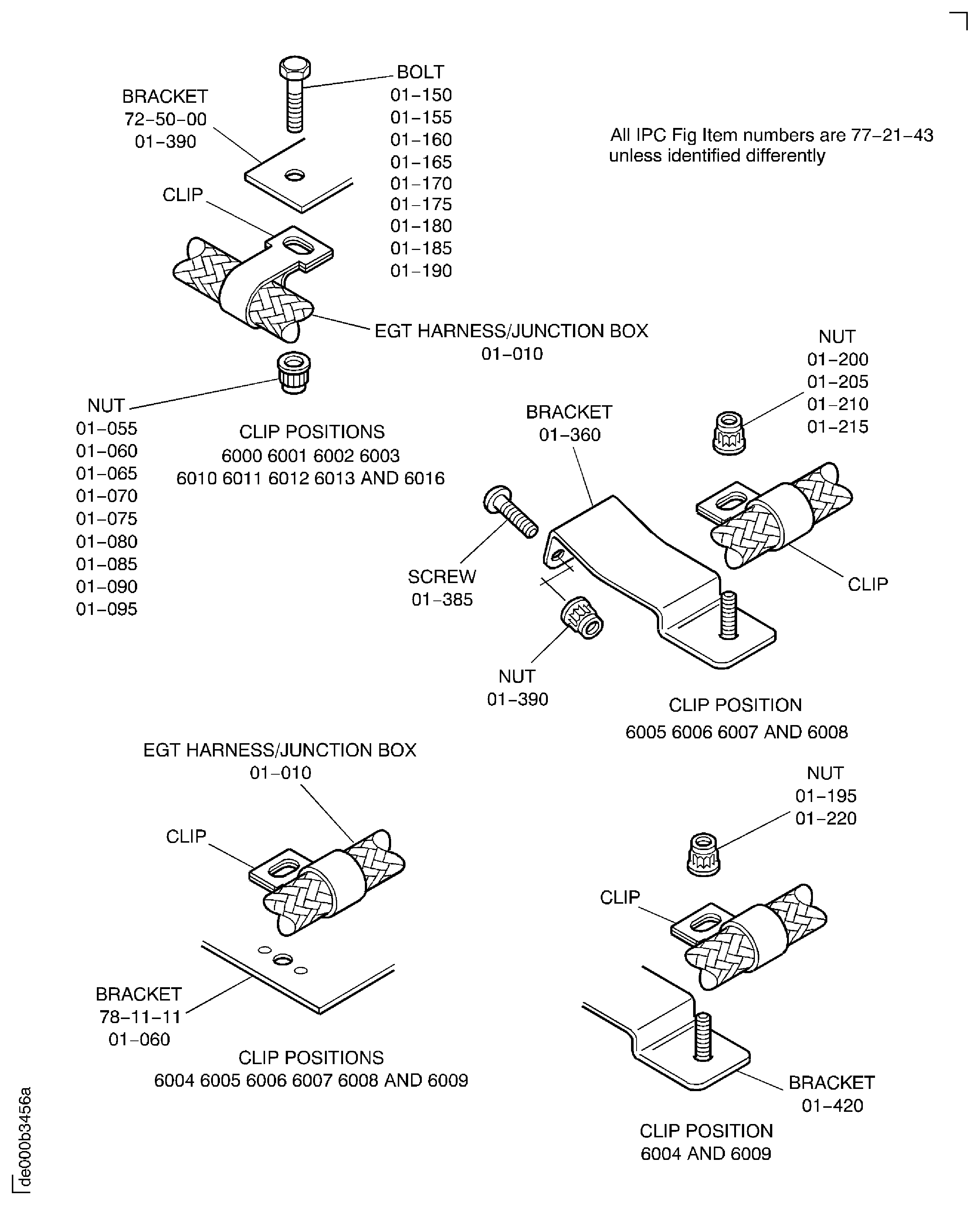

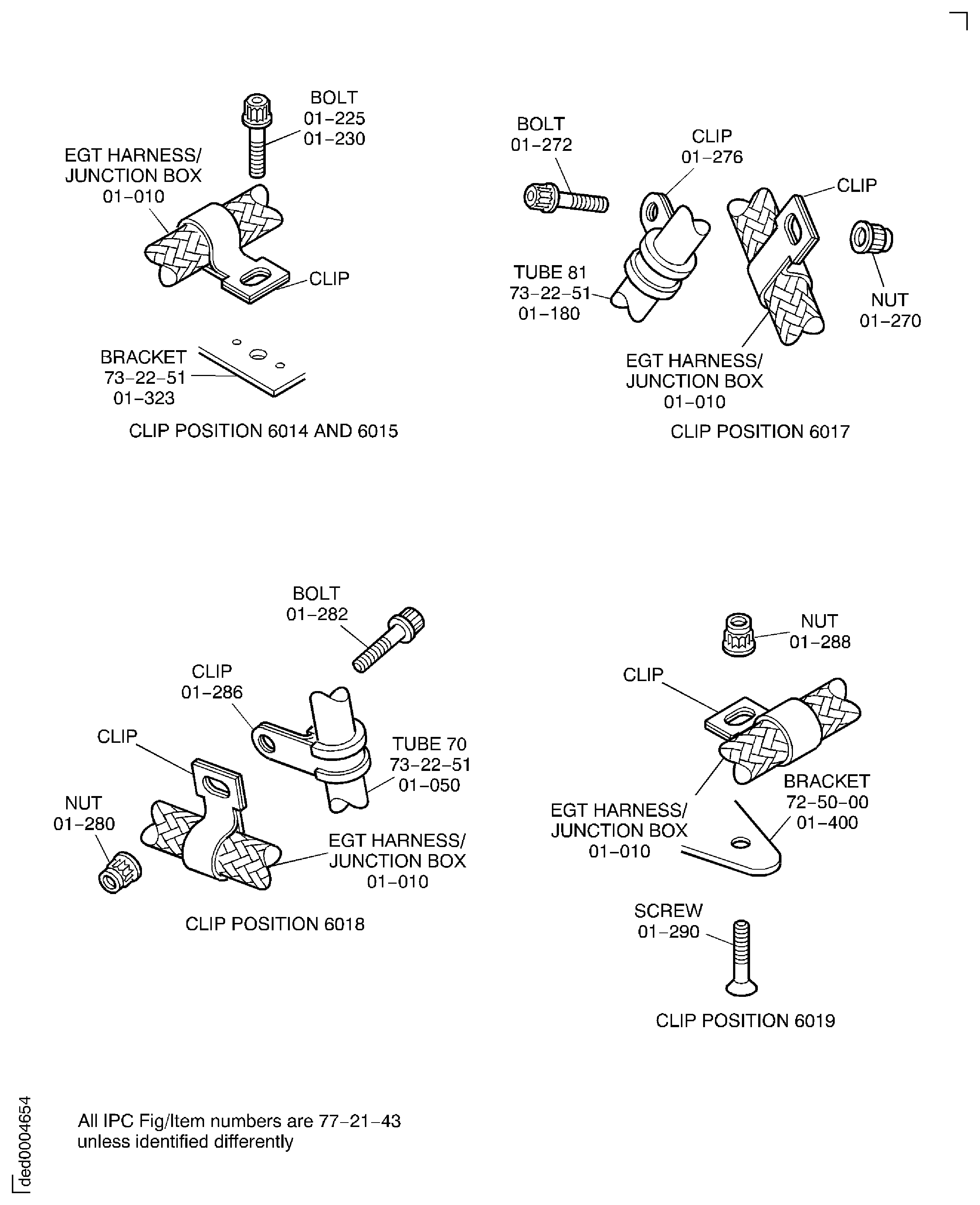

Because of the differences between the harness diameters, the specified clip could be too large or too small. You can use a clip from a range of six clips that have the same part numbers. If the harness diameter is between two of the clips in the range, use the larger clip. When you do this use CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) to increase the harness diameter.

For the data on the electrical connectors refer to the SPM TASK 70-43-00-400-501 and SPM TASK 70-43-01-400-501.

SUBTASK 72-00-50-420-192 Electrical Harness Installation Procedure

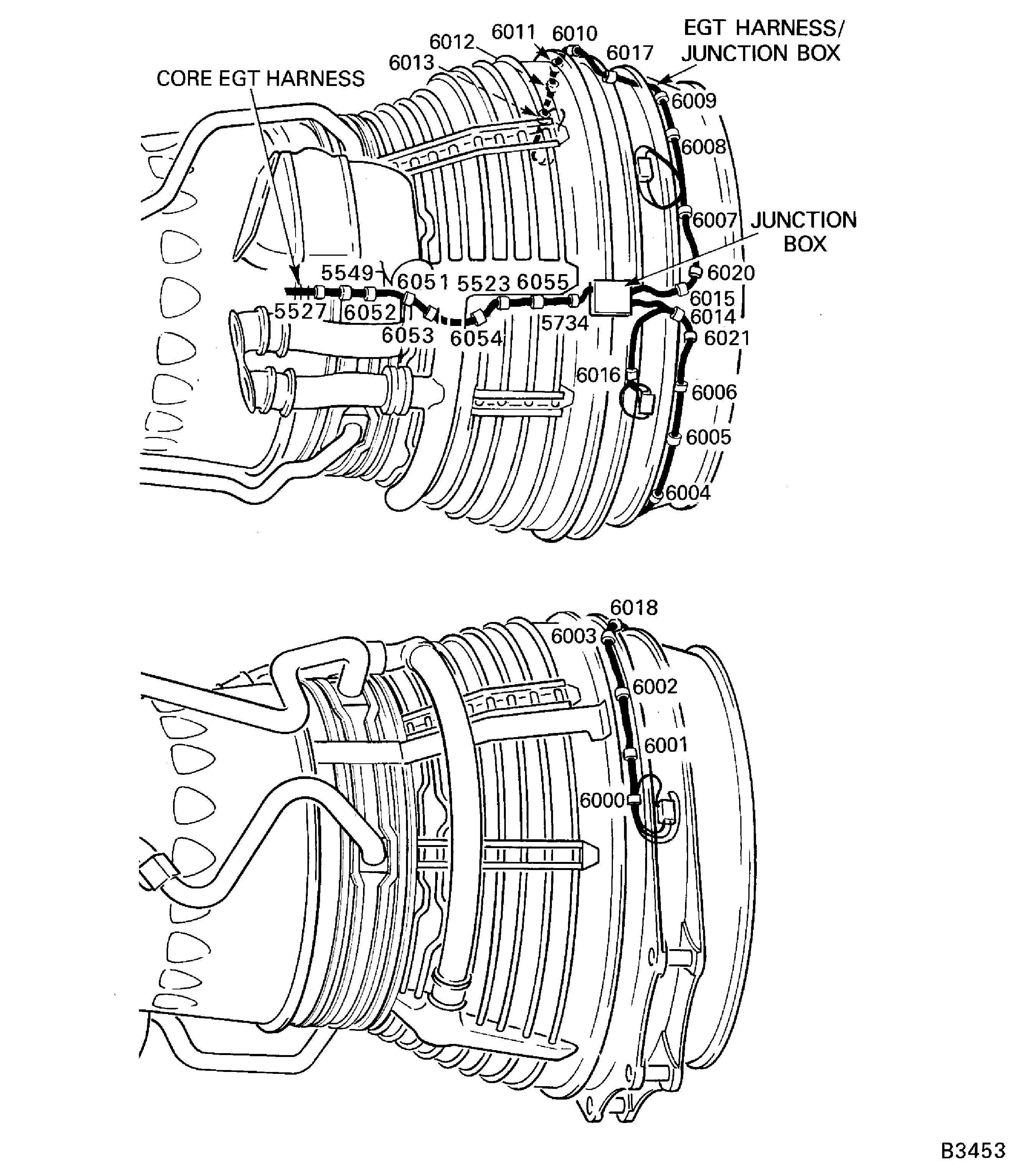

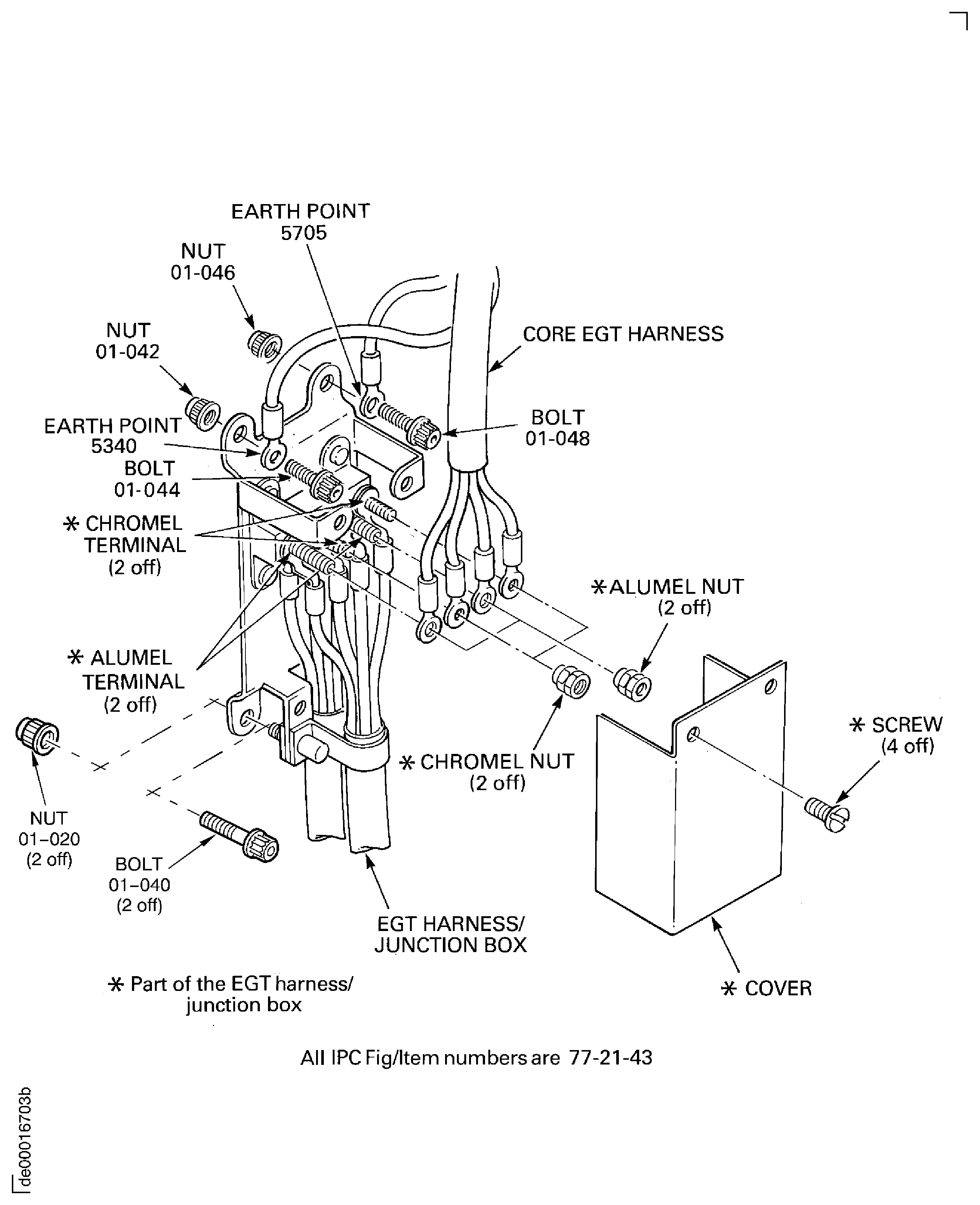

Put the remaining parts of the core EGT harness Exhaust Gas Temperature (EGT) Harness (71-52-45, 01-005) in position.

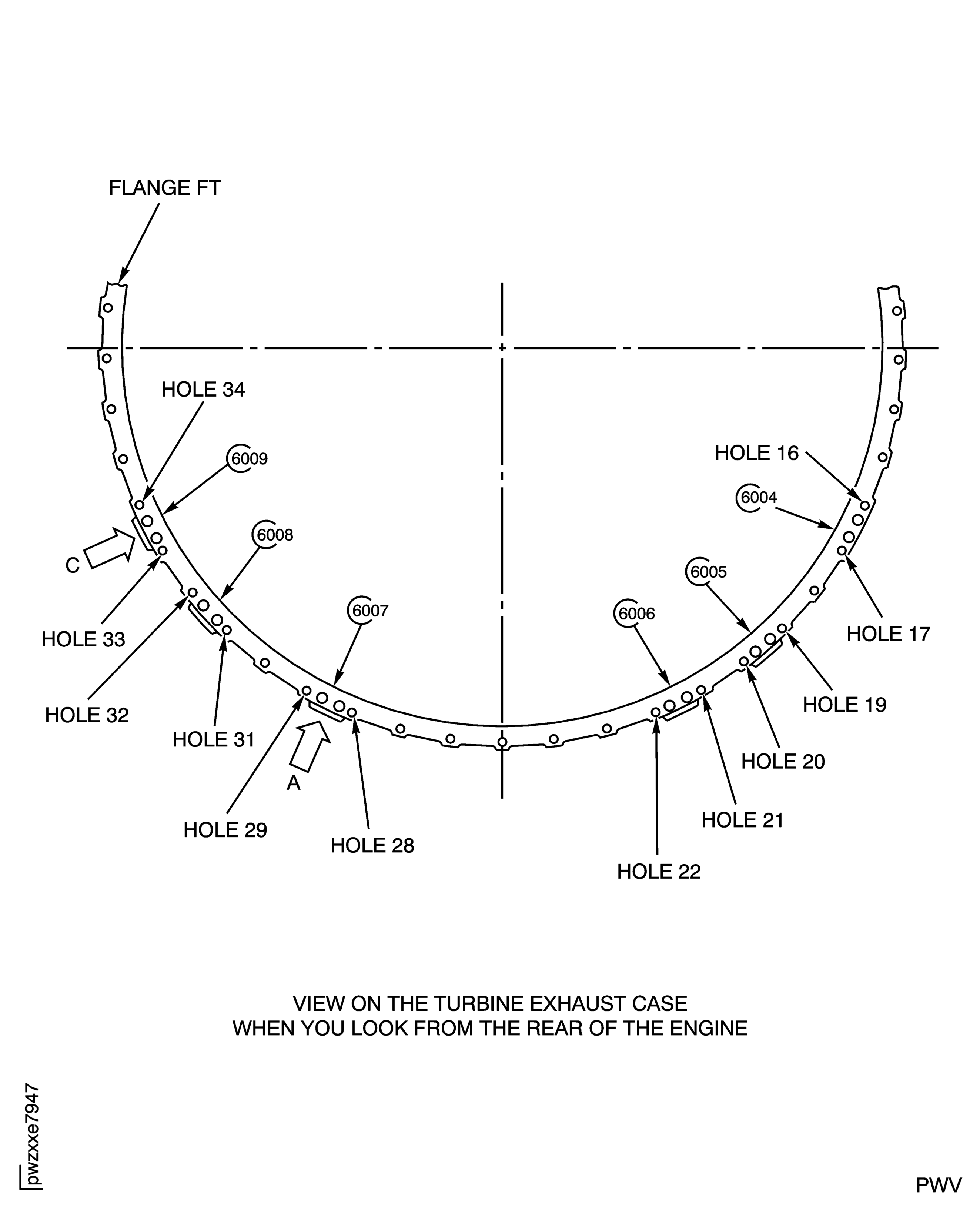

Put the EGT harness/junction box EGT Harness And Junction Box (77-21-43, 01-010) in position on the engine. Make sure that the harness goes between the LP turbine case and the tubes 70 and 81, between the clip positions 6004/6003 and 6009/6010.

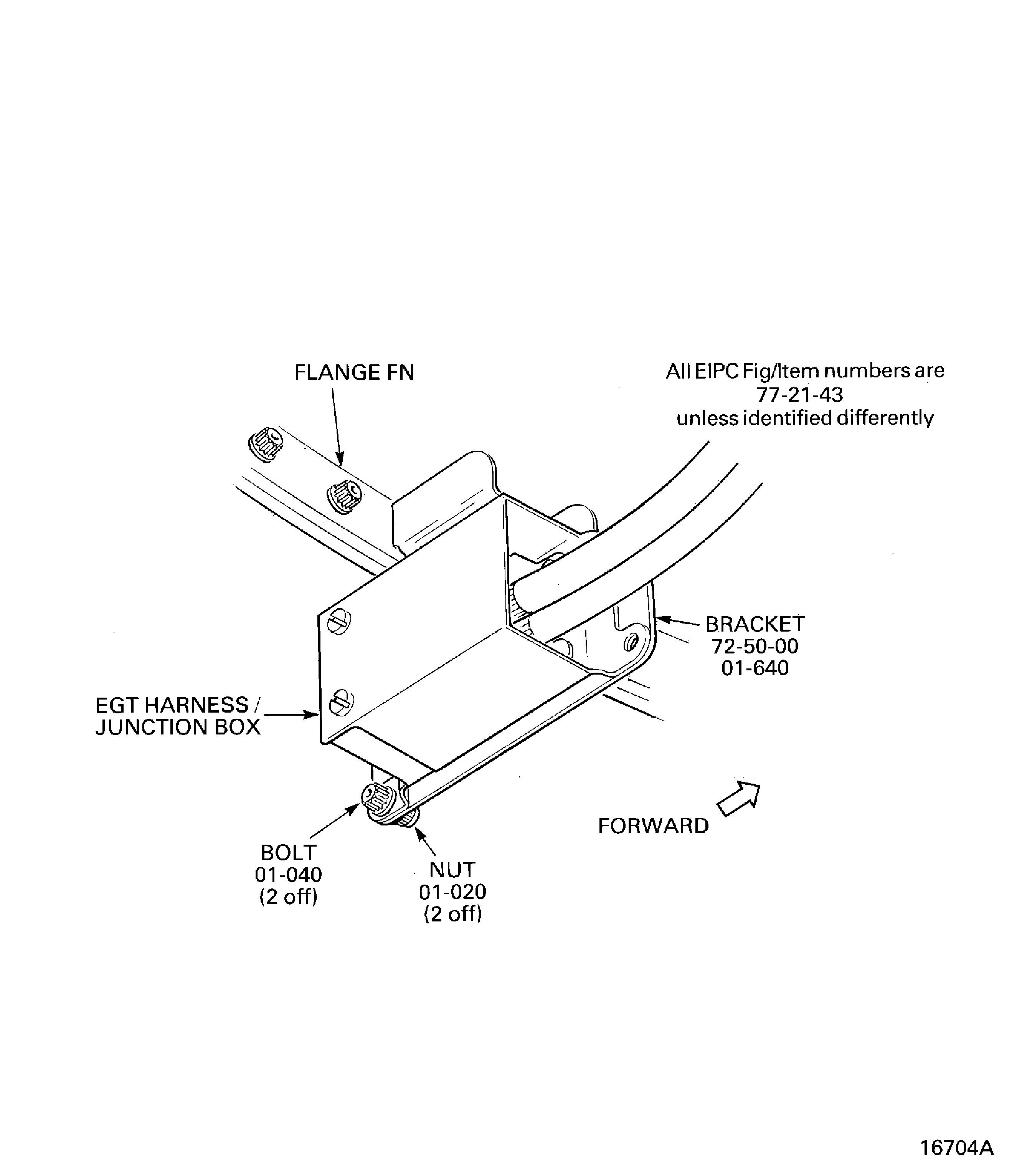

Attach the junction box to the bracket LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit(72-50-00, 01-640) with two of the bolts EGT Harness And Junction Box (77-21-43, 01-040) and two of the nuts EGT Harness And Junction Box (77-21-43, 01-020). Torque the nuts to 85 to 105 lbfin. (10 to 12 Nm).

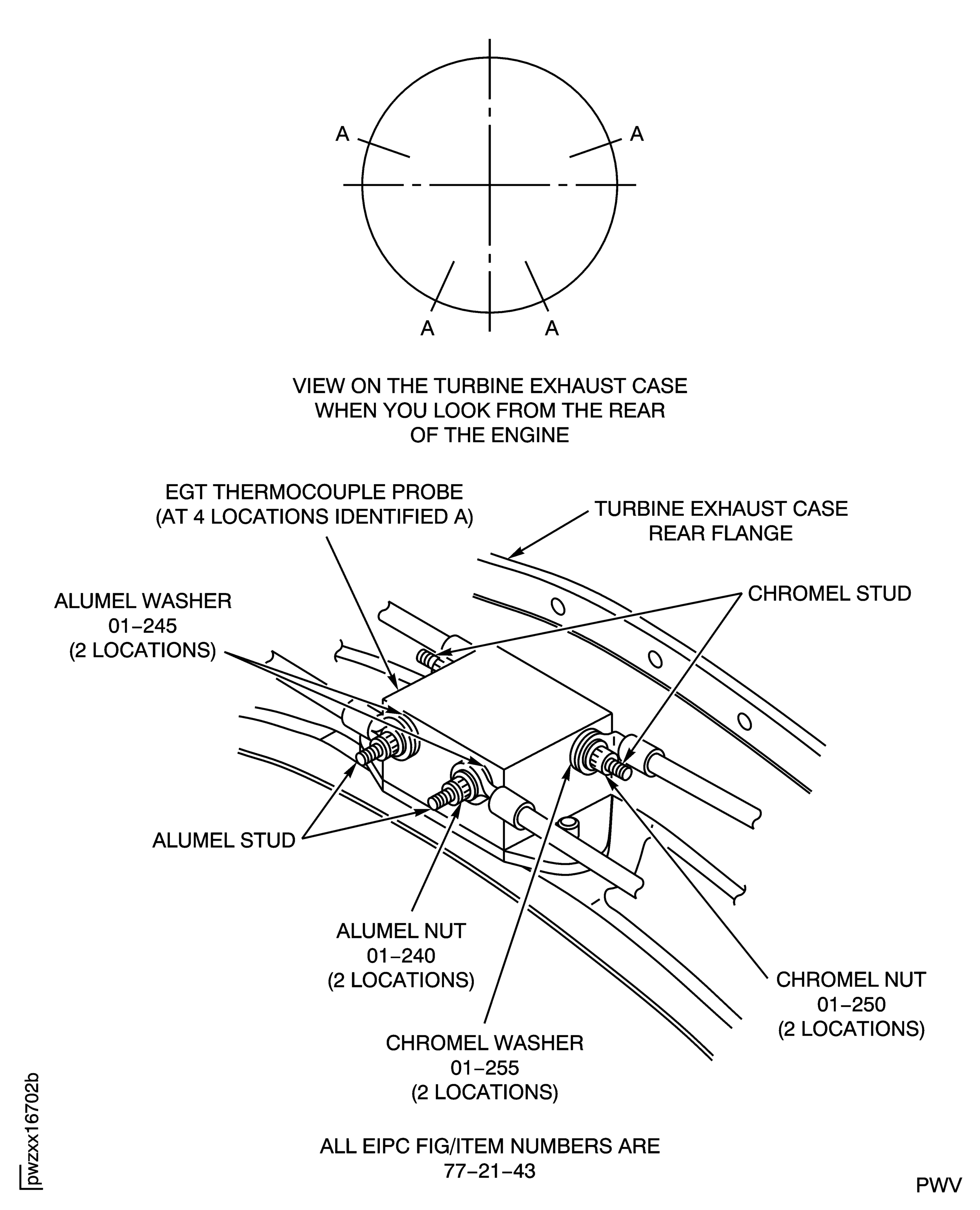

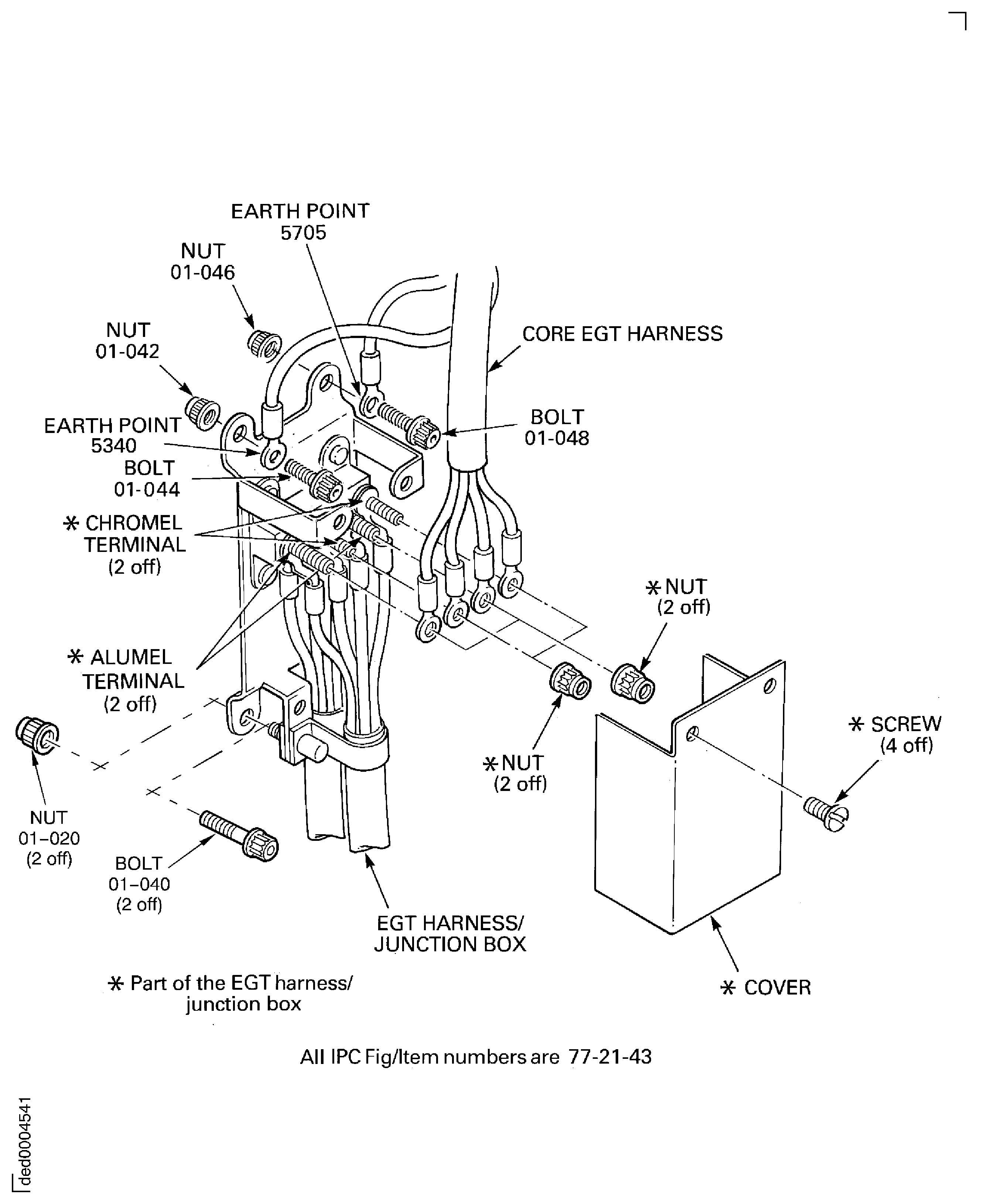

Attach the eight alumel leads to the applicable alumel studs on the EGT probes. Use the eight alumel nuts (larger) EGT Harness And Junction Box (77-21-43, 01-240). Make sure that the lips on the alumel leads face outwards. Torque the nuts to 10 to 15 * lbfin. (1.13 to 1.69 Nm).

Attach the eight chromel leads, to the applicable chromel studs on the EGT probes. Use the eight chromel nuts (smaller) EGT Harness And Junction Box (77-21-43, 01-250). Torque the nuts to 8 to 12 * lbfin. (0.90 to 1.36 Nm).

NOTE

It is not necessary to lubricate the terminal threads or fasteners with engine oil.Connect the 16 harness leads to the applicable EGT probe terminals.

CAUTION

YOU MUST MAKE SURE THAT THE EGT THERMOCOUPLE BOLTS ARE CORRECTLY SAFETIED. INCORRECT SAFETYING OF THE BOLTS CAN RESULT IN LOOSE BOLTS AND SUBSEQUENT LOSS OF EGT INDICATION.Make sure the lockwire correctly safeties the eight EGT thermocouple bolts V2500-A5-77-21-15-01A-941A-D(77-21-15, 01-120). Refer to view which shows the acceptable method to safety the bolts, Figure.

Safety the bolts with wire V2500-A5-77-21-15-01A-941A-D (77-21-15, 01-200) - CoMat 02-141 LOCKWIRE as the inspection criteria requires it.

Examine the lockwire which safeties the EGT thermocouple bolts.

Install the brackets Common Nozzle Assembly (CNA) (78-11-11, 01-060) with the bolts EGT Harness And Junction Box (77-21-43, 01-195 to EGT Harness And Junction Box 01-200) and nuts EGT Harness And Junction Box (77-21-43, 01-195 to EGT Harness And Junction Box 01-220) to the LP turbine case rear flange, at the hole positions 16, 17, 19, 20, 21, 22, 28, 29, 31, 32, 33 and 34. The hole No.1 is at TDC. Torque the nuts to 100 to 140 lbfin. (11 to 16 Nm).

Attach six brackets.

Install the brackets EGT Harness And Junction Box (77-21-43, 01-360) with the screws EGT Harness And Junction Box (77-21-43, 01-385) and the nuts EGT Harness And Junction Box (77-21-43, 01-390) to the LP turbine case rear flange, at the bolt hole positions 22, 23, 26, 27, 35, 36, 40 and 41. The hole No.1 is at TDC. Torque the nuts to 85 to 105 lbfin. (10 to 12 Nm).

Attach four brackets.

Install the brackets EGT Harness And Junction Box (77-21-43, 01-420) with the screws EGT Harness And Junction Box (77-21-43, 01-385) and nuts EGT Harness And Junction Box (77-21-43, 01-390) to the LP turbine case rear flange at the hole positions 17, 18 44 and 45. Torque the nuts to 85 to 105 lbfin. (10 to 12 Nm).

Attach 2 brackets.

Use the other two nuts EGT Harness And Junction Box (77-21-43, 01-042 and EGT Harness And Junction Box 01-046) and the two bolts EGT Harness And Junction Box (77-21-43, 01-044) and EGT Harness And Junction Box (77-21-43, 01-048) to attach the earth points 5340 and 5705 to the junction box. Torque the nuts to 85 to 105 lbfin. (10 to 12 Nm).

Attach the cover to the EGT harness junction box with the four screws. Torque the screws to 20 to 26 lbfin. (2.26 to 2.94 Nm). Safety the screws with CoMat 02-126 LOCKWIRE.

Pre SBE 77-0009: Attach the core EGT harness to the EGT harness/junction box.

Use the other two nuts EGT Harness And Junction Box (77-21-43, 01-042) and EGT Harness And Junction Box (77-21-43, 01-046) and the two bolts EGT Harness And Junction Box (77-21-43, 01-044) and EGT Harness And Junction Box (77-21-43, 01-048) to attach the earth points 5340 and 5705 to the junction box. Torque the nuts to 85 to 105 lbfin. (10 to 12 Nm).

Attach the cover to the EGT harness junction box with the four screws. Torque the screws to 20 to 26 lbfin. (2.26 to 2.94 Nm). Safety the screws with CoMat 02-126 LOCKWIRE.

CAUTION

THE USE OF LUBRICATION IS NOT PERMITTED ON EITHER THE STUDS OR LOCK NUTS.

CAUTION

ONCE A NEW STYLE NUT IS INSTALLED ON TO THE MATING STUD YOU MUST NOT INSTALL AN OLD NUT ON THAT STUD.SBE 77-0009: Attach the core EGT harness to the EGT harness/junction box. Refer to Figure.

Do a continuity test and short circuit test, refer to the approved procedure in the Service Bulletin, SBE 77-0009.

Refer to TASK 71-00-00-700-052-B00 for the applicable EGT and junction box tests.

Testing and Fault Isolation checks.

SUBTASK 72-00-50-420-193 Install the Core Exhaust Gas Thermocouple (EGT) Harness, and the Exhaust Gas Thermocouple Harness/Junction Box (Pre SBE 77-0009 and SBE 77-0009)

SBE 77-0009: Provide new EGT harness junction box terminal nuts

Check the clearance at the four bracket postions, refer to view A and section B for brackets EGT Harness And Junction Box (77-21-43, 01-360).

Check the clearance at the four bracket postions, refer to view C and section D for brackets EGT Harness And Junction Box (77-21-43, 01-420).

SUBTASK 72-00-50-420-389 Check the Clearance between Flange FT and the Core EGT Harness Support Brackets

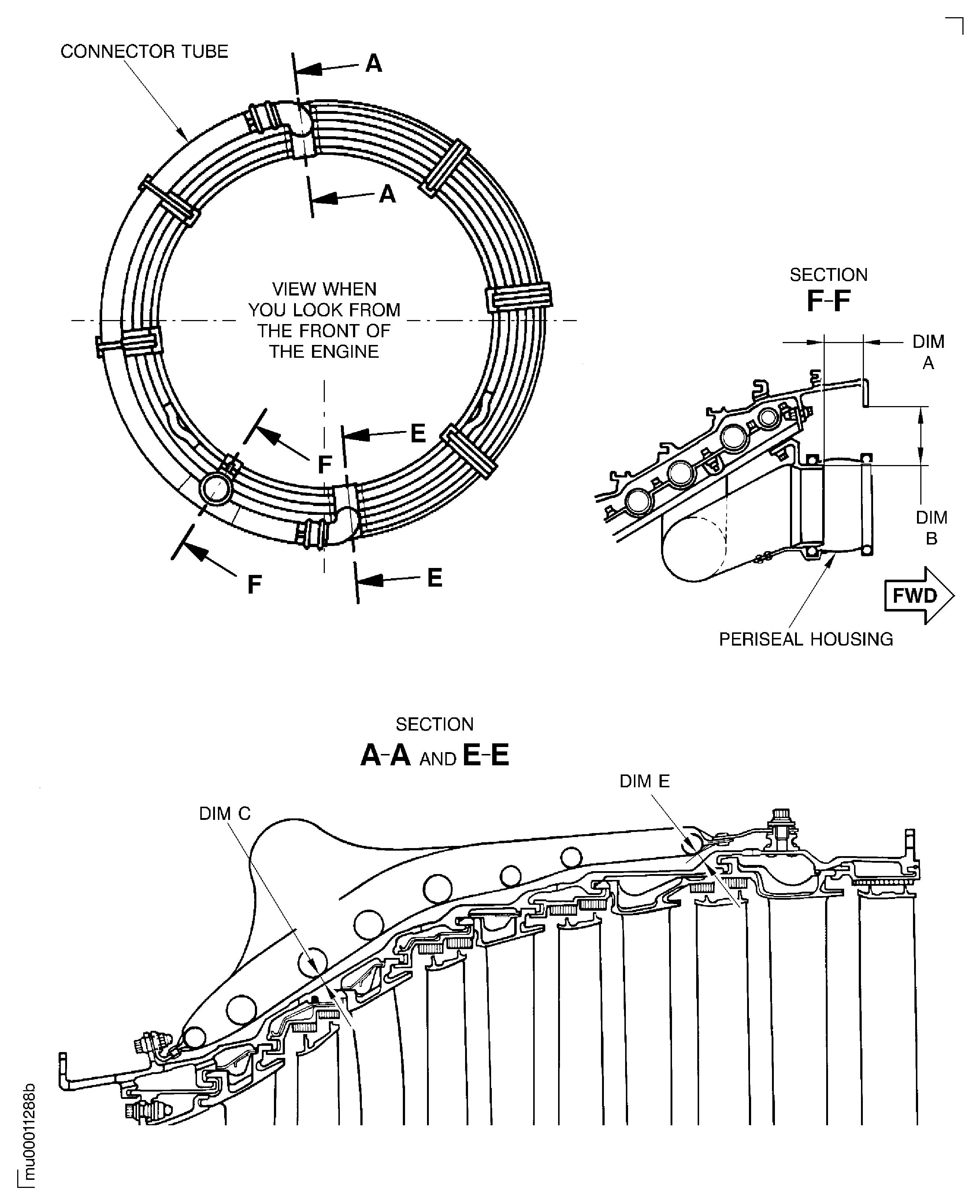

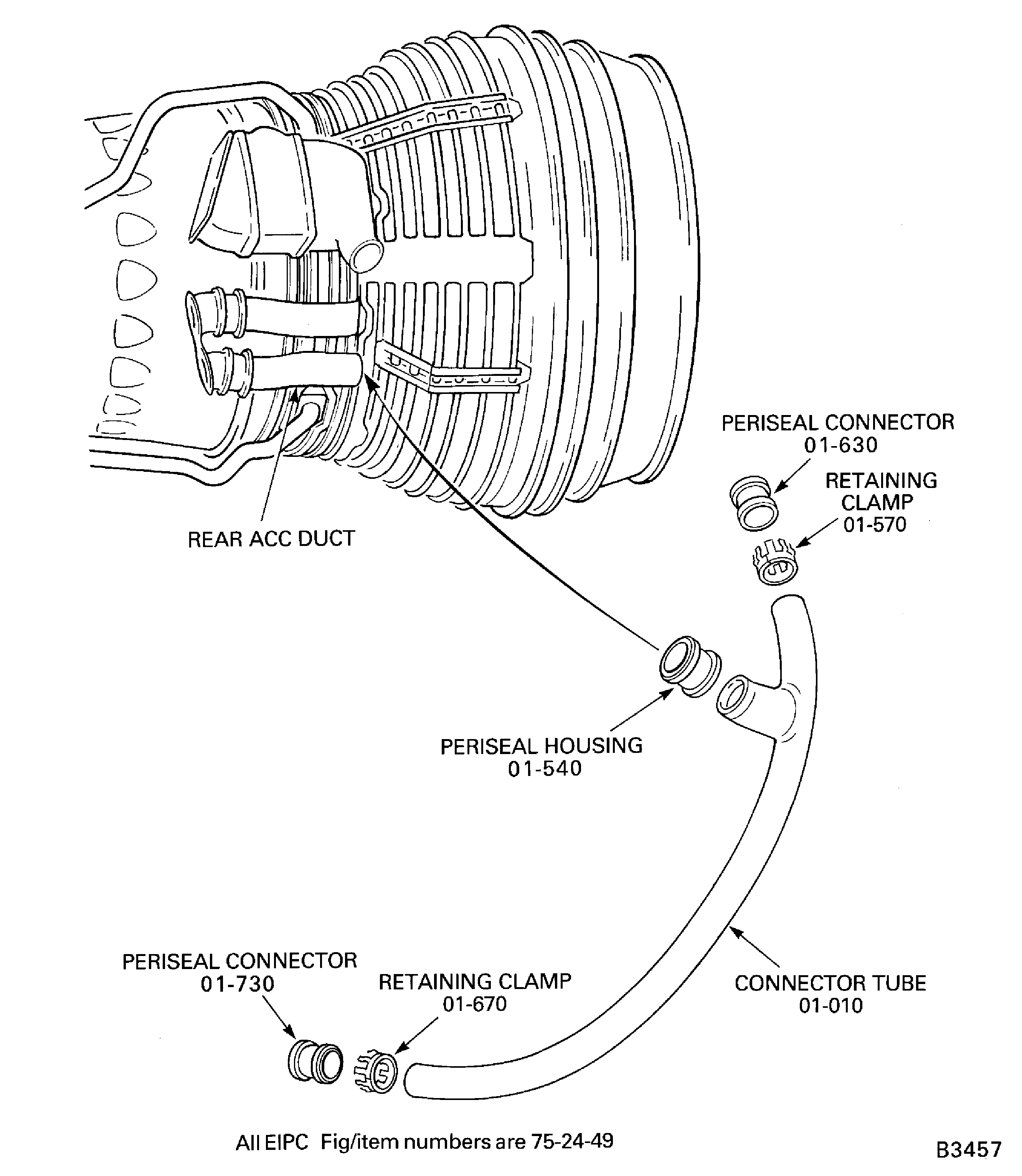

Install the bolts LPT ACC Air Ducts And Tubes (75-24-49, 01-030), the washers LPT ACC Air Ducts And Tubes (75-24-49, 01-050) and the spacer LPT ACC Air Ducts And Tubes (75-24-49, 01-070) that attach the T-piece angle bracket of the connector tube LPT ACC Air Ducts And Tubes (75-24-49, 01-010) to the support assembly.

Put the connector tube LPT ACC Air Ducts And Tubes (75-24-49, 01-010) in to position between the upper and lower LP Turbine cooling air ducts.

Attach the clamps LPT ACC Air Ducts And Tubes (75-24-49, 01-130) and LPT ACC Air Ducts And Tubes (75-24-49, 01-090) loosely with the four bolts LPT ACC Air Ducts And Tubes (75-24-49, 01-030) and the four washers LPT ACC Air Ducts And Tubes (75-24-49, 01-050) to the support assemblies.

Move the periseal connectors LPT ACC Air Ducts And Tubes (75-24-49, 01-730) and LPT ACC Air Ducts And Tubes (75-24-49, 01-630) from their retracted positions above the upper and lower LP Turbine cooling air ducts.

Make sure that each pin of retaining clamps LPT ACC Air Ducts And Tubes (75-24-49, 01-670) and LPT ACC Air Ducts And Tubes (75-24-49, 01-570) engages in the location holes in the connector tube LPT ACC Air Ducts And Tubes (75-24-49, 01-010).

SUBTASK 72-00-50-420-194 Install the Connector Tube on to the LP Turbine ACC

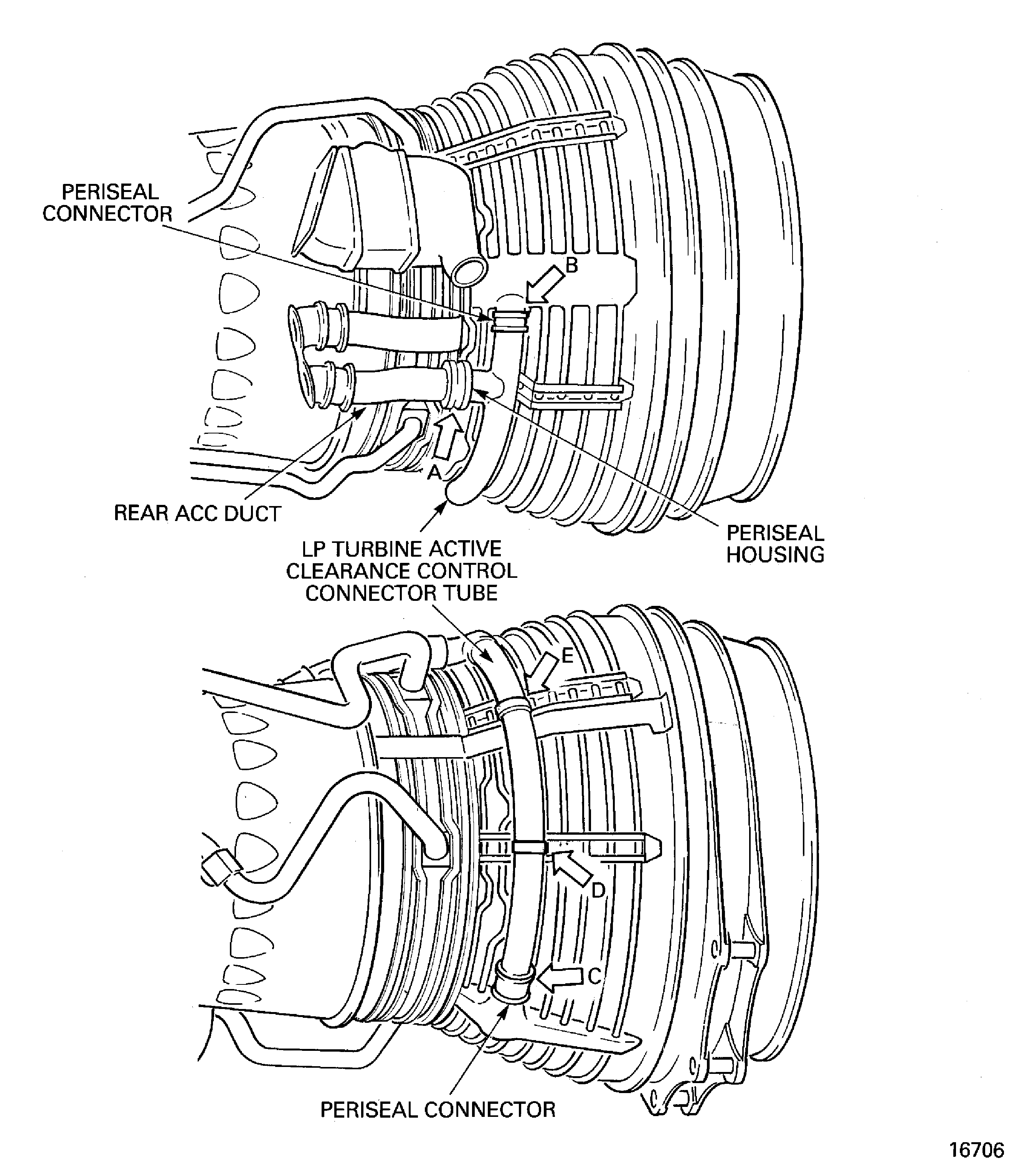

Refer to Figure.

Examine the radial clearance with the IAE 1M14118 Checking go/no-go gage 1 off.

Examine and adjust the radial clearance, Dimension B.

Examine the axial clearance with the IAE 1M14117 Checking go/no-go gage 1 off.

Examine and adjust the axial clearance, Dimension A.

Torque the bolts LPT ACC Air Ducts And Tubes (75-24-49, 01-030) of the clamps LPT ACC Air Ducts And Tubes (75-24-49, 01-130) and LPT ACC Air Ducts And Tubes (75-24-49, 01-090) to between 27 to 30 lbfin (3.0 to 3.4 Nm).

Torque the bolts LPT ACC Air Ducts And Tubes (75-24-49, 01-030) on the T-piece angle bracket to between 27 to 30 lbfin (3.0 to 3.4 Nm).

Install the nuts and the bolts of the two retaining clamps LPT ACC Air Ducts And Tubes (75-24-49, 01-670) and LPT ACC Air Ducts And Tubes (75-24-49, 01-570).

Tighten the nuts of the retaining clamps LPT ACC Air Ducts And Tubes (75-24-49, 01-670) and LPT ACC Air Ducts And Tubes (75-24-49, 01-570) until the lugs of the clamps attach the opposite flange.

Safety the spring clips with CoMat 02-128 LOCKWIRE.

SUBTASK 72-00-50-420-411 Adjust the Connector Tube (Pre SBE 75-0051)

Refer to Figure.

Examine the radial clearance with the IAE 1M14118 Checking go/no-go gage 1 off.

Examine and adjust the radial clearance, Dimension B.

Examine the axial clearance with the IAE 1M14117 Checking go/no-go gage 1 off.

Examine and adjust the axial clearance, Dimension A.

Torque the bolts LPT ACC Air Ducts And Tubes (75-24-49, 01-030) of the clamps LPT ACC Air Ducts And Tubes (75-24-49, 01-130) and LPT ACC Air Ducts And Tubes (75-24-49, 01-090) to between 27 and 30 lbfin (3.0 to 3.4 Nm).

Torque the bolts LPT ACC Air Ducts And Tubes (75-24-49, 01-030) on the T-piece angle bracket to between 27 and 30 lbfin (3.0 to 3.4 Nm).

Install the nuts and the bolts of the two retaining clamps LPT ACC Air Ducts And Tubes (75-24-49, 01-670) and LPT ACC Air Ducts And Tubes (75-24-49, 01-570).

Tighten the nuts of the retaining clamps LPT ACC Air Ducts And Tubes (75-24-49, 01-670) and LPT ACC Air Ducts And Tubes (75-24-49, 01-570) until the lugs of the clamps attach the opposite flange.

Move the periseal housing LPT ACC Air Ducts And Tubes (75-24-49, 01-540) from the retracted position on the ACC rear duct to the T-piece of the connector tube.

Install the two bolts LPT ACC Air Ducts And Tubes (75-24-49, 01-490) and the two periseal clamps LPT ACC Air Ducts And Tubes (75-24-49, 01-480) which safety the periseal housing at the T-piece of the connector tube.

SUBTASK 72-00-50-420-412 Adjust the Connector Tube (SBE 75-0051)

SBE 75-0051: LP Turbine ACC revised connector tube assembly with new periseal housing clamps

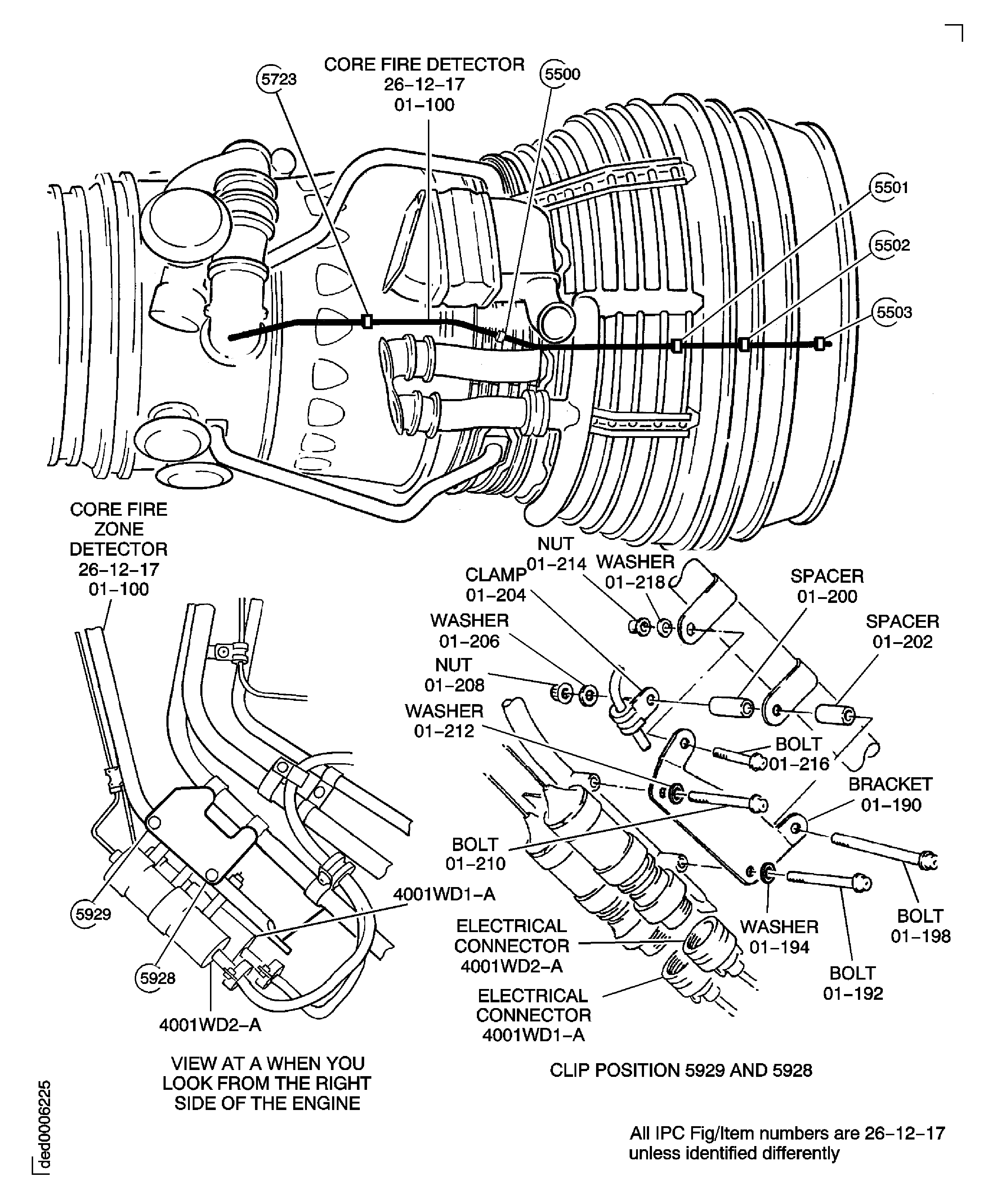

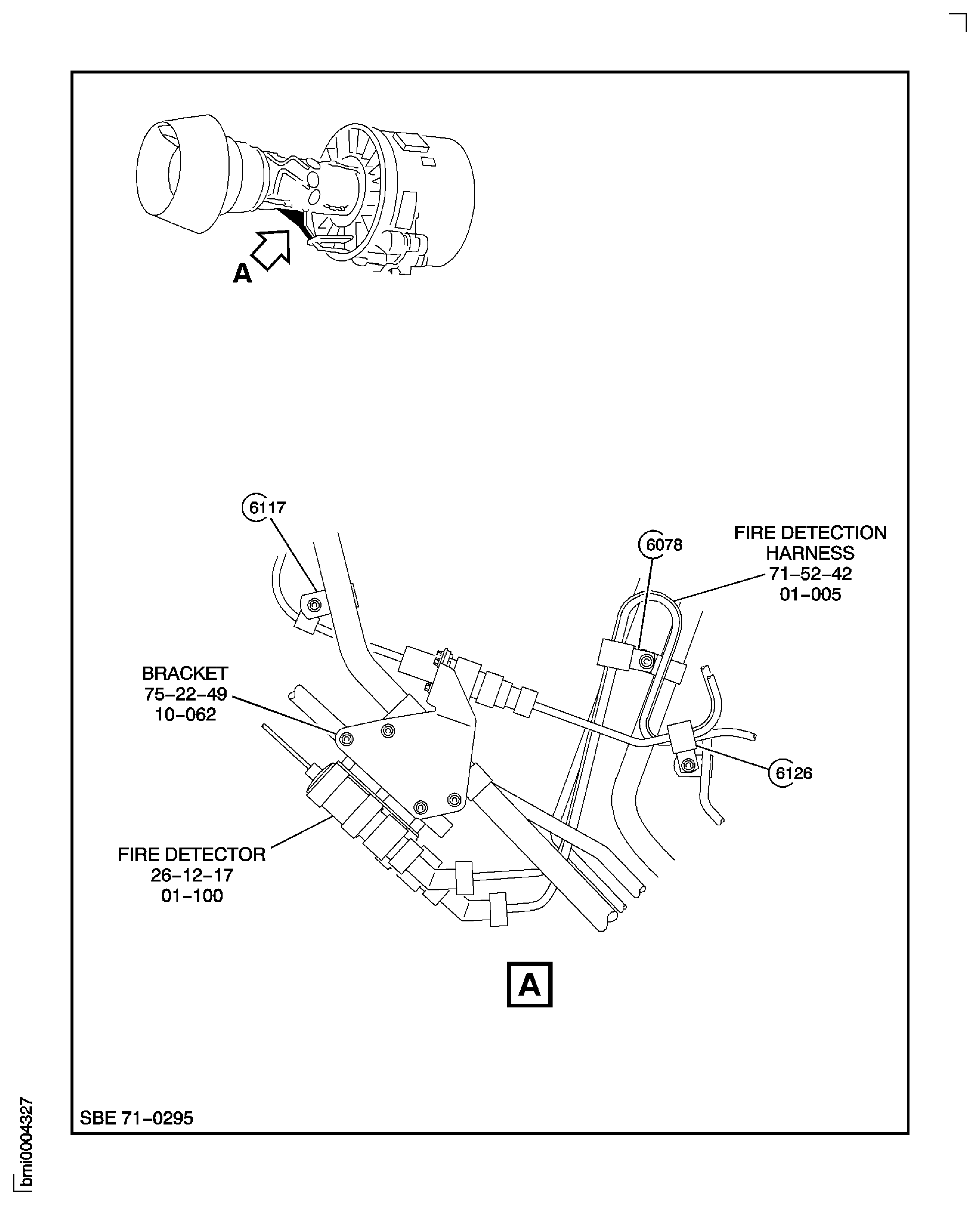

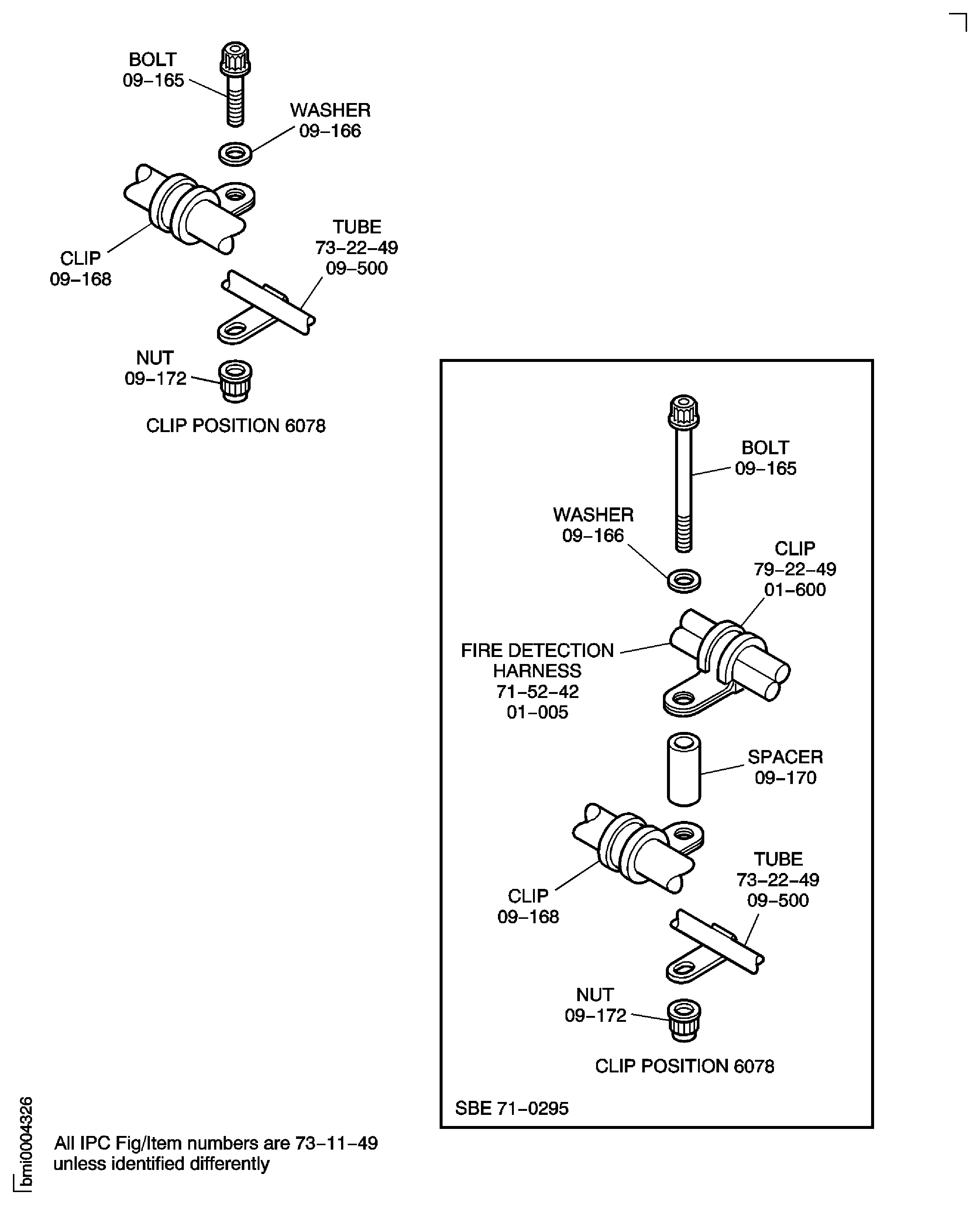

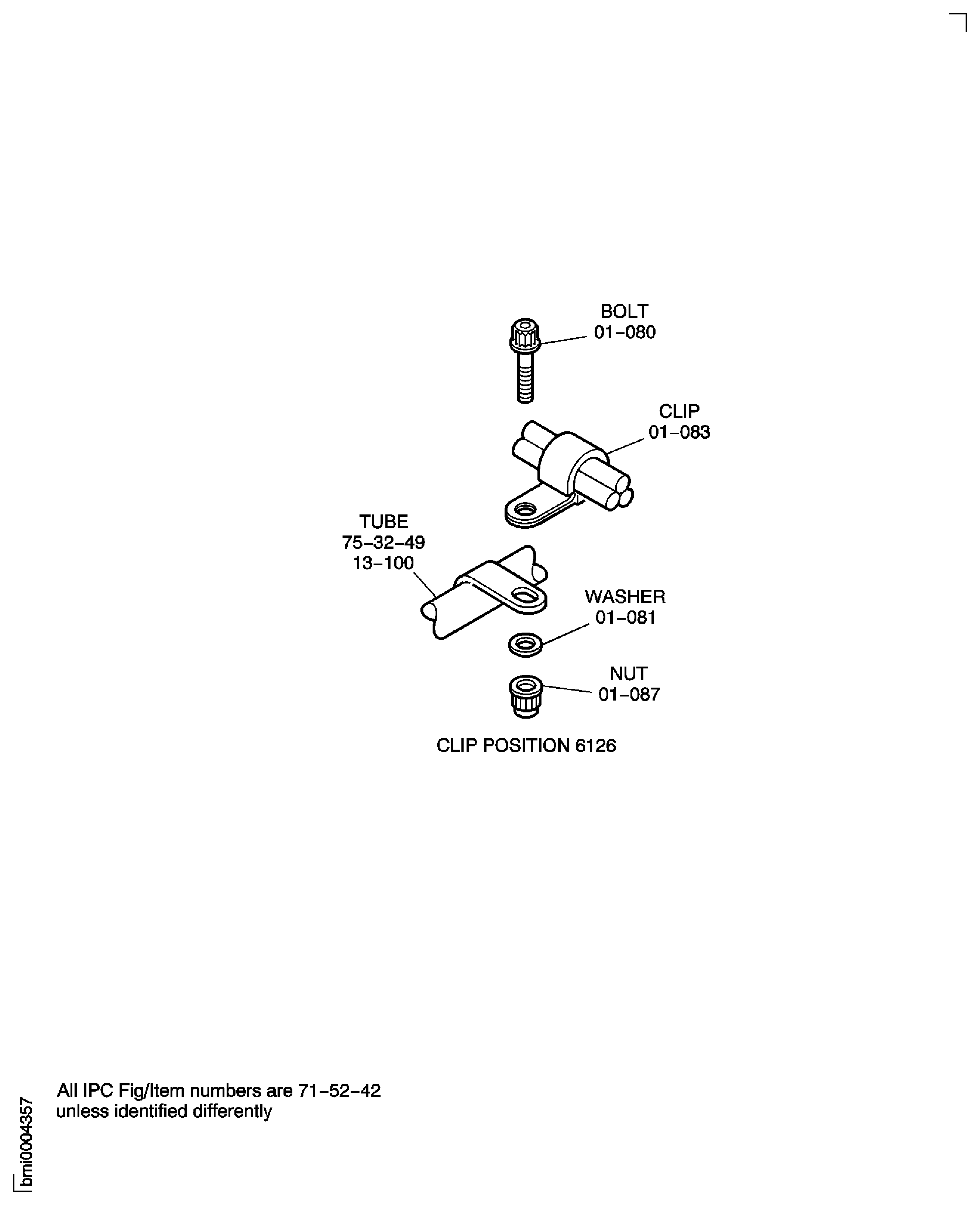

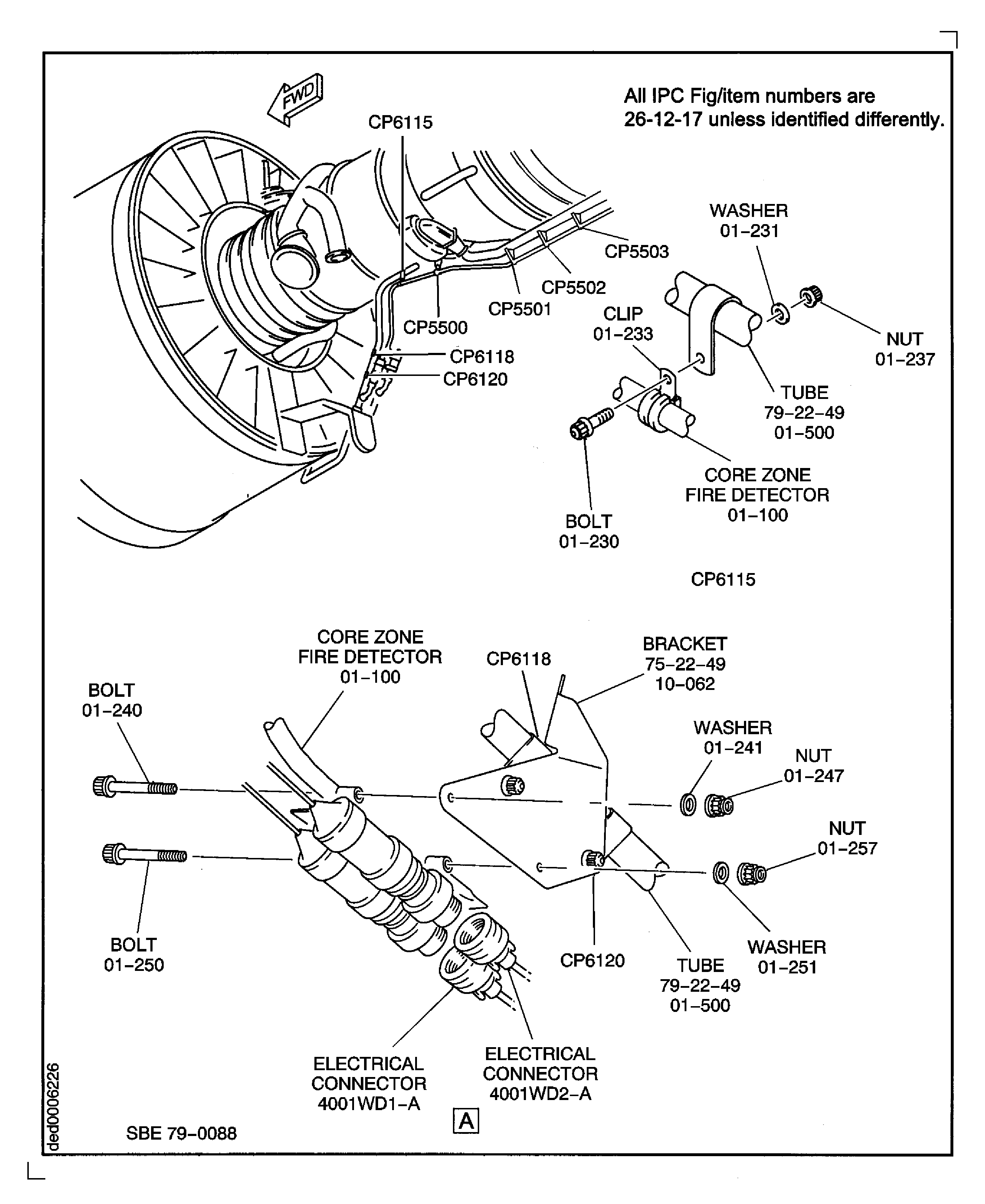

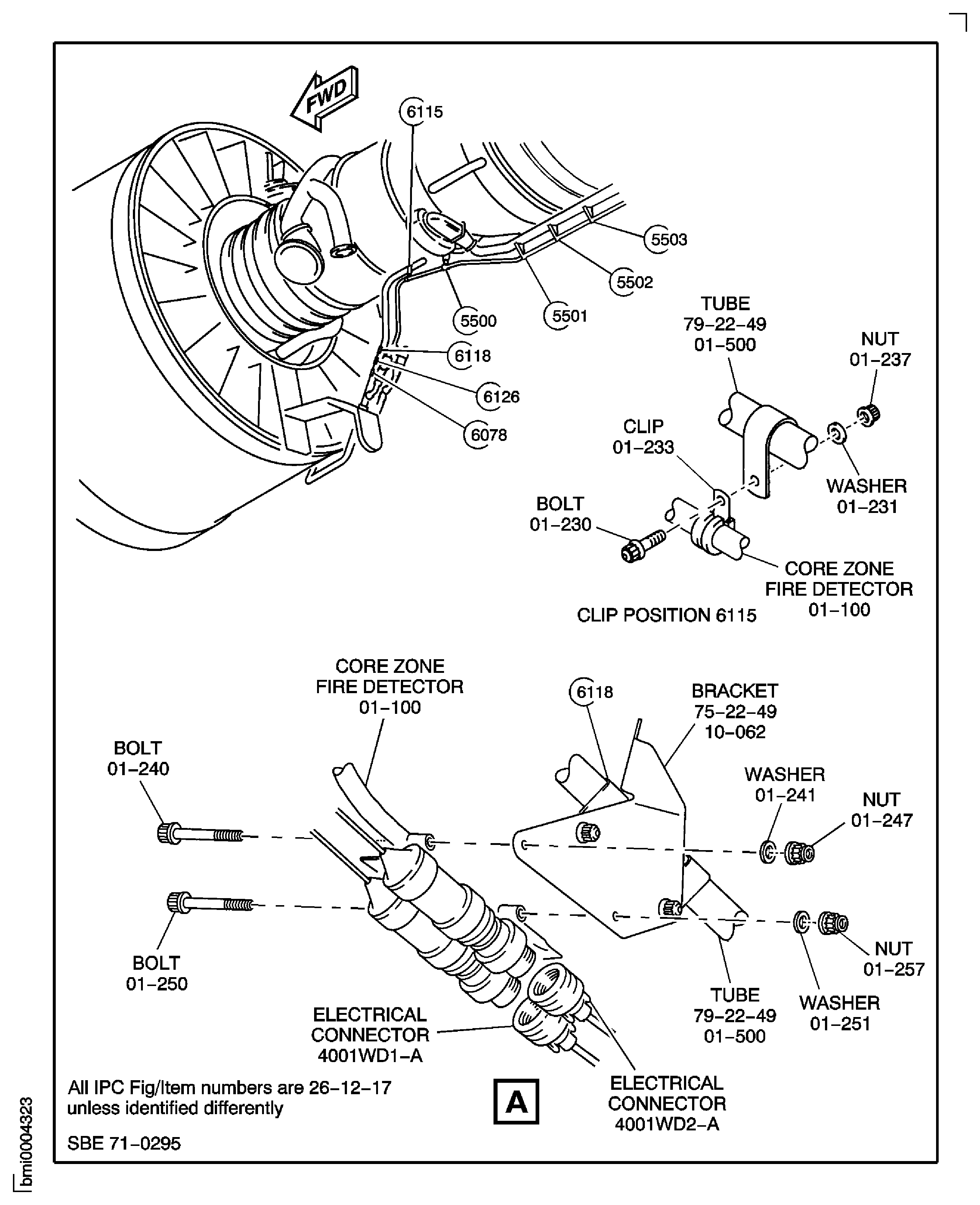

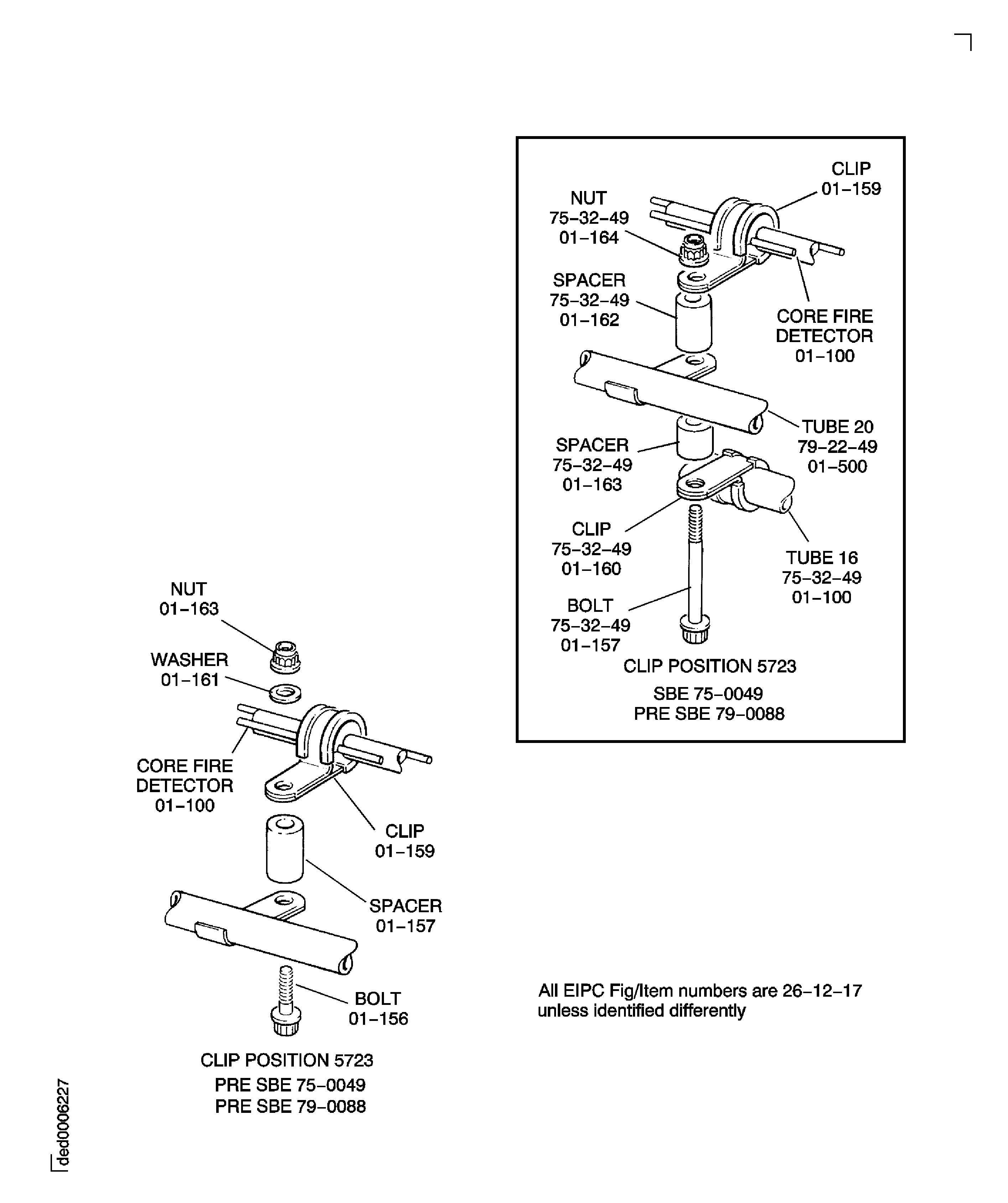

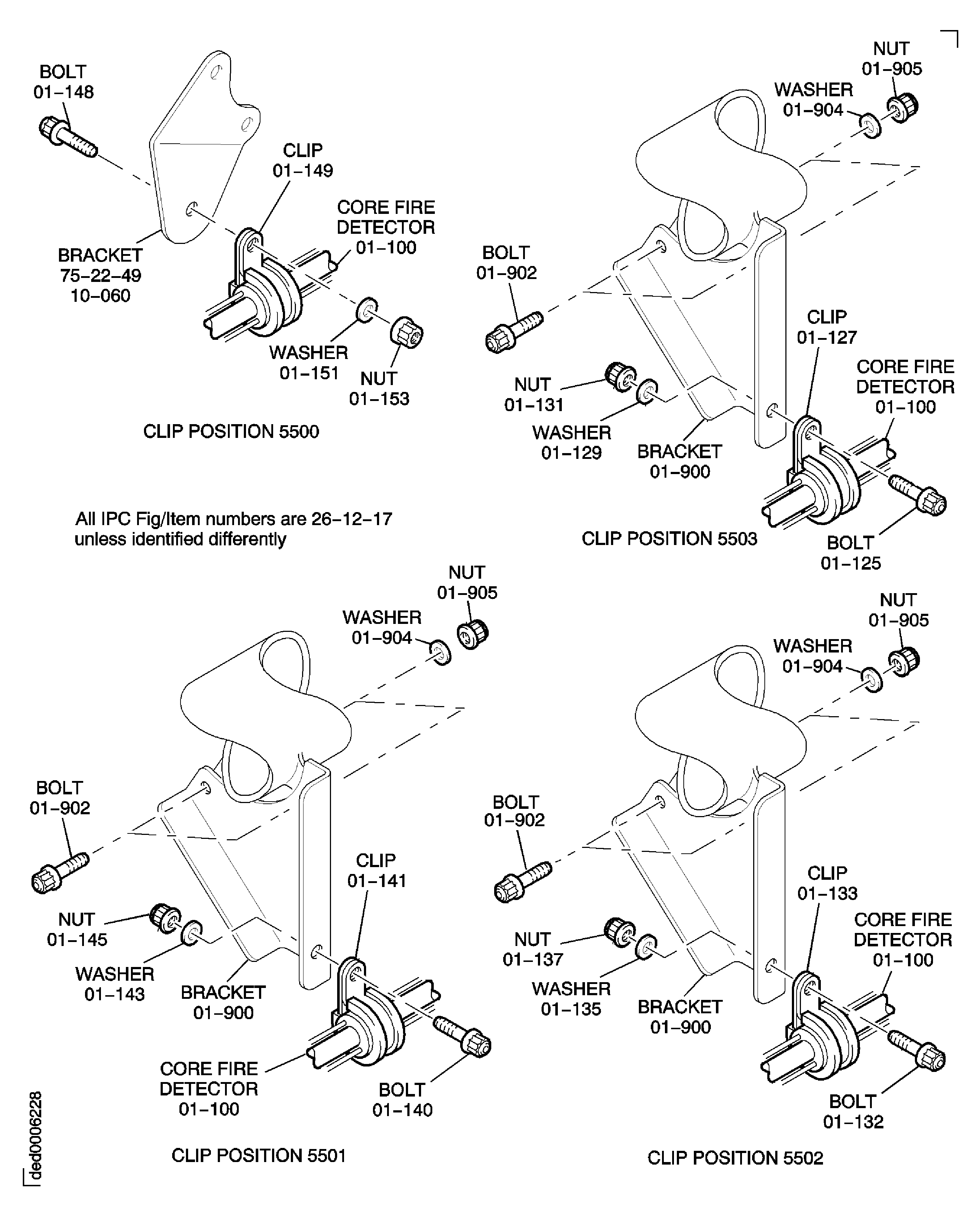

Put the core fire detector FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-100) in to position.

Pre SBE 75-0049: Install the clip, the washer, the spacer, the bolt and the nut at the clip position 5723.

SBE 75-0049: Install the two clips, the two spacers, the bolt and the nut at the clip position 5723.

SUBTASK 72-00-50-420-195-A00 Install the Core Zone Fire Detector (Pre SBE 79-0088)

Put the core fire detector FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-100) in to position.

SUBTASK 72-00-50-420-195-B00 Install the Core Zone Fire Detector (SBE 79-0088)

SBE 79-0088: Oil - Scavenge oil tubes - Re-route of No.4 bearing scavenge tube

A minimum clearance of 0.100 in. (2.54 mm) is necessary between the Exhaust Gas Thermocouple harness/Junction Box, and the tubes, in an area between clip points 5523 and 5549. Refer to Figure.

Measure the clearance between all the different harnesses and the engine parts:

SUBTASK 72-00-50-220-150 Measure the Harness Clearances and Examine the Harness Routing

Refer to Figure.

Make sure that all the applicable backshells and cable clamps are safetied with CoMat 02-126 LOCKWIRE. Refer to the SPM TASK 70-42-05-400-501.

SUBTASK 72-00-50-210-073 Visually Inspect the Electrical Backshells and Cable Clamps

Figure: Install the Aft Engine Mount

Sheet 1

Figure: Install the Aft Engine Mount

Sheet 2

Figure: Install the Exhaust Gas Thermocouple Probes

Install the Exhaust Gas Thermocouple Probes

Figure: Install the HP Turbine Active Clearance Control Manifolds

Sheet 1

Figure: Install the HP Turbine Active Clearance Control Manifolds

Sheet 2

Figure: Install the HP Turbine Active Clearance Control Manifolds

Sheet 3

Figure: Remove the LP Turbine Active Clearance Control Manifold from the Support Fixture

Remove the LP Turbine Active Clearance Control Manifold from the Support Fixture

Figure: Install the LP Turbine Active Clearance Control Manifolds

Sheet 1

Figure: Install the LP Turbine Active Clearance Control Manifolds

Sheet 2

Figure: Install the LP Turbine Active Clearance Control Manifolds

Sheet 3

Figure: Install the LP Turbine Active Clearance Control Manifolds

Sheet 4

Figure: Install the Stage 2 Turbine Cooling Air Supply Tubes

Sheet 1

Figure: Install the Stage 2 Turbine Cooling Air Supply Tube No.5

Sheet 2

Figure: Install the Stage 2 Turbine Cooling Air Supply Tube No.5

Sheet 3

Figure: Install the Stage 2 Turbine Cooling Air Supply Tubes Nos.6 and 7

Sheet 4

Figure: Install the Stage 2 Turbine Cooling Air Supply Tubes Nos.6 and 7

Sheet 5

Figure: Install the Stage 2 Turbine Cooling Air Supply Tube No.8

Sheet 6

Figure: Install the Stage 2 Turbine Cooling Air Supply Tube No.8

Sheet 7

Figure: Install the Stage 2 Turbine Cooling Air Supply Tube No.8

Sheet 8

Figure: Install the Stage 2 Turbine Cooling Air Supply Tube No.8

Sheet 9

Figure: Install the No.4 Bearing Compartment Air Cooler

Sheet 1

Figure: Install the No.4 Bearing Compartment Air Cooler

Sheet 2

Figure: Install the No.4 Bearing Compartment Air Cooler

Sheet 3

Figure: Install the P4.9 Pressure Rake Tubes

Sheet 1

Figure: Install the P4.9 Pressure Rake Tubes

Sheet 2

Figure: Install the No. 4 Bearing Oil weep Tube

Install the No. 4 Bearing Oil weep Tube

Figure: Install the No.5 Bearing Oil Scavenge Tube

Sheet 1

Figure: Install the No.5 Bearing Oil Scavenge Tube

Sheet 2

Figure: Install the No.5 Bearing Oil Feed Tube

Sheet 1

Figure: Install the No.5 Bearing Oil Feed Tube

Sheet 2

Figure: Install the EGT Harness/Junction Box and the Core EGT Harness

Sheet 1

Figure: Install the EGT Harness/Junction Box and the Core EGT Harness

Sheet 2

Figure: Install the EGT Harness/Junction Box and the Core EGT Harness

Sheet 3

Figure: Install the EGT Harness/Junction Box and the Core EGT Harness

Sheet 4

Figure: Install the EGT Harness/Junction Box and the Core EGT Harness

Sheet 5

Figure: Install the EGT Harness/Junction Box and the Core EGT Harness

Sheet 6

Figure: Install the EGT Harness/Junction Box and the Core EGT Harness

Sheet 7

Figure: Install the EGT Harness/Junction Box and the Core EGT Harness

Sheet 8

Figure: Pre SBE 77-0009 : Install the EGT Harness/Junction Box and the Core EGT Harness

Sheet 9

Figure: SBE 77-0009 : Install the EGT Harness/Junction Box and the Core EGT Harness

Sheet 10

Figure: Check the Clearance Between Flange FT and the Core EGT Harness Support Brackets

Sheet 1

Figure: Check the Clearance Between Flange FT and the Core EGT Harness Support Brackets

Sheet 2

Figure: Check the Clearance Between Flange FT and the Core EGT Harness Support Brackets

Sheet 3

Figure: Prepare the LP Turbine Active Clearance Control Connector Tube for Installation

Sheet 1

Figure: Pre SBE-75-0051: Install the LP Turbine Active Clearance Control Connector Tube

Sheet 2

Figure: Pre SBE-75-0051: Install the LP Turbine Active Clearance Control Connector Tube

Sheet 3

Figure: Install the LP Turbine Active Clearance Control Connector Tube

Sheet 1

Figure: Install the LP Turbine Active Clearance Control Connector Tube

Sheet 2

Figure: Install the Core Zone Fire Detector

Sheet 1

Figure: SBE 71-0295: Install the Core Zone Fire Detector

Sheet 2

Figure: Pre SBE 71-0295 and SBE 71-0295: Install the Core Zone Fire Detector

Sheet 3

Figure: SBE 71-0295: Install the Core Zone Fire Detector

Sheet 4

Figure: Pre SBE 71-0295: Install the Core Zone Fire Detector

Sheet 5

Figure: SBE 71-0295: Install the Core Zone Fire Detector

Sheet 6

Figure: Install the Core Zone Fire Detector

Sheet 7

Figure: Install the Core Zone Fire Detector

Sheet 8

Figure: Visually Inspect the Backshells and Cable Clamps

Visually Inspect the Backshells and Cable Clamps

Figure: Torque Sequence of the Support Assembly Bolts

Torque Sequence of the Support Assembly Bolts