Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-44-20-200-001-C01 HPT Stage 1 Vane - Examine, Inspection-001

General

This TASK gives the procedure for the inspection of the stage 1 HPT vane assembly. For the other stage 1 HPT vane cluster assembly parts refer to TASK 72-44-20-200-000 (INSPECTION-000).

Fig/item numbers in parentheses in the procedure agree with those used in the IPC.

The policy that is necessary for inspection is given in the SPM TASK 70-20-00-200-501.

All the parts must be cleaned before any part is examined. Refer to the SPM TASK 70-10-00-100-501.

All parts must be visually examined for damage, corrosion and wear. Any defects that are not identified in the procedure must be referred to IAE.

A ** following repair reference in this inspection indicates that the repair is not yet published in the current revision of the manual and the part must be rejected. Contact IAE for additional information concerning FAA approved repair date.

The procedure for those parts which must have a crack test is given in Step. Do the test before the part is visually examined.

Do not discard any part until you are sure there are no repairs available. Refer to the instructions in Repair before a discarded part is used again or oversize parts are installed.

Parts which should be discarded can be held although no repair available. The repair of a discarded part could be shown to be necessary at a later date.

All parts must be examined to make sure that all the repairs have been completed satisfactorily.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

References

Refer to the SPM for data on these items.

Definition of Damages, SPM TASK 70-02-02-350-501

Cleaning, SPM TASK 70-12-09-120-501

Air flow - Turbine Blades and Vanes, SPM TASK 70-72-01-720-501

Ultrasonic Clean all Metal (But not Magnesium), SPM TASK 70-13-01-300-503

Inspection of Parts, SPM TASK 70-20-00-200-501

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Oven | LOCAL | Oven | (air furnace) |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-029 MASKING TAPE (CLOTH BACKING) | 0AM53 | CoMat 02-029 | ||

| CoMat 02-030 MASKING TAPE (CLOTH BACKING) | IE479 | CoMat 02-030 |

Spares

NONESafety Requirements

NONEProcedure

Clean the part. Refer to TASK 72-44-20-100-000 (CLEANING-000).

Repair, VRS3784 TASK 72-44-20-300-040 (REPAIR-040).

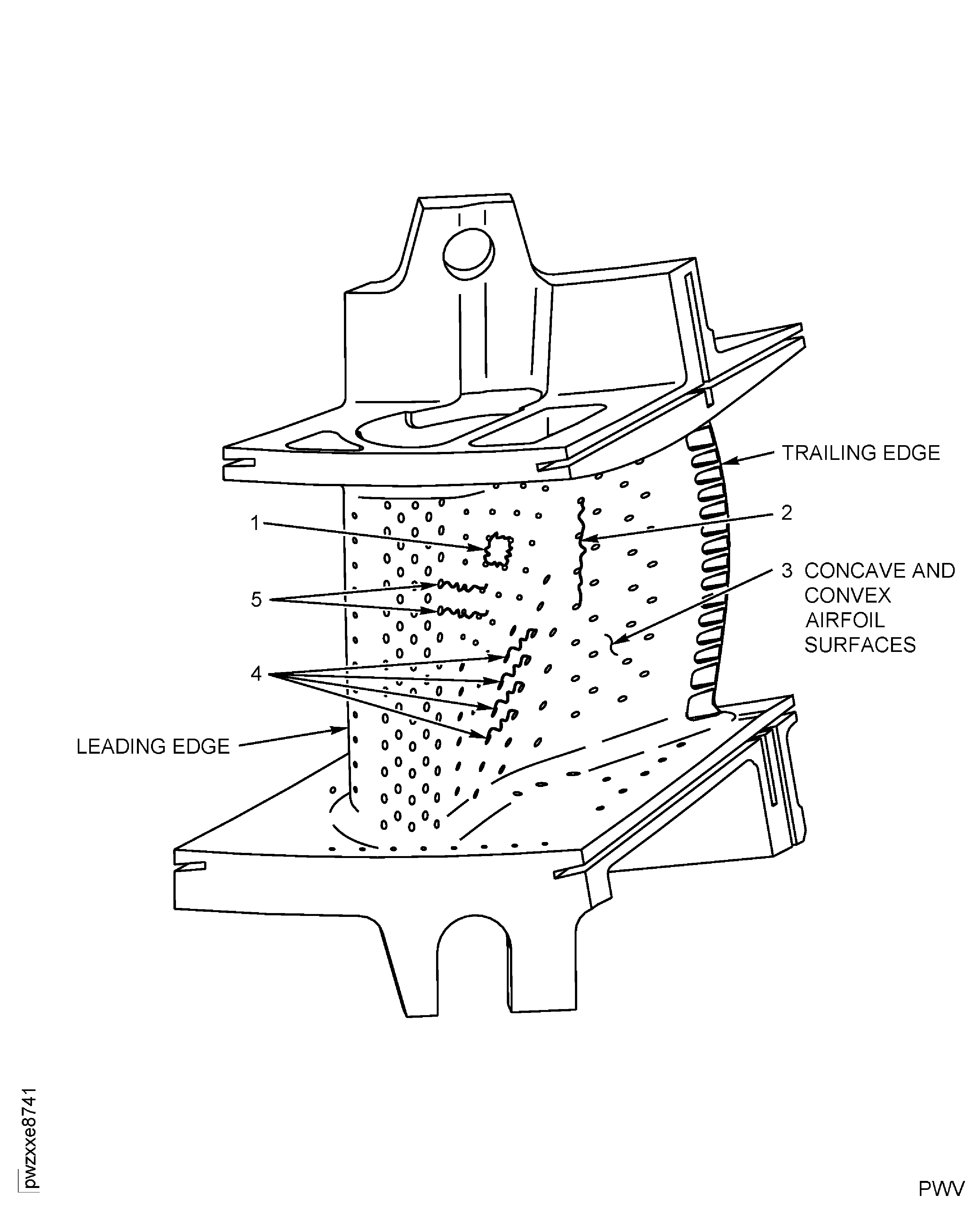

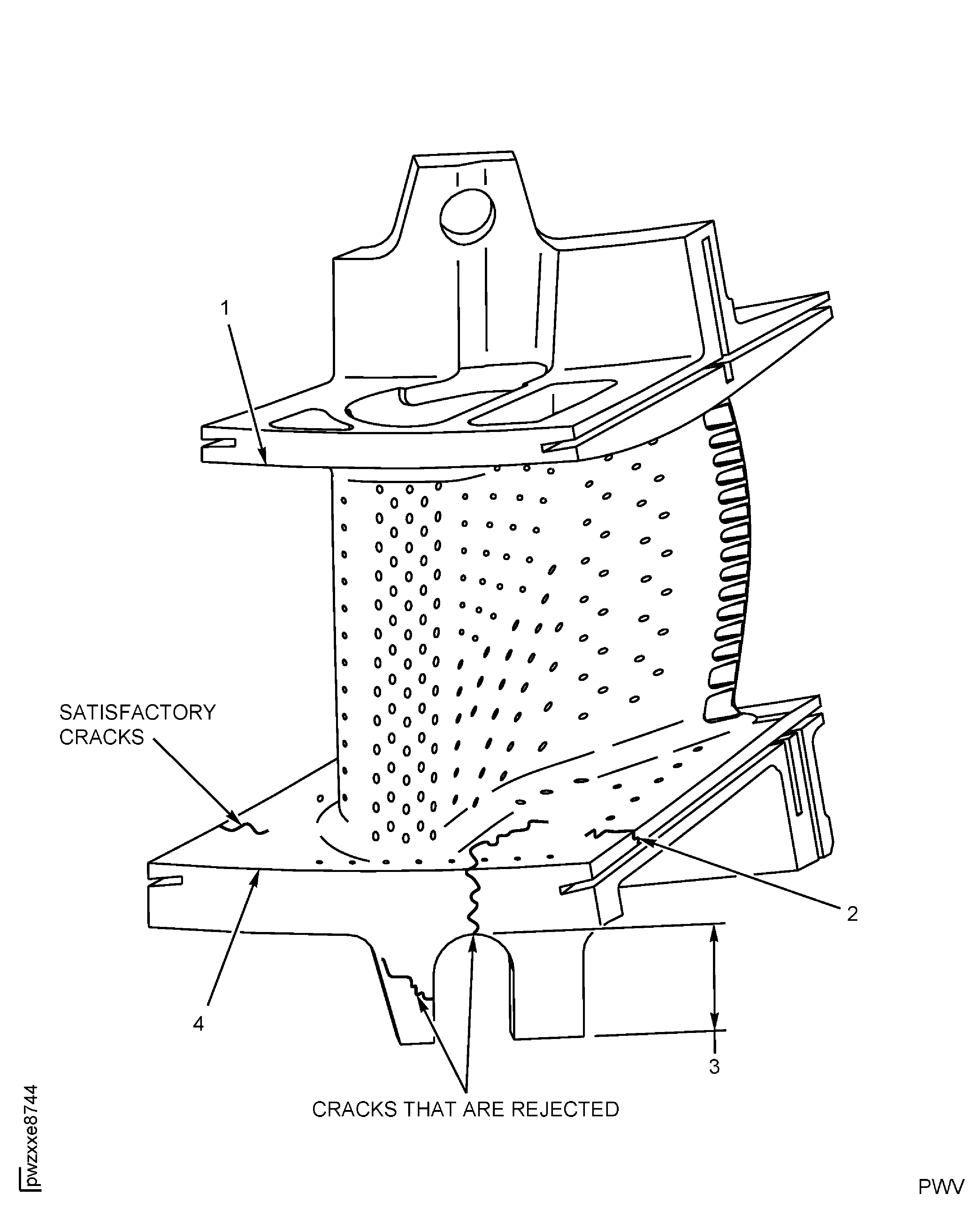

Examine the vane assembly airfoil surfaces (concave and convex sides) for axial and radial cracks, Figure.

Repair, VRS3784 TASK 72-44-20-300-040 (REPAIR-040).

Other than Step.

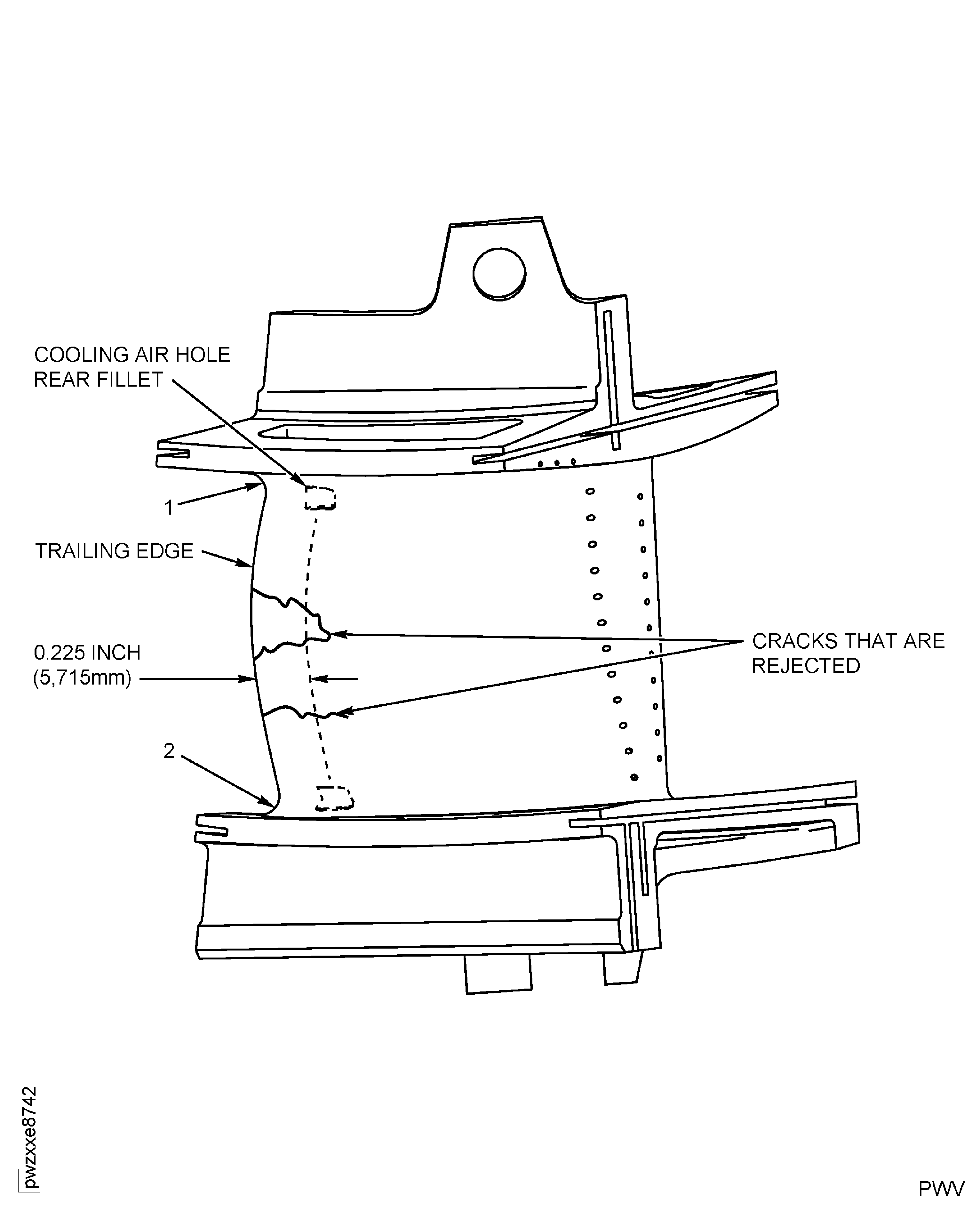

Examine the vane assembly trailing edge convex sides for cracks. Cracks are only permitted at locations 1 and 2, Figure.

Repair, VRS3784 TASK 72-44-20-300-040 (REPAIR-040).

Other than Step.

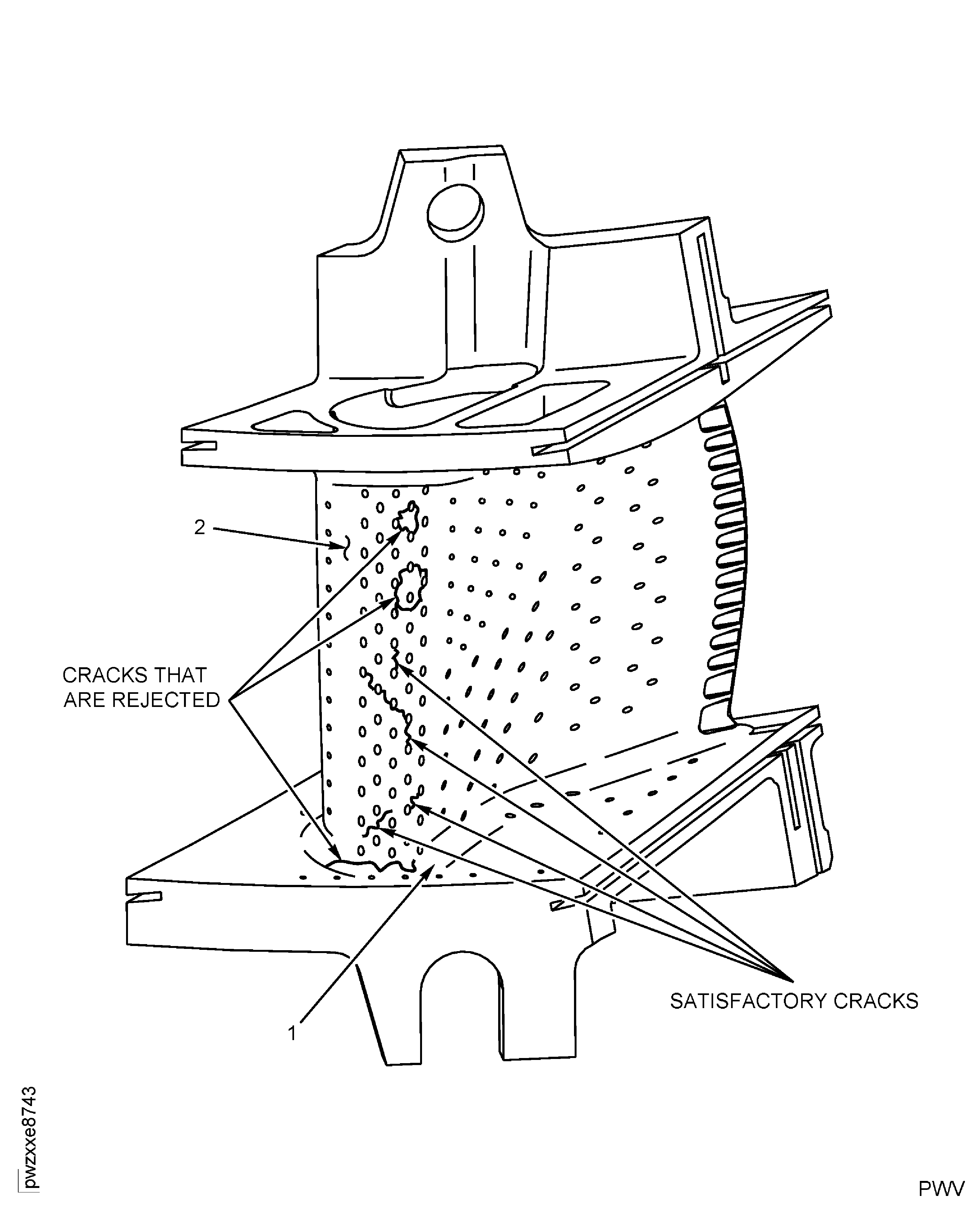

Examine the vane assembly leading edge for cracks at location 2, Figure.

Repair, VRS3784 TASK 72-44-20-300-040 (REPAIR-040).

Other than Step.

Examine the vane assembly leading edge platform fillet area at location 1, Figure.

Repair, VRS3784 TASK 72-44-20-300-040 (REPAIR-040).

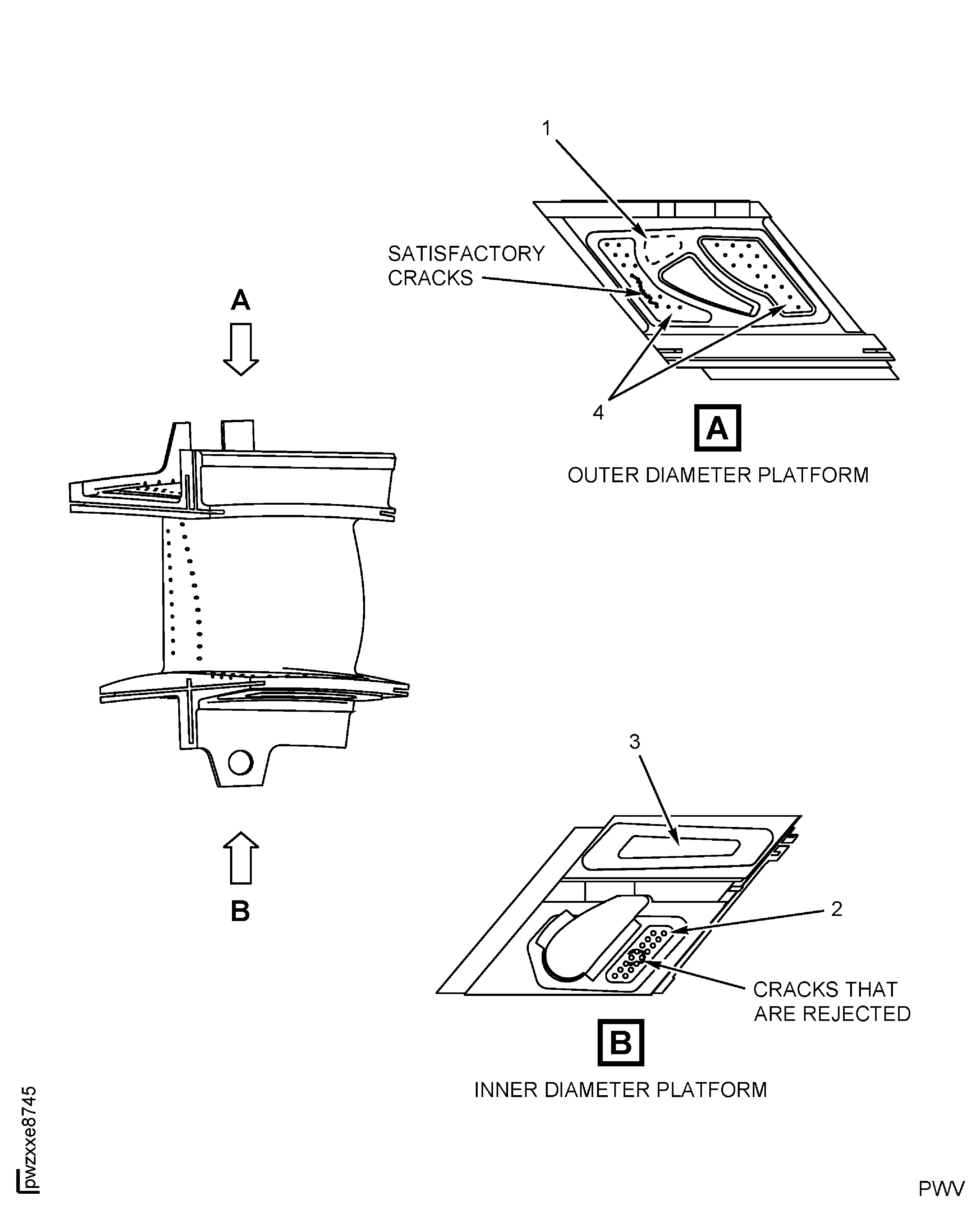

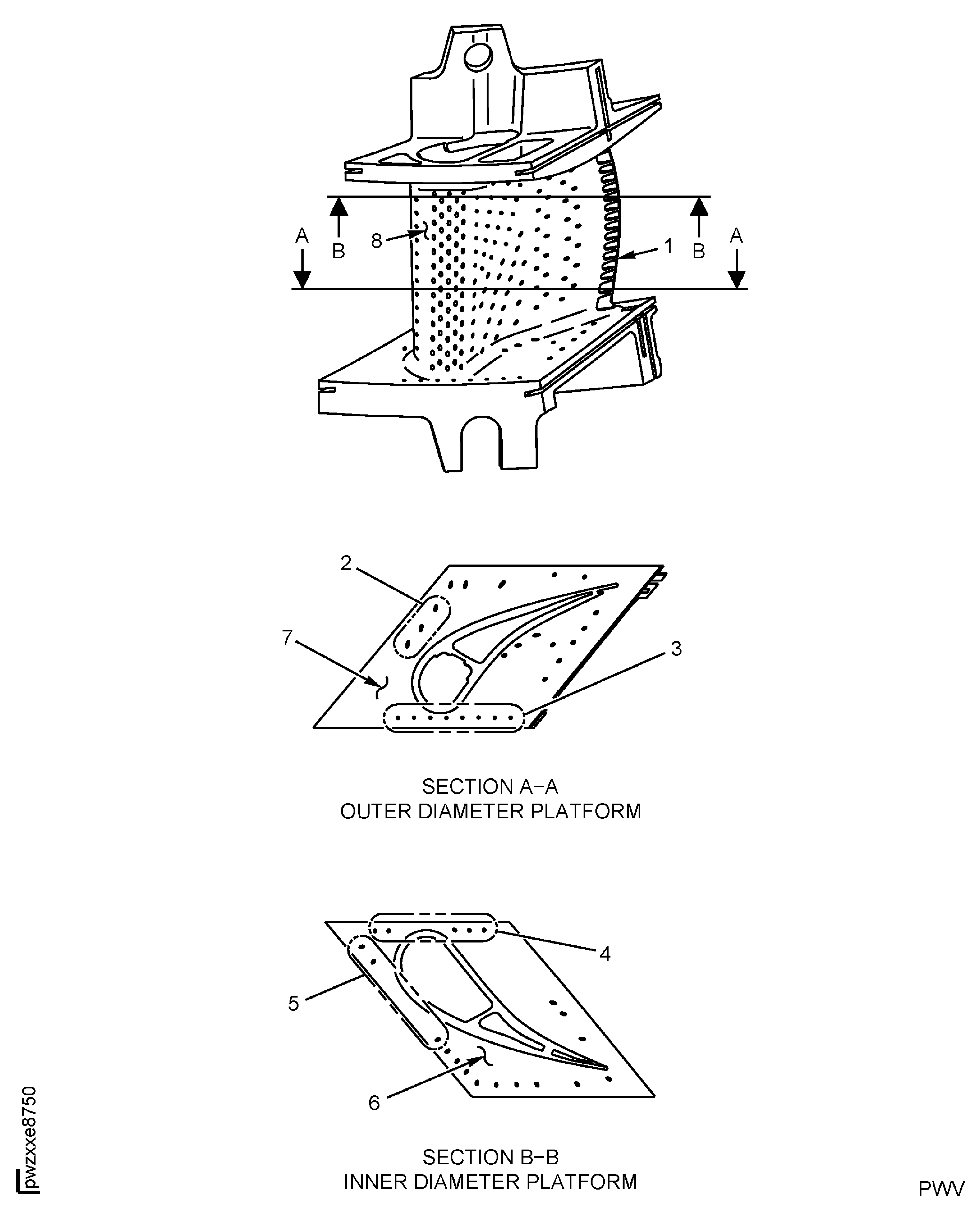

Examine the vane assembly inner and outer platforms for cracks, Figure.

Repair, VRS3541 TASK 72-44-20-300-022 (REPAIR-022).

Cracks

Repair, VRS3541 TASK 72-44-20-300-022 (REPAIR-022).

Cracks

Examine the vane assembly insert and impingement covers for cracks at locations 1, 2, 3 and 4, Figure.

Repair, VRS3784 TASK 72-44-20-300-040 (REPAIR-040).

Other than Step.

Cracks

Examine the vane assembly for cracks in the feather seal slot plug welds at locations 1, 2 and 3, Figure.

SUBTASK 72-44-20-230-059 Examine the Stage 1 HPT Vane Assembly (01-240) for Cracks

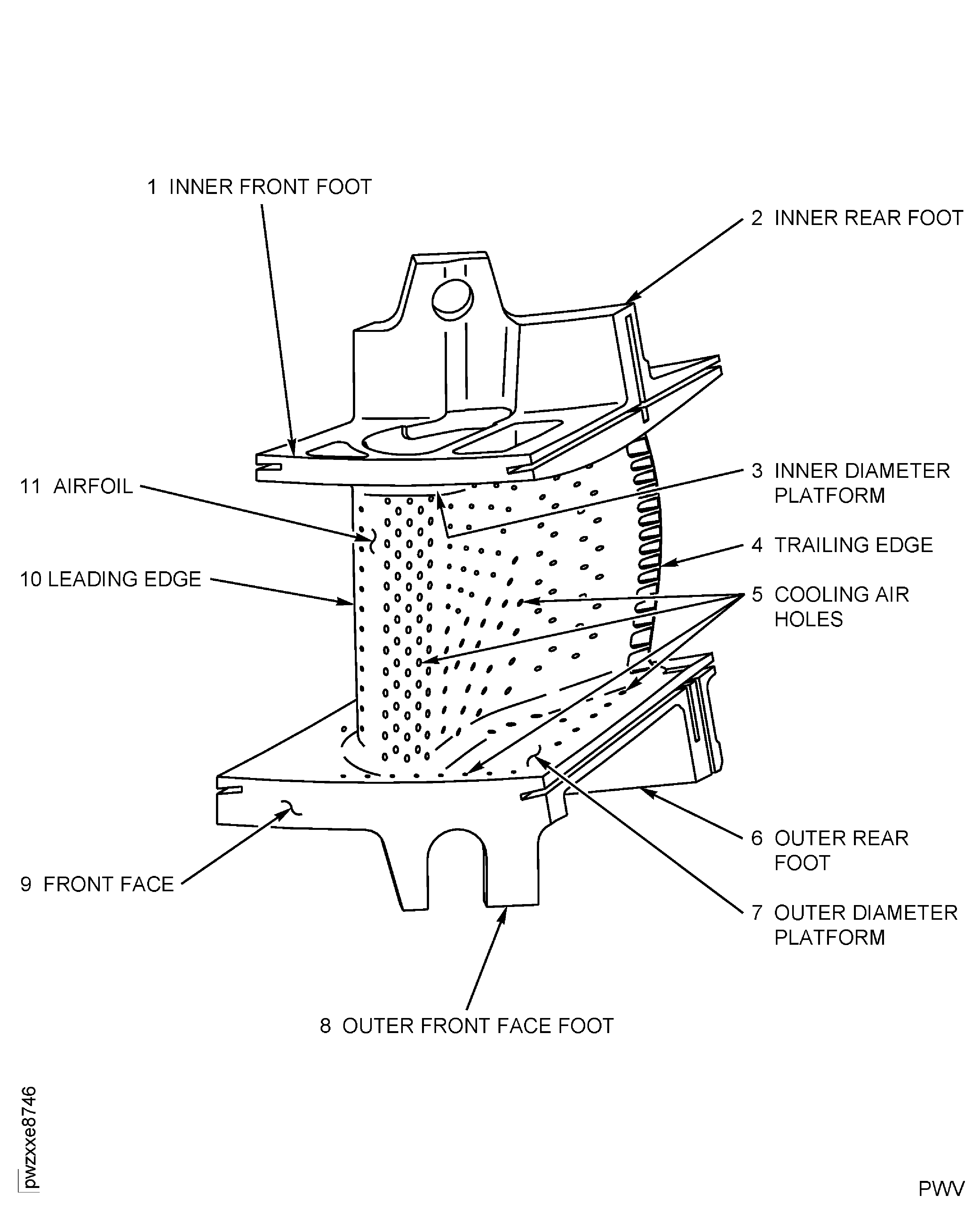

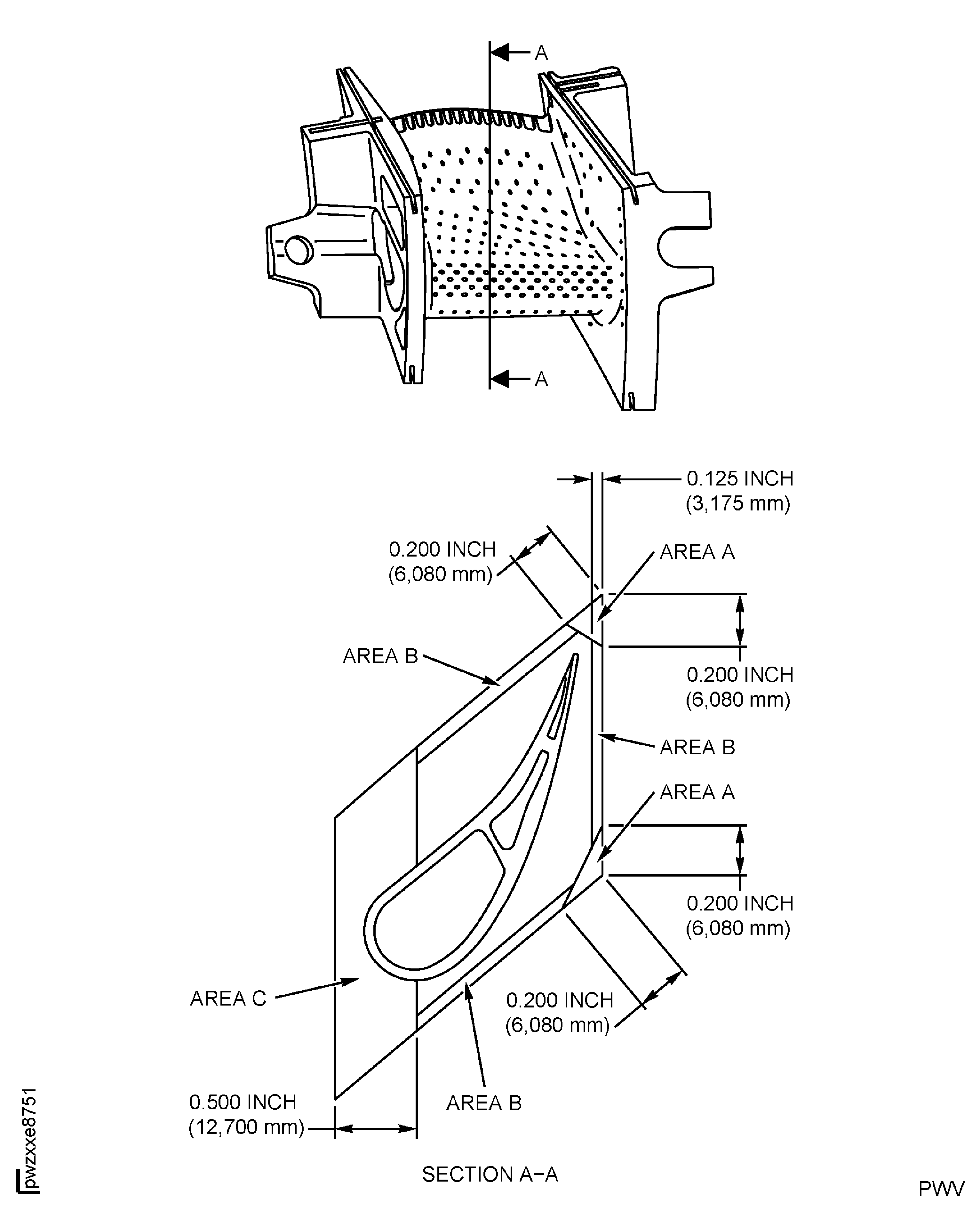

Examine the vane assembly at locations 3, 7 and 11 Figure for burn-through or material that is not there on the airfoil and platforms.

Repair, VRS3584 TASK 72-44-20-300-028 (REPAIR-028).

NOTE

Make an analysis of serviceable vanes for more expanded amounts of ceramic coat that is not there with thought to the next inspection date for the build. For example a vane with important eroded ceramic coat or ceramic coat that is not there and with cracks or other damage to the maximum limits if used again can not always be repaired at the next shop visit because of more damage.Complete coat strip and new coat is necessary to repair the ceramic coat. The strip procedure can cause the vane wall to thin. It is recommended that the cracks, burns and erosion condition of the vanes and the ceramic coat condition result in a decision to coat or not to coat the vanes.

Repair, VRS3154 TASK 72-44-20-300-011 (REPAIR-011).

Other than Step.

Burns and erosion.

Examine the vane assembly at locations 4, 10 and 11 Figure for burns and erosion on the airfoil, leading and trailing edges.

Repair, VRS3154 TASK 72-44-20-300-011 (REPAIR-011).

Burns and erosion.

Examine the vane assembly at locations 3 and 7 Figure for burns and erosion on the inner and outer platforms.

Repair, VRS3154 TASK 72-44-20-300-011 (REPAIR-011).

Nicks at locations 3, 4, 7, 10 and 11.

Repair, VRS3154 TASK 72-44-20-300-011 (REPAIR-011).

Other than Step.

Dents

Examine the vane assembly for dents and nicks on the airfoil, platforms, leading and trailing edges Figure.

SUBTASK 72-44-20-220-096 Examine the Stage 1 HPT Vane Assembly (01-240) Airfoils and Platforms

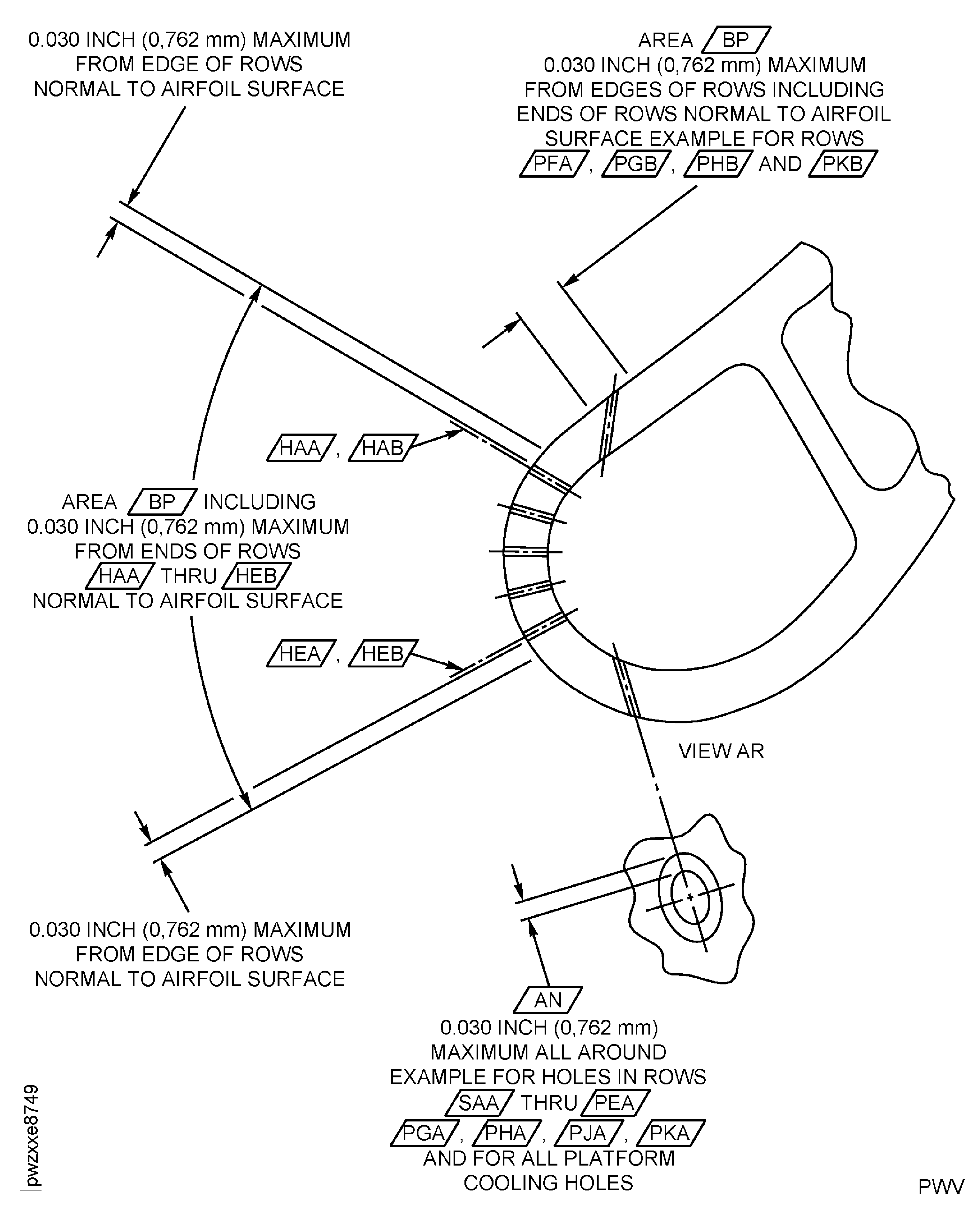

Refer to Figure.

Repair, VRS3145 TASK 72-44-20-300-013 (REPAIR-013) or, Repair, VRS3498 TASK 72-44-20-300-021 (REPAIR-021).

NOTE

Repair VRS3498 is a vendor repair only to unplug holes/slots.

Plugging

Examine the vane assembly airfoil at location 8 (each side, all around), cooling air holes and the trailing edge at location 1 cooling air slots for plugging.

Repair, VRS3145 TASK 72-44-20-300-013 (REPAIR-013) or Repair, VRS3498 TASK 72-44-20-300-021 (REPAIR-021)

NOTE

Repair VRS3498 is a vendor repair only to unplug holes/slots.

Other than Step.

Plugging.

Examine the vane assembly platforms cooling air holes for plugging at locations 6 and 7. Do not examine the holes at locations 2, 3, 4 and 5.

SUBTASK 72-44-20-220-097 Examine the Stage 1 HPT Vane Assembly (01-240) Airfoil and Platform Cooling Air Holes/Slots for Plugging

Refer to Figure.

Repair, VRS3541 TASK 72-44-20-300-022 (REPAIR-022)

NOTE

Repair VRS3541 is for replacement of inserts and impingement covers usually repaired by vendors.

Plugging and unwanted material.

Examine the vane assembly for unwanted material and plugged cooling air holes on all the inserts and impingement covers at locations 1, 2, 3 and 4.

SUBTASK 72-44-20-220-098 Examine the Stage 1 HPT Vane Assembly (01-240) for Unwanted Material and Plugging on the Front and Rear Inserts and Platform Impingement Covers

Refer to Figure.

Repair, VRS3584 TASK 72-44-20-300-028 (REPAIR-028), or Repair, VRS3784 TASK 72-44-20-300-040 (REPAIR-040).

Other than Step.

Examine the vane assembly platforms for chipped coating.

SUBTASK 72-44-20-220-099 Examine the Stage 1 HPT Vane Assembly (01-240) for Chipped Coating on the Platforms

Refer to Figure.

Repair, VRS3592 TASK 72-44-20-300-034 (REPAIR-034).

Other than Step.

Thickness.

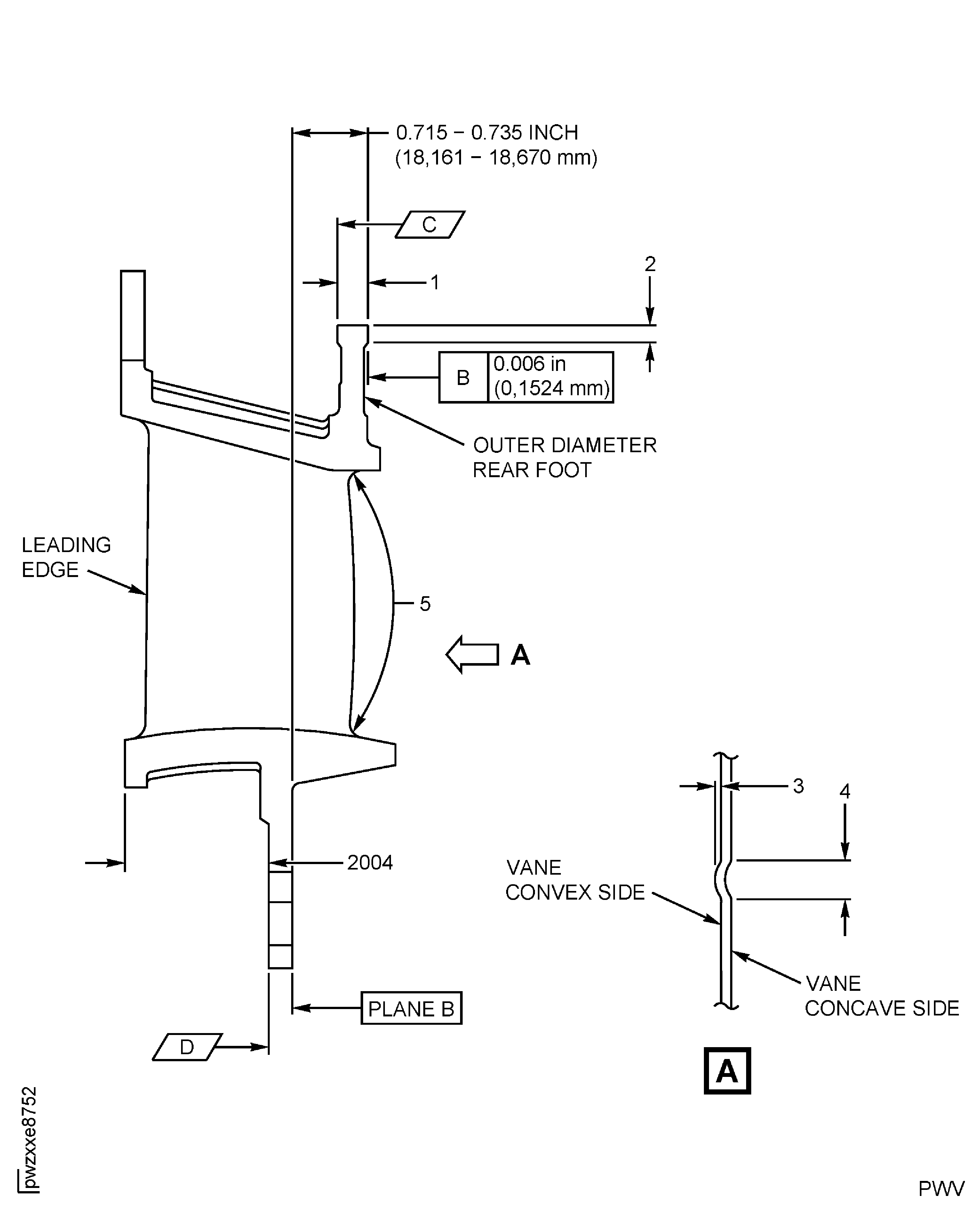

Examine the vane assembly at location 1 for thickness of the outer diameter rear foot.

SUBTASK 72-44-20-220-101 Examine the Stage 1 HPT Vane Assembly (01-240) for the Outer Diameter Rear Foot Wear

Refer to Figure.

Repair, VRS3592 TASK 72-44-20-300-034 (REPAIR-034).

Other than Step.

Wear

Examine the vane assembly at location 2 for wear.

SUBTASK 72-44-20-220-108 Examine the Stage 1 HPT Vane Assembly (01-240) for Wear on the Rear Foot

Refer to Figure.

Other than Step.

Axial dimension.

Examine the vane assembly at location 2004 for axial dimension.

SUBTASK 72-44-20-220-102 Examine the Stage 1 HPT Vane Assembly (01-240) for the Axial Dimension between the Inner Diameter Platform Leading Edge and the Front Edge of the Inner Diameter Rear Foot

Refer to Figure.

Other than Step.

Wear

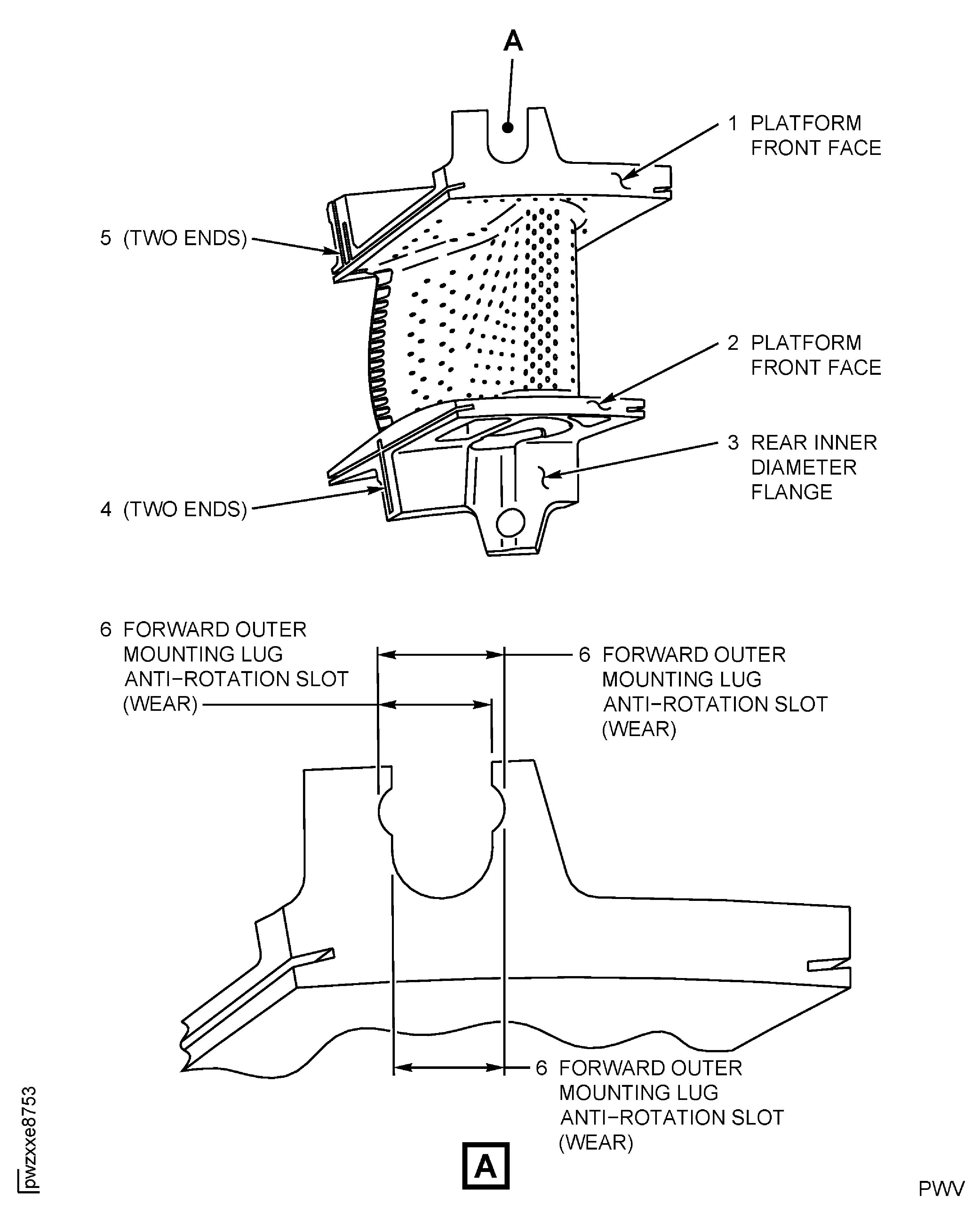

Examine the vane assembly at locations 1 and 2 and two sides at location 3 for wear on the contact surface.

SUBTASK 72-44-20-220-103 Examine the Stage 1 HPT Vane Assembly (01-240) for the Wear on the Platform Front Faces and Two Sides on the Rear Inner Diameter Flange Surfaces

Refer to Figure.

SUBTASK 72-44-20-220-104 Examine the Stage 1 HPT Vane Assembly (01-240) for Burned Areas and Unwanted Material on all the Feather Seal Slots

Refer to Figure.

Repair, VRS3562 TASK 72-44-20-300-025 (REPAIR-025)

NOTE

Wear can be on one or both sides of the mounting lug anti-rotation slot.

If the slot is a maximum of 0.422 in. (10.72 mm).

Wear

Examine the vane at location 6 for wear on the anti-rotation slot.

SUBTASK 72-44-20-220-105 Examine the Stage 1 HPT Vane Assembly (01-240) for Wear on the Forward Outer Mounting Lug Anti-Rotation Slot

Refer to Repair, VRS3784, TASK 72-44-20-300-040 (REPAIR-040).

Do the airflow procedure for the stage 1 HPT vane assembly.

SUBTASK 72-44-20-220-106 Examine the Stage 1 HPT Vane Assembly (01-240) by the Airflow Check

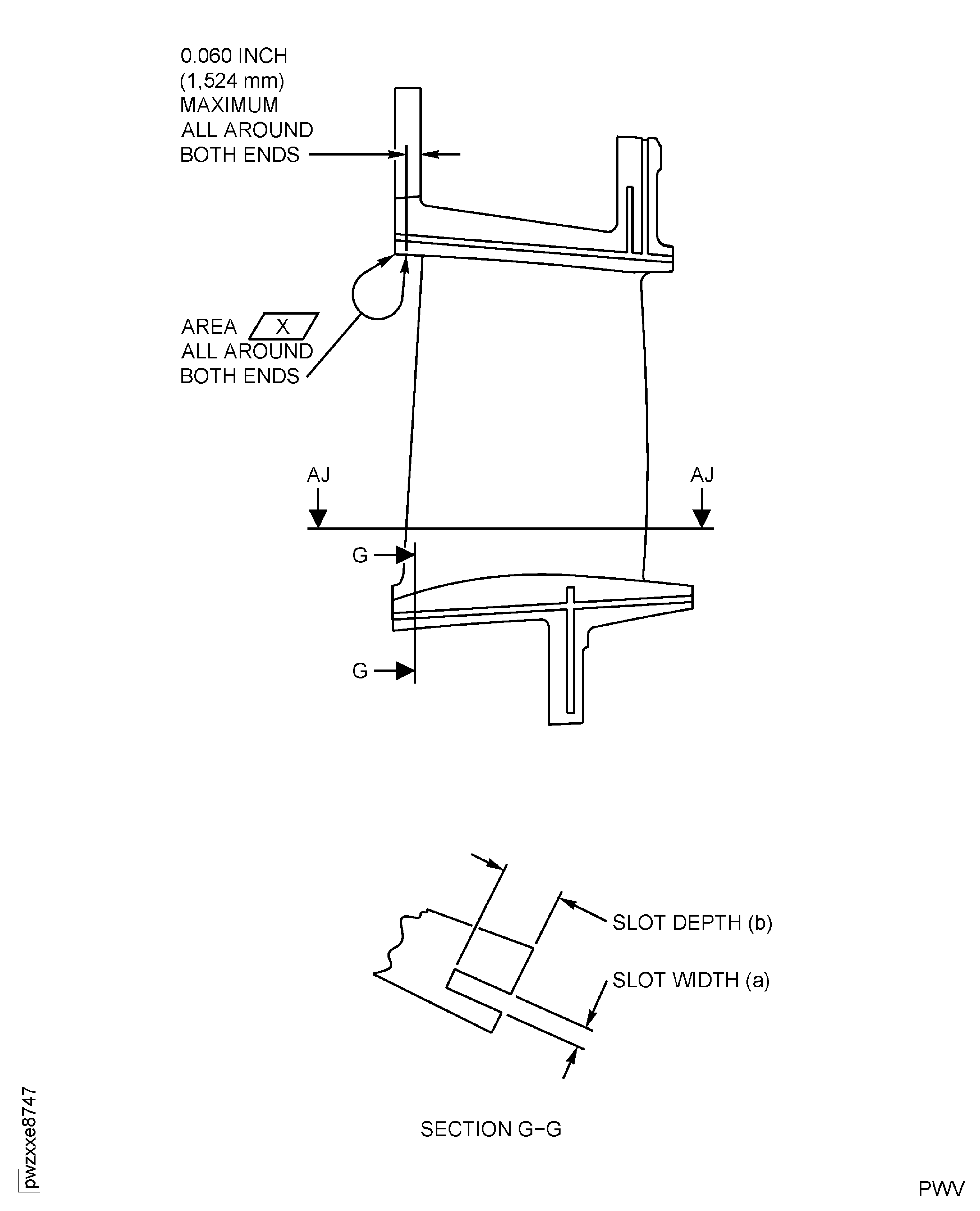

Refer to Figure.

If the dimension is more than 0.035 in. (0.88 mm) or less than 0.025 in. (0.64 mm), Repair, VRS3784 TASK 72-44-20-300-040 (REPAIR-040)

Examine the slot width (a)

If the dimension is more than 0.137 in. (3.48 mm) or less than 0.117 in. (2.97 mm), Repair, VRS3784 TASK 72-44-20-300-040 (REPAIR-040)

Examine the slot depth (b).

SUBTASK 72-44-20-220-107 Examine the Stage 1 HPT Vane Assembly Dimensions at the ID Feather Seal Slot

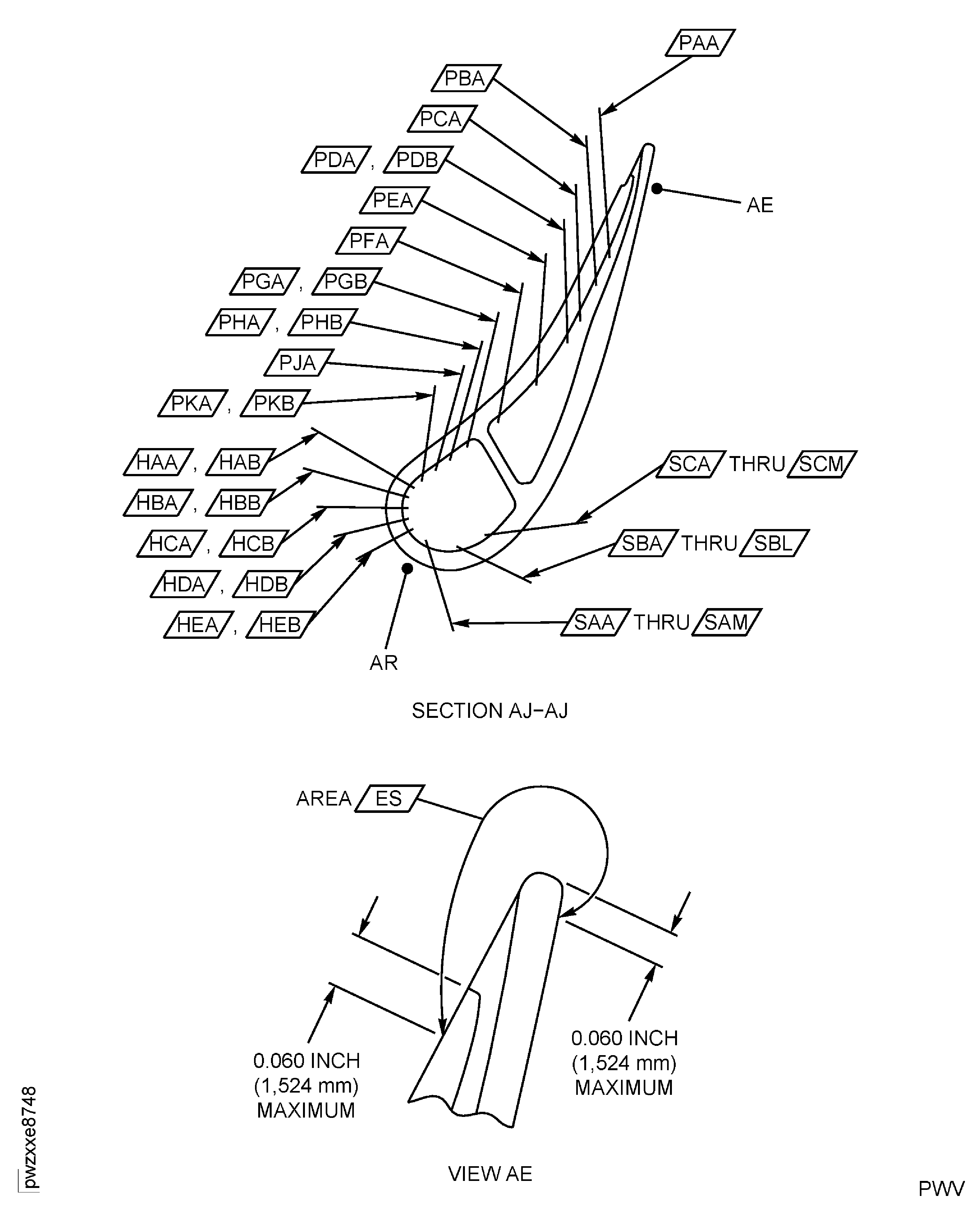

Figure: Stage 1 HPT Vane Assembly Axial and Radial Cracks Inspection Locations

Stage 1 HPT Vane Assembly Axial and Radial Cracks Inspection Locations

Figure: Stage 1 HPT Vane Assembly Trailing Edge Cracks (Convex Side) Inspection Locations

Stage 1 HPT Vane Assembly Trailing Edge Cracks (Convex Side) Inspection Locations

Figure: Stage 1 HPT Vane Assembly Leading Edge Cracks Inspection Locations

Stage 1 HPT Vane Assembly Leading Edge Cracks Inspection Locations

Figure: Stage 1 HPT Vane Assembly Inner and Outer Platform Cracks Inspection Location

Stage 1 HPT Vane Assembly Inner and Outer Platform Cracks Inspection Location

Figure: Stage 1 HPT Vane Assembly Platforms, Inserts and Impingement Cover Cracks Inspection Location

Stage 1 HPT Vane Assembly Platforms, Inserts and Impingement Cover Cracks Inspection Location

Figure: Stage 1 HPT Vane Assembly Inspection Locations

Stage 1 HPT Vane Assembly Inspection Locations

Figure: Stage 1 HPT Vane Assembly Coating Inspection

Sheet 1

Figure: Stage 1 HPT Vane Assembly Coating Inspection

Sheet 2

Figure: Stage 1 HPT Vane Assembly Coating Inspection

Sheet 3

Figure: Stage 1 HPT Vane Assembly Cooling Air Holes Inspection Locations

Stage 1 HPT Vane Assembly Cooling Air Holes Inspection Locations

Figure: Stage 1 HPT Vane Assembly Platform Coating Inspection Locations

Stage 1 HPT Vane Assembly Platform Coating Inspection Locations

Figure: Stage 1 HPT Vane Assembly Inspection Locations

Stage 1 HPT Vane Assembly Inspection Locations

Figure: Stage 1 HPT Vane Assembly Inspection Locations

Stage 1 HPT Vane Assembly Inspection Locations