Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-00-02-400-009 (A1/A5-PPBU) - Install The Hydraulic Pump And Filter Assembly, Installation-009

General

For lockwire data and procedures refer to SPM TASK 70-42-05-400-501.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures refer to the SPM TASK 70-41-01-400-501 and the SPM TASK 70-41-02-400-501.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS unless other lubricants are referred to in the procedure.

Lightly lubricate the threads and abutment faces of the hydraulic system tube/hose nuts, unions and couplings with the hydraulic fluid used in the aircraft hydraulic system.

To identify, lubricate and install seal rings refer to the SPM TASK 70-44-01-400-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to damaged surface protection, joint flanges and attach parts. Use the correct color of air drying enamel. Refer to the SPM TASK 70-38-21-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must not be removed until immediately before installation of the components.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Packing | 1 | |||

| Packing | 1 | |||

| Seal | 1 | |||

| Seal | 1 | |||

| Seal | 1 | |||

| Seal | 1 | |||

| Seal | 1 | |||

| Gasket | 1 | |||

| Gasket | 1 |

Safety Requirements

NONEProcedure

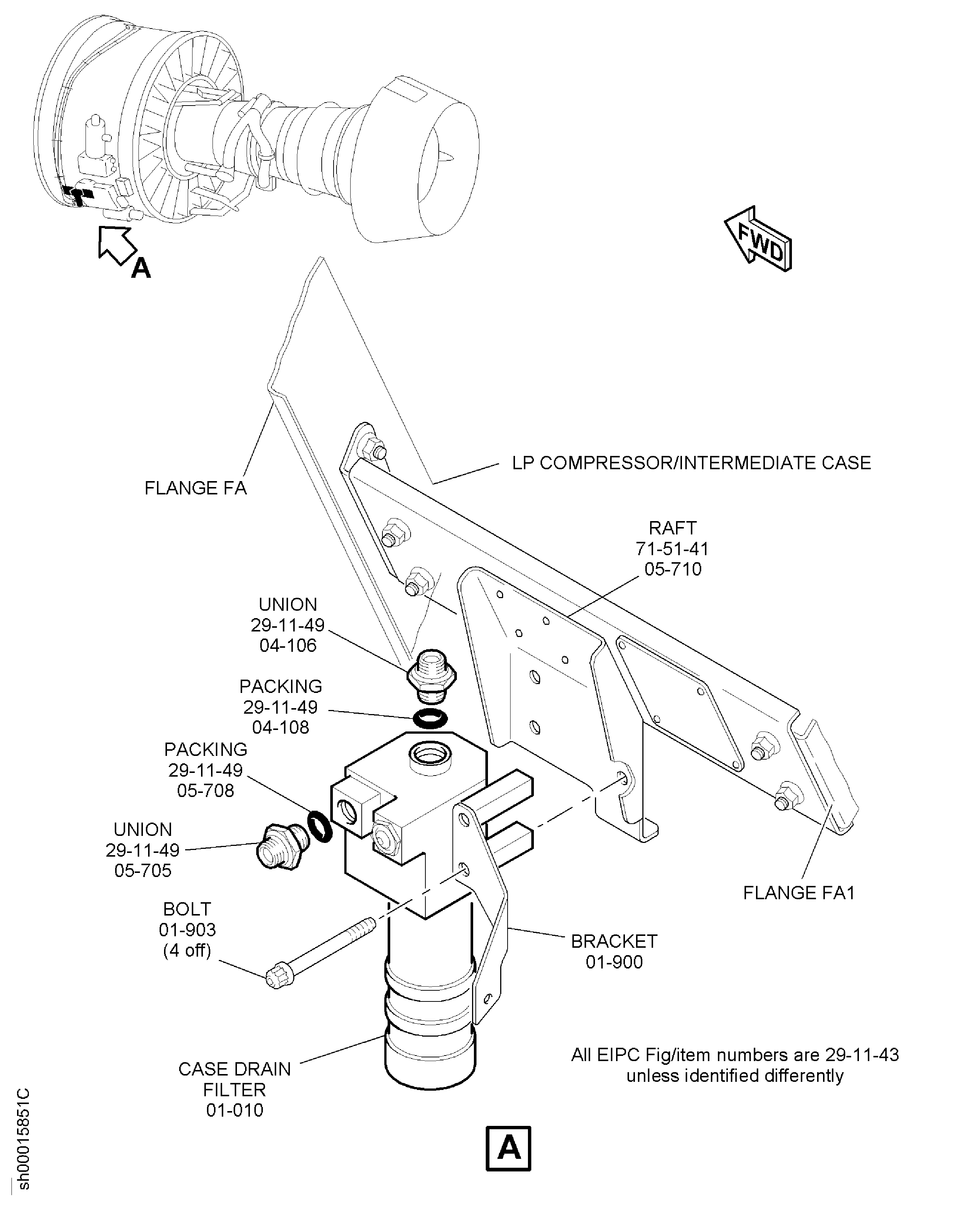

Refer to Figure.

Install the union HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-106) and the packing HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-108) to the case drain filter CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-010). Torque the union to 155 to 165 lbf.in (17.5 to 18.5 Nm).

Install the union HYDRAULIC POWER - ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 05-705) and the packing HYDRAULIC POWER - ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 05-708) to the case drain filter CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-010). Torque the union to 155 to 165 lbf.in (17.5 to 18.5 Nm).

Attach the case drain filter CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-010) and the bracket CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-900) on the raft EEC Fan Harness (71-51-41, 05-710) with the four bolts CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-903). Torque the bolts to 100 lbf.in (11.3 Nm).

SUBTASK 71-00-02-420-147 Install the Hydraulic Case Drain Filter Assembly

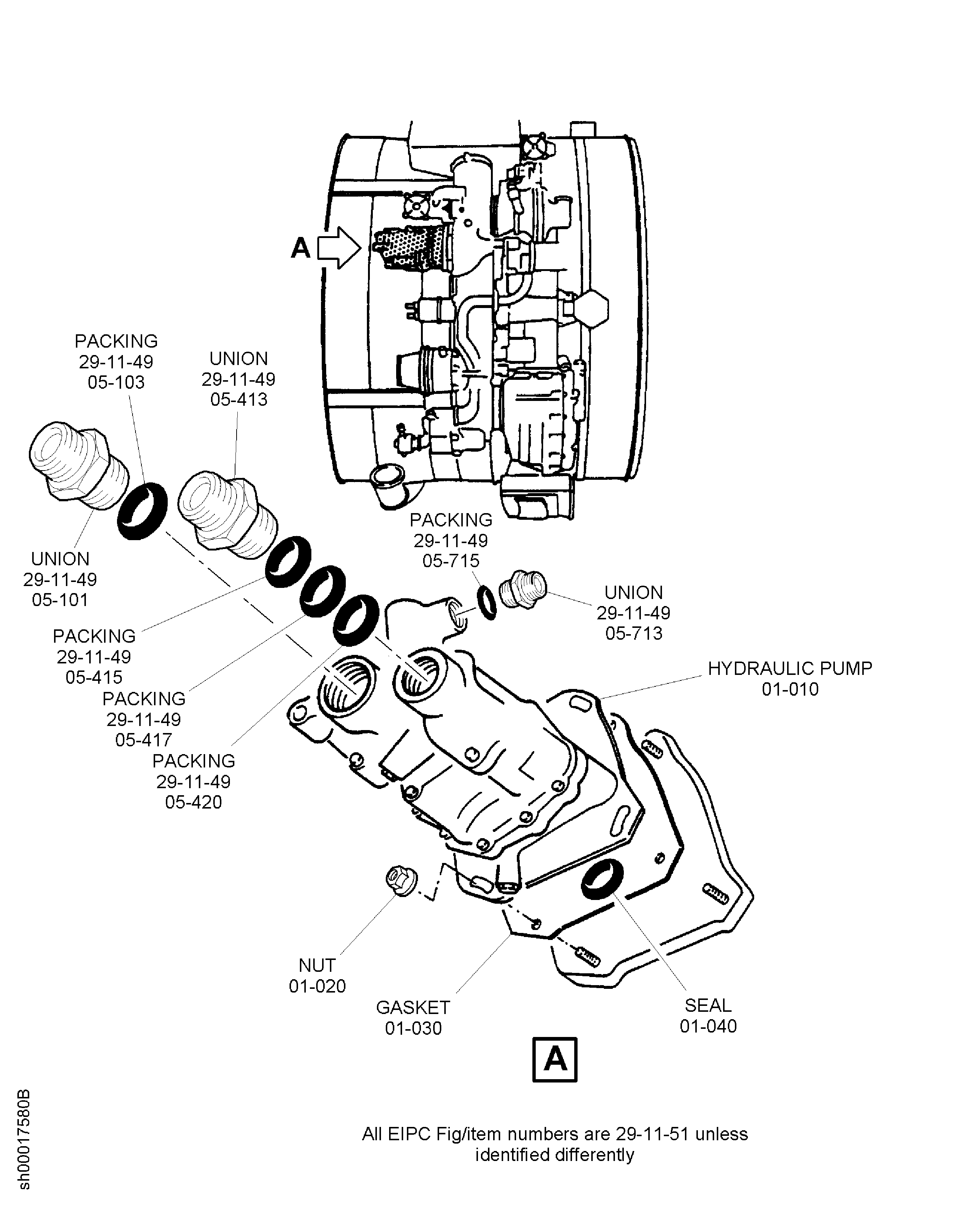

Refer to Figure.

Install the new packings HYDRAULIC POWER - ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 05-415), HYDRAULIC POWER - ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 05-417) and HYDRAULIC POWER - ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 05-420) and the union HYDRAULIC POWER - ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 05-413) in the pressure port of the hydraulic pump.

Install the new packing HYDRAULIC POWER - ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 05-103) and the union HYDRAULIC POWER - ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 05-101) in the suction port of the hydraulic pump.

Install the new packing HYDRAULIC POWER - ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 05-715) and the union HYDRAULIC POWER - ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 05-713) in the case drain port of the hydraulic pump.

Put a new HYDRAULIC POWER-HYDRAULIC PUMP (29-11-51, 01-040) seal 1 off on the engine pump shaft.

Lubricate the splines of the engine pump shaft with CoMat 10-077 APPROVED ENGINE OILS.

CAUTION

DO NOT APPLY SIDE LOADS WHICH COULD BEND THE SPLINED DRIVE SHAFT DURING THE INSTALLATION OF THE PUMP. A BENT DRIVE SHAFT WILL PREVENT CORRECT INSTALLATION OF THE PUMP AND DAMAGE IT IN OPERATION.Put the new HYDRAULIC POWER-HYDRAULIC PUMP (29-11-51, 01-030) gasket 1 off on the gearbox mating face.

Lubricate the mounting studs with CoMat 10-077 APPROVED ENGINE OILS.

Install the four nuts HYDRAULIC POWER-HYDRAULIC PUMP (29-11-51, 01-020) loosely on the studs.

Torque the nuts HYDRAULIC POWER-HYDRAULIC PUMP (29-11-51, 01-020) to 260 to 320 lbf.in (29.4 to 36.2 Nm).

SUBTASK 71-00-02-450-011 Install the Hydraulic Pump

Figure: Install the Hydraulic Case Drain Filter Assembly

Install the Hydraulic Case Drain Filter Assembly

Figure: Installation of the Hydraulic Pump

Installation of the Hydraulic Pump