Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-32-450-001 LPC/Intermediate Case Module Components - Installation Of The Electronic Engine Control (EEC), Installation-008

General

This TASK gives the procedure to install the electronic engine control (EEC) on the LP compressor/intermediate case module.

For standard torque data procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

For installation of preformed packings, refer to SPM TASK 70-44-01-400-501.

For the connection of electrical plugs during engine maintenance, refer to SPM TASK 70-43-00-400-501.

For installation and the reuse of self-locking fasteners, refer to SPM TASK 70-42-01-400-501.

For lockwire data and procedures refer to SPM TASK 70-42-05-400-501.

For safety cable data and procedures refer to SPM TASK 70-42-08-400-501.

Safety the threaded fasteners in the ATA Chapter/Section/Subject 71-51-41 as applicable with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT.

Special torque data is identified with the symbol * after the torque value.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants, refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the application Chapter/Section/Subject comes before the Fig/item number.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1R19416 EEC harness wrench | 0AM53 | IAE 1R19416 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Seal ring | 1 | |||

| Seal ring | 1 | |||

| Seal ring | 1 | |||

| Seal ring | 2 |

Safety Requirements

NONEProcedure

Refer to Figure

NOTE

Do not apply white petrolatum to the new seal rings V2500-A5-73-22-34-01A-941A-D (73-22-34, 01-271, V2500-A5-73-22-34-01A-941A-D 73-22-34, 01-275, V2500-A5-73-22-34-01A-941A-D 73-22-34, 01-278 or V2500-A5-73-22-34-01A-941A-D 73-22-34, 01-282).Install the seal ring V2500-A5-73-22-34-01A-941A-D (73-22-34, 01-271) 1 off, on the union V2500-A5-73-22-34-01A-941A-D (73-22-34, 01-270).

Install the seal rings on the adaptors and unions.

SUBTASK 72-00-32-450-067 Prepare the Replacement EEC

WARNING

BE CAREFUL DURING THE INSTALLATION OF THE EEC. IT WEIGHS APPROXIMATELY 41 LBS (18.6 KG).Refer to Figure.

Apply clean CoMat 10-077 APPROVED ENGINE OILS to the threads of the four bolts V2500-A5-73-22-34-01A-941A-D (73-22-34, 01-300).

Apply clean CoMat 10-077 APPROVED ENGINE OILS to the threads of the bolt V2500-A5-73-22-34-01A-941A-D (73-22-34, 01-340).

SUBTASK 72-00-32-450-068 Install the EEC

Refer to Figure

Apply clean CoMat 10-077 APPROVED ENGINE OILS to the threads of the vent plug assembly V2500-A5-73-22-34-01A-941A-D (73-22-34, 01-290).

Torque the vent plug assembly to 90 lbfin to 100 lbfin (10.17 Nm to 11.30 Nm) and safety with CoMat 02-141 LOCKWIRE.

SUBTASK 72-00-32-450-069 Install the Vent Plug Assembly

Connect the 4000KS-J5, 4000KS-J7, 4000KS-J8, 4000KS-J9 and 4000KS-J10 electrical connectors to its related receptacle on the rear side of the EEC. Torque the connectors to 32 * lbfin (3.6 Nm). Use theIAE 1R19416 EEC harness wrench 1 off.

Connect the 4000KS-J11, 4000KS-J1, 4000KS-J2, 4000KS-J3 and 4000KS-J4 electrical connectors to its related receptacle on the front side of the EEC. Torque the connectors to 32 * lbfin (3.6 Nm). Use the IAE 1R19416 EEC harness wrench 1 off.

Connect the data entry plug assembly to the receptacle J6 on the rear side of the EEC. Torque the connector 32 * lbfin (3.6 Nm). Use the IAE 1R19416 EEC harness wrench 1 off.

SUBTASK 72-00-32-450-070 Connect the Electrical Connectors to the Front and Rear Sides of the EEC

Refer to Figure.

Connect the flexible hose ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49,12-500) to the adapter V2500-A5-73-22-34-01A-941A-D (73-22-34, 01-284) and torque the nut to 142 lbfin to 150 lbfin (16 Nm to 17 Nm).

Connect the flexible hose Fuel System Air Tubes (73-22-49, 08-500) to the union V2500-A5-73-22-34-01A-941A-D (73-22-34, 01-277) and torque the nut to 182 lbfin to 199 lbfin (20.5 Nm to 22.5 Nm).

Connect the flexible hose Fuel System Air Tubes (73-22-49, 04-100) to the union V2500-A5-73-22-34-01A-941A-D (73-22-34, 01-274) and torque the nut to 182 lbfin to 199 lbfin (20.5 Nm to 22.5 Nm).

Connect the flexible hose Fuel System Air Tubes (73-22-49, 07-500) to the union V2500-A5-73-22-34-01A-941A-D (73-22-34, 01-270) and torque the nut to 142 lbfin to 150 lbfin (16 Nm to 17 Nm).

Connect the flexible hose ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 11-500) to the adapter V2500-A5-73-22-34-01A-941A-D (73-22-34, 01-284) and torque the nut to 142 lbfin to 150 lbfin (16 Nm to 17 Nm).

Connect the flexible hose to the adapters and unions on the bottom of the EEC and torque the nuts.

SUBTASK 72-00-32-450-071 Connect the Flexible Hoses

Refer to TASK 71-00-00-700-052-A00 (TESTING-000, CONFIG-001).

SUBTASK 72-00-32-750-053-A00 V2500-A1: Do a Test of the EEC

Refer to TASK 71-00-00-700-052-B00 (TESTING-000, CONFIG-002).

SUBTASK 72-00-32-750-053-B00 V2500-A5: Do a Test of the EEC

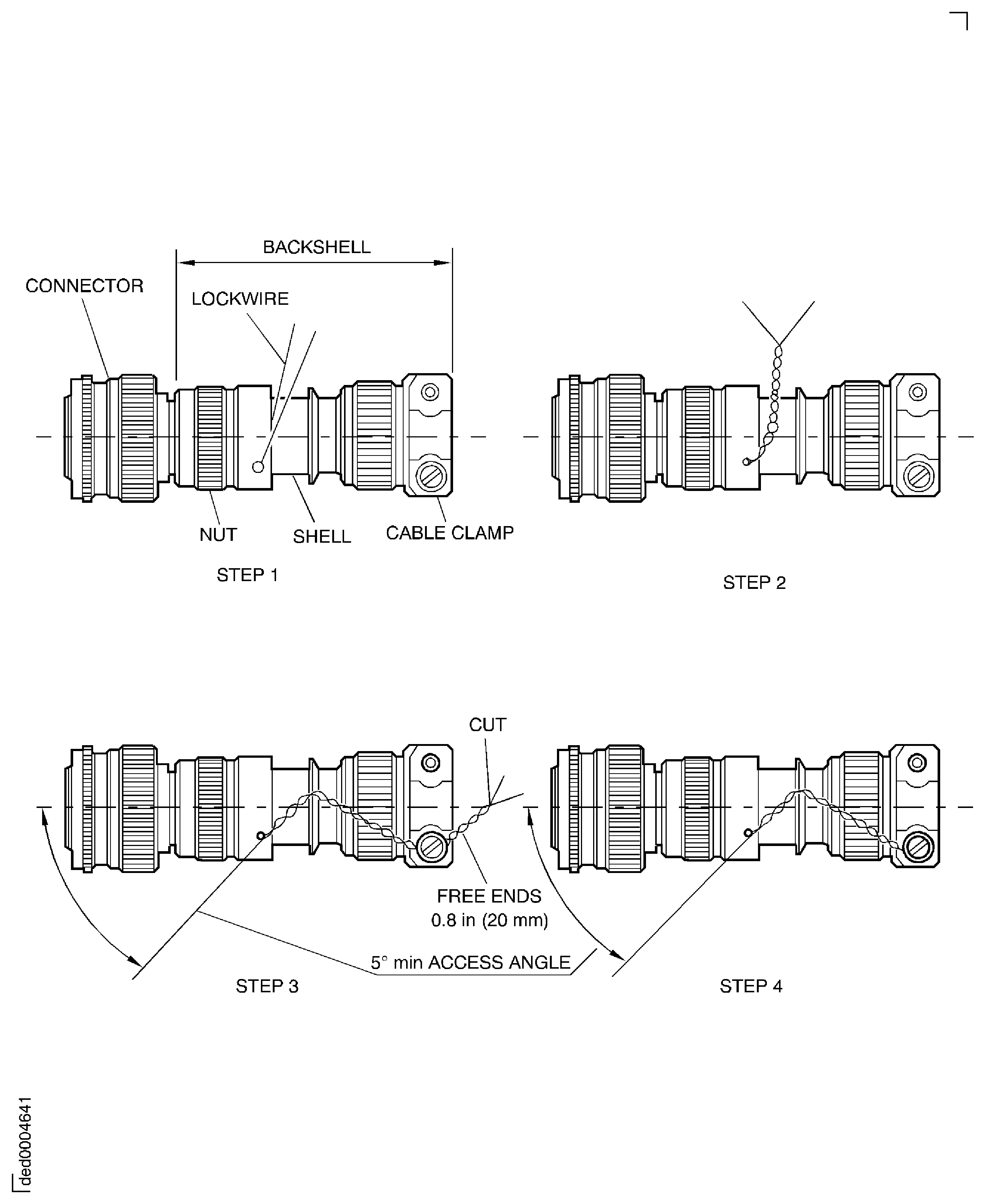

Refer to Figure.

Make sure that all the applicable backshells and cable clamps are safetied with CoMat 02-126 LOCKWIRE. Refer to SPM TASK 70-42-05-400-501.

SUBTASK 72-00-32-210-055 Visually Inspect the Electrical Backshells and Cable Clamps

NOTE

Use this procedure to safety the EEC harness backshells and cable clamps with safety cable.Refer to Figure.

Make sure that all the EEC harness backshells and cable clamps are safetied. Safety with CoMat 02-274 SAFETY CABLE KIT or with CoMat 02-275 SAFETY CABLE KIT. Refer to SPM TASK 70-42-08-400-501.

Examine EEC ground strap ends to ensure strap is securely fastened at (2) crimping locations. Refer to Figure.

NOTE

Replace the strap if wire crimp is found disconnected or moveable.

SUBTASK 72-00-32-210-056 Visually Inspect the EEC Harness (01-005) Electrical Backshells and Cable Clamps (SBE 70-0813)

SBE 70-0813: Announcement of introduction of safety cable as a preferred method to lockwire.

Figure: Installation of the Electronic Engine Control (EEC)

Sheet 1

Figure: Installation of the electronic engine control (EEC)

Sheet 2

Figure: Visually inspect the backshells and cable clamps

Visually inspect the backshells and cable clamps

Figure: Ground Cable

Ground Cable