Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-60-450-003 External Gearbox Components - Install The Oil Pressure Pump And Filter Assembly, Installation-007

NOTE

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of the nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, the lubricate and install seal rings refer to TASK 70-44-01-400-501.

After assembly apply CoMat 07-012 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of air drying enamel. Refer to TASK 70-38-06-380-501 .

The number of each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must be removed immediately before the installation of the component.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-012 AIR DRYING ENAMEL | 0AM53 | CoMat 07-012 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Packing | 1 | |||

| Packing | 1 | |||

| Packing | 2 | |||

| Packing | 4 | |||

| Packing | 1 | |||

| Oil Filter | LOCAL | Oil Filter | 1 |

Safety Requirements

NONEProcedure

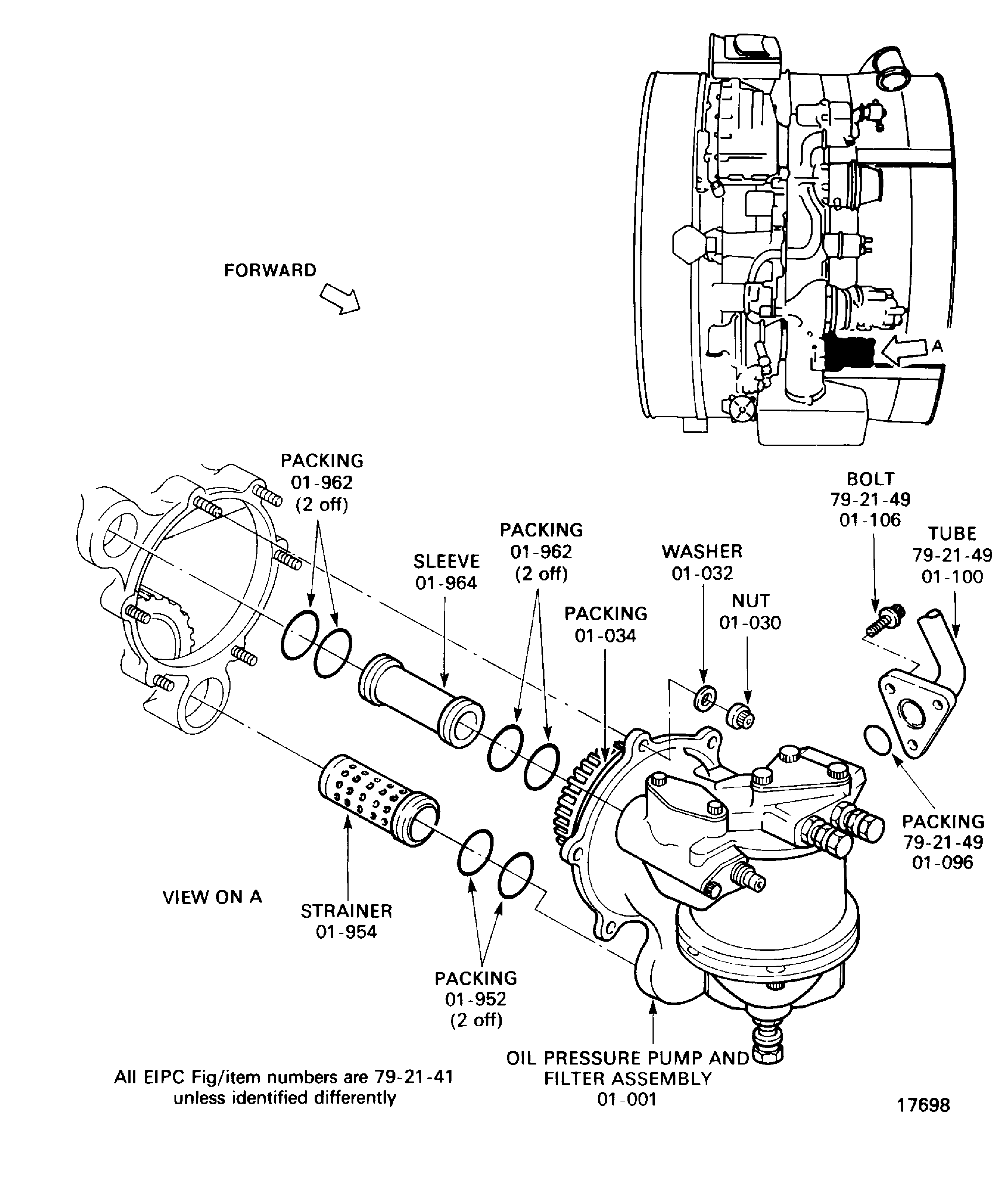

Refer to Figure.

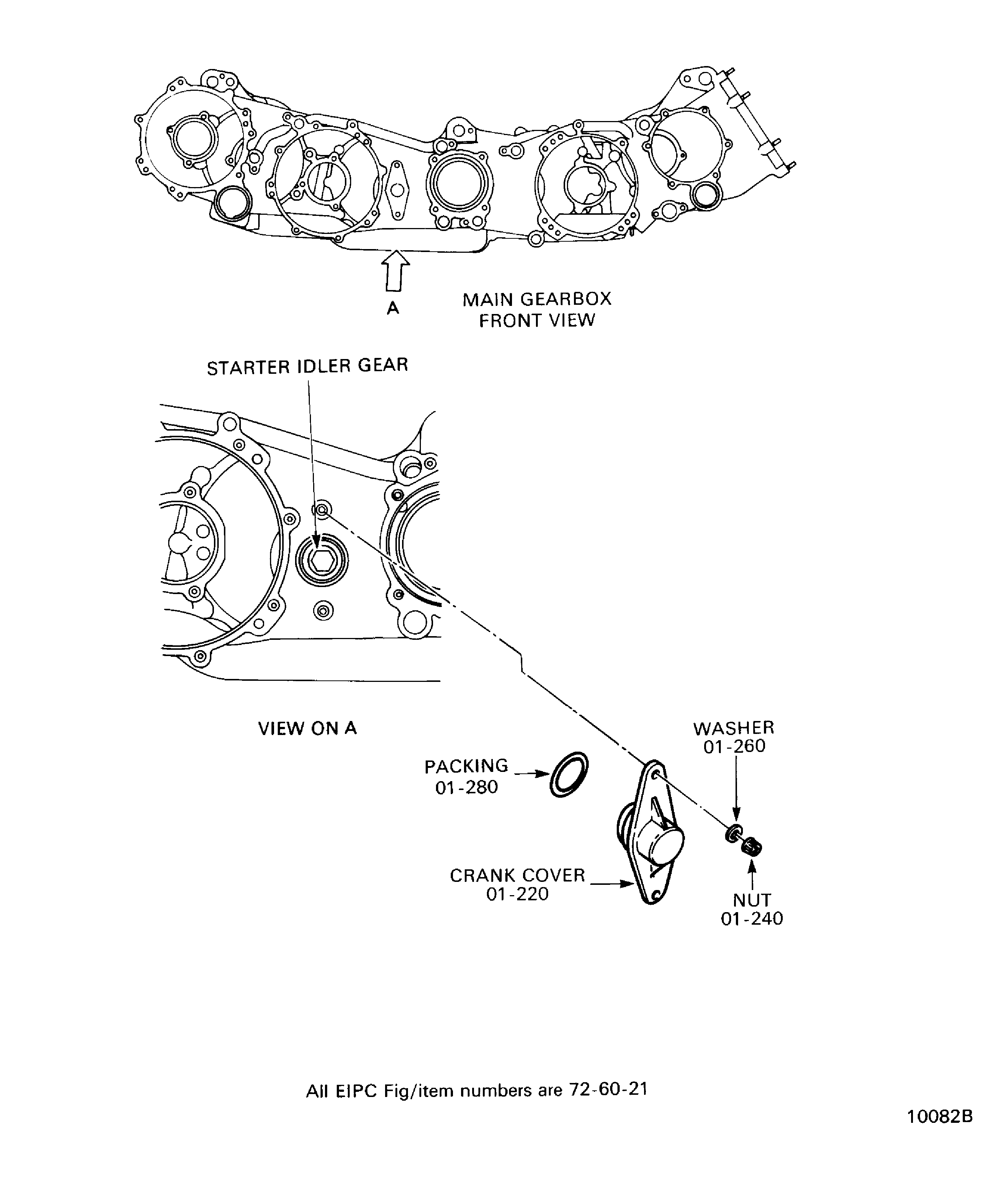

SUBTASK 72-00-60-050-101 Remove the Crank Cover

Refer to Figure.

Lubricate the new OIL-PRESSURE PUMP/FILTER HOUSING (79-21-41, 01-962) packings 4 off with CoMat 10-077 APPROVED ENGINE OILS and install onto the two ends of the sleeve.

Lubricate the new OIL-PRESSURE PUMP/FILTER HOUSING (79-21-41, 01-952) packings 2 off with CoMat 10-077 APPROVED ENGINE OILS and install onto the strainer.

SUBTASK 72-00-60-450-103 Install the Sleeve and the Strainer

Refer to Figure.

If you install a new or overhauled oil pressure pump and filter assembly, install a new oil filter. Refer to TASK 72-00-60-450-011.

NOTE

Spare oil pressure pump and filter assemblies are delivered without filter element installed.Lubricate the new OIL-PRESSURE PUMP/FILTER HOUSING (79-21-41, 01-034) packing 1 off, with CoMat 10-077 APPROVED ENGINE OILS and install on the flange of the oil pressure pump.

Lubricate the oil pump seat on the gearbox casing with CoMat 10-077 APPROVED ENGINE OILS.

SUBTASK 72-00-60-450-104 Install the Oil Pressure Pump and Filter Assembly

Refer to Figure.

Lubricate the new OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-096) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and install onto the flange of the tube.

SUBTASK 72-00-60-450-105 Connect the ACOC Oil Supply Tube

Refer to Figure.

Lubricate the new ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-280) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and install onto the flange of the crank cover.

Lubricate the crank cover seat on the gearbox casing with CoMat 10-077 APPROVED ENGINE OILS.

SUBTASK 72-00-60-450-106 Install the Crank Cover

Fit the oil tank with new CoMat 10-077 APPROVED ENGINE OILS until the tank is full.

Replace OIL-OIL TANK (79-11-41, 01-760) packing 1 off of the cap if the cuts or other defects are found.

Install the oil tank cap.

Prime the engine oil system. Refer to TASK 71-00-00-700-061-A00 or TASK 71-00-00-700-061-B00.

SUBTASK 72-00-60-610-053 Fill the Oil Tank and the Engine Oil System

Figure: Crank cover

Crank cover

Figure: Oil pressure pump and filter assembly

Oil pressure pump and filter assembly