Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-00-430-010-D00 LPC/Intermediate Case Module - Install The LPC Booster Stage Assembly onto The LPC/Intermediate Case Module, Assembly-010

General

This TASK gives the procedure to install the LP compressor booster stage assembly onto the LP compressor/intermediate case module on which the HP system module and the external gearbox module are installed.

Where TASK 72-32-00-030-006-D00 (DISASSEMBLY-006, CONFIG-004) is used for removal of the LP compressor booster stage assembly, it is recommended to use this TASK for installation of the LP compressor booster stage assembly onto the LP compressor/intermediate case module.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1J12026 Turning handle | 0AM53 | IAE 1J12026 | 1 | |

| IAE 1J12105 Cantileer sling | 0AM53 | IAE 1J12105 | 1 | |

| IAE 1J12106 Aligning pin set | 0AM53 | IAE 1J12106 | 1 | |

| IAE 1J12108 Sling adapter | 0AM53 | IAE 1J12108 | 1 | |

| IAE 1J12505 0AM53 heater | 0AM53 | IAE 1J12505 | 1 | |

| IAE 6F10027 Heater control unit | 0AM53 | IAE 6F10027 | 1 | |

| IAE 1J12182 Retaining protector | 0AM53 | IAE 1J12182 | 1 | |

| IAE 1J12541 Holding support | 0AM53 | IAE 1J12541 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE | LOCAL | CoMat 04-004 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Make sure that the engine is in a horizontal position. If not, turn the engine from the vertical to the horizontal position. Refer to TASK 72-00-40-560-002 (INSTALLATION-002) or TASK 72-00-50-560-004 (INSTALLATION-013).

SUBTASK 72-32-00-430-361 Make sure that the Engine is in a Horizontal Position

NOTE

The retaining protector is installed in TASK 72-32-00-030-006-D00 (DISASSEMBLY-006, CONFIG-004).Remove the retaining protector (IAE 1J12182 Retaining protector) from the LPC stub shaft.

Install the three aligning pins (part of the IAE 1J12106 Aligning pin set 1 off) into three of 24 nuts of the rotor center shaft through the holes B.

Install IAE 1J12026 Turning handle 1 off onto the stub shaft with the two wing bolts and washers (part of the turning handle).

Adjust the angular position of the stub shaft.

SUBTASK 72-32-00-430-362 Adjust the Angular Position of the LPC Stub Shaft

Refer to Figure.

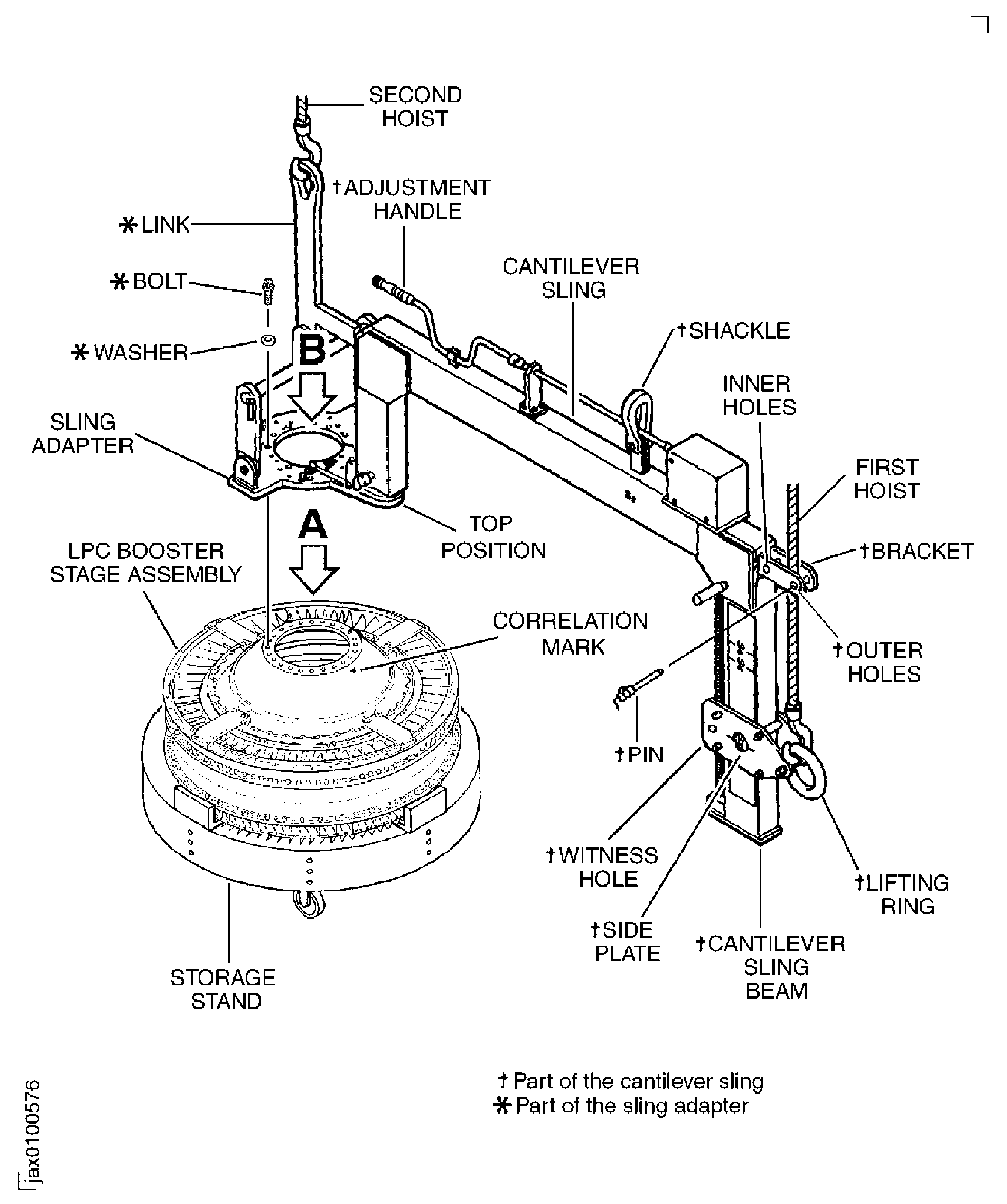

Attach the first hoist to link (part of IAE 1J12108 Sling adapter 1 off) and lift up.

Attach the second hoist to the shackle (part of IAE 1J12105 Cantileer sling 1 off).

SUBTASK 72-32-00-430-363 Prepare the Cantilever Sling and the Sling Adapter (Sling Assembly)

Install the IAE 1J12505 0AM53 heater 1 off to the LPC assembly.

Connect the cables of the local heater to the IAE 6F10027 Heater control unit 1 off.

NOTE

Install the LPC assembly to LPC stage 2.5 stator assembly (Stage 2.5 Stator) before the front flange of the LPC assembly becomes cool and the jointing compound becomes dry.Increase the temperature of the LPC assembly, Figure.

Use a clean cloth made moist with CoMat 01-124 ISOPROPYL ALCOHOL to clean the mating faces.

Apply CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to the mating faces with a soft brush.

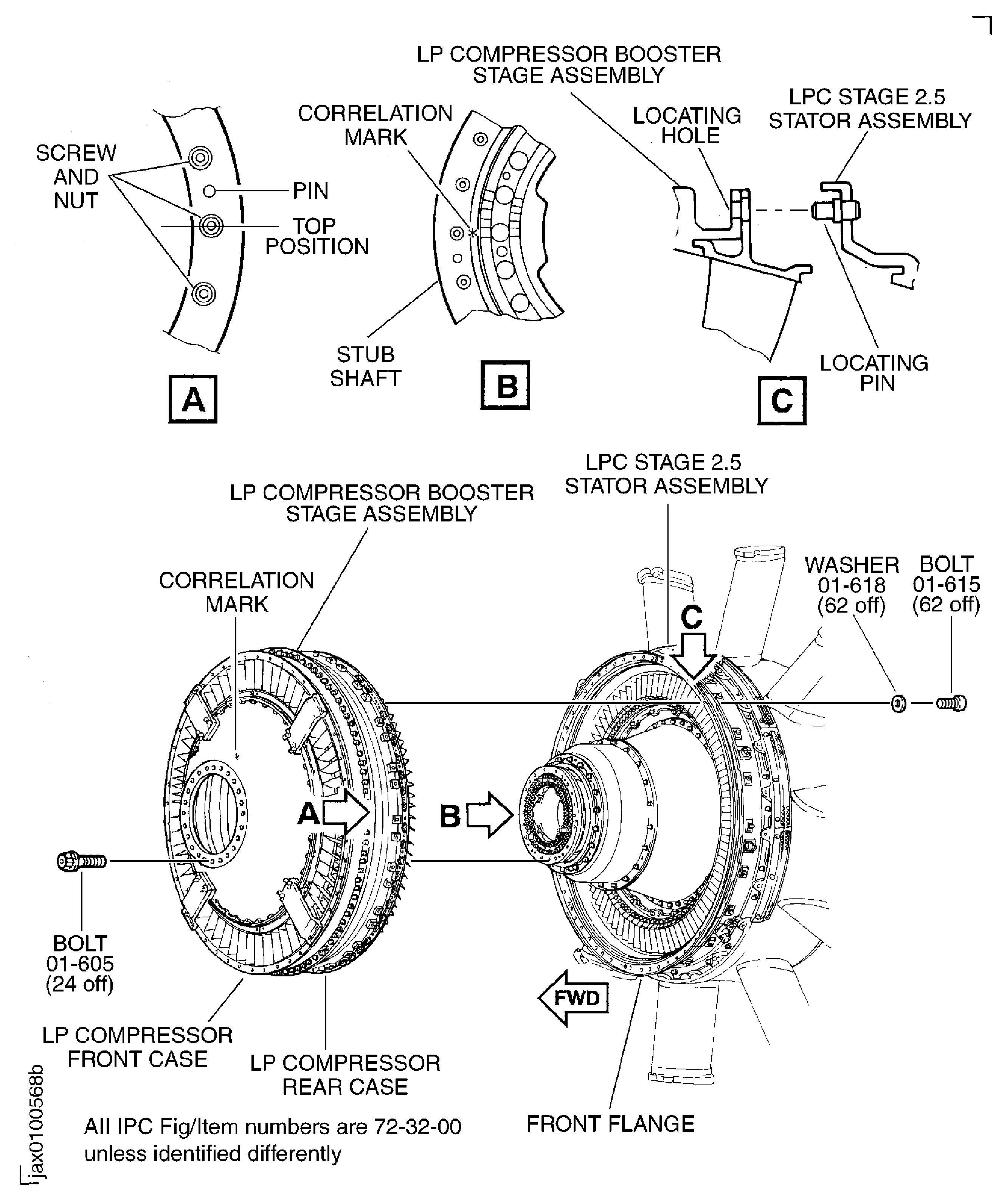

Apply jointing compound to the mating faces of the stage 2.5 stator, Figure.

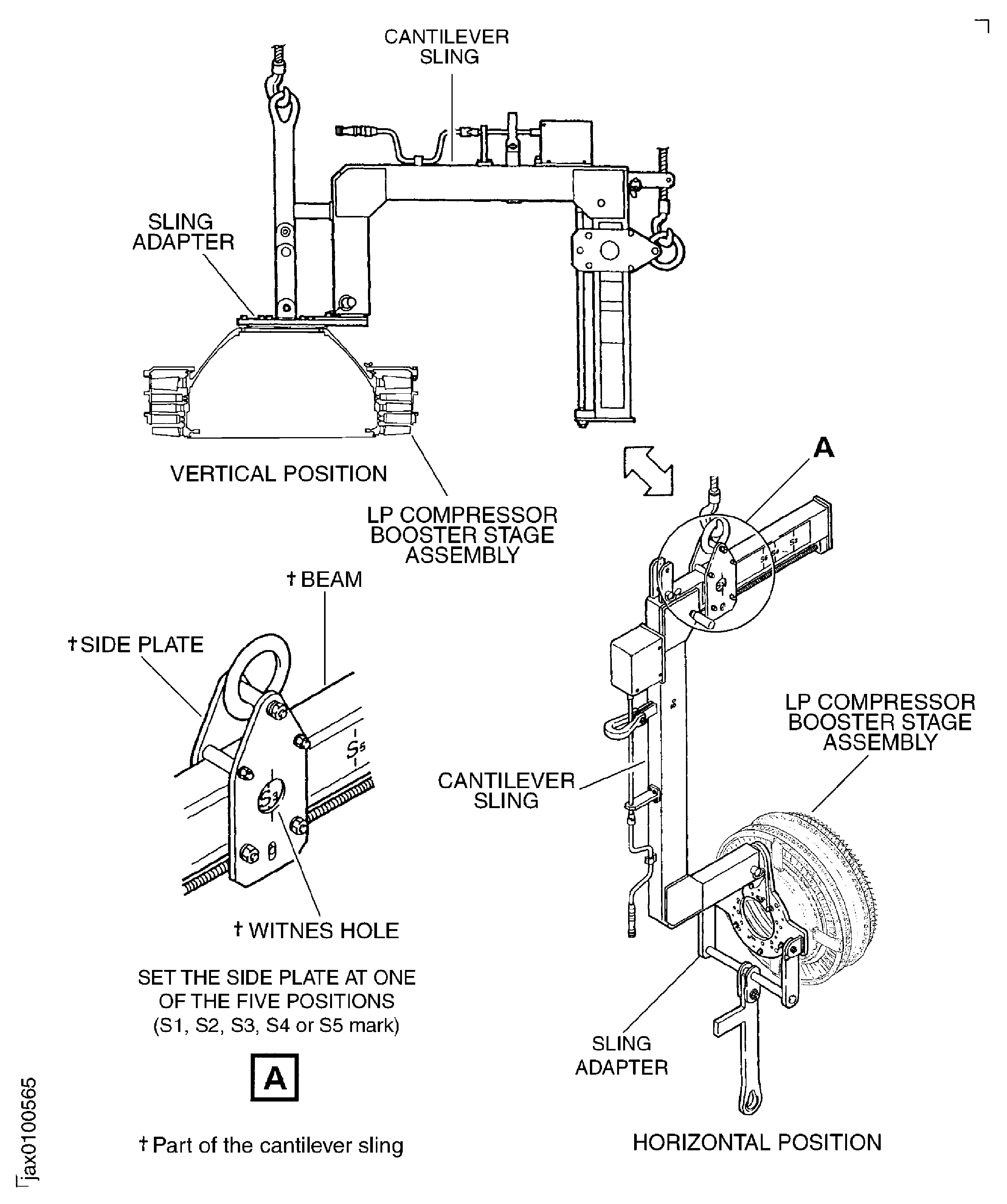

Adjust the position of the LPC stage 1.5-2.5 disk to align the top position of the sling adapter with the correlation mark * on the LPC stage 1.5-2.5 disk, Figure.

Slowly lift the two hoists equally at the same time until the LPC assembly is clear of the storage stand, Figure.

Remove the LPC assembly from the storage stand.

WARNING

DO NOT TOUCH THE LPC ASSEMBLY WITHOUT PROTECTIVE GLOVES.

WARNING

HOT PARTS CAN CAUSE REDDENING AND BLISTERING OF THE SKIN IF THE HANDS ARE NOT PROTECTED.

WARNING

IMMERSE THE CONTACTED AREA IN COLD WATER FOR 10 MINUTES IF THE SKIN IS BURNED. IMMEDIATELY GET MEDICAL ATTENTION IF PAIN OR BLISTERING PERSISTS.Install the sling assembly to the LPC assembly.

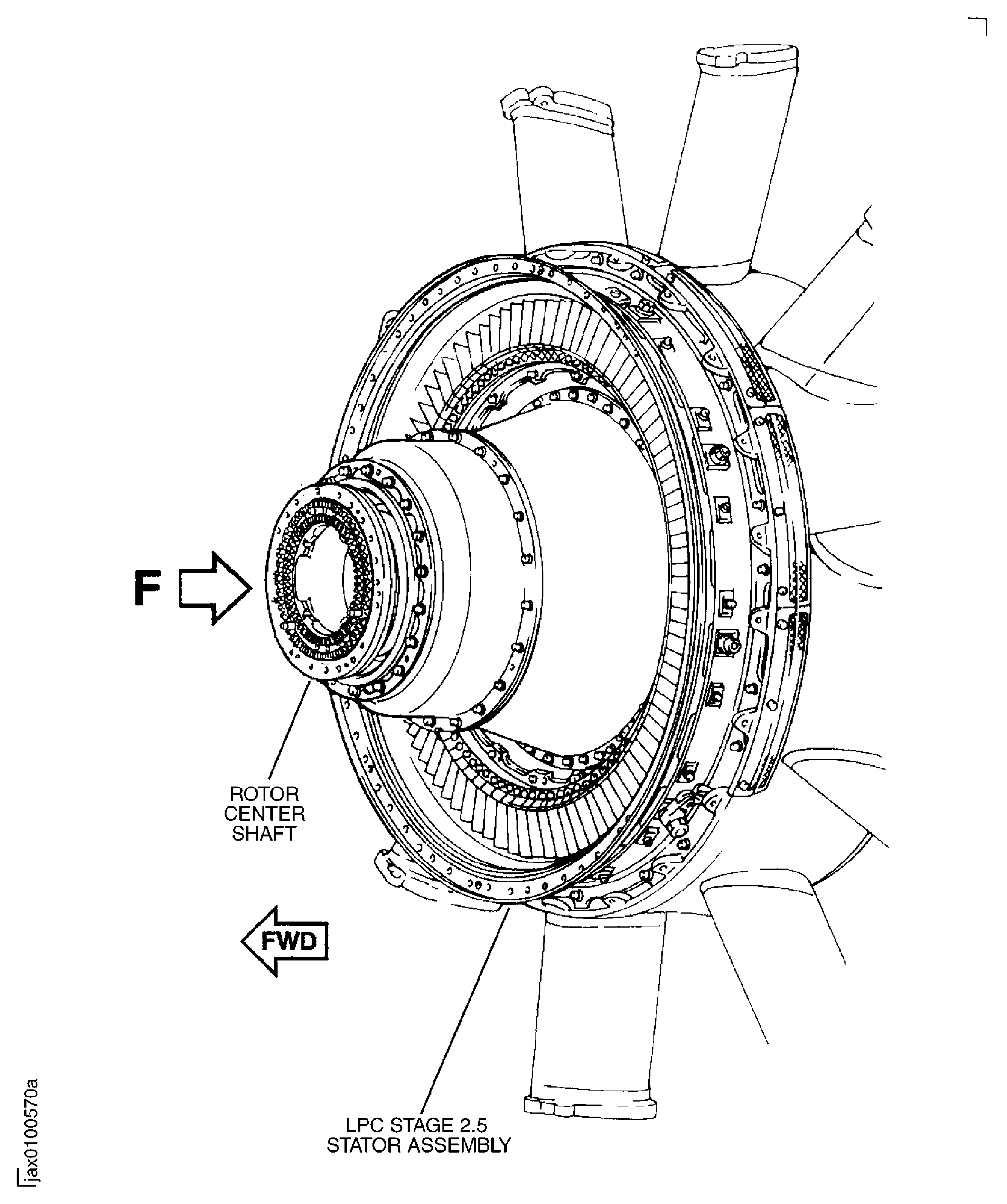

Slowly move the LPC assembly to the rotor center shaft along the aligning pins, Figure.

Attach the LPC assembly to the rotor center shaft with the four of 24 bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-605) at the holes E, Figure and Figure. Tighten the bolts lightly.

Turn the adjustment handle to align the witness hole in the side plate with S3-mark on the beam (part of the cantilever sling), Figure.

Remove the six bolts and washers (part of the sling adapter) which attach the sling adapter to the LPC assembly, Figure.

Remove the sling assembly from the LPC assembly.

Install the remaining 20 bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-605) which attach the LPC assembly to the rotor center shaft, Figure. Tighten the bolts lightly.

Attach the LPC assembly to the rotor center shaft, Figure.

NOTE

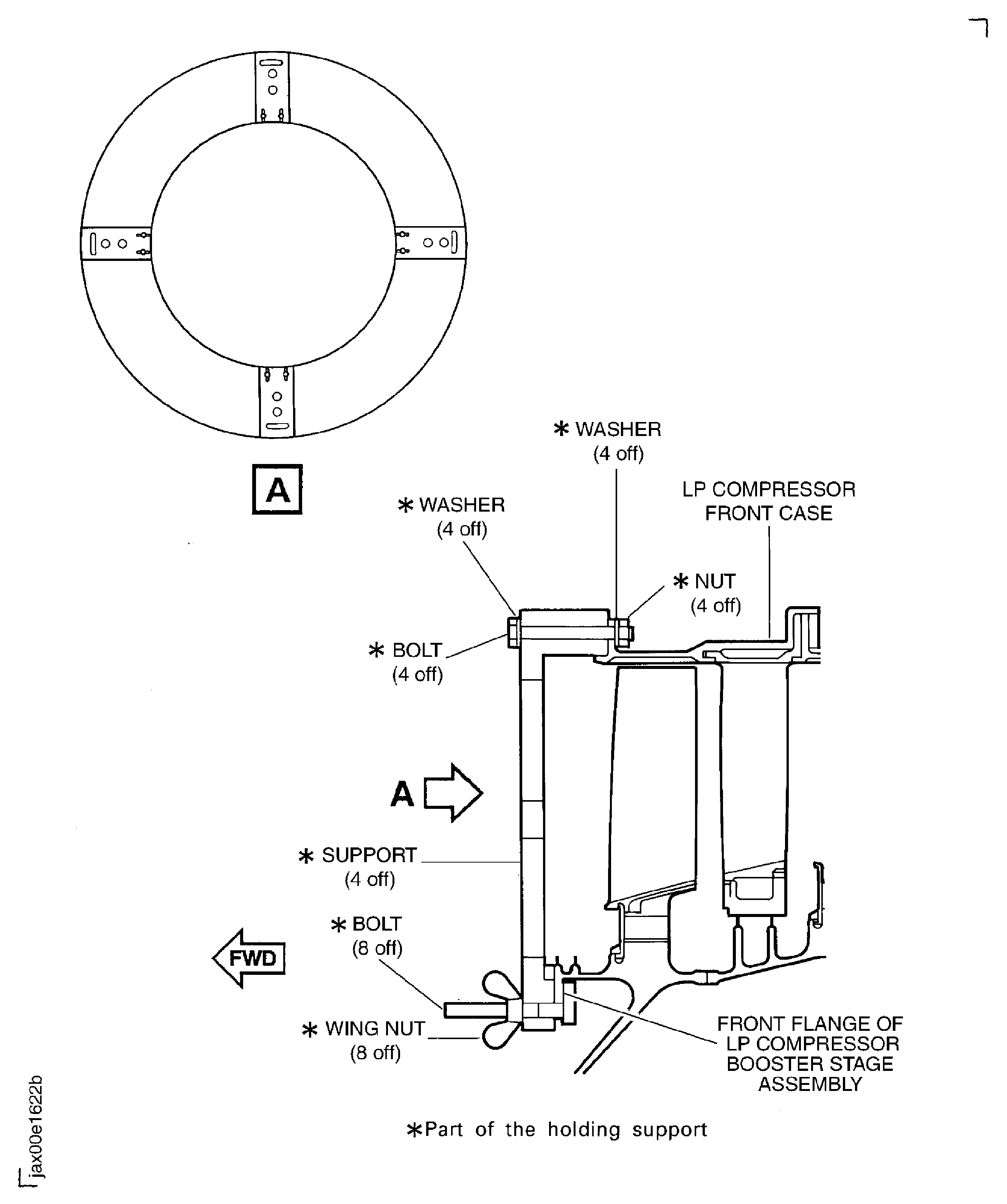

The holding supports are installed to the LPC assembly in TASK 72-32-00-030-006-D00 (DISASEMBLY-006, CONFIG-004) or TASK 72-32-80-440-001-B00 (ASSEMBLY, CONFIG-002).Remove the holding supports set (IAE 1J12541 Holding support) from the LPC assembly.

Attach the LPC assembly to the stage 2.5 stator with the 62 bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-615) and the 62 washers LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-618).

When the LPC assembly becomes cool, loosen the 24 bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-605). Then, torque the 24 bolts to 180 to 220 lbfin (20.00 to 25.00 Nm), Figure.

Torque the 62 bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-615) to 36 to 45 lbfin (4.00 to 5.00 Nm).

Make sure that no gap between the LPC assembly and the rotor center shaft is found, Figure.

Install the LPC assembly to the engine.

SUBTASK 72-32-00-430-364 Install the LP Compressor Booster Stage Assembly (LPC Assembly) to the Engine

Align the three guide pin holes in IAE 1J12182 Retaining protector with the three guide pins of the stub shaft.

SUBTASK 72-32-00-430-365 Install the Retaining Protector onto the Curvic Teeth of the Stub Shaft

Install the LPC inlet guide vane assembly. Refer to TASK 72-32-00-430-013-B00 (ASSEMBLY-013, CONFIG-002).

SUBTASK 72-32-00-430-366 Install the LPC Inlet Guide Vane Assembly to the LP Compressor Front Case

Refer to Figure.

Install the rear fairing, the 20 FEGV's, the 10 front liner panels and the splitter fairing. Refer to TASK 72-32-00-430-014-B00 (ASSEMBLY-014, CONFIG-002).

SUBTASK 72-32-00-430-367 Install the Rear Fairing, the FEGV's, the Front Liner Panels and the Splitter Fairing on the Engine

Install the LP compressor (fan) module. Refer to TASK 72-00-31-420-001 (INSTALLATION).

SUBTASK 72-32-00-430-368 Install the LP Compressor (Fan) Module

Figure: Sectional view of the LP compressor/intermediate case module

Sectional view of the LP compressor/intermediate case module

Figure: Remove the retaining protector from the LPC stub shaft

Remove the retaining protector from the LPC stub shaft

Figure: Install the aligning pins to the LPC stub shaft

Sheet 1

Figure: Install the aligning pins to the LPC stub shaft

Sheet 2

Figure: Install the LP compressor booster stage assembly onto the rotor center shaft and the LPC stage 2.5 stator assembly

Install the LP compressor booster stage assembly onto the rotor center shaft and the LPC stage 2.5 stator assembly

Figure: Install the turning handle onto the stub shaft

Install the turning handle onto the stub shaft

Figure: Assemble the cantilever sling and the sling adapter

Assemble the cantilever sling and the sling adapter

Figure: Increase the temperature of the LP compressor booster stage assembly

Increase the temperature of the LP compressor booster stage assembly

Figure: Apply jointing compound to the mating faces on the LPC stage 2.5 stator assembly

Apply jointing compound to the mating faces on the LPC stage 2.5 stator assembly

Figure: Install the sling assembly to the LP compressor booster stage assembly

Sheet 1

Figure: Install the sling assembly to the LP compressor booster stage assembly

Sheet 2

Figure: Turn the LP compressor booster stage assembly to horizontal position

Turn the LP compressor booster stage assembly to horizontal position

Figure: Install the sling assembly to the LP compressor booster stage assembly

Install the sling assembly to the LP compressor booster stage assembly

Figure: Remove the holding supports from the LP compressor booster stage assembly

Remove the holding supports from the LP compressor booster stage assembly

Figure: Gap between the LP compressor booster stage assembly and the rotor center shaft

Gap between the LP compressor booster stage assembly and the rotor center shaft