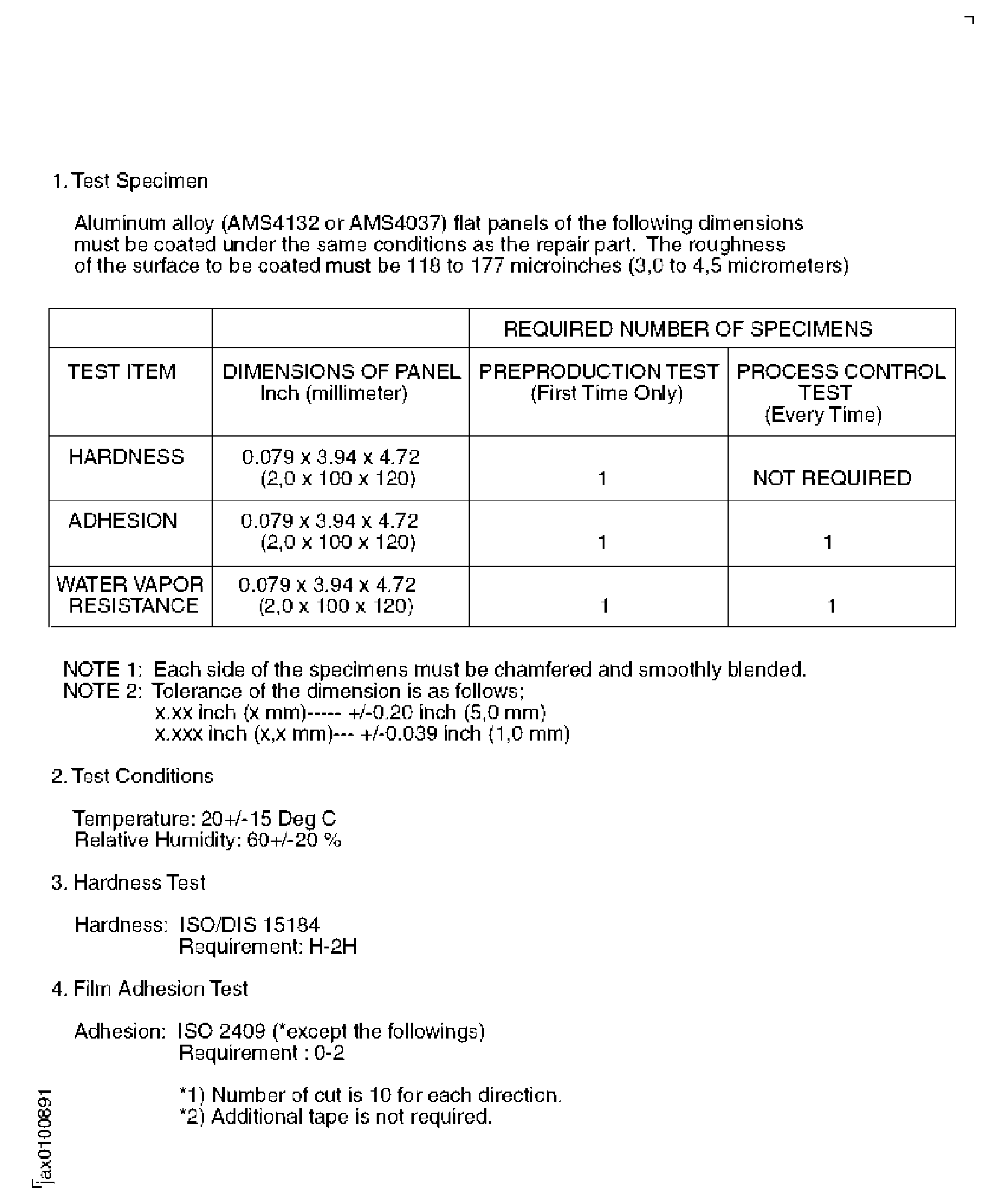

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-72-300-009 LPC Bleed Valve Ring - Restore The Teflon Coating, Repair-009 (VRS1748)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

For the method to clean the parts, refer to TASK 72-32-72-100-000.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-339 ALKALI CLEANER (GENERAL PURPOSE) | LOCAL | CoMat 01-339 | ||

| CoMat 01-410 ISOPROPYL ALCOHOL, REAGENT GRADE | 0AL61 | CoMat 01-410 | ||

| CoMat 01-555 ALKALINE CLEANER | SCW17 | CoMat 01-555 | ||

| CoMat 01-556 REMOVER | SCW17 | CoMat 01-556 | ||

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL | K6835 | CoMat 02-006 | ||

| CoMat 02-051 HIGH TEMPERATURE GLASS CLOTH TAPE | X111X | CoMat 02-051 | ||

| CoMat 02-099 LINT-FREE CLOTH | X222X | CoMat 02-099 | ||

| CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) | 07512 | CoMat 02-198 | ||

| CoMat 05-022 ALUMINUM OXIDE ABRASIVE | 62596 | CoMat 05-022 | ||

| CoMat 07-170 FLUOROCARBON RESIN | 23037 | CoMat 07-170 | ||

| CoMat 07-171 THINNER | 23037 | CoMat 07-171 |

Spares

NONESafety Requirements

NONEProcedure

Refer to VRS1751, TASK 72-32-72-300-006 (REPAIR-006).

Remove the seal.

Refer to VRS1752, TASK 72-32-72-300-005 (REPAIR-005).

Remove the bush.

Refer to VRS1785, TASK 72-32-72-300-007 (REPAIR-007).

Remove the guide.

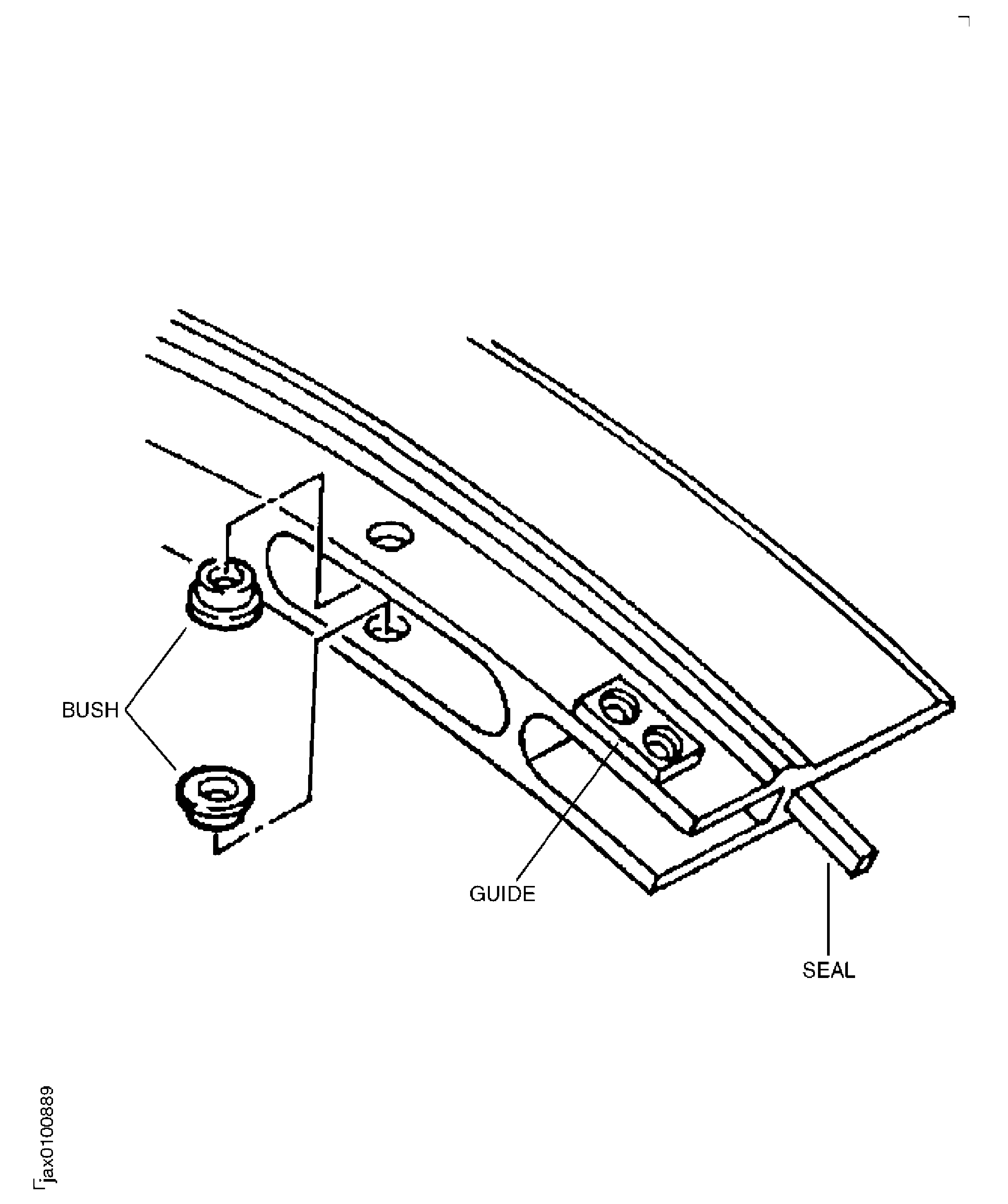

SUBTASK 72-32-72-350-067 Remove the Bush, Seal and Guide from the Valve Ring Assembly

CAUTION

WHEN YOU REMOVE THE SEAL, DO NOT CAUSE DAMAGE TO THE PARENT MATERIAL.Refer to Figure.

Use CoMat 01-339 ALKALI CLEANER (GENERAL PURPOSE) of 15 to 30 percent.

Refer to the SPM TASK 70-11-48-110-501, SUBTASK 70-11-48-110-021.

Soak the part in solution for 10 to 30 minutes, at temperature of 122 to 140 deg F (50 to 60 deg C), as necessary.

Use CoMat 01-555 ALKALINE CLEANER of 4 to 6.7 oz/gal (30 to 50 g/L).

Soak the part in solution for 5 to 15 minutes, at temperature of 158 to 194 deg F (70 to 90 deg C).

Use CoMat 01-556 REMOVER of 15 to 25 percent.

CAUTION

THE TOTAL IMMERSION TIME MUST NOT BE MORE THAN 150 SECONDS TO PREVENT THE BASE MATERIAL DAMAGE.Soak the part in solution for 30 to 90 seconds, at temperature of 59 to 86 deg F (15 to 30 deg C).

SUBTASK 72-32-72-350-068 Remove the Chromate Conversion Coating

Use CoMat 05-022 ALUMINUM OXIDE ABRASIVE. Use a dry blast system cabinet.

Use an air pressure of 42.67 to 56.89 psi (0.29 to 0.39 MPa).

The surface roughness to be coated must be 118 to 177 microinches (3.0 to 4.5 micrometers).

Dry abrasive blast the Test Pieces.

SUBTASK 72-32-72-350-069 Prepare the Test Pieces

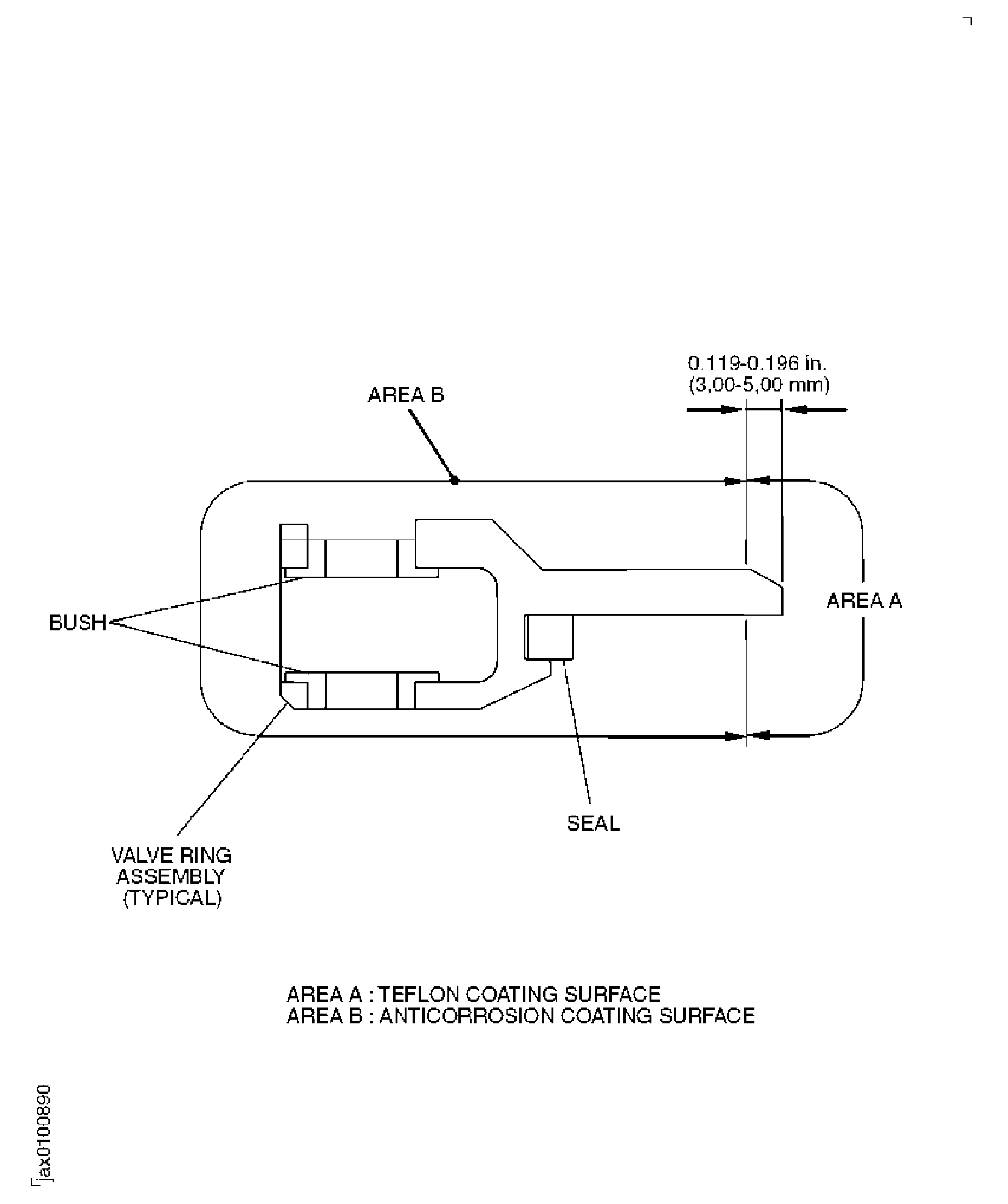

Refer to Figure.

Use CoMat 02-001 ADHESIVE TAPE (MASKING), CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL, CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) and/or mechanical masking.

Mask areas (AREA B) where teflon coating is not applied.

Use CoMat 05-022 ALUMINUM OXIDE ABRASIVE. Use a dry blast system cabinet. Use an air pressure of 42.67 to 56.89 psi (0.29 to 0.39 MPa).

The surface roughness on the area to be coated must be 118 to 177 microinches (3.0 to 4.5 micrometers) after removel of all damaged teflon coating.

Dry abrasive blast to remove the Teflon coating.

Refer to the SPM TASK 70-11-26-300-503.

Wipe blasted surfaces.

SUBTASK 72-32-72-350-070 Remove the Damaged Teflon Coating

CAUTION

AFTER REMOVAL, TO PREVENT CONTAMINATION, DO NOT TOUCH THE COMPONENT BY HAND AND COVER BY CRAFT PAPER OR EQUIVALENT.Mix CoMat 07-171 THINNER maximum 20 percent with Teflon coating, as necessary.

Coating thickness is required between 0.00150 in. (0.038 mm) and 0.00248 in. (0.063 mm) after curing.

Spray coat of Teflon on area A of the valve ring and test pieces.

Starting from room temperature, increase the temperature to 275 to 293 deg F (135 to 145 deg C) within 10 to 15 minutes.

Hold the temperature for 10 to 15 minutes. Then increase the temperature to 347 to 365 deg F (175 to 185 deg C) within 25 to 35 minutes and hold for 60 to 70 minutes.

Then decrease the temperature from 347 to 365 deg F (175 to 185 deg C) to room temperature at any rate.

Cure the coating.

SUBTASK 72-32-72-350-071 Apply the Teflon Coating to the Valve Ring and Test Pieces

Refer to Figure.

Refer to the SPM TASK 70-38-02-300-503, SUBTASK 70-38-02-300-001.

NOTE

Wet or dry blast may be used as surface treatment for dipping procedure, refer to the SPM TASK 70-12-01-120-501 or SPM TASK 70-12-02-120-501. Use aluminum oxide grit from 220 to 500 mesh.

Apply chromate conversion coating on area B.

SUBTASK 72-32-72-350-073 Apply the Chromate Conversion Coating to the Valve Ring

Refer to VRS1751, TASK 72-32-72-300-006 (REPAIR-006).

Install the seal.

Refer to VRS1752, TASK 72-32-72-300-005 (REPAIR-005).

Install the bush.

Refer to VRS1785, TASK 72-32-72-300-007 (REPAIR-007).

Install the guide.

SUBTASK 72-32-72-350-074 Install the Bush, Seal and Guide to the Valve Ring

Refer to the SPM TASK 70-38-02-300-503, SUBTASK 70-38-02-300-002.

If necessary, apply chromate conversion coating to the part, if the coating is damaged during installation of the Bush, Seal and guide.

SUBTASK 72-32-72-350-075 Touch up the Chromate Conversion Coating to the Valve Ring

Refer to the SPM TASK 70-38-02-300-503, SUBTASK 70-38-02-300-002.

Apply chromate conversion coating to the vibro engraved mark.

SUBTASK 72-32-72-350-076 Identify the Repair

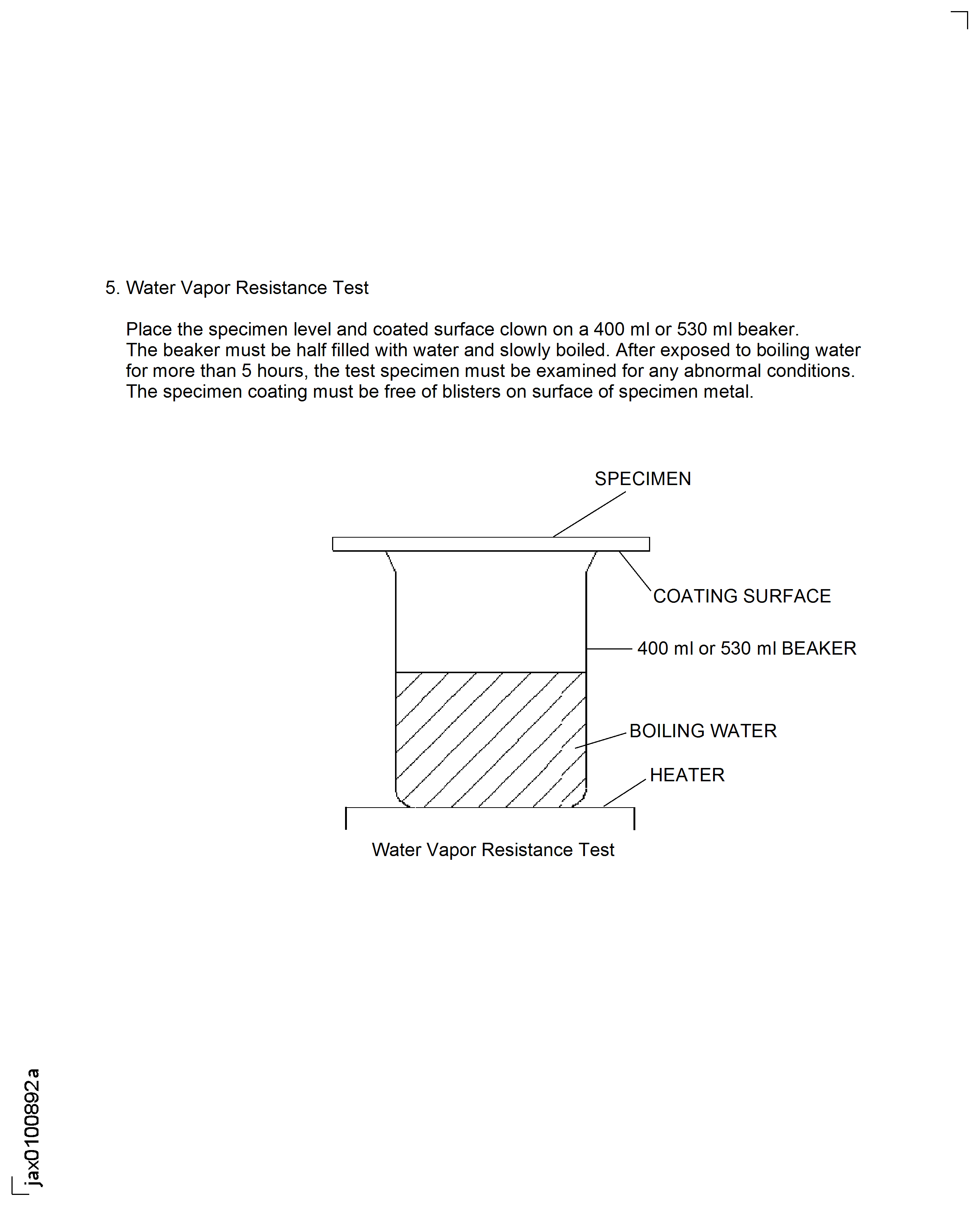

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2