Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-40-00-430-005 HP System Module - Install The HPT Stage Nozzle Assembly (Vertical) - Method 2, Assembly-005

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK 70-64-02-640-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must be removed immediately before the installation of the components.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1P16077 Fixture | 0AM53 | IAE 1P16077 | 1 | |

| IAE 1P16087 Air flow adapter | 0AM53 | IAE 1P16087 | 1 | |

| IAE 1P16109 cover | 0AM53 | IAE 1P16109 | 1 | |

| IAE 1P16111 cover | 0AM53 | IAE 1P16111 | 1 | |

| IAE 1P16122 Installation fixture | 0AM53 | IAE 1P16122 | 1 | |

| IAE 6P16353 Air flow cart | 0AM53 | IAE 6P16353 | 1 | |

| IAE 1P16112 cover | 0AM53 | IAE 1P16112 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 | ||

| CoMat 10-041 PETROLATUM, WHITE | LOCAL | CoMat 10-041 |

Spares

NONESafety Requirements

NONEProcedure

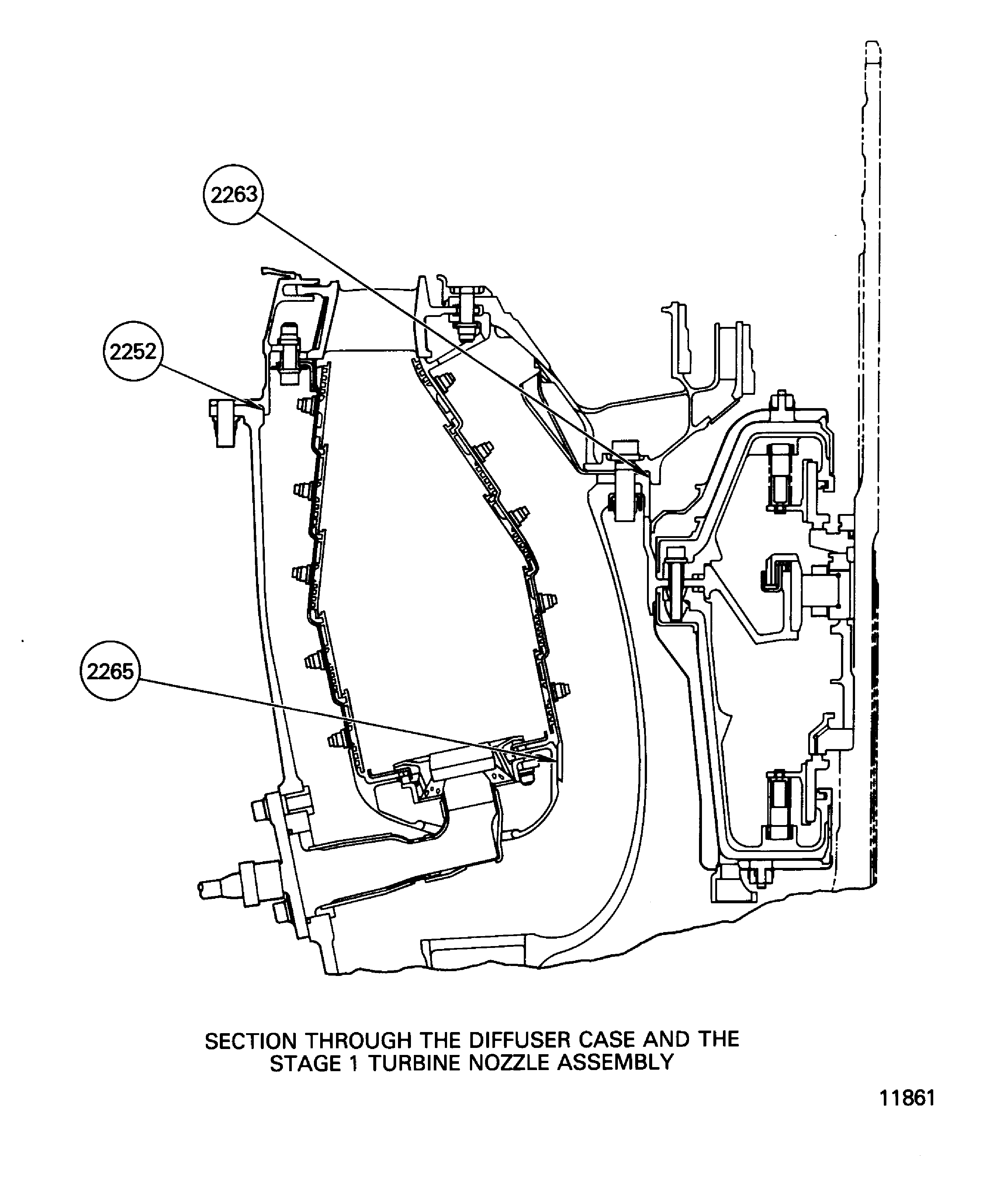

Refer to Figure.

Reference interference at location 2252. If required, use the data written as a note in TASK 72-42-11-200-000 (INSPECTION-000) and TASK 72-44-10-200-000 (INSPECTION-000).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2252

Diffuser Case Assembly Diffuser Case (72-42-11, 01-010), Bore

Stage 1 HPT Support Assembly HPT Stage 1 Support Assembly And Support Seal (72-44-10, 01-010), Front Outside Location Diameter

Diffuser Case Bore

28.233

Intf

28.233

Intf

28.227

0.002

28.222

0.002

Support Diameter

28.241

0.014

28.241

0.014

28.235

Intf

28.230

Intf

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2252

Diffuser Case Assembly Diffuser Case (72-42-11, 01-010), Bore

Stage 1 HPT Support Assembly HPT Stage 1 Support Assembly And Support Seal (72-44-10, 01-010), Front Outside Location Diameter

Diffuser Case Bore

717.118

Intf

71.712

Intf

716.966

0.050

71.684

0.050

Support Diameter

71.7321

0.360

717.321

0.360

717.169

Intf

717.040

Intf

SUBTASK 72-40-00-220-059 Reference Fits and Clearances of the Diffuser Case Assembly and Stage 1 HPT Support at Location 2252

Refer to Figure.

Reference interference at location 2263. If required, use the data written as a note in TASK 72-42-31-200-000 (INSPECTION-000) and TASK 72-44-50-200-000 (INSPECTION-000).

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2263

No. 4 Bearing Support ENGINE-NO.4 BEARING SUPPORT ASSEMBLY (72-42-31, 01-010), Bore

Stage 1 HPT Cooling Duct Assembly HPT Stage 1 Cooling (TOBI) Duct And Duct Deflector (72-44-50, 01-010), Front Outside Location Diameter

Support Bore

13.033

Intf

13.027

0.000

Duct Diameter

13.039

0.012

13.033

Intf

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2263

No. 4 Bearing Support ENGINE-NO.4 BEARING SUPPORT ASSEMBLY (72-42-31, 01-010), Bore

Stage 1 HPT Cooling Duct Assembly HPT Stage 1 Cooling (TOBI) Duct And Duct Deflector (72-44-50, 01-010), Front Outside Location Diameter

Support Bore

331.038

Intf

330.886

0.000

Duct Diameter

331.191

0.300

331.038

Intf

SUBTASK 72-40-00-220-060 Reference Fits and Clearances of the No. 4 Bearing Support and Stage 1 HPT Cooling Duct Assembly at Location 2263

Refer to Figure.

Reference clearance/interference at location 2265. If required, use the data written as a note in TASK 72-42-61-200-000 (INSPECTION-000) and TASK 72-44-30-200-000 (INSPECTION-000) .

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2265

Combustion Chamber Assembly Outer Combustion Chamber Assembly (72-42-61, 01-020), Hood Bore

Inner Combustion Chamber Assembly Inner Combustion Chamber Assembly (72-44-30, 01-020), Location Diameter

Hood Bore

16.628

Intf

16.624

Intf

16.640

0.003

16.640

0.007

Chamber Diameter

16.619

0.021

16.616

0.024

16.631

Clear

16.631

Clear

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2265

Combustion Chamber Assembly Outer Combustion Chamber Assembly (72-42-61, 01-020), Hood Bore

Inner Combustion Chamber Assembly Inner Combustion Chamber Assembly (72-44-30, 01-020), Location Diameter

Hood Bore

422.351

Intf

422.250

Intf

422.656

0.076

422.656

0.178

Chamber Diameter

422.123

0.533

422.046

0610

422.427

Clear

422.427

Clear

SUBTASK 72-40-00-220-061 Reference Fits and Clearances of the Combustion Chamber Assembly and Inner Combustion Chamber Assembly at Location 2265

Refer to TASK 72-40-00-430-003 (ASSEMBLY-003).

SUBTASK 72-40-00-430-062 Install the No. 4 Bearing and Rear Compartment

Remove the cover from the stage 1 HPT Support Assembly. Refer to Figure.

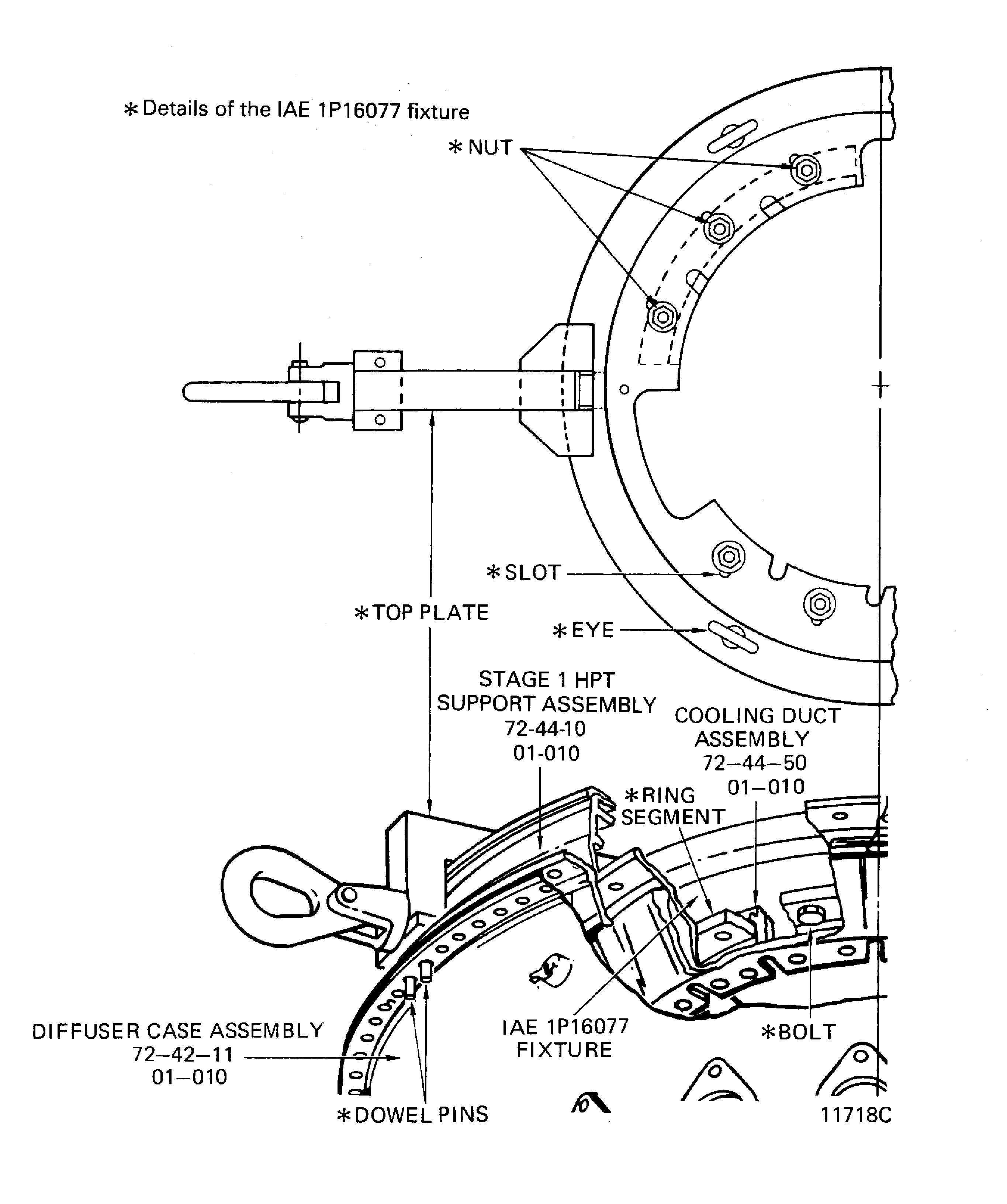

Attach a standard three cable sling to the three eyes on the IAE 1P16077 Fixture 1 off. Refer to Figure.

Move the ring segments to the center and below the flange of the cooling duct assembly, HPT Stage 1 Cooling (TOBI) Duct And Duct Deflector (72-44-50, 01-010).

Attach the fixture to the stage 1 HPT Support Assembly, HPT Stage 1 Support Assembly And Support Seal (72-44-10, 01-010).

SUBTASK 72-40-00-430-063 Install the Fixture on to the Stage 1 HPT Support Assembly

Position the stage 1 turbine nozzle assembly and get access to the stage 1 HPT seal ENGINE-STAGE 1 HPT OUTER SEAL ASSEMBLY (72-44-40, 01-010), Figure.

Install a 0.250-28 tool bolt and a non-locking tool nut on the stage 1 HPT Seal Assembly ENGINE-STAGE 1 HPT OUTER SEAL ASSEMBLY (72-44-40, 01-010) without the spacer.

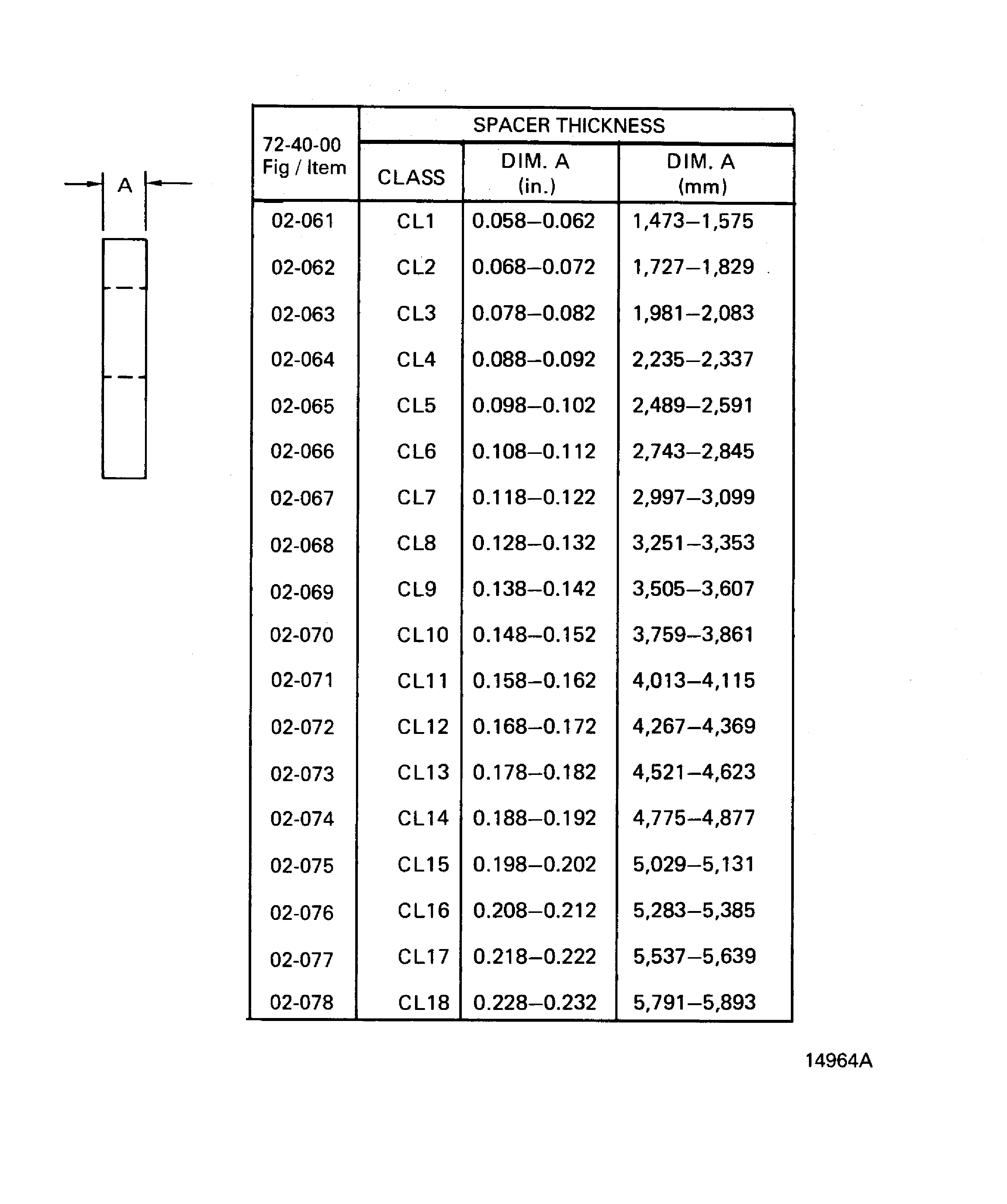

Get the correct class or classes of spacer(s) that is nearest to Dimension G, Figure.

Find the correct dimension for the combustion chamber clamp spacer(s) (02-061 thru 02-078).

NOTE

Correct spacer selection is important to make sure you get maximum post assembly engine performance and durability. Incorrect spacer selection will effect performance (EGT margin) and high pressure turbine durability.Install the spacer(s) between the stage 1 HPT Seal Assembly flanges, Figure.

SUBTASK 72-40-00-430-064 Find the Correct Dimension for the Combustion Chamber Clamp Spacer(s) and Install the Spacer(s),

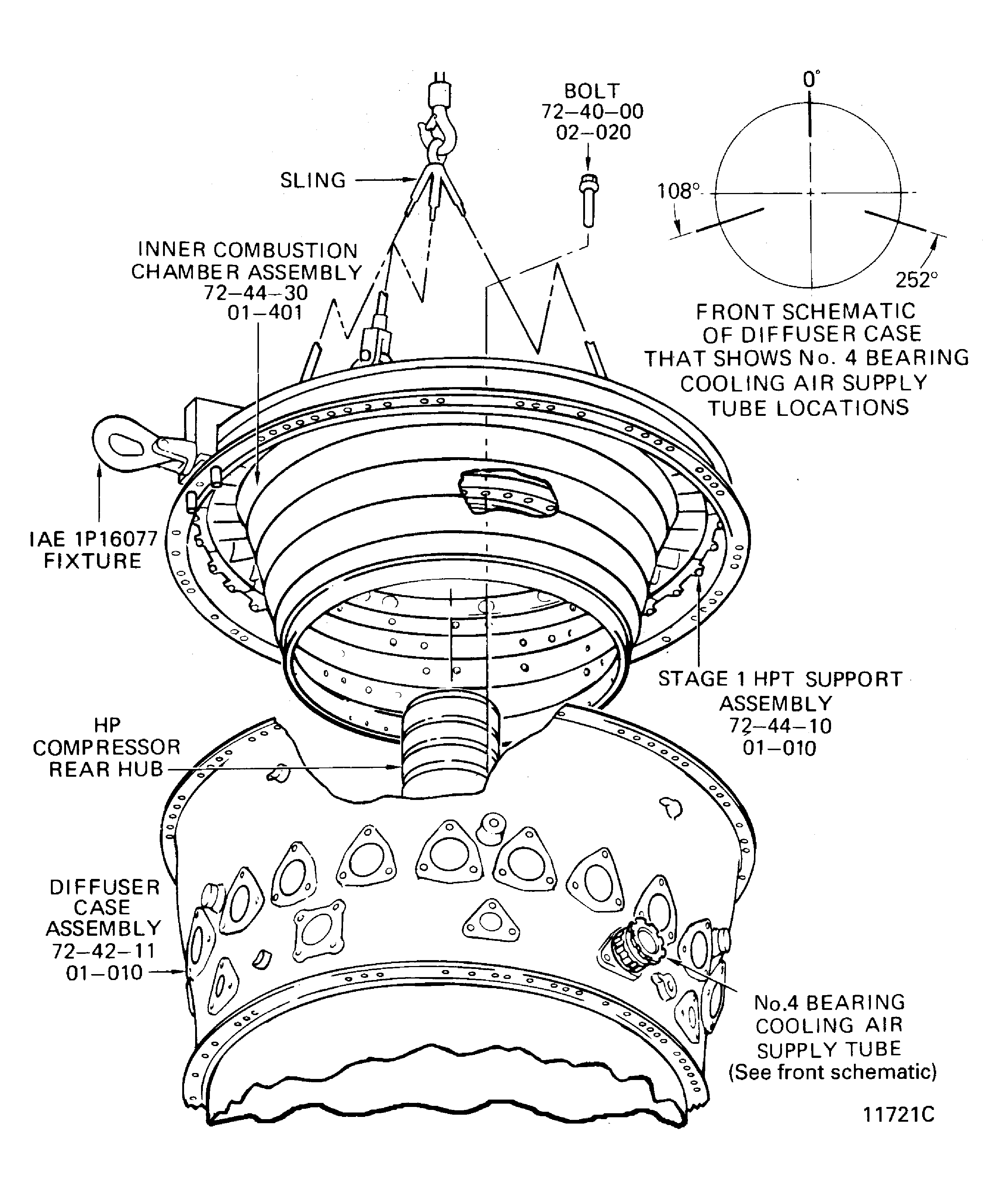

Lubricate the slip joints of the inner combustion chamber and the outer combustion chamber with CoMat 10-041 PETROLATUM, WHITE or CoMat 10-077 APPROVED ENGINE OILSFigure.

Raise the assembly above the engine, Figure.

CAUTION

DO NOT INSTALL BOLTS (02-020) OR PULL STAGE 1 HPT SUPPORT ASSEMBLY AND DIFFUSER CASE ASSEMBLY TOGETHER UNLESS CLEARANCES ARE EQUAL AND PARTS ARE ALIGNED, OR DAMAGE TO THE COMBUSTION CHAMBERS CAN RESULT.Keep an equal clearance all around between the stage 1 HPT Support Assembly and the diffuser case assembly.

Work by hand and start to engage the assemblies.

Lower the assembly on to the combustion system.

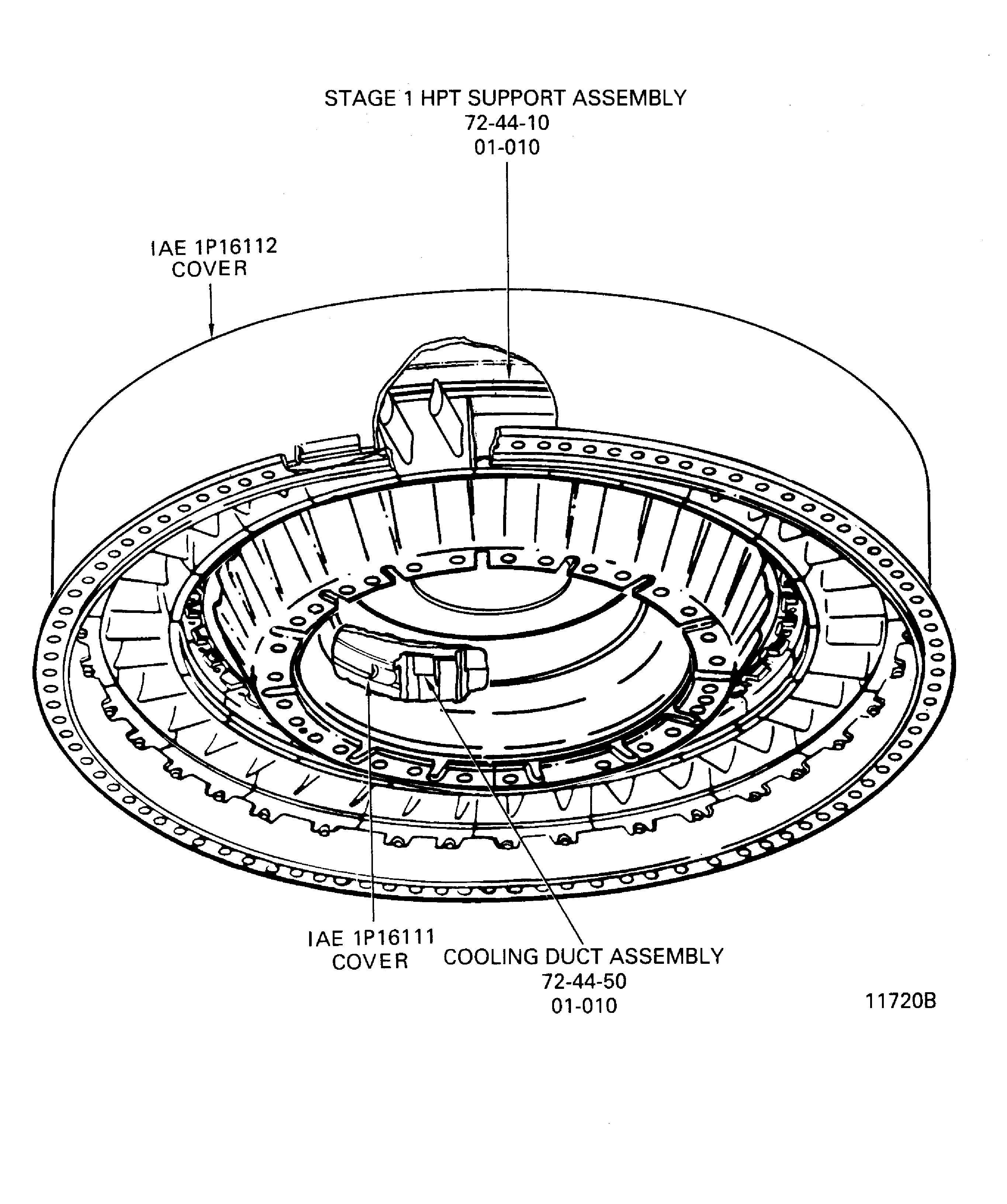

Install the IAE 1P16111 cover 1 off over the cooling duct assembly, Figure.

Install the IAE 1P16112 cover 1 off over the trailing edges of the turbine vane assemblies, Figure.

Install the 30 bolts (02-020) that attach the cooling duct assembly to the diffuser case assembly at the inner flange, Figure.

Measure dimension B, the clearance between the stage 1 HPT Support Assembly and the diffuser case assembly, Figure.

Do a visual check of Dimension A, Figure. the clearance at the front of the inner combustion chamber liner assembly.

Torque the bolts (02-020) to 225 lbfin to 300 lbfin (25.442 Nm to 33.985 Nm). Refer to Figure.or torque sequence.

SUBTASK 72-40-00-430-065 Install the Stage 1 Turbine Nozzle Assembly on the Combustion System,

Refer to Figure.

Install the three hoses of the IAE 1P16087 Air flow adapter 1 off to the three No. 4 bearing cooling air supply tube nuts on the diffuser case.

Connect the IAE 6P16353 Air flow cart 1 off to the air flow adapter.

If the test is in limits, continue the engine build. If the test is not in limits remove the nozzle assembly, refer to TASK 72-40-00-030-002 (DISASSEMBLY-002) and remove the No. 4 bearing compartment parts, refer to TASK 72-40-00-030-004 (DISASSEMBLY-004).

SUBTASK 72-40-00-720-051 Do a Check of the No. 4 Bearing Compartment Cooled Air System

Safety the cooling duct assembly bolts with CoMat 02-141 LOCKWIRE.

Install the IAE 1P16109 cover 1 off on the stage 1 HPT Support Assembly.

SUBTASK 72-40-00-420-051 Safety the Bolts, Remove the Workbolts and Nuts and Remove and Install the Covers

Figure: The IAE 1P16109 Cover Installation

The IAE 1P16109 Cover Installation

Figure: Installation of the Stage 1 Turbine Nozzle Assembly on the IAE 1P16077 Fixture

Installation of the Stage 1 Turbine Nozzle Assembly on the IAE 1P16077 Fixture

Figure: Measure the Spacer Clearance

Measure the Spacer Clearance

Figure: Combustion Chamber Clamp Spacer Installation

Combustion Chamber Clamp Spacer Installation

Figure: Install the Stage 1 Turbine Nozzle Assembly

Install the Stage 1 Turbine Nozzle Assembly

Figure: The IAE 1P16111 and IAE 1P16112 Covers Installation

The IAE 1P16111 and IAE 1P16112 Covers Installation

Figure: Assembly Clearances and Torque Sequence

Assembly Clearances and Torque Sequence

Figure: Stage 1 Turbine Nozzle Assembly Fits and Clearances

Stage 1 Turbine Nozzle Assembly Fits and Clearances

Figure: Combustion Chamber Clamp Spacer Classes

Combustion Chamber Clamp Spacer Classes