Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-23-300-020 HPC Rear Outer Case, Stage 7 Borescope Hole Damage, Weld Repair, Repair-020 (VRS9525)

Effectivity

FIG/ITEM | PART NO. | ASSEMBLY |

|---|---|---|

02-400 | 6A4154 | A |

02-400 | 6A5495 | A |

02-400 | 6A5682 | A |

02-400 | 6A8162 | A |

02-400 | 6B1427 | A |

General

This repair must only be done when the instruction to do so is given in TASK 72-41-23-300-023 (REPAIR-023).

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Remove all details from the part in the damaged area by the applicable repairs. Refer to the V2500 A1/A5 Series EM. | |

| For the lining, follow VRS6179 (REPAIR-002) | TASK 72-41-23-300-002 |

| For the thinwall inserts, follow VRS6306 (REPAIR-019) | TASK 72-41-23-300-019 |

| Make sure that all the cleaning and inspection procedures are done before the repair. |

Support Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-181 WELDING WIRE 12% Cr. STEEL | LOCAL | CoMat 03-181 |

Spares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-31-13-310-501.

Prepare the damage locations for weld.

If welding is not performed within 24 hours, repeat Step

SUBTASK 72-41-23-380-064 Prepare the Part for Repair

Refer to SPM TASK 70-31-13-310-501.

It is recommended to use a fixture and/or chill blocks to prevent distortion.

Weld build up inner diameter surface of holes.

SUBTASK 72-41-23-310-002 Weld Build-Up Damaged HPC Rear Outer Case Stage 7 Borescope Hole(s)

Refer to SPM TASK 70-37-00-370-501.

Heat to a temperature of 1130 deg F (610 deg C) for 60 minutes.

Cool down to room temperature in air or argon environment.

Locally heat-treat the repaired areas.

SUBTASK 72-41-23-370-002 Heat-Treat the HPC Rear Outer Case Stage 7 Borescope Hole(s)

Refer to SPM TASK 70-11-03-300-503.

Clean the HPC Rear Outer Case Stage 7 Borescope Hole(s).

SUBTASK 72-41-23-110-110 Chemically Clean

Hardness must be 334 to 366 HV or equivalent.

Do a hardness check on the surfaces within the heat treated areas, but away from the weld and heat-affected areas. Additionally, the hardness check must be away from the insert holes.

SUBTASK 72-41-23-350-150 Do a Hardness Test

Refer to SPM TASK 70-23-05-230-501.

Use high sensitivity fluorescent penetrant crack inspection.

No cracks are permitted.

Do a local penetrant crack test of the repaired area(s).

SUBTASK 72-41-23-230-253 Do a Local Florescent Penetrant Inspection

Return to Step.

If repaired hole(s) are more than the given limits.

Reject.

If case is distorted.

Visually examine and measure the dimension of the HPC Rear Outer Case Stage 7 Borescope Hole(s).

SUBTASK 72-41-23-220-225 Examine the HPC Rear Outer Case Stage 7 Borescope Hole(s)

Refer to SPM TASK 70-09-00-400-501.

Vibration peen VRS9525 adjacent to the part number.

SUBTASK 72-41-23-350-152 Identify the Repair

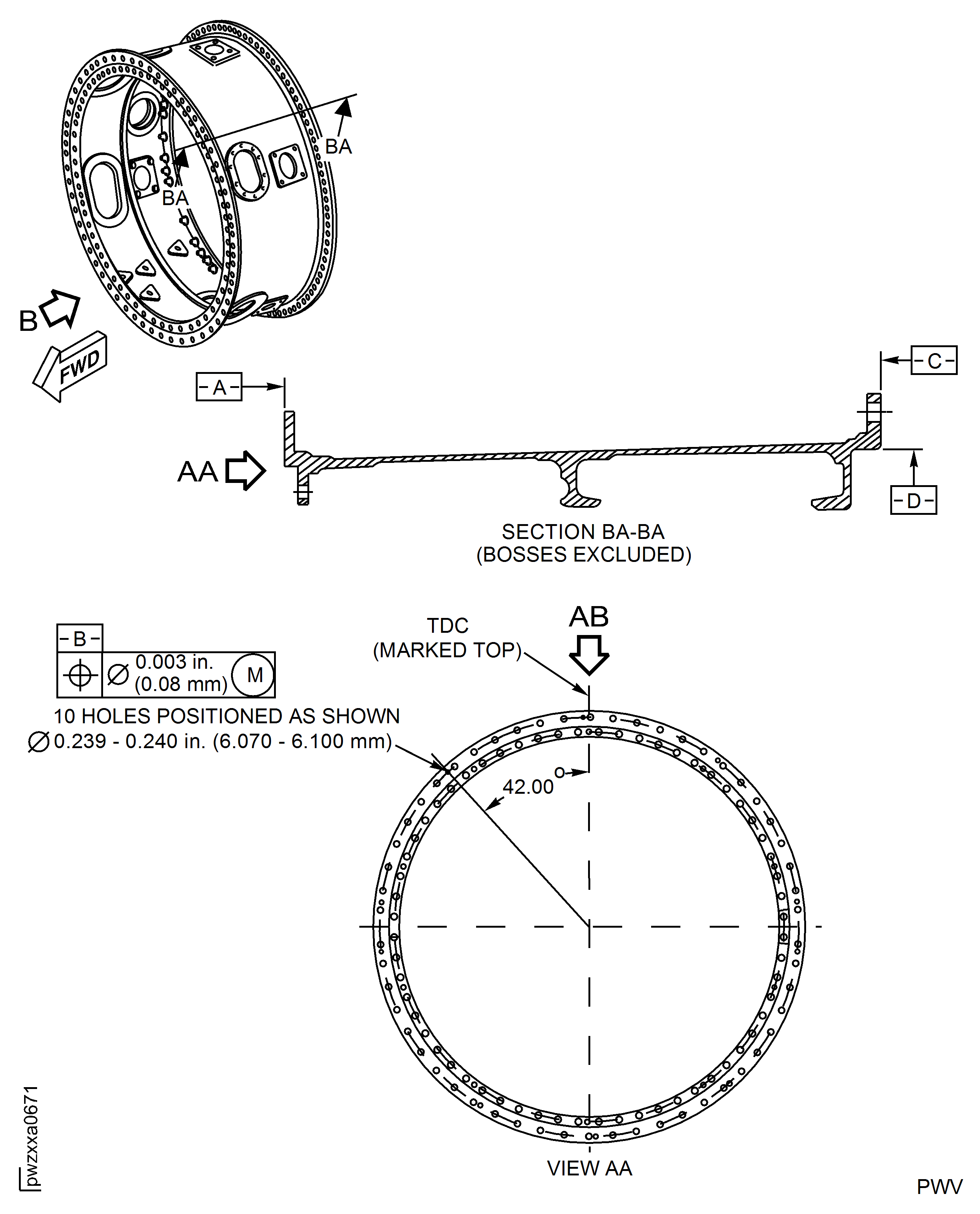

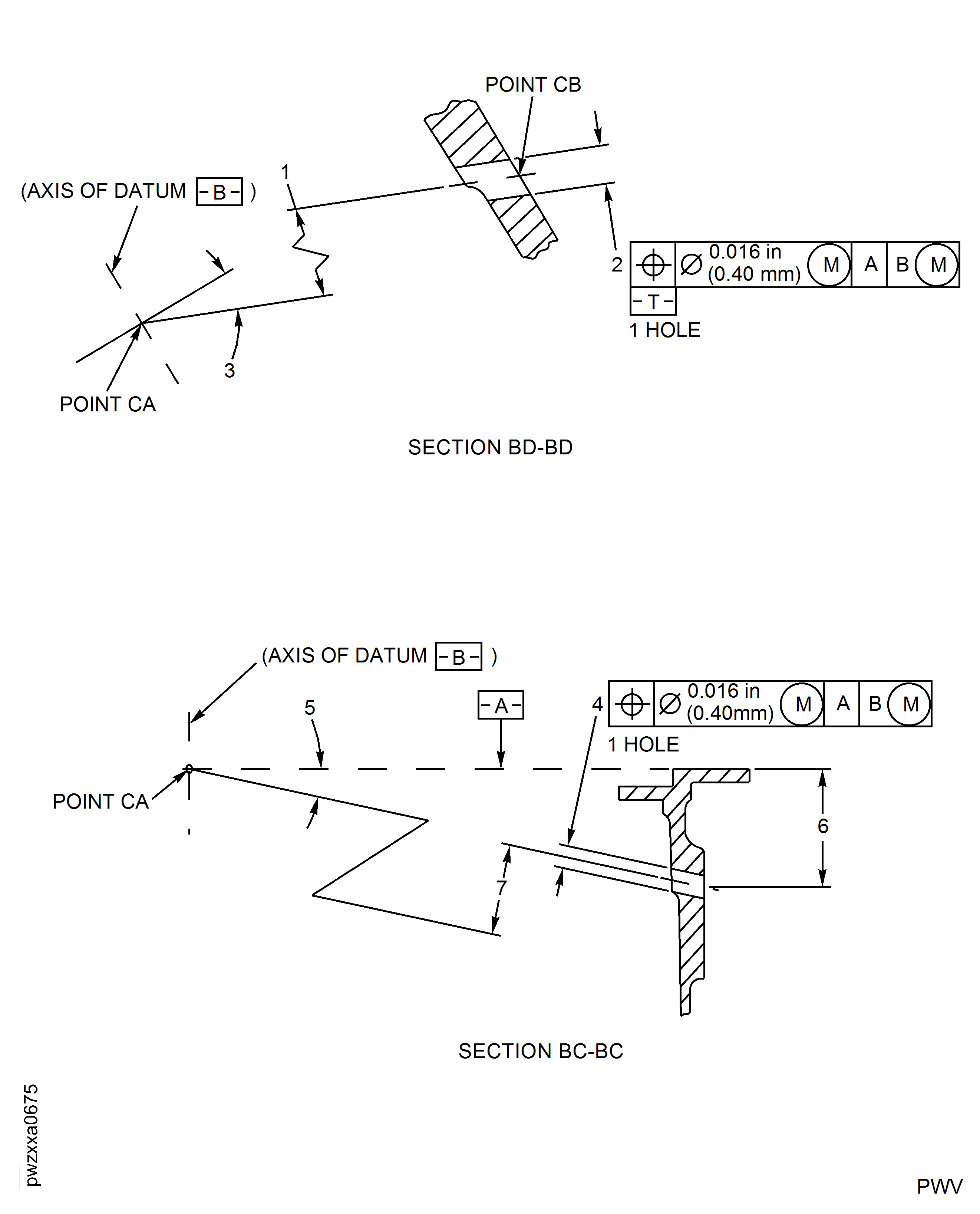

Figure: HPC Rear Outer Case, Stage 7 Borescope Hole Damage, Weld Repair, Repair-020 (VRS9525)

HPC Rear Outer Case, Stage 7 Borescope Hole Damage, Weld Repair, Repair-020 (VRS9525)

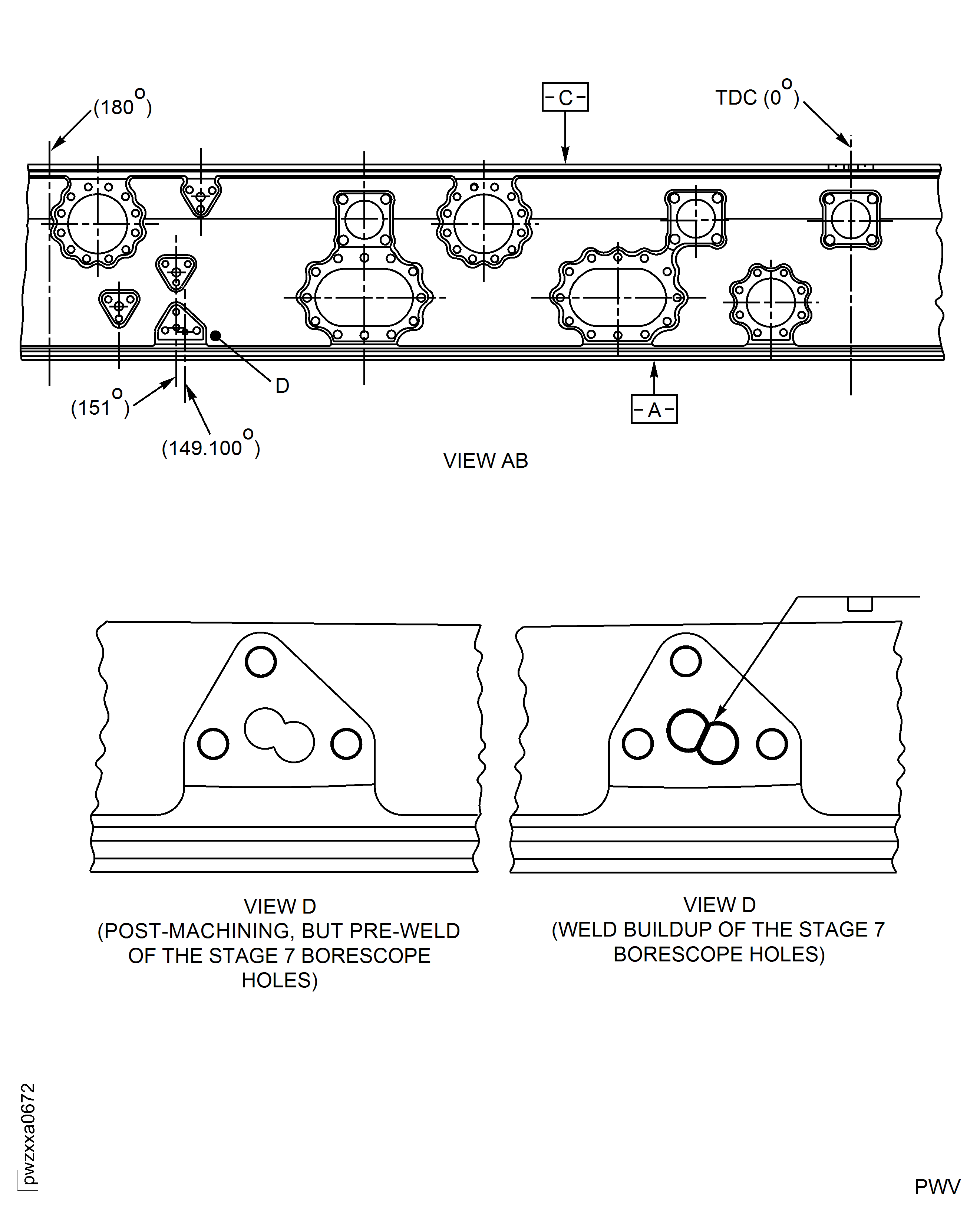

Figure: HPC Rear Outer Case, Stage 7 Borescope Hole Damage, Weld Repair, Repair-020 (VRS9525)

HPC Rear Outer Case, Stage 7 Borescope Hole Damage, Weld Repair, Repair-020 (VRS9525)

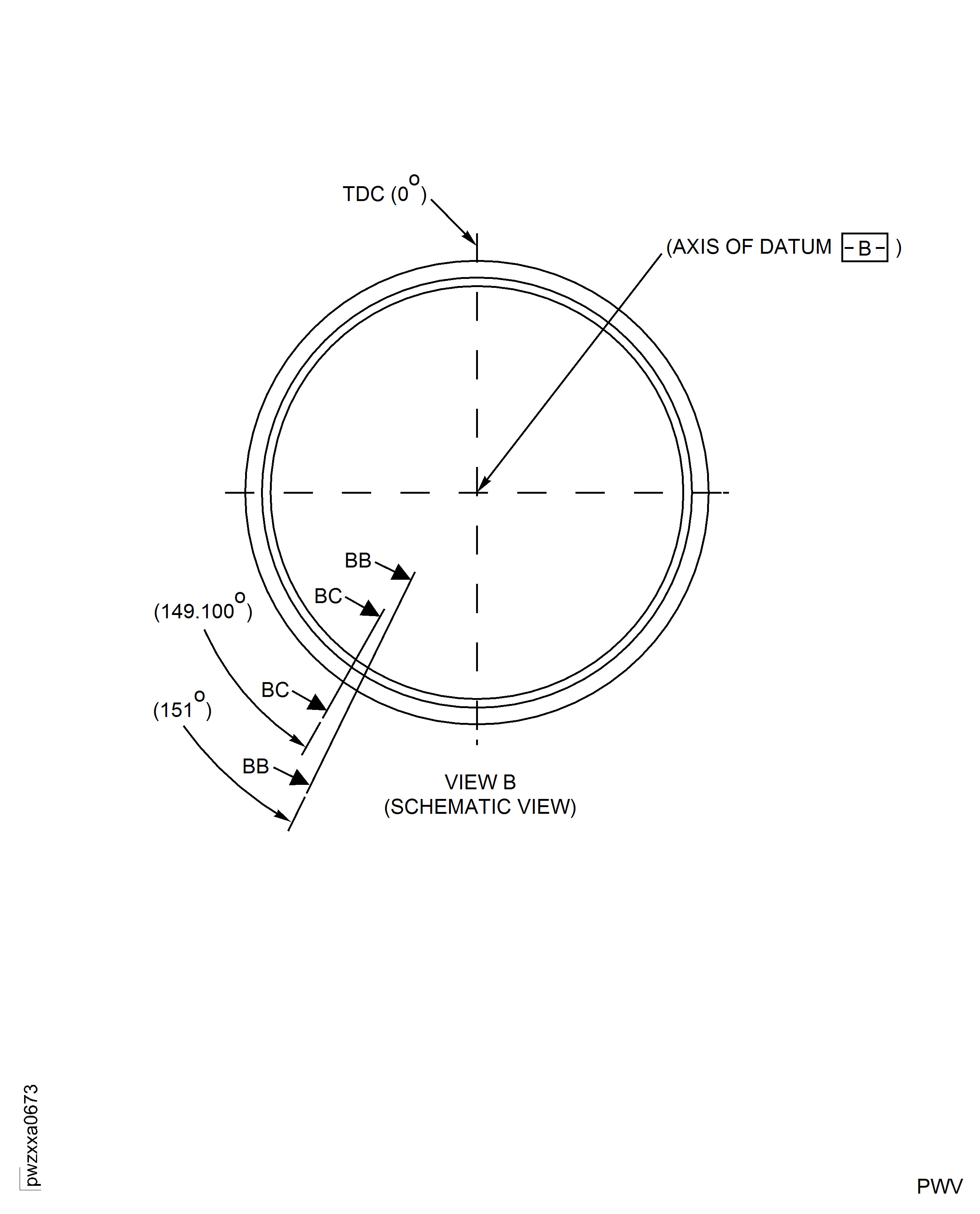

Figure: HPC Rear Outer Case, Stage 7 Borescope Hole Damage, Weld Repair, Repair-020 (VRS9525)

HPC Rear Outer Case, Stage 7 Borescope Hole Damage, Weld Repair, Repair-020 (VRS9525)

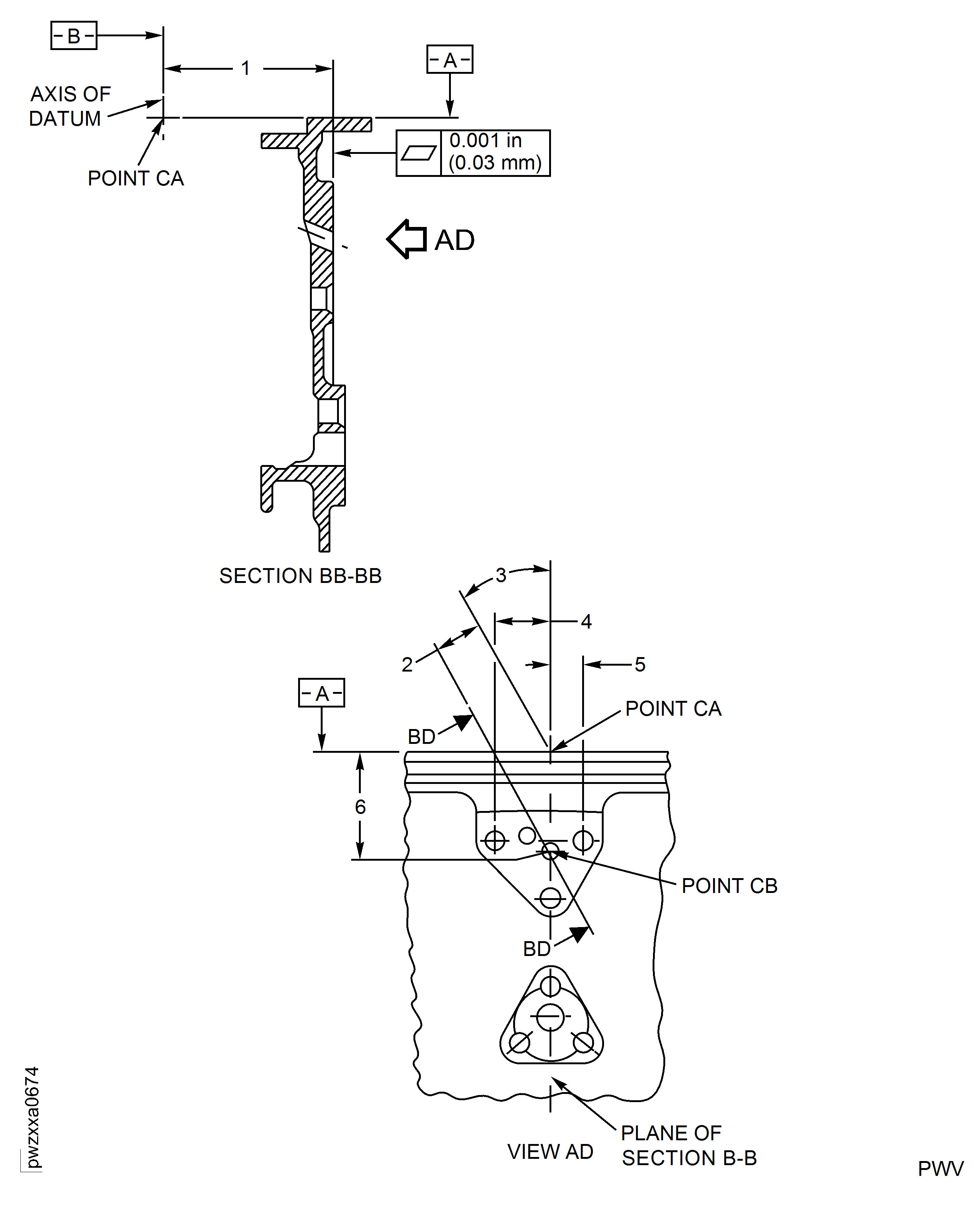

Figure: HPC Rear Outer Case, Stage 7 Borescope Hole Damage, Weld Repair, Repair-020 (VRS9525)

HPC Rear Outer Case, Stage 7 Borescope Hole Damage, Weld Repair, Repair-020 (VRS9525)

Figure: HPC Rear Outer Case, Stage 7 Borescope Hole Damage, Weld Repair, Repair-020 (VRS9525)

HPC Rear Outer Case, Stage 7 Borescope Hole Damage, Weld Repair, Repair-020 (VRS9525)

Requirements After Job Completion

Follow-On Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Replace all details from the part in the damaged area by the applicable repairs. | |

| For the lining, follow VRS6179 (REPAIR-002) | TASK 72-41-23-300-002 |

| For the Thinwall Inserts, follow VRS6306 (REPAIR-019) | TASK 72-41-23-300-019 |

| Apply surface protection coating | TASK 72-41-23-300-003 |