Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-20-300-018 No. 4 Bearing Scavenge Oil Tube Elbow - Weld Repair The Groove Surface Damage, Repair-018 (VRS3656)

General

Price and availability - refer to IAE.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fusion welding equipment | LOCAL | Fusion welding equipment | ||

| Machining equipment | LOCAL | Machining equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-286 WELDING WIRE | LOCAL | CoMat 03-286 |

Spares

NONESafety Requirements

NONEProcedure

Do procedure in SPM TASK 70-33-90-300-503.

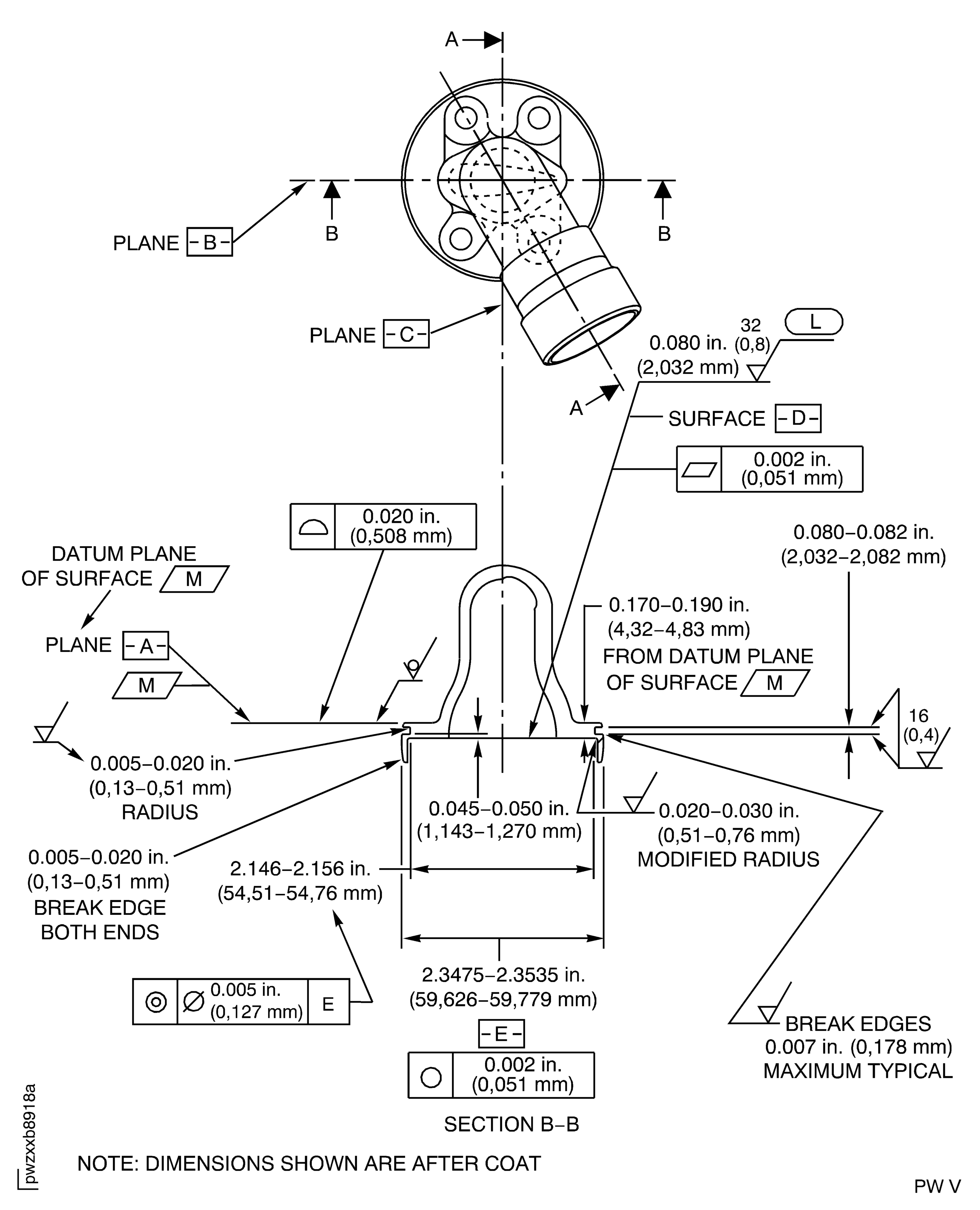

Refer to Figure.

Strip IAE 53-5 coating from repair area.

SUBTASK 72-42-20-320-079 Remove Hardface

Locally machine damaged area as necessary, to remove wear indications or areas of distress. Remove minimum amount of parent material necessary.

SUBTASK 72-42-20-320-080 Machine the Damaged Area

Refer to SPM TASK 70-11-03-300-503.

Clean the elbow.

Refer to SPM TASK 70-11-26-300-503.

Wipe repair area just before you weld it.

SUBTASK 72-42-20-110-128 Clean the Repair Area

Refer to SPM TASK 70-31-13-310-501.

Apply sufficient material to make sure you can meet the finish dimensions.

Manually gas tungsten arc weld repair area.

SUBTASK 72-42-20-310-055 Weld Repair the Worn Area of the Elbow

Refer to SPM TASK 70-37-31-370-501.

Stress-relieve the elbow by SPOP 462.

SUBTASK 72-42-20-370-054 Stress-Relieve the Elbow

Refer to Figure.

Machine repaired area to the finish dimensions

SUBTASK 72-42-20-320-081 Machine the Repaired Area

Refer to SPM TASK 70-11-03-300-503.

Clean elbow after finish machining.

SUBTASK 72-42-20-110-129 Clean the Elbow

Refer to SPM TASK 70-23-01-230-501.

No cracks are permitted.

FPI repaired area of the elbow.

SUBTASK 72-42-20-230-076 Fluorescent Penetrant Inspect the Repaired Area of the Elbow

Refer to SPM TASK 70-34-03-340-501.

Apply IAE 53-5 plasma coating to the elbow.

SUBTASK 72-42-20-340-002 Apply IAE 53-5 Plasma Coating to the Elbow

Refer to Inspection-000 TASK 72-42-20-200-100.

Inspect elbow after repair.

SUBTASK 72-42-20-220-123 Inspect the Elbow

Make a permanent mark by the procedure given in SPM TASK 70-09-00-400-501.

Remove high metal caused by marking the number.

Make a mark VRS3656 on repaired elbow adjacent to the part number.

SUBTASK 72-42-20-350-072 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions