Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-61-300-009 Outer Combustion Chamber Liner - Size Or Roll To Restore The Rear Outside Diameter Seal, Repair-009 (VRS3099)

Effectivity

FIG/ITEM | PART No. |

|---|---|

01-501 | 2A0550-01 |

01-501 | 2A1383 |

01-501 | 2A1385 |

01-501 | 2A1399 |

01-501 | 2A1618 |

01-501 | 2A1620 |

01-501 | 2A1666 |

01-501 | 2A2013 |

01-501 | 2A2032 |

01-501 | 2A2723-01 |

01-501 | 2A2837-01 |

01-501 | 2A3345-01 |

01-501 | 2A3345-001 |

01-501 | 2A3345-002 |

01-501 | 2A3345-003 |

01-501 | 2A3345-004 |

01-501 | 2A3347-01 |

01-501 | 2A3347-001 |

01-501 | 2A3347-002 |

01-501 | 2A3347-003 |

01-501 | 2A3347-004 |

01-501 | 2A3347-005 |

01-501 | 2A3439-01 |

01-501 | 2A3439-001 |

01-501 | 2A3439-002 |

01-501 | 2A3439-003 |

01-501 | 2A3439-004 |

01-501 | 2A3439-005 |

01-501 | 2A3439-006 |

01-501 | 2A3439-007 |

01-501 | 2A3439-008 |

01-501 | 2A3440-01 |

01-501 | 2A3440-001 |

01-501 | 2A3440-002 |

01-501 | 2A3440-003 |

01-501 | 2A3440-004 |

01-501 | 2A3440-005 |

01-501 | 2A3440-006 |

01-501 | 2A3440-007 |

01-501 | 2A3441-01 |

01-501 | 2A3441-001 |

01-501 | 2A3441-002 |

01-501 | 2A3441-003 |

01-501 | 2A3441-004 |

01-501 | 2A3441-005 |

01-501 | 2A3441-006 |

01-501 | 2A3441-007 |

01-501 | 2A3441-008 |

01-501 | 2A3442-01 |

01-501 | 2A3442-001 |

01-501 | 2A3442-002 |

01-501 | 2A3442-003 |

01-501 | 2A3442-004 |

01-501 | 2A3442-005 |

01-501 | 2A3442-006 |

01-501 | 2A3442-007 |

01-501 | 2A3442-008 |

01-501 | 2A4284-01 |

01-501 | 2A4309-01 |

01-501 | 2A4312-01 |

01-501 | 2A4314-01 |

01-501 | 2A4314-001 |

01-520 | 2A2711-01 |

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

Combustion chamber outer liner | - | Wrought non-hardenable |

nickel base alloy |

General

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before this repair. | |

| If you use a chemical removal procedure, all details must be removed by the given repairs: | TASK 72-42-61-300-004 |

| TASK 72-42-61-300-008 | |

| TASK 72-42-61-300-015 | |

| TASK 72-42-61-300-007 | |

| TASK 72-42-61-300-006 |

Support Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 3P16238 Angle box wrench | 0AM53 | IAE 3P16238 | 1 | |

| IAE 3P16239 Ratchet wrench | 0AM53 | IAE 3P16239 | 1 | |

| IAE 3P16240 Igniter guide segment wrench | 0AM53 | IAE 3P16240 | 1 | |

| IAE 3P16241 Ratchet wrench | 0AM53 | IAE 3P16241 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER | 53012 | CoMat 07-175 | ||

| CoMat 10-049 MOLYBDENUM DISULFIDE | 3CU95 | CoMat 10-049 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Safety Requirements

NONEProcedure

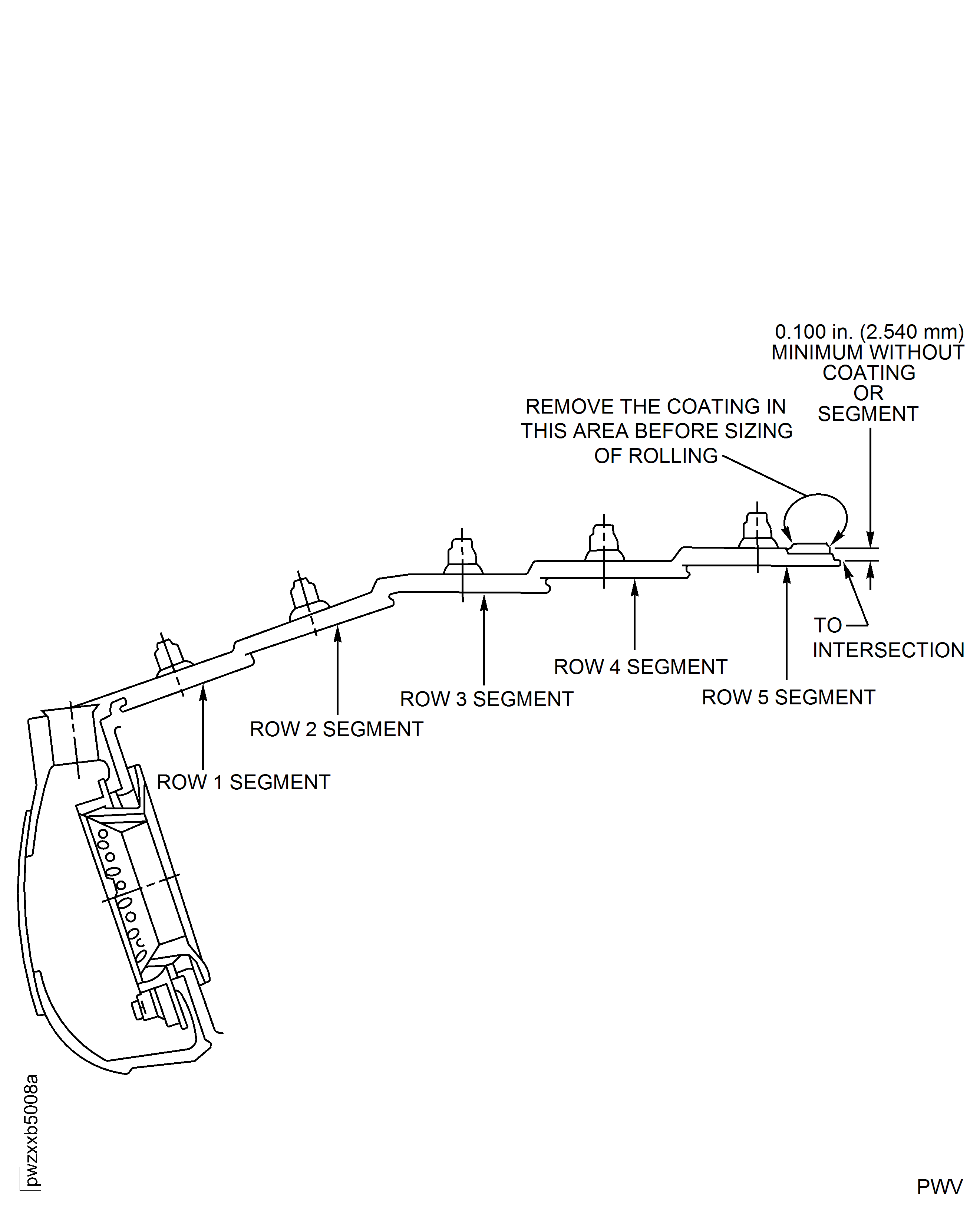

Refer to Figure.

Use IAE 3P16240 Igniter guide segment wrench 1 off to remove the nuts on the liner segments located at the igniters.

Use IAE 3P16241 Ratchet wrench 1 off to remove the nuts at all other locations.

You can use a mechanical nut splitter to remove the nuts instead of a breakaway torque measurement at all other locations.

Loosen the liner segments in Rows 1 and 2 as necessary. Remove and discard the nuts.

SUBTASK 72-42-61-350-077 Remove the Liner Segments in Rows 3, 4 and 5 from the Combustion Chamber Outer Liner

Refer to Figure.

Deleted.

Remove the coating that is on the part by SPM TASK 70-32-07-100-501.

Make sure you remove all the details.

Apply a mask or maskants to all the areas that are not to be removed by SPM TASK 70-38-24-300-503.

Remove the coating that is on the part by chemical removal procedure. Refer to the SPM TASK 70-33-90-300-503.

Remove the coating that is on the part by high pressure water jet. Refer to the SPM TASK 70-15-01-160-501.

Remove the coating that is on the part by one or more of the procedures that follow:

SUBTASK 72-42-61-330-051 Remove the Coating from the Shell of the Combustion Chamber Outer Liner

Clean the part by SPM TASK 70-11-03-300-503.

SUBTASK 72-42-61-110-055 Clean the Combustion Chamber Outer Liner

Do a fluorescent penetrant inspection of the repair area by the SPM TASK 70-23-03-230-501.

Do a fluorescent penetrant inspection of the repair area by the SPM TASK 70-23-08-230-501.

Do a fluorescent penetrant inspection of the repair area by one of the methods that follow. Refer to Figure.

SUBTASK 72-42-61-230-057 Fluorescent Penetrant Inspect the Repair Area

Refer to Figure.

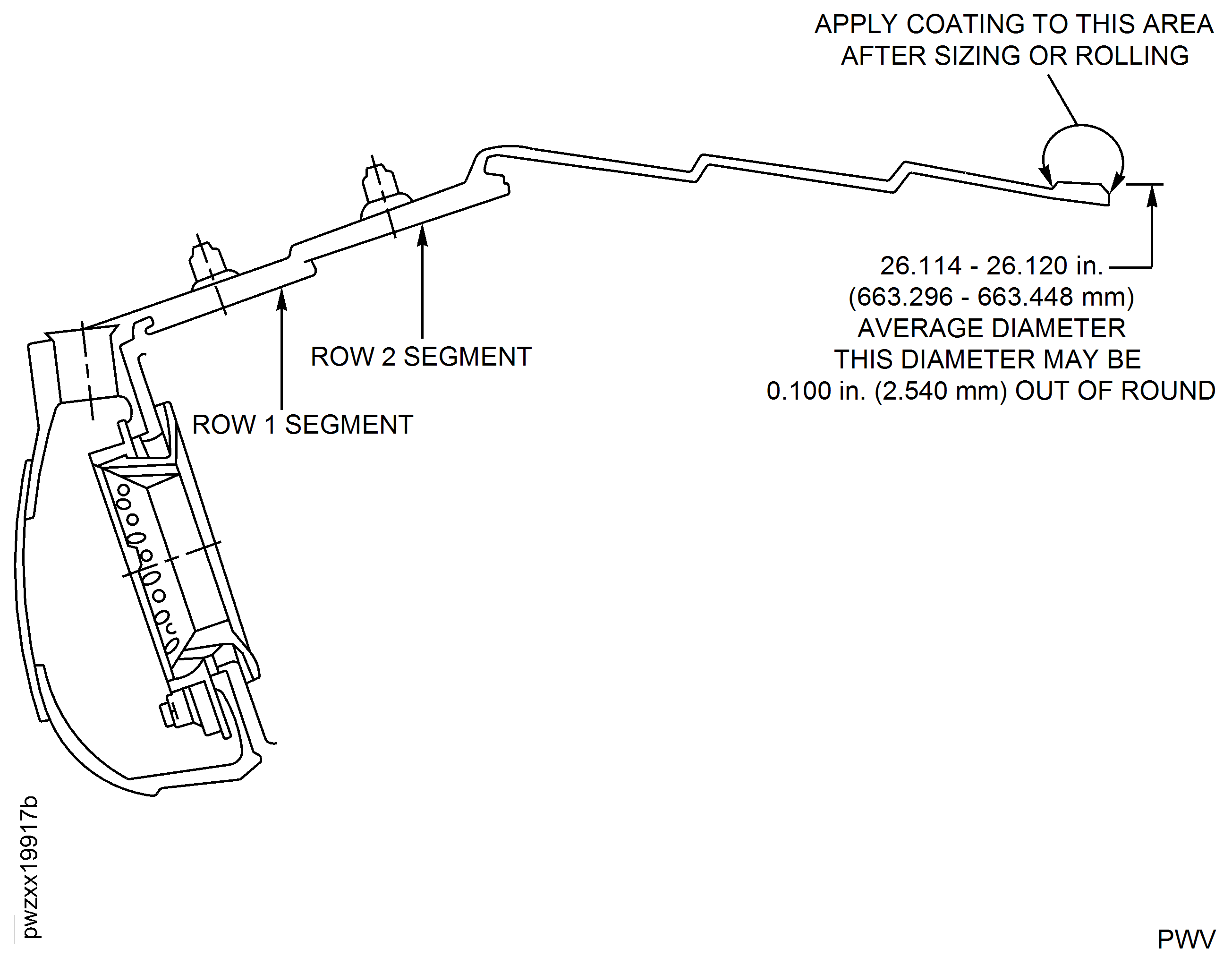

SUBTASK 72-42-61-350-078-001 Size to Restore the Rear Outside Diameter Seal of the Combustion Chamber Outer Liner

Refer to Figure.

SUBTASK 72-42-61-350-078-002 Roll to Restore the Rear Outside Diameter Seal of the Combustion Chamber Outer Liner

Do a fluorescent penetrant inspection of the repair area by the SPM TASK 70-23-03-230-501.

Do a fluorescent penetrant inspection of the repair area by the SPM TASK 70-23-08-230-501.

Fluorescent penetrant inspect the shell and the weld after sizing is completed by one of the methods that follow. Refer to Figure.

SUBTASK 72-42-61-230-053 Examine the Shell and the Weld After Sizing or Rolling

Repair, VRS3100 TASK 72-42-61-300-010 (REPAIR-010).

Apply coat to the shell of the outer liner.

SUBTASK 72-42-61-340-059 Coat the Rear Outside Diameter Seal of the Combustion Chamber Outer Liner

Install oval-shaped washers with dimple facing to the liner shell and seated in slot.

If engine oil is preferred on Rows 2 thru 5 liner segments, apply engine oil on the stud threads. Do not use engine oil on Row 1 liner segment stud threads.

Install the nuts with IAE 3P16238 Angle box wrench 1 off.

Use IAE 3P16240 Igniter guide segment wrench 1 off to install the liner segments at the igniter locations.

Torque the segment's center stud first followed by the two adjacent studs then the segment's two outer-most studs. Tighten nuts down on the stud between 40 to 50 lbfin (4.519 to 5.649 Nm) of torque and make sure that the washer is not free to move. Back the nut off one-half turn, then use IAE 3P16239 Ratchet wrench (ratchet wrench) 1 off to torque the nut to 25 to 35 lbfin (2.824 to 3.954 Nm).

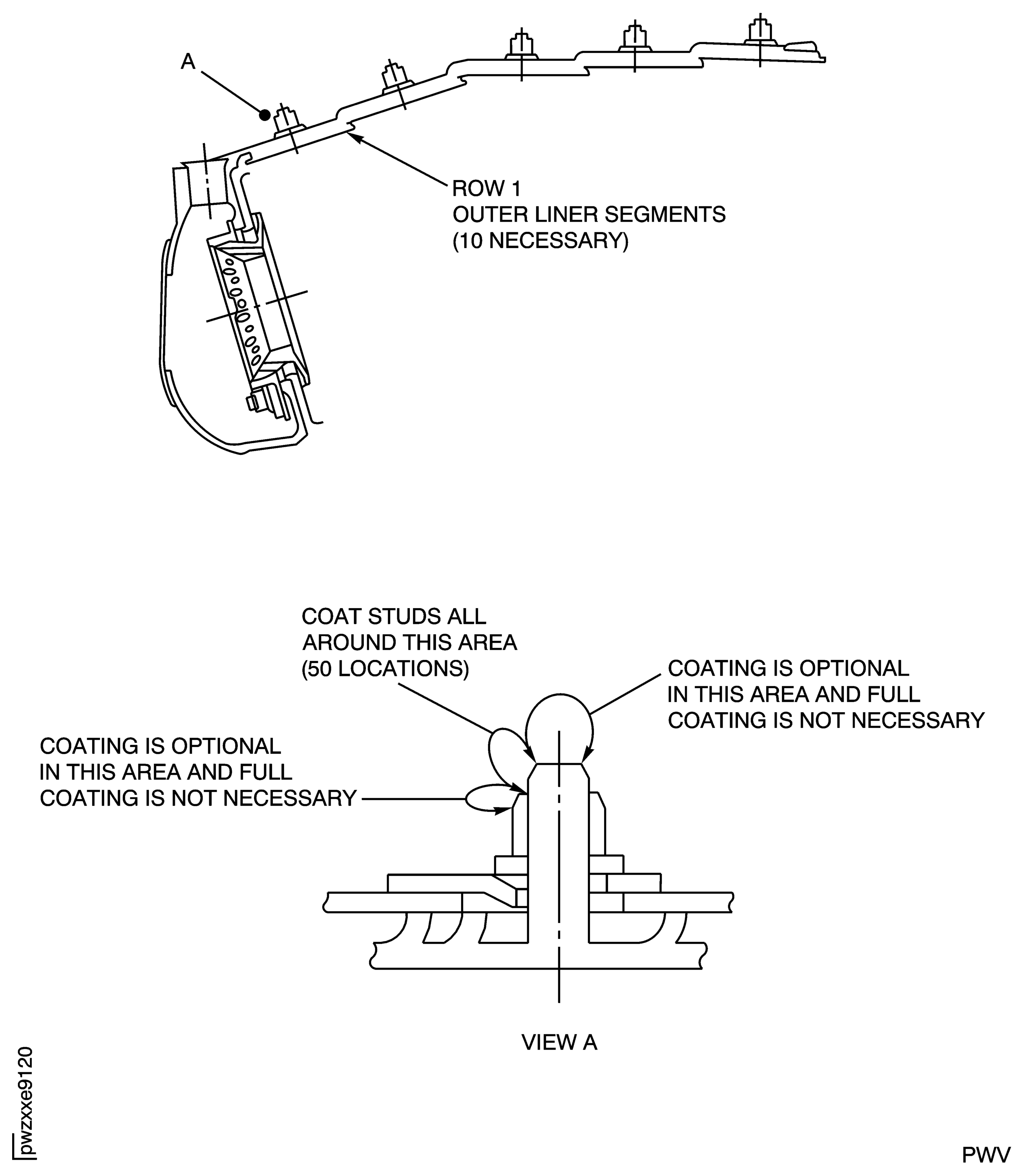

Apply CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER coating compound on the threaded studs of the Row 1 liner segments, you can use a small artist's brush. Full coverage is necessary, but there is no thickness limit. Refer to Figure for coating application.

If engine oil was not used on liner segments Row 2 thru 5, apply CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER on the threaded studs using a small artist's brush. Complete coverage is necessary but there is no thickness requirement. Refer to Figure as a reference for coating application.

CAUTION

DO NOT USE CoMat 10-049 MOLYBDENUM DISULFIDE TO LUBRICATE THE NUT THREADS. MOLYBDENUM DISULFIDE CAN CAUSE CORROSION. ENGINE OIL IS NOT NECESSARY FOR THIS ASSEMBLY PROCESS.

CAUTION

DO NOT USE ENGINE OIL AND COATING CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER ON THE SAME STUDS.

CAUTION

IT IS REQUIRED TO USE COATING CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER ON ROW 1 LINER SEGMENTS AFTER FINAL TORQUE THE NUTS. DO NOT USE COATING CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER ON ALL THE STUD THREADS DURING INSTALLATION.

CAUTION

COATING CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER IS OPTIONAL ON OTHER LINER SEGMENTS (ROWS 2 THRU 5), HOWEVER, DO NOT USE COATING CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER IF ENGINE OIL WAS ALREADY APPLIED ON THE STUD THREADS.

CAUTION

IF COATING CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER WAS USED IN LINER SEGMENTS, LIGHTLY USE A STAINLESS STEEL WIRE BRUSH TO REMOVE LOOSE DEBRIS BEFORE NEW COATING.Install the liner segments in Rows 3, 4 and 5 from back to front with washers and new nuts. Replace the nuts on the segments you loosened in Rows 1 and 2 with new nuts.

SUBTASK 72-42-61-350-079 Install the Liner Segments

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Requirements After Job Completion

Follow-On Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| If removed, all details must be installed by the given repairs: | TASK 72-42-61-300-004 |

| TASK 72-42-61-300-008 | |

| TASK 72-42-61-300-015 | |

| TASK 72-42-61-300-007 | |

| TASK 72-42-61-300-006 |