Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

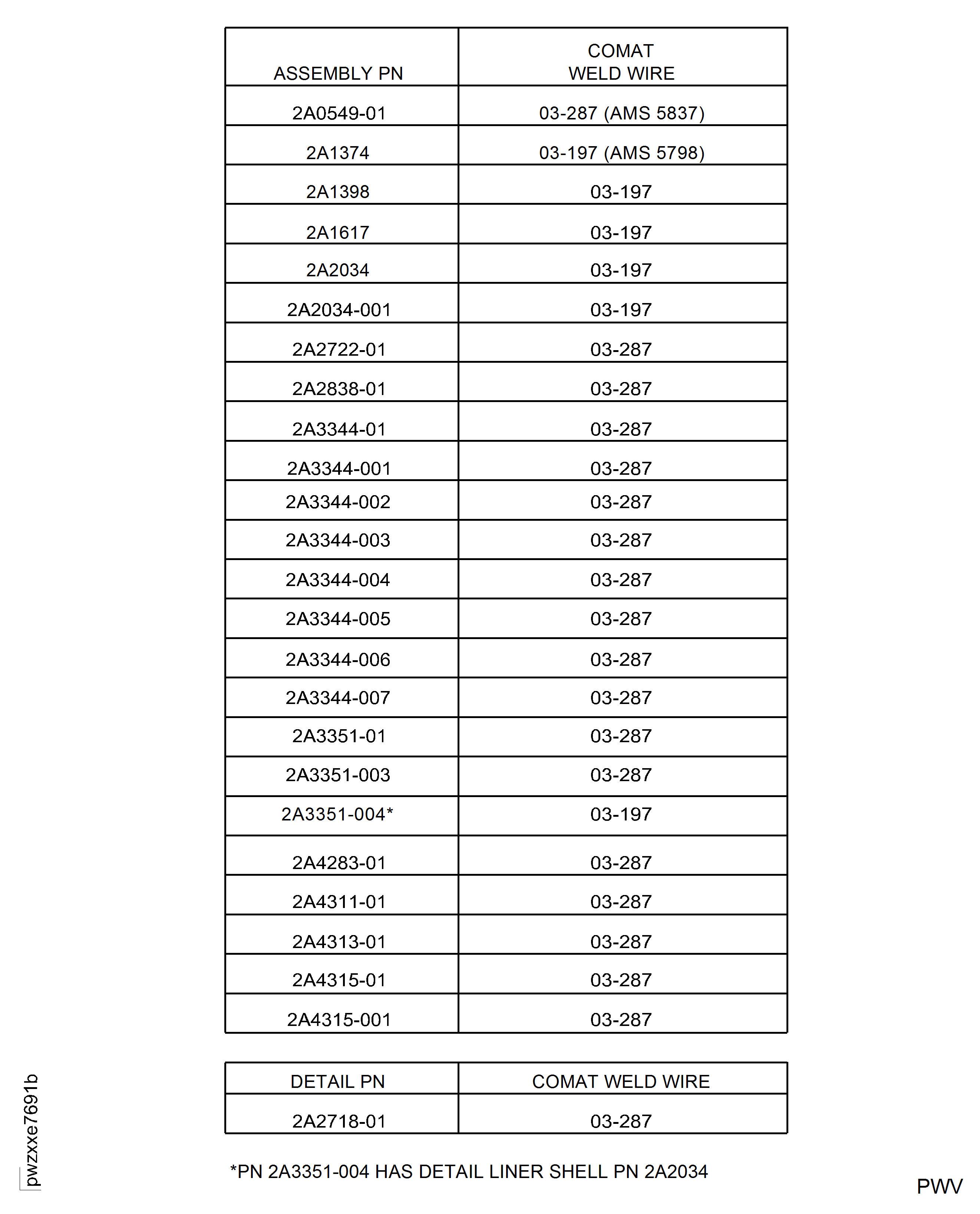

2A0549-01 2A1374 2A1398 2A1617 2A2034 2A2034-001 2A2722-012A2838-01 2A3344-001 2A3344-002 2A3344-003 2A3344-004 2A3344-005 2A3344-0062A3344-007 2A3344-01 2A3351-003 2A3351-004 2A3351-01 2A4283-01 2A4311-012A4313-01 2A4315-001 2A4315-01

Common Information

TASK 72-44-30-300-019 Inner Combustion Chamber Liner - Weld Repair The Rear Flange Holes, Repair-019 (VRS3741)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-401 | 2A0549-01 |

01-401 | 2A1374 |

01-401 | 2A1398 |

01-401 | 2A1617 |

01-401 | 2A2034 |

01-401 | 2A2034-001 |

01-401 | 2A2722-01 |

01-401 | 2A2838-01 |

01-401 | 2A3344-01 |

01-401 | 2A3344-001 |

01-401 | 2A3344-002 |

01-401 | 2A3344-003 |

01-401 | 2A3344-004 |

01-401 | 2A3344-005 |

01-401 | 2A3344-006 |

01-401 | 2A3344-007 |

01-401 | 2A3351-01 |

01-401 | 2A3351-003 |

01-401 | 2A3351-004 |

01-401 | 2A4283-01 |

01-401 | 2A4311-01 |

01-401 | 2A4313-01 |

01-401 | 2A4315-01 |

01-401 | 2A4315-001 |

01-420 | 2A2718-01 |

General

Price and availability - Refer to IAE

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-197 WELDING FILLER WIRE | LOCAL | CoMat 03-197 | ||

| CoMat 03-287 WELDING FILLER WIRE | LOCAL | CoMat 03-287 |

Spares

NONESafety Requirements

NONEProcedure

Refer to VRS3173 TASK 72-44-30-300-001 (REPAIR-001) and VRS3264 V2500-A0-72-44-3001-00A-920A-C (REPAIR-003).

Remove the liner segments and the gangnut channels.

Refer to VRS3170 TASK 72-44-30-300-004 (REPAIR-004).

Remove the plasma spray from the rear flange.

SUBTASK 72-44-30-350-094 Remove the Detail Parts from the Combustion Chamber Inner Liner

Refer to the SPM TASK 70-37-24-370-501 (Cycle 22), except do not use a hydrogen case. Cool by air or faster.

Solution heat treat the combustion chamber liner.

SUBTASK 72-44-30-370-054 For PNs 2A1374, 2A1398, 2A1617, 2A2034 and 2A2034-001: Solution Heat Treat the Combustion Chamber Liner

Refer to the SPM TASK 70-23-03-230-501 or SPM TASK 70-23-08-230-501. Use high sensitivity.

Fluorescent penetrant inspect the liner.

SUBTASK 72-44-30-230-057 For PNs 2A1374, 2A1398, 2A1617, 2A2034 and 2A2034-001: Examine the Damaged Combustion Chamber Inner Liner

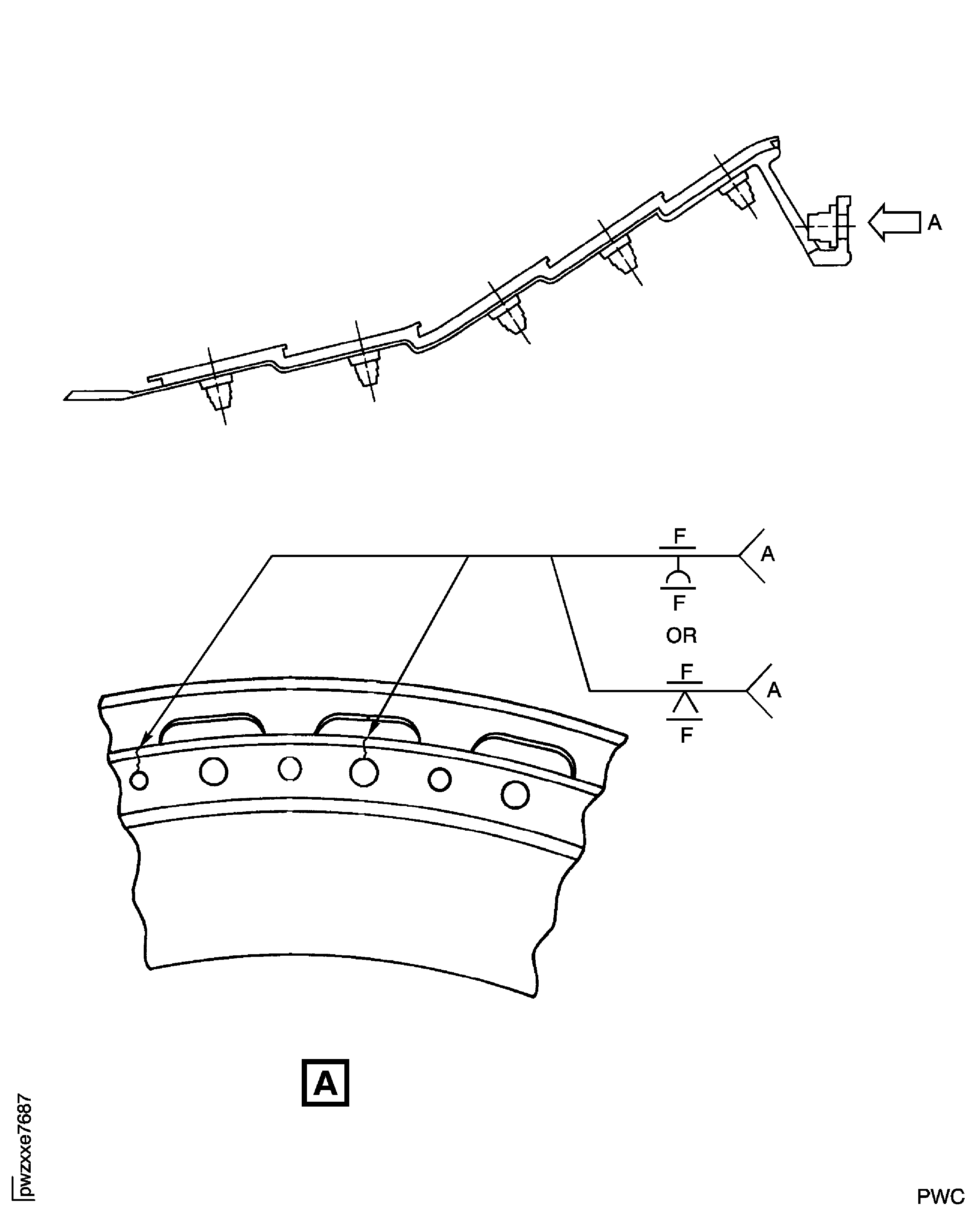

Refer to Figure.

SUBTASK 72-44-30-320-001 For All PNs: Rout Out Cracks in the Rear Flange

Refer to the SPM TASK 70-11-26-300-503.

Wipe the repair area with isopropyl alcohol.

SUBTASK 72-44-30-110-054 Clean the Repair Areas

Refer to Figure.

Refer to the SPM TASK 70-31-13-310-501, IAE 16-3.

Use the applicable CoMat welding filler wire listed in Figure.

Weld repair the prepared areas.

SUBTASK 72-44-30-310-053 Weld Repair the Combustion Chamber Inner Liner Rear Flange Hole Cracks

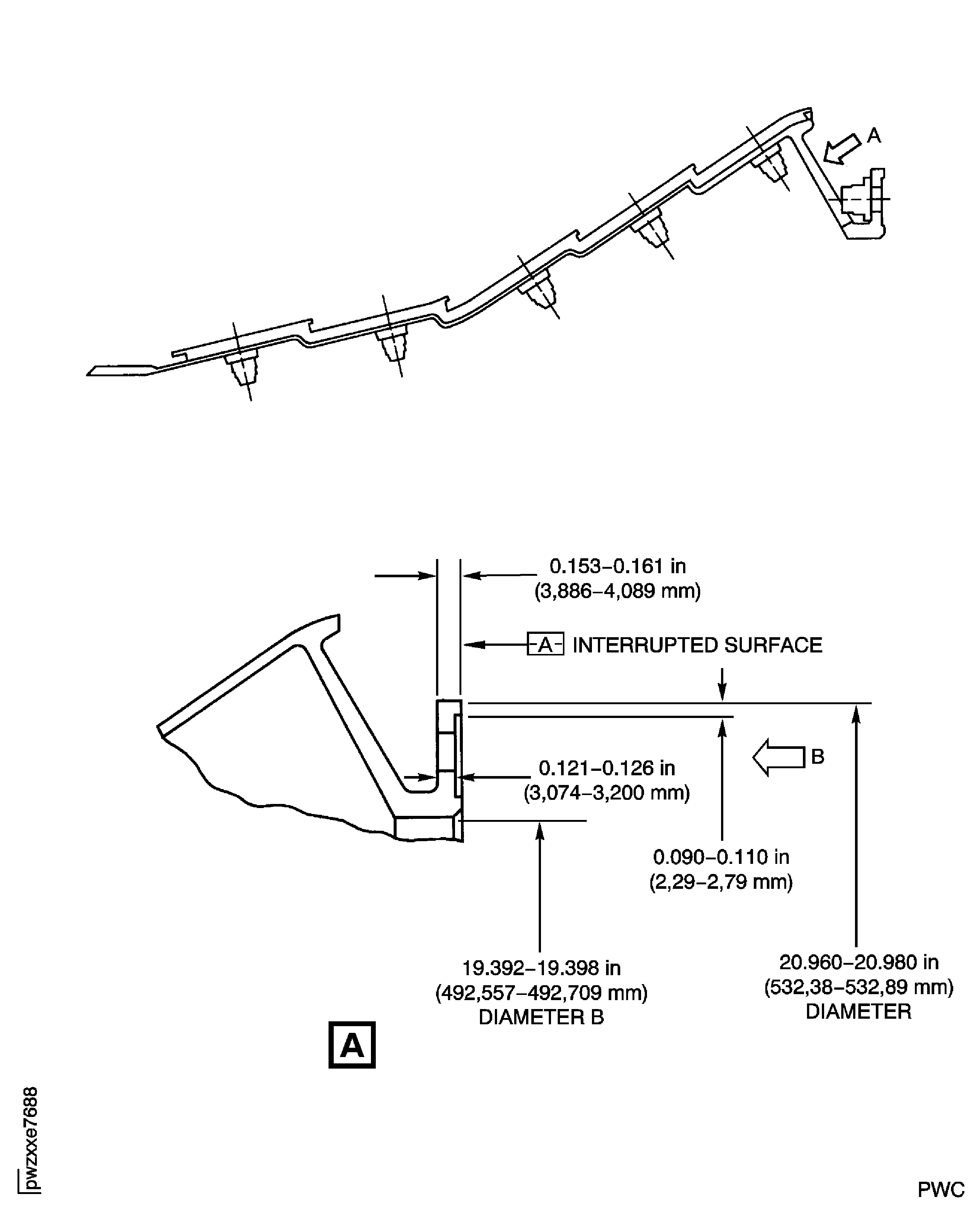

Refer to Figure.

If necessary, size the diameter of the rear inner liner by Repair, VRS3628 TASK 72-44-30-300-017 (REPAIR-017).

Inspect the diameter of the rear inner liner.

SUBTASK 72-44-30-220-088 Inspect the Diameter of the Rear Inner Liner

Refer to the SPM TASK 70-37-24-370-501 (Cycle 22), except hydrogen is not permitted. Air cool or faster.

Solution heat treat the combustion chamber inner liner.

SUBTASK 72-44-30-370-055-A00 For PNs 2A1374, 2A1398, 2A1617, 2A2034, 2A2034-001 and 2A3351-004: Solution Heat Treat the Combustion Chamber Inner Liner

SPM TASK 70-37-16-370-501 (Cycle 10). Use argon or a vacuum. Air cool or faster.

Or.

SPM TASK 70-37-24-370-501 (Cycle 22), except hydrogen is not permitted. Air cool or faster.

Refer to one of the TASKs that follow:

Heat treat the combustion chamber inner liner.

SUBTASK 72-44-30-370-055-B00 For PNs 2A0549-01, 2A2722-01, 2A2838-01, 2A3344-01, 2A3344-001, 2A3344-002, 2A3344-003, 2A3344-004, 2A3344-005, 2A3344-006, 2A3344-007, 2A3351-01, 2A3351-003, 2A4283-01, 2A4311-01, 2A4313-01, 2A4315-01, 2A4315-001 and 2A2718-01: Heat Treat the Combustion Chamber Inner Liner

Refer to the SPM TASK 70-23-03-230-501 or SPM TASK 70-23-08-230-501. Use high sensitivity.

Fluorescent penetrant inspect the areas that you welded.

SUBTASK 72-44-30-230-058 Fluorescent Penetrant Inspect the Combustion Chamber Inner Liner

Repair, VRS3170 TASK 72-44-30-300-004 (REPAIR-004).

Replace the plasma spray on the rear flange.

SUBTASK 72-44-30-370-056 Replace the Plasma Spray on the Rear Flange

Refer to TASK 72-44-30-200-000 (INSPECTION/CHECK-000).

Inspect the hardcoat of the front outside diameter seal and the inner liner.

SUBTASK 72-44-30-220-089 Examine the Hardcoat on the Front Outside Diameter Seal and the Combustion Chamber Inner Liner

Refer to VRS3173 TASK 72-44-30-300-001 (REPAIR-001) and VRS3264 V2500-A0-72-44-3001-00A-920A-C (REPAIR-003).

Install the liner segments and the gangnut channels.

SUBTASK 72-44-30-350-095 Install the Detail Parts to the Combustion Chamber Inner Liner

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

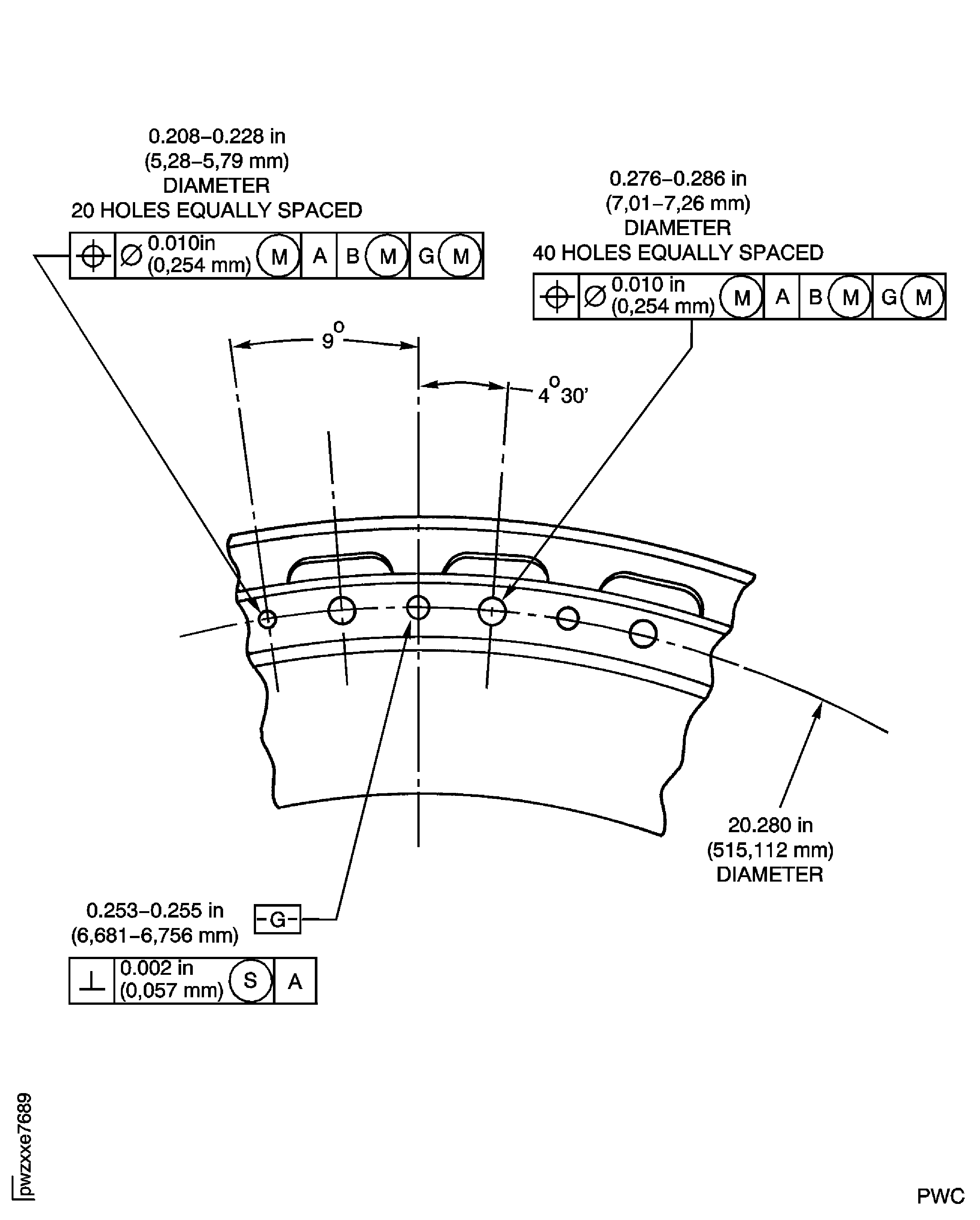

Figure: Repair Details and Dimensions

Repair Details and Dimensions