Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-32-300-002 HPT Stage 2 Blade - Touch-Up The Coating, Repair-002 (VRS3242)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-010 | 2A1102-002 |

01-010 | 2A2202 |

01-010 | 2A2202-001 |

01-010 | 2A2202-002 |

01-010 | 2A2202-003 |

01-010 | 2A2702 |

01-010 | 2A2702-001 |

01-010 | 2A4422 |

01-010 | 2A4722 |

01-010 | 2A4822 |

01-010 | 2A8702 |

01-010 | 2A8902 |

01-010 | 2A9002 |

General

The blade assembly blend limits are looked at by the serviceable structure of the blade. If you have many repaired blades in the same turbine assembly at or near the maximum repair limits or that have repair areas, they can affect the turbine efficiency and engine performance.

CoMat 07-057 SLURRY, ALUMINIUM-SILICON or CoMat 02-183 ALUMINIDE COATING - LOCALIZED APPLICATION, LOW ACTIVITY can be used to repair the stage 2 HPT blade assembly to touch-up coating.

This repair must only be done when there is no oxidation or corrosion shown on the base material.

Do not use CoMat 07-057 SLURRY, ALUMINIUM-SILICON and CoMat 02-183 ALUMINIDE COATING - LOCALIZED APPLICATION, LOW ACTIVITY or this repair when you replace all the primary coating on the blade.

The practices and processes referred to in the procedure by TASK number are in the SPM.

Price and availability - none

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-183 ALUMINIDE COATING - LOCALIZED APPLICATION, LOW ACTIVITY | IAE86 | CoMat 02-183 | ||

| CoMat 05-029 CAST STEEL SHOT, S110 | LOCAL | CoMat 05-029 | ||

| CoMat 05-032 CAST STEEL SHOT, S170 | 42736 | CoMat 05-032 | ||

| CoMat 05-138 SHOT, CAST STEEL, S110 | 81349 | CoMat 05-138 | ||

| CoMat 05-176 CAST STEEL SHOT, S170 | 42736 | CoMat 05-176 | ||

| CoMat 05-177 CUT WIRE SHOT,CW-14 | LOCAL | CoMat 05-177 | ||

| CoMat 05-178 CUT WIRE SHOT, CW-20 | LOCAL | CoMat 05-178 | ||

| CoMat 05-234 CAST STEEL SHOT, HIGH HARDNESS, S110 | LOCAL | CoMat 05-234 | ||

| CoMat 07-057 SLURRY, ALUMINIUM-SILICON | 0FGH2 | CoMat 07-057 | ||

| DELETED | LOCAL | DELETED |

Spares

NONESafety Requirements

NONEProcedure

Refer to VRS3361, TASK 72-45-32-300-008 (REPAIR-008).

Remove the blade root cover.

SUBTASK 72-45-32-350-059 Remove the Stage 2 HPT Blade Assembly Root Cover

Refer to the Heat Tint Inspection in TASK 72-45-32-200-001-A00 (INSPECTION-001, CONFIG-001) or TASK 72-45-32-200-001-B00 (72-45-32-200-001-B00 (INSPECTION-001, CONFIG-002).

Do a heat tint inspection on the blade assembly.

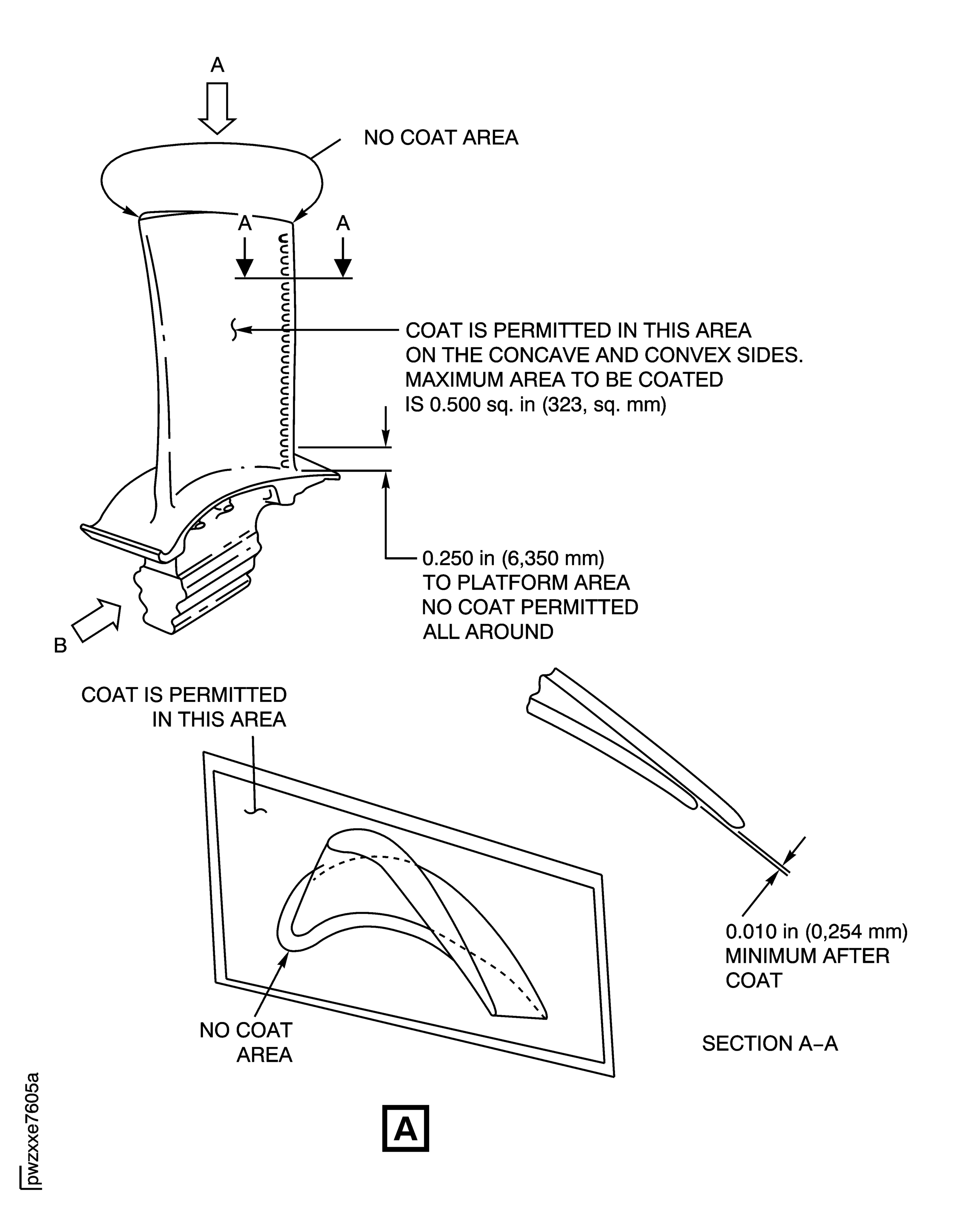

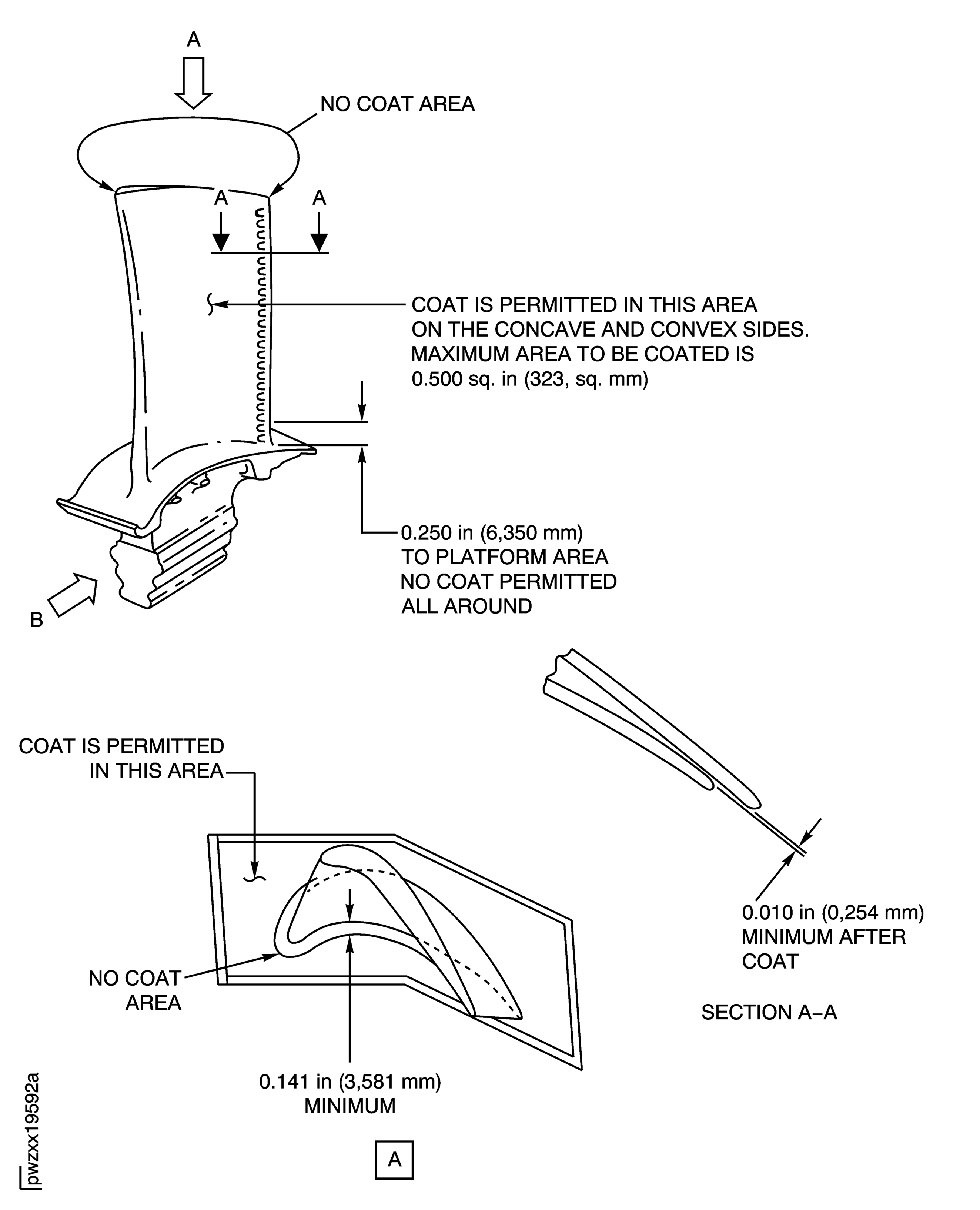

The total maximum blade area to be touch-up coated on the airfoil concave and convex sides is 0.500 sq in. (3.23 sqcm).

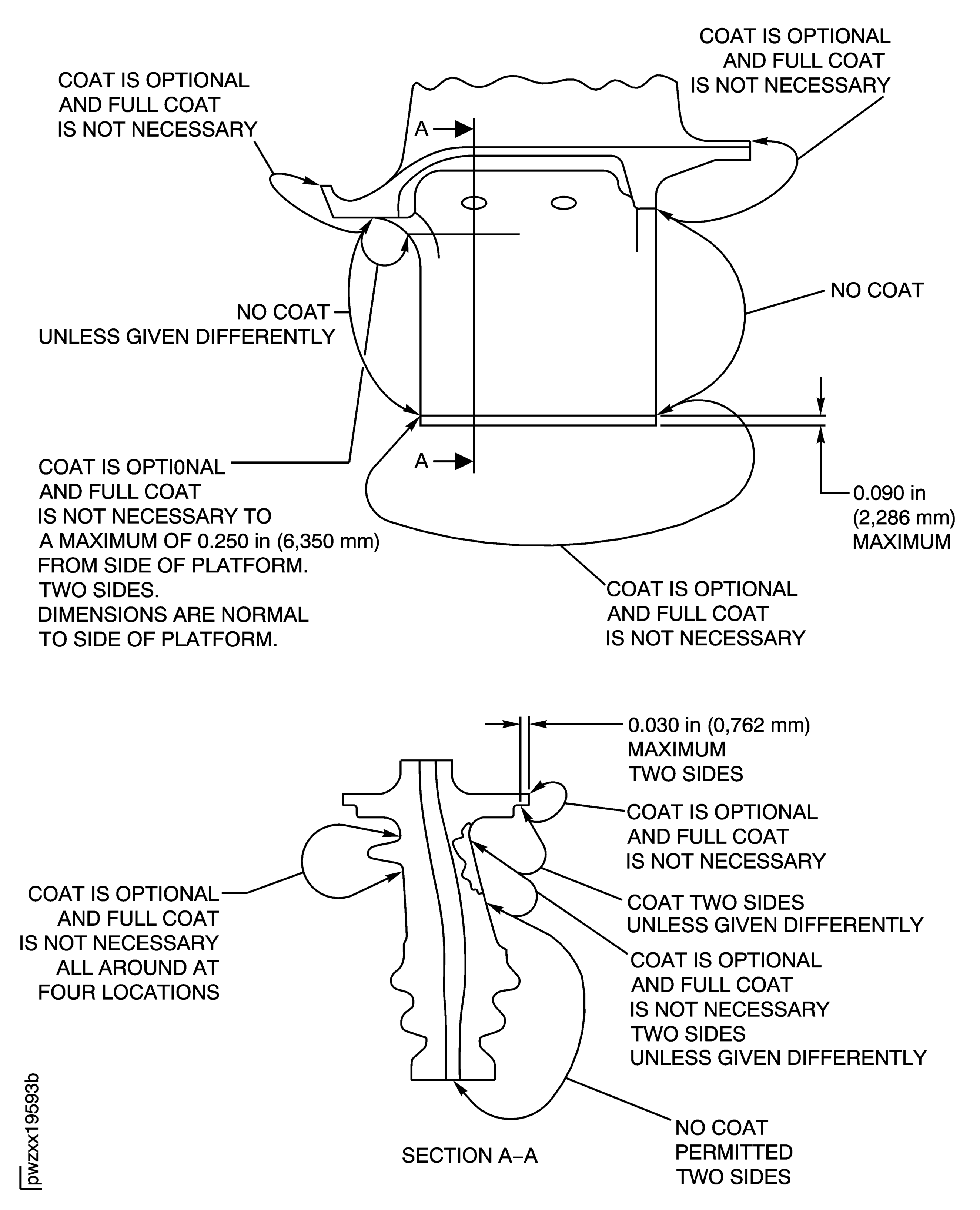

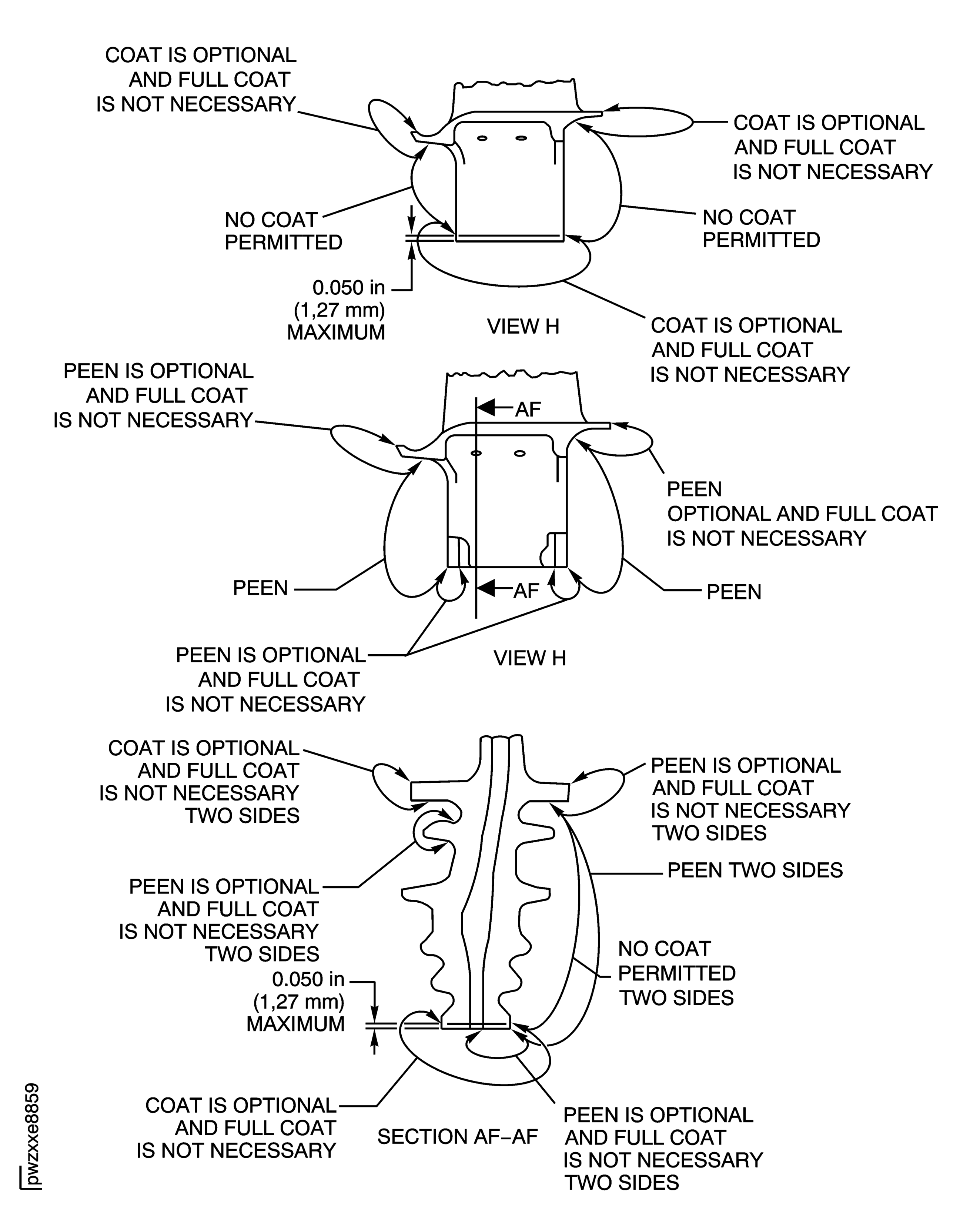

You can touch-up coat the platform areas given in the figure.

Do the procedure given in the SPM TASK 70-38-14-380-501.

Prepare and touch-up the blade assembly coating.

Do the procedure given in the SPM TASK 70-38-13-380-501.

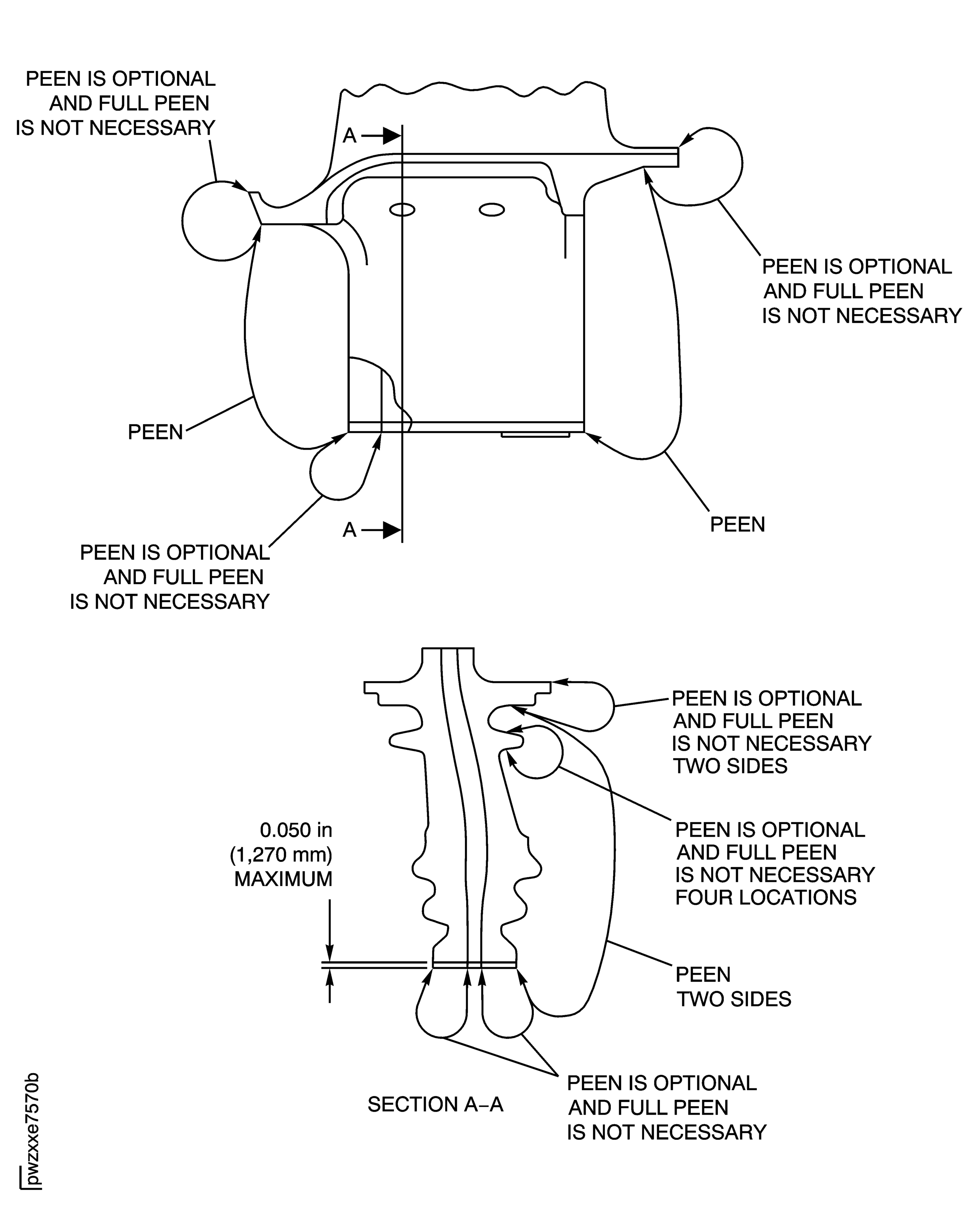

Use CoMat 05-029 CAST STEEL SHOT, S110, CoMat 05-032 CAST STEEL SHOT, S170, CoMat 05-138 SHOT, CAST STEEL, S110, CoMat 05-176 CAST STEEL SHOT, S170, CoMat 05-234 CAST STEEL SHOT, HIGH HARDNESS, S110 or CoMat 05-177 CUT WIRE SHOT,CW-14, CoMat 05-178 CUT WIRE SHOT, CW-20. Peen with an intensity of 6A. Refer to the SPM TASK 70-38-13-380-501, SUBTASK 70-38-13-380-006.

Shot peen the blade root area.

If the heat tint inspection is unsatisfactory, do the touch-up coating repair again.

Refer to the Heat Tint Inspection in TASK 72-45-32-200-001-A00 (INSPECTION-001, CONFIG-001) or TASK 72-45-32-200-001-B00 (INSPECTION-001, CONFIG-002).

Do a heat tint inspection on the repaired blade assembly.

For PN 2A2202, 2A2202-001, 2A2202-002, 2A2202-003, Precipitation Heat Treat at 1600 deg F (871.1 deg C) for 32 hours. Refer to the SPM TASK 70-37-27-370-501.

For PN 2A1102-002, 2A2702, 2A2702-001, 2A4422, 2A4722, 2A4822, 2A8702, 2A8902, 2A9002, Precipitation Heat Treat at 1600 deg F (871.1 deg C) for eight or 12 hours. Refer to the SPM TASK 70-37-27-370-501.

Do a precipitation heat treat on the repaired blade.

Replace the blade root cover. Refer to VRS3361, TASK 72-45-32-300-008 (REPAIR-008).

Replace the blade root cover.

Refer to TASK 72-45-32-200-001-A00 (INSPECTION-001, CONFIG-001) or TASK 72-45-32-200-001-B00 (INSPECTION-001, CONFIG-002).

Do an airflow check on the blade assembly.

Make a permanent mark, Refer to the SPM TASK 70-09-00-400-501.

Identify the repair. Make a mark VRS3242 adjacent to the part number, if necessary.

SUBTASK 72-45-32-350-053-001 Touch-Up the Stage 2 HPT Blade Assembly Coating with CoMat 07-057 Aluminum-Silicon Slurry

Refer to the Heat Tint Inspection in TASK 72-45-32-200-001-A00 (INSPECTION-001, CONFIG-001) or TASK 72-45-32-200-001-B00 (INSPECTION-001, CONFIG-002).

Do a heat tint inspection on the blade assembly.

The total maximum blade area to be touch-up coated on the airfoil concave and convex sides is 0.500 sqin. (3.23 sqcm).

You can touch-up coat the platform areas given in the figure.

Do the procedure given in the SPM TASK 70-38-26-380-501.

Prepare and touch-up the blade assembly coating.

Do the procedure given in the SPM TASK 70-38-13-380-501.

Use CoMat 05-029 CAST STEEL SHOT, S110, CoMat 05-032 CAST STEEL SHOT, S170, CoMat 05-138 SHOT, CAST STEEL, S110, CoMat 05-176 CAST STEEL SHOT, S170, CoMat 05-234 CAST STEEL SHOT, HIGH HARDNESS, S110 or CoMat 05-177 CUT WIRE SHOT,CW-14, CoMat 05-178 CUT WIRE SHOT, CW-20. Peen with an intensity of 6A. Refer to the SPM TASK 70-38-13-380-501, SUBTASK 70-38-13-380-006.

Shot peen the blade root area.

Refer to the Heat Tint Inspection in TASK 72-45-32-200-001-A00 (INSPECTION-001, CONFIG-001) or TASK 72-45-32-200-001-B00 (INSPECTION-001, CONFIG-002).

If heat tint inspection is unsatisfactory, do the touch-up coating repair again.

Do a heat tint inspection on the repaired blade assembly.

For PN 2A2202, 2A2202-001, 2A2202-002, 2A2202-003, Precipitation Heat Treat at 1600 deg F (871.1 deg C) for 32 hours. Refer to the SPM TASK 70-37-27-370-501.

For PN 2A1102-002, 2A2702, 2A2702-001, 2A4422, 2A4722, 2A4822, 2A8702, 2A8902, 2A9002, Precipitation Heat Treat at 1600 deg F (871.1 deg C) for eight or 12 hours. Refer to the SPM TASK 70-37-27-370-501.

Do a precipitation heat treat on the repaired blade.

Replace the blade root cover. Refer to VRS3361, TASK 72-45-32-300-008 (REPAIR-008).

Replace the blade root cover.

Refer to TASK 72-45-32-200-001-A00 (INSPECTION-001, CONFIG-001) or TASK 72-45-32-200-001-B00 (INSPECTION-001, CONFIG-002).

Do an airflow check on the blade assembly.

Make a permanent mark, Refer to the SPM TASK 70-09-00-400-501.

Identify the repair. Make a mark VRS3242 adjacent to the part number, if necessary.

SUBTASK 72-45-32-350-054-002 Touch-Up the Stage 2 HPT Blade Assembly Coating with CoMat 02-183 Cobalt-Aluminum Slurry

Figure: V2500-A1: Repair Details and Dimensions

Sheet 1

Figure: V2500-A1: Repair Details and Dimensions

Sheet 2

Figure: V2500-A1: Repair Details and Dimensions

Sheet 3

Figure: V2500-A5: Repair Details and Dimensions

Sheet 1

Figure: V2500-A5: Repair Details and Dimensions

Sheet 2