Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-32-200-001-B00 HPT Stage 2 Blade - Examine, Inspection-001

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-010 | 2A2202 |

01-010 | 2A2202-001 |

01-010 | 2A2202-002 |

01-010 | 2A2202-003 |

01-010 | 2A2702 |

01-010 | 2A2702-001 |

01-010 | 2A8702 |

01-010 | 2A9002 |

01-010 | 2A4722 |

General

This TASK gives the procedure for the inspection of the stage 2 HPT blade assembly. For the other stage 2 HPT blade assembly parts, refer to TASK 72-45-32-200-000 (INSPECTION-000).

Fig/item numbers in parentheses in the procedure agree with those used in the IPC.

The policy that is necessary for inspection is given in SPM TASK 70-20-00-200-501.

All the parts must be cleaned before any part is examined. Refer to SPM TASK 70-10-00-100-501.

All parts must be visually examined for damage, corrosion and wear. Any defects that are not identified in the procedure must be referred to IAE.

The procedure for those parts which must have a crack test is given in SUBTASK 72-45-32-230-053-001. Do the test for cracks only if the visual examination of the blade is unsatisfactory.

Do not discard any part until you are sure there are no repairs available. Refer to the instructions in Repair before a discarded part is used again or oversize parts are installed.

Parts which should be discarded can be held although no repair is available. The repair of a discarded part could be shown to be necessary at a later date.

All parts must be examined to make sure that all the repairs have been completed satisfactorily.

The practices and processes referred to in the procedure by the TASK numbers are in SPM.

References

Refer to SPM for data on these items.

Definitions of Damage, SPM TASK 70-02-02-350-501.

Metal Temperature Analysis (Nickel Base Alloys) SPM TASK 70-02-03-220-501.

Aqueous Cleaning, SPM TASK 70-11-03-300-503.

Moderate Cleaning, SPM TASK 70-11-03-300-503.

Cleaning, SPM TASK 70-12-09-120-501.

Fluorescent Penetrant Inspection, SPM TASK 70-23-08-230-501.

Shot peening, SPM TASK 70-38-13-380-501.

Airflow - Turbine Blades and Vanes, SPM TASK 70-72-01-720-501.

Inspection of Parts, SPM TASK 70-20-01-200-501.

Precipitation Heat Treatment of Nickel Castings, SPM TASK 70-37-27-370-501.

Magnetic Permeability Inspection, SPM TASK 70-22-06-220-501.

Some data on these items is contained in this TASK. For more data on these items refer to SPM.

Method of Testing for Crack Indications.

Chemical Processes.

Surface Protection.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Oven | LOCAL | Oven | ||

| Magnetoscope(R) Meter, Model 1.069 or equivalent, Model 1.067, or 1.068 | LOCAL | Magnetoscop(R), Meter, Model 1.069 or equivalent, Model 1.067, or 1.068 | Manufacturer: Institute Dr. Foerster GmbH und Co, KM Im Laisen 70, D-72766, Reutlingen, Germany | |

| Permeability Probe | LOCAL | 1.069.01-3001 | ||

| Adapter, Probe | LOCAL | 9064001 | Reference Standard PN 1.067-101-12 Manufacturer: Foerster Instruments Inc., RIDC Park West, 140 Industry Drive, Pittsburgh, PA 15275 USA or equivalent | |

| IAE 2P16101 Airflow base | 0AM53 | IAE 2P16101 | ||

| IAE 2P16113 Airflow fixture | 0AM53 | IAE 2P16113 | ||

| IAE 2P16119 Airflow insert | 0AM53 | IAE 2P16119 | ||

| IAE 2P16359 Blade length gage | 0AM53 | IAE 2P16359 | ||

| IAE 2P16411 Airflow master | 0AM53 | IAE 2P16411 | ||

| IAE 2P16508 Reference card | 0AM53 | IAE 2P16508 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-081 PENCIL - METAL MARKING(HARD) | 86874 | CoMat 02-081 | ||

| CoMat 03-010 ARGON GAS | 0B434 | CoMat 03-010 | ||

| CoMat 05-029 CAST STEEL SHOT, S110 | 55807 | CoMat 05-029 | ||

| CoMat 05-032 CAST STEEL SHOT, S170 | 55807 | CoMat 05-032 | ||

| CoMat 05-138 SHOT, CAST STEEL, S110 | 55807 | CoMat 05-138 | ||

| CoMat 05-176 CAST STEEL SHOT, S170 | 55807 | CoMat 05-176 | ||

| CoMat 05-177 CUT WIRE SHOT,CW-14 | 0FUN2 | CoMat 05-177 | ||

| CoMat 05-178 CUT WIRE SHOT, CW-20 | 0FUN2 | CoMat 05-178 | ||

| CoMat 05-187 STAINLESS STEEL CUT WIRE SHOT, SCW-20 | 0FUN2 | CoMat 05-187 | ||

| CoMat 05-188 STAINLESS STEEL CUT WIRE SHOT, SPECIAL CONDITIONED, SCW-20 | 0FUN2 | CoMat 05-188 | ||

| CoMat 05-234 CAST STEEL SHOT, HIGH HARDNESS, S110 | 55807 | CoMat 05-234 | ||

| CoMat 06-120 METAL MARKING PENCIL (HARD) | 86874 | CoMat 06-120 |

Spares

NONESafety Requirements

NONEProcedure

NOTE

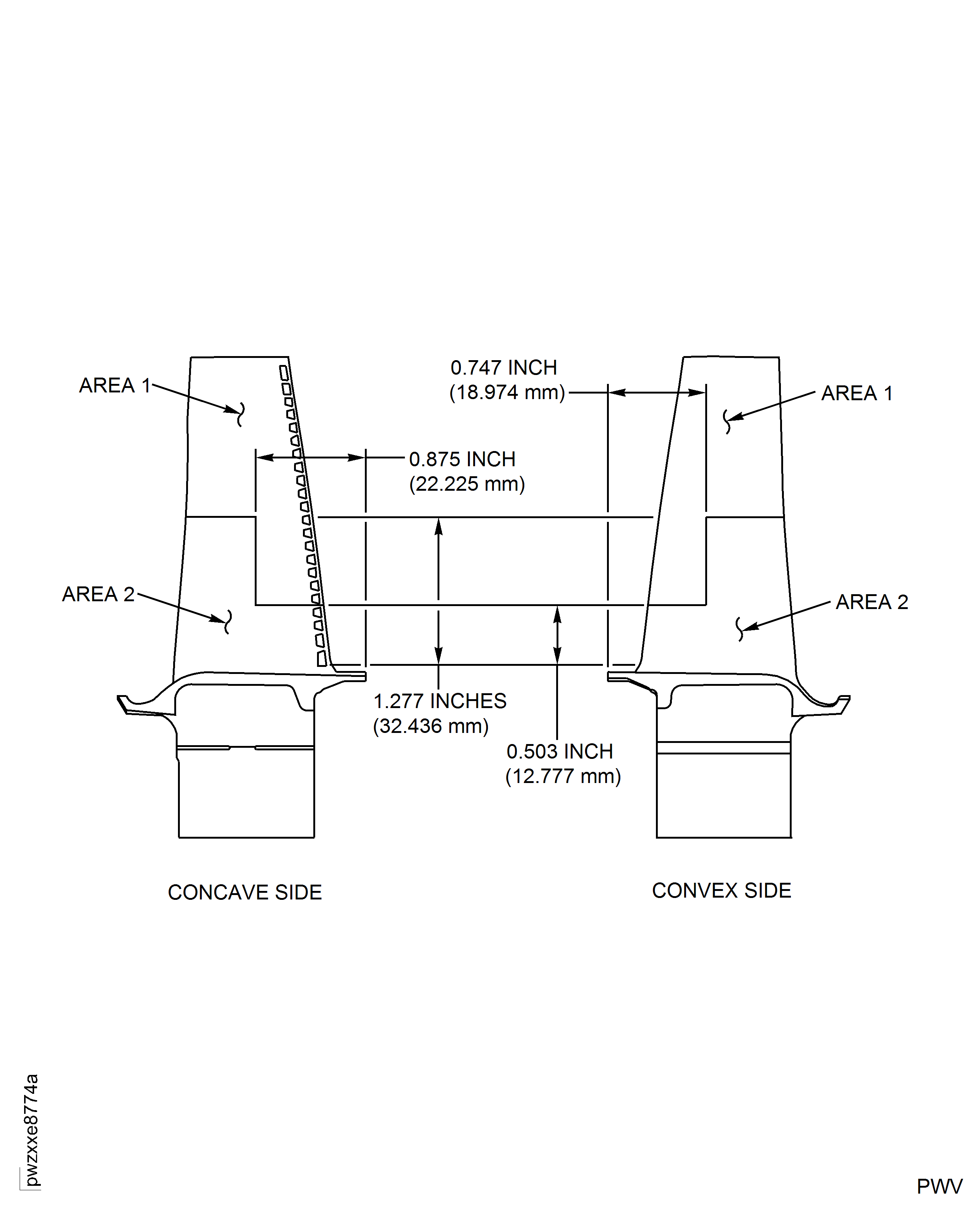

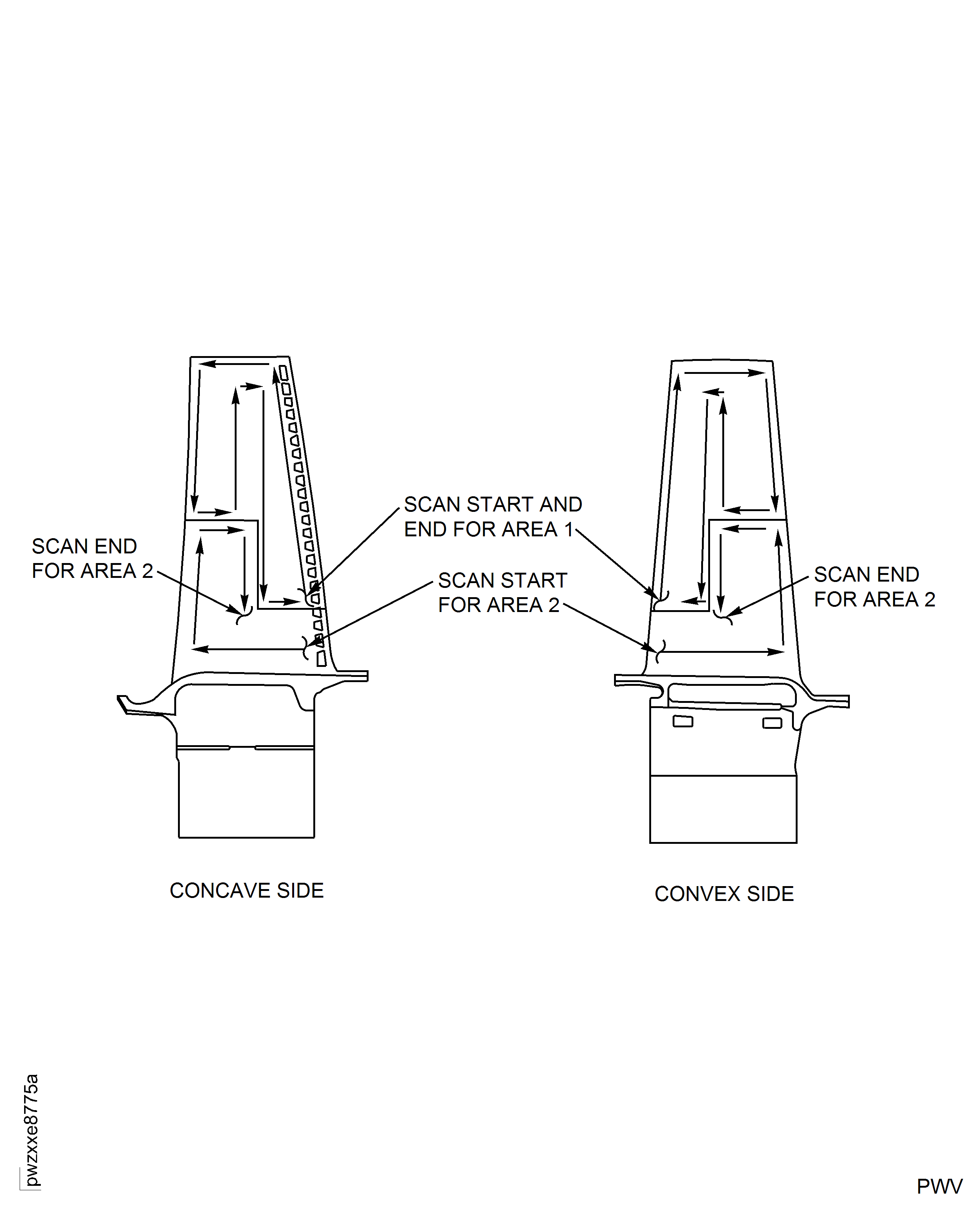

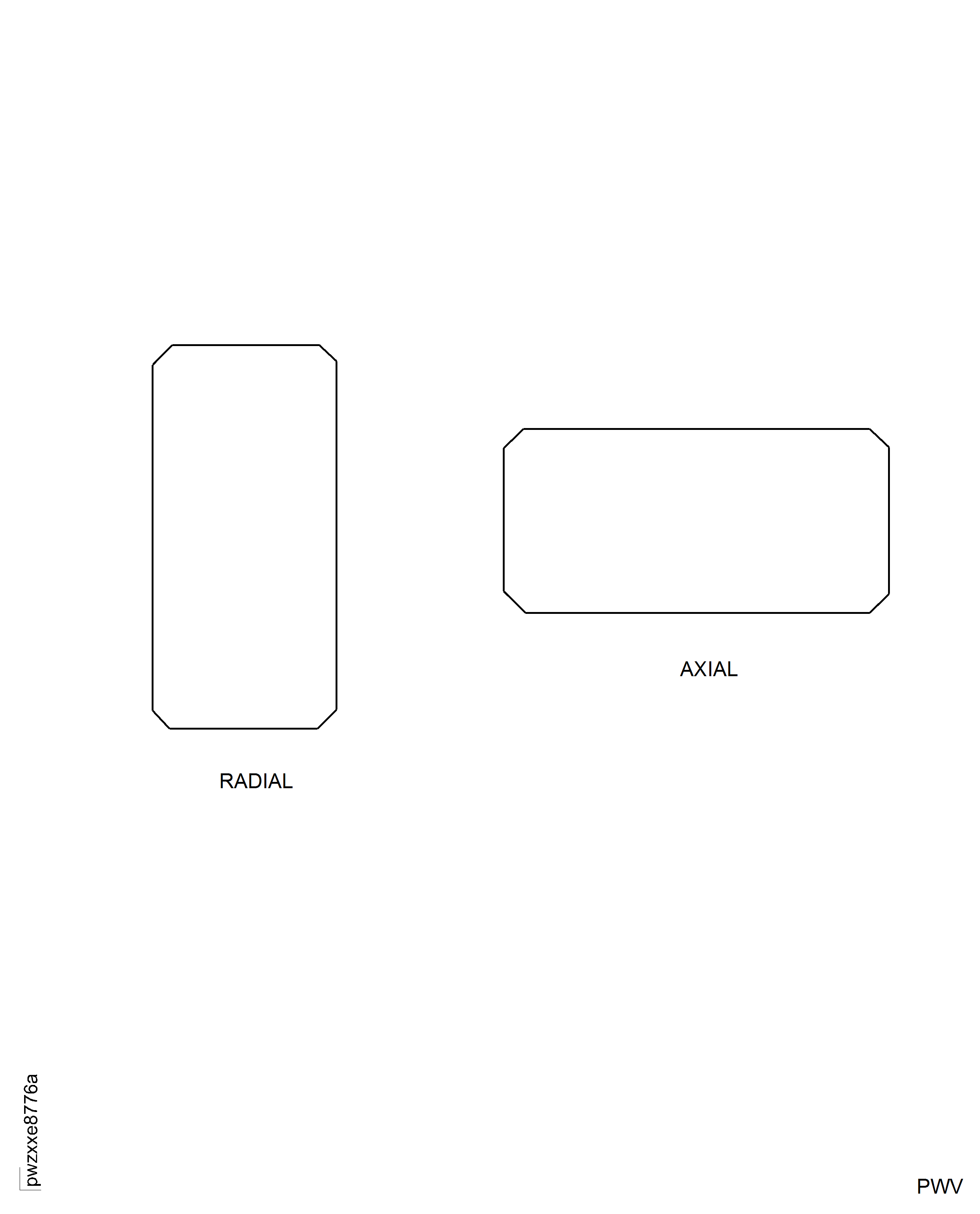

It is permitted to clean the external blade surfaces by the SPM TASK 70-11-03-300-503 or SPM TASK 70-12-09-120-501 before you do this inspection.Examine Area 1 with the permeability probe in a radial orientation. Refer to Figure.

Examine Area 2 with the permeability probe in an axial orientation. Refer to Figure.

1.034 in. (26.264 mm) or less in Area 1.

1.024 in. (26.010 mm) or less in Area 2.

Accept blades with a permeability value of:

More than 1.034 in. (26.264 mm) in Area 1.

More than 1.024 in. (26.010 mm) in Area 2.

Repair by Repair, VRS3440 TASK 72-45-32-300-013 (REPAIR-013), Repair, VRS3602 TASK 72-45-32-300-021 (REPAIR-021), or Repair, VRS3838 TASK 72-45-32-300-033 (REPAIR-033) as applicable, if blades have a permeability value of:

If you use FOERSTER Magnetoscope Model 1.069:

1.0170 in. (25.8318 mm) or less in Area 1.

1.0120 in. (25.7048 mm) or less in Area 2.

Accept blades with a permeability value of:

More than 1.0170 in. (25.8318 mm) in Area 1.

More than 1.0120 in. (25.7048 mm) in Area 2.

Repair by Repair, VRS3440 TASK 72-45-32-300-013 (REPAIR-013), Repair, VRS3602 TASK 72-45-32-300-021 (REPAIR-021), or Repair, VRS3838 TASK 72-45-32-300-033 (REPAIR-033) as applicable, if blades have a permeability value of:

If you use FOERSTER Magnetoscope Model 1.070:

Do a permeability inspection by SPM TASK 70-22-06-220-501.

SUBTASK 72-45-32-220-110 Do a Permeability Inspection of the Stage 2 HPT blade Assembly Internal Airfoil Surfaces

CAUTION

DO NOT CLEAN THE INTERNAL CAVITIES OF THE ENGINE RUN BLADES BEFORE YOU DO THIS INSPECTION.Refer to Figure.

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or VRS3440 TASK 72-45-32-300-013 (REPAIR-013) or VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

Other than Step.

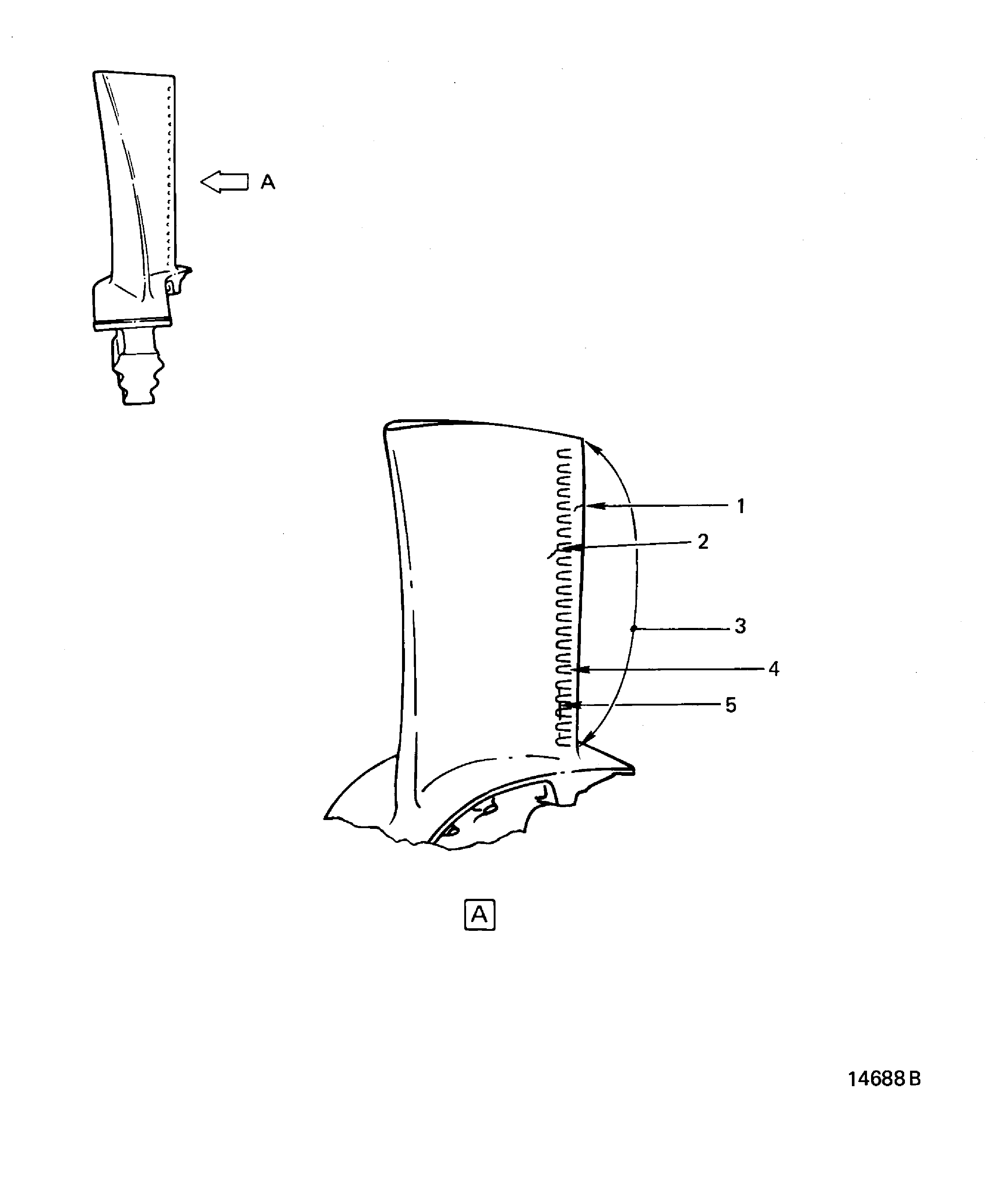

Examine the blade platform area for corrosion and burned areas.

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or VRS3440 TASK 72-45-32-300-013 (REPAIR-013) or VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

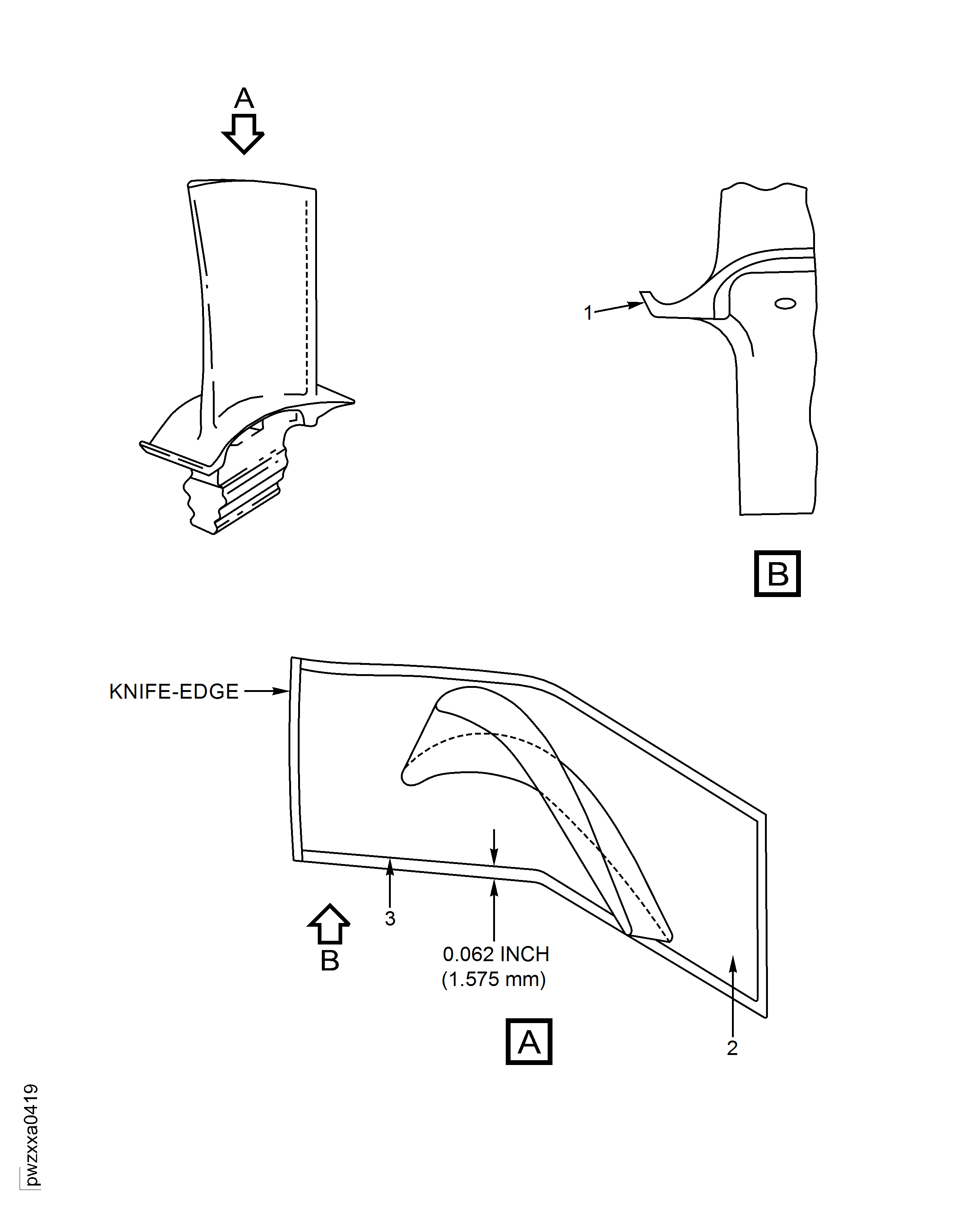

Cracks at the knife edge location 1.

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or VRS3440 TASK 72-45-32-300-013 (REPAIR-013) or VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

Cracks, nicks and chipped coating at location 2.

Examine the blade platform area for cracks, nicks and chipped coating. Use a white light and 10X magnification to examine for cracks.

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or VRS3340 TASK 72-45-32-300-013 (REPAIR-013) or VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

Other than Step.

Examine the blade platform area for dents at locations 2 and 3.

Repair, VRS3582 TASK 72-45-32-300-023 (REPAIR-023) or VRS3839 TASK 72-45-32-300-031 (REPAIR-031).

Meet the limits given in repair, VRS3517 TASK 72-45-32-300-015 (REPAIR-015) or VRS3837 TASK 72-45-32-300-032 (REPAIR-032).

Reject.

Other than Step.

Examine the blade underplatform as follows:

SUBTASK 72-45-32-220-071 Examine the Stage 2 HPT Blade Assembly (01-010) Blade Platform Area

NOTE

To find if the base metal is shown, use the heat tint examination in Step.NOTE

It is permitted to have not more than three casting holes for each side on the HPT Stage 2 blade airfoil (also referred to as chaplet holes). This is a maximum of six casting holes for each blade, if there were no more than three holes each side. These holes are typically located out near the tip on the concave and convex side of the airfoil and are less than 0.030 in. (0.76 mm) in diameter. The blade is required to have passed an airflow check and magnetoscope inspection.

To find if the base metal is shown, use the heat tint examination in Step.

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010), VRS3440 TASK 72-45-32-300-013 (REPAIR-013) or VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

Other than Step.

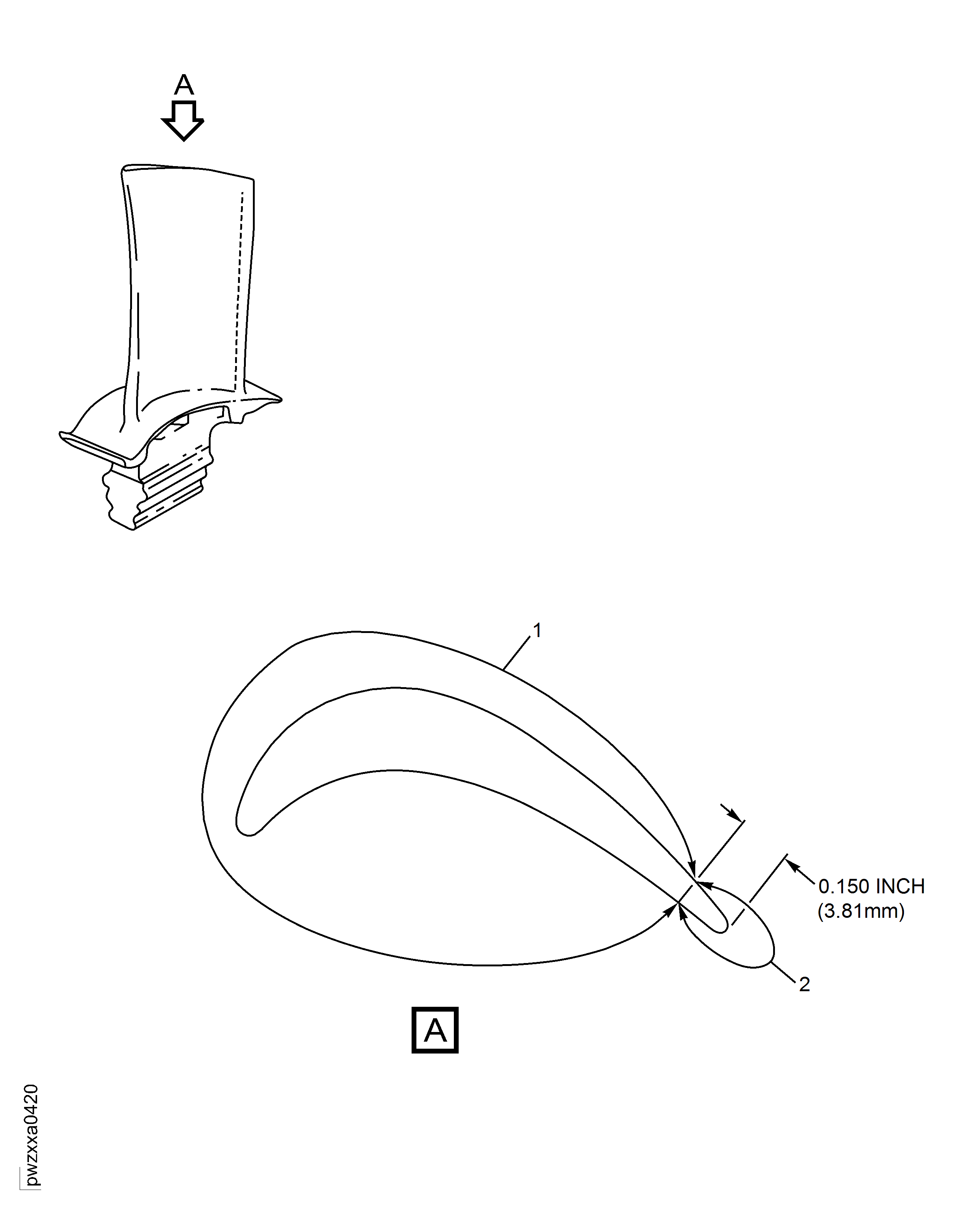

Examine the blade airfoil surfaces at locations 1 and 2, for burned areas, corrosion and erosion, Figure.

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010), VRS3440 TASK 72-45-32-300-013 (REPAIR-013) or VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

NOTE

Refer to Step for cracks on the trailing edge.

Chipped and nicked coating.

Examine the blade airfoil surfaces at locations 1 and 2, for chipped and nicked coating.

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010), VRS3440 TASK 72-45-32-300-013 (REPAIR-013) or VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

Cracks.

Examine the blade airfoil surfaces at location 1, for cracks. Use a white light and 10X magnification.

Dents must be separated a minimum of 0.100 in. (2.54 mm).

Dents not more than a diameter of 0.100 in. (2.54 mm).

Accept if the following conditions are met.

Two dents on the convex airfoil surfaces, but at a location that is not less than 0.400 in. (10.16 mm) from the blade's platform as noted by Index 5.

Dents not more than a diameter of 0.100 in. (2.54 mm).

Dents must be separated a minimum of 0.100 in. (2.54 mm).

Accept if the following conditions are met.

Five dents on the concave airfoil surfaces, but at a location that is not less than 0.400 in. (10.16 mm) from the blade's platform as noted by Index 5.

For PN's 2A9002 and 2A4722 only.

Accept.

Two dents on each side of the concave and convex airfoil surfaces.

For all other PN's.

The acceptable dent limits at Location 3 (aft-chord) is as follows.

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010), VRS3440 TASK 72-45-32-300-013 (REPAIR-013) or VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

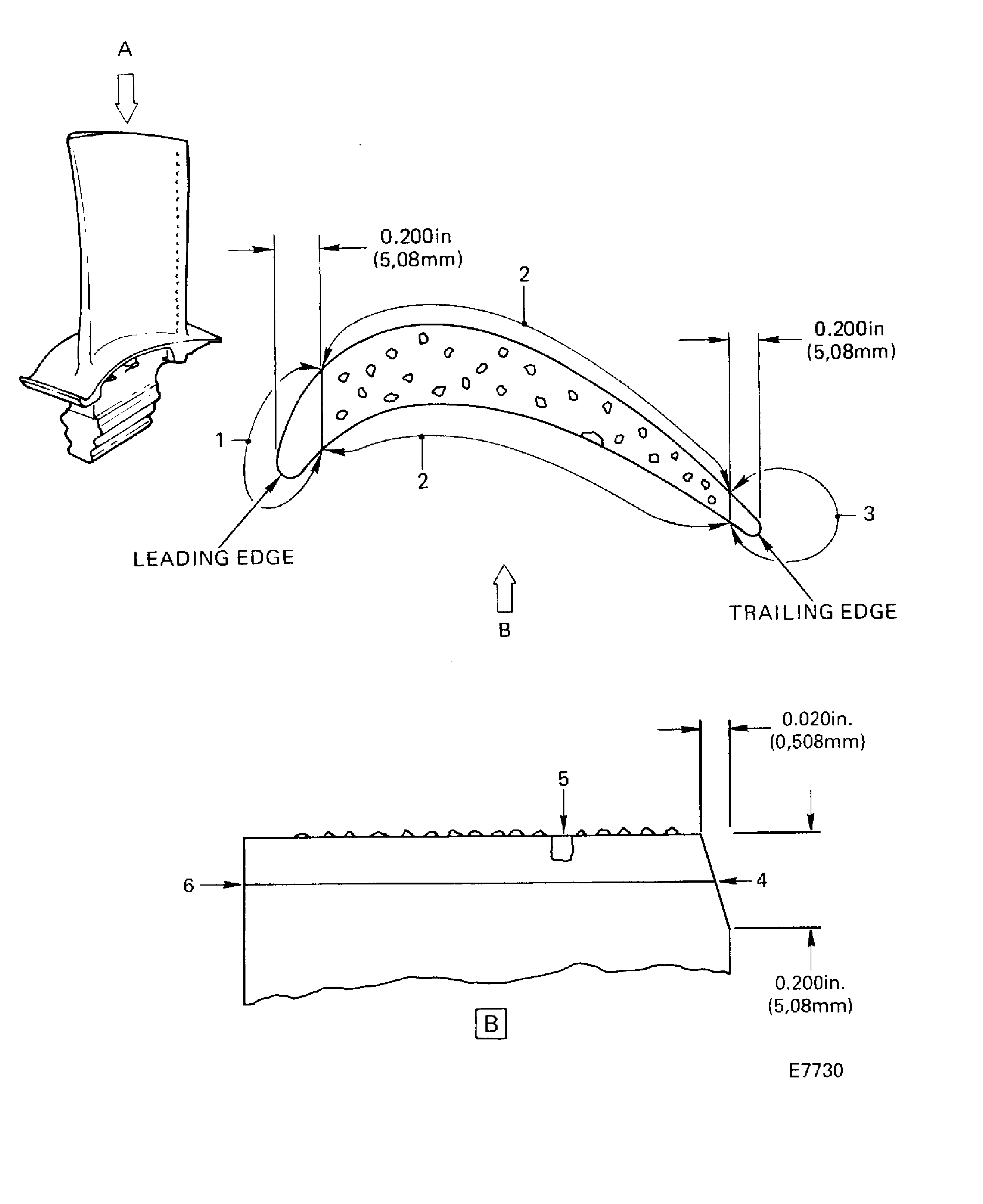

Examine the blade airfoil surfaces for dents and nicks, Figure.

SUBTASK 72-45-32-220-072 Examine the Stage 2 HPT Blade Assembly (01-010) Airfoil

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or VRS3516 TASK 72-45-32-300-014 (REPAIR-014) or VRS3836 TASK 72-45-32-300-030 (REPAIR-030).

NOTE

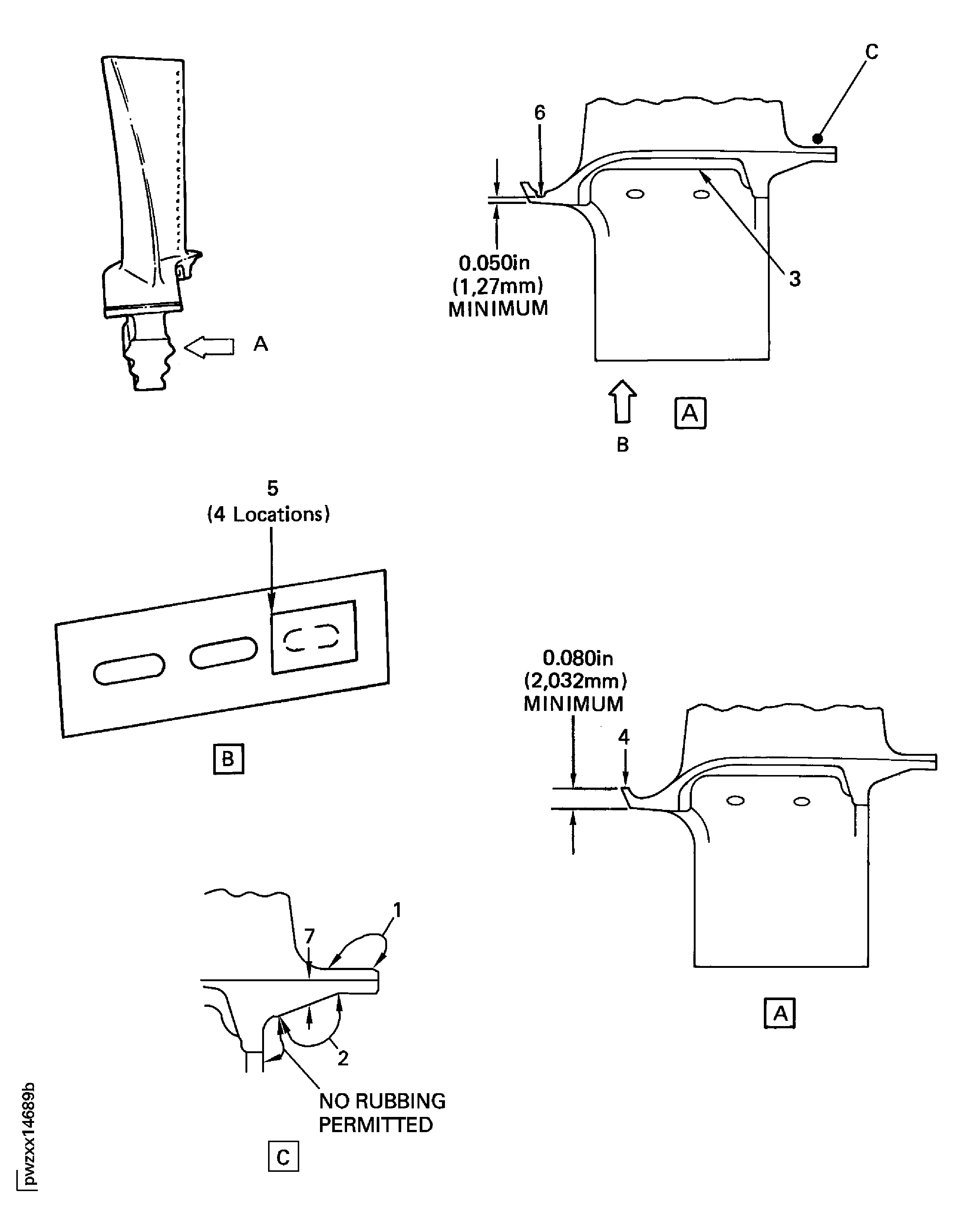

The base metal/tip interface is shown at location 6.

If there is base metal shown on the base metal/tip interface at location 2.

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or VRS3516 TASK 72-45-32-300-014 (REPAIR-014) or VRS3836 TASK 72-45-32-300-030 (REPAIR-030).

Other than Step.

Examine the blade tip to see if the base metal is shown

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or VRS3516 TASK 72-45-32-300-014 (REPAIR-014) or VRS3836 TASK 72-45-32-300-030 (REPAIR-030).

Other than Step.

Examine the blade abrasive tip for taper on the trailing edge at location 4.

SUBTASK 72-45-32-220-073 Examine the Stage 2 HPT Blade Assembly (01-010) Abrasive Tip

Install the blade assembly into the IAE 2P16359 Blade length gage 1 off.

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or VRS3516 TASK 72-45-32-300-014 (REPAIR-014) or VRS3836 TASK 72-45-32-300-030 (REPAIR-030).

NOTE

A suspect engine has a set of blades which has any blades with negative stretch readings (less than minus 0.005 in. (minus 0.127 mm) or positive stretch readings that are more than three times the average of the entire set.

Other than Step.

Measure the dimension for the distance from the end surface of the gage to the surface of the middle pin.

Examine the blade assembly for the blade length dimension.

Do the procedure in Step below if you think a blade has incorrect markings.

Examine the blades for incorrect marking.

SUBTASK 72-45-32-220-074 Examine the Stage 2 HPT Blade Assembly (01-010) Blade Length

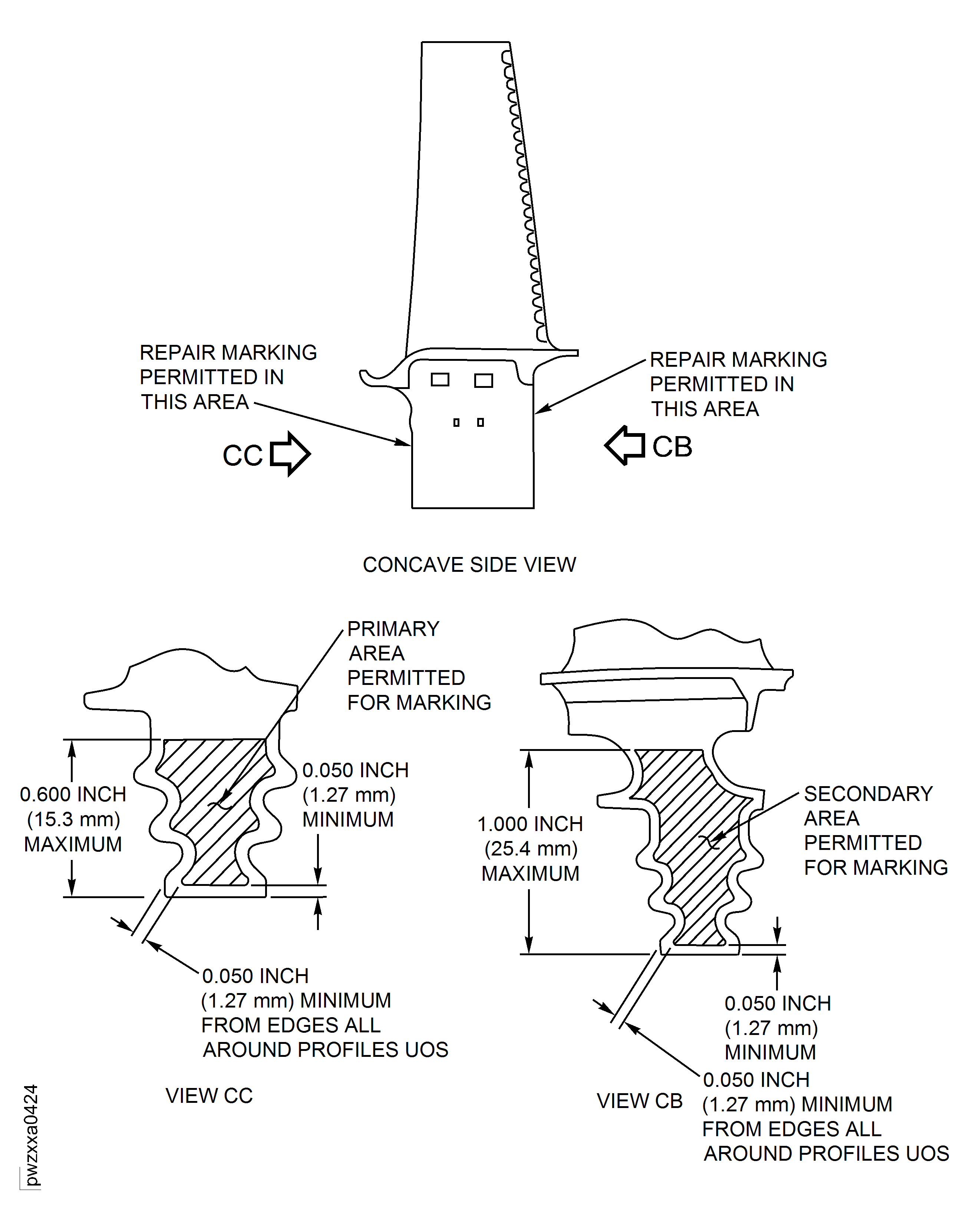

Refer to Figure.

Find the measured length of the blade by the procedure given in Step. Use Z-plane and the growth measurement hole.

Make a mark on the suspect blades only, of the calculated length from the step above. Use the vibro-peen or dot-peen method. Refer to the SPM TASK 70-09-00-400-501. Make a mark in the same area as the initial mark.

Find the quantity of suspect readings.

SUBTASK 72-45-32-220-092 Examine the Stage 2 HPT Blade Assembly (01-010) Blade Length

Refer to Figure.

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

NOTE

Example of a crack is shown at location 1.

Cracks at the trailing edge at location 3

Repair, VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or Repair, VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

NOTE

Example of a linear crack indication that is caused by the blade casting die separation line is shown at location 5. These are not cracks.

Cracks that extend from the concave surface of the cooling air slots at location 2

Examine the blade trailing edge for cracks. Use a white light and a 10X magnification.

CAUTION

WHEN YOU DO PENCIL GRIT BLAST, BE CAREFUL NOT TO ERODE THE TRAILING EDGE SLOT.NOTE

Example of a cooling air slot is shown at location 4.Unplug with a wire probe and power flush or pencil grit blast and high pressure air blast or Repair, VRS3360 TASK 72-45-32-300-005 (REPAIR-005).

SUBTASK 72-45-32-220-075 Examine the Stage 2 HPT Blade Assembly (01-010) Trailing Edge

Refer to Figure.

Repair, VRS3409 TASK 72-45-32-300-006 (REPAIR-006)

NOTE

Rubbing must not go past the tapered area or into the fillet radius.

Up to 25 percent of the local, total platform thickness at location 7, or up to 0.025 in. (0.635 mm) in depth, whichever is less

Other than Step.

Rub.

Examine the trailing edge platform at location 2, for signs of rub with the LPT inner duct.

SUBTASK 72-45-32-220-076 Examine the Stage 2 HPT Blade Assembly (01-010) Leading and Trailing Edge Platform

Refer to Figure.

Other than Step.

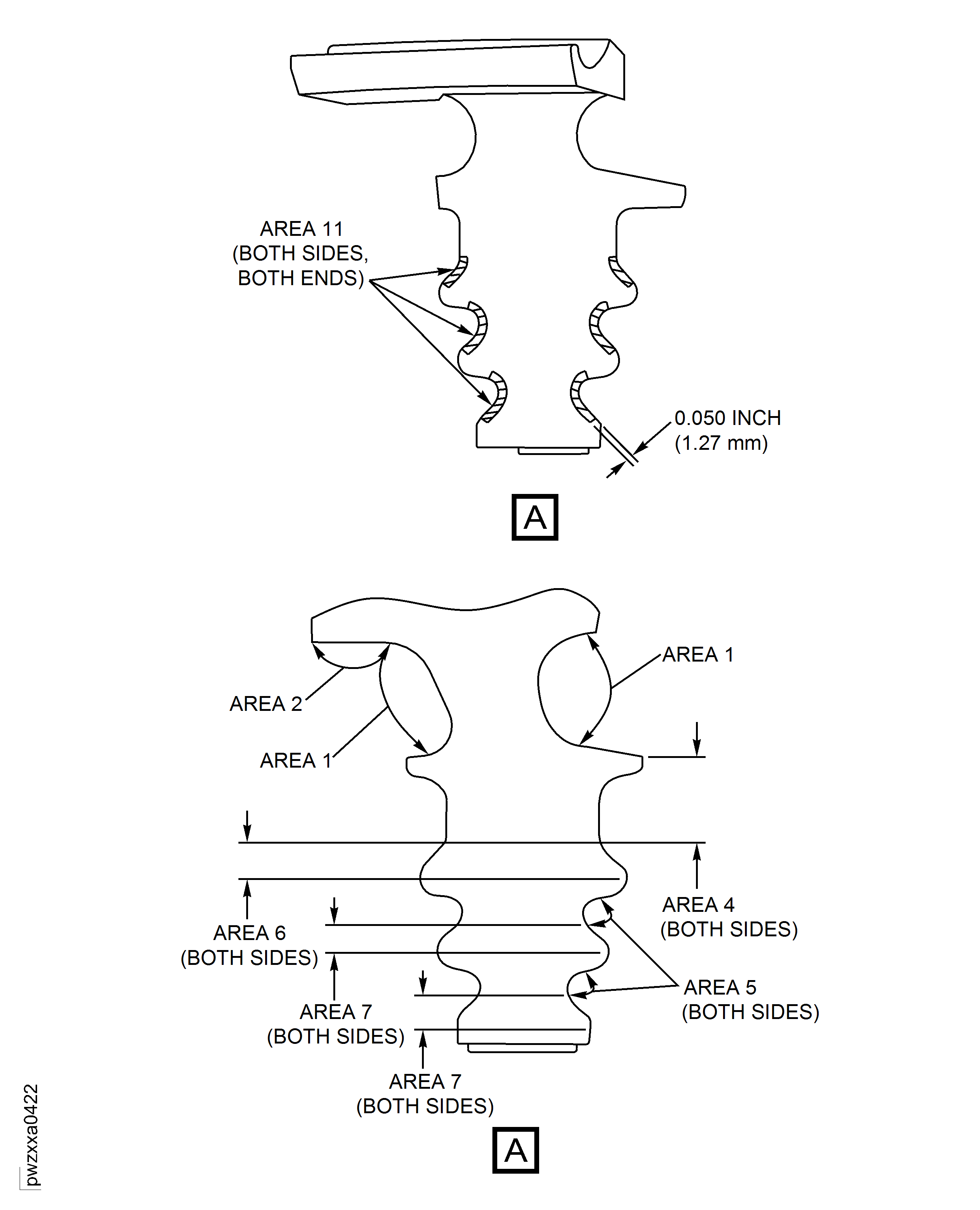

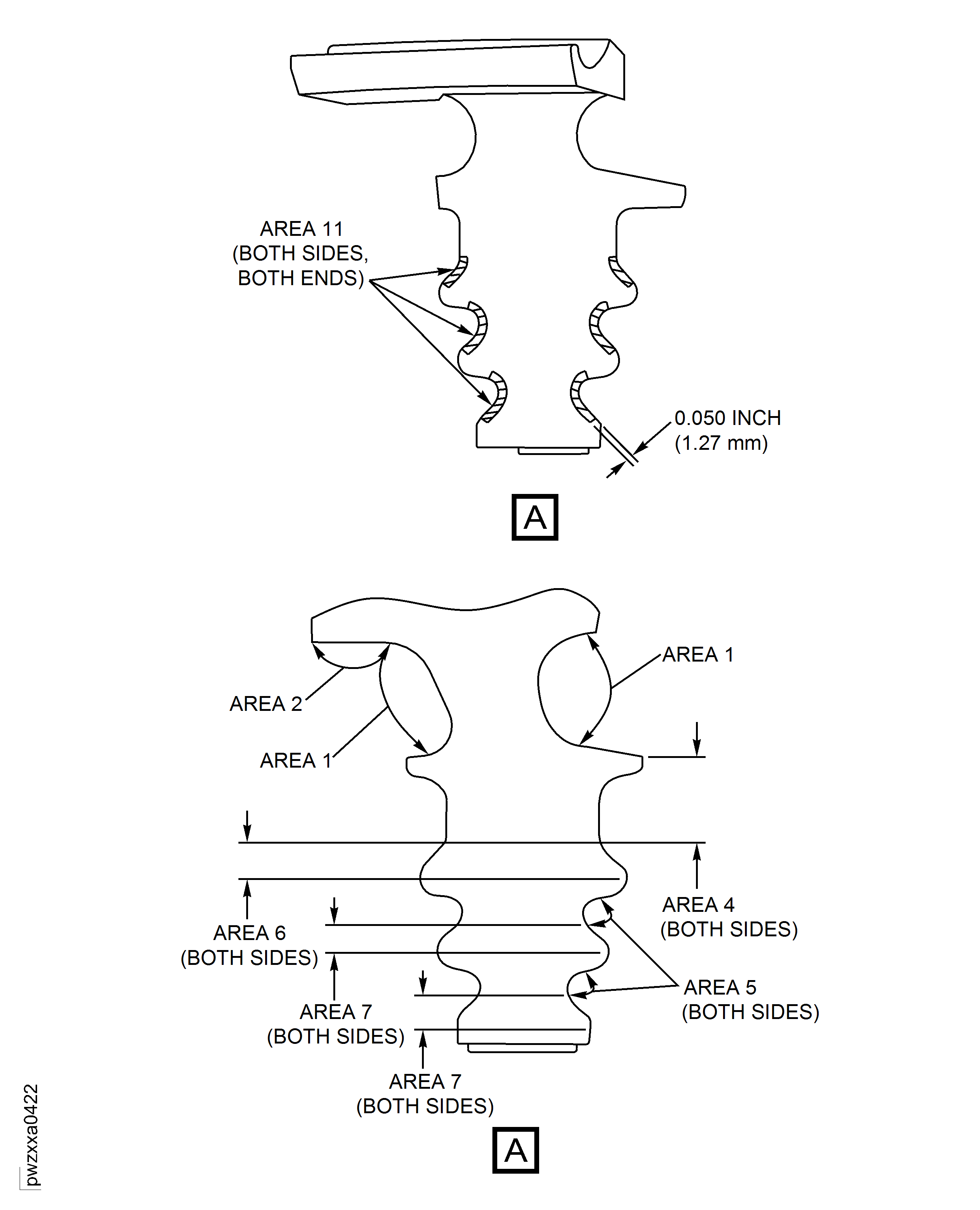

Examine the blade root attachment area for erosion and corrosion at Locations 1, 6, 7 and 11.

Repairs, VRS3240 TASK 72-45-32-300-001 (REPAIR-001) or VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or VRS3440 TASK 72-45-32-300-013 (REPAIR-013) or VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

Other than Step.

Examine the blade root attachment area for erosion and corrosion at Locations 3, 4 and 10.

Other than (Step).

Examine the blade root attachment area for fretting and galling at Locations 4, 6 and 7.

Reject.

Cracks at Locations 1, 2, 5, 7 and 11.

Repair, VRS3517 TASK 72-45-32-300-015 (REPAIR-015) or VRS3837 TASK 72-45-32-300-032 (REPAIR-032).

Cracks at Location 6.

Repairs, VRS3517 TASK 72-45-32-300-015 (REPAIR-015) or VRS3837 TASK 72-45-32-300-032 (REPAIR-032).

Reject.

Pitting at Locations 5 and 11.

Pitting at location 1.

Examine the blade root attachment area for pitting, nicks and cracks at Locations 1, 2, 5, 6, 7 and 11. Use a white light and a 10X magnification to examine for cracks.

Other than (Step).

Examine the blade root attachment area for contact wear that is not equal (tooth to tooth and side to side) at Locations 6 and 7.

Reject.

Any cracks found present.

Accept.

No cracks found.

Parts not rejected by Step, examine the blade root face for cracks. Fluorescent Penetrant Inspection (FPI) under black light, examine by white light with a minimum of 10X magnification to verify that there are no cracks.

Examine the blade root face for previous repair code markings.

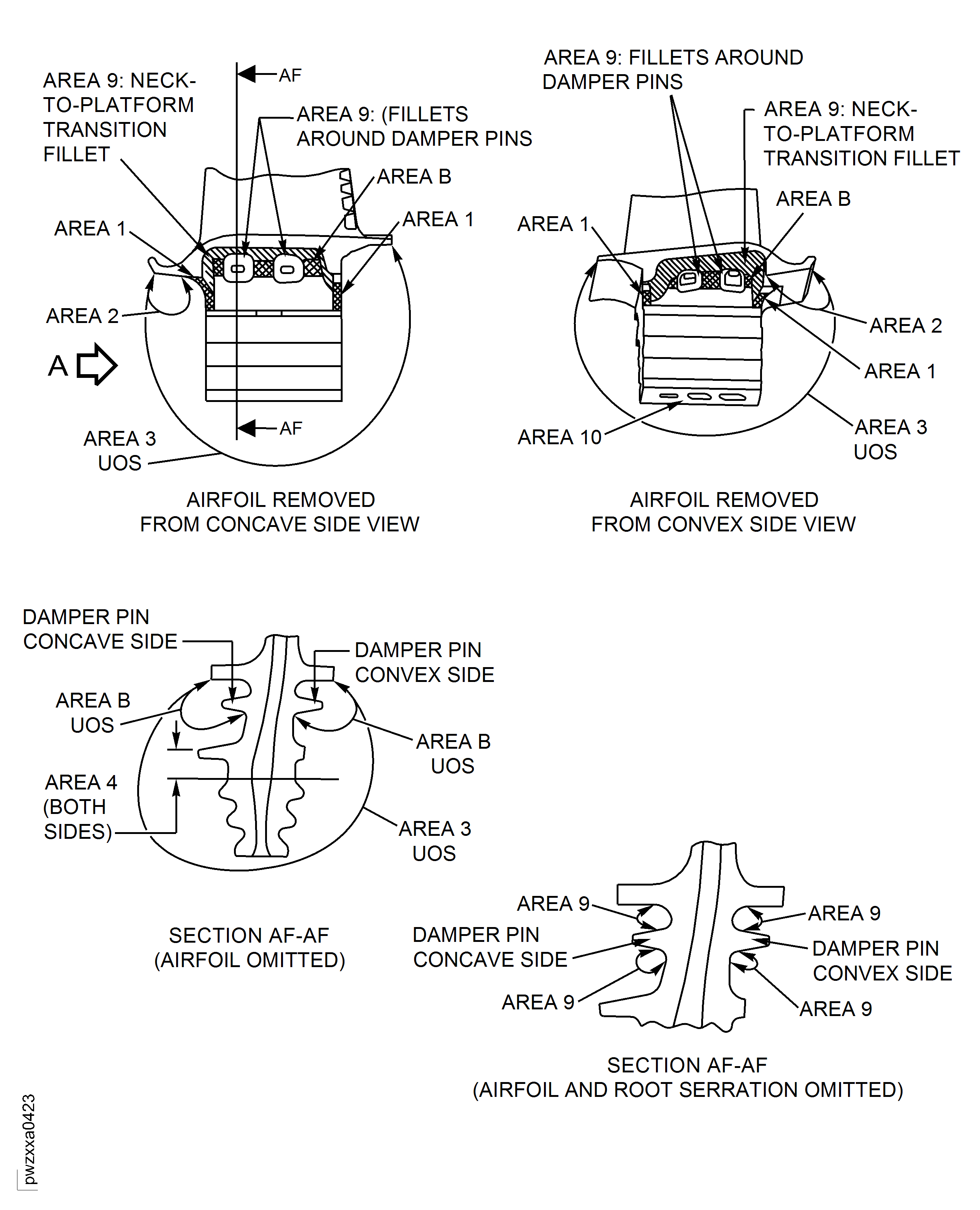

SUBTASK 72-45-32-220-078 Examine the Stage 2 HPT Blade Assembly (01-010) Blade Root Attachment Area

Repairs, VRS3240 TASK 72-45-32-300-001 (REPAIR-001) or VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or VRS3440 TASK 72-45-32-300-013 (REPAIR-013) or VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

Cracks or nicks.

Do a fluorescent penetrant inspection, Step.

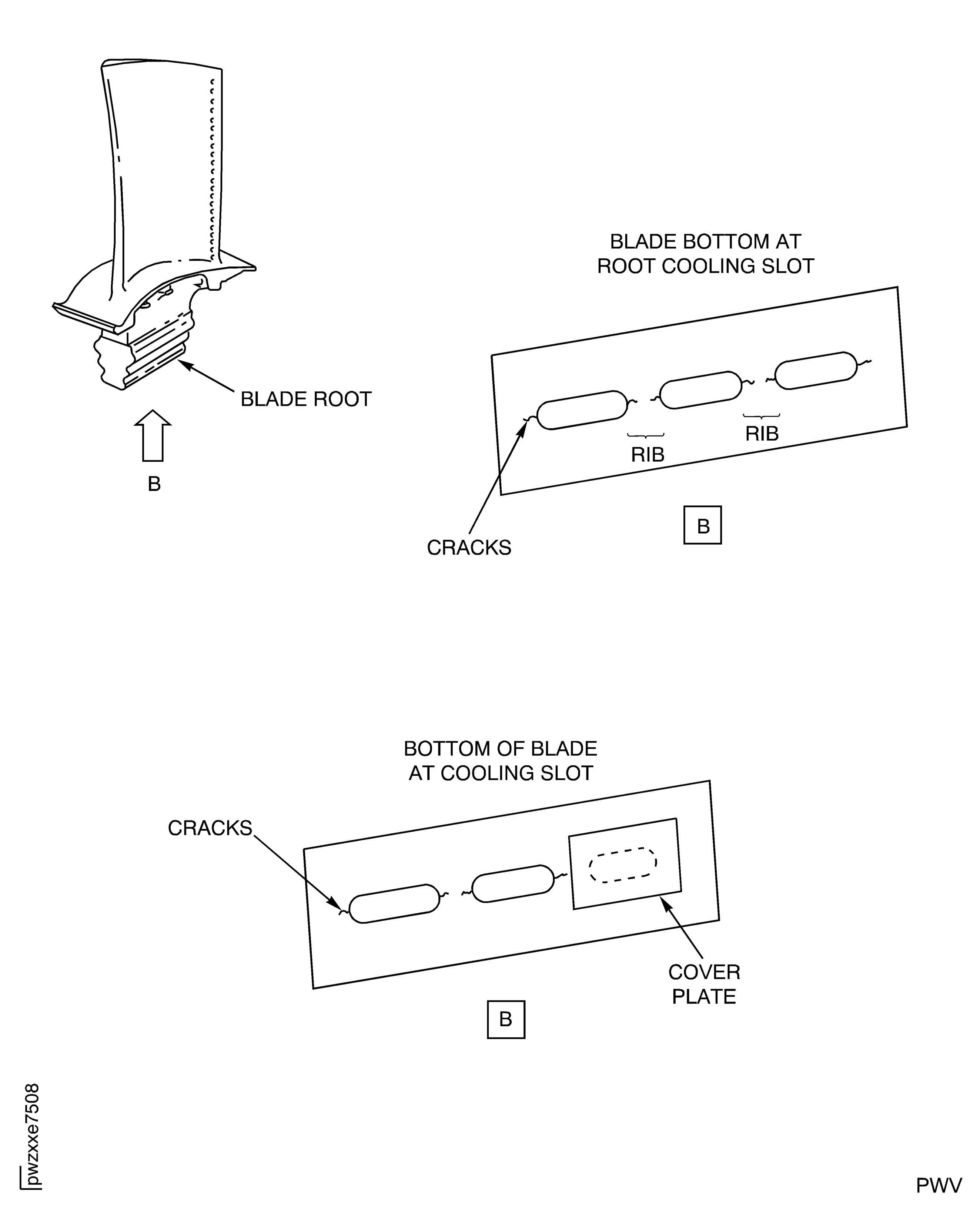

Cracks at the bottom root cooling slot.

Examine the blade root area for nicks and cracks at Locations 3, 4 and 10. Use a white light and a 10X magnification to examine for cracks.

Reject.

Other than Step.

Pitting at Locations 3 and 4.

Reject.

Other than Step.

Pitting at Location 10.

Repair, VRS3582 TASK 72-45-32-300-023 (REPAIR-023).

For all part numbers except 2A4722, not more than 0.010 in. (0.254 mm) at Location 8. Refer to Figure.

Repair, VRS3839 TASK 72-45-32-300-031 (REPAIR-031).

For part number 2A4722, not more than 0.005 in. (0.127 mm) at Location 8. Refer to Figure.

Pitting at Location 8.

Repair by TASK 72-45-32-300-031 (REPAIR-031).

For PN 2A4722, not more than 0.003 in. (0.076 mm) at Location 9. Refer to Figure.

Pitting at Location 9.

Examine the blade root area for pitting at Locations 3, 4, 8, 9 and 10.

Repairs, VRS3240 TASK 72-45-32-300-001 (REPAIR-001) or VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or VRS3440 TASK 72-45-32-300-013 (REPAIR-013) or VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

Accept.

Blades which show depressed and/or raised casting imperfections on ends of seal support lug (damper pin).

Examine the blade root area for blends and dents.

SUBTASK 72-45-32-220-079 Examine the Stage 2 HPT Blade Assembly (01-010) Root Area

Refer to Figure.

Repair, VRS3361 TASK 72-45-32-300-008 (REPAIR-008).

More than one crack on each blade.

Examine the blade root metering plate welds at Location 5 (four locations) for cracks.

SUBTASK 72-45-32-220-080 Examine the Stage 2 HPT Blade Assembly (01-010) Root Metering Plate Welds

Blades that were at temperatures more than the limit of 2100 deg F (1149 deg C) for a short time will cause a change in the alloy microstructure of the blade.

In the case of an EGT overtemperature, such that the AMM requires metallurgical analysis, the stage 2 HPT blades must be examined for overtemperature even if the stage 1 HPT blades are not rejected for overtemperature.

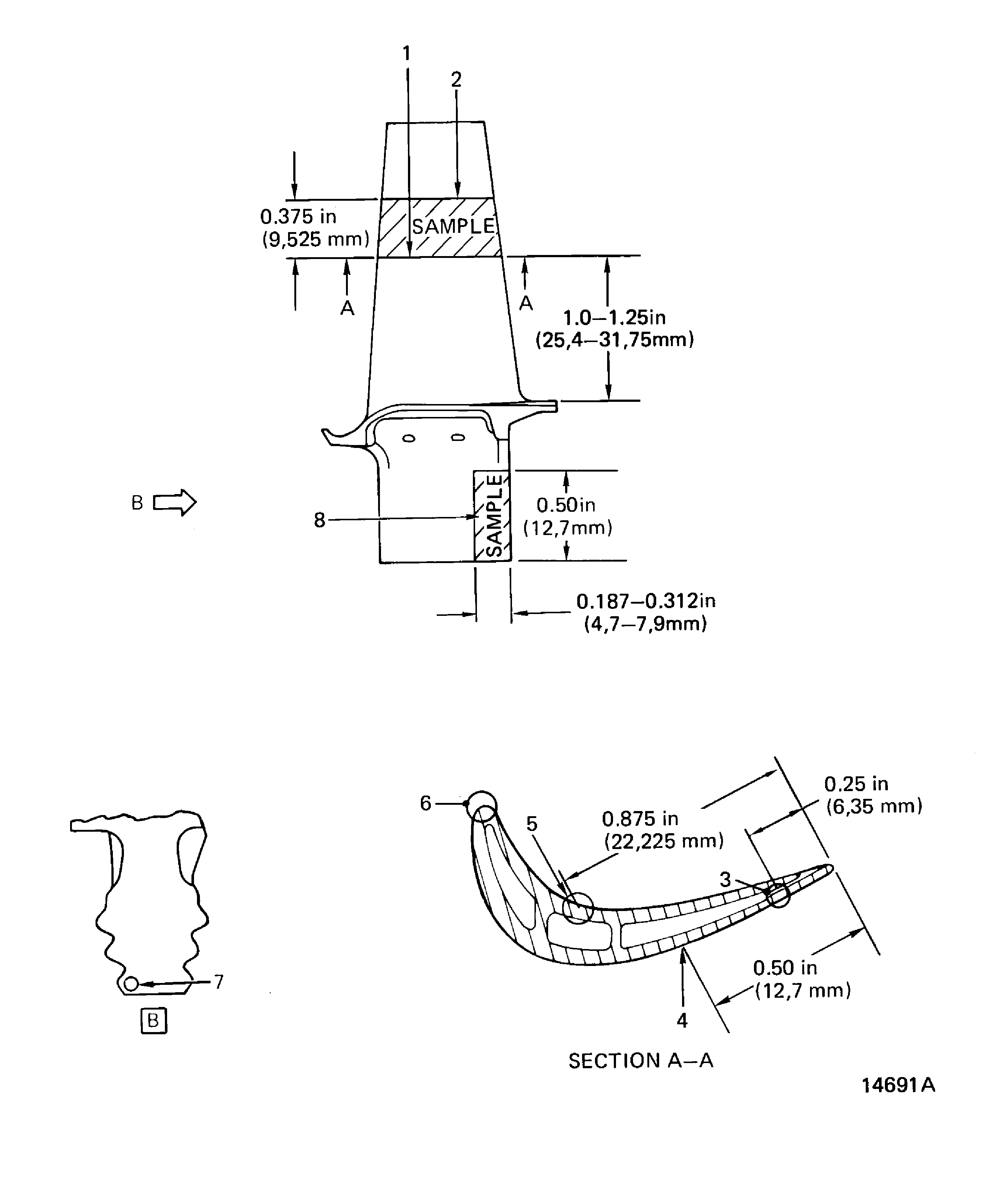

Refer to Figure.

Attach and polish the blade samples, refer to SPM TASK 70-02-03-220-501 as follows:

Examine the microstructure of the blade samples. Refer to SPM TASK 70-02-03-220-501.

Examine one blade assembly for overtemperature by metallurgical analysis if the engine was removed for EGT overlimit. Refer to SPM TASK 70-02-03-220-501.

SUBTASK 72-45-32-280-056 Examine the Stage 2 HPT Blade Assembly (01-010) for Overtemperature

NOTE

Refer to Figure.

Remove the root cover plate. Refer to VRS3361 TASK 72-45-32-300-008 (REPAIR 008).

Clean the internal cavities of the blade. Refer to VRS3360 TASK 72-45-32-300-005 (REPAIR 005).

Reject blades and contact IAE Technical Services.

Cracks.

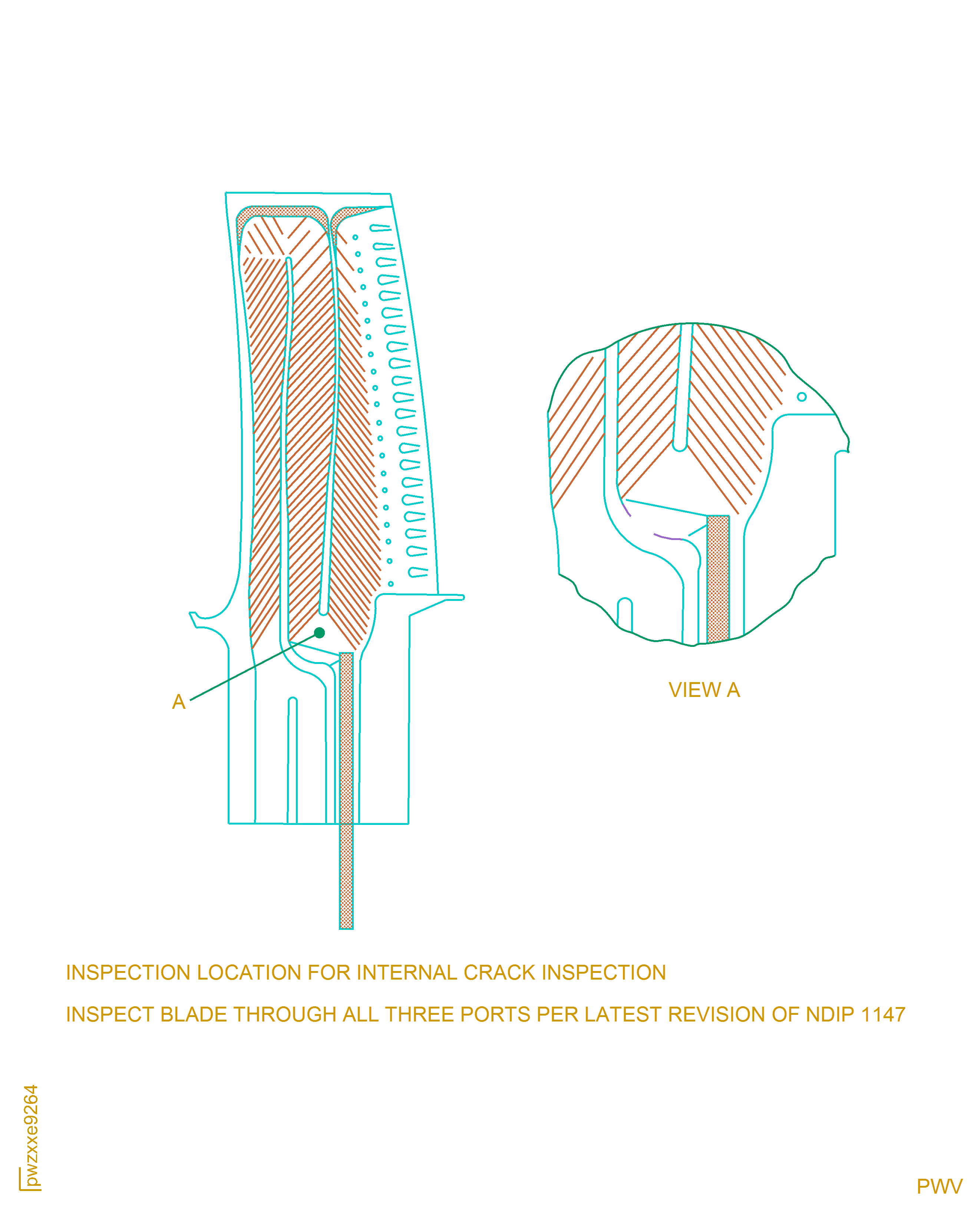

Do a boroscope inspection of the internal cavities of the blade per latest revision of NDIP-1147.

Replace the root cover plate prior to completion of blade airflow inspection/check Step. Refer to VRS3361 TASK 72-45-32-300-008 (REPAIR 008).

SUBTASK 72-45-32-220-052-001 Examine the Stage 2 HPT Blade (01-010) for Internal Stress Corrosion Cracks

Before you clean the blade, remove the root cover plate by grinding. When you remove the cover plate, make sure the grinding motion is from the concave to the convex side, or from the convex to the concave side. This will make grinding marks perpendicular to root bottom axial cracks (if they exist).

Clean the part. Refer to TASK 72-45-32-100-003 (CLEANING-003, CONFIG-001).

NOTE

Removal of root cover plate and cleaning the blade may have been already performed per the previous step.

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURERS MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS INFORMATION SUCH AS HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL REGULATION INTO CONSIDERATION.Heat treat the blade to open up cracks before inspection.

If you find any crack indications, make a temporary mark on the indications with CoMat 02-081 PENCIL - METAL MARKING(HARD).

Refer to SPM TASK 70-37-27-370-501.

Precipitation heat treat the blade assembly as follows:

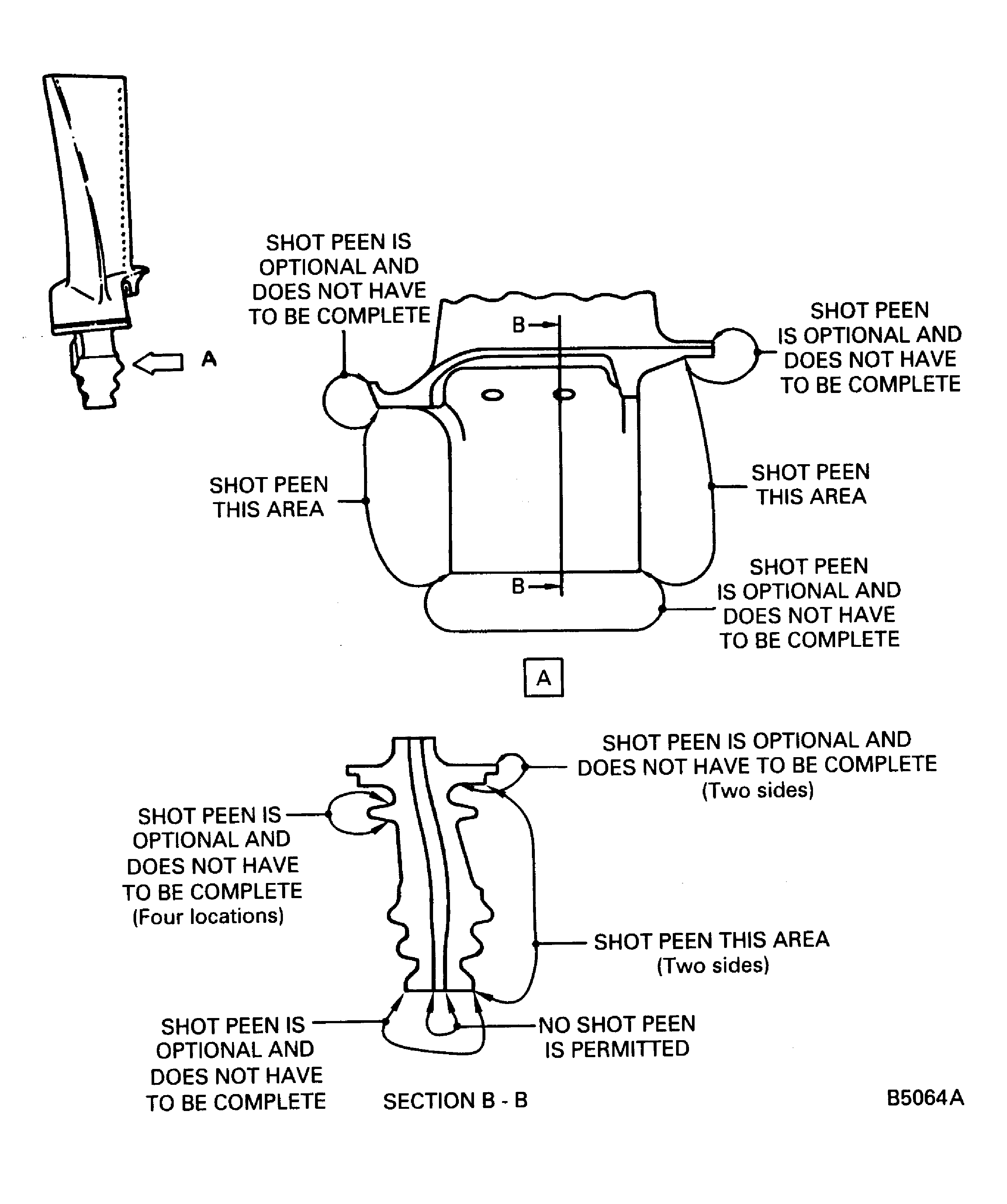

Use cast steel shot CoMat 05-029 CAST STEEL SHOT, S110, CoMat 05-032 CAST STEEL SHOT, S170, CoMat 05-138 SHOT, CAST STEEL, S110, CoMat 05-176 CAST STEEL SHOT, S170, CoMat 05-234 CAST STEEL SHOT, HIGH HARDNESS, S110 or CoMat 05-177 CUT WIRE SHOT,CW-14, CoMat 05-178 CUT WIRE SHOT, CW-20 or CoMat 05-187 STAINLESS STEEL CUT WIRE SHOT, SCW-20, CoMat 05-188 STAINLESS STEEL CUT WIRE SHOT, SPECIAL CONDITIONED, SCW-20. Peen with an intensity of 6A. Refer to SPM TASK 70-38-13-380-501, SUBTASK 70-38-13-380-006.

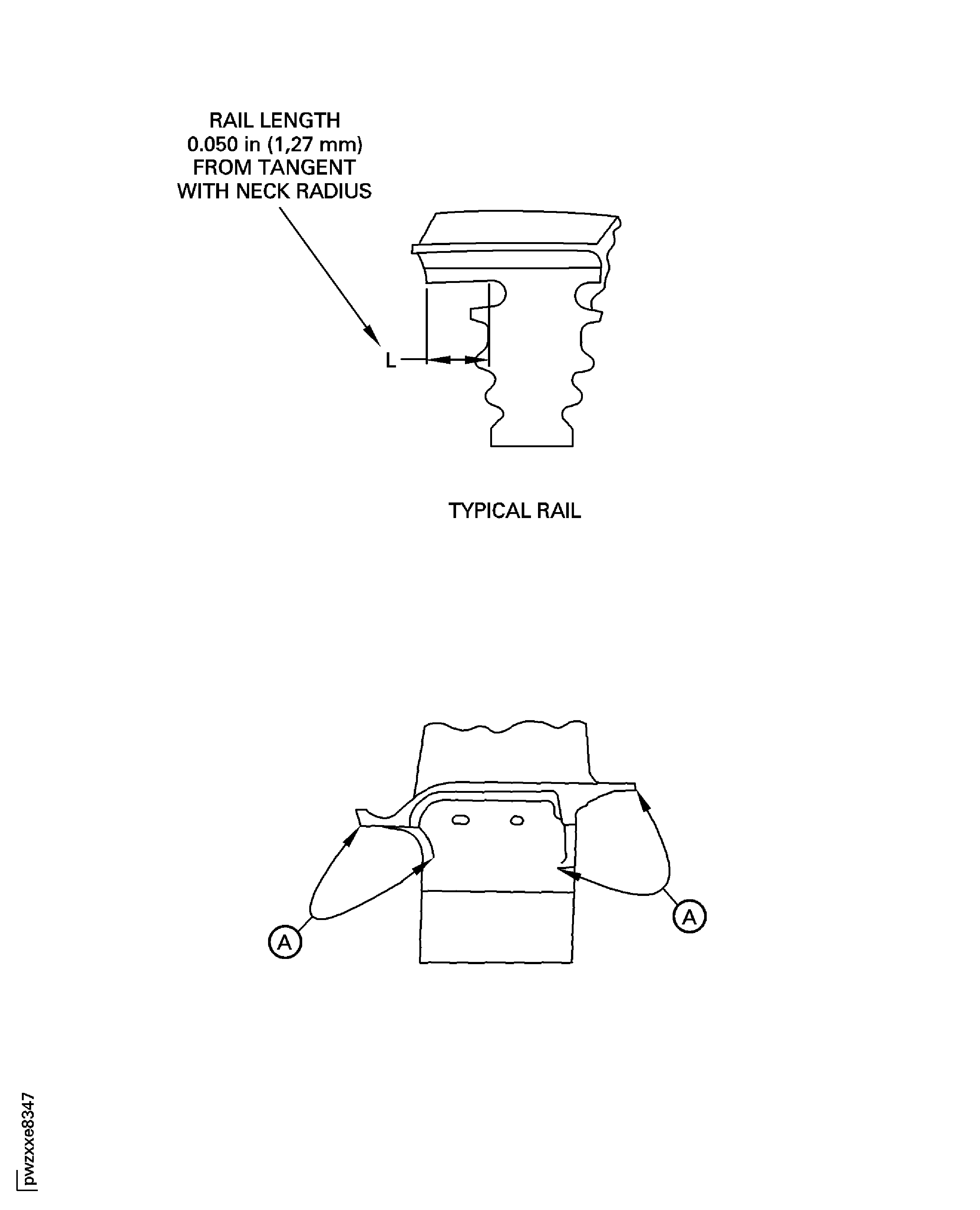

Shot peen the blade root area by SPM TASK 70-38-13-380-501. Refer to Figure.

SUBTASK 72-45-32-230-053-001 Examine the Stage 2 HPT Blade (01-010) for Cracks

Moderately clean the blade assembly by SPM TASK 70-11-03-300-503.

CAUTION

DO NOT DRY BLAST THE BLADE ASSEMBLY COATED AREA TOO MUCH. THIS CAUSES THE COATING TO BE REMOVED.Clean the blade assembly by SPM TASK 70-12-09-120-501.

Repairs, VRS3496 TASK 72-45-32-300-010 (REPAIR-010) or VRS3440 TASK 72-45-32-300-013 (REPAIR-013) or Repair, VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or Repair, VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

Blue color that is not shiny shows the blade has no coating

Heat tint.

Examine the blade assembly coating for heat tint.

SUBTASK 72-45-32-280-057 Examine the Stage 2 HPT Blade Assembly (01-010) Coating by Heat Tint

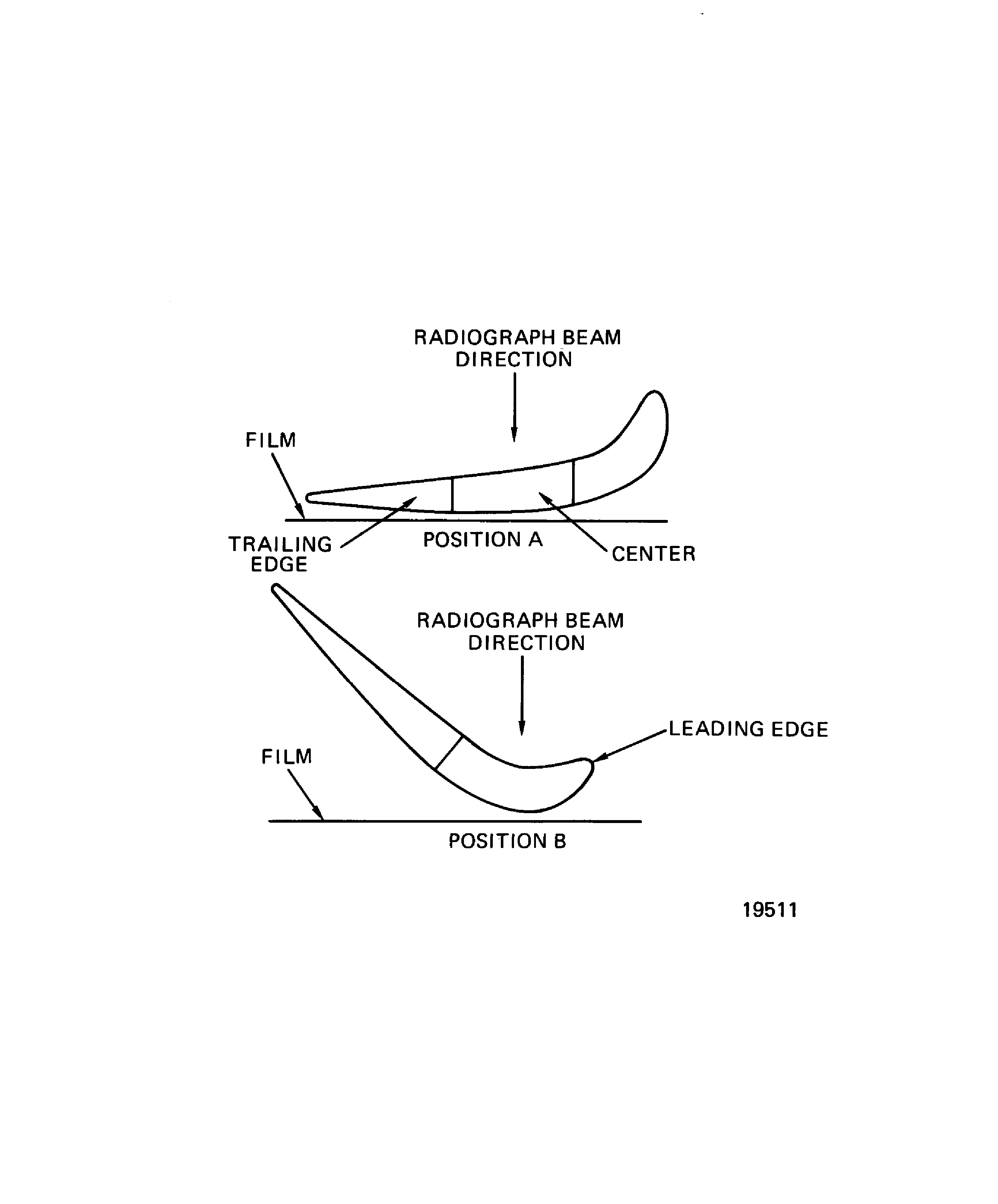

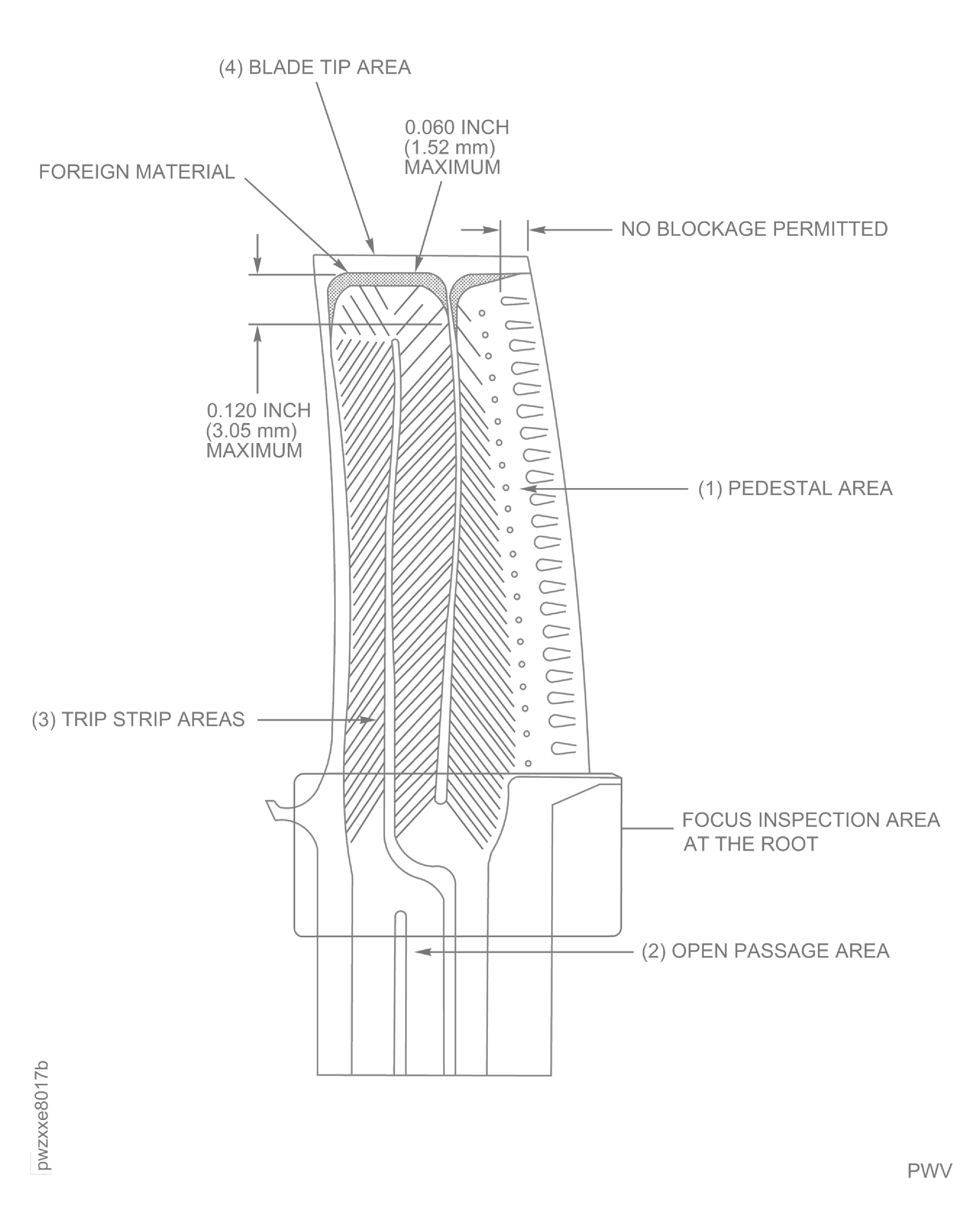

Do a radiographic inspection in Positions A and B by Figure and SPM TASK 70-26-01-260-501.

NOTE

The radiographic inspection in positions A and B may require different exposure and film speeds in order to provide adequate contrast to inspect for cracks, due to the thicker section at the root with respect to the airfoil (Refer to TASK 70-26-01-260-501, Section 7).NOTE

Surface indication that are acceptable to the visual inspection are not cause to be rejected by radiographic inspection.Reject.

NOTE

The entire blade should be inspected for cracks with a focus inspection at the root area as shown in Figure.

Cracks.

Power flush or Repair, VRS3360 TASK 72-45-32-300-005 (REPAIR-005).

NOTE

If there are any indications of shot peen and/or other forms of foreign material, e.g. metal chips or broken wire that are distinguishable by the their shape, form, or density, the parts must be rejected.After cleaning the internal cavities refer to VRS3360, TASK 72-45-32-300-005 (REPAIR-005), unwanted metal and material are acceptable if the size, density and location of the indication(s) have remained unchanged from Step. Refer to the limits in Figure and Figure, area (4).

Unwanted material in the internal cavities.

Power flush or Repair, VRS3360, TASK 72-45-32-300-005 (REPAIR-005)

NOTE

If there are any indications of shotpeen and/or other forms of foreign material, e.g., metal chips or broken wire that are distinguishable by their shape, form or density, the parts must be rejected.After cleaning the internal cavities, refer to VRS3360, TASK 72-45-32-300-005 (REPAIR-005). Unwanted metal and material are acceptable provided the size, density and location of the indication(s) have remained unchanged from Step. Refer to the limits in Figure and Table 801, area (4).

Unwanted material in the internal cavities at the blade tip area

Make an analysis on the radiographic indications.

Examine the blade assembly for internal cracks and unwanted material by radiographic inspection.

SUBTASK 72-45-32-260-052 Examine the Stage 2 HPT Blade Assembly (01-010) for Internal Cracks and Unwanted Material by Radiographic Inspection)

Other than (Step).

Growth.

Examine the blade assembly for the growth measurement.

NOTE

The thinner airfoils can be identified when the internal shape of the blade design becomes visible. External surfaces between shapes will be damaged.

SUBTASK 72-45-32-220-083 Examine the Stage 2 HPT Blade Assembly (01-010) for the Growth Measurement

Refer to Figure.

NOTE

This procedure applies only to blades that have not previously been remarked for length.A blade set is considered suspect if either of the following applies:

It is found to contain individual blades with negative measured stretch greater than minus 0.005 in. (minus 0.127 mm), (minus 0.006 in., minus 0.010 in. etc.), (minus 0.152 mm, minus 0.254 mm etc.).

It is found to contain individual blades that are rejected by the blade stretch measurement technique presently contained in SUBTASK 72-45-32-220-083.

Within a suspect set of blades, individual suspect blades are defined as:

All blades within the set that are found with any negative stretch.

All blades within the set that are found with positive stretch greater than 0.010 in. (0.254 mm).

All blades within the set that are found with more than 3 times the average stretch of the non-suspect blades in the set.

Determine measured length of individual blade by Step. Make note of airfoil thinning inspection. Record three-decimal place results as directed (example, 3.657 in. would read 657 (92.888 mm would read 888).

Calculate the growth of individual blades by subtracting the original marked length from the last three digits of the measured length values found in Step.

NOTE

If all blades in a set display negative stretch 0.001 in. - 0.005 in. (0.0254 mm - 0.127 mm) remark the blade length as described in Step I.Determine which blades within the set are suspect. See applicability above. A statistical analysis must be done on this initial set of growth readings to determine which measurements will be considered suspect versus those that are non-suspect. Suspect blade measurements are not to be evaluated again to further reduce the quantity of suspect parts in the set.

Determine quantity of suspect readings. If 75 percent of the set or more blades are suspect, skip to Step.

Determine the average stretch for the non-suspect blades (see Step.). Define a lot of standard non-suspect blades (10 blades minimum).

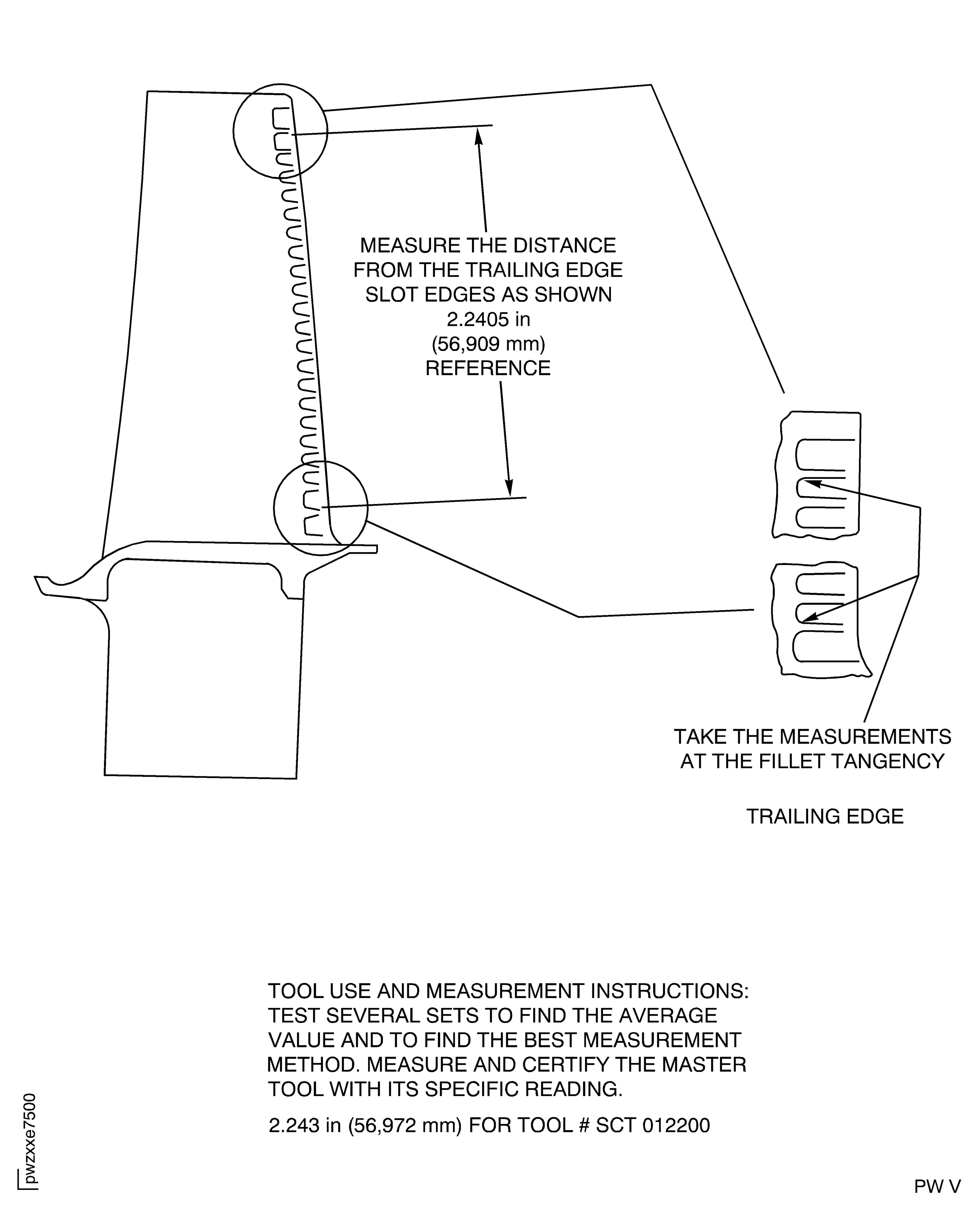

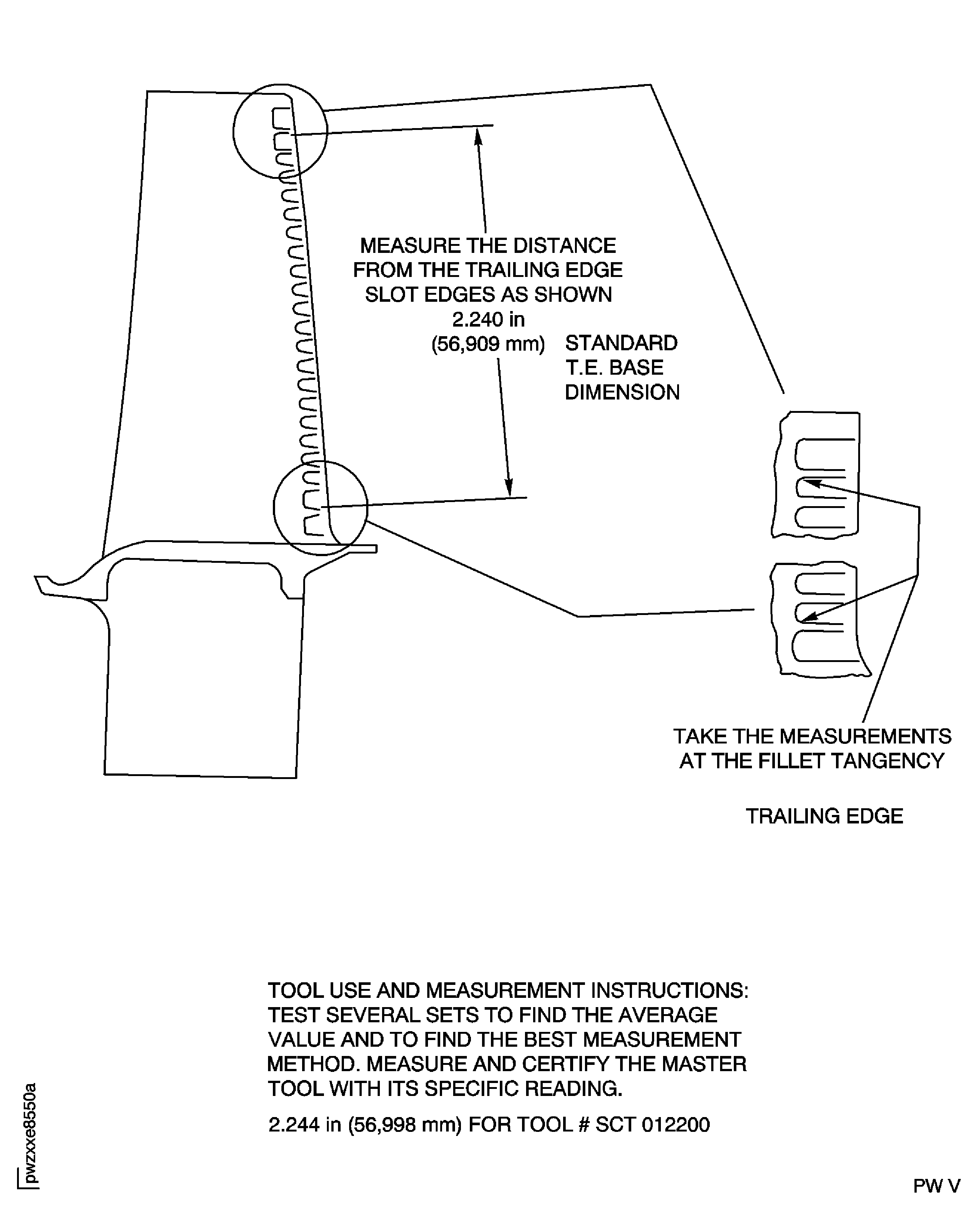

Measure the dimension from the top edge of the second trailing edge (T/E) slot from the tip to the bottom edge of the second T/E slot from the platform, as shown in Figure for the lot.

Average the values measured in Step. Subtract the average stretch of the non-suspect blades, from Step. This is the T/E base dimension.

Example: Non-suspect blade lot T/Es are measured and average 2.243 in. (56.972 mm). Average growth of these non-suspect blades was found to be 0.003 in. (0.0762 mm) at Step. T/E base dimension is set at 2.240 in. (56.897 mm).

For each suspect blade, measure the dimension from the top edge of the second T/E slot from the tip to the bottom edge of the second T/E slot from the platform, as shown in Figure.

Calculate the growth of each suspect blade by subtracting the T/E base dimension Step from the T/E dimension Step of each suspect blade.

Example: Non-suspect blade lot shows average 0.003 in. (0.0762 mm) growth and T/E base dimension of 2.240 in. (56.897 mm). Suspect blade T/E measures 2.242 in. (56.947 mm), so calculated growth of the suspect blade is 0.002 in. (0.0508 mm) (0.001 in. (0.0254 mm) less than the average established by the non-suspect blades in the set).

If less than 75 percent of the blades in the set are suspect, do the following:

For each suspect blade, measure the dimension from the top edge of the second T/E slot from the tip to the bottom edge of the second T/E slot from the platform, as shown in Figure.

NOTE

A locally fabricated tool based on a sample part may be used to confirm the standard T/E base dimension during inspection.Calculate the growth of each suspect blade by subtracting the standard T/E base dimension of 2.240 in. (56.897 mm) from the suspect blade T/E dimension Step.

Example: Base T/E dimension is 2.240 in. (56.897 mm). suspect blade T/E measures 2.244 in. (56.997 mm) so the calculated growth of the suspect blades 0.004 in. (0.1016 mm).

Do the following if the blade set meets one of the conditions that follow:

If 75 percent or more of the blades in the set are suspect.

The quantity of non-suspect blades is 15 or less.

The blades are previously repaired and mismarking condition has not been identified.

The calculated OEM length of a suspect blade is determined by subtracting the calculated growth Step or Step from the measured length Step as follows:

Example: Blade is found at Step A. to measure 3.657 in. (92.888 mm) but OEM length marked is 655 (3.655 in.) (837 (92.837 mm)). Calculated growth of blade is determined to be 0.002 in. (0.0508 mm), 3.657 in. minus 0.002 in. equals 3.655 in. Blade is identified as 655 (92.888 mm minus 0.0508 mm equals 92.837 mm. Blade is identified as 837).

Mark only the suspect blades with the calculated length from Step. with vibro-peen or dot-peen technique by SPM TASK 70-09-00-400-501. Mark the last three digits of the measurements, rounded to the nearest 0.001 in. (0.0254 mm). Example, if the length is 2.449 in. (62.204 mm), mark 449 (204). Mark in the same area as the original marking. Cross out or line out the original marked length with vibro-peen or dot-peen technique by SPM TASK 70-09-00-400-501.

SUBTASK 72-45-32-220-095 Examine the Stage 2 HPT Blade Assembly (01-010) for the Growth Measurement and Average Growth Calculation

Wall thickness inspection details have been removed. Refer to Repairs, VRS3440 TASK 72-45-32-300-013 (REPAIR-013) or VRS3602 TASK 72-45-32-300-021 (REPAIR-021) or VRS3838 TASK 72-45-32-300-033 (REPAIR-033).

Examine the blade assembly for the wall thickness dimension only when the coating is removed and you can see erosion, or when airfoil blending has removed the coating locally.

SUBTASK 72-45-32-280-059 Examine the Stage 2 HPT Blade Assembly (01-010) for the Wall Thickness Dimension

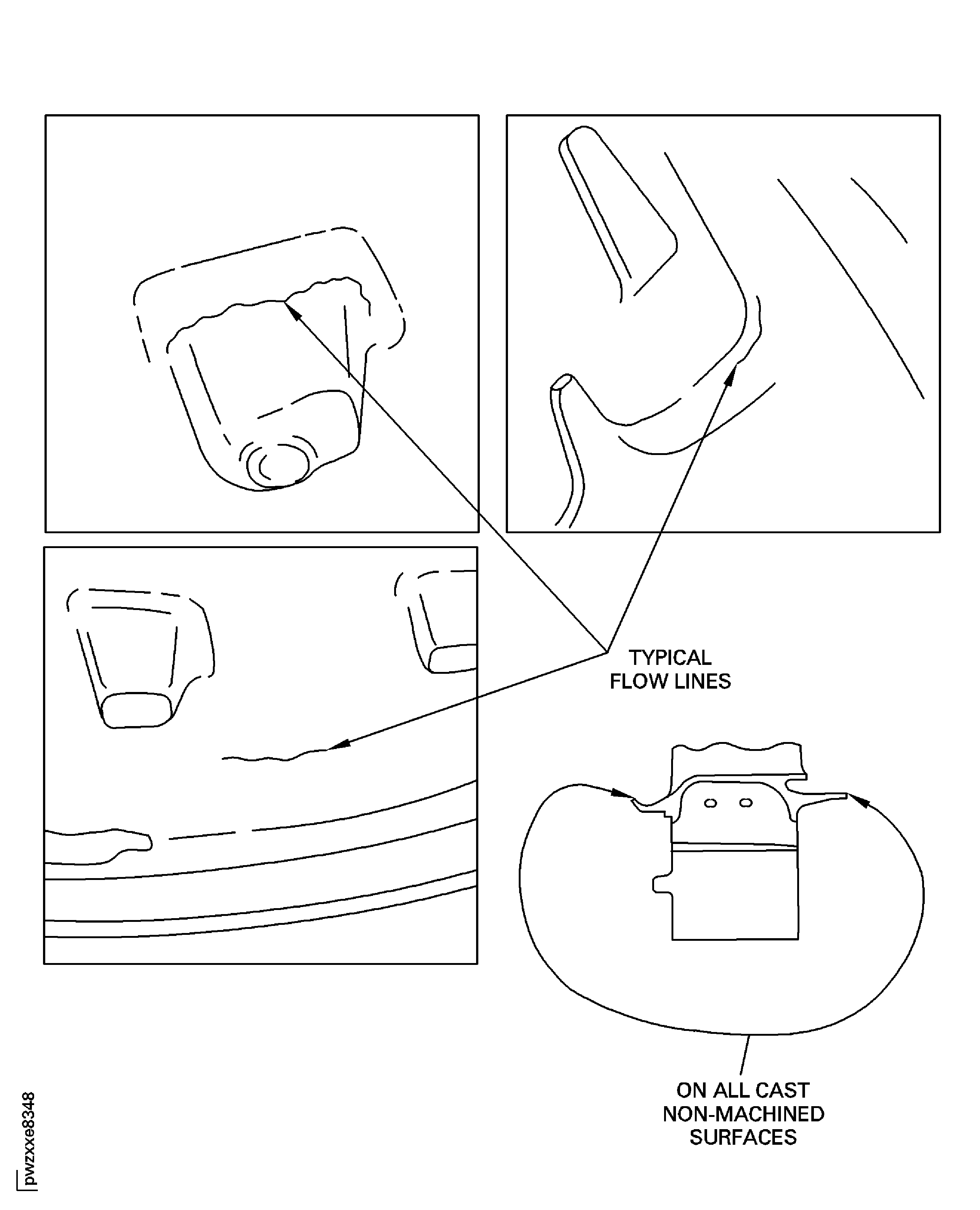

Refer to Figure.

Reject.

NOTE

All other inspection criteria apply.

A flow line is a slight depression which you can see without equipment.

Do not examine casting flow lines in the root cooling slot. Refer to Figure. If the cracks are large enough to reject the blade, the cracks would be detected at SUBTASK 72-45-32-220-079 and SUBTASK 72-45-32-230-053-001.

Flow lines with cracks.

Examine all cast non-machined surfaces for casting flow lines by fluorescent penetrant inspection. If a flow line is detected during fluorescent penetrant inspection under black light, examine by white light with a minimum of 10X magnification to verify that there are no cracks.

Examine the base of the underplatform damper pins for casting voids by visual inspection with a white light and a minimum of 3X magnification. These voids must be smooth, shallow in depth, and flat-bottomed. IAE 2P16508 Reference card 1 off shows an example of an acceptable casting void. These casting voids are a maximum of 0.030 in. (0.76 mm) in diameter. Any quantity of voids is permitted.

Examine the base of the underplatform damper pins for anomalies by visual inspection with a white light and a minimum of 10X magnification. Acceptable anomalies have a length of 0.070 in. (1.78 mm) or less. Indications that go from the centerline of the damper pin radius to the blade root, are not acceptable. Indications on the blade root are not acceptable. Any quantity of linear anomalies is permitted. IAE 2P16508 Reference card 1 off shows examples of acceptable linear anomalies. Cracks inside or which start from linear anomalies are not permitted. Fluorescent penetrant inspect questionable indications. Acceptable linear anomalies will not retain fluorescent penetrant fluid.

SUBTASK 72-45-32-230-063 Examine the Stage 2 HPT Blade (01-010) For Casting Flow Lines and Imperfections

Refer to Figure.

SUBTASK 72-45-32-280-064 Examine the Stage 2 HPT Blade (01-010) For Porosity and Shrinkage

NOTE

Porosity is regular in shape with rounded bottoms and shallow depth. Pitting is irregular in shape, deeper, with a very irregular, sponge-like surface texture.Refer to Figure.

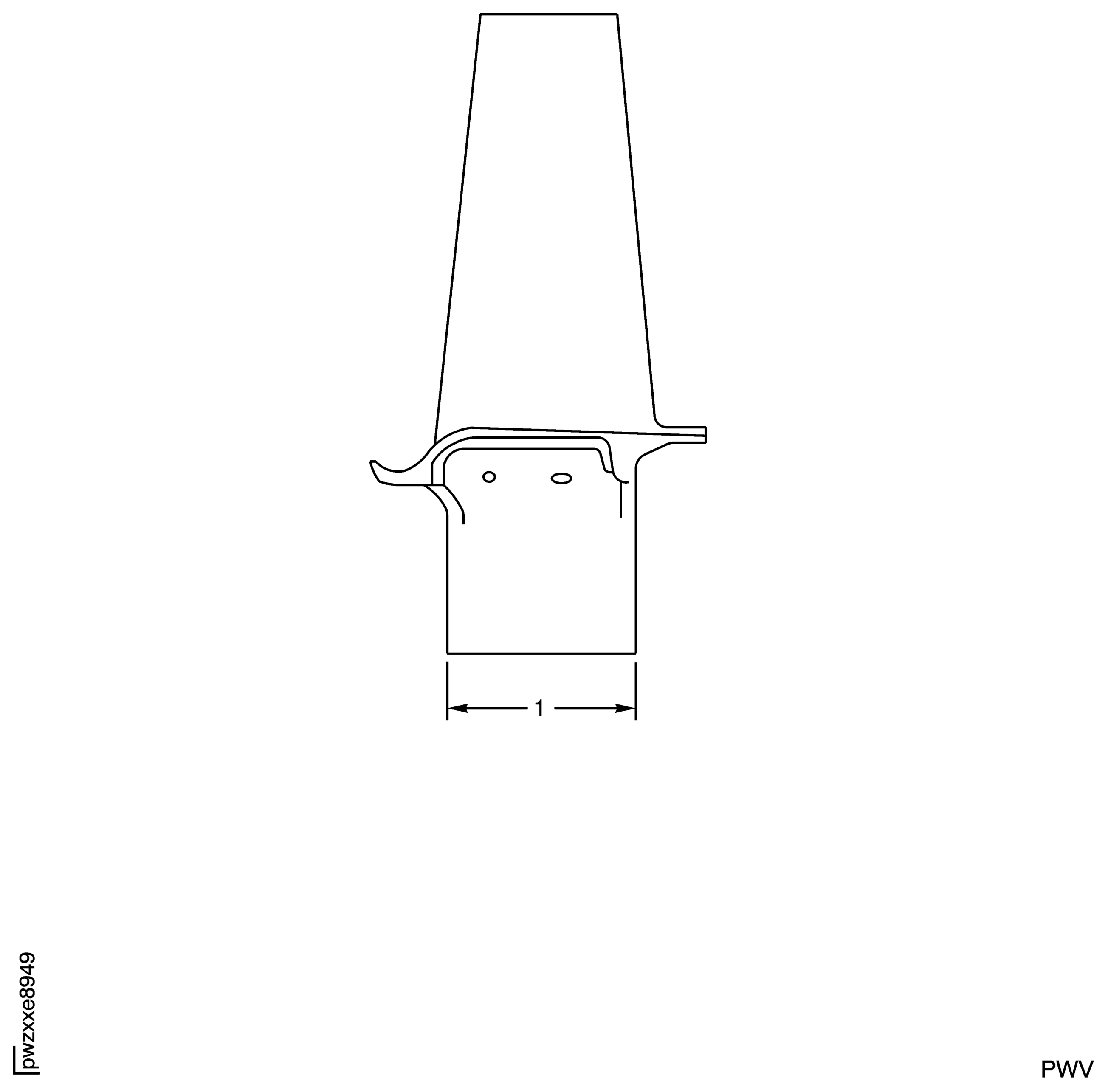

For PN 2A2202, 2A2202-001, 2A2202-002, 2A2202-003: If the dimension is 1.152 in. (29.26 mm) or more, and less than (Step).

Do a dimensional inspection to examine the blade width dimension at Location 1.

SUBTASK 72-45-32-220-115 Examine the Stage 2 HPT Blade (01-010) for Blade Width Dimensions

Figure: Stage 2 HPT Blade Permeability Inspection Areas

Stage 2 HPT Blade Permeability Inspection Areas

Figure: Stage 2 HPT Blade Permeability Inspection Path

Stage 2 HPT Blade Permeability Inspection Path

Figure: Stage 2 HPT Blade Probe Orientations

Stage 2 HPT Blade Probe Orientations

Figure: Stage 2 HPT Blade Assembly Platform Inspection Locations

Stage 2 HPT Blade Assembly Platform Inspection Locations

Figure: Stage 2 HPT Blade Assembly Airfoil Inspection Locations

Stage 2 HPT Blade Assembly Airfoil Inspection Locations

Figure: Stage 2 HPT Blade Assembly Airfoil Dents Inspection Locations

Stage 2 HPT Blade Assembly Airfoil Dents Inspection Locations

Figure: Stage 2 HPT Blade Assembly Abrasive Tip Inspection Locations

Stage 2 HPT Blade Assembly Abrasive Tip Inspection Locations

Figure: Stage 2 HPT Blade Assembly Blade Length

Stage 2 HPT Blade Assembly Blade Length

Figure: Stage 2 HPT Blade Assembly Trailing Edge Inspection Locations

Stage 2 HPT Blade Assembly Trailing Edge Inspection Locations

Figure: Stage 2 HPT Blade Assembly Platform Surfaces Inspection Locations

Stage 2 HPT Blade Assembly Platform Surfaces Inspection Locations

Figure: Stage 2 HPT Blade Root and Root Attachment Area Inspection Locations For Part Number 2A4722

Stage 2 HPT Blade Root and Root Attachment Area Inspection Locations For All Part Numbers Except 2A4722

HPT Blade Root and Root Attachment Area Inspection Locations For All Part Numbers Except 2A4722

HPT Blade Root and Root Attachment Area Inspection Locations For Part Number 2A4722

Stage 2 HPT Blade Root and Root Attachment Area Inspection Locations For Part Number 2A4722

Stage 2 HPT Blade Root and Root Attachment Previous Repair Code Markings Acceptance Area

Figure: Stage 2 HPT Blade Metal Temperature Analysis Locations

Stage 2 HPT Blade Metal Temperature Analysis Locations

Figure: Stage 2 HPT Blade Assembly Shot Peen Locations

Stage 2 HPT Blade Assembly Shot Peen Locations

Figure: Excess Metal and Foreign Material Limits (After Cleaning)

Excess Metal and Foreign Material Limits (After Cleaning)

Figure: Stage 2 HPT Blade Assembly Radiographic Positions Inspection Locations

Stage 2 HPT Blade Assembly Radiographic Positions Inspection Locations

Figure: X-Ray Inspection Internal Cavity (After Cleaning)

X-Ray Inspection Internal Cavity (After Cleaning)

Figure: Stage 2 HPT Blade Assembly Casting Flow Line Inspection

Stage 2 HPT Blade Assembly Casting Flow Line Inspection

Figure: Stage 2 HPT Blade Assembly Inspection For Porosity and Shrinkage

Stage 2 HPT Blade Assembly Inspection For Porosity and Shrinkage

Figure: Stage 2 HPT Blade Assembly Blade Root Cooling Slot Inspection

Stage 2 HPT Blade Assembly Blade Root Cooling Slot Inspection

Figure: Stage 2 HPT Blade Assembly Growth Measurement

Stage 2 HPT Blade Assembly Growth Measurement

Figure: Stage 2 HPT Blade Assembly Dimensional Inspection for Blade Width

Stage 2 HPT Blade Assembly Dimensional Inspection for Blade Width

Figure: BSI Inspection of HPT Stage 2 Blade Through Port 3 of The Blade

BSI Inspection of HPT Stage 2 Blade Through Port 3 of The Blade