Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-31-200-002-C00 LPT Stage 6 Disk - Examine

General

This TASK gives the procedure for the inspection of the stage 6 LP turbine disk. For the other LP turbine disk parts, refer to TASK 72-50-31-200-000 (INSPECTION-000).

Fig/item numbers in parentheses in the procedure agree with those used in the IPC.

The policy that is necessary for inspection is given in the SPM TASK 70-20-01-200-501.

All parts must be cleaned before any part is examined. Refer to TASK 72-50-00-100-000 (CLEANING).

All parts must be visually examined for damage, corrosion, and wear. Any defects that are not identified in the procedure must be referred to IAE.

The procedure for those parts which must have a crack test is given in SUBTASK 72-50-31-230-001. Do the crack test before the part is visually examined.

Do not discard any part until you are sure there are no repairs available. Refer to the instructions in Repair before a discarded part is used again or oversize parts are installed.

Parts which should be discarded can be held although no repair is available. The repair of a discarded part could be shown to be necessary at a later date.

All parts must be examined to make sure that all the repairs have been completed satisfactorily.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

References

Refer to the SPM for data on these items.

Definition of Damage, SPM TASK 70-02-02-350-501

Record and Control of the Lives of Parts, SPM TASK 70-05-00-220-501

Inspection of Parts, SPM TASK 70-20-01-200-501

Some data on these items are contained in this TASK. For more data on these items refer to the SPM.

Method of Testing for Crack Indications

Chemical Processes

Surface Protection

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Dial gage | LOCAL | Dial gage | ||

| Dial indicator with needle insert | LOCAL | Dial indicator with needle insert | ||

| Horizontal rotating table | LOCAL | Horizontal rotating table | ||

| Vickers hardness tester | LOCAL | Vickers hardness tester |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

SUBTASK 72-50-31-220-016 General Instructions for the Inspection of the Stage 6 Turbine Disk

NOTE

Examine the disk. If there are signs of overheating or the LPT module was reported for overheating do the hardness check. Refer to SUBTASK 72-50-31-220-019.

Dimensions are given at a temperature of 68 deg F (20 deg C).

Clean the parts. Refer to TASK 72-50-00-100-000 (CLEANING).

SUBTASK 72-50-31-230-002 Examine the Stage 6 Turbine Disk for Cracks

Reject

More than in Step

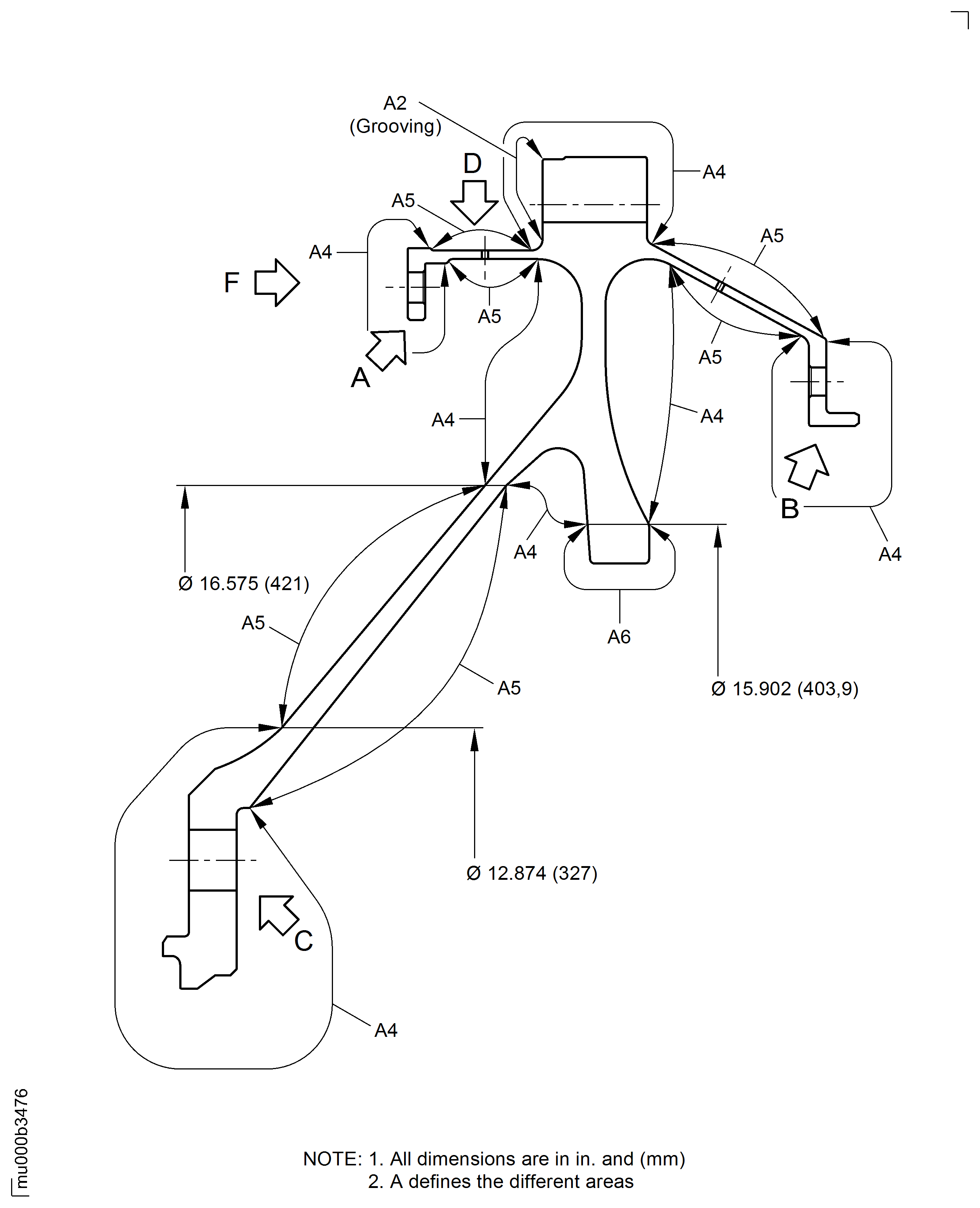

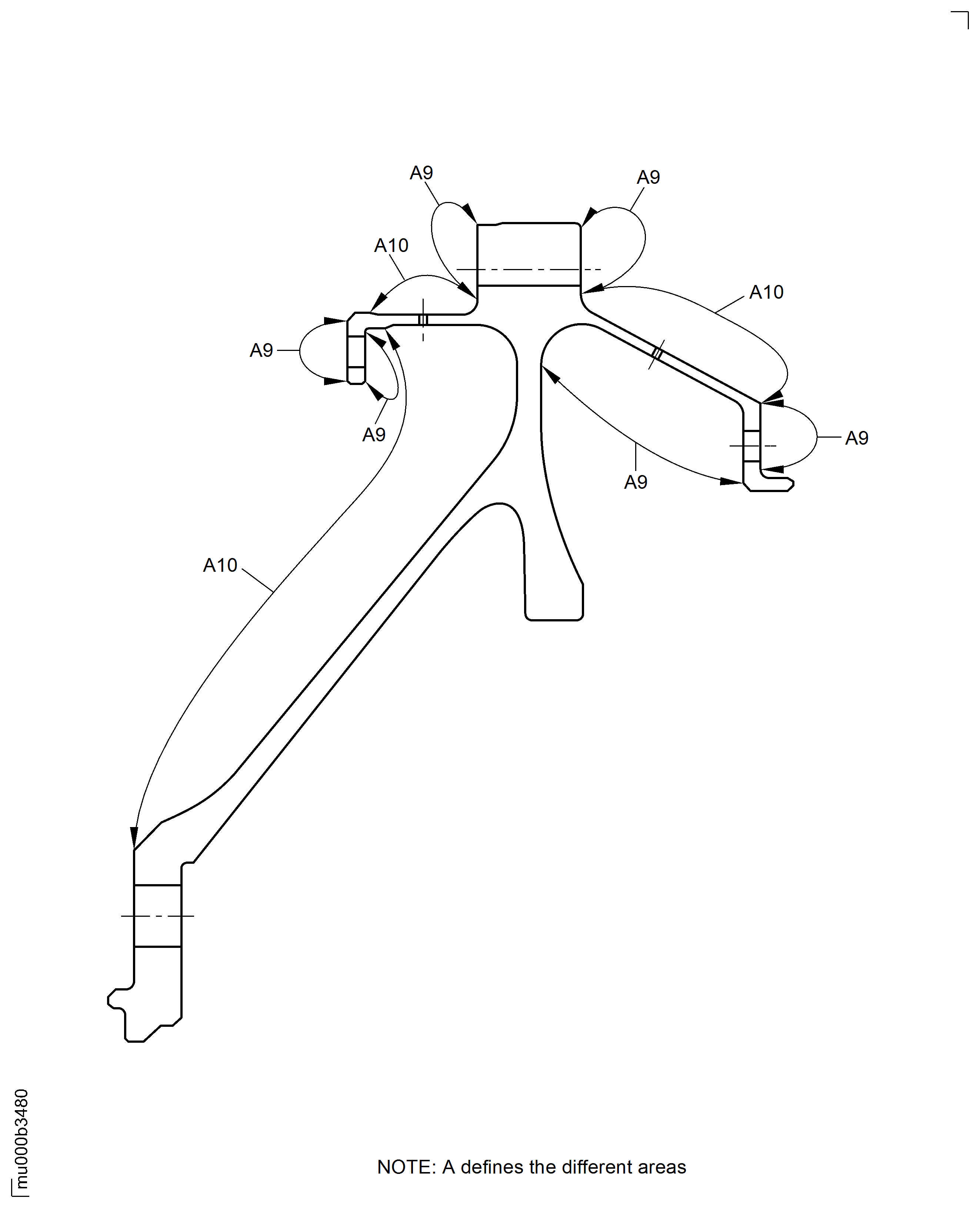

Examine the surface for corrosion pitting in area A9, not in area A7.

Repair-041, VRS4545 TASK 72-50-31-300-041

Corrosion pitting

Examine the surface for corrosion pitting in area A10.

SUBTASK 72-50-31-220-017 Examine the Stage 6 Turbine Disk for Corrosion

Refer to Figure.

Repair-004, VRS4157 TASK 72-50-31-300-004

More than in Step and not more than 0.006 in. (0.15 mm) maximum depth

Grooved (due to seal ring contact)

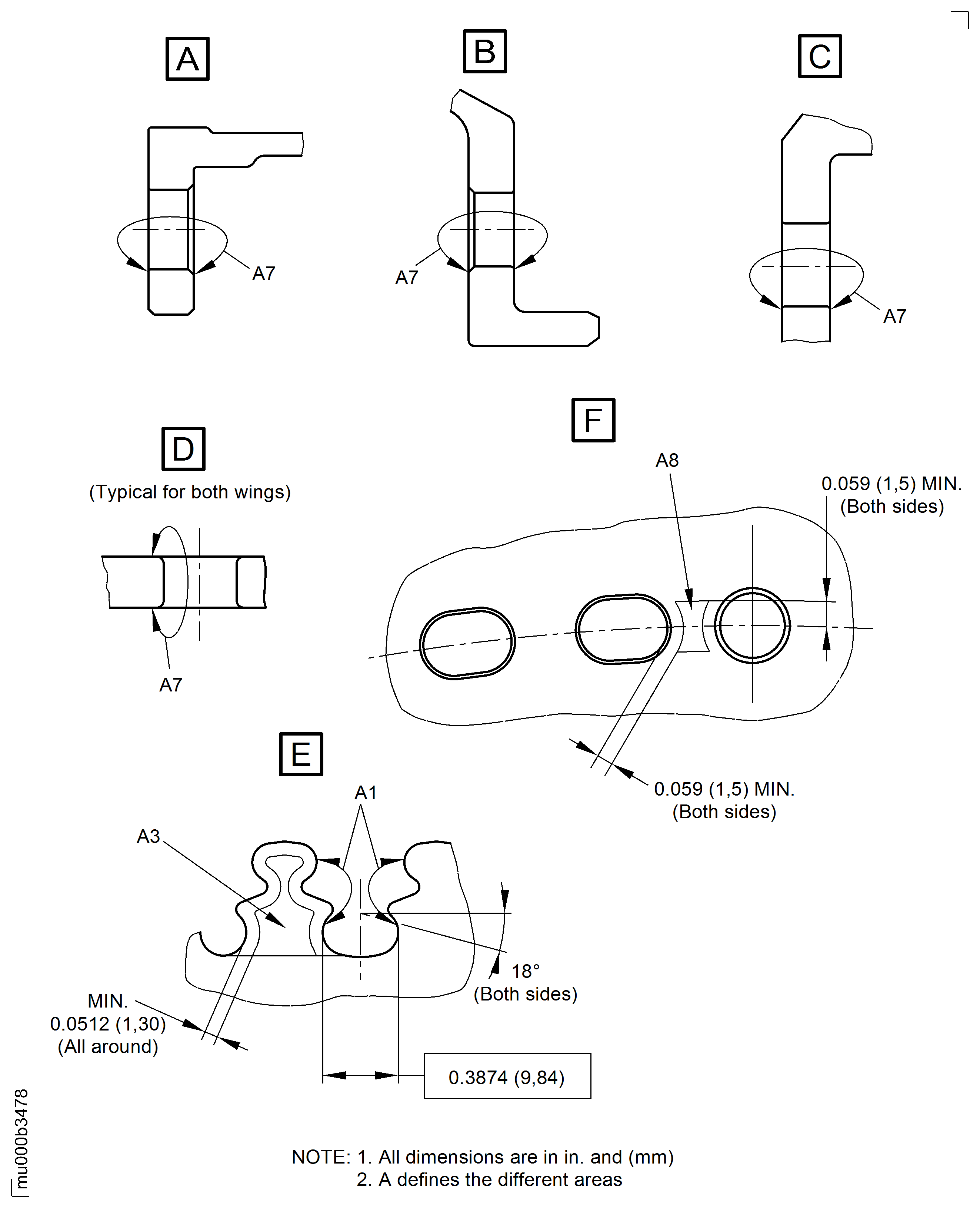

Examine the surface in area A2 for grooves. Use Dial gage, Dial indicator with needle insert, and Horizontal rotating table.

SUBTASK 72-50-31-220-018 Examine the Stage 6 Turbine Disk for Surface Damage

Refer to Figure.

SUBTASK 72-50-31-220-019 Examine the Stage 6 Turbine Disk for Hardness

Refer to Figure.

Repair-004, VRS4157 TASK 72-50-31-300-004

More than in Step

Nicked, dented

Repair-004, VRS4157 TASK 72-50-31-300-004

More than in Step

Scratched

Examine the surface in area A4.

SUBTASK 72-50-31-220-020 Examine the Stage 6 Turbine Disk for Surface Damage

Refer to Figure.

Repair-004, VRS4157 TASK 72-50-31-300-004

More than in Step

Nicked

Repair-004, VRS4157 TASK 72-50-31-300-004

More than in Step

Dented

Repair-004, VRS4157 TASK 72-50-31-300-004

More than in Step

Scratched

Examine the surface in area A5.

SUBTASK 72-50-31-220-021 Examine the Stage 6 Turbine Disk for Surface Damage

Refer to Figure.

Repair-004, VRS4157 TASK 72-50-31-300-004

More than in Step and not more than 0.0022 in. (0.055 mm) maximum depth

Nicked, dented

Repair-004, VRS4157 TASK 72-50-31-300-004

More than in Step and not more than 0.0022 in. (0.055 mm) maximum depth

Scratched

Examine the surface in area A6.

SUBTASK 72-50-31-220-022 Examine the Stage 6 Turbine Disk for Surface Damage

Refer to Figure.

More than in Step

Fretted

Repair-004, VRS4157 TASK 72-50-31-300-004

Other than in Step

Nicked, dented, scratched

Examine the surface in area A7.

SUBTASK 72-50-31-220-023 Examine the Stage 6 Turbine Disk for Surface Damage

Refer to Figure.

SUBTASK 72-50-31-220-024 Examine the Stage 6 Turbine Disk for Surface Damage

Refer to Figure.

More than in Step

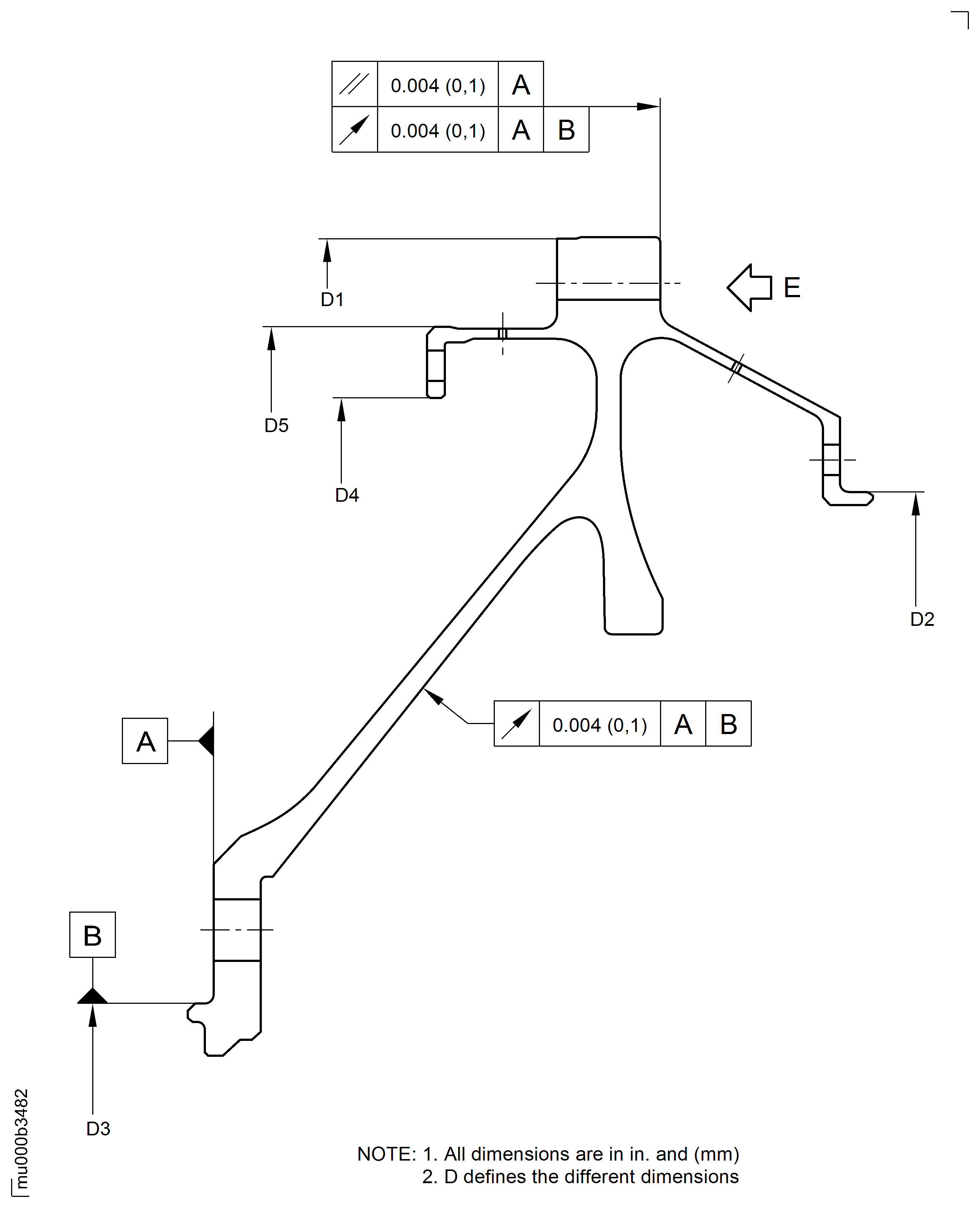

Measure the diameter D1 for growth at 120, 240, and 360 degrees. Get an average dimension.

More than in Step

Measure the diameter D1 for shrinkage at 120, 240, and 360 degrees. Get an average dimension.

SUBTASK 72-50-31-220-025 Examine the Stage 6 Turbine Disk Outer Diameter D1

Refer to Figure.

More than in Step

Do a check run-out of the outer flange to plane A and diameter B. Use Dial gage and Horizontal rotating table.

More than in Step

Do a check parallelism of the outer flange to plane A. Use Dial gage and Horizontal rotating table.

Reject

More than in Step

Do a check run-out of the inner web to plane A and diameter B. Use Dial gage and Horizontal rotating table.

SUBTASK 72-50-31-220-026 Examine the Stage 6 Turbine Disk for Excessive Deflection

Refer to Figure.

Repair-007, VRS4160 TASK 72-50-31-300-007

Less than in Step

Measure the diameter D2 for wear at 120, 240, and 360 degrees. Get an average dimension.

Accept the part for selected fit only

NOTE

This part can be used only if the mating part has a diameter that will result in a fit of reference 3365 or 3665 or 3765. Refer to TASK 72-50-10-430-010.

Between 17.707 in. and 17.697 in. (449.75 mm and 449.50 mm)

Measure the diameter D2 for shrinkage and growth at 120, 240, and 360 degrees. Get an average dimension.

SUBTASK 72-50-31-220-027 Examine the Stage 6 Turbine Disk Snap Diameter D2

Refer to Figure.

Repair-008, VRS4162 TASK 72-50-31-300-008

Less than in Step

Measure the diameter D3 for wear at 120, 240, and 360 degrees. Get an average dimension.

Accept the part for selected fit only

NOTE

This part can be used only if the mating part has a diameter that will result in a fit of reference 3392 or 3402 or 3782 or 3802. Refer to TASK 72-50-00-430-001.

Between 8.981 in. and 8.976 in. (228.10 mm and 228.00 mm)

Measure the diameter D3 for shrinkage and growth at 120, 240, and 360 degrees. Get an average dimension.

SUBTASK 72-50-31-220-028 Examine the Stage 6 Turbine Disk Snap Diameter D3

Refer to Figure.

Repair-005, VRS4158 TASK 72-50-31-300-005

More than in Step

Measure the diameter D4 for wear at 120, 240, and 360 degrees. Get an average dimension.

Accept the part for selected fit only.

NOTE

This part can be used only if the mating part has a diameter that will result in a fit of reference 3359 or 3659 or 3759. Refer to TASK 72-50-10-430-008.

Between 19.297 in. and 19.287 in. (490.15 mm and 489.90 mm)

Measure the diameter D4 for shrinkage and growth at 120, 240, and 360 degrees. Get an average dimension.

SUBTASK 72-50-31-220-029 Examine the Stage 6 Turbine Disk Snap Diameter D4

Refer to Figure.

Repair-005, VRS4158 TASK 72-50-31-300-005

Less than in Step

Measure the diameter D5 for wear at 120, 240, and 360 degrees. Get an average dimension.

Accept the part for selected fit only.

NOTE

This part can be used only if the mating part has a diameter that will result in a fit of reference 3358 or 3658 or 3758. Refer to TASK 72-50-30-440-004.

Between 20.494 in. and 20.484 in. (520.55 mm and 520.30 mm)

Measure the diameter D5 for shrinkage and growth at 120, 240, and 360 degrees. Get an average dimension.

SUBTASK 72-50-31-220-030 Examine the Stage 6 Turbine Disk Snap Diameter D5

Figure: Examine the Stage 6 Turbine Disk

Examine the Stage 6 Turbine Disk

Figure: Examine the Stage 6 Turbine Disk

Examine the Stage 6 Turbine Disk

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Examine the Stage 6 Turbine Disk

Examine the Stage 6 Turbine Disk