Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-32-200-005-D00 LPT Stage 3 Blade - Examine, Inspection-005

General

This TASK gives the procedure for the inspection of the stage 3 turbine blades.

If there are signs of overheating, refer to TASK 72-50-32-200-006-A00 (INSPECTION/CHECK-006, CONFIG-001) before you do this inspection.

Deleted.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC.

The policy that is necessary for inspection is given in the SPM TASK 70-20-00-200-501.

All parts must be cleaned before any part is examined. Refer to the TASK 72-50-32-100-000 (72-050-032,CLEANING-000).

All parts must be visually examined for damage, corrosion and wear. Any defects that are not identified in the procedure must be referred to IAE.

The procedure for those parts which must have a crack test is given in SUBTASK 72-50-32-230-177. Do the crack test before the part is visually examined.

Do not discard any part until you are sure there are no repairs available. Refer to the instructions in Repair before a discarded part is used again or oversize parts are installed.

Parts which should be discarded can be held although no repair is available. The repair of a discarded part could be shown to be necessary at a later date.

All parts must be examined to make sure that all the repairs have been completed satisfactorily.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

References

Refer to the SPM for data on these items.

Definitions of Damage, SPM TASK 70-02-02-350-501

Record and Control of the Lives of Parts, SPM TASK 70-05-00-220-501

Inspection of Parts, SPM TASK 70-20-00-200-501

Some data on these items is contained in this TASK. For more data on these items refer to the SPM.

Method of Testing for Crack Indications

Chemical Processes

Surface Protection

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 2M14188 Inspection gage | 0AM53 | IAE 2M14188 | 1 | |

| IAE 2M14195 Inspection mounting block | 0AM53 | IAE 2M14195 | 1 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Clean the parts. Refer to TASK 72-50-32-100-000 (CLEANING-000).

Repair, VRS4206 TASK 72-50-32-300-028 (REPAIR-028)

Cracked in the shroud notches

Repair, VRS4204 TASK 72-50-32-300-026 (REPAIR-026)

Not more than 0.040 in. (1.00 mm) maximum depth

Repair, VRS4510 TASK 72-50-32-300-069 (REPAIR-069)

More than in Step

Cracked in the knife edge seals.

Do the test for cracks on the parts that are given below. Use the applicable penetrant procedure.

PART IDENT

TASK/SUBTASK

Stage 3 turbine blades

SUBTASK 72-50-32-230-177-001 Examine the Stage 3 Turbine Blades for Cracks

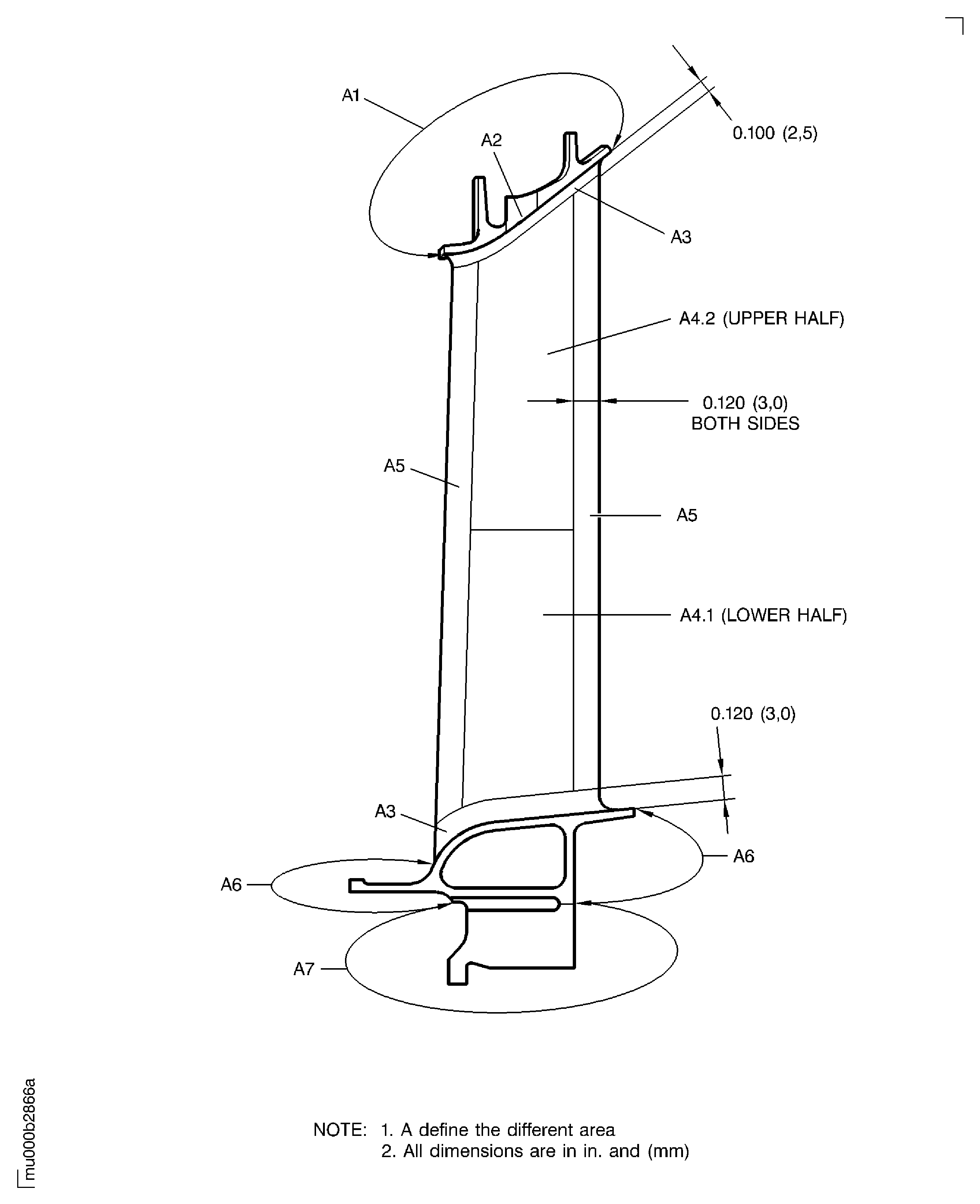

Refer to Figure.

NOTE

This examination includes surface defects which are permitted per production standard. Surface defects are not caused by hit of some objects or service operation.Fluorescent penetrant examine or visually examine areas A1 to A7 for surface defects. Refer to the SPM TASK 70-23-08-230-501 or SPM TASK 70-21-01-220-501.Surface defects larger than 0.015 in. (0.38 mm) diameter must have a bottom which can be seen.Surface defects not larger than 0.015 in. (0.38 mm) can be non bottomed.A cluster is a defect of four or more surface defects, clearly apart, which can be contained within a 0.200 in. (5.08 mm) diameter circle. In the cluster all surface defects must be 0.015 in. (0.38 mm) or less.If not differently specified, surface defects of 0.015 in. (0.38 mm) or less must be ignored if they are not found in linear alignment or clusters, or in areas where 0.015 in. (0.38 mm) is the maximum permitted size.In areas where 0.015 in. (0.38 mm) is the maximum permitted size, surface defects 0.010 in. (0.25 mm) or less, not in linear alignment or clusters must be ignored.If permitted limits on coated surfaces are exceeded, remove the coating and make a estimate of the surface defects again. Repair coating per VRS4298 TASK 72-50-32-300-047 (REPAIR-047) or VRS4300 TASK 72-50-32-300-049 (REPAIR-049).More than in Step

Examine the surface in area A3.

More than in Step

Examine the surface in area A5.

SUBTASK 72-50-32-220-353 Examine the Stage 3 Turbine Blades for Surface Defects

Refer to Figure.

Repair, VRS4204 TASK 72-50-32-300-026 (REPAIR-026)

Not more than 0.010 in. (0.25 mm) maximum depth

Repair, VRS4510 TASK 72-50-32-300-069 (REPAIR-069)

More than in Step

Dented

Repair, VRS4204 TASK 72-50-32-300-026 (REPAIR-026)

Not more than 0.005 in. (0.13 mm) maximum depth

Repair, VRS4510 TASK 72-50-32-300-069 (REPAIR-069)

More than in Step

Nicked or pitted

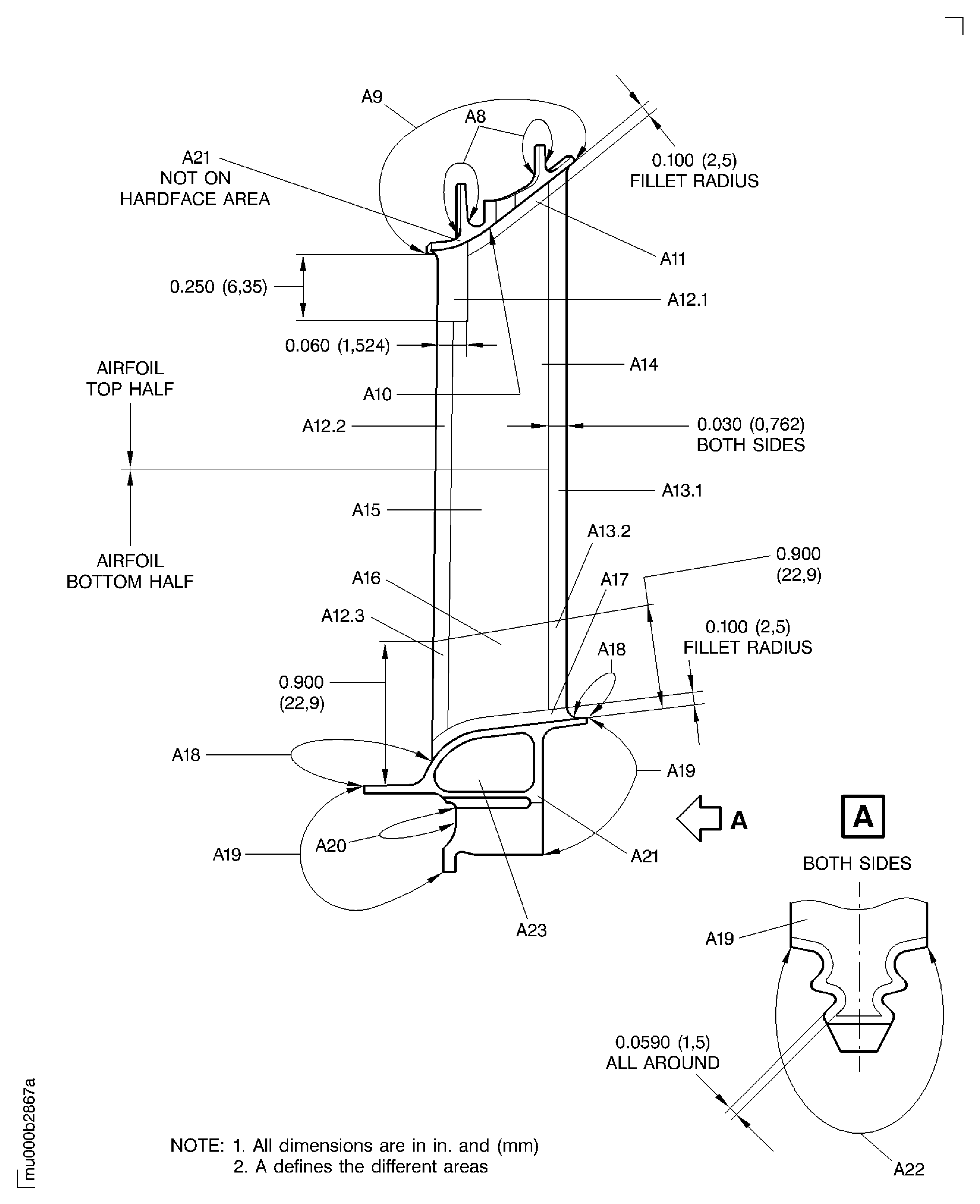

Examine the knife edge seals in area A8.

SUBTASK 72-50-32-220-354 Examine the Stage 3 Turbine Blade in Area A8 for Surface Damage

Refer to Figure.

Repair, VRS4509 TASK 72-50-32-300-063 (REPAIR-063)

Nicked, dented or pitted

Examine the surface in area A9.

Repair, VRS4509 TASK 72-50-32-300-063 (REPAIR-063)

Nicked, dented, pitted

Examine the surface in area A10.

Repair, VRS4509 TASK 72-50-32-300-063, (REPAIR-063)

Nicked, dented, pitted

Examine the surface in area A11.

Repair, VRS4509 TASK 72-50-32-300-063 (REPAIR-063)

Examine the surface in area A12.

Repair, VRS4509 TASK 72-50-32-300-063, (REPAIR-063)

Examine the surface in area A13.

Repair, VRS4509 TASK 72-50-32-300-063, (REPAIR-063)

Nicked, dented, pitted

Examine the surface in area A14.

Repair, VRS4509 TASK 72-50-32-300-063, (REPAIR-063)

Nicked, dented, pitted

Examine the surface in area A15.

Repair, VRS4509 TASK 72-50-32-300-063, (REPAIR-063)

More than in Step

Nicked, dented, pitted

Examine the surface in area A16.

More than in Step

Nicked, dented, pitted

Examine the surface in area A17.

More than in Step

Nicked, dented, pitted

Examine the surface in area A19.

More than in Step

Grooved because of airseal contact

Examine the surface in area A20.

More than in Step

Chipped, nicked, dented or pitted

Examine the surface in area A22.

More than in Step

Pitted

Examine the surface in area A23.

SUBTASK 72-50-32-220-355 Examine the Stage 3 Turbine Blade in Area A9 - A23 for Surface Damage

Refer to Figure.

NOTE

Sulphidation pits have a dark bottom after dry grit abrasive blast per the SPM TASK 70-12-09-120-501.If dark bottom pits are visible after dry blast, remove coating per VRS4300 TASK 72-50-32-300-049 (REPAIR-049) before any part is examined.Other than in Step

Sulphidation pits or pustules

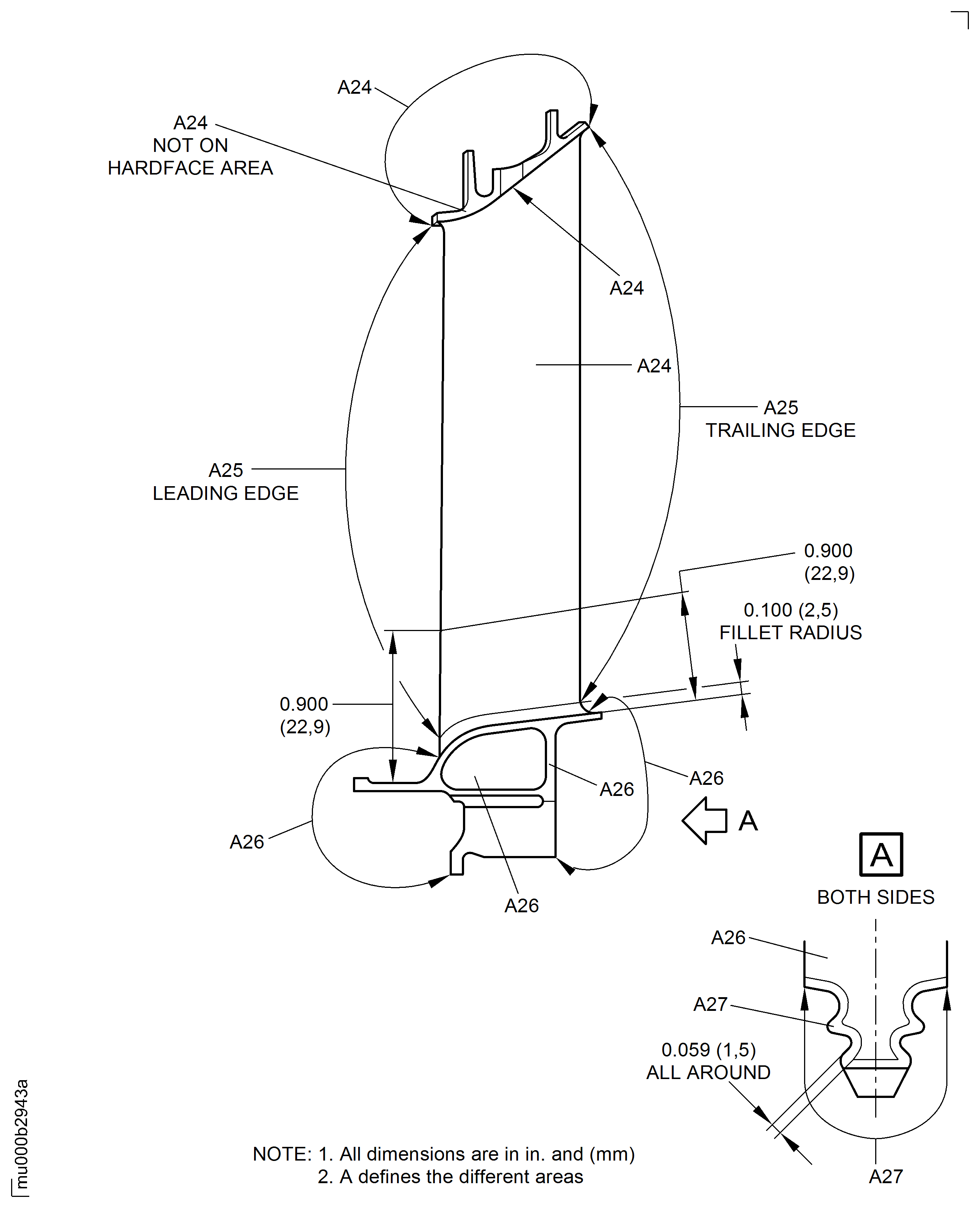

Examine the surface in area A24.

Repair, VRS4509 TASK 72-50-32-300-063, (REPAIR-063)

Sulphidation pits or pustules

Examine the surface in area A25.

Other than in Step

Sulphidation pits or pustules

Examine the surface in area A26.

Other than in Step

Sulphidation pits or pustules

Examine the surface in area A27.

SUBTASK 72-50-32-220-434 Examine the Stage 3 Turbine Blade in Area A24 - A27 for Sulphidation

Refer to Figure.

Repair, VRS4300 TASK 72-50-32-300-049 (REPAIR-049)

Cracked coating

Repair, VRS4298 TASK 72-50-32-300-047 (REPAIR-047)

Blistered, damaged or chipped coating not more than 1.000 sq.in. (645.16 sq.mm) total area per blade (shrouds and airfoils together)

Repair, VRS4300 TASK 72-50-32-300-049 (REPAIR-049)

Other than in Step

Examine the coating.

Examine the surface in area A10 - A18.

SUBTASK 72-50-32-220-356 Examine the Stage 3 Turbine Blade for Coating Damage

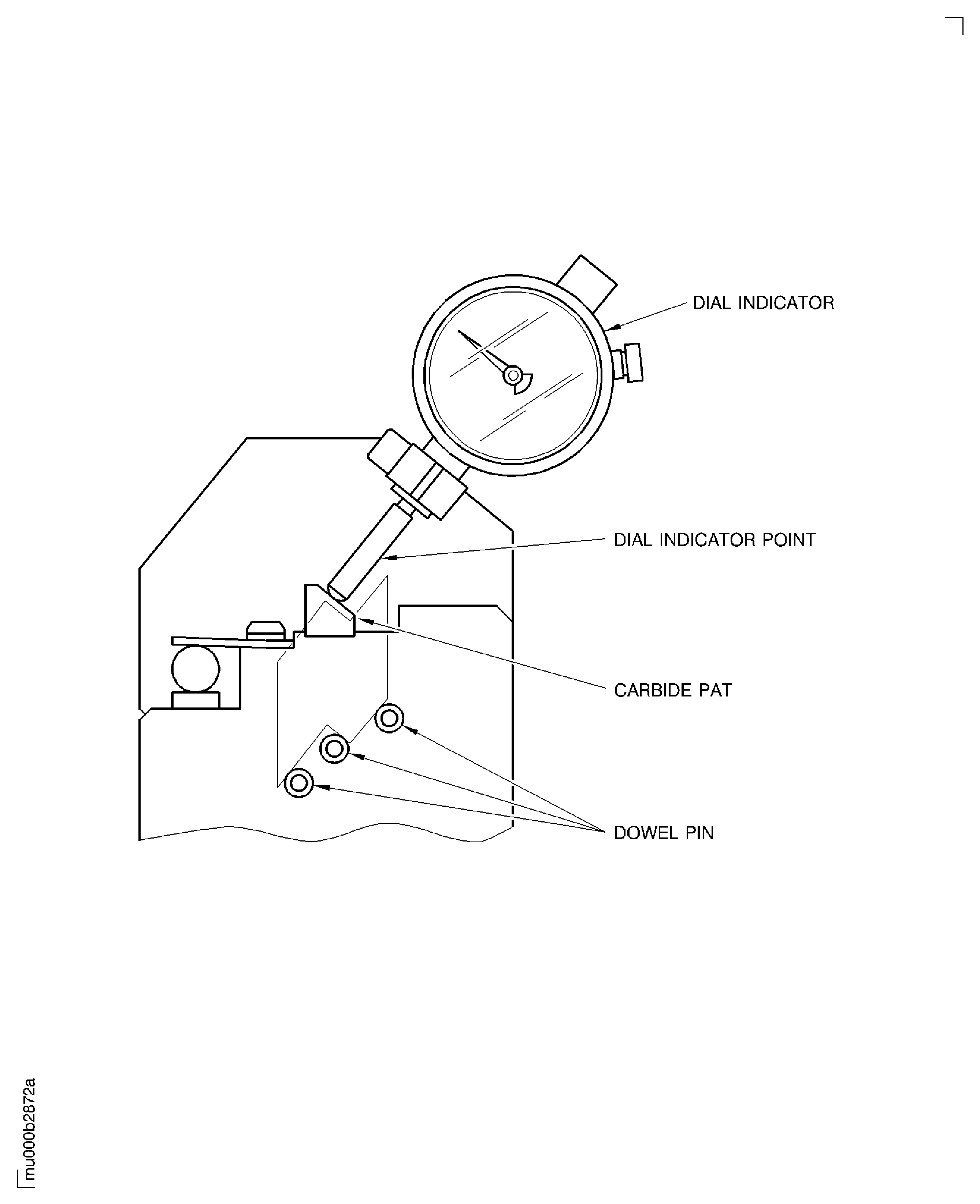

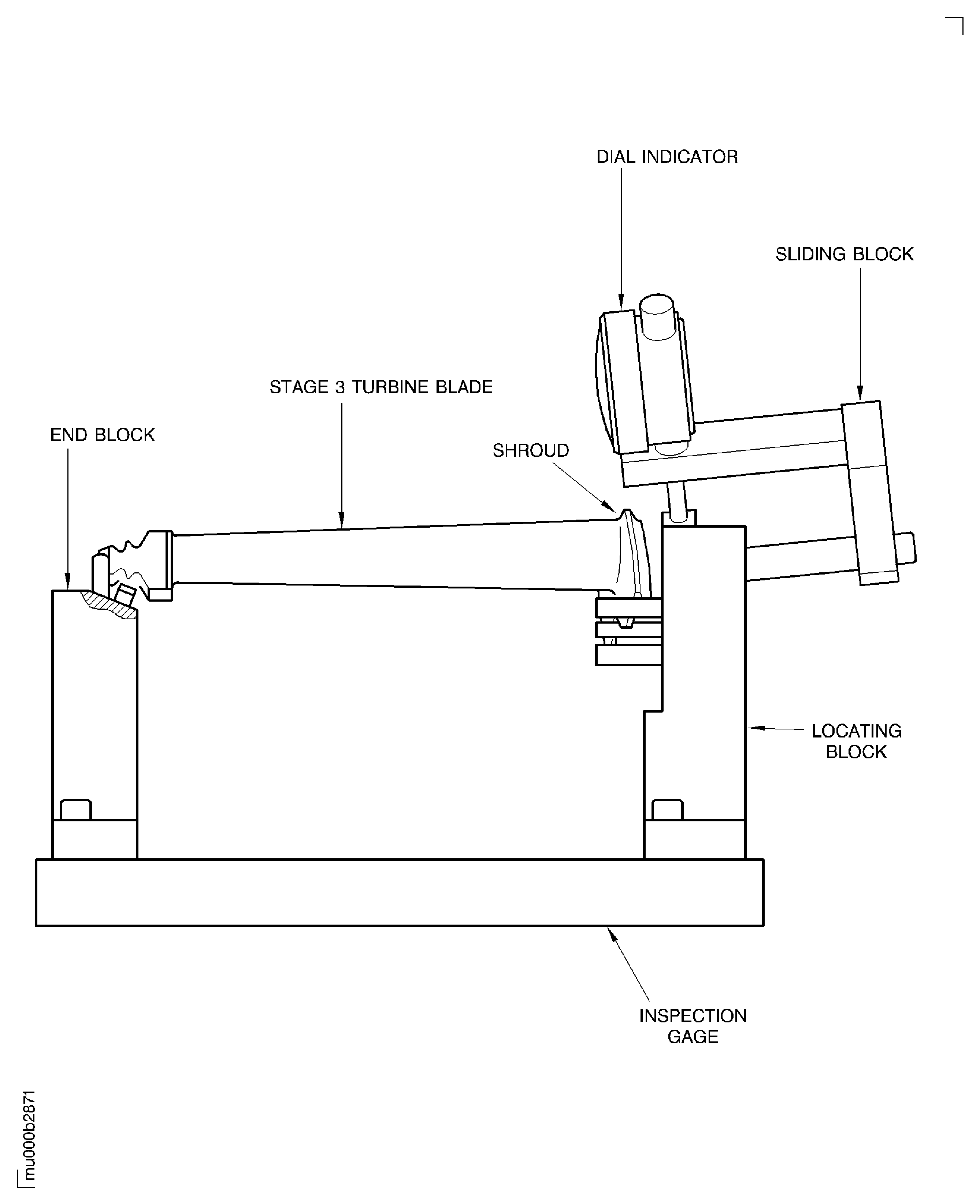

Install the stage 3 turbine blade with the convex side down on to the IAE 2M14188 Inspection gage 1 off. Make sure that the stage 3 turbine blade is correctly installed in the IAE 2M14188 Inspection gage.

Repair, VRS4512 TASK 72-50-32-300-073 (REPAIR-073)

Less than in Step and not less than 0.786 in. (19.96 mm)

Less than in Step

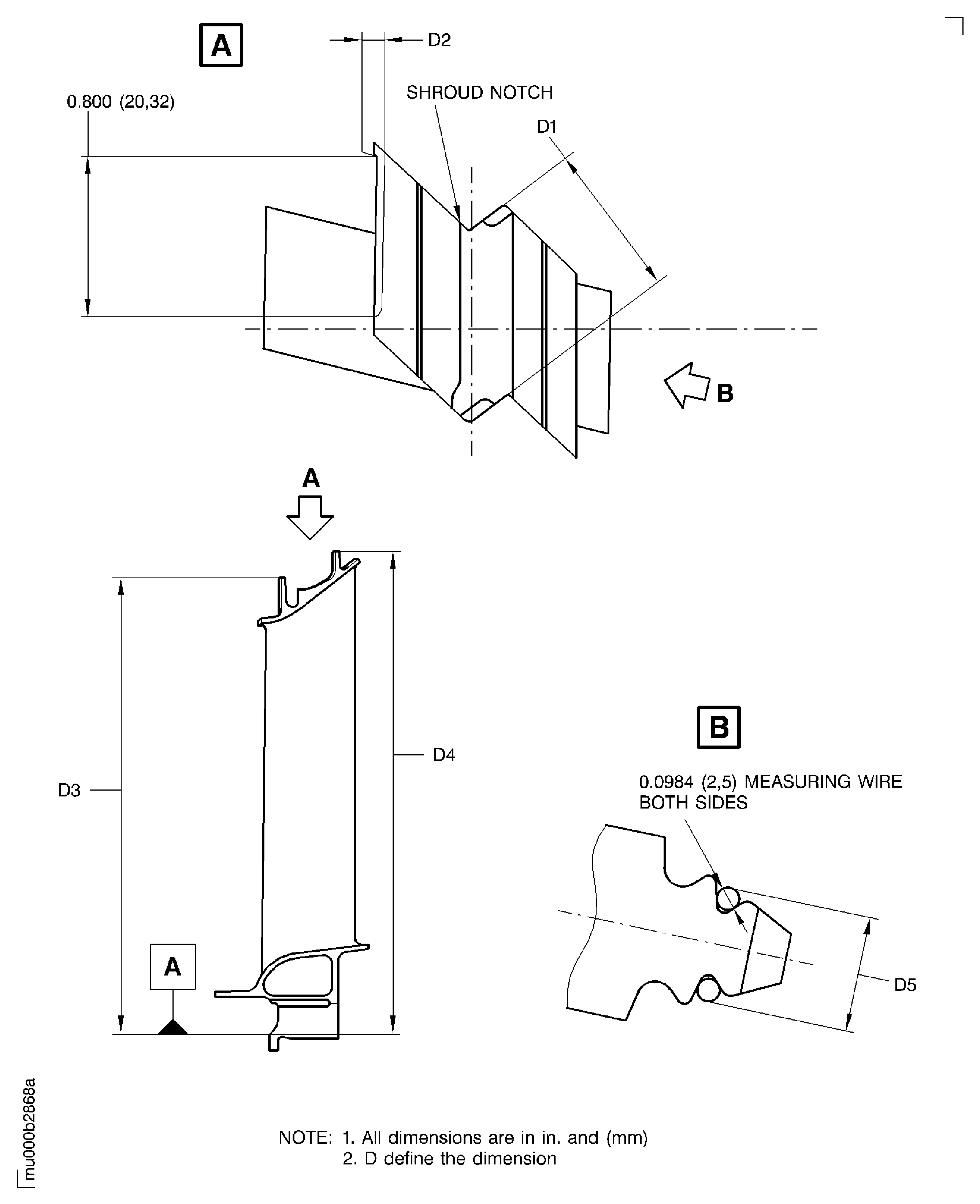

Find the actual result of the outer shroud dimension D1 as follows:

Remove the stage 3 turbine blade from the IAE 2M14188 Inspection gage.

SUBTASK 72-50-32-220-357 Examine the Outer Shroud Dimension D1 of the Turbine Blade

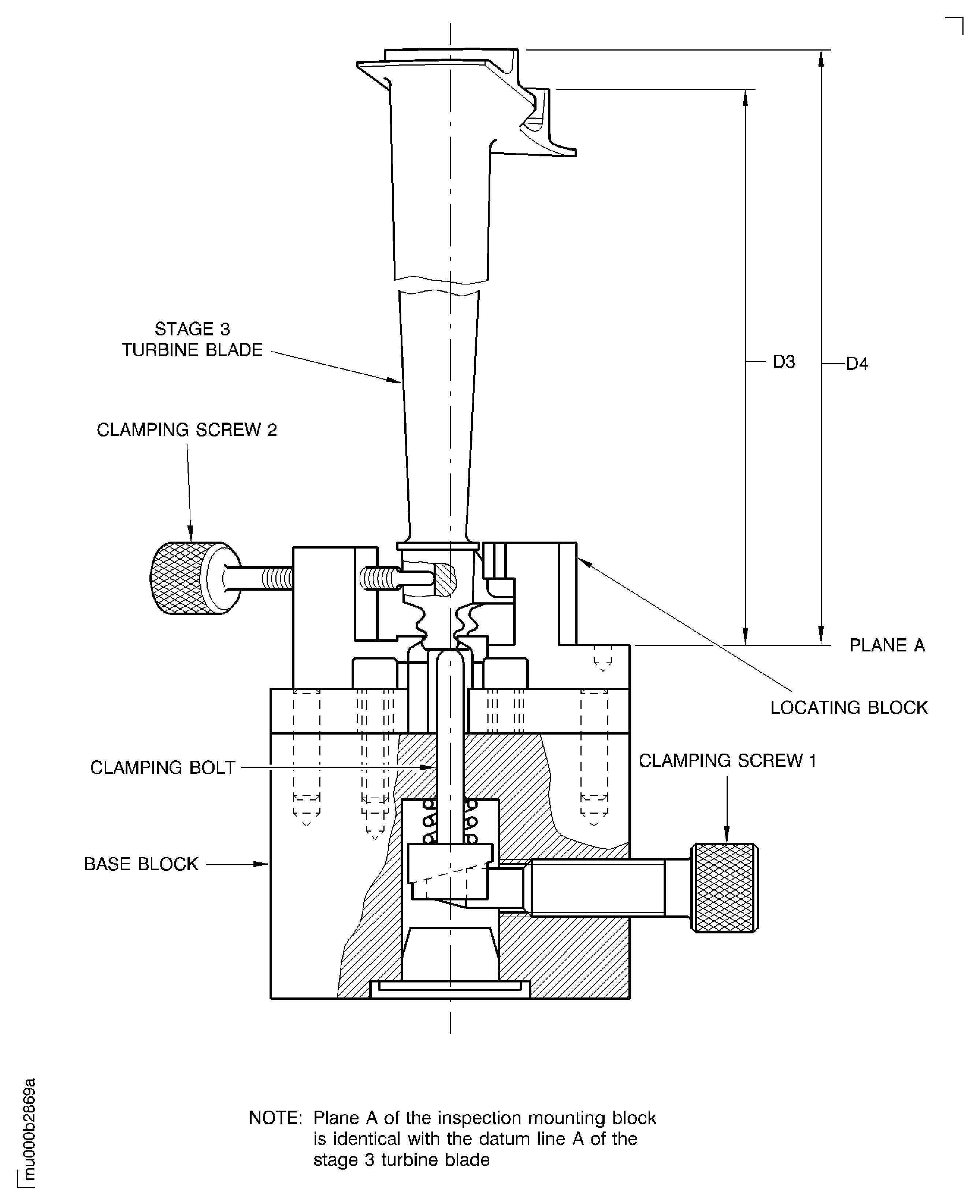

Install the stage 3 turbine blade with the rear knife edge seal located to the front of the IAE 2M14195 Inspection mounting block. The blade root nose must touch the locating block.

Press the stage 3 turbine blade with finger pressure to the locating block. Turn clockwise the clamping screw 1 by hand to lock the blade in the vertical position on the IAE 2M14195 Inspection mounting block.

Install the stage 3 turbine blade on the IAE 2M14195 Inspection mounting block 1 off as follows, refer to Figure and Figure:

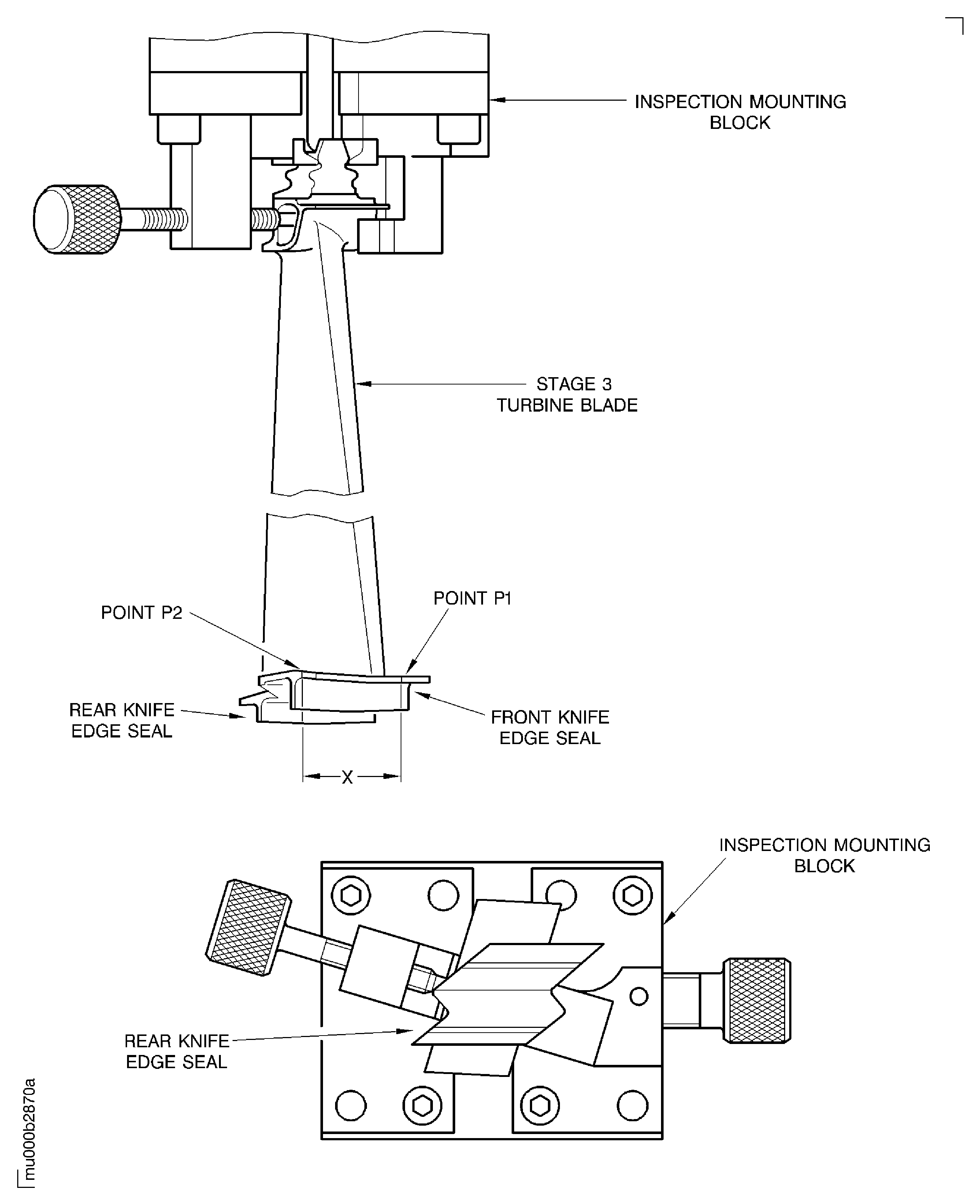

Turn by 90 degrees the IAE 2M14195 Inspection mounting block to bring the stage 3 turbine blade in the horizontal position. The rear knife edge seal of the stage 3 turbine blade must be down.

Repair, VRS4511 TASK 72-50-32-300-065 (REPAIR-065)

Other than in Step

Measure the deviation between point P1 and point P2 on the front blade shroud face as follows:

SUBTASK 72-50-32-220-358 Examine the Twist of the Turbine Blade

Repair, VRS4510 TASK 72-50-32-300-069 (REPAIR-069)

Less than in Step

Measure the dimension D3 between the front knife edge seal and the plane A on the IAE 2M14195 Inspection mounting block.

Repair, VRS4510 TASK 72-50-32-300-069 (REPAIR-069)

Less than in Step

Measure the dimension D4 between the rear knife edge seal and the plane A on the IAE 2M14195 Inspection mounting block.

Remove the stage 3 turbine blade from the IAE 2M14195 Inspection mounting block.

SUBTASK 72-50-32-220-359 Examine the Knife Edge Seal of the Turbine Blade

Figure: Examine the Stage 3 Turbine Blades

Examine the Stage 3 Turbine Blades

Figure: Examine the Stage 3 Turbine Blades

Examine the Stage 3 Turbine Blades

Figure: Examine the Stage 3 Turbine Blades

Examine the Stage 3 Turbine Blades

Figure: Examine the Stage 3 Turbine Blades

Examine the Stage 3 Turbine Blades

Figure: Install the Stage 3 Turbine Blade on to the Inspection Mounting Block

Install the Stage 3 Turbine Blade on to the Inspection Mounting Block

Figure: Install the Stage 3 Turbine Blade on to the Inspection Mounting Block

Install the Stage 3 Turbine Blade on to the Inspection Mounting Block

Figure: Install the Stage 3 Turbine Blade on to the Inspection Gage

Install the Stage 3 Turbine Blade on to the Inspection Gage

Figure: Install the Stage 3 Turbine Blade on to the Inspection Gage

Install the Stage 3 Turbine Blade on to the Inspection Gage