Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-50-450-002-A00 LPT Module Components - Install The EGT Harness And Junction Box Assembly (4012KS-5), Installation-011

General

This TASK gives the procedure to install the EGT harness and junction box assembly on the LP turbine system module.

For standard torque data procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501

For installation and the reuse of self-locking fasteners, refer to the SPM TASK 70-42-01-400-501.

For installation of lockwire, refer to the SPM TASK 70-42-05-400-501.

Fig/item numbers are in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants, refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-127 LOCKWIRE | LOCAL | CoMat 02-127 | ||

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 | ||

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 |

Spares

NONESafety Requirements

NONEProcedure

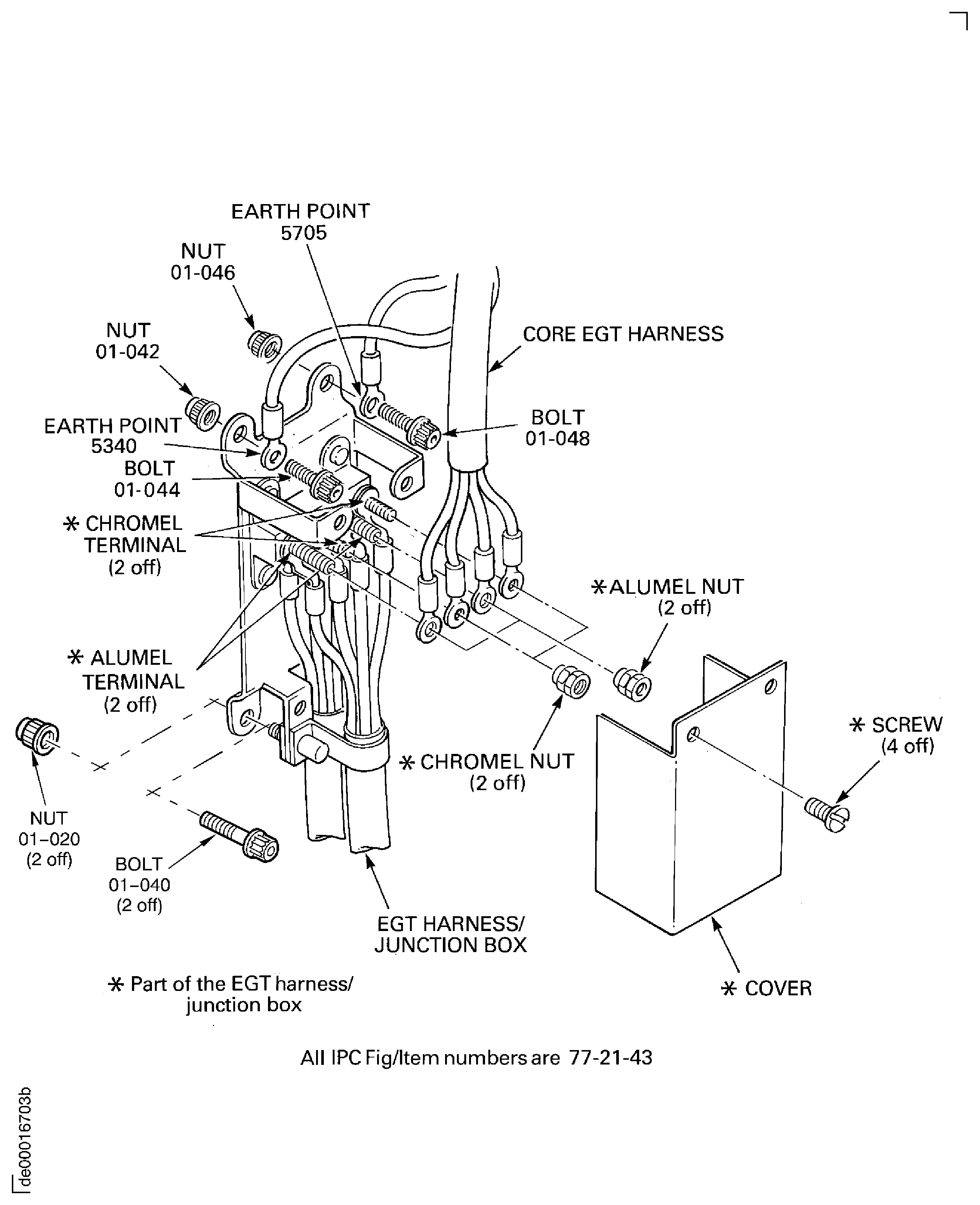

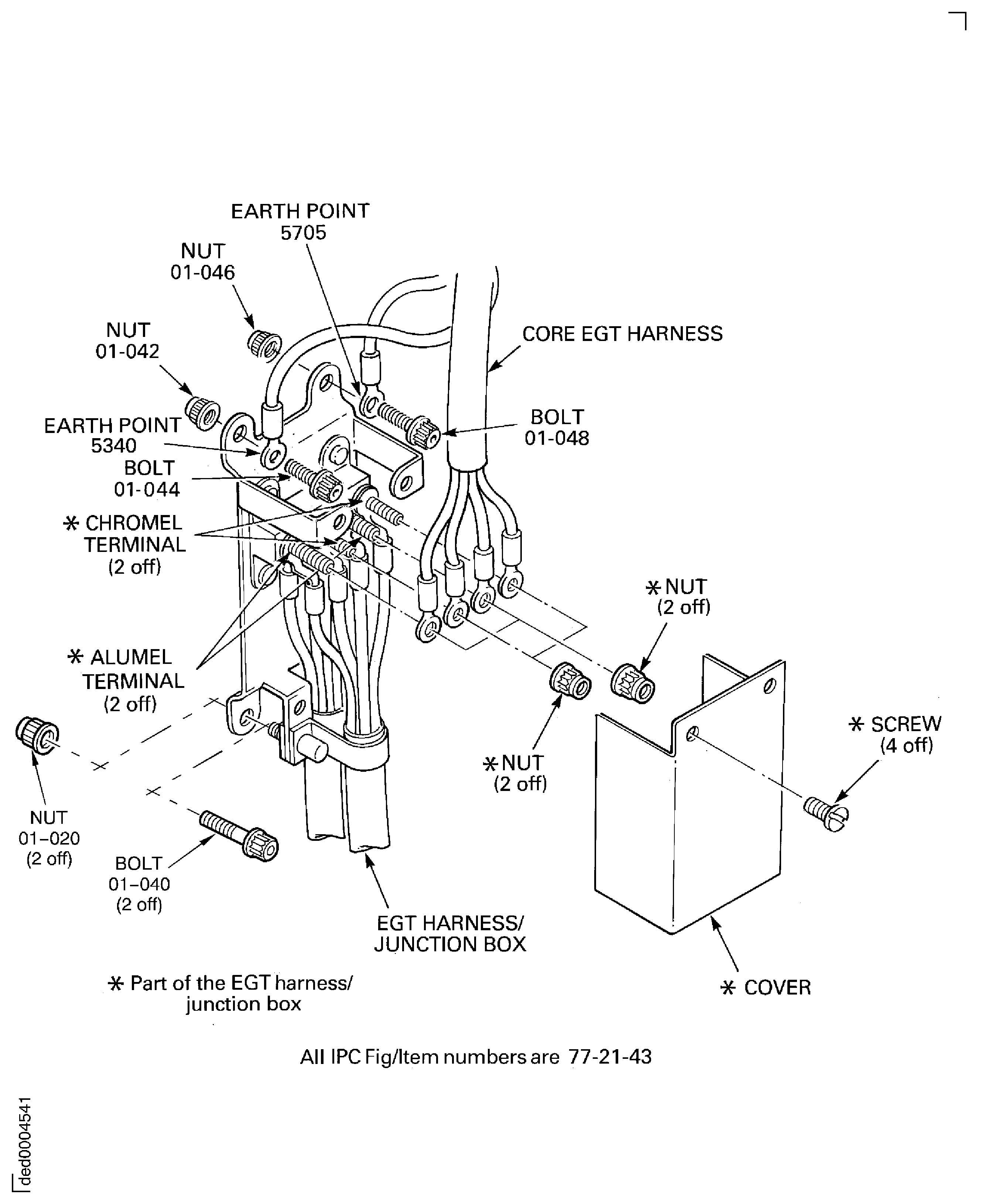

Install the EGT harness and junction box assembly ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-010) to the bracket on the bottom of the exhaust case, refer to Figure.

Apply CoMat 10-077 APPROVED ENGINE OILS to the threads of two bolts ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-040), one bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-044) and one bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-048).

Install two nuts ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-020), one nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-042) and one nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-046) on the bolts.

SUBTASK 72-00-50-450-056 Install the EGT Harness and Junction Box Assembly

Refer to Figure.

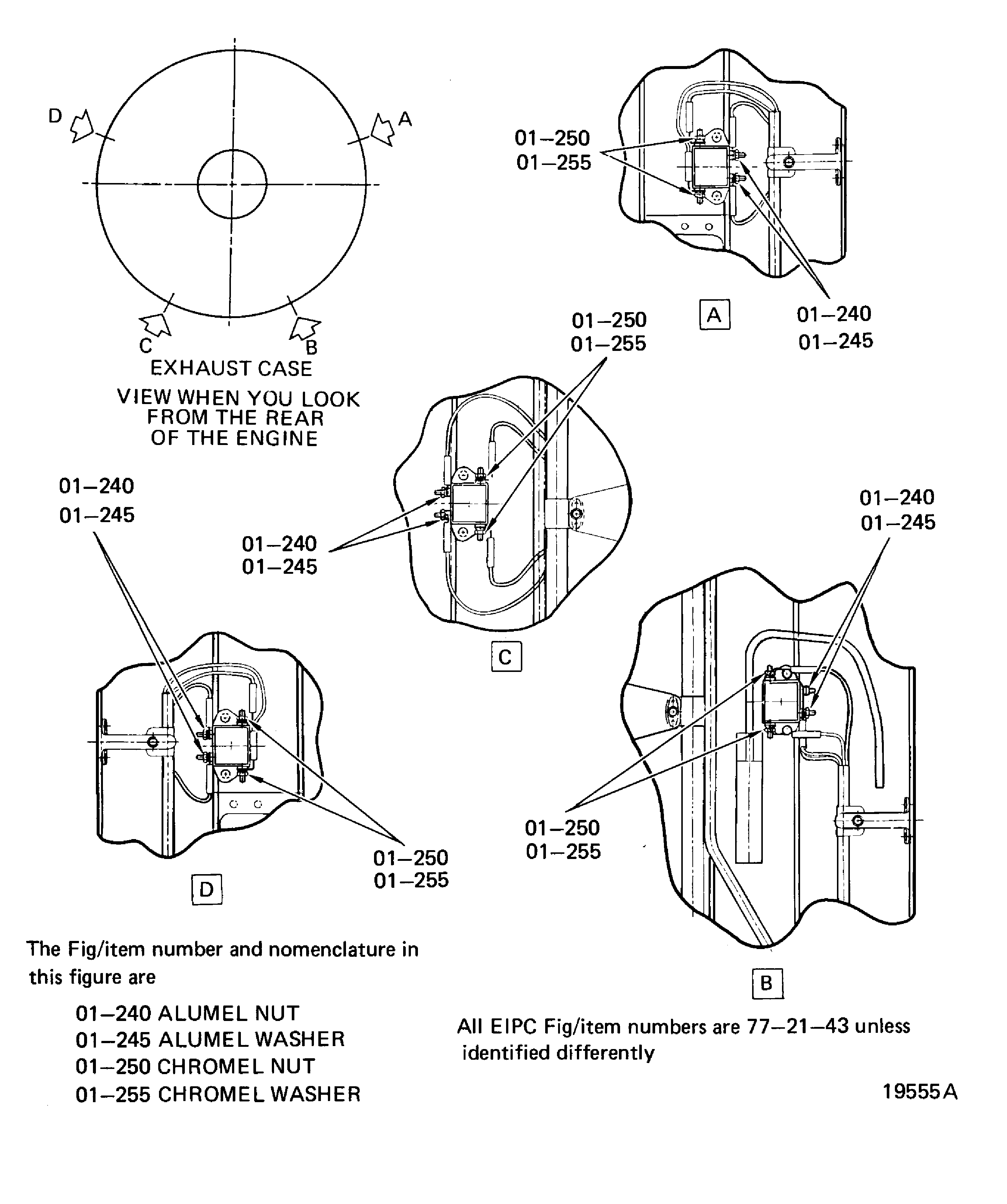

Remove the two alumel (larger) nuts ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-240), the two alumel washers ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-245), the two chromel (smaller) nuts ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-250) and the two chromel washers ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-255) from the thermocouple terminals at four positions, refer to Figure.

SUBTASK 72-00-50-450-052 Attach the EGT Harness Lugs to the Thermocouples

CAUTION

DO NOT USE LUBRICATION ON THE THREADS OF THE THERMOCOUPLE CONNECTIONS. ENGINE OIL CAN CONTAMINATE THE EGT HARNESS INSULATION MATERIAL AND RESULT IN ERRATIC OR UNRELIABLE EGT INDICATION.Make sure the lockwire correctly safeties the eight EGT thermocouple bolts ENGINE INDICATING-EGT THERMOCOUPLE (77-21-15, 01-120). Refer to the view which shows the acceptable method to safety the bolts, Figure.

If it is necessary safety the bolts with wire ENGINE INDICATING-EGT THERMOCOUPLE (77-21-15, 01-200) - CoMat 02-141 LOCKWIRE as the inspection criteria requires it.

Examine the lockwire which safeties the EGT thermocouple bolts.

SUBTASK 72-00-50-210-070 Examine the Safetying of the EGT thermocouple Bolts.

CAUTION

YOU MUST MAKE SURE THAT THE EGT THERMOCOUPLE BOLTS ARE CORRECTLY SAFETIED. INCORRECT SAFETYING OF THE BOLTS CAN RESULT IN LOOSE BOLTS AND SUBSEQUENT LOSS OF EGT INDICATION.Refer to Figure.

Remove the two alumel (larger) nuts and the two chromel (smaller) nuts from the junction box ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-010) terminals.

Use the other two nuts ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-042) and ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-046) and the two bolts ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-044) and ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-048) to attach the earth points 5340 and 5705 to the junction box. Torque the nuts to 85 to 105 lbfin (10 to 12 Nm).

Attach the cover to the EGT harness junction box with the four screws. Torque the screws to 16 to 22 lbfin (1.81 to 2.49 Nm). Safety the screws with CoMat 02-126 LOCKWIRE.

Pre SBE 77-0009: Attach the core EGT harness to the EGT harness/junction box. Refer to Figure.

SUBTASK 72-00-50-450-053-A00 Connect the Core EGT Harness to the Junction Box (Pre SBE 77-0009)

CAUTION

DO NOT USE LUBRICATION ON THE THREADS OF THE HARNESS CONNECTIONS. ENGINE OIL CAN CONTAMINATE THE EGT HARNESS INSULATION MATERIAL AND RESULT IN ERRATIC OR UNRELIABLE EGT INDICATION.Remove the two alumel (larger) nuts and the two chromel (smaller) nuts from the junction box ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-010) terminals.

Use the other two nuts ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-042 and ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX 01-046) and the two bolts ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-044 and ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX 01-048) to attach the earth points 5340 and 5705 to the junction box. Torque the nuts to 85 to 105 lbfin (10 to 12 Nm).

Attach the cover to the EGT harness junction box with the four screws. Torque the screws to 16 to 22 lbfin (1.81 to 2.49 Nm). Safety the screws with CoMat 02-126 LOCKWIRE.

CAUTION

DO NOT USE LUBRICATION ON THE THREADS OF THE HARNESS CONNECTIONS. ENGINE OIL CAN CONTAMINATE THE EGT HARNESS INSULATION MATERIAL AND RESULT IN ERRATIC OR UNRELIABLE EGT INDICATION.

CAUTION

ONCE A NEW STYLE NUT IS INSTALLED ON TO THE MATING STUD YOU MUST NOT INSTALL AN OLD NUT ON THAT STUD.Refer to Figure.

Do a continuity test and short circuit test, refer to the approved procedure in the Service Bulletin, SBE 77-0009.

NOTE

An insulation resistance test is necessary when a stud is replaced.

Testing and Fault Isolation checks.

SUBTASK 72-00-50-450-053-B00 Connect the Core EGT Harness to the Junction Box (SBE 77-0009)

SBE 77-0009: Provide new EGT harness junction box terminal nuts

SBE 77-0009: Attach the core EGT harness to the EGT harness/junction box.

At View B, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-190) and the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-095).

At View C, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-185) and the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-090).

At View D, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-180) and the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-085).

At View E, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-175) and the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-080).

At View G, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-290) and the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-288).

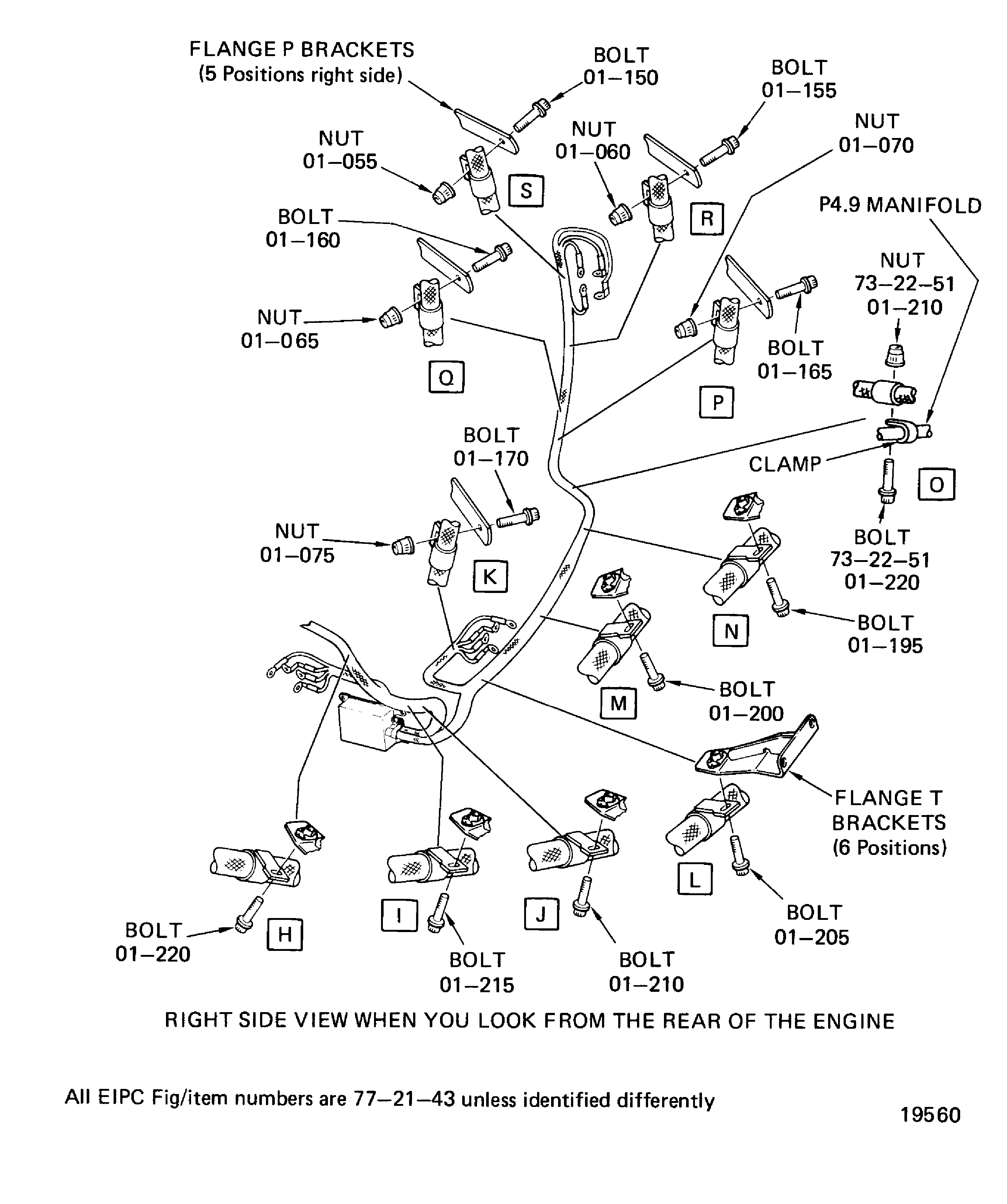

Attach the harness clamps to the five brackets located on the left side of the Flange P, refer to Figure.

At View S, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-150) and the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-055).

At View R, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-155) and the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-060).

At View Q, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-160) and the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-065).

At View P, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-165) and the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-070).

At View K, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-170) and the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-075).

Attach the harness clamps to the five brackets located on the right side of the Flange P, refer to Figure.

SUBTASK 72-00-50-450-054 Install the EGT Harness at the Flange P Locations

At View N, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-195).

At View M, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-200).

At View L, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-205).

At View J, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-210).

At View I, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-215).

At View H, install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-220).

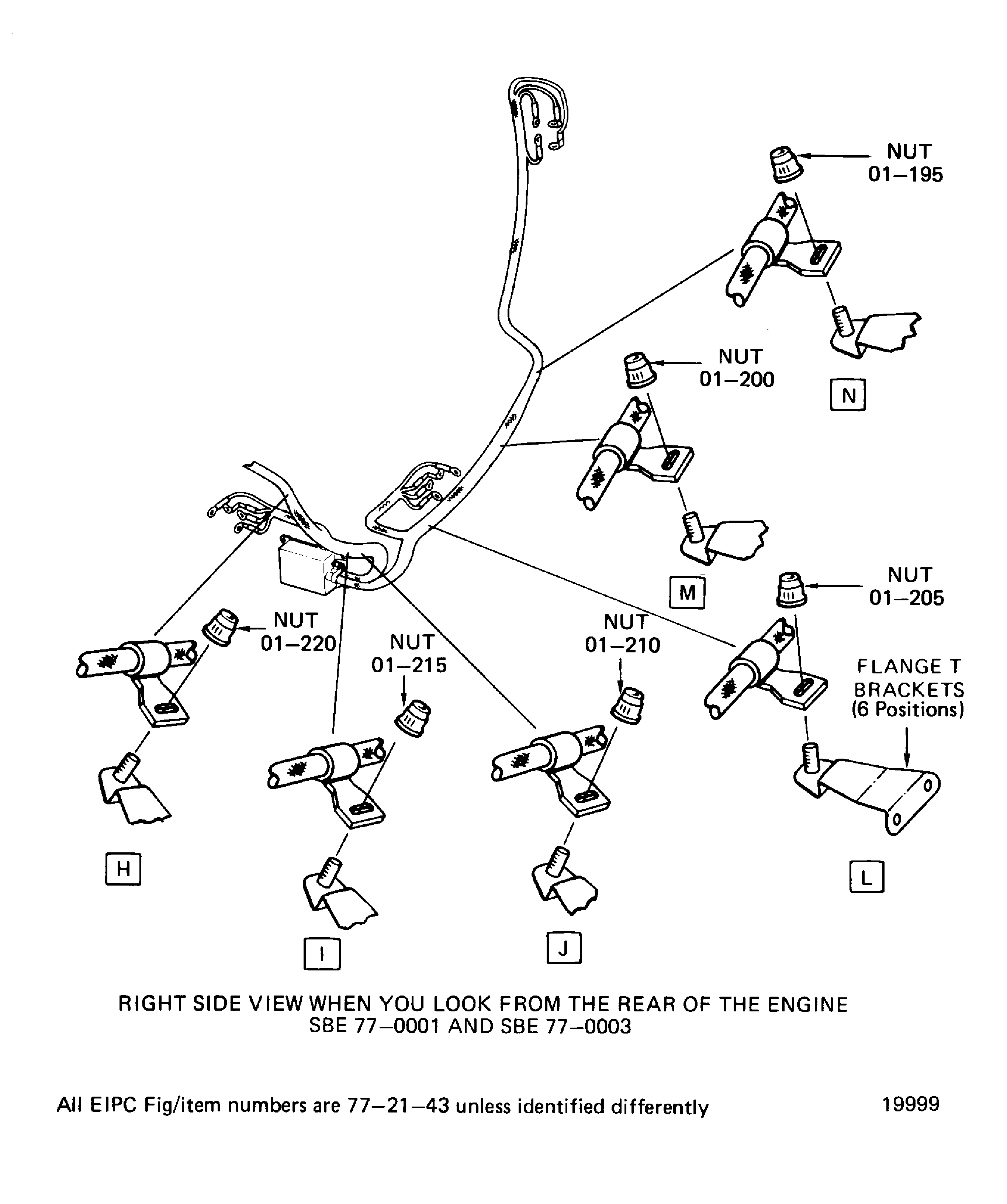

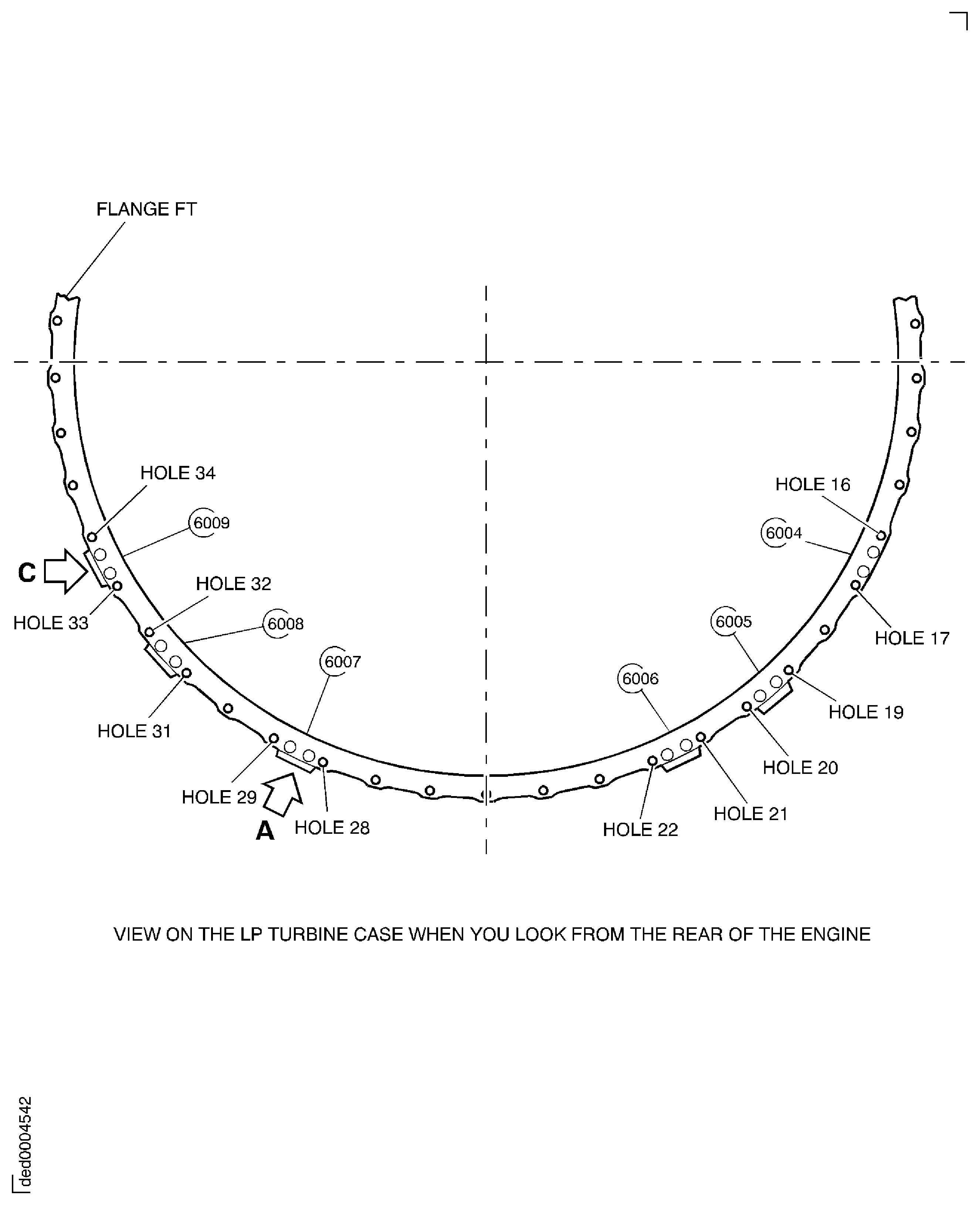

Attach the harness clamps to the six brackets located on the Flange T, refer to Figure.

SUBTASK 72-00-50-450-057 Install the EGT Harness at the Flange T Bracket Locations

At View N, install the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-195), refer to Figure.

At View M, install the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-200), refer to Figure.

At View L, install the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-205).

At View J, install the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-210).

At View I, install the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-215).

At View H, install the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-220).

Attach the harness clamps to the six brackets located on the Flange T.

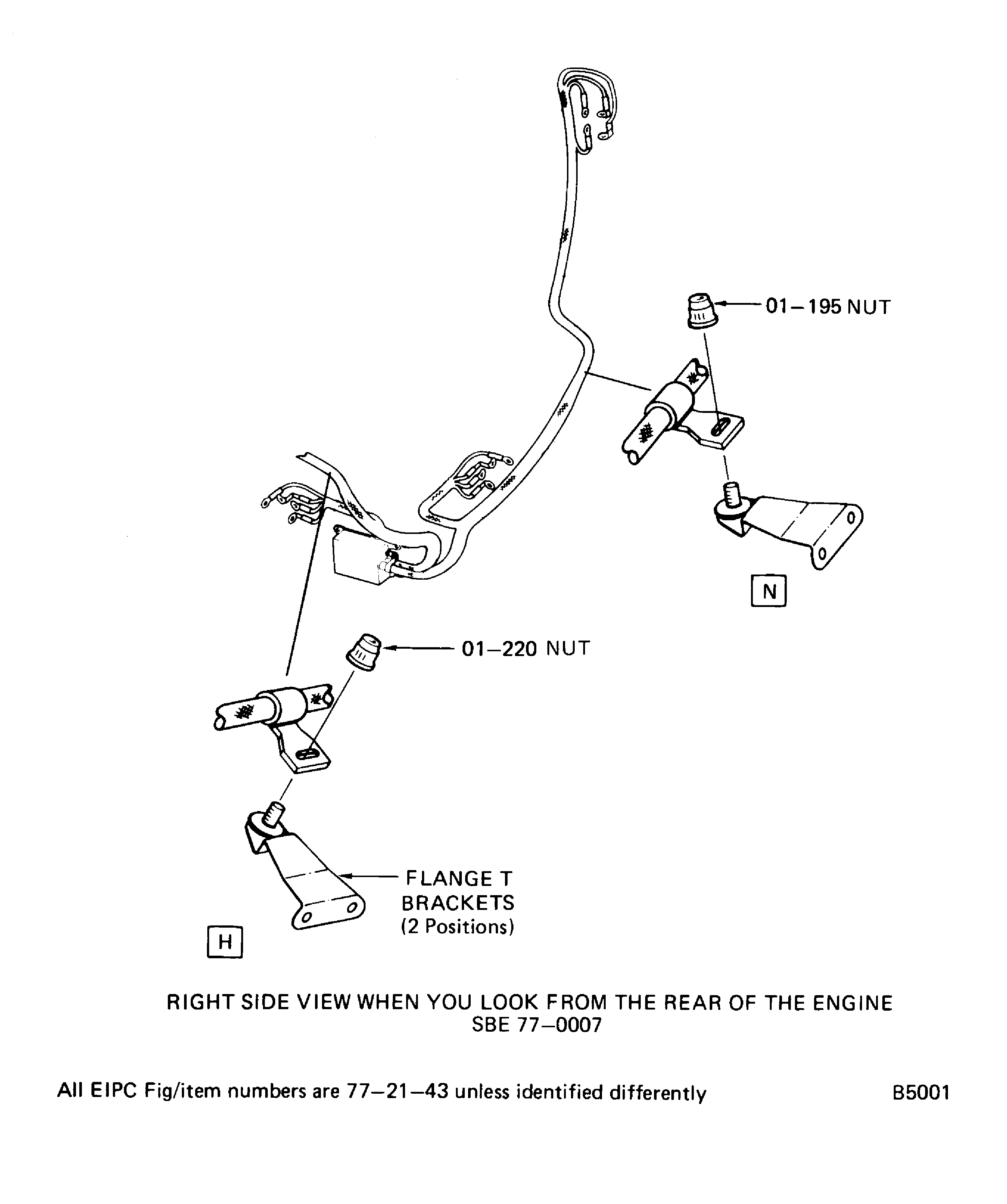

SUBTASK 72-00-50-450-058 Install the EGT Harness at the Flange T Bracket Locations (SBE 77-0001, SBE 77-0003 and SBE 77-0007)

SBE 77-0001: Replacement of turbine exhaust case and installation of a revised EGT bracket configuration

SBE 77-0003: Replacement of EGT loop clamp brackets

SBE 77-0007: Provide permanently attached washers to bracket at clipping points CP6004 and CP6009

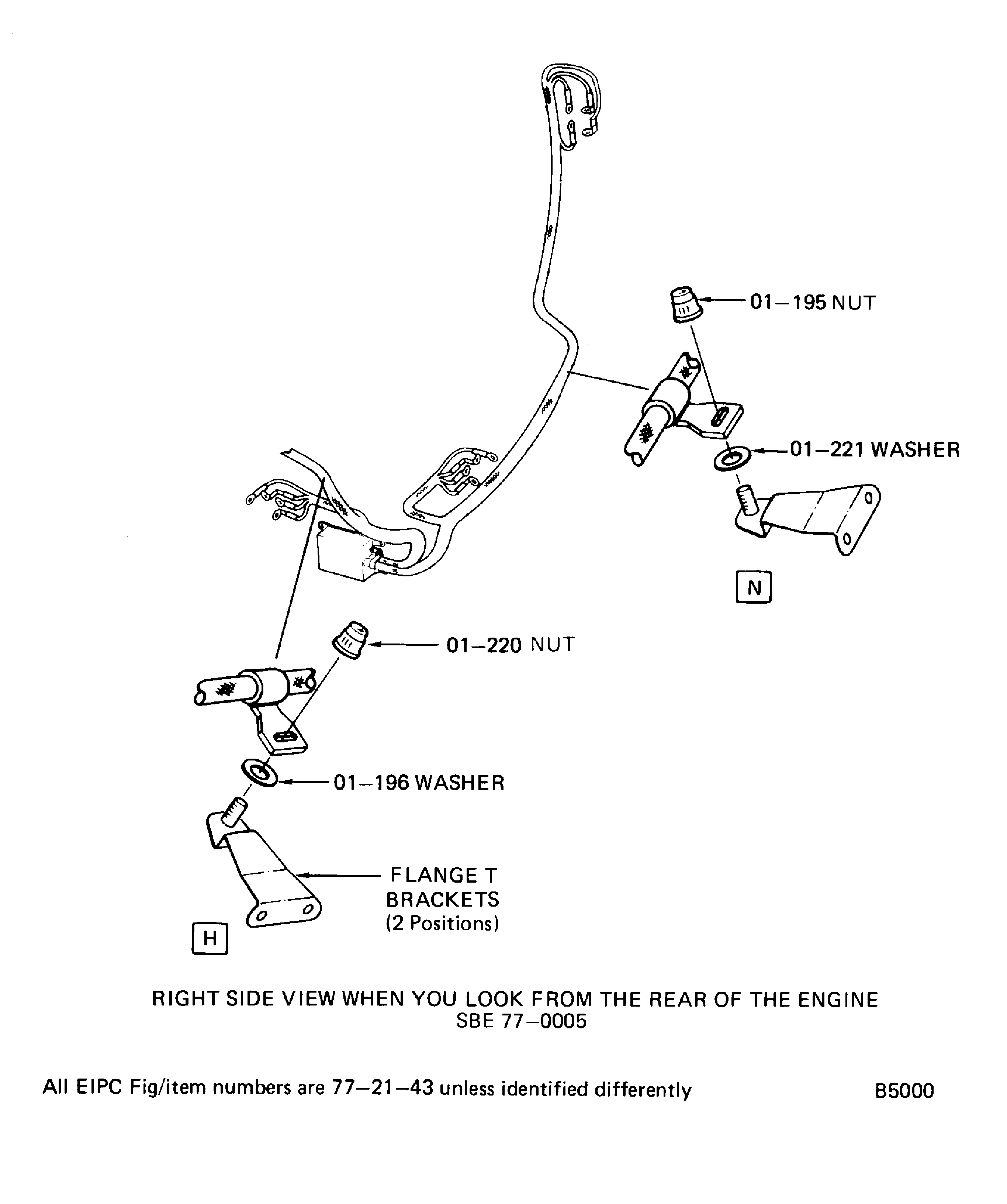

At View N, install the washer ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-221) and the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-195), refer to Figure.

At View M, install the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-200), refer to Figure.

At View L, install the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-205).

At View J, install the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-210).

At View I, install the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-215).

At View H, install the washer ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-196) and the nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-220), refer to Figure.

Attach the harness clamps to the six brackets located on the Flange T.

SUBTASK 72-00-50-450-059 Install the EGT Harness at the Flange T Bracket Locations (SBE 77-0005)

SBE 77-0005: Add washers at clipping points CP6004 and CP6009

At View F, install the bolt ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51,01-090) and the nut ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51,01-080), refer to Figure.

At View O, install the bolt ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51,01-220) and the nut ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51,01-210), refer to Figure.

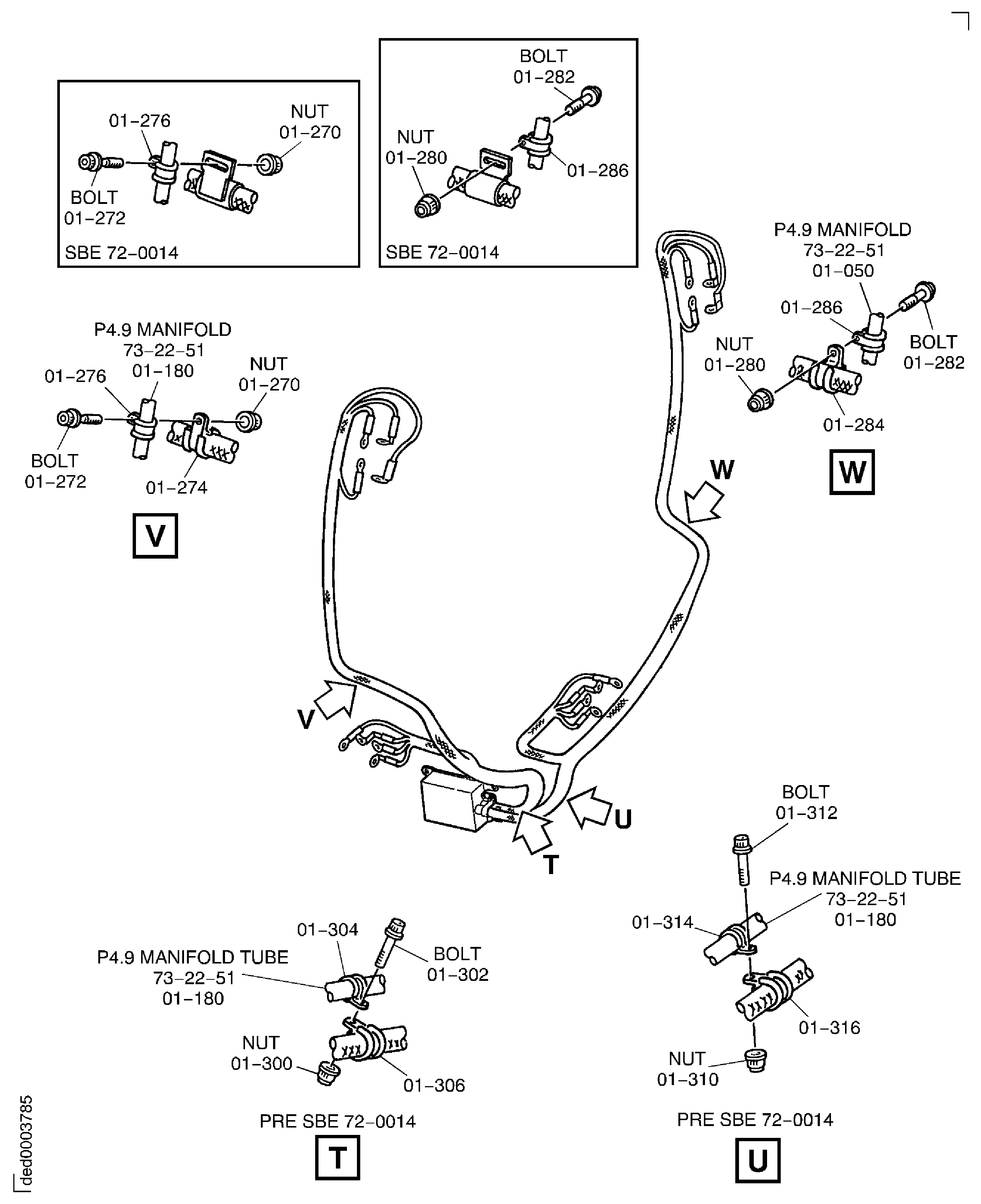

Install the harness clamp to the P4.9 manifold clamp at two locations.

Pre SBE 72-0014 : Attach the harness to the P4.9 manifold tube ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 01-180) at location T with the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-304), two clamps ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-304 and ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX 01-306) and nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-300).

Attach the harness to the P4.9 manifold tube ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 01-180) at location U with the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-312), two clamps ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-314 and ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX 01-316) and nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-310).

Attach the harness to the P4.9 manifold tube ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 01-180) at location V with the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-272), two clamps ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-274 and ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX 01-276) and nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-270).

Attach the harness to the P4.9 manifold tube ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 01-050) at location W with the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-282), two clamps ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-284 and ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX 01-286) and nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-280).

SBE 72-0014 : Attach the harness to the P4.9 manifold tube ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 01-180) at location V with the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-272), clamp ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-276) and nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-270).

Attach the harness to the P4.9 manifold tube ENGINE FUEL AND CONTROL-P4.9 SENSOR AND MANIFOLD (73-22-51, 01-050) at location W with the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-282), clamp ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-286) and nut ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-280).

Install the harness clamp at the remaining locations, refer to Figure.

SUBTASK 72-00-50-450-060 Install the EGT Harness at the P4.9 Manifold Clamp Locations (Pre SBE 72-0014 and SBE 72-0014)

SBE 72-0014: LP turbine and exhaust gas temperature (EGT) indicating system - incorporate re-routed EGT harness assembly

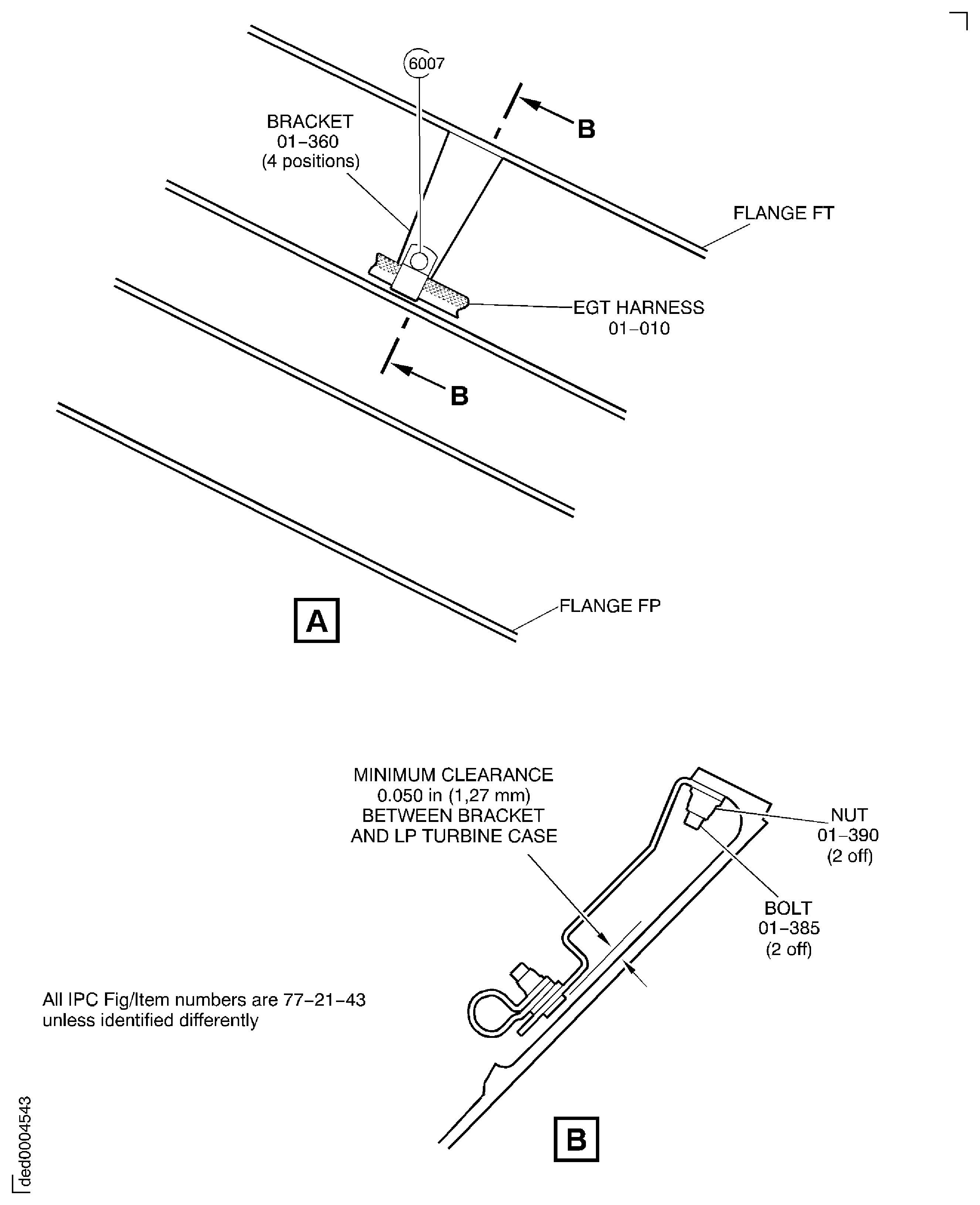

Install the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-225) and the bolt ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43,01-230) through the harness clamps in to the bracket at the bottom of the exhaust case, refer to Figure.

SUBTASK 72-00-50-450-055 Install the EGT Harness to the Exhaust Case Bracket

Refer to: Figure, Fig. 72-00-50-990-465-002 and Fig. 72-00-50-990-465-003

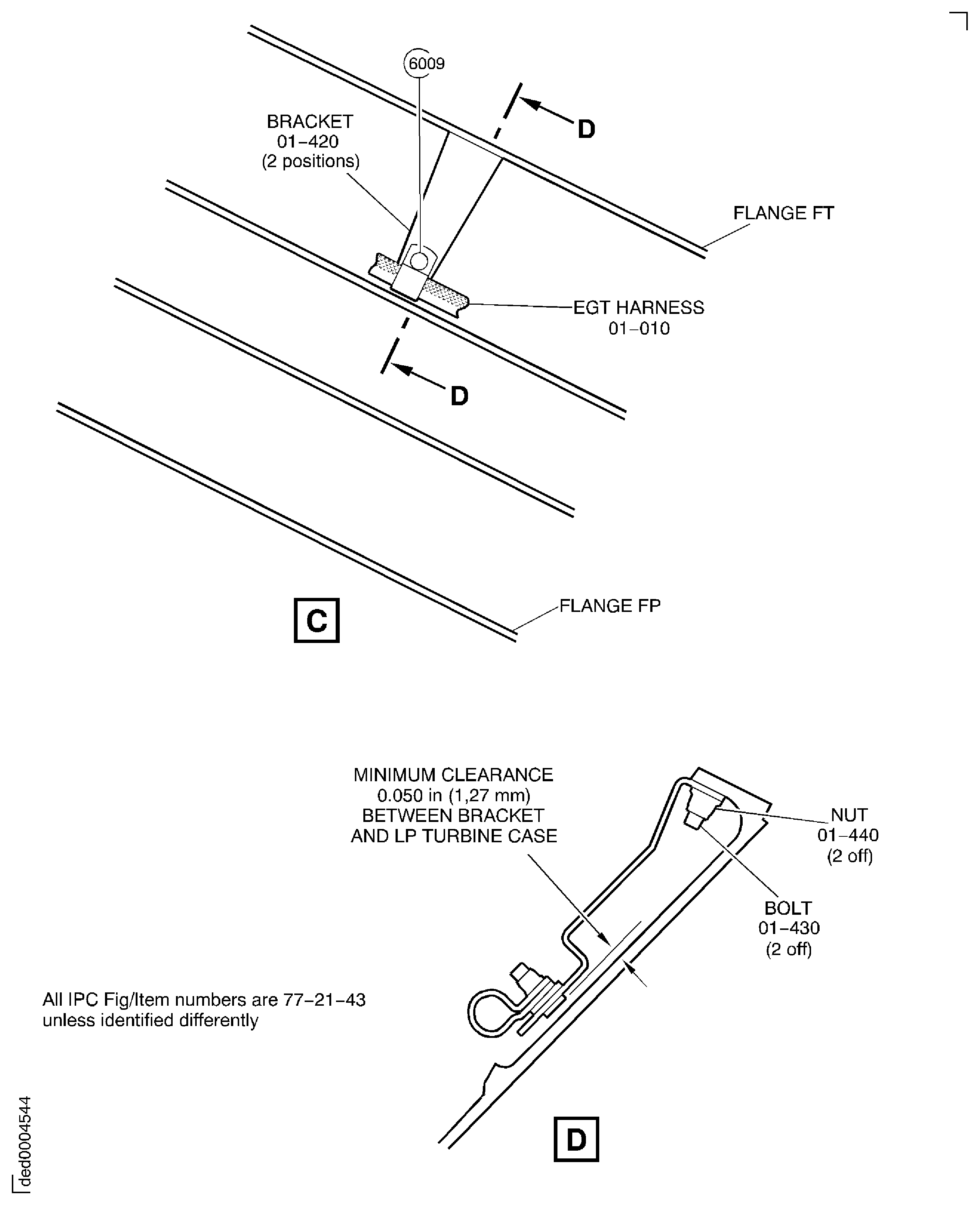

Check the clearance at the four bracket postions, refer to view A and section B for brackets ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-360).

Check the clearance at the four bracket postions, refer to view C and section D for brackets ENGINE INDICATING-EGT HARNESS AND JUNCTION BOX (77-21-43, 01-420).

SUBTASK 72-00-50-420-388 Check the Clearance between Flange FT and the Core EGT Harness Support Brackets

Refer to TASK 71-00-00-700-052-A00 (TESTING-000, CONFIG-001).

SUBTASK 72-00-50-750-051 Do a Test of the EGT Harness and Junction Box Assembly

Figure: Installation on the EGT Harness and Junction Box Assembly

Sheet 1

Figure: Installation of the EGT Harness and Junction Box Assembly

Sheet 2

Figure: Installation of the EGT Harness and Junction Box Assembly

Sheet 3

Figure: Installation of the EGT Harness and Junction Box Assembly

Sheet 4

Figure: Installation of the EGT Harness and Junction Box Assembly

Sheet 5

Figure: Installation of the EGT Harness and Junction Box Assembly

Sheet 6

Figure: Installation of the EGT Harness and Junction Box Assembly

Sheet 7

Figure: Installation of the EGT Harness and Junction Box Assembly

Sheet 8

Figure: Pre SBE 77-0009: Installation of the EGT Harness and Junction Box Assembly

Sheet 9

Figure: SBE 77-0009: Install the EGT Harness/Junction Box and the Core EGT Harness

Sheet 10

Figure: Install the EGT Harness and Junction Box Assembly

Install the EGT Harness and Junction Box Assembly

Figure: Check the Clearance between Flange FT and the Core EGT Harness Support Brackets

Sheet 1

Figure: Check the Clearance between Flange FT and the Core EGT Harness Support Brackets

Sheet 2

Figure: Check the Clearance between Flange FT and the Core EGT Harness Support Brackets

Sheet 3