Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-32-00-430-014-A00 LPC/Intermediate Case Module - Install The Front Fairings, No. 1 And No. 6 Strut Fairing Panels, Fan Exit Pressure Boss, And Block, Assembly-014

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-410-501 .

Special torque data and assembly tolerances are included in the procedure.

Special torque data is identified with the symbol * after the torque value.

Lubricate all threads and abutment faces of nuts and bolts with the CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To install lockwire, refer to the SPM TASK 70-42-05-400-501.

The abbreviation Intf shows an interference or tight fit. This causes REJECT IF MORE THAN to become REJECT IF LESS THAN. The abbreviation Clear shows a clearance fit.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

The No.1 strut, which is the top position strut of the fan frame assembly, is identified by the five pressure tubes on the No. 1 strut leading edge.

This TASK gives the procedure to install the front fairings, the No. 1 and No. 6 strut fairing panels, the fan exit pressure boss and the block. For the other parts of the LP compressor/intermediate case module, refer to TASK 72-32-00-430-000 (ASSEMBLY-000).

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Sealant dispenser | LOCAL | Sealant dispenser | ||

| IAE 1J12508 Measuring stretch | 0AM53 | IAE 1J12508 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 02-119 LOCKWIRE | LOCAL | CoMat 02-119 | ||

| CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE | LOCAL | CoMat 04-004 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | 0AM53 | CoMat 08-014 | ||

| CoMat 08-045 SILICONE RUBBER COMPOUND | LOCAL | CoMat 08-045 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

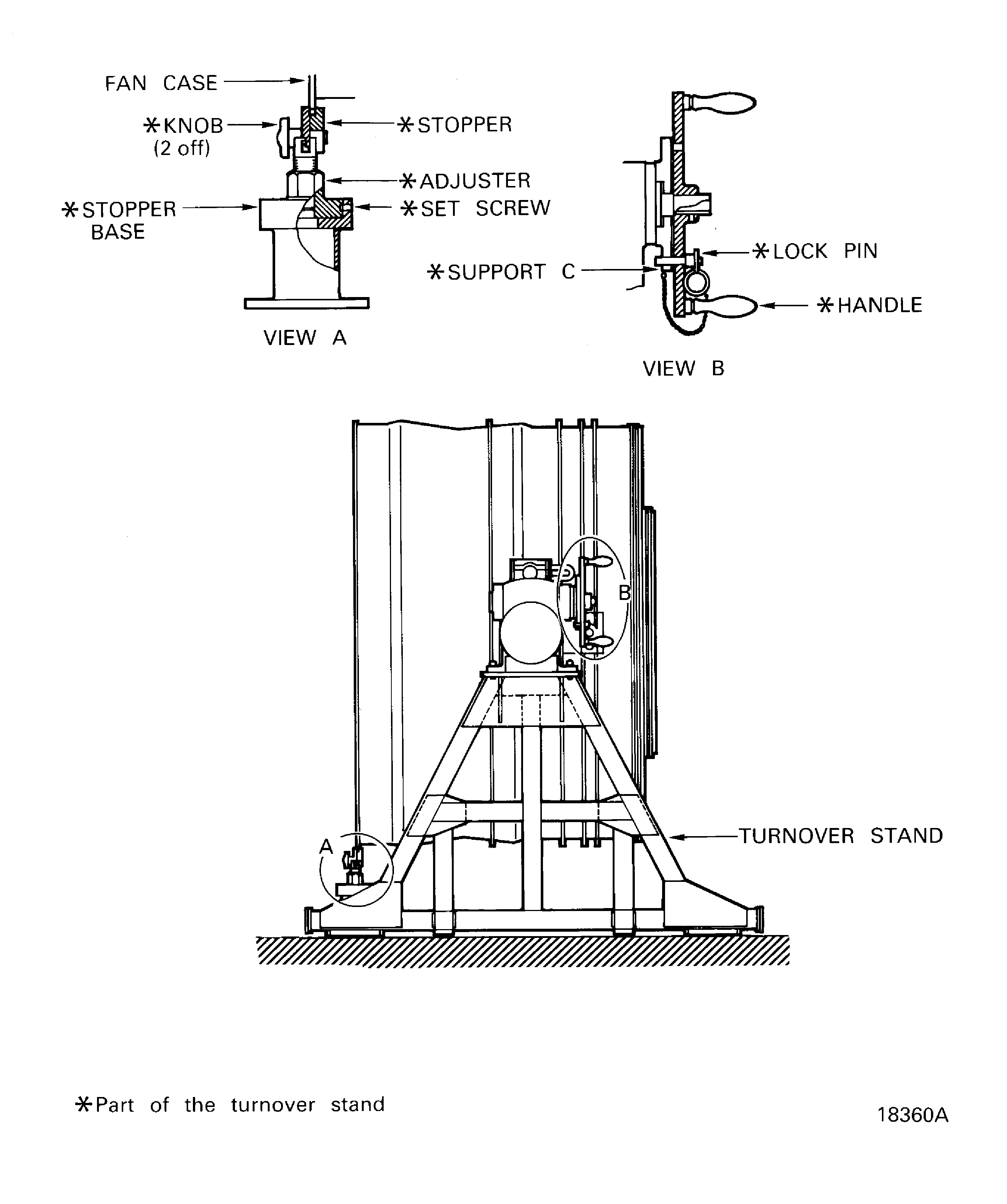

Make sure that the fan frame and fan case assembly is installed horizontally on the turnover stand. Refer to TASK 72-32-00-430-013-A00 (ASSEMBLY-013, CONFIG-001).

Make sure that the work mat is in position in the fan case. Refer to TASK 72-32-00-430-012-A00 (ASSEMBLY-012, CONFIG-001).

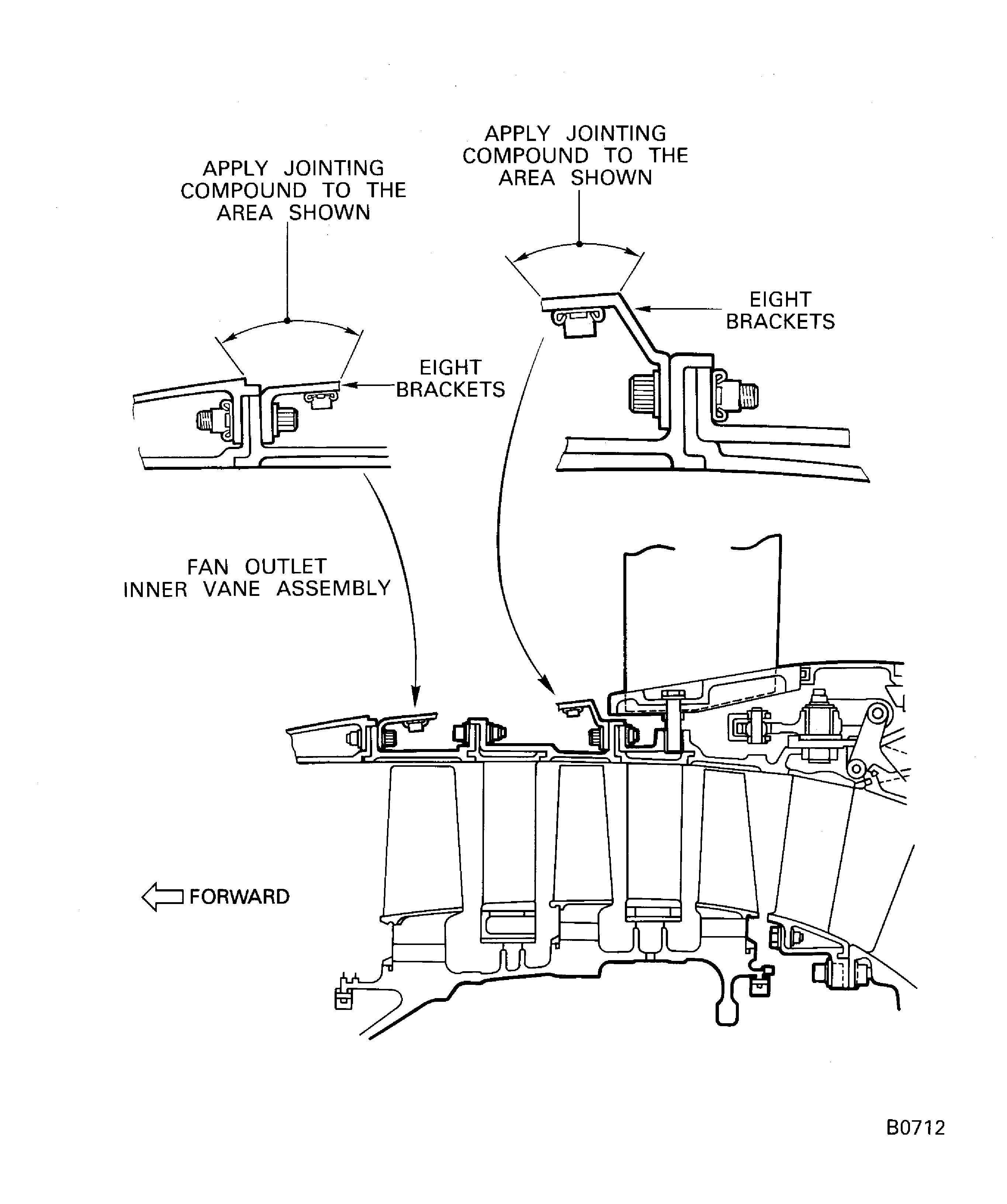

Make a clean cloth moist with CoMat 01-124 ISOPROPYL ALCOHOL to clean the mating faces on the 16 brackets.

NOTE

Do not get the jointing compound into the threaded holes of the clinch nuts on the brackets.

Install the front fairings on the brackets before the jointing compound becomes dry.

Apply CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE with a stiff brush to the mating faces on the brackets.

SUBTASK 72-32-00-430-170 Apply the Jointing Compound to the Mating Faces on the Brackets

Refer to Figure.

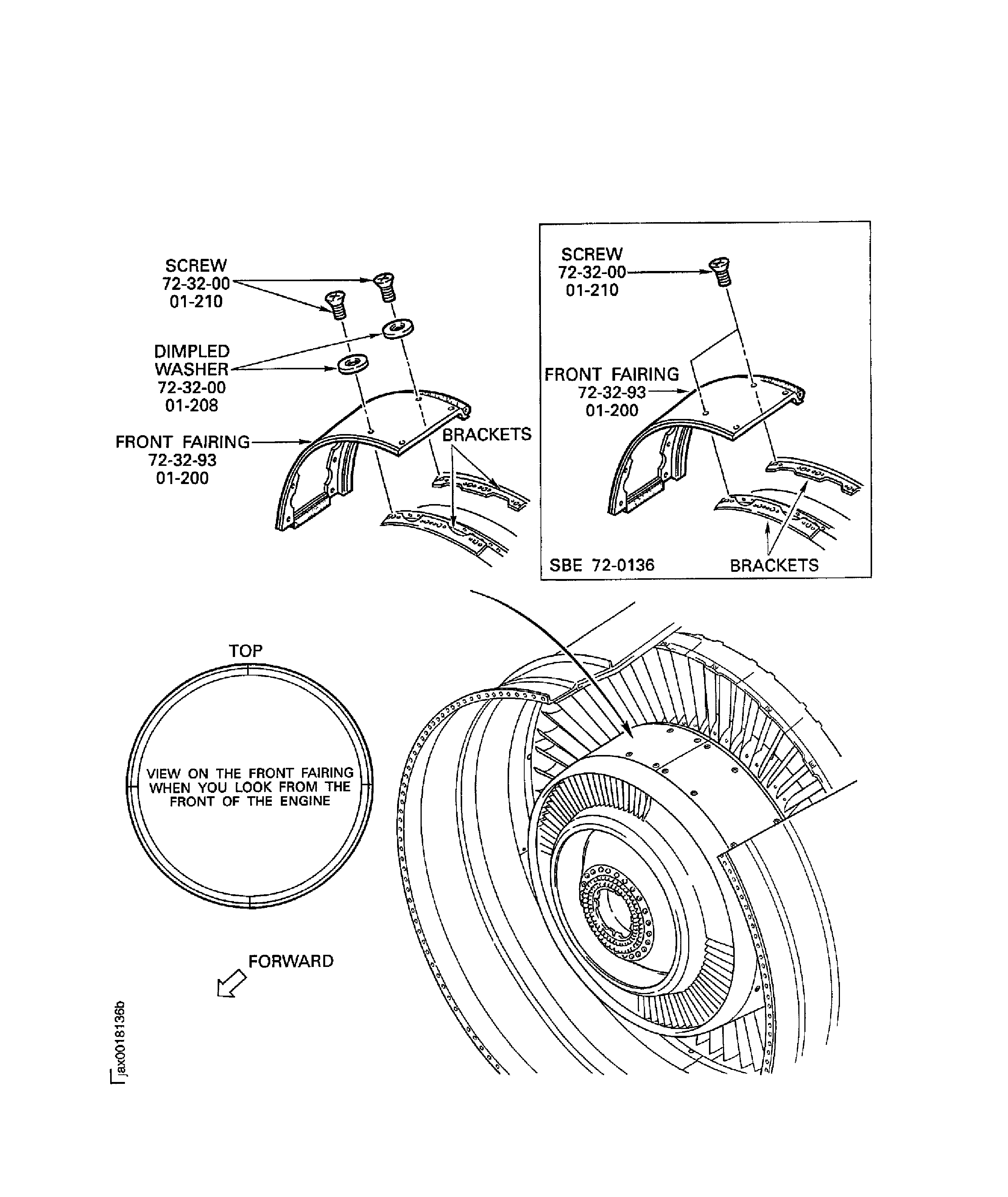

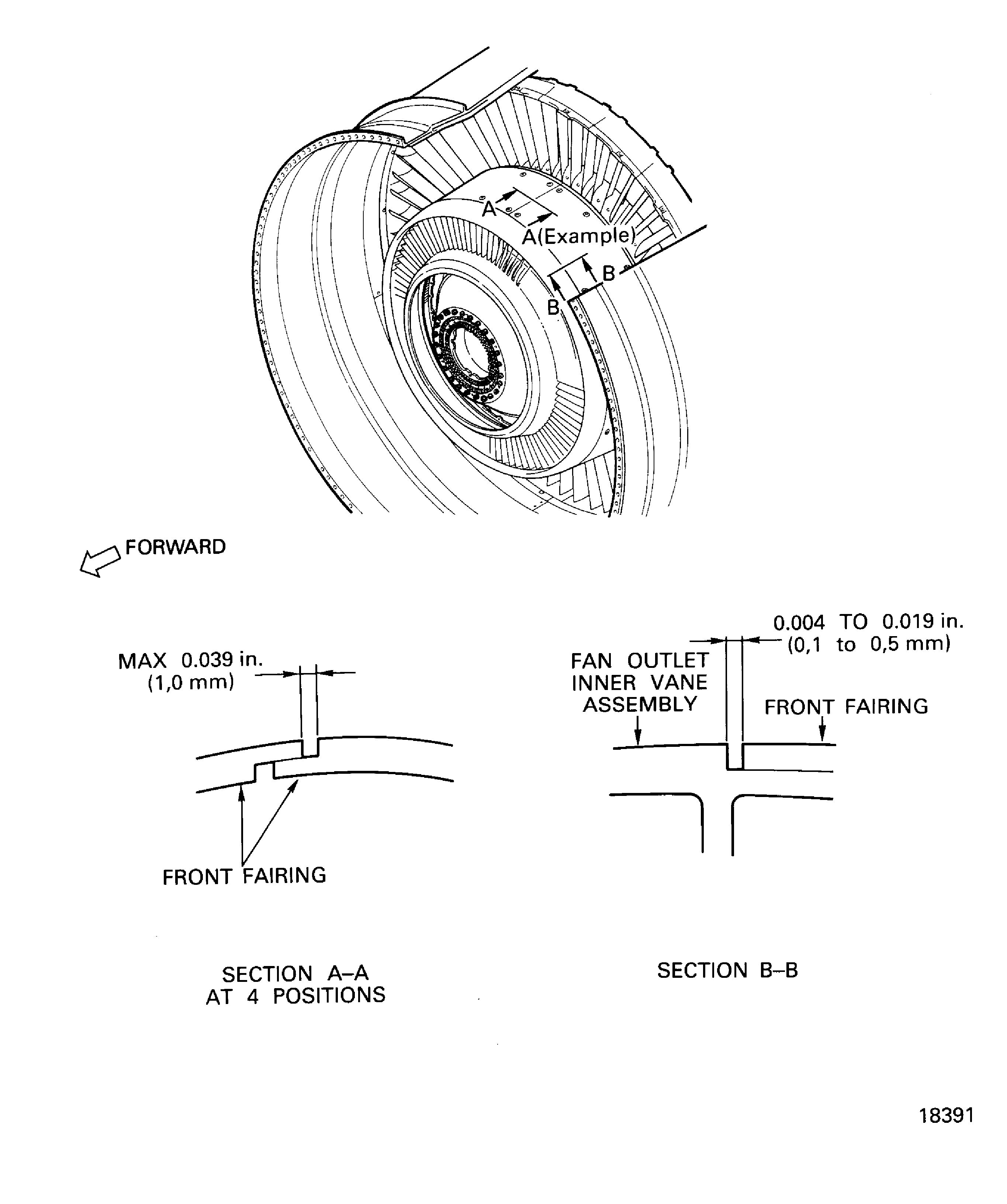

SUBTASK 72-32-00-430-171-A00 Install the Front Fairings on the Brackets (Pre SBE 72-0136)

SUBTASK 72-32-00-430-171-B00 Install the Front Fairing onto the Brackets (SBE 72-0136)

SBE 72-0136: Deletion of polyurethane coating of front fairing assembly

Refer to Figure.

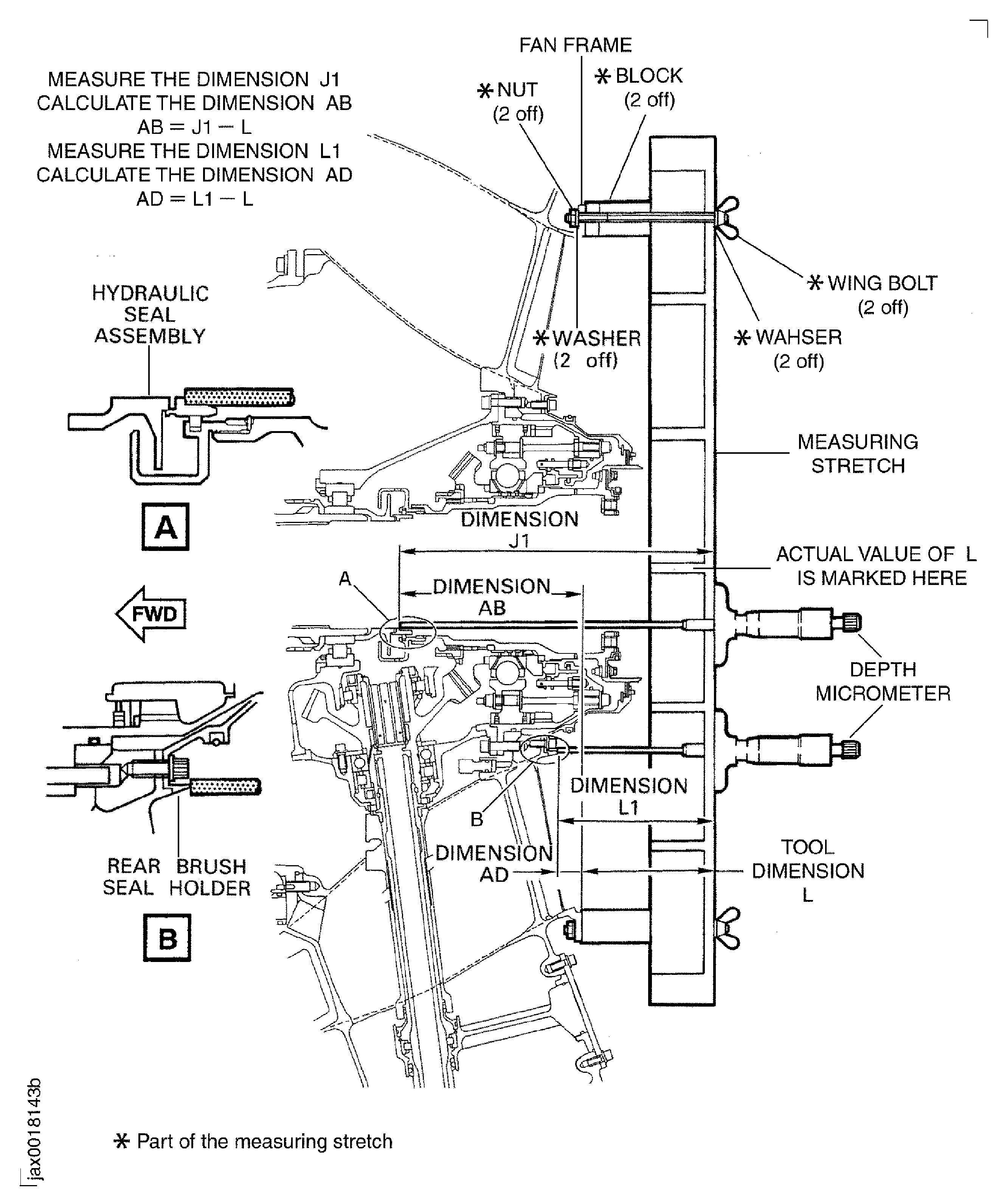

Read the tool dimension L marked on IAE 1J12508 Measuring stretch 1 off.

Apply force of 33lbs (15 Kg) or more to push LP stub shaft rearward by hand until its movements stops. Continue pushing to keep the LP stub shaft in the position until Step is completed.

NOTE

No. 1 bearing axial play causes the LP stub shaft to be moveable if the module is horizontal. The LP stub shaft must be at the rear position in the movement range for correct measurement of J1. The LP stub shaft moves correctly to the rear end position if you push it with sufficient force.Measure the dimension J1 with a depth micrometer.

Measure the dimension J1 at 12 and 6 o' clock positions.

SUBTASK 72-32-00-430-173-A00 Measure the Module Interface Dimension for the Installation of the HP System Module (Pre SBE 72-0391)

Refer to Figure.

Read the tool dimension L marked on IAE 1J12508 Measuring stretch 1 off.

Apply force of 33lbs (15 Kg) or more to push LP stub shaft rearward by hand until its movements stops. Continue pushing to keep the LP stub shaft in the position until Step is completed.

NOTE

No. 1 bearing axial play causes the LP stub shaft to be moveable if the module is horizontal. The LP stub shaft must be at the rear position in the movement range for correct measurement of J1. The LP stub shaft moves correctly to the rear end position if you push it with sufficient force.Measure the dimension J1 with a depth micrometer.

Measure the dimension J1 at 12 and 6 o' clock positions.

Do Step to install the blocks and the measuring stretch at 3 and 9 o'clock positions.

Measure the dimensions J1 and L1 and make sure of the dimensions AB and AD at 3 and 9 o'clock positions.

SUBTASK 72-32-00-430-173-B00 Measure the Module Interface Dimension for the Installation of the HP System Module (SBE 72-0391)

SBE 72-0391: New separate type No. 1 bearing support asembly

Refer to Figure.

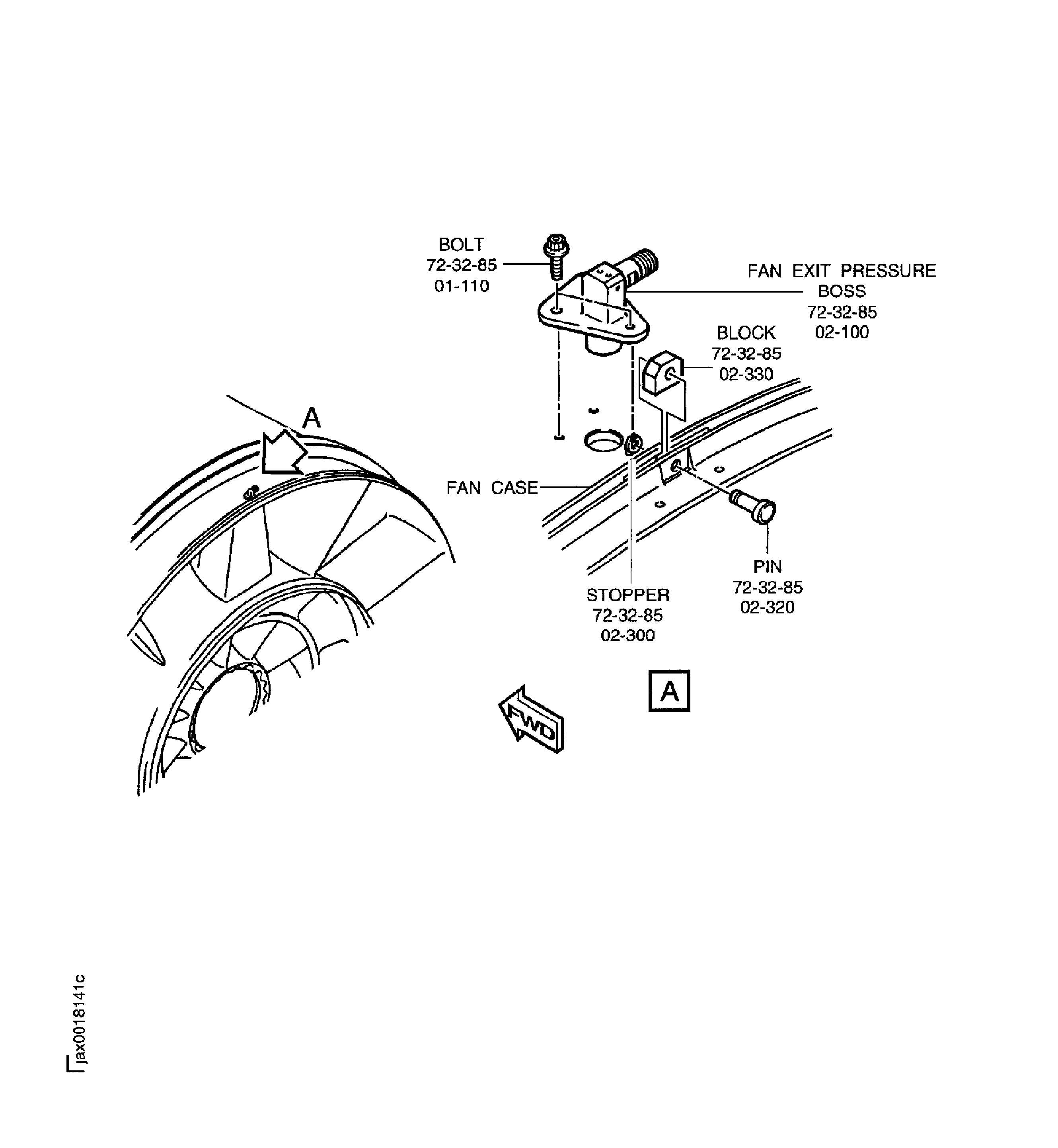

Attach the pressure boss ENGINE-FAN CASE (72-32-85, 02-100) to the fan case at the 12 o'clock position wth the three bolts ENGINE-FAN CASE (72-32-85, 02-110).

SUBTASK 72-32-00-430-317-A00 Install the Fan Exit Pressure Boss onto the Fan Case (Pre SBE 75-0010)

Refer to Figure.

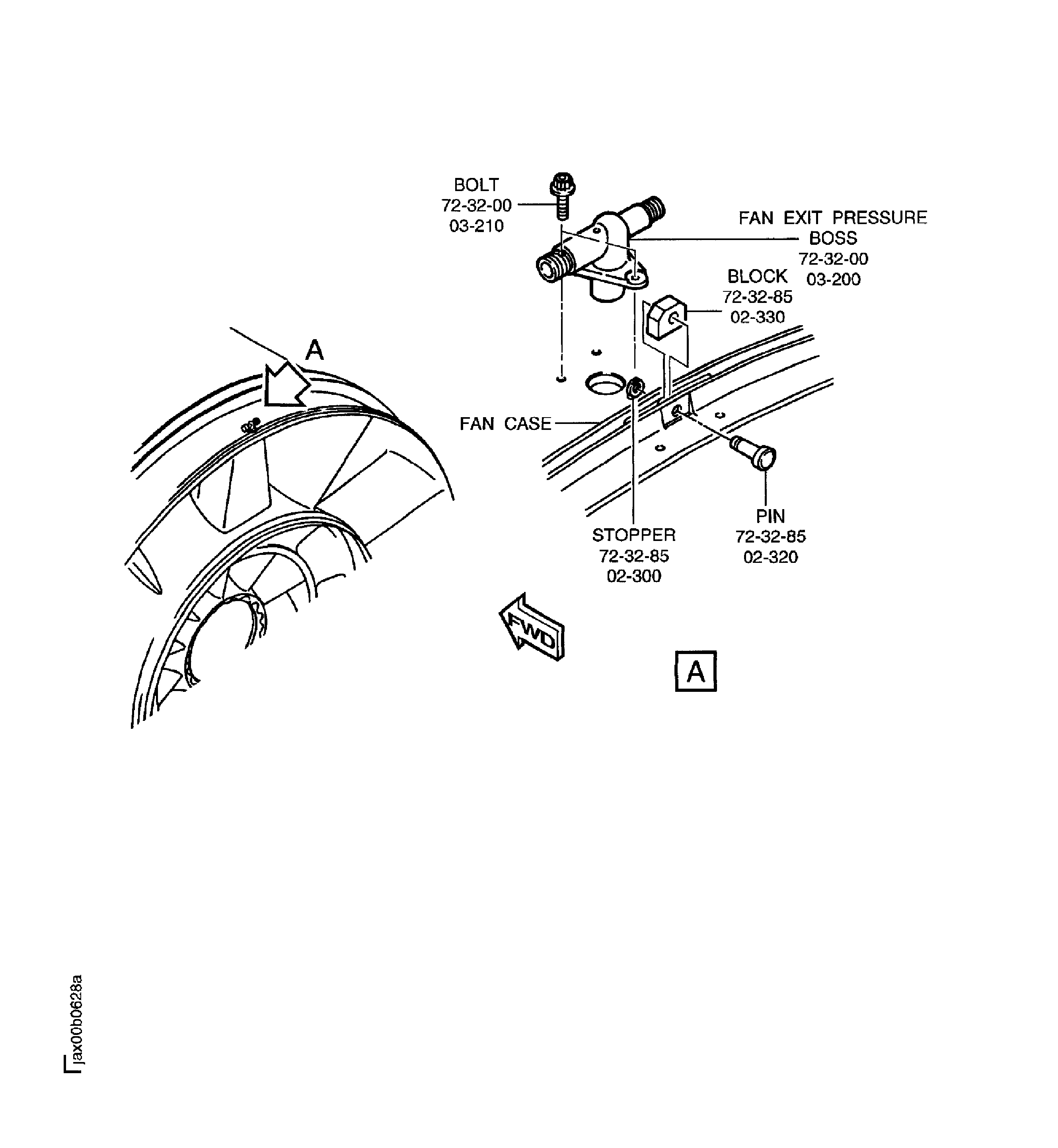

SUBTASK 72-32-00-430-317-B00 Install the Fan Exit Pressure Boss onto the Fan Case (SBE 75-0010)

SBE 75-0010: Cooling air supply to dedicated alternator.

Align the holes in the block ENGINE-FAN CASE (72-32-85, 02-330) with the holes in the two flanges on the fan case.

Install the pin ENGINE-FAN CASE (72-32-85, 02-320) into the aligned holes and safety with the stopper ENGINE-FAN CASE (72-32-85, 02-300).

SUBTASK 72-32-00-430-318 Install the Block onto the Fan Case

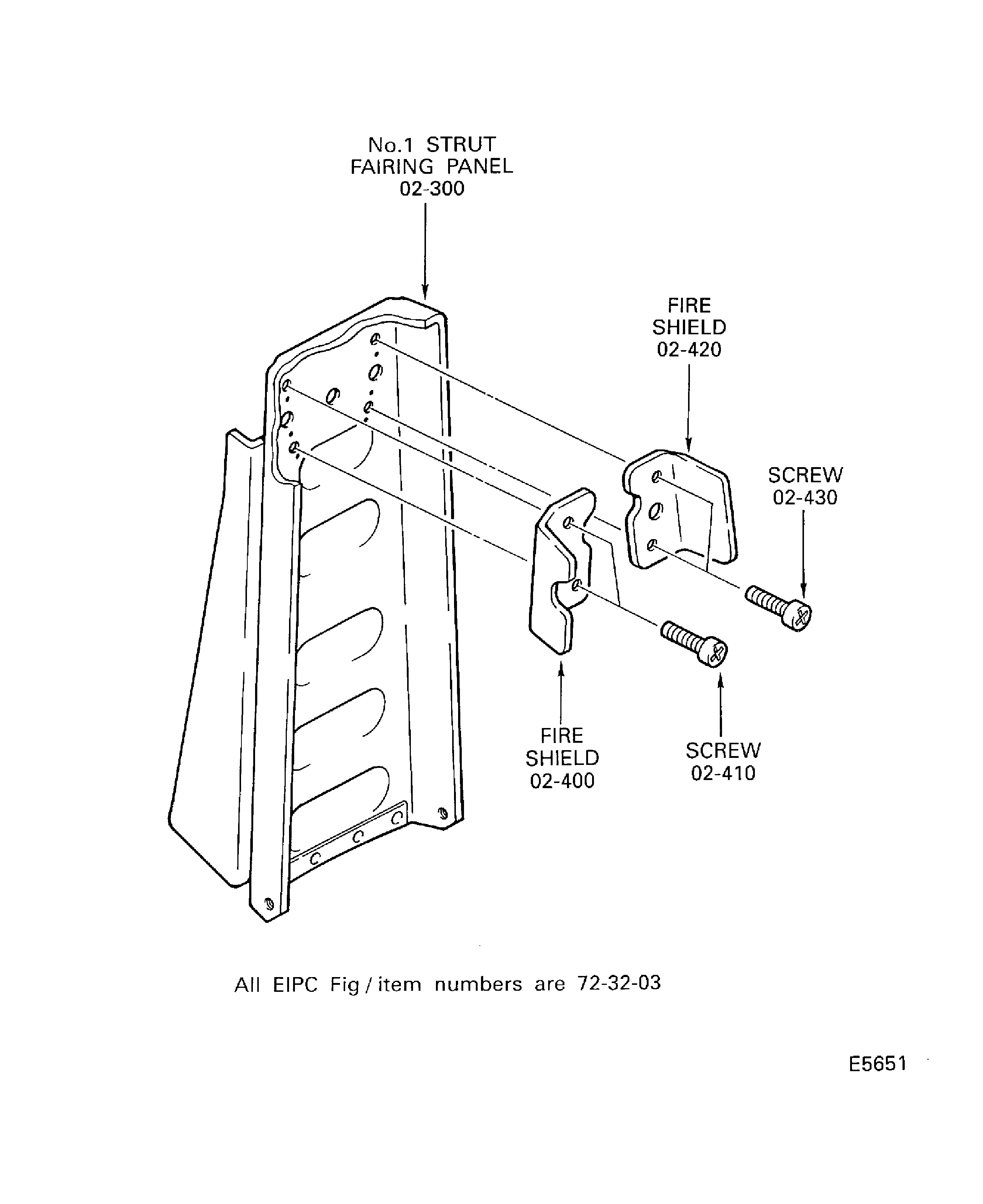

Refer to Figure.

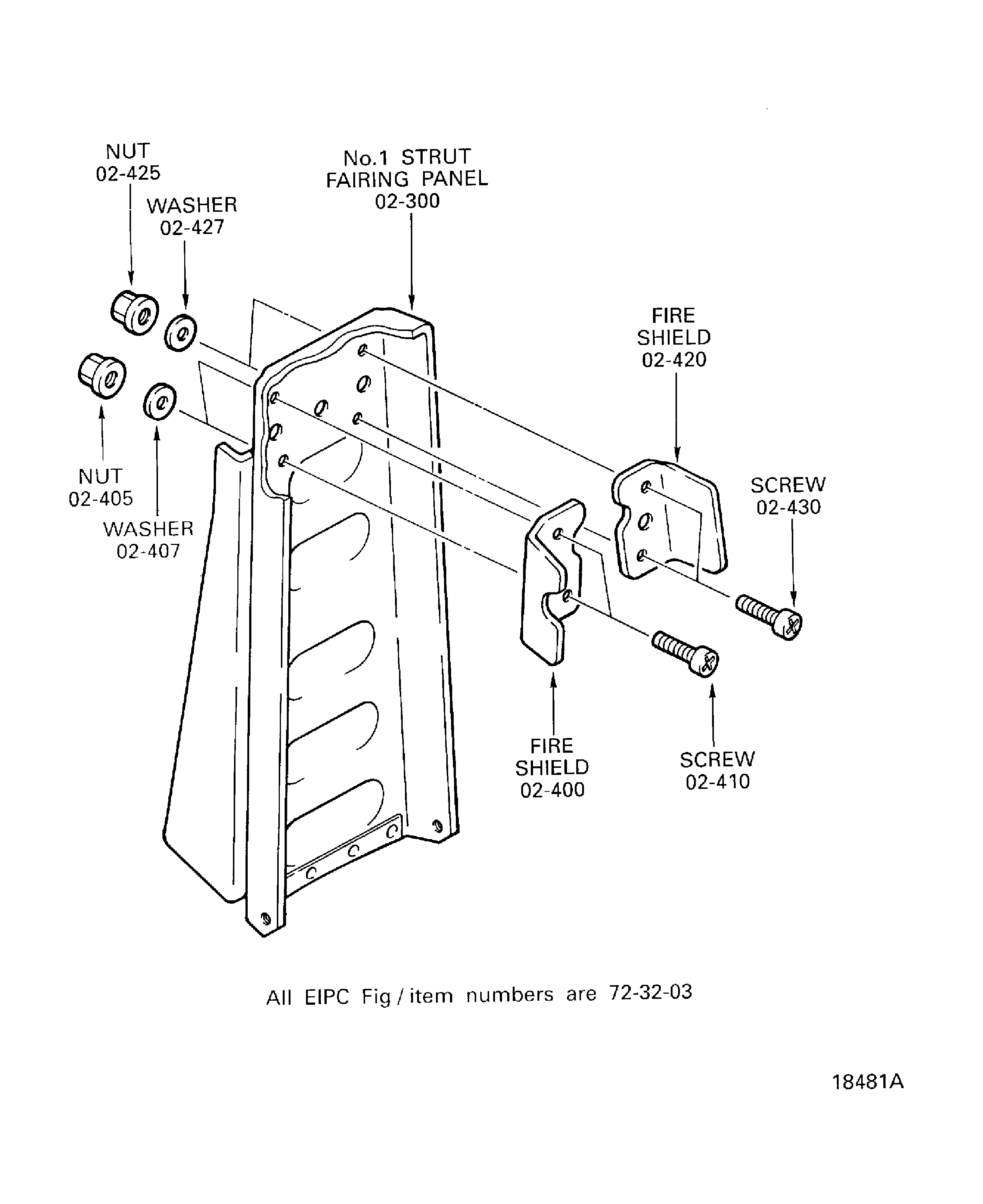

Install the shield ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-400) on the No. 1 strut fairing panel ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-300) with the two screws ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-410), washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-407) and nuts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-405).

Install the shield ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-420) on the No. 1 strut fairing panel ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-300) with the two screws ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-430), washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-427) and nuts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-425).

Install the two shields on the No.1 strut fairing panel.

SUBTASK 72-32-00-430-287-A00 Install the Fire Shields to the No.1 Strut Fairing Panel (Pre SBE 72-0216)

Refer to Figure.

Install the shield ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-400) on the no. 1 strut fairing panel ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-300) with the two screws ENGINE-INTERMEDIATE STRUCTURE (72-32- 03,02-410).

Install the shield ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-420) on to the No. 1 strut fairing panel ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-300) with the two screws ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-430).

Install the two shields on the No.1 strut fairing panel.

SUBTASK 72-32-00-430-287-B00 Install the Fire Shields to the No. 1 Strut Fairing Panel (SBE 72-0216 and Pre SBE 72-0230)

SBE 72-0216: Additional plate nut on the No.1 strut fairing panel

Refer to Figure.

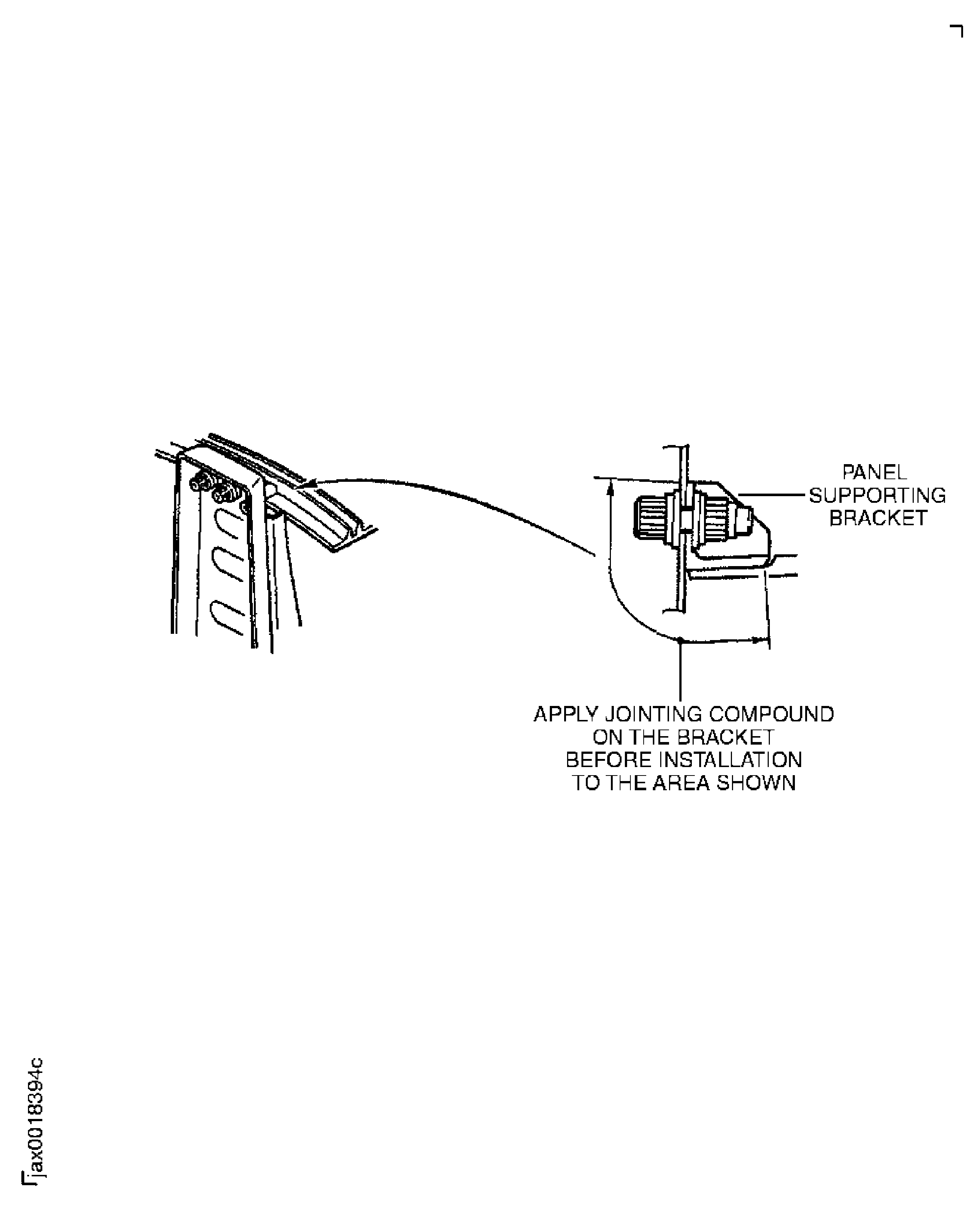

Make a clean cloth moist with CoMat 01-124 ISOPROPYL ALCOHOL to clean the mating faces on the two panel supporting brackets ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-500 and ENGINE-INTERMEDIATE STRUCTURE 02-550).

NOTE

Install the panel supporting brackets onto the fan case before the jointing compound becomes dry.Apply CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE with a stiff brush to the mating faces.

SUBTASK 72-32-00-430-319 Apply Jointing Compound to the Mating Faces on the Panel Supporting Brackets

Refer to Figure.

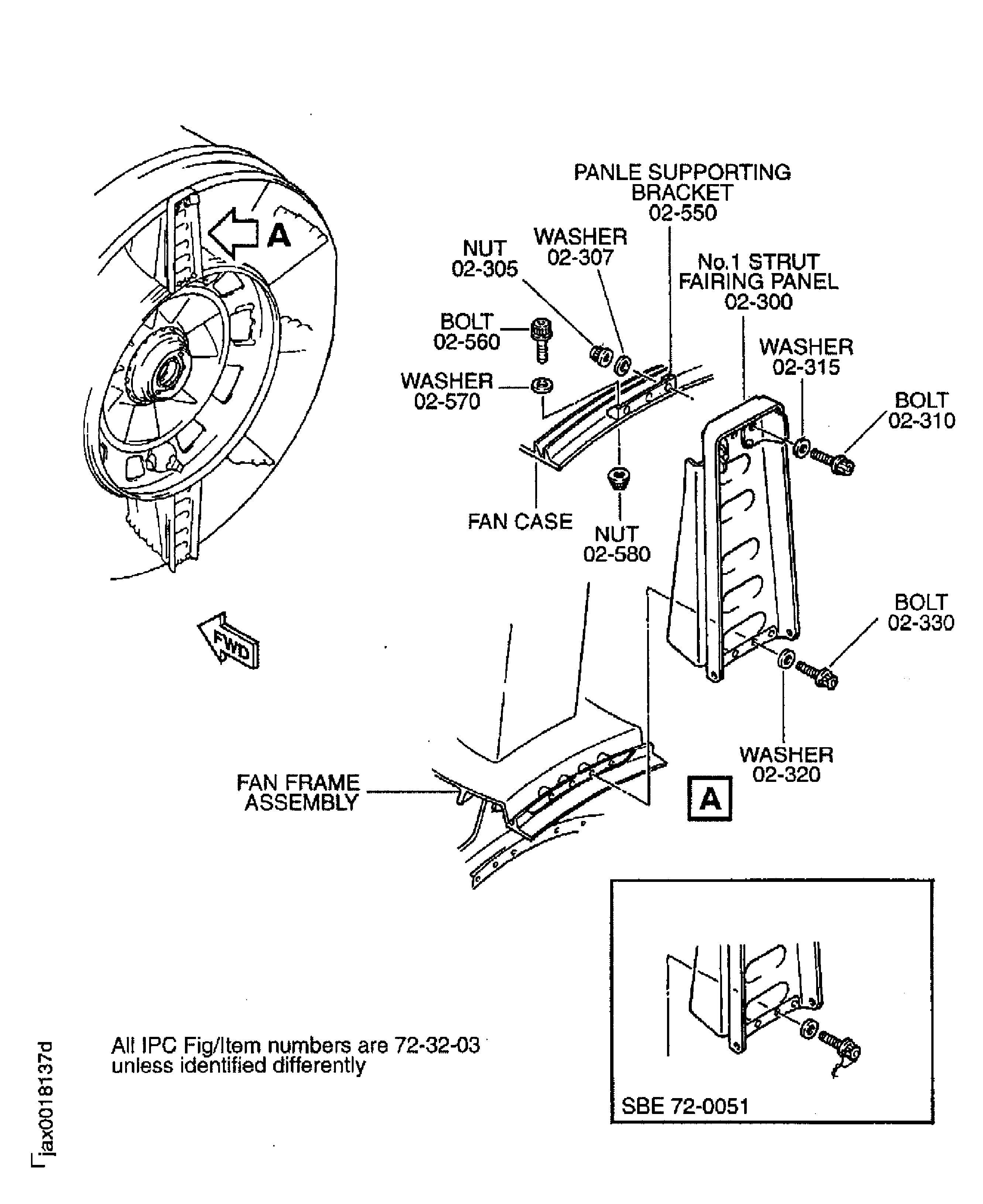

Attach the panel supporting bracket ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-550) to the fan case at the 12 o'clock position with the two washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-570), bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-560) and nuts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-580).

Attach the panel supporting brackets to the fan case.

Install the three washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-315), bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-310), washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-307) and nuts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-305) which attach the panel to the bracket. Tighten the bolts lightly.

Install the four washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-320) and bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-330) which attach the panel to the fan frame. Tighten the bolts lightly.

Torque the bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-310) to 85 to 105 lbfin (10.00 to 12.00 Nm).

Torque the bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-330) to 36 to 45 lbfin (4.00 to 5.00 Nm).

Attach the No. 1 strut fairing panel ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-300) to the fan frame and the bracket.

SUBTASK 72-32-00-430-175-A00 Install the No. 1 Strut Fairing Panel onto the Fan Frame and the Fan Case (Pre SBE 72-0051)

Refer to Figure.

Attach the panel supporting bracket ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-550) to the fan case at the 12 o'clock position with the two washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-570), bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-560) and nuts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-580).

Attach the panel supporting brackets to the fan case.

Install the three washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-315), bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-310), washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-307) and nuts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-305) which attach the panel to the bracket. Tighten the bolts lightly.

Install the four washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-320) and bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-330) which attach the panel to the fan frame. Tighten the bolts lightly.

Torque the bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-310) to 85 to 105 lbfin (10.00 to 12.00 Nm).

Torque the bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-330) to 36 to 45 lbfin (4.00 to 5.00 Nm).

Safety the bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-330) with CoMat 02-119 LOCKWIRE.

Attach the No.1 strut fairing panel ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-300) to the fan frame and the bracket.

SUBTASK 72-32-00-430-175-B00 Install the No. 1 Strut Fairing Panel onto the Fan Frame and the Fan Case (SBE 72-0051)

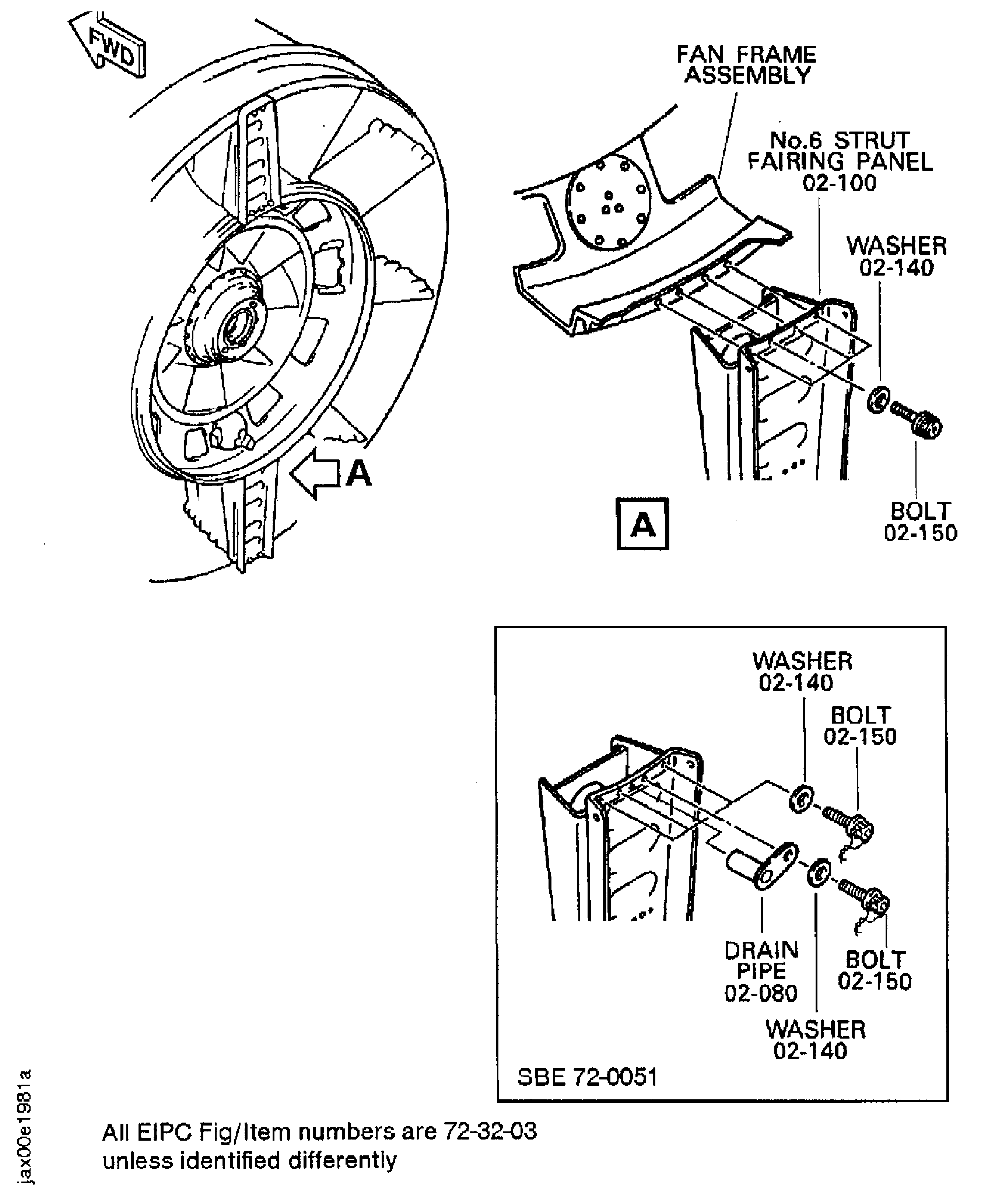

SBE 72-0051: Incorporating a fuel drain tube in the fan frame assembly

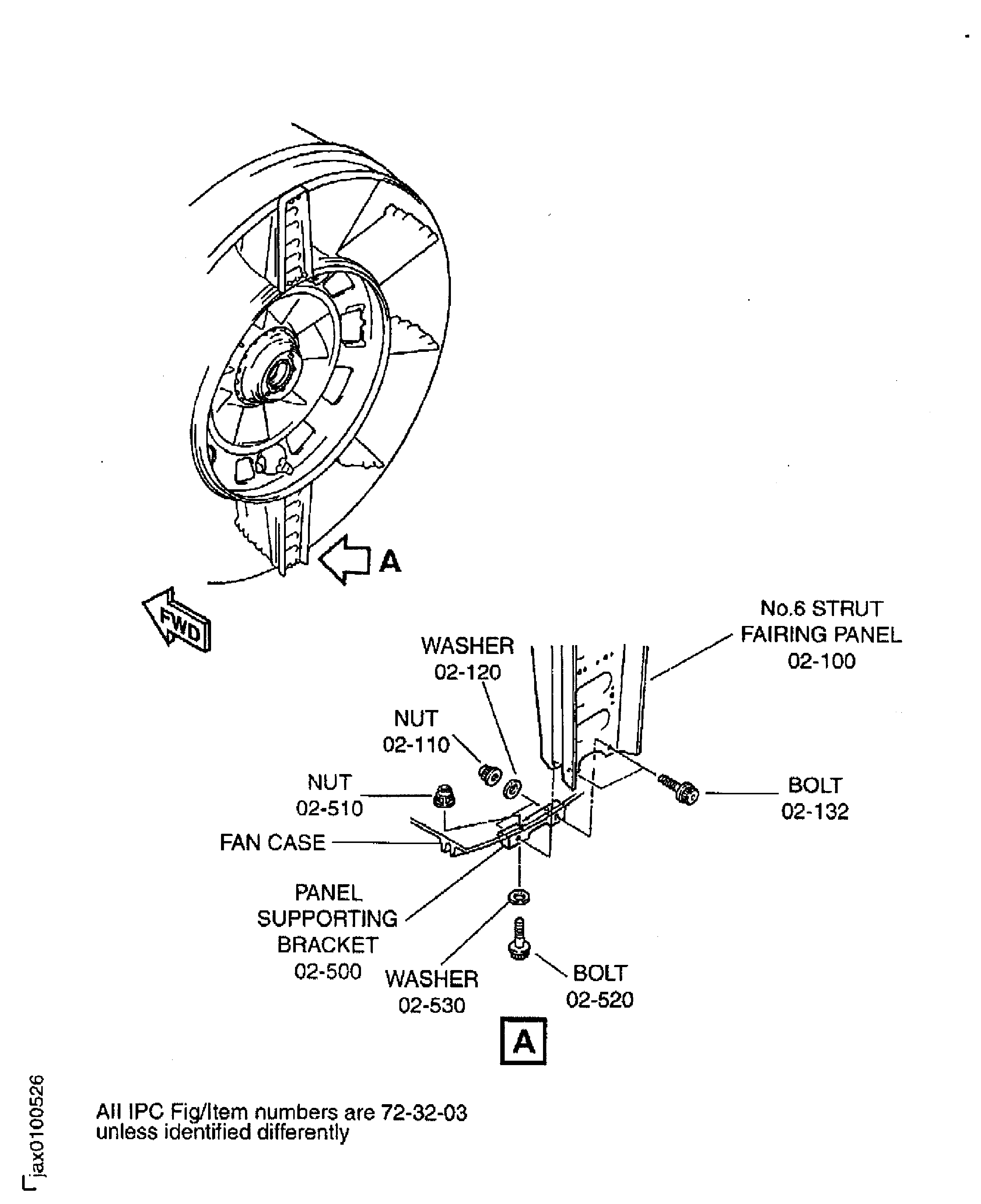

Put the panel supporting bracket ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-500) onto the fan case at the 6 o'clock position.

Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

Safety with the two washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-530), bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-520) and nuts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-510).

Attach the panel supporting bracket to the fan case.

Install the two bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-132), washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-120) and nuts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-110) which attach the panel to the bracket. Tighten the bolts lightly.

Install the four washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-140) and bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-150) which attach the panel to the fan frame assembly. Tighten the bolts lightly.

Torque the bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-132) to 85 to 105 lbfin (10.00 to 12.00 Nm).

Torque the bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-150) to 85 to 105 lbfin (10.00 to 12.00 Nm).

Attach the No.6 strut fairing panel ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-100) to the fan frame and the panel supporting bracket.

SUBTASK 72-32-00-430-320-A00 Install the No. 6 Strut Fairing Panel onto the Fan Frame Assembly and the Fan Case (Pre SBE 72-0051, SBE 72-0175 and SBE 72-0435)

SBE 72-0175: Provide longer attaching bolts for the open latch indicator bracket

SBE 72-0435: Fan case panel and bracket scalloped for No.4 scavenge tube reroute

Put the panel supporting bracket ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-500) onto the fan case at the 6 o'clock position.

Safety with the two washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-530), bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-520) and nuts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-510).

Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

Attach the panel supporting bracket to the fan case.

Install the two bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-132), washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-120) and nuts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-110) which attach the panel to the bracket. Tighten the bolts lightly.

Install the drain pipe ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-080), the four washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-140) and bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-150) which attach the panel to the fan frame assembly. Tighten the bolts lightly.

Torque the two bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-132) to 85 to 105 lbfin (10.00 to 12.00 Nm).

Torque the bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-150) to 85 to 105 lbfin (10.00 to 12.00) Nm).

Safety the bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-150) with CoMat 02-119 LOCKWIRE.

Attach the No.6 strut fairing panel ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-100) to the fan frame and the panel supporting bracket.

SUBTASK 72-32-00-430-320-B00 Install the No. 6 Strut Fairing Panel onto the Fan Frame Assembly and the Fan Case (SBE 72-0051, SBE 72-0175 and SBE 72-0435)

SBE 72-0051: Incorporate a fuel drain tube in the fan frame assembly.

SBE 72-0175: Provide longer attaching bolts for the open latch indicator bracket.

SBE 72-0435: Fan case, panel and bracket scalloped for No. 4 scavenge tube reroute

Refer to Figure.

Install the stopper ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-450) with the two screws ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-454) and nuts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-451).

SUBTASK 72-32-00-430-224 Install the Stopper on the Fan Frame Assembly (SBE 72-0150)

SBE 72-0150: Provide a new weight reduced fan frame assembly and associated details.

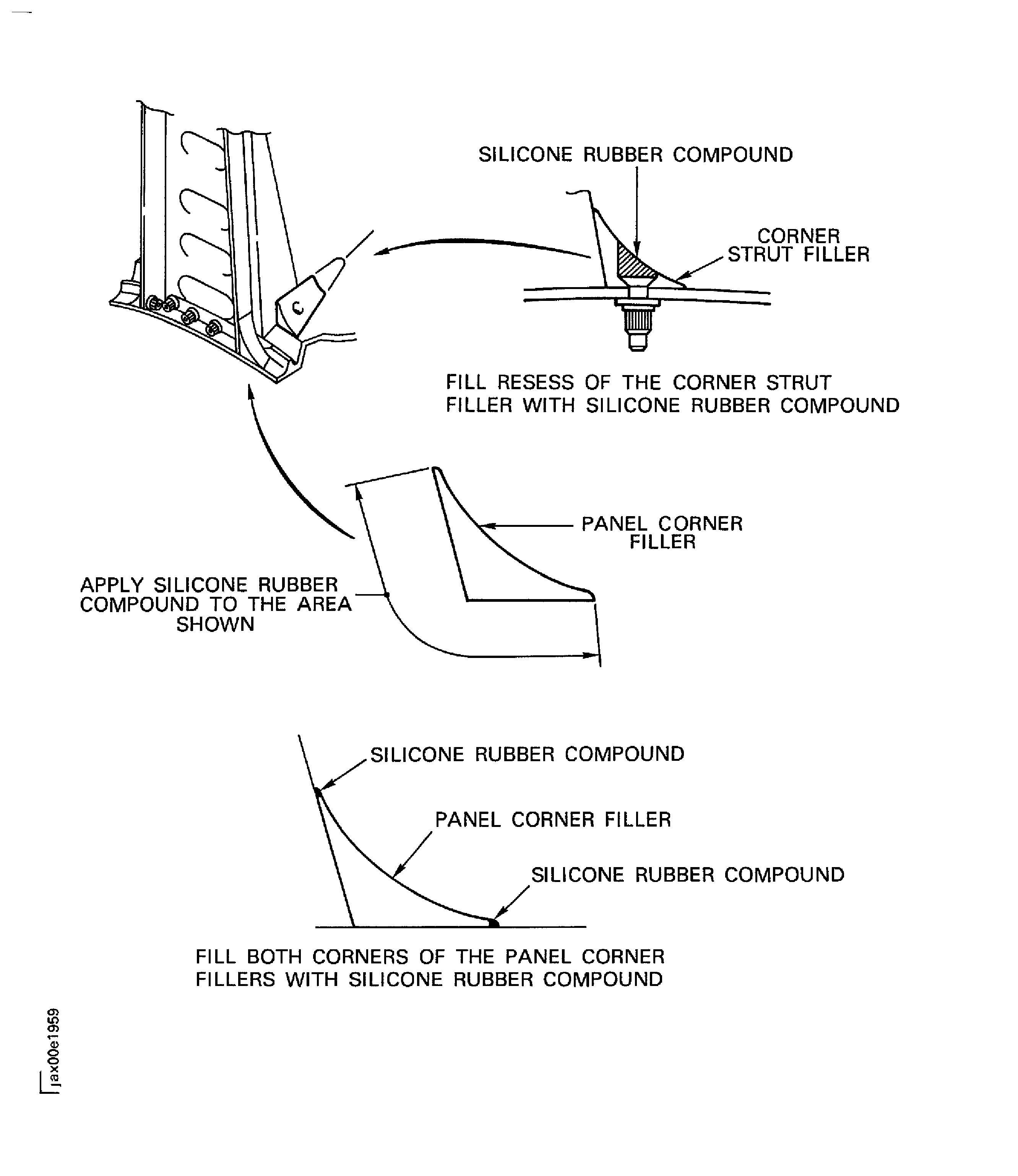

Refer to Figure.

the LH corner strut filler ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-700).

the RH corner strut filler ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-750).

the LH corner strut filler ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-850).

the RH corner strut filler ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-800).

Make a clean cloth or a soft brush moist with CoMat 01-031 ACETONE (CH3)2CO or CoMat 01-124 ISOPROPYL ALCOHOL.

NOTE

Apply the primer in less than eight hours after the mating faces are cleaned.Apply a thin layer of CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT with a soft brush to the mating faces. Air dry for 30 minutes minimum.

Apply CoMat 08-045 SILICONE RUBBER COMPOUND from the nozzle of the sealant tube to the mating faces.

SUBTASK 72-32-00-430-176 Apply Sealant to the Mating Faces on the Corner Fillers

Refer to Figure.

Attach the LH corner strut filler with the screw ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-340), the washer ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-320) and the nut ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-310). Torque the nut to 36 to 45 lbfin (4.00 to 5.00 Nm).

Attach the RH corner strut filler with the screw ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-440), the washer ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-420) and the nut ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-410). Torque the nut to 36 to 45 lbfin (4.00 to 5.00 Nm).

Install the LH corner strut filler ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-300) and the RH corner strut filler ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-400) on to the No. 1 strut.

Attach the LH corner strut filler with the screw ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-240), the washer ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-220) and nut ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-210). Torque the nut to 36 to 45 lbfin (4.00 to 5.00 Nm).

Attach the RH Corner strut filler with the screw ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-140), the washer ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-120) and nut ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-110). Torque the nut to 36 to 45 lbfin (4.00 to 5.00 Nm).

Install the LH corner strut filler ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 02-200) and the RH corner strut filler ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-100) on the No. 6 strut.

Attach the LH panel corner filler with the two washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-704 and ENGINE-INTERMEDIATE STRUCTURE 01-708) and bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-702 and ENGINE-INTERMEDIATE STRUCTURE 01-706). Torque the bolts to 36 to 45 lbfin (4.00 to 5.00 Nm).

Attach the RH panel corner filler with the two washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-754 and ENGINE-INTERMEDIATE STRUCTURE01-758) and bolts ENGINE-INTERMEDIATE STRUCTURE(72-32-03, 01-752 and ENGINE-INTERMEDIATE STRUCTURE01-756). Torque the bolts to 36 to 45 lbfin (4.00 to 5.00 Nm).

Install the LH panel corner filler ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-700) and the RH panel corner filler ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-750) on the No. 1 strut fairing panel.

Attach the LH panel corner filler with the two washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-854 and ENGINE-INTERMEDIATE STRUCTURE 01-858) and bolts ENGINE-INTERMEDIATE STRUCTURE(72-32-03, 01-852 and ENGINE-INTERMEDIATE STRUCTURE 01-856). Torque the bolts to 36 to 45 lbfin (4.00 to 5.00 Nm).

Attach the RH panel corner filler with the two washers ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-804 and ENGINE-INTERMEDIATE STRUCTURE 01-808) and bolts ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-802 and ENGINE-INTERMEDIATE STRUCTURE 01-806). Torque the bolts to 36 to 45 lbfin (4.00 to 5.00 Nm).

Install the LH panel corner filler ENGINE-INTERMEDIATE STRUCTURE (72-32-03, 01-850) and the RH panel corner filler ENGINE-INTERMEDIATE STRUCTURE(72-32-03,01-800) on the No. 6 strut fairing panel.

SUBTASK 72-32-00-430-177 Install the Corner Strut Fillers and the Panel Corner Fillers on to the Struts and the Strut Fairing Panels

Refer to Figure.

Make a soft brush moist with CoMat 01-031 ACETONE (CH3)2CO or CoMat 01-124 ISOPROPYL ALCOHOL.

NOTE

Apply the primer in less than eight hours after the cleaning of the mating faces.Apply thin layer of CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT with a soft brush to the surfaces of the recesses. Air dry for 30 minutes minimum.

Fill CoMat 08-045 SILICONE RUBBER COMPOUND from the nozzle of the sealant tube into the recesses.

SUBTASK 72-32-00-430-178 Fill the Recesses in the Corner Strut Fillers with Sealant

Refer to Figure.

SUBTASK 72-32-00-430-180 Turn the LP Compressor/Intermediate Case Module Vertical with the Rear End Up

Refer to Figure.

NOTE

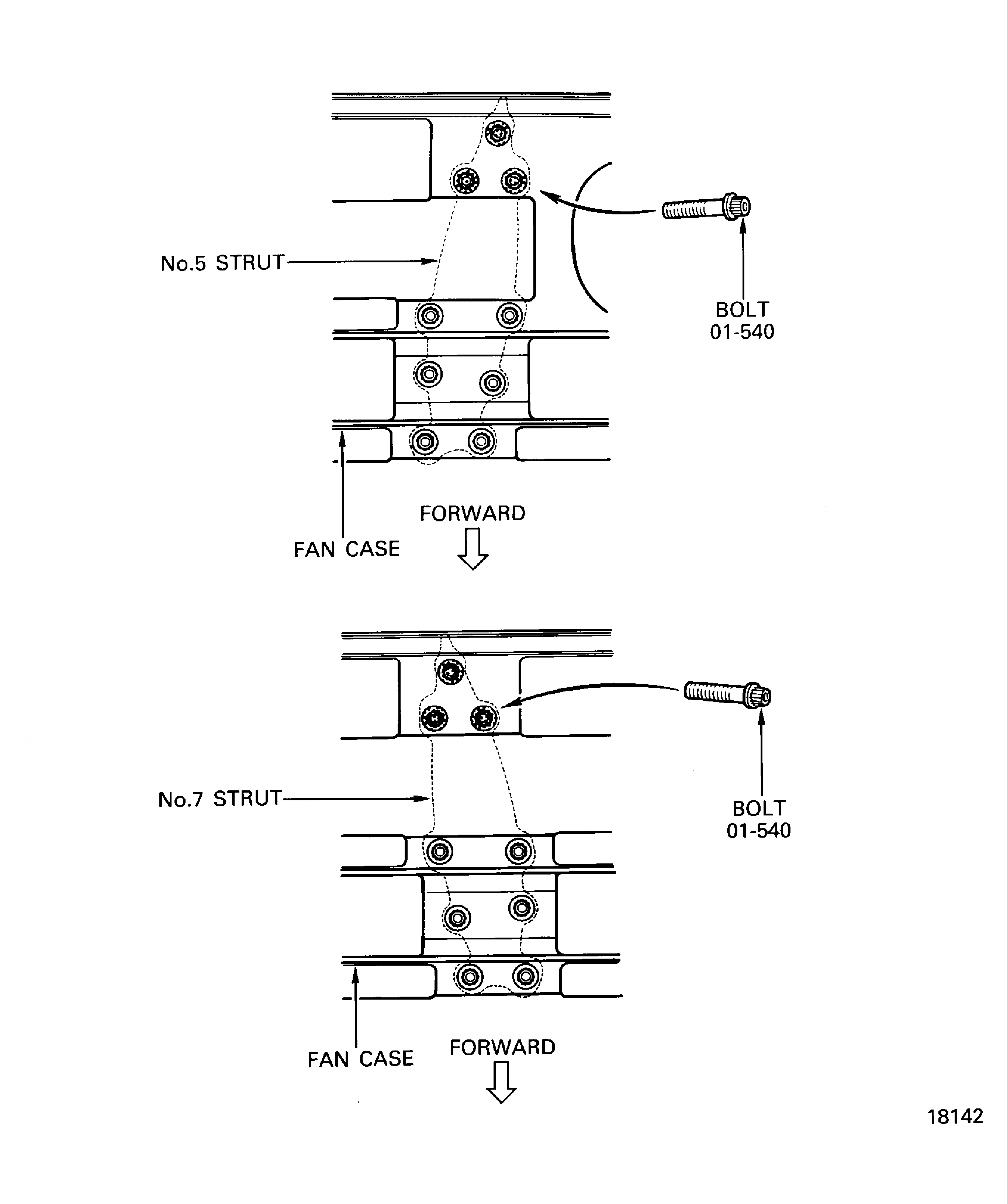

The bolts are tightened to the specified torque value after the installation of the brackets in TASK 71-00-21-400-001 (INSTALLATION).Install the six bolts (01-540) through the fan case holes into the six threaded holes in the No.5 and No.7 struts. Tighten the bolts lightly.

SUBTASK 72-32-00-430-181 Install the Six Bolts into the Threaded Holes in the No.5 and No.7 Struts

Figure: Apply Jointing Compound to the Mating Faces on the Brackets

Apply Jointing Compound to the Mating Faces on the Brackets

Figure: Install the Front Fairings on to the Brackets

Sheet 1

Figure: Install the Front Fairings on to the Brackets

Sheet 2

Figure: Clean the Surfaces of the Corners F around the Dimpled Washers and Apply Primer

Clean the Surfaces of the Corners F around the Dimpled Washers and Apply Primer

Figure: Fill Silicone Compound in to the Corners F and Press it into Position

Fill Silicone Compound in to the Corners F and Press it into Position

Figure: Measure the Module Interface Dimensions for the Installation of the HP System Module

Measure the Module Interface Dimensions for the Installation of the HP System Module

Figure: Apply Jointing Compound to the Panel Supporting Brackets

Apply Jointing Compound to the Panel Supporting Brackets

Figure: Install the No.1 Strut Fairing Panel on the Fan Frame Assembly and the Fan Case

Install the No.1 Strut Fairing Panel on the Fan Frame Assembly and the Fan Case

Figure: Pre SBE 72-0175: Install the No.6 Strut Fairing Panel on the Fan Case

Sheet 1

Figure: SBE 72-0175 and SBE 72-0435: Install the No.6 Strut Fairing Panel on the Fan Case

Sheet 2

Figure: Install the No.6 Strut Fairing Panel on the Fan Frame Assembly

Install the No.6 Strut Fairing Panel on the Fan Frame Assembly

Figure: SBE 72-0150: Install the Stopper on the Fan Frame Assembly

SBE 72-0150: Install the Stopper on the Fan Frame Assembly

Figure: Apply Silicone Rubber Compound to the Corner Strut Fillers and the Panel Corner Fillers

Apply Silicone Rubber Compound to the Corner Strut Fillers and the Panel Corner Fillers

Figure: Install the Panel Corner Fillers and the Corner Strut Fillers on the Fan Frame Assembly

Sheet 1

Figure: Install the Panel Corner Fillers and the Corner Strut Fillers on the Fan Frame Assembly

Sheet 2

Figure: Pre SBE 75-0010: Install the Fan Exit Pressure Boss and the Block on the Fan Case

Sheet 1

Figure: SBE 75-0010: Install the Fan Exit Pressure Boss and the Block on the Fan Case

Sheet 2

Figure: Remove the Stopper and Release the Lock Pin to turn the Fan Frame and Fan Case Assembly from Horizontal to Vertical

Remove the Stopper and Release the Lock Pin to turn the Fan Frame and Fan Case Assembly from Horizontal to Vertical

Figure: Install the Six Bolts into the Threaded Holes in the No.5 and No.7 Struts

Install the Six Bolts into the Threaded Holes in the No.5 and No.7 Struts

Figure: Pre SBE 72-0216: Install the Shields on the No.1 Strut Fairing Panel

Sheet 1

Figure: SBE 72-0216 and Pre SBE 72-0230: Install the Shields on the No.1 Strut Fairing Panel

Sheet 2