Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-50-450-002-B00 LPT Module Components - Install The EGT Harness And Junction Box Assembly (4012KS-5), Installation-011

General

This TASK gives the procedure to install the EGT harness and junction box assembly on the LP turbine system module.

For standard torque data procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

For installation and the reuse of self-locking fasteners, refer to SPM TASK 70-42-01-400-501.

For installation of lockwire, refer to SPM TASK 70-42-05-400-501.

Fig/item numbers are in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants, refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-127 LOCKWIRE | LOCAL | CoMat 02-127 | ||

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 10-077 APPROVED ENGINE OILS | IAE00 | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

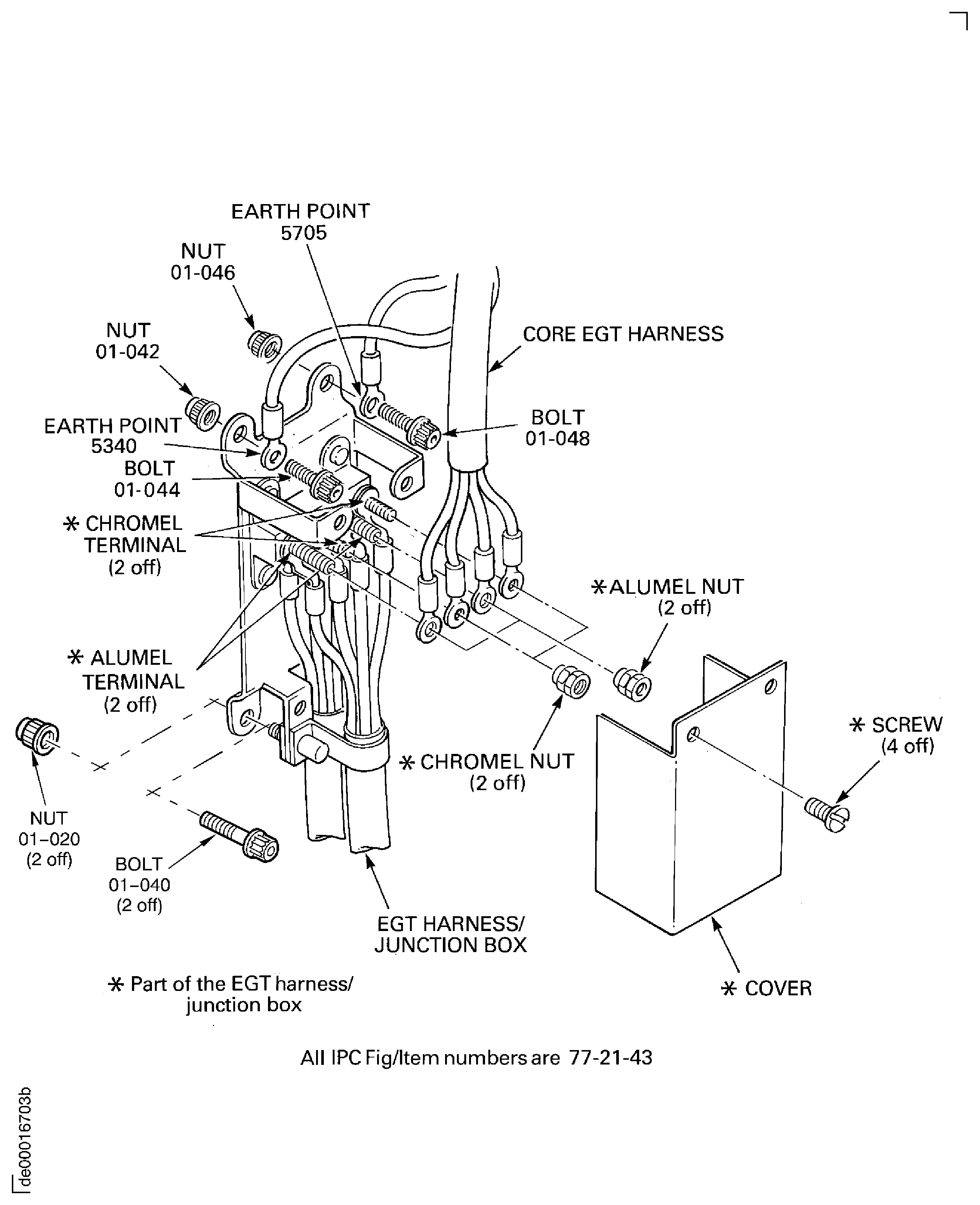

Install the EGT harness and junction box assembly EGT Harness And Junction Box (77-21-43, 01-010) to the bracket on the bottom of the exhaust case, refer to Figure.

Apply CoMat 10-077 APPROVED ENGINE OILS to the threads of two bolts EGT Harness And Junction Box (77-21-43, 01-040), one bolt EGT Harness And Junction Box (77-21-43, 01-044) and one bolt EGT Harness And Junction Box (77-21-43, 01-048).

Install two nuts EGT Harness And Junction Box (77-21-43, 01-020), one nut EGT Harness And Junction Box (77-21-43, 01-042) and one nut EGT Harness And Junction Box (77-21-43, 01-046) on the bolts.

SUBTASK 72-00-50-450-061 Install the EGT Harness and Junction Box Assembly

Refer to Figure.

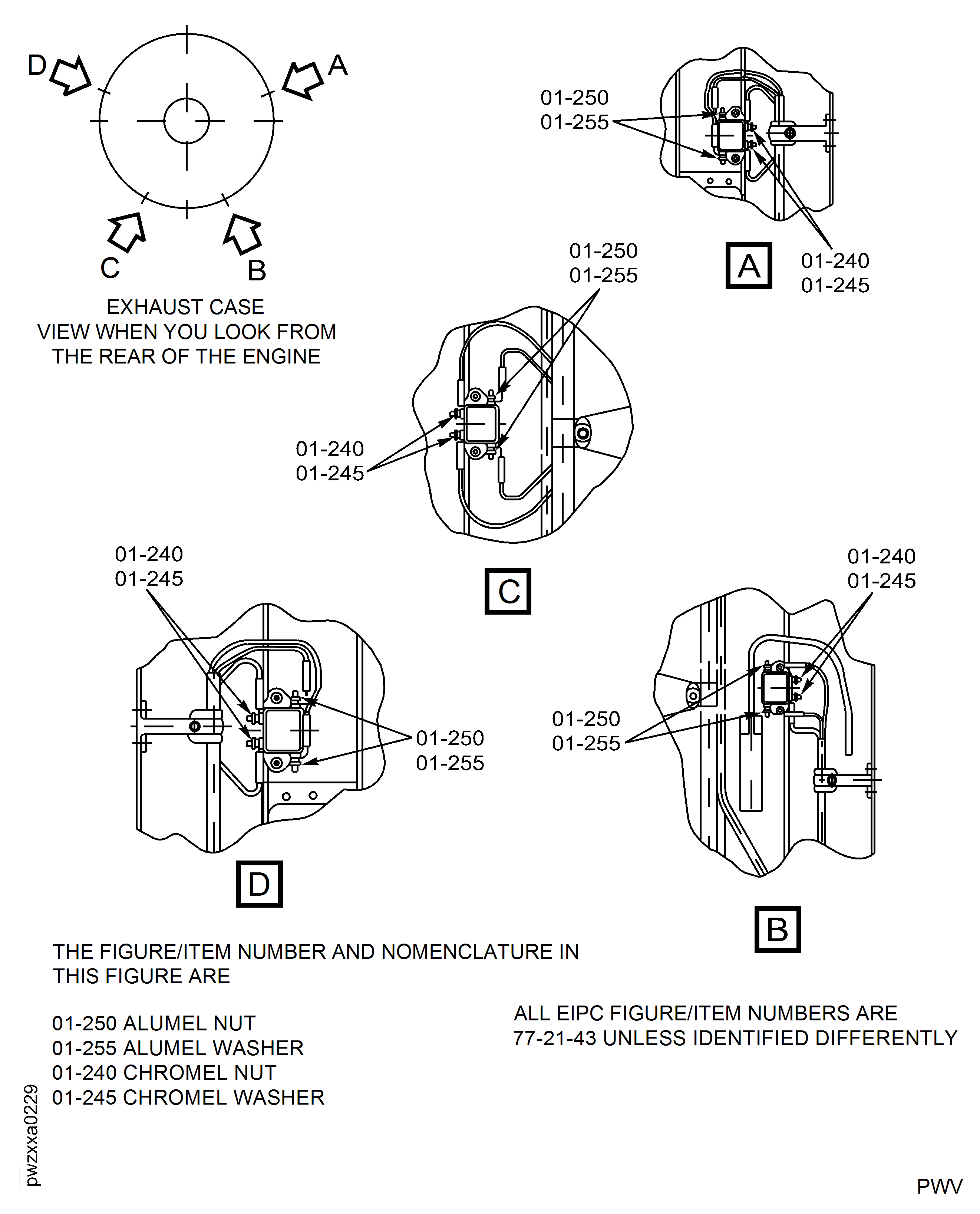

Remove the two alumel (larger) nuts EGT Harness And Junction Box (77-21-43, 01-240), the two alumel washers EGT Harness And Junction Box (77-21-43, 01-245), the two chromel (smaller) nuts EGT Harness And Junction Box (77-21-43, 01-250) and the two chromel washers EGT Harness And Junction Box (77-21-43, 01-255) from the thermocouple terminals at four positions.

SUBTASK 72-00-50-450-062 Attach the EGT Harness Lugs to the Thermocouples

CAUTION

DO NOT USE LUBRICATION ON THE THREADS OF THE THERMOCOUPLE CONNECTIONS. ENGINE OIL CAN CONTAMINATE THE EGT HARNESS INSULATION MATERIAL AND RESULT IN ERRATIC OR UNRELIABLE EGT INDICATION.

CAUTION

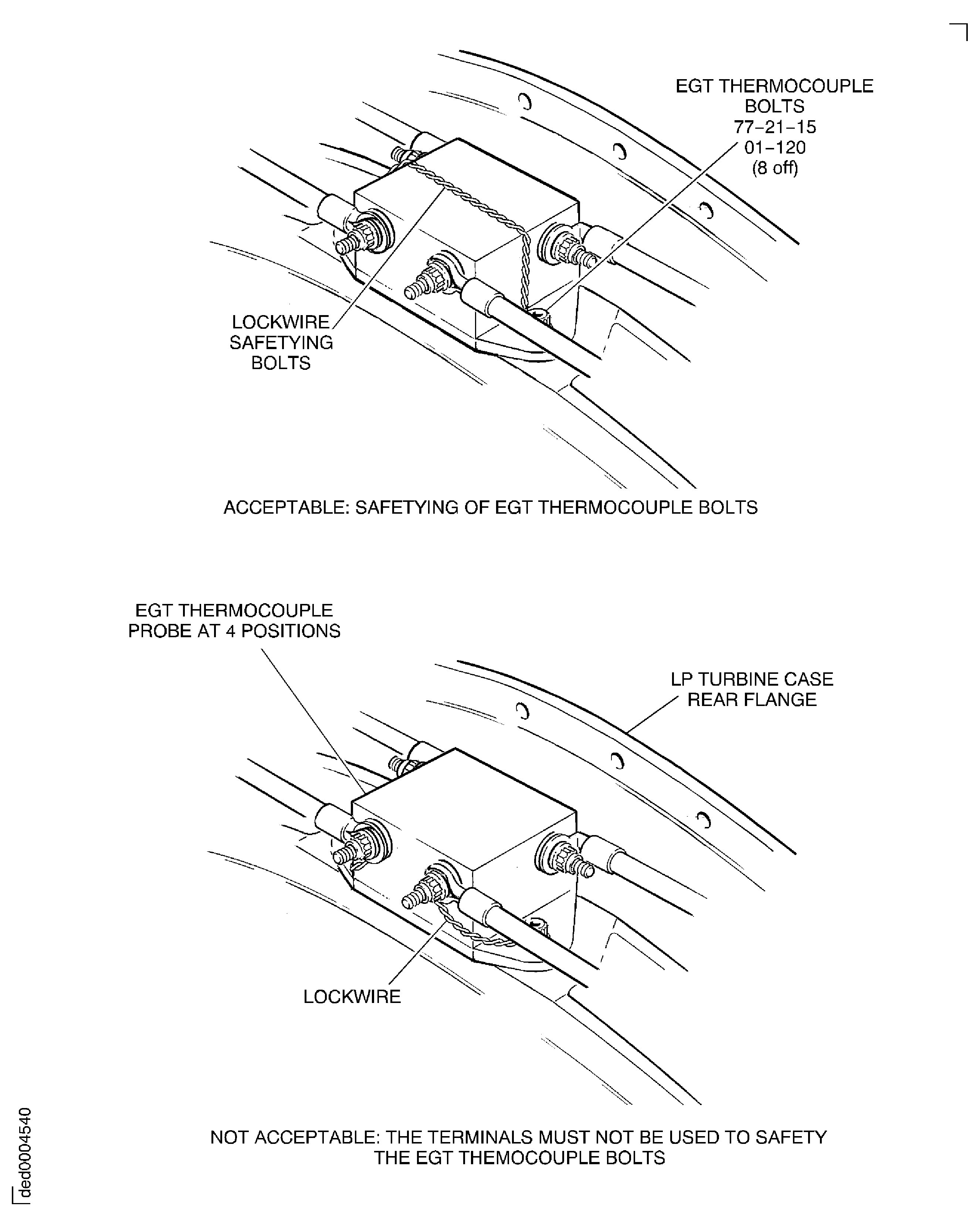

YOU MUST MAKE SURE THAT THE EGT THERMOCOUPLE BOLTS ARE CORRECTLY SAFETIED. INCORRECT SAFETYING OF THE BOLTS CAN RESULT IN LOOSE BOLTS AND SUBSEQUENT LOSS OF EGT INDICATION.Make sure the lockwire correctly safeties the eight EGT thermocouple bolts V2500-A5-77-21-15-01A-941A-D (77-21-15, 01-120). Refer to the view which shows the acceptable method, Figure.

Safety the bolts with wire V2500-A5-77-21-15-01A-941A-D (77-21-15, 01-200) - CoMat 02-141 LOCKWIRE as the inspection criteria requires it.

Examine the lockwire which safeties the EGT thermocouple bolts.

SUBTASK 72-00-50-210-071 Examine the Safetying of the EGT thermocouple Bolts.

Refer to Figure.

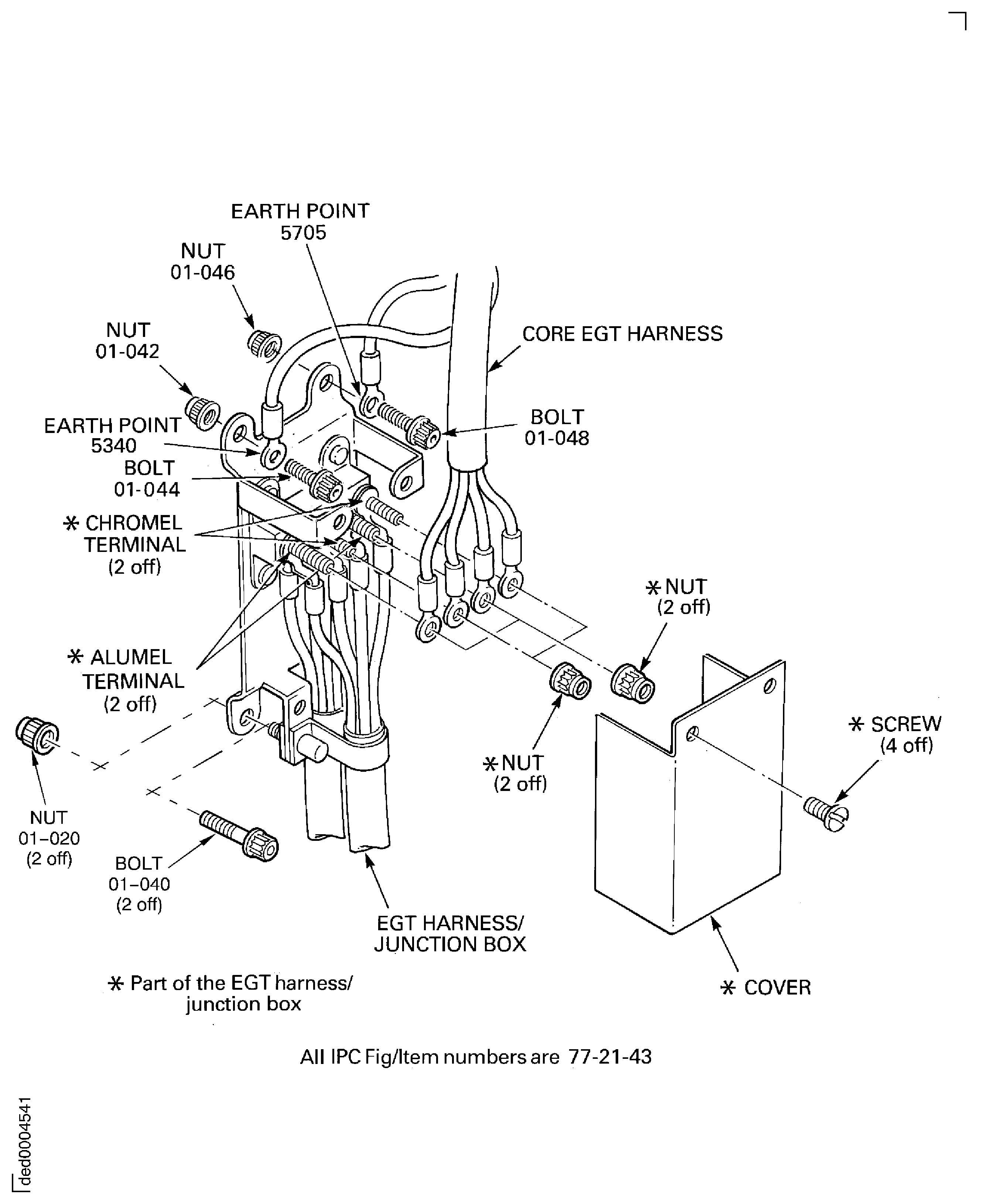

Remove the two alumel (larger) nuts and the two chromel (smaller) nuts from the junction box EGT Harness And Junction Box (77-21-43, 01-010) terminals, refer to Figure.

Use the other two nuts EGT Harness And Junction Box (77-21-43, 01-042 and EGT Harness And Junction Box 01-046) and the two bolts EGT Harness And Junction Box (77-21-43, 01-044 and EGT Harness And Junction Box 01-048) to attach the earth points 5340 and 5705 to the junction box. Torque the nuts to 85 lbfin to 105 lbfin (10 Nm to 12 Nm).

Attach the cover to the EGT harness junction box with the four screws. Torque the screws to 16 lbfin to 22 lbfin (1.81 Nm to 2.49 Nm). Safety the screws with CoMat 02-126 LOCKWIRE.

Pre SBE 77-0009: Attach the core EGT harness to the EGT harness/junction box. Refer to Figure.

SUBTASK 72-00-50-450-063-A00 Connect the Core EGT Harness to the Junction Box (Pre SBE 77-0009)

CAUTION

DO NOT USE LUBRICATION ON THE THREADS OF THE HARNESS CONNECTIONS. ENGINE OIL CAN CONTAMINATE THE EGT HARNESS INSULATION MATERIAL AND RESULT IN ERRATIC OR UNRELIABLE EGT INDICATION.Remove the two alumel (larger) nuts and the two chromel (smaller) nuts from the junction box EGT Harness And Junction Box (77-21-43, 01-010) terminals.

Use the other two nuts EGT Harness And Junction Box (77-21-43, 01-042 and EGT Harness And Junction Box 01-046) and the two bolts EGT Harness And Junction Box (77-21-43, 01-044 and EGT Harness And Junction Box 01-048) to attach the earth points 5340 and 5705 to the junction box. Torque the nuts to 85 lbfin to 105 lbfin (10 Nm to 12 Nm).

Attach the cover to the EGT harness junction box with the four screws. Torque the screws to 16 lbfin to 22 lbfin (1.81 Nm to 2.49 Nm). Safety the screws with CoMat 02-126 LOCKWIRE.

CAUTION

DO NOT USE LUBRICATION ON THE THREADS OF THE HARNESS CONNECTIONS. ENGINE OIL CAN CONTAMINATE THE EGT HARNESS INSULATION MATERIAL AND RESULT IN ERRATIC OR UNRELIABLE EGT INDICATION.

CAUTION

ONCE A NEW STYLE NUT IS INSTALLED ON TO THE MATING STUD YOU MUST NOT INSTALL AN OLD NUT ON THAT STUD.SBE 77-0009: Attach the core EGT harness to the EGT harness/junction box. Refer to Figure.

Refer to TASK 71-00-00-700-052-B00 for the applicable EGT and junction box tests.

Testing and Fault Isolation checks.

SUBTASK 72-00-50-450-063-B00 Connect the Core EGT Harness to the Junction Box (SBE 77-0009)

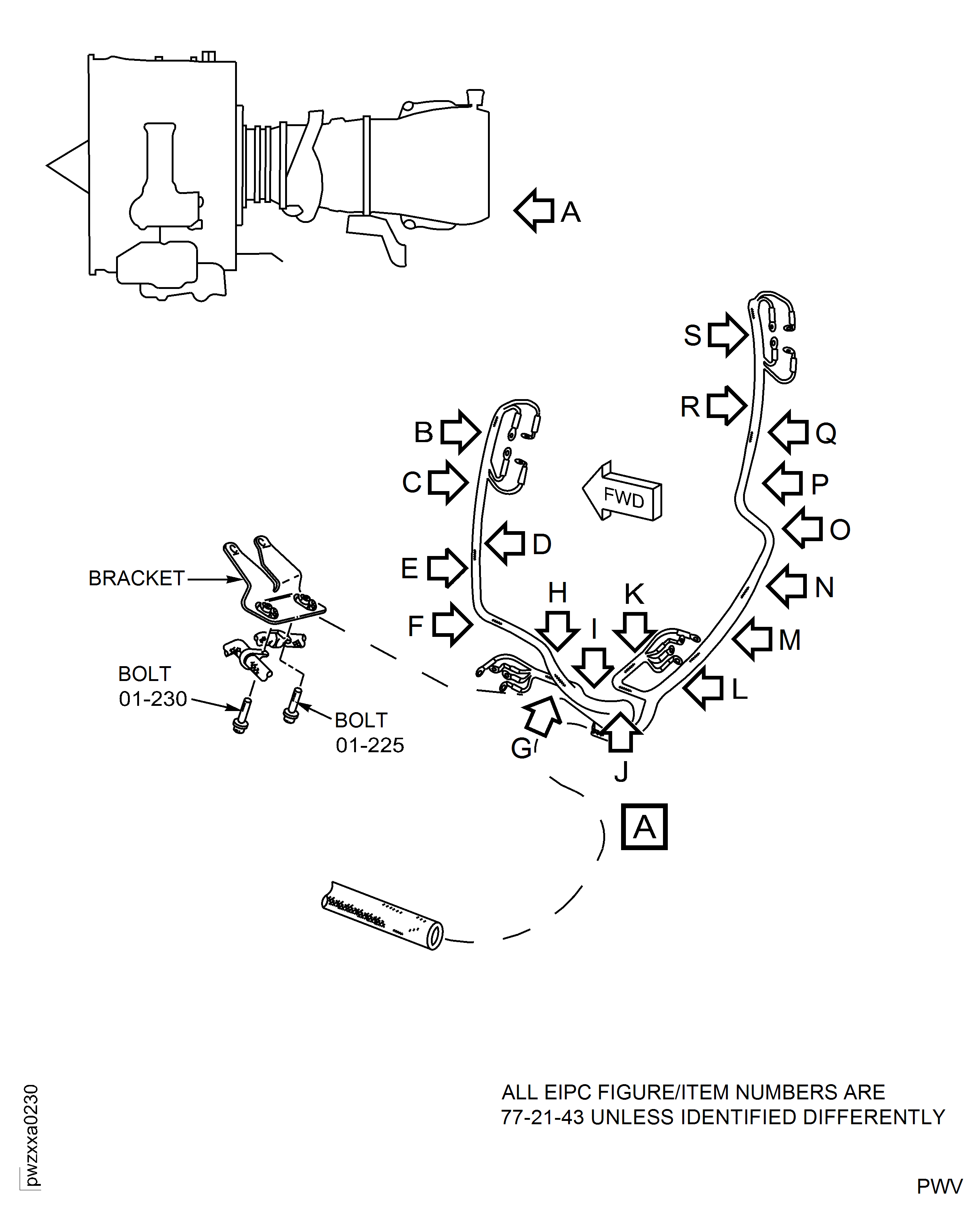

Refer to Figure.

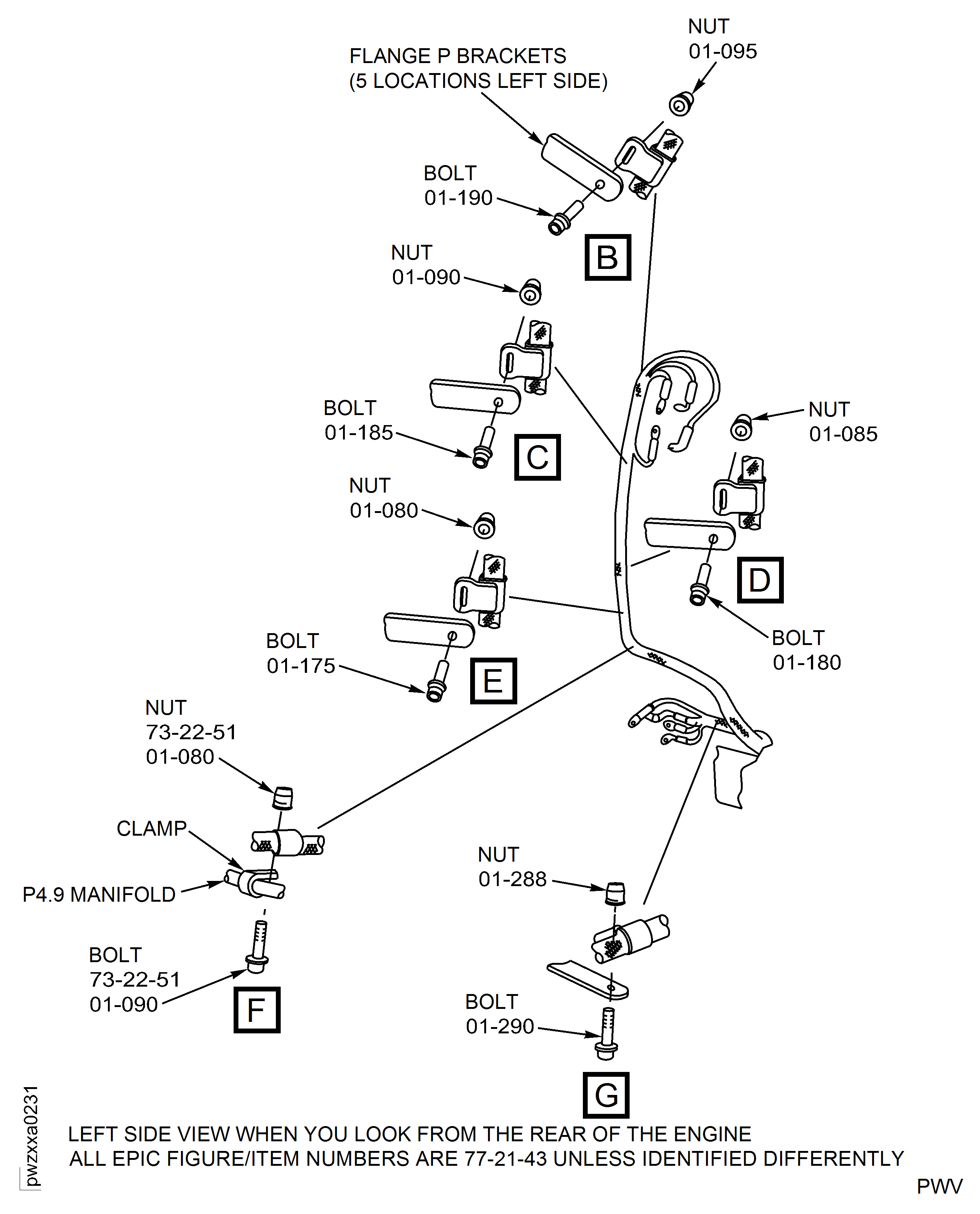

At View B, install the bolt EGT Harness And Junction Box (77-21-43, 01-190) and the nut EGT Harness And Junction Box (77-21-43, 01-095).

At View C, install the bolt EGT Harness And Junction Box (77-21-43, 01-185) and the nut EGT Harness And Junction Box (77-21-43, 01-090).

At View D, install the bolt EGT Harness And Junction Box (77-21-43, 01-180) and the nut EGT Harness And Junction Box (77-21-43, 01-085).

At View E, install the bolt EGT Harness And Junction Box (77-21-43, 01-175) and the nut EGT Harness And Junction Box (77-21-43, 01-080).

At View G, install the bolt EGT Harness And Junction Box (77-21-43, 01-290) and the nut EGT Harness And Junction Box (77-21-43, 01-288).

Attach the harness clamps to the five brackets located on the left side of the Flange P. Refer to Figure.

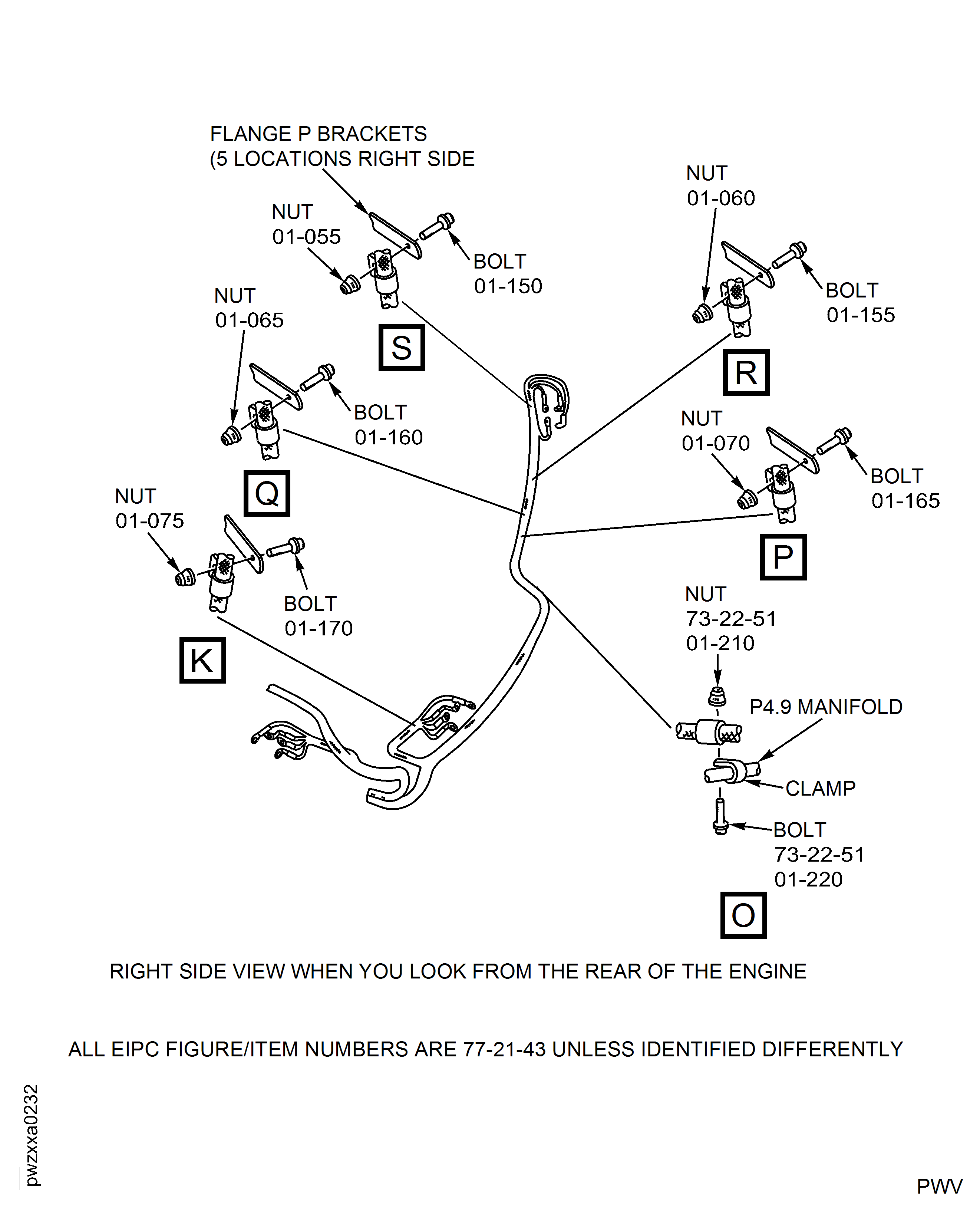

At View S, install the bolt EGT Harness And Junction Box (77-21-43, 01-150) and the nut EGT Harness And Junction Box (77-21-43, 01-055).

At View R, install the bolt EGT Harness And Junction Box (77-21-43, 01-155) and the nut EGT Harness And Junction Box (77-21-43, 01-060).

At View Q, install the bolt EGT Harness And Junction Box (77-21-43, 01-160) and the nut EGT Harness And Junction Box (77-21-43, 01-065).

At View P, install the bolt EGT Harness And Junction Box (77-21-43, 01-165) and the nut EGT Harness And Junction Box (77-21-43, 01-070).

At View K, install the bolt EGT Harness And Junction Box (77-21-43, 01-170) and the nut EGT Harness And Junction Box (77-21-43, 01-075).

Attach the harness clamps to the five brackets located on the right side of the Flange P. Refer to Figure.

SUBTASK 72-00-50-450-064 Install the EGT Harness at the Flange P Locations

Refer to Figure.

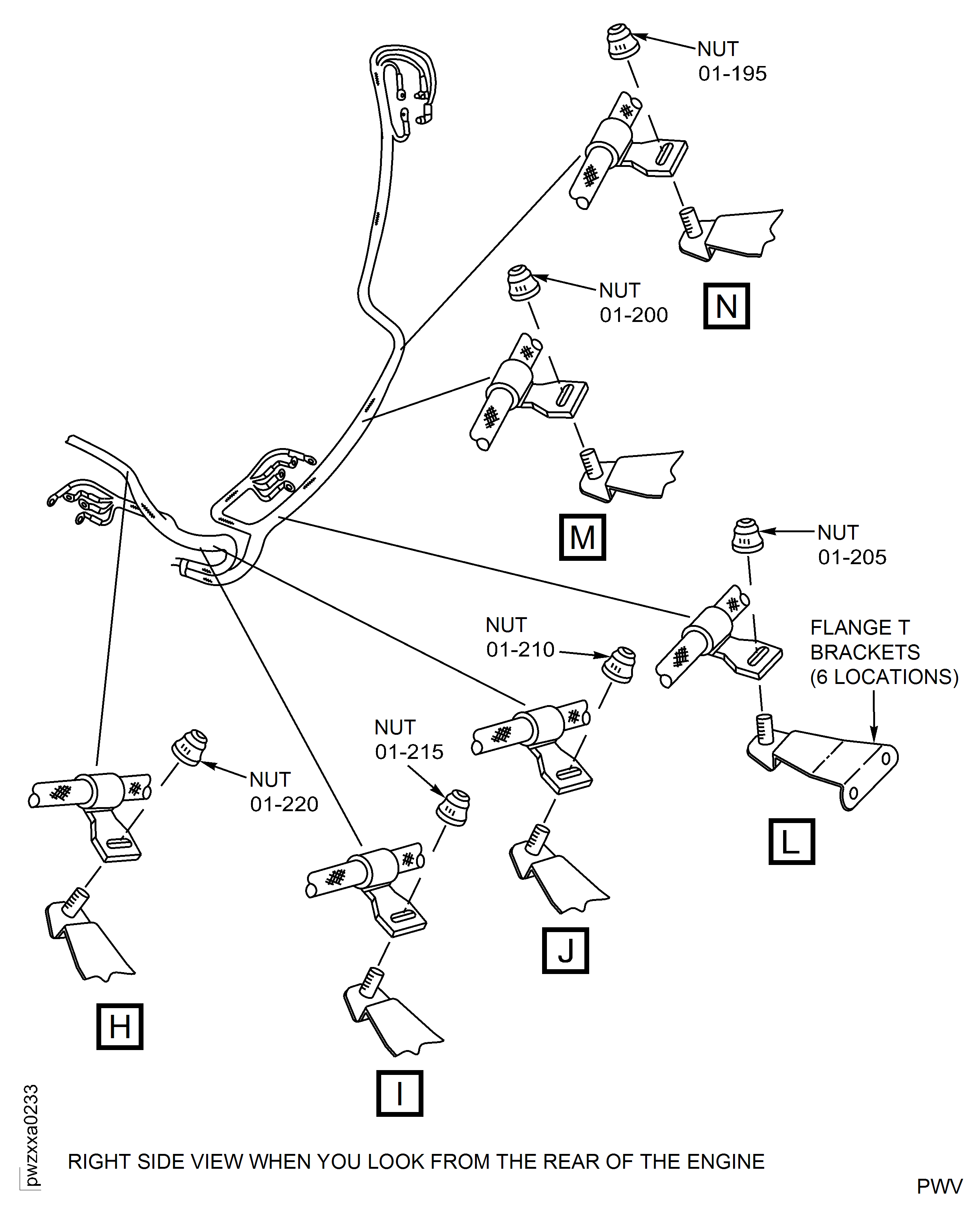

At View N, install the nut EGT Harness And Junction Box (77-21-43, 01-195).

At View M, install the nut EGT Harness And Junction Box (77-21-43, 01-200).

At View L, install the nut EGT Harness And Junction Box (77-21-43, 01-205).

At View J, install the nut EGT Harness And Junction Box (77-21-43, 01-210).

At View I, install the nut EGT Harness And Junction Box (77-21-43, 01-215).

At View H, install the nut EGT Harness And Junction Box (77-21-43, 01-220).

Attach the harness clamps to the six brackets located on the Flange T.

SUBTASK 72-00-50-450-065 Install the EGT Harness at the Flange T Bracket Locations

At View F, install the bolt V2500-A5-73-22-51-01A-941A-D (73-22-51, 01-090) and the nut V2500-A5-73-22-51-01A-941A-D (73-22-51, 01-080). Refer to Figure.

At View O, install the bolt V2500-A5-73-22-51-01A-941A-D (73-22-51, 01-220) and the nut V2500-A5-73-22-51-01A-941A-D (73-22-51, 01-210). Refer to Figure.

Install the harness clamp to the P4.9 manifold clamp at two locations.

SUBTASK 72-00-50-450-066 Install the EGT Harness at the P4.9 Manifold Clamp Locations

Refer to Figure.

Install the bolt EGT Harness And Junction Box (77-21-43, 01-225) and the bolt EGT Harness And Junction Box (77-21-43, 01-230) through the harness clamps in to the bracket at the bottom of the exhaust case. Refer to Figure.

SUBTASK 72-00-50-450-067 Install the EGT Harness to the Exhaust Case Bracket

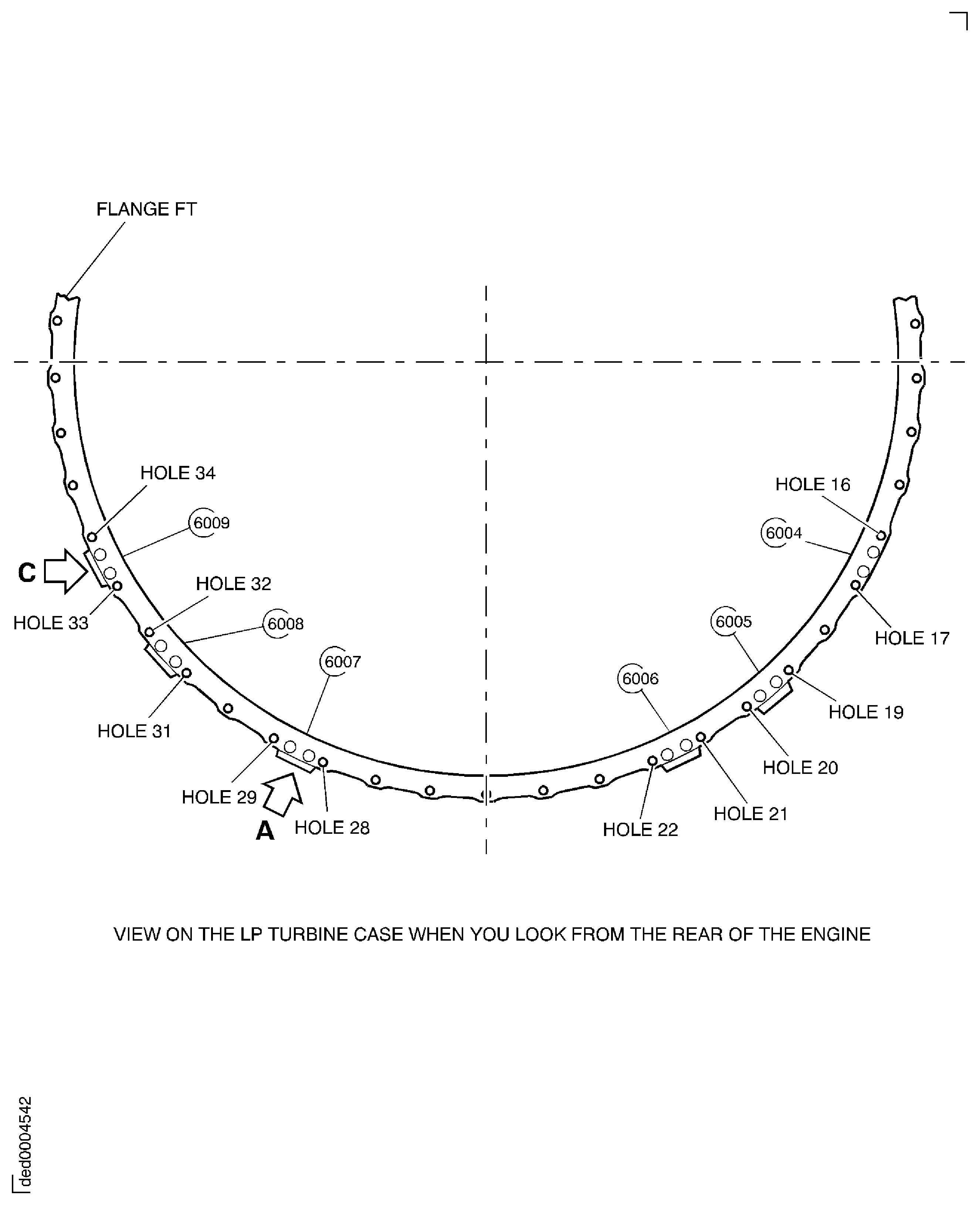

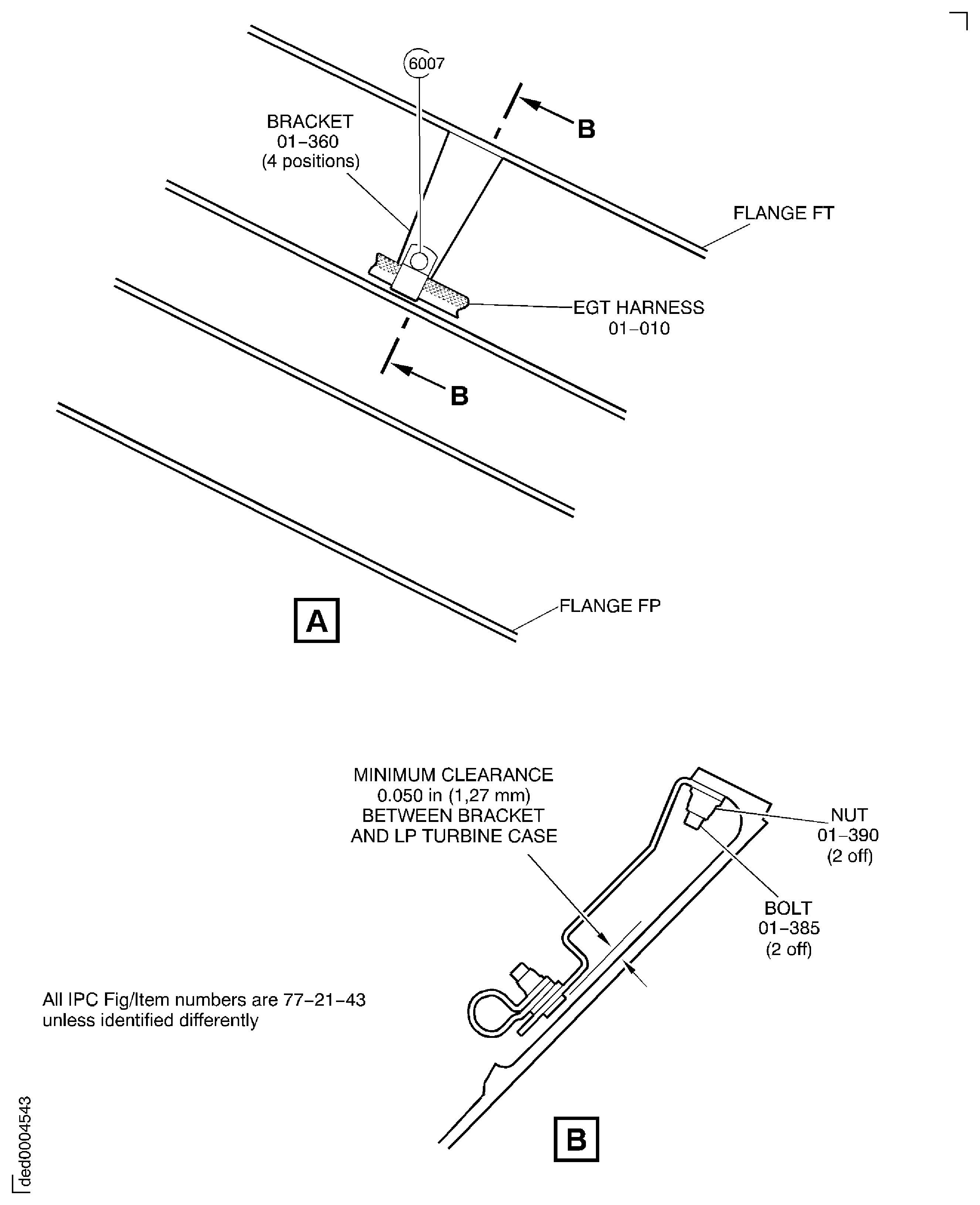

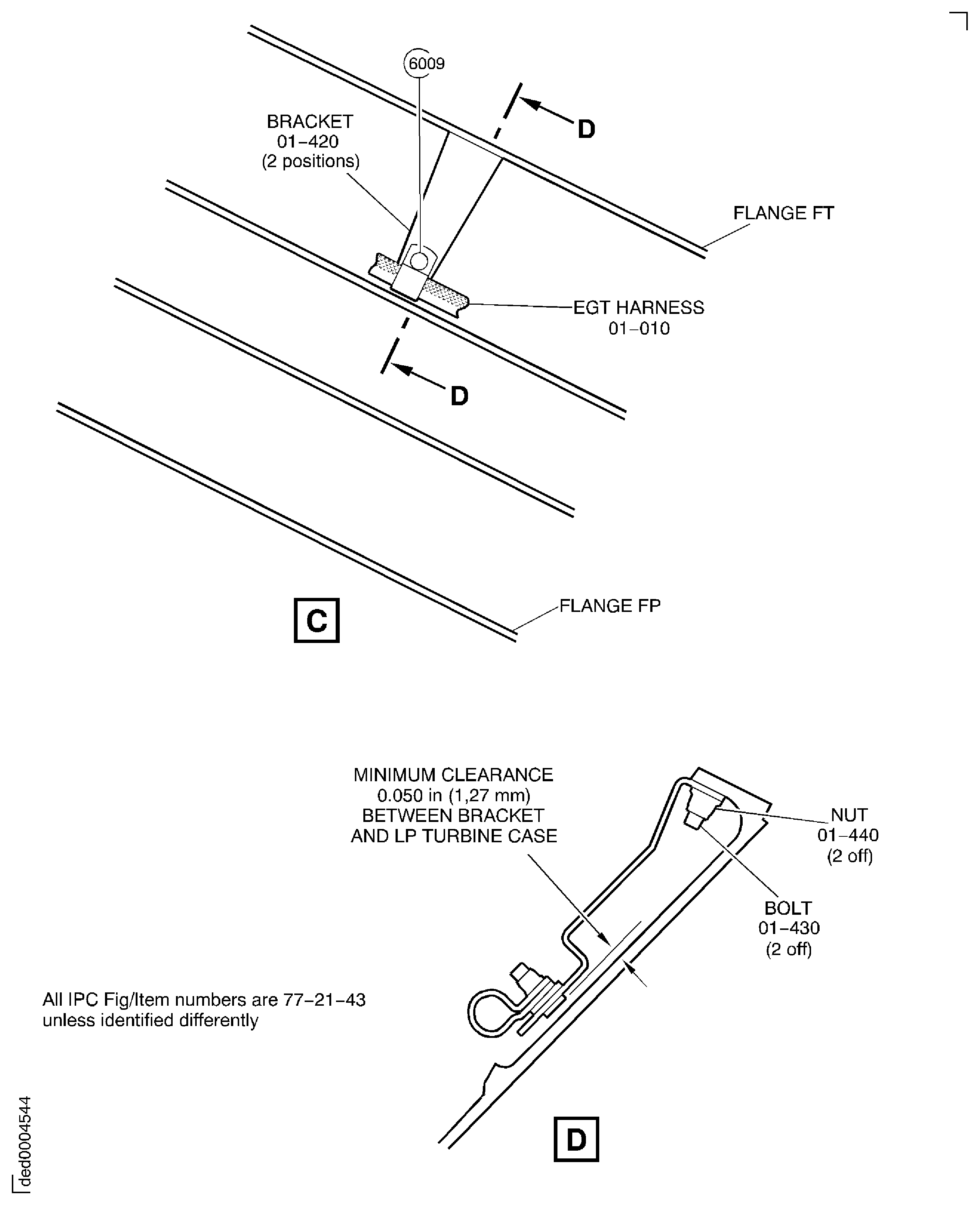

Check the clearance at the four bracket positions, refer to view A and section B for brackets EGT Harness And Junction Box (77-21-43, 01-360).

Check the clearance at the four bracket positions, refer to view C and section D for brackets EGT Harness And Junction Box (77-21-43, 01-420).

SUBTASK 72-00-50-420-390 Check the Clearance between Flange FT and the Core EGT Harness Support Brackets (Pre SBE 77-0015 and Post SBE 77-0015)

Refer to TASK 71-00-00-700-052-B00.

SUBTASK 72-00-50-750-068 Do a Test of the EGT Harness and Junction Box Assembly

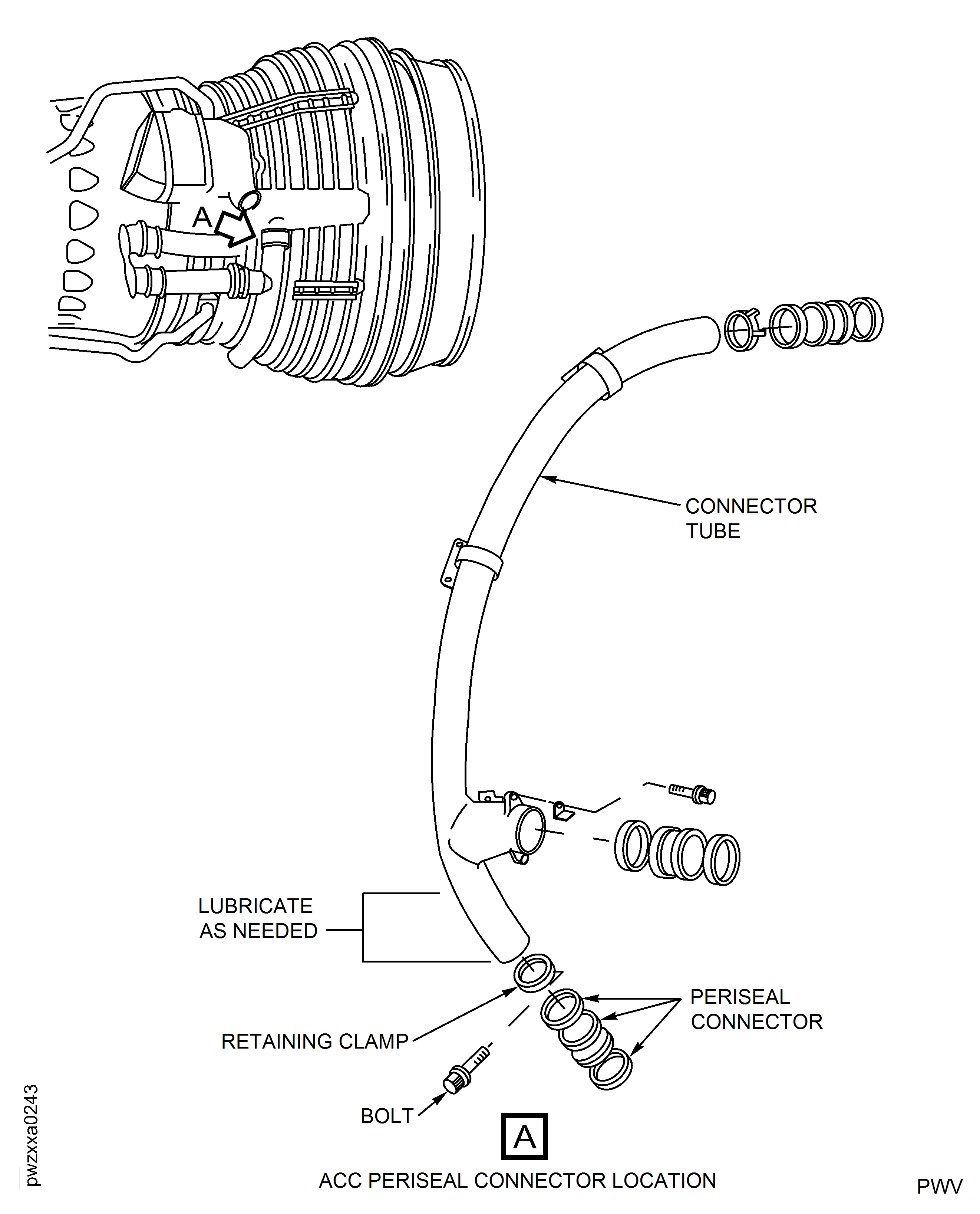

Post SBE 77-0015: Installation of the EGT Harness Assembly (4012KS-5).

Refer to Figure.

Loosen bolt on retaining clamp to allow clamp to move along tube.

Slide periseal connector along ACC tube until sufficient gap is present to route new EGT harness (approximately 0.5 in. (12.7 mm)).

NOTE

Lubricate the lower end of connector tube with soap and water, if needed.Feed wiring harness assembly, PN 2A4524, at harness marked locations through periseal gap.

Move periseal connector on lower ACC tube to the original position to cover the opening.

Ensure that the pin of the retaining clamp engages in the location hole in the ACC tube.

Ensure that the two periseals are correctly seated in the U-slots of the periseal connector.

Torque the bolt on the retaining clamp to the periseal connector to between 36 lbfin - 45 lbfin (4.1 Nm - 5.1 Nm).

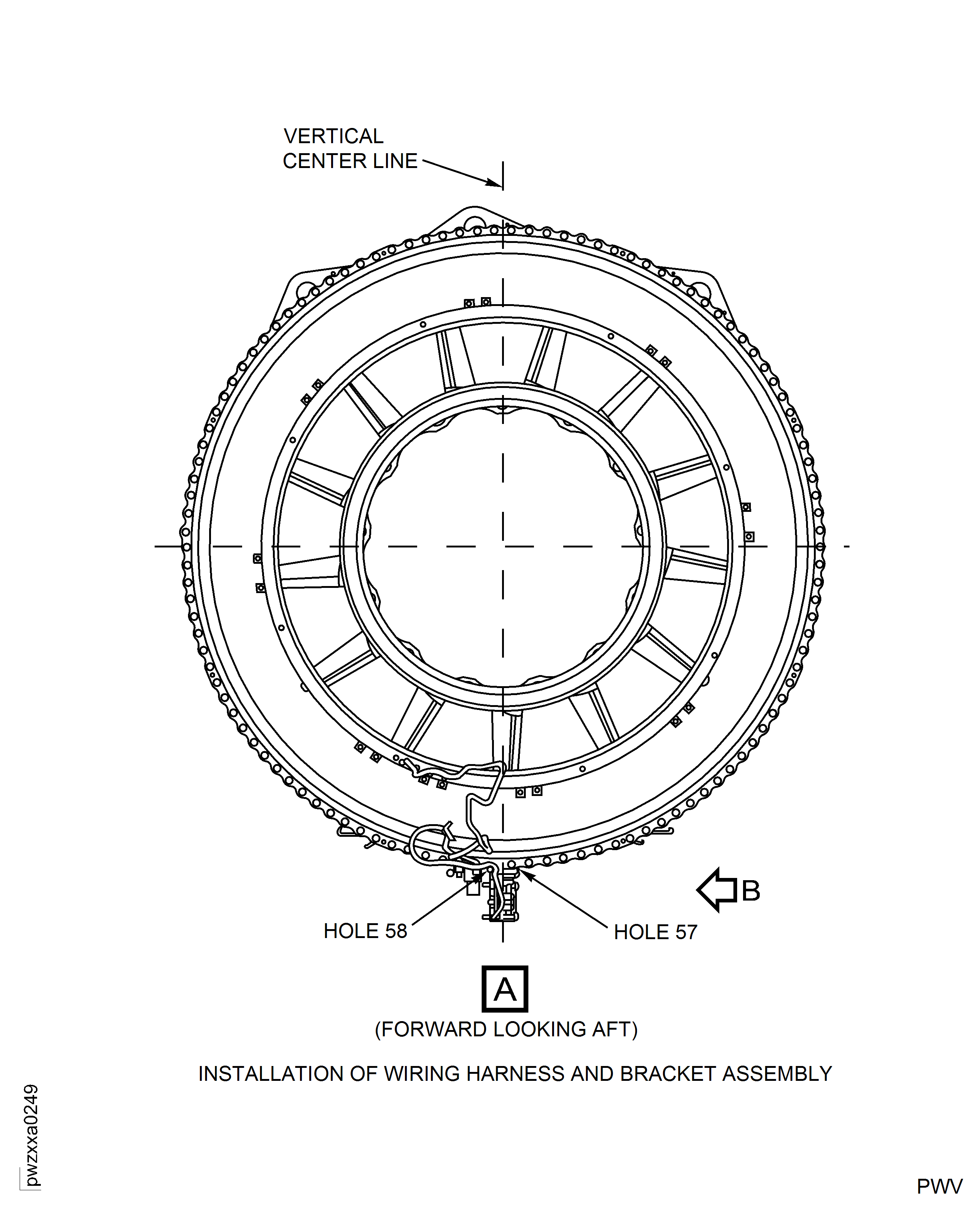

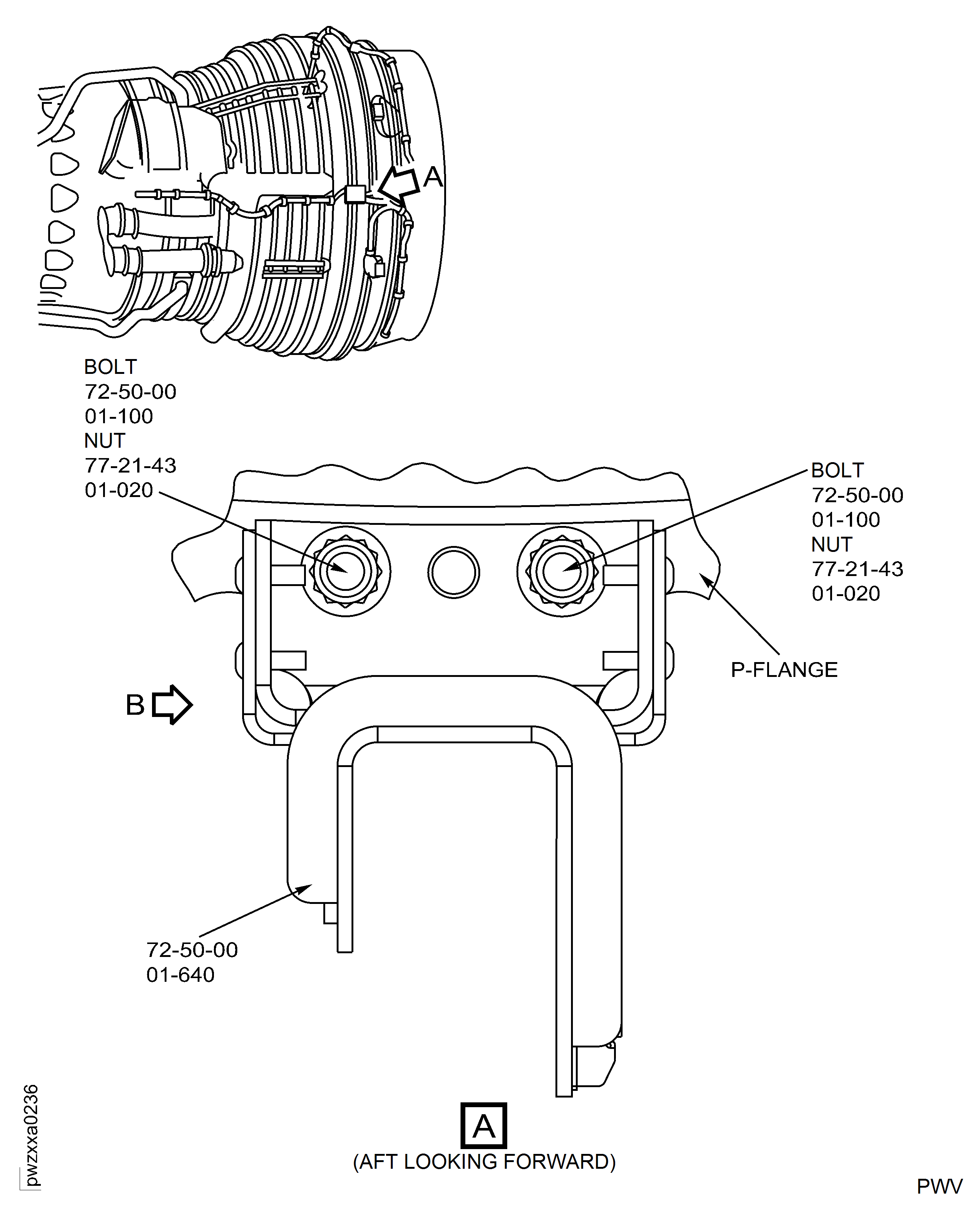

SUBTASK 72-00-50-440-053 Assemble the Active Clearance Control (ACC) Periseal Housing

Install the two bolts LP turbine (LPT) and turbine exhaust case (TEC) unit LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00, 01-100) and two nuts EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-020) to attach the EGT wiring harness bracket assembly (water shield) LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00, 01-640) to the engine at the P-flange holes 57 and 58.

Torque the bolts to between 85 lbfin - 105 lbfin (9.60 Nm - 11.86 Nm). Refer to TASK 70-41-02-410-501 in the Standard Practices and Processes Manual.

SUBTASK 72-00-50-450-068 Install the Wiring Harness Bracket Assembly

Refer to Figure.

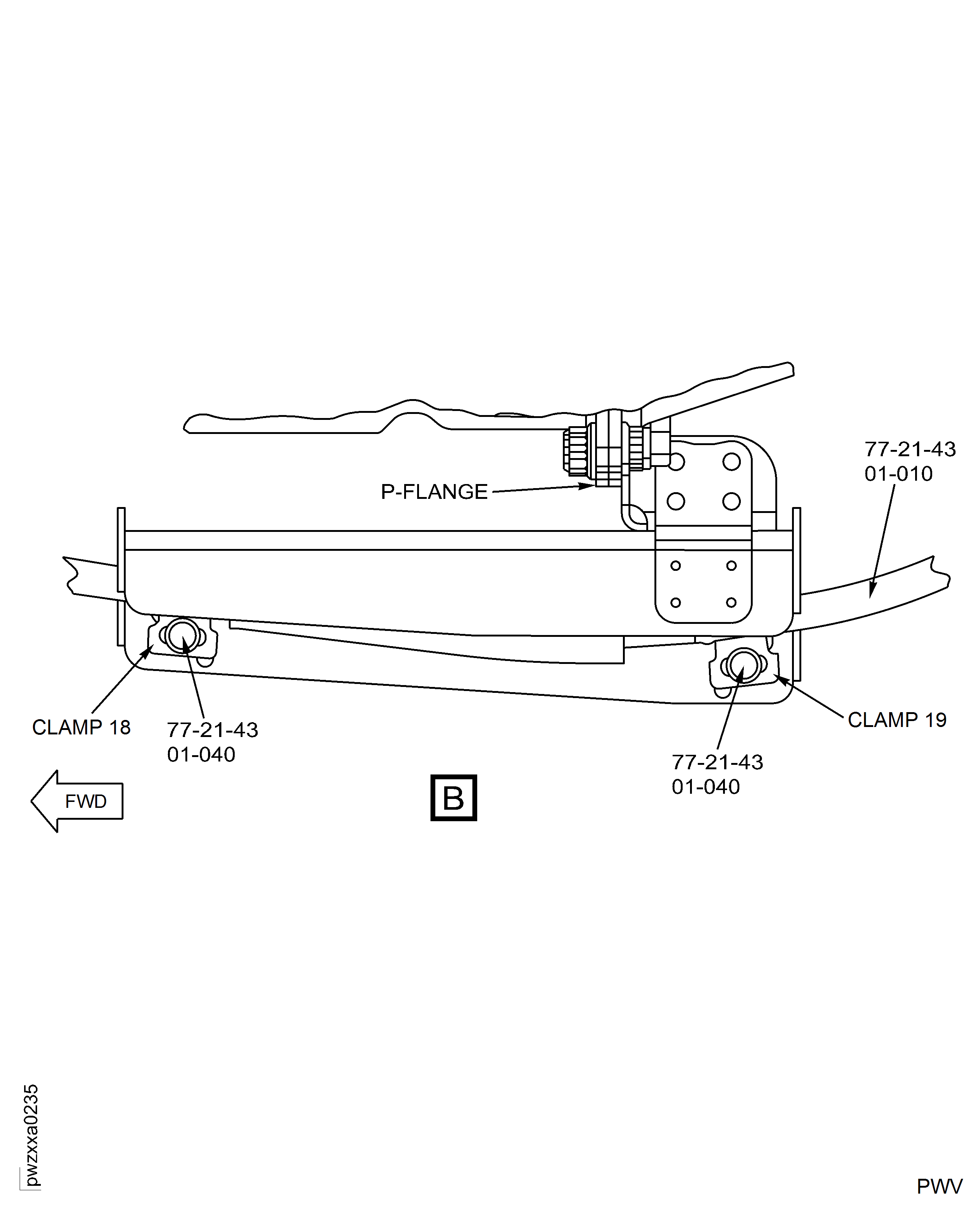

Install the two bolts which attach the EGT harness EGT Harness And Junction Box (77-21-43, 01-010) to integral clamps 18 and 19 on the wiring harness bracket assembly LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00, 01-640) (water shield).

SUBTASK 72-00-50-450-069 Install the new EGT harness to the Wiring Harness Bracket Assembly at the P-flange (Forward Side)

Refer to Figure.

Install the EGT harness, EGT Harness And Junction Box (77-21-43, 01-010) to the flange brackets AFT of the wiring harness bracket assembly. Refer to TASK 72-00-50-450-002-B00.

NOTE

The side of the rear EGT harness marked "probe 2" on the ID band is installed on the right side of the Engine (AFT looking FWD). The side of the rear EGT harness marked "probe 3" on the ID band is installed on the left side of the Engine (AFT looking FWD).

SUBTASK 72-00-50-450-070 Install the new EGT Harness to the Wiring Harness Bracket Assembly at the P-flange (AFT Side)

Refer to Figure.

Remove the two alumel (larger) nuts EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-240), the two alumel washers EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-245), the two chromel (smaller) nuts EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-250) and the two chromel washers EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-255) from the thermocouple terminals at four positions.

Attach the EGT harness lugs from the thermocouple terminals.

Install the alumel and chromel washers and nuts to the thermocouple terminals at four positions.

CAUTION

DO NOT TIGHTEN THE NUTS MORE THAN THE MAXIMUM TORQUE. TOO MUCH TORQUE CAN DAMAGE THE THERMOCOUPLE STUDS AND RESULT IN ERRATIC OR UNRELIABLE EGT INDICATION.Torque the alumel (larger) nuts to 18 lbfin to 22 lbfin (2.03 Nm to 2.49 Nm).

Torque the chromel (smaller) nuts to 15 lbfin to 18 lbfin (1.69 Nm to 2.03 Nm).

SUBTASK 72-00-50-450-071 Attach the Thermocouple Harnesses to the EGT Thermocouples sdd (Pre SBE 77-0015 and Post SBE 77-0015)

At View B, install the bolt EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-190) and the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-095).

At View C, install the bolt EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-185) and the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-090).

At View D, install the bolt EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-180) and the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-085).

At View E, install the bolt EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-175) and the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-080).

At View G, install the bolt EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-290) and the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-288).

Attach the harness clamps to the five brackets located on the left side of the Flange P. Refer to Figure.

At View S, install the bolt EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-150) and the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-055).

At View R, install the bolt EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-155) and the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-060).

At View Q, install the bolt EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-160) and the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-065).

At View P, install the bolt EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-165) and the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-070).

At View K, install the bolt EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-170) and the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-075).

Attach the harness clamps from the five brackets located on the right side of the Flange P. Refer to Figure.

Torque the clamp bolts to 36 lbfin to 45 lbfin (4.1 Nm to 5.1 Nm).

SUBTASK 72-00-50-450-072 Install the EGT Harness at the Flange P Locations

Refer to Figure.

At View N, install the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-195).

At View M, install the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-200).

At View L, install the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-205).

At View J, install the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-210).

At View I, install the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-215).

At View H, install the nut EGT harness and junction box EGT Harness And Junction Box (77-21-43, 01-220).

Attach the harness clamps to the six brackets located on the Flange T. Refer to Figure.

Torque the clamp nuts to 36 lbfin to 45 lbfin (4.1 Nm to 5.1 Nm).

SUBTASK 72-00-50-450-073 Install the EGT Harness at the Flange T Bracket Locations

At View F, install the bolt engine fuel and control-P4.9 sensor and manifold (73-22-51, 01-090) and the nut engine fuel and control-P4.9 sensor and manifold (73-22-51, 01-080). Refer to Figure.

At View O, install the bolt engine fuel and control-P4.9 sensor and manifold (73-22-51, 01-220) and the nut engine fuel and control-P4.9 sensor and manifold (73-22-51, 01-210). Refer to Figure.

Install the harness clamp to the P4.9 manifold clamp at two locations.

Torque the clamp bolts to 36 lbfin to 45 lbfin (4.1 Nm to 5.1 Nm).

SUBTASK 72-00-50-450-074 Install the EGT Harness at the P4.9 Manifold Clamp Locations

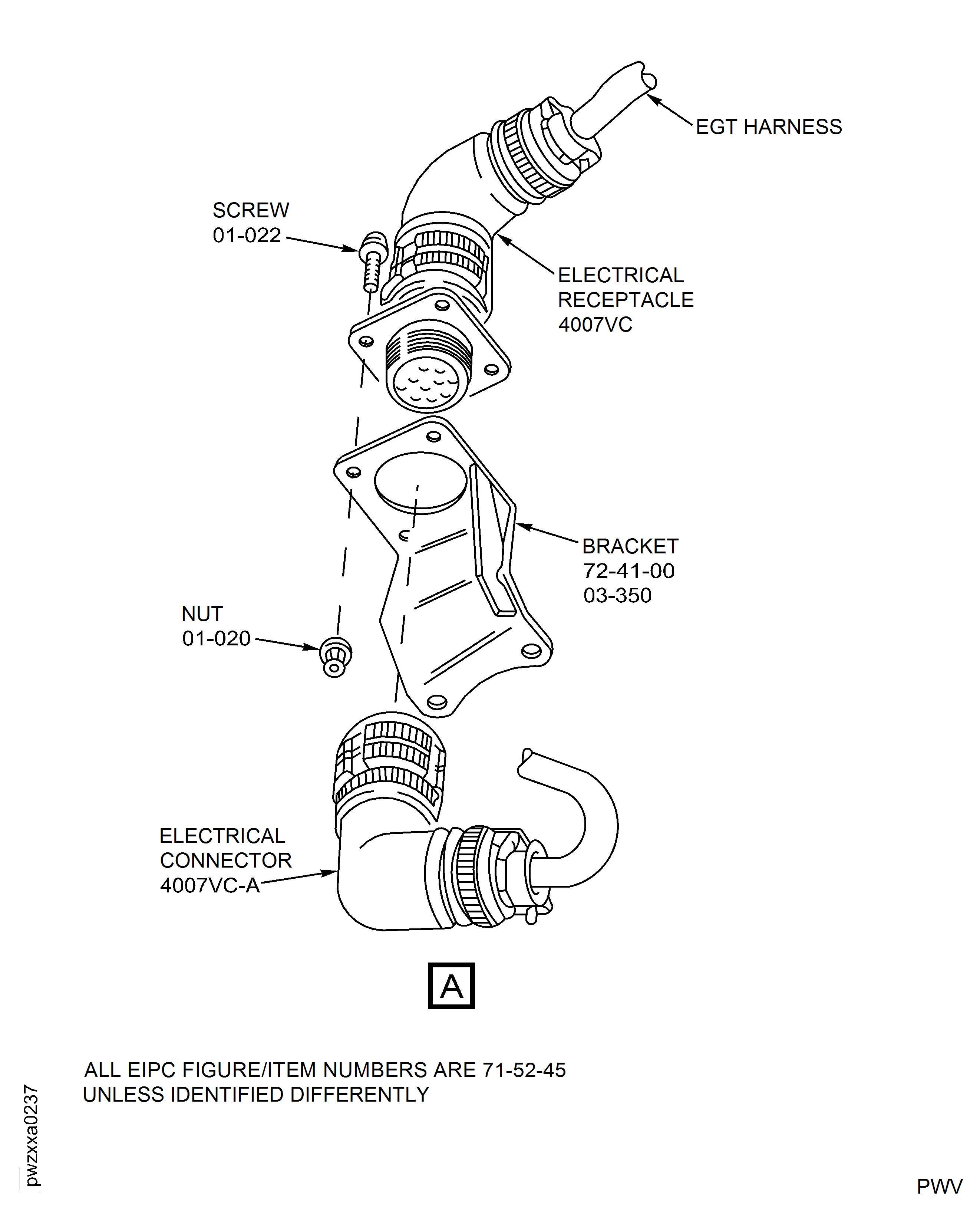

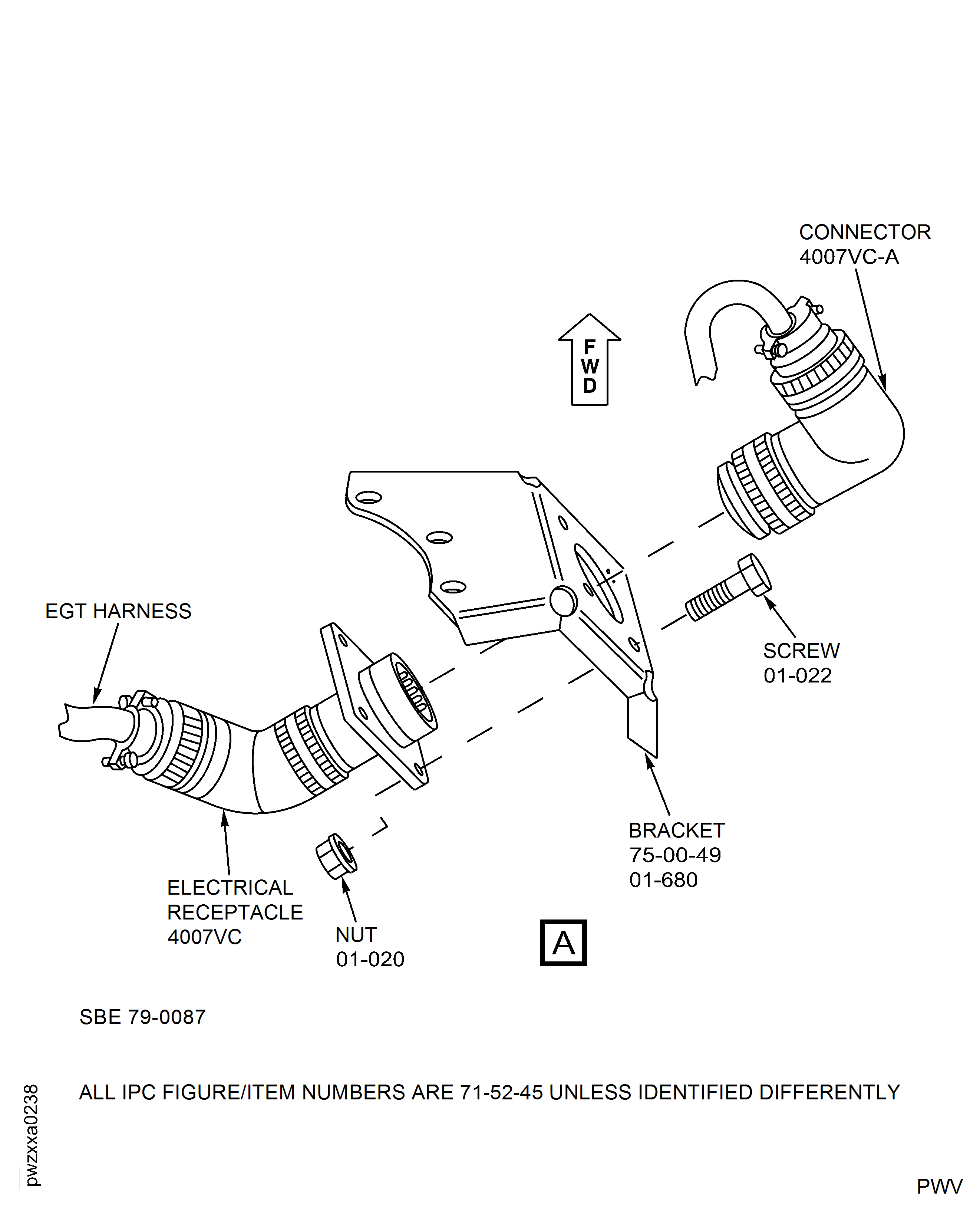

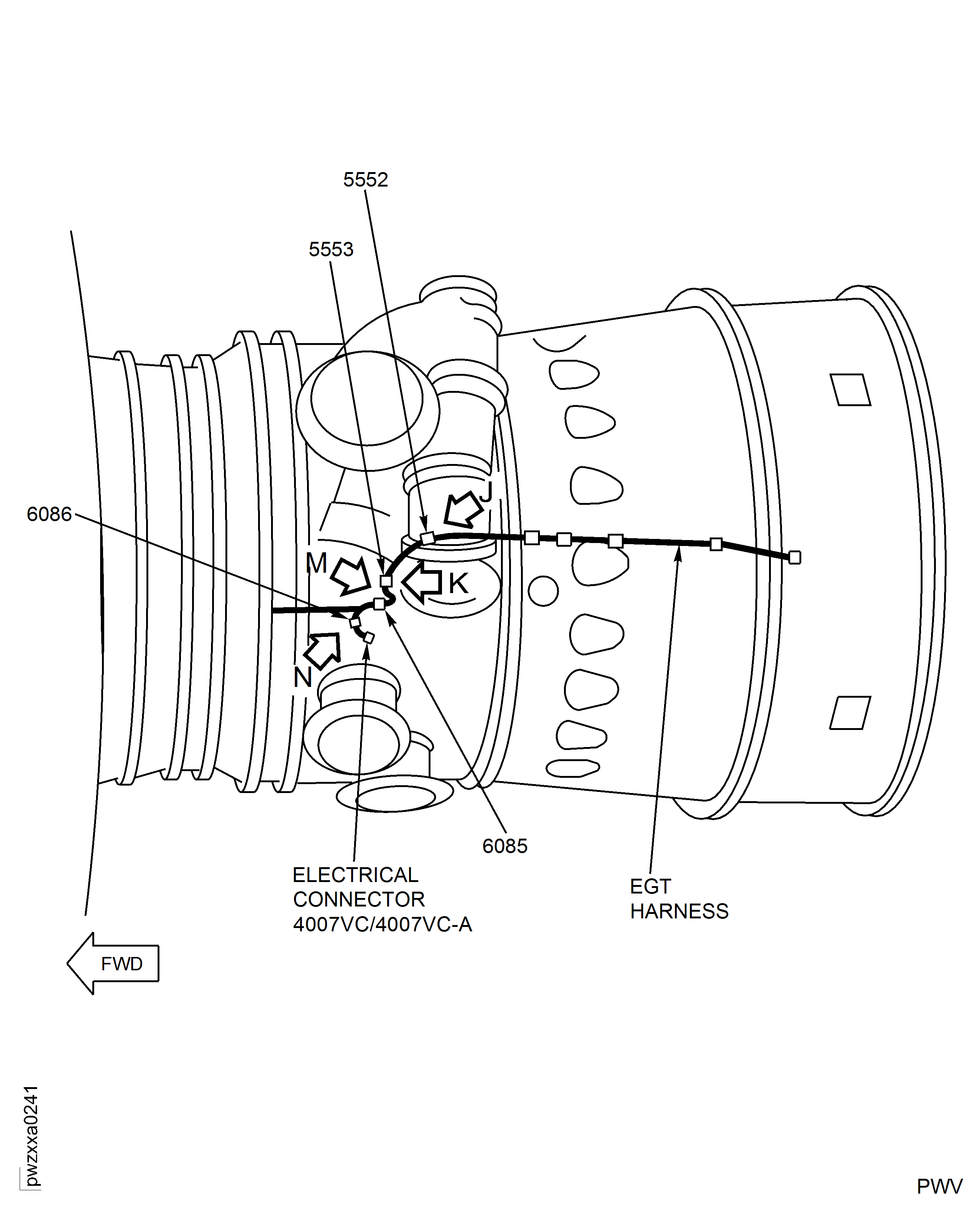

Connect the electrical connector 4007VC-A to the electrical receptacle 4007VC.

NOTE

Remove plastic caps from the 4007VC before connecting the 4007VC-A to the 4007VC.Install the four nuts exhaust gas temperature (EGT) harness Exhaust Gas Temperature (EGT) Harness (71-52-45, 01-020) and the four screws exhaust gas temperature (EGT) harness Exhaust Gas Temperature (EGT) Harness (71-52-45, 01-022) the electrical receptacle 4007VC to the bracket engine air off-take air ducts Engine Air Off-Take Air Ducts (75-00-49, 01-680).

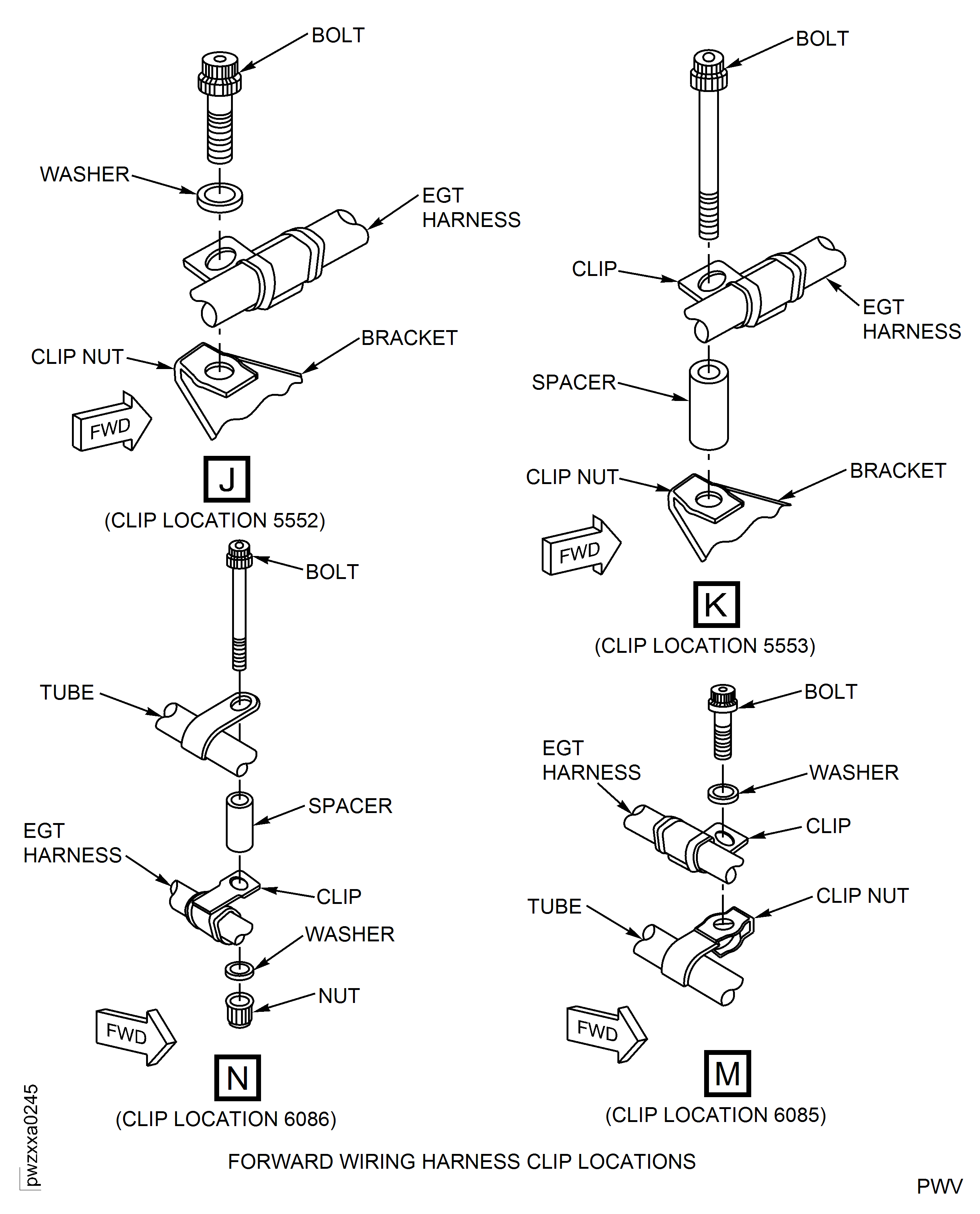

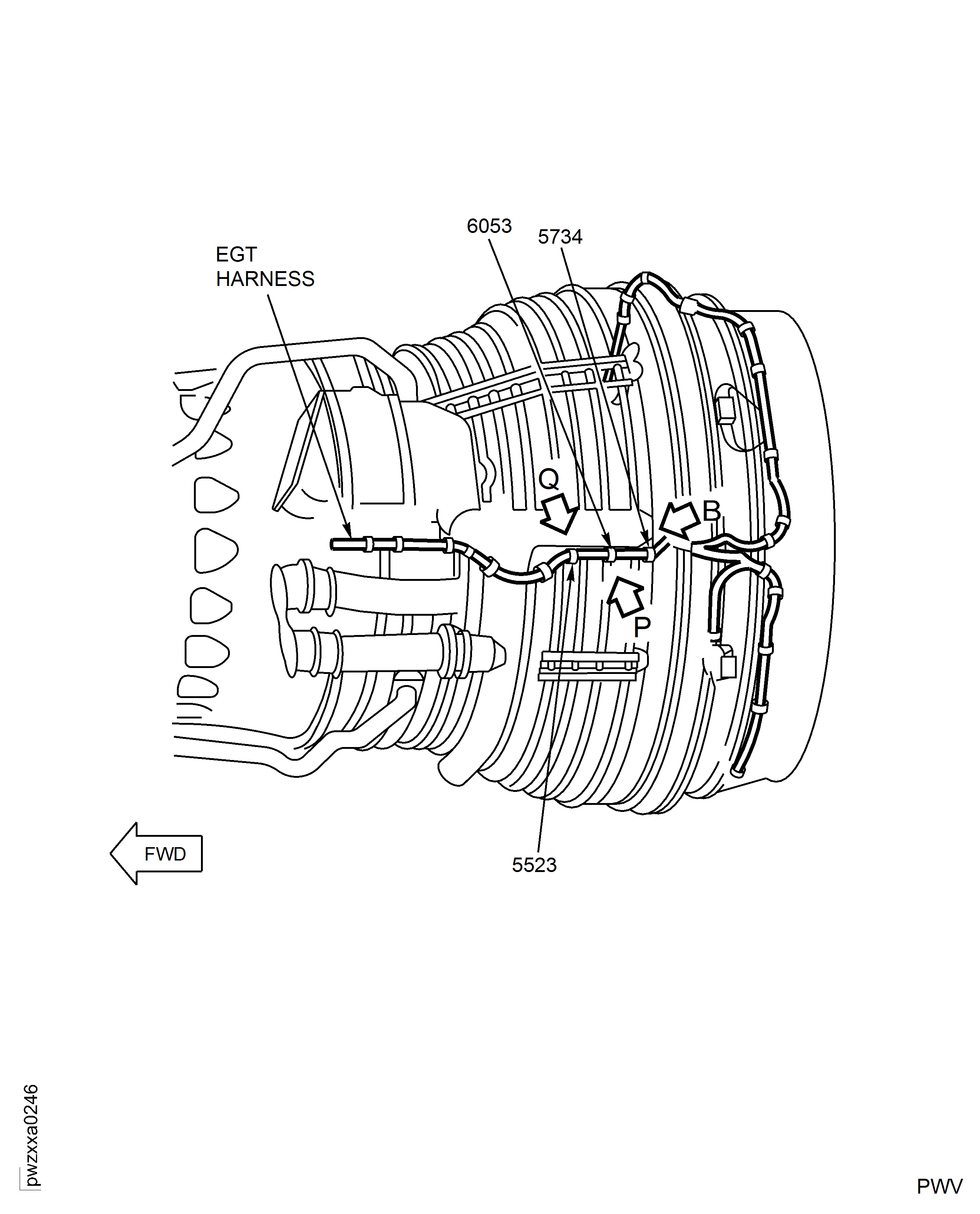

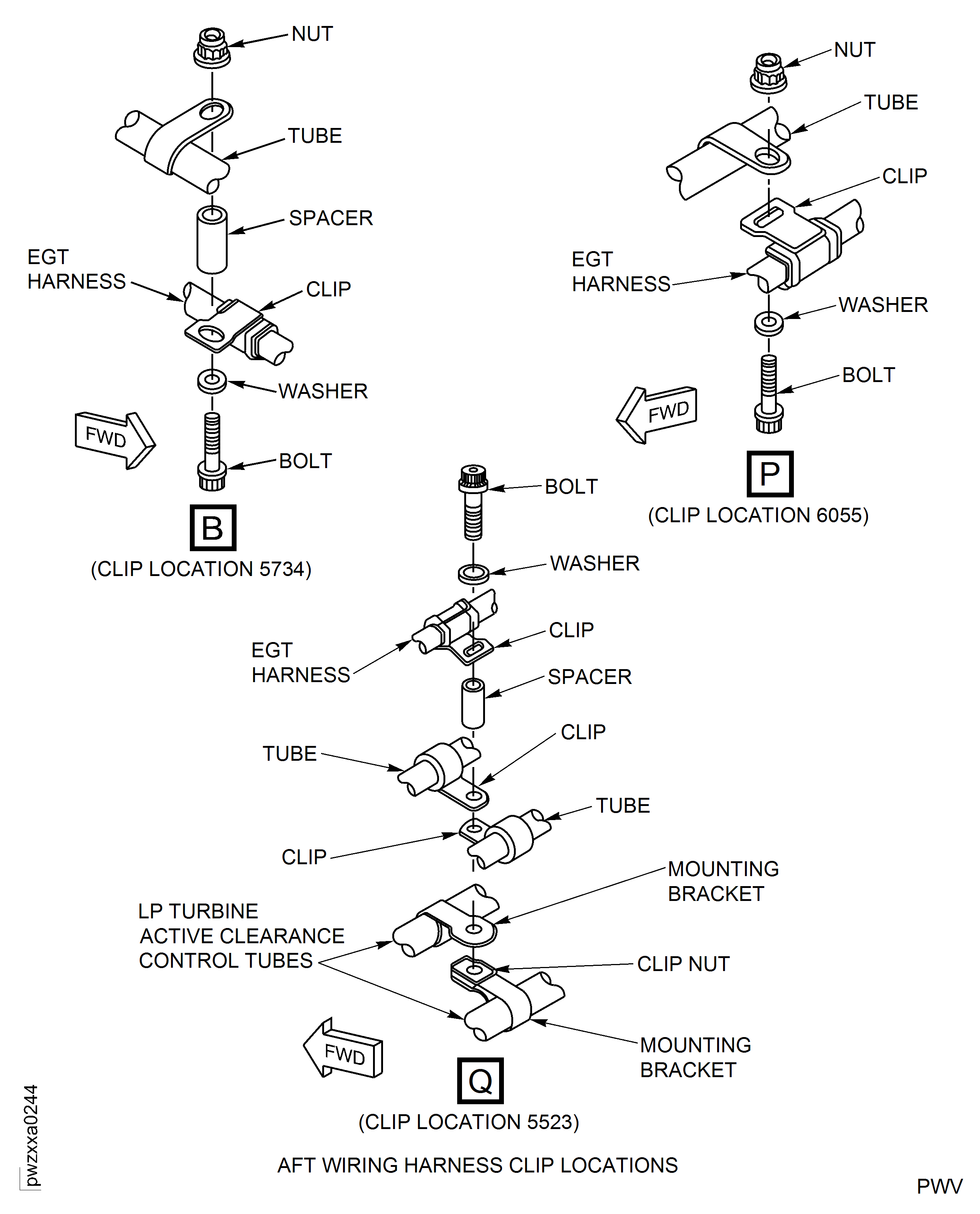

Attach the bolts, the washers, the integrated clamps, and the nuts at four clip positions 6086, 6085, 5553, 5552.

Attach the bolts, the washers, the clamps, and the nuts at 10 clip positions 5551, 5211, 5529, 5550, 5527, 5549, 6052, 6051, 6053, 6054.

Attach the bolts, the washers, the integrated clamps, and the nuts at three clip positions 5523, 6053, 5734.

SUBTASK 72-00-50-450-075 Install the EGT Harness on the HPC Case

Figure: Installation on the EGT Harness and Junction Box Assembly

Installation on the EGT Harness and Junction Box Assembly

Figure: Installation of EGT Harness on Left Side of P - Flange

Installation of EGT Harness on Left Side of P - Flange

Figure: Installation of EGT Harness on Right Side of P - Flange

Installation of EGT Harness on Right Side of P - Flange

Figure: Installation of EGT Harness on T - Flange Brackets

Installation of EGT Harness on T - Flange Brackets

Figure: Installation of the EGT Harness and Junction Box Assembly

Installation of the EGT Harness and Junction Box Assembly

Figure: Pre SBE 77-0009: Install the EGT Harness/Junction Box and the Core EGT Harness

Pre SBE 77-0009: Install the EGT Harness/Junction Box and the Core EGT Harness.

Figure: SBE 77-0009: Install the EGT Harness/Junction Box and the Core EGT Harness

SBE 77-0009: Install the EGT Harness/Junction Box and the Core EGT Harness.

Figure: Install the EGT Harness and Junction Box Assembly - Examine the Safetying of the EGT Thermocouple Bolts

Install the EGT Harness and Junction Box Assembly - Examine the Safetying of the EGT Thermocouple Bolts

Figure: Check the Clearance between Flange FT and the Core EGT Harness Support Brackets

Check the Clearance between Flange FT and the Core EGT Harness Support Brackets: Sheet 1

Figure: Check the Clearance between Flange FT and the Core EGT Harness Support Brackets

Check the Clearance between Flange FT and the Core EGT Harness Support Brackets: Sheet 2

Figure: Check the Clearance Between Flange FT and the Core EGT Harness Support Brackets

Check the Clearance Between Flange FT and the Core EGT Harness Support Brackets: Sheet 3

Figure: Post SBE 77-0015: ACC Periseal Connector Housing

Post SBE 77-0015: ACC Periseal Connector Housing

Figure: Post SBE 77-0015: Installation of EGT Harness

Post SBE 77-0015: Installation of EGT Harness

Figure: Post SBE 77-0015: Installation of cla mps 18 and 19 on P Flange

Post SBE 77-0015: Installation of cla mps 18 and 19 on P Flange

Figure: Post SBE 77-0015: Installation of EGT Wiring Harness on P - Flange

Post SBE 77-0015: Installation of EGT Wiring Harness on P - Flange

Figure: Post SBE 77-0015: Installation of EGT Harness

Post SBE 77-0015: Installation of EGT Harness

Figure: Post SBE 77-0015: View of EGT Harness on Left and Right Side of P - Flange

Post SBE 77-0015: View of EGT Harness on Left and Right Side of P - Flange

Figure: Post SBE 77-0015: Installation of Connector 4007VC-A TO 4007 (PRE SBE 79-0067)

Post SBE 77-0015: Installation of Connector 4007VC-A TO 4007 (PRE SBE 79-0067)

Figure: Post SBE 77-0015: Installation of Connector 4007VC-A TO 4007 (Post SBE 79-0067)

Post SBE 77-0015: Installation of Connector 4007VC-A TO 4007 (Post SBE 79-0067)

Figure: Post SBE 77-0015: Wiring Harness Clip Location AFT of HPC

Post SBE 77-0015: Wiring Harness Clip Location AFT of HPC

Figure: Post SBE 77-0015: Installation of EGT Harness Clips on AFT Side HPC

Post SBE 77-0015: Installation of EGT Harness Clips on AFT Side HPC

Figure: Post SBE 77-0015: Wiring Harness Clip Locations Forward of HPC

Post SBE 77-0015: Wiring Harness Clip Locations Forward of HPC

Figure: Post SBE 77-0015: Installation of EGT Harness Clips on Forward Side HPC

Post SBE 77-0015: Installation of EGT Harness Clips on Forward Side HPC