Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-32-00-430-011-B00 LPC/Intermediate Case Module - Install The Fan Case, Center Bearing Housing, Oil Seal Tube, No. 1, 2, 3 Bearing Scavenge Tube, Hot Vent Tube, Seal, PTO Shaft, And Identification Plates, Assembly-011

General

Fig/item numbers in parentheses in the procedure agree with those used in the EIPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the EIPC.

For all the parts identified in a different ATA Chapter/Section/Subject, the applicable ATA Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

To identify, lubricate and install seal rings, refer to SPM TASK 70-64-02-640-501.

Special torque data are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To install lockwire, refer to SPM TASK 70-42-05-400-501.

The abbreviation Intf shows an interference or tight fit. This causes REJECT IF MORE THAN. To become REJECT IF LESS THAN. The abbreviation Clear shows a clearance fit.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

The No. 1 Strut, which is the top position strut of the Fan Frame is identified by the five pressure tubes on the No. 1 Strut leading edge.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Sealant dispenser | LOCAL | Sealant dispenser | ||

| IAE 1J12010 Storage stand | 0AM53 | IAE 1J12010 | 1 | |

| IAE 1J12023 Hooking puller | 0AM53 | IAE 1J12023 | ||

| IAE 1J12082 Holding cap | 0AM53 | IAE 1J12082 | 1 | |

| IAE 1J12157 Setting Master | 0AM53 | IAE 1J12157 | 1 | |

| IAE 1J12158 Installation Guide | 0AM53 | IAE 1J12158 | 1 | |

| IAE 1J12159 Installation Pusher | 0AM53 | IAE 1J12159 | 1 | |

| IAE 1J12205 Oil tube cover | 0AM53 | IAE 1J12205 | 1 | |

| IAE 1J12206 Scavenge tube cover | 0AM53 | IAE 1J12206 | 1 | |

| IAE 1J12207 Hot Vent tube cover | 0AM53 | IAE 1J12207 | 1 | |

| IAE 1J12300 Installation pusher | 0AM53 | IAE 1J12300 | 1 | |

| IAE 1J12311 Turnover stand | 0AM53 | IAE 1J12311 | 1 | |

| IAE 1J12327 Handling holder | 0AM53 | IAE 1J12327 | 1 | |

| IAE 1J12384 Swash check ring | 0AM53 | IAE 1J12384 | 1 | |

| IAE 1J12432 Base holder | 0AM53 | IAE 1J12432 | 1 | |

| IAE 1J12470 Leak check fixture | 0AM53 | IAE 1J12470 | 1 | |

| IAE 1J12487 Rear sling | 0AM53 | IAE 1J12487 | 1 | |

| IAE 1J12508 Measuring stretch | 0AM53 | IAE 1J12508 | 1 | |

| IAE 1J12521 Holding fixture | 0AM53 | IAE 1J12521 | ||

| IAE 1J12527 Setting master | 0AM53 | IAE 1J12527 | 1 | |

| IAE 1J12536 Mechanical pusher | 0AM53 | IAE 1J12536 | ||

| IAE 6F10030 Vacuum test cart | 0AM53 | IAE 6F10030 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 02-147 LOCKWIRE | LOCAL | CoMat 02-147 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Sealing ring | 1 | |||

| Sealing ring | 1 | |||

| Sealing ring | 1 | |||

| Sealing ring | 1 | |||

| Sealing ring | 1 | |||

| Sealing ring | 1 | |||

| Sealing ring | 1 | |||

| Sealing ring | 1 | |||

| Sealing ring | 1 | |||

| Retaining ring | 1 |

Safety Requirements

NONEProcedure

Refer to Figure.

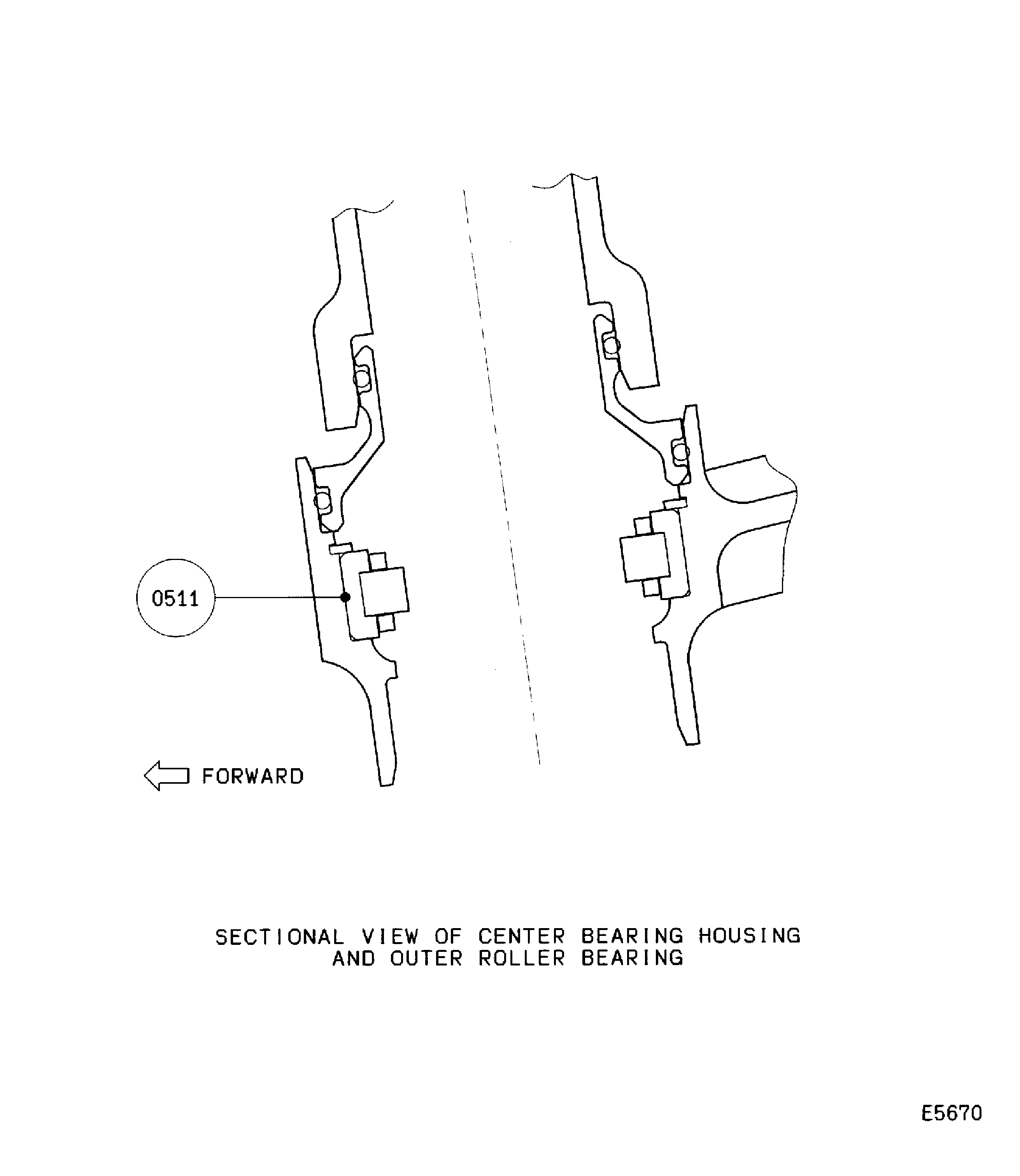

Reference dimensions at location 0511. If required, use the data written as a note in TASK 72-32-05-200-000 (INSPECTION-000).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0511

Center Bearing Housing ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-300), Inside Diameter

Outer Roller Bearing ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-250), Outside Diameter

Center Bearing Housing Inside Diameter

2.1261

2.1254

0.0003

Outer Roller Bearing Outside Diameter

2.1259

0.0005

2.1258

Intf

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0511

Center Bearing Housing ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-300), Inside Diameter

Outer Roller Bearing ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-250), Outside Diameter

Center Bearing Housing Inside Diameter

54.004

53.985

0.010

Outer Roller Bearing Outside Diameter

54.000

0.015

53.994

Intf

SUBTASK 72-32-00-220-134 Reference Fits and Clearances of the Center Bearing Housing and the Outer Roller Bearing at Location 0511

Refer to Figure.

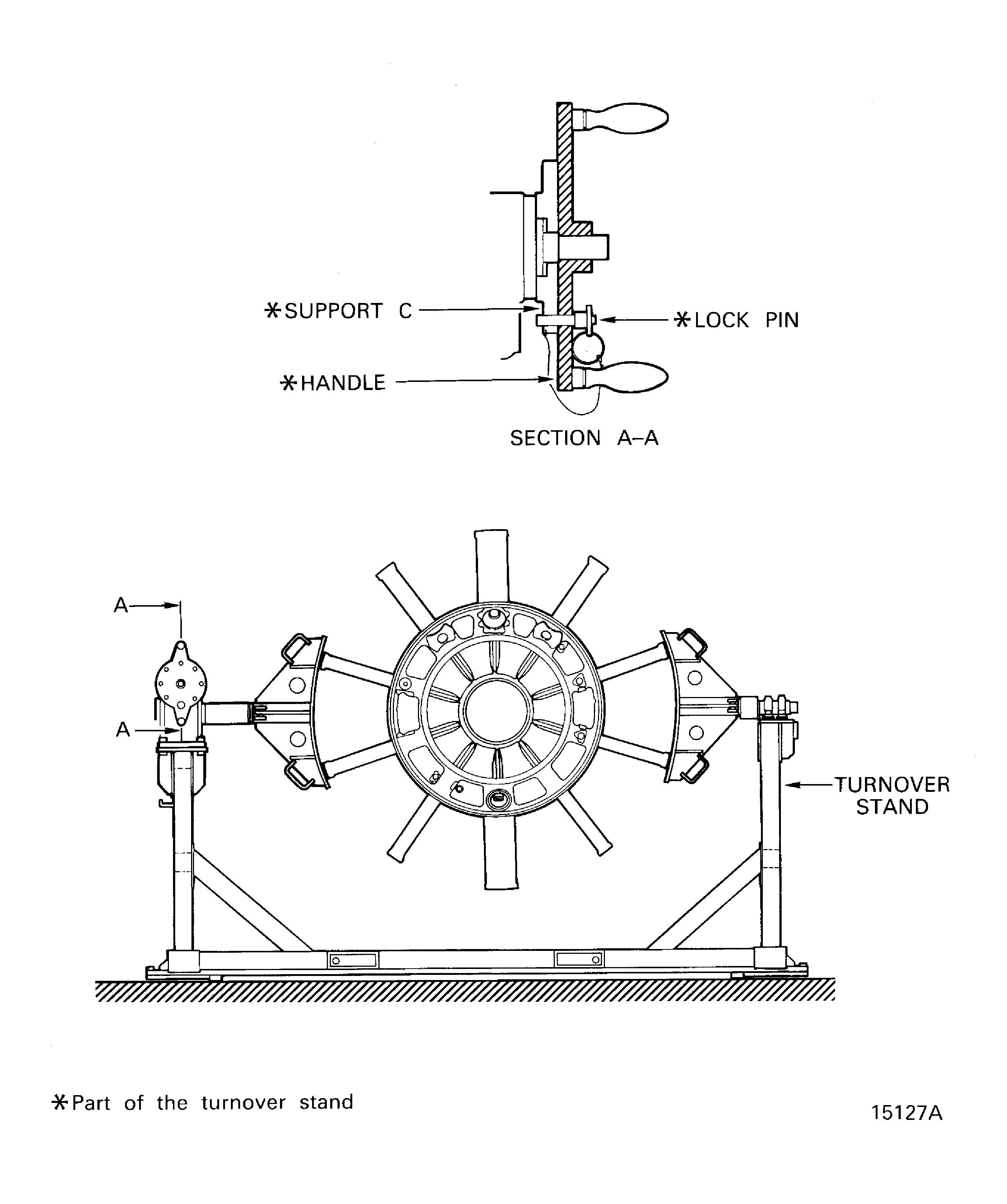

Make sure that the Fan Frame is installed, vertically with the front end up, on the turnover stand. Refer to TASK 72-32-00-430-010-B00 (ASSEMBLY-010).

SUBTASK 72-32-00-430-244 Turn the Fan Frame to the Rear End Up Position

Refer to Figure.

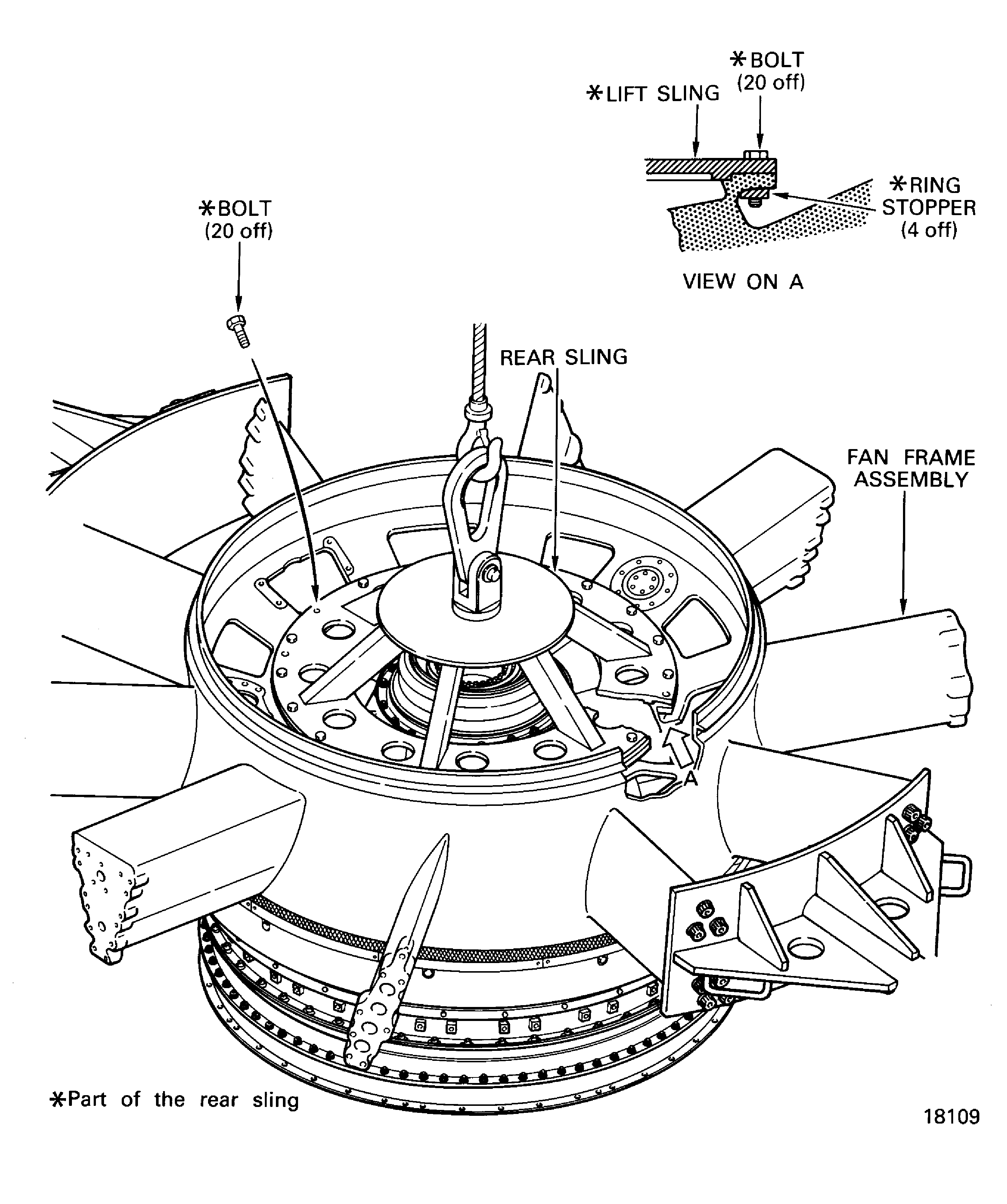

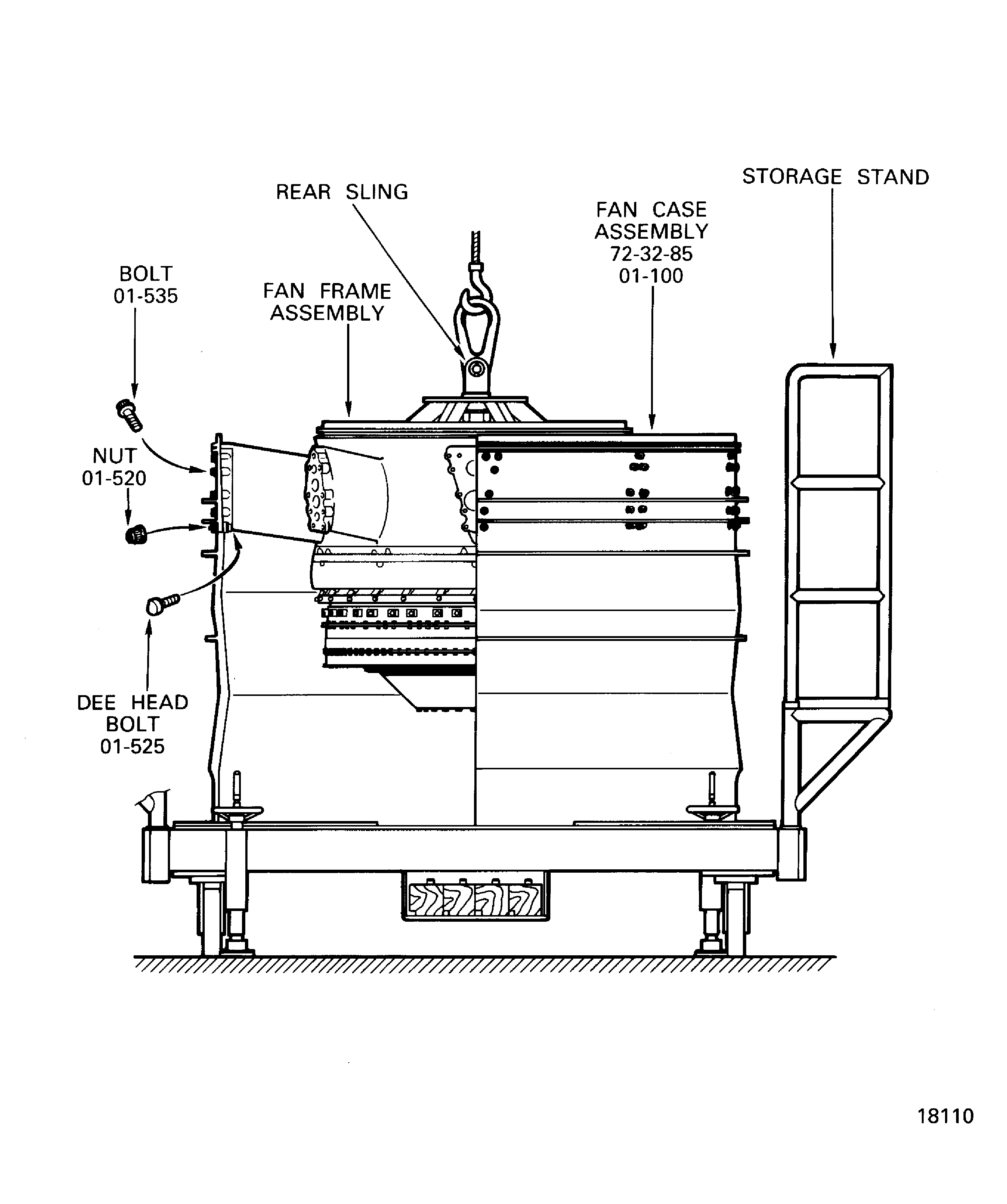

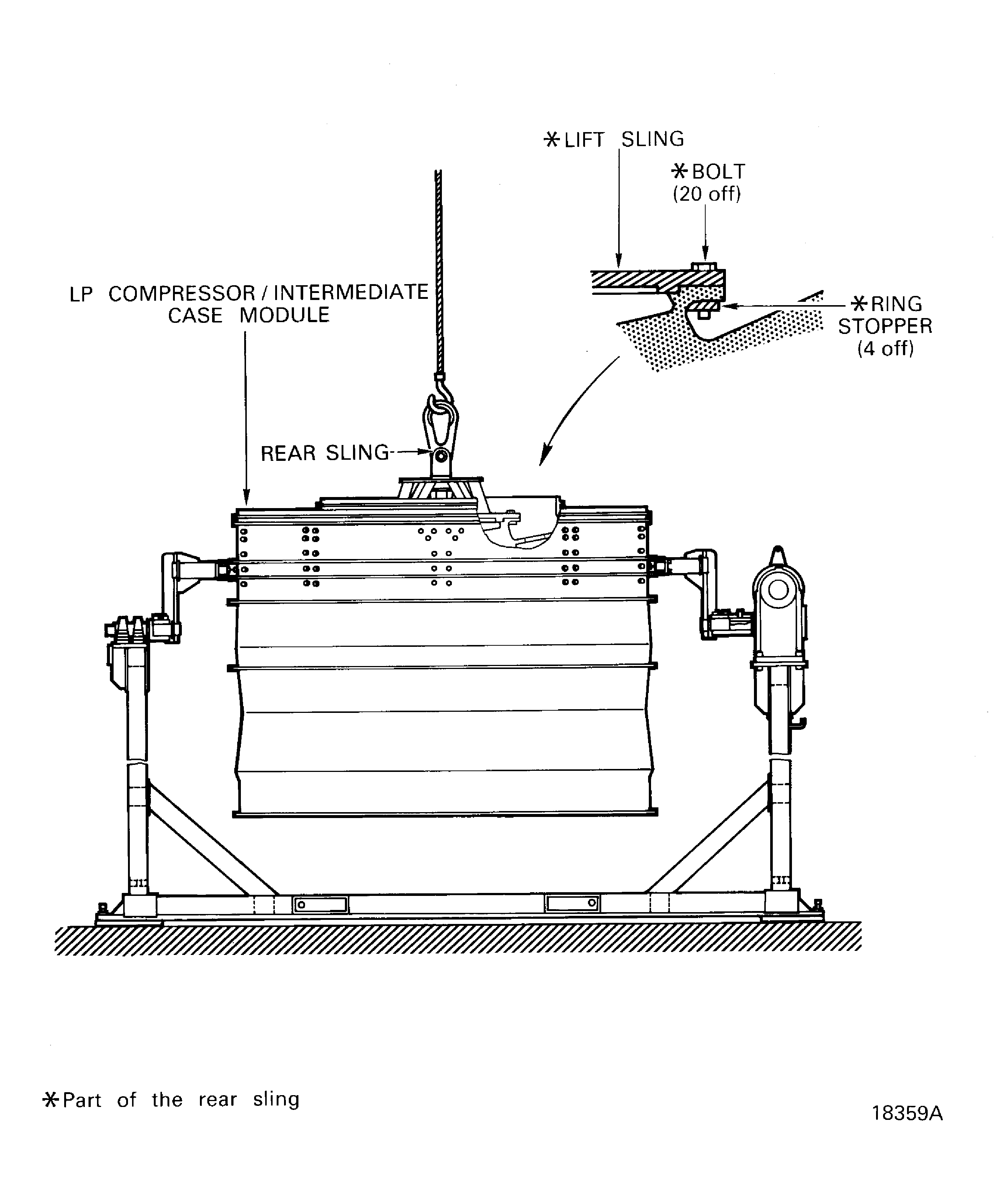

Attach a hoist to IAE 1J12487 Rear sling 1 off.

SUBTASK 72-32-00-430-245 Install the Rear Sling on to the Fan Frame

Refer to Figure.

SUBTASK 72-32-00-430-246 Remove the Fan Frame from the Turnover Stand

Put the Fan Case Fan Case And Related Parts (72-32-85, 01-100) on to IAE 1J12010 Storage stand 1 off with the rear end up.

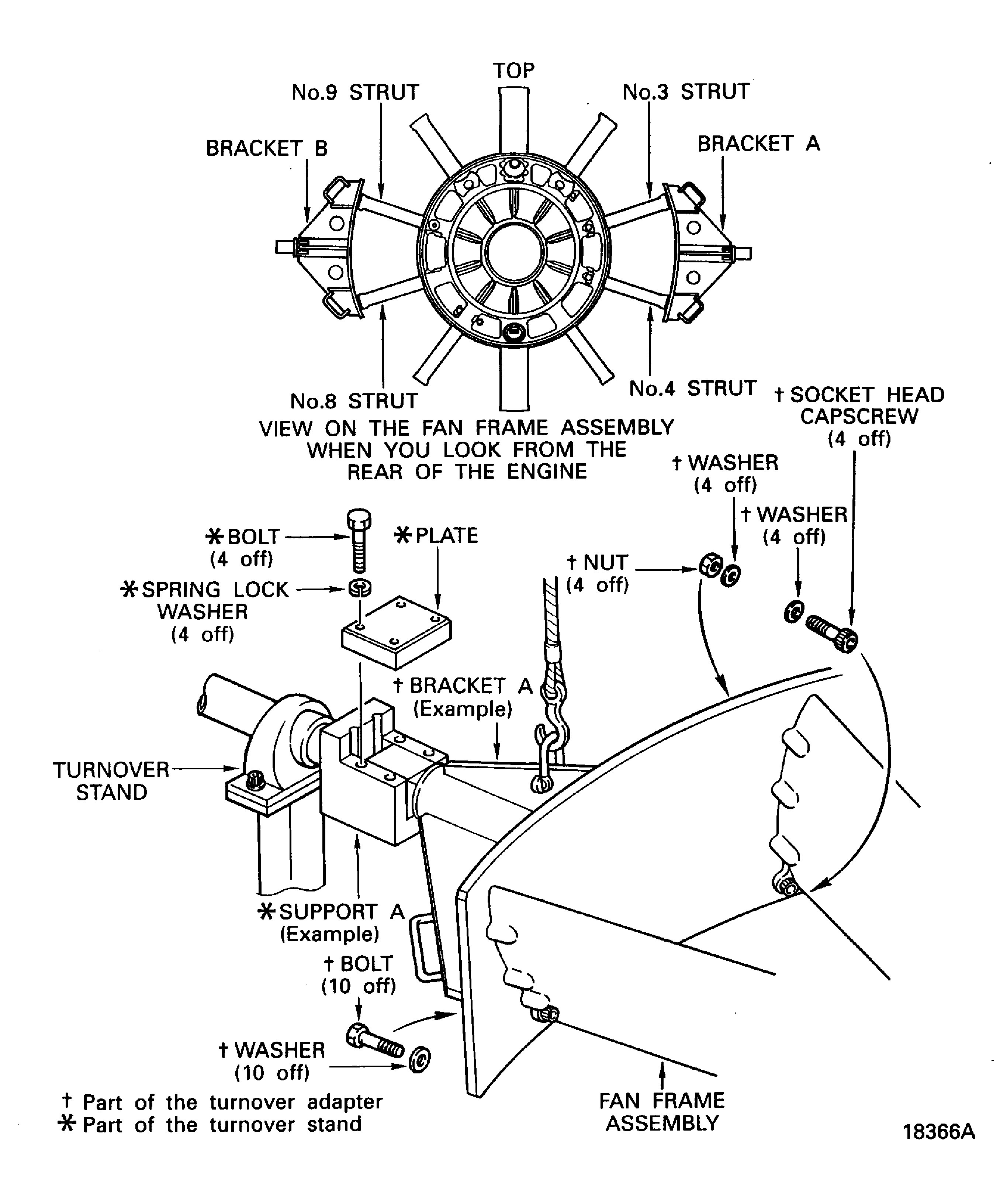

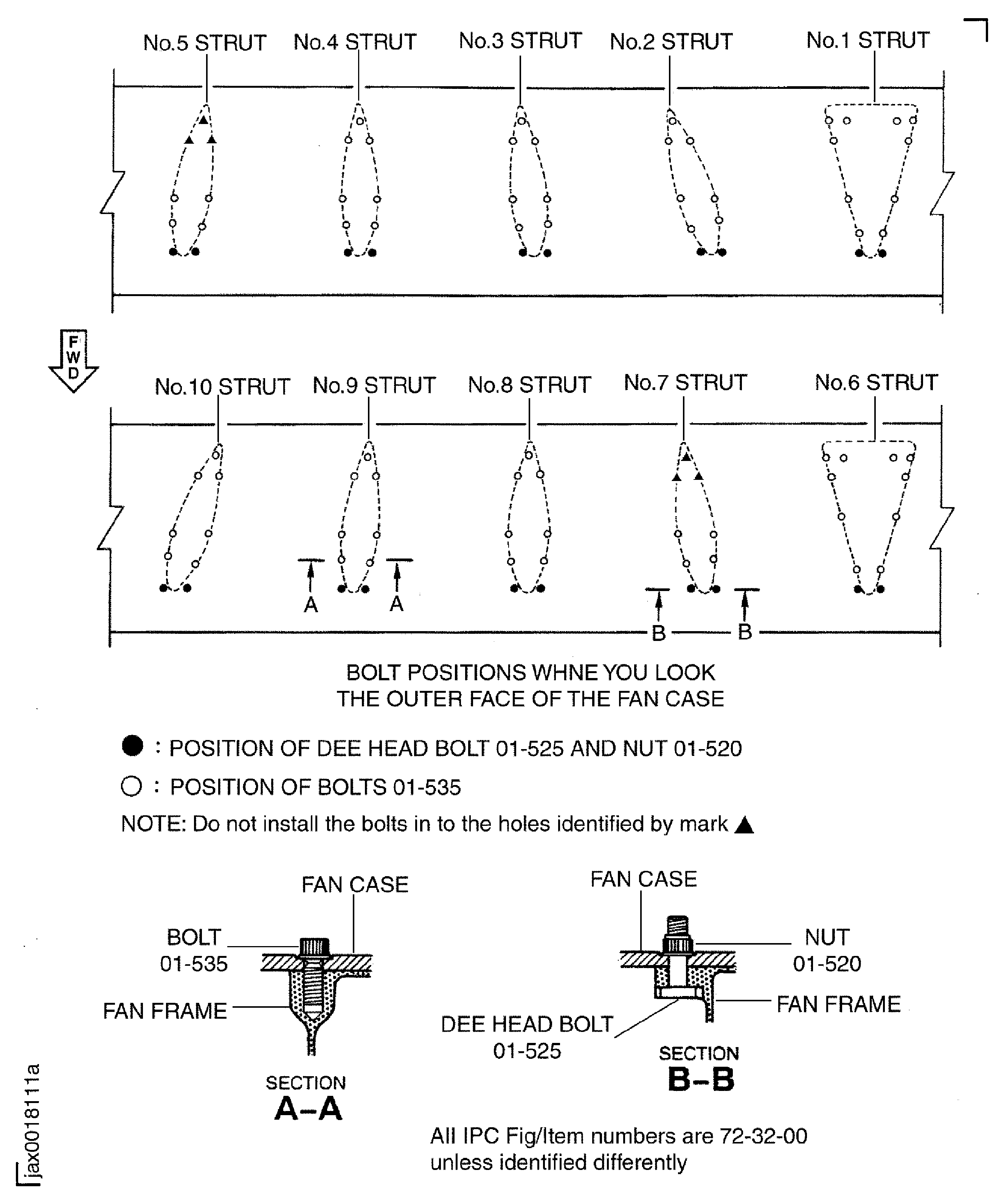

Install the 20 dee head bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-525) and nuts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-520) which attach the Fan Frame to the Fan Case. Tighten the nuts lightly.

Install the 70 bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-535) which attach the Fan Frame to the Fan Case.

Torque the nuts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-520) to between 180 lbfin and 220 lbfin (20.00 Nm and 25.00 Nm). Strut sequence to torque the nuts is:

No. 1 Strut, No. 6 Strut, No. 3 Strut, No. 8 Strut, No. 4 Strut, No. 9 Strut, No. 2 Strut, No. 7 Strut, No. 5 Strut and No. 10 Strut.

Torque the bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-535) to between 180 lbfin and 220 lbfin (20.00 Nm and 25.00 Nm). Strut sequence to torque the bolts is the same as that of Step.

SUBTASK 72-32-00-430-248-A00 Install the Fan Frame in to the Fan Case (Pre SBE 72-0435)

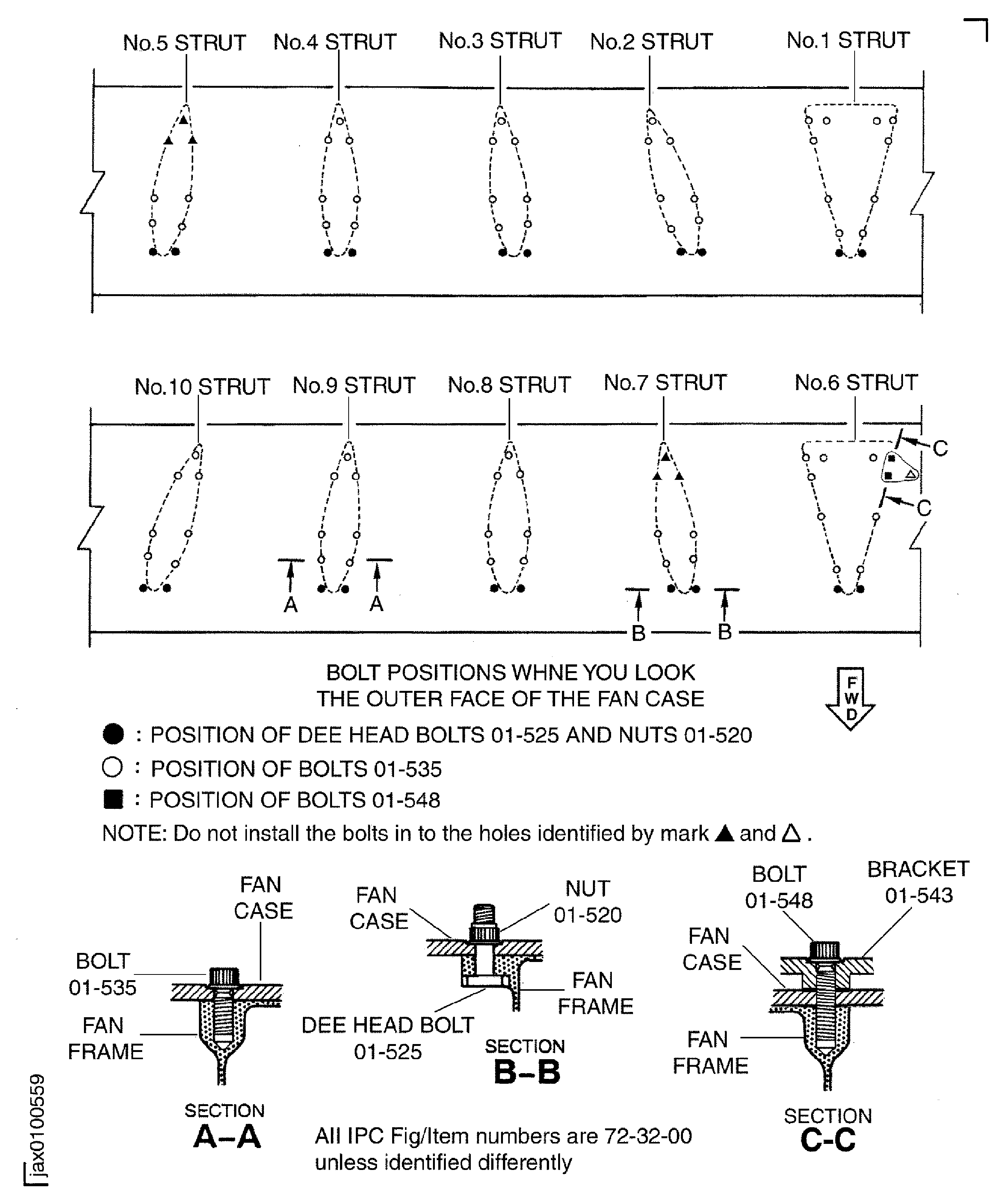

Put the Fan Case Fan Case And Related Parts (72-32-85, 01-100) on to IAE 1J12010 Storage stand storage stand 1 off with the rear end up.

Install the 20 dee head bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-525) and nuts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-520) which attach the Fan Frame to the Fan Case. Tighten the nuts lightly.

Install the 68 bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-535) which attach the Fan Frame to the Fan Case.

Attach the bracket LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-543) to the Fan Case at 6 o'clock positions with the two bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-548).

Torque the nuts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-520) to between 180 lbfin and 220 lbfin (20.00 Nm and 25.00 Nm). Strut sequence to torque the nuts is:

No. 1 Strut, No. 6 Strut, No. 3 Strut, No. 8 Strut, No. 4 Strut, No. 9 Strut, No. 2 Strut, No. 7 Strut, No. 5 Strut and No. 10 Strut.

Torque the bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-535) and the bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-548) to between 180 lbfin and 220 lbfin (20.00 Nm and 25.00 Nm). Strut sequence to torque the bolts is the same as that of the Step.

SUBTASK 72-32-00-430-248-B00 Install the Fan Frame in to the Fan Case (SBE 72-0435)

SBE 72-0435: Introduction of Fan Case, panel and bracket scalloped for No. 4 Scavenge Tube reroute.

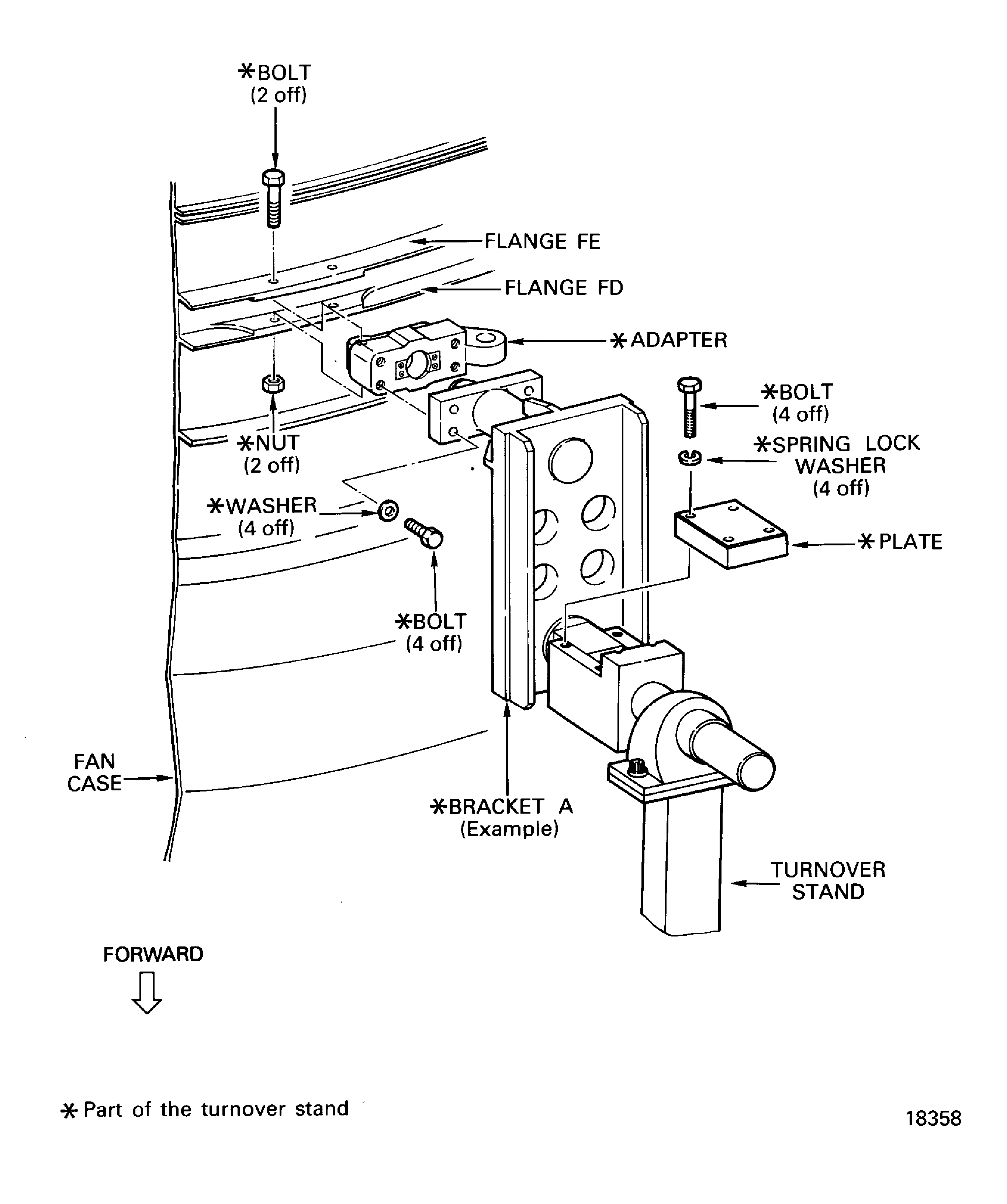

Refer to Figure.

SUBTASK 72-32-00-430-247 Remove and Brackets A and B from the Turnover Stand

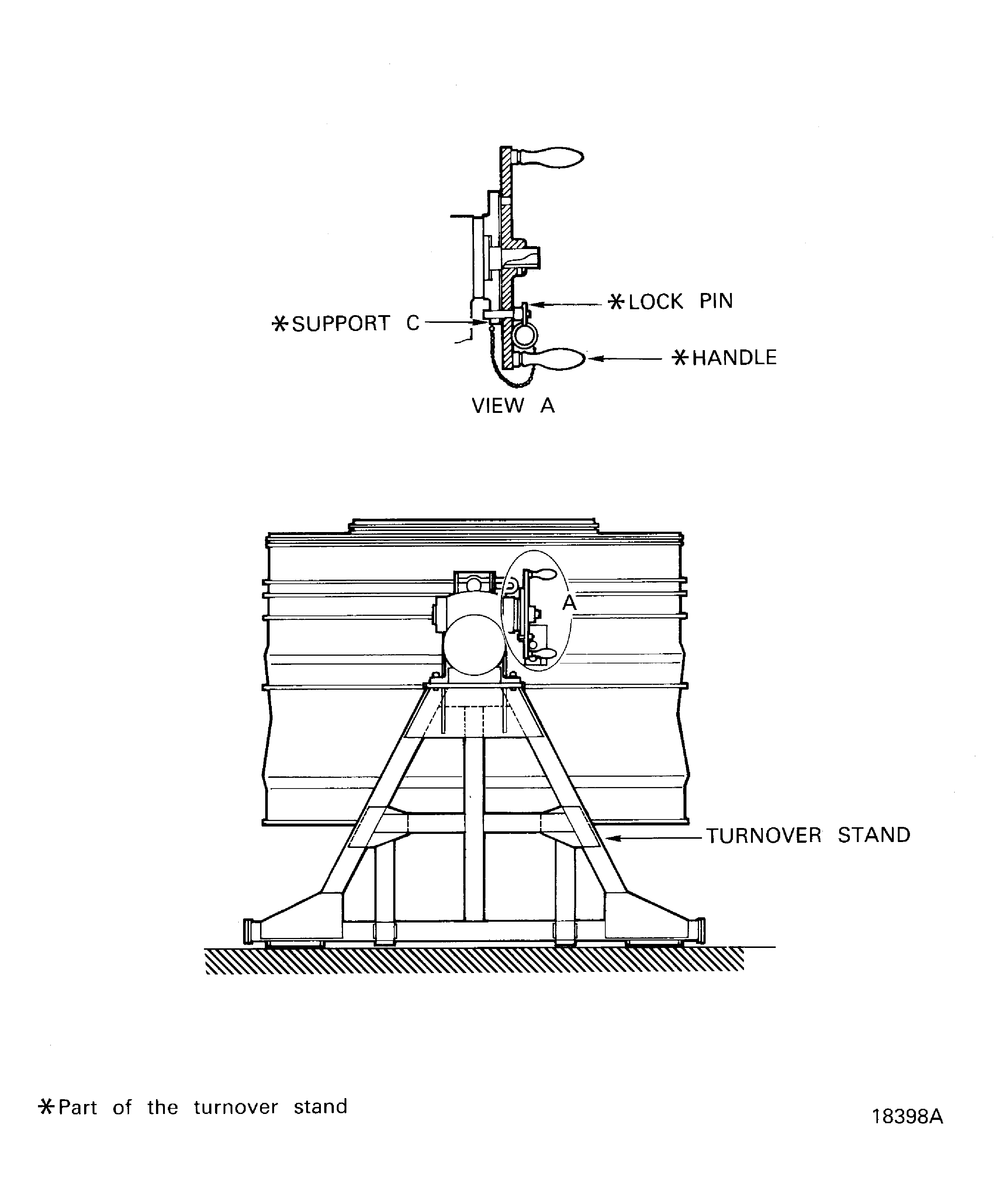

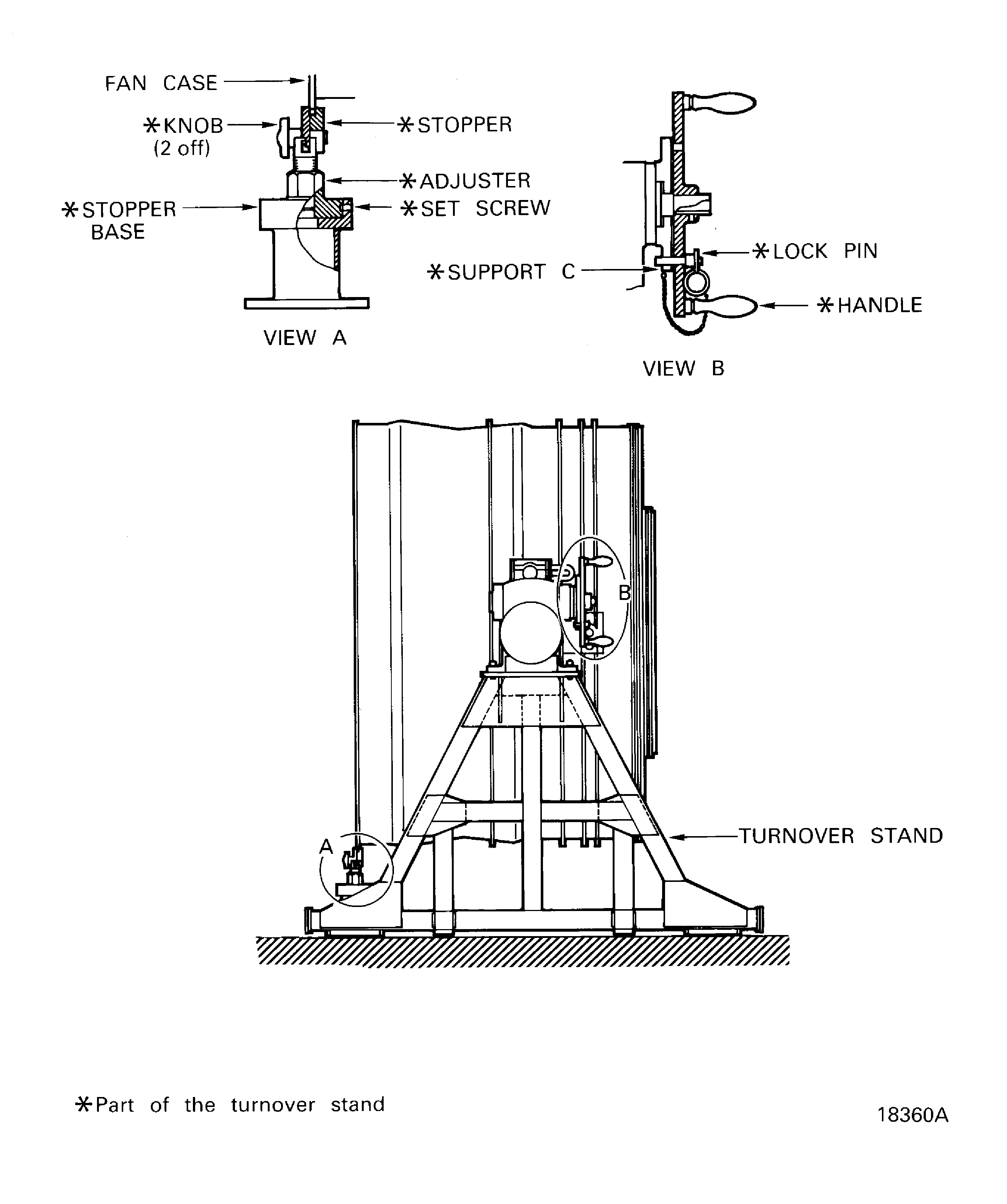

Install the two adapters (part of IAE 1J12311 Turnover stand 1 off) to the flanges FD and FE on the Fan Case at 3 and 9 o'clock positions. Attach with the four bolts and nuts (part of the turnover stand). Tighten the bolts.

SUBTASK 72-32-00-430-249 Install the Brackets A and B on to the Fan Case

WARNING

DO NOT REMOVE THE REAR SLING UNTIL AFTER THE INSTALLATION OF THE LOCK PIN IN TO THE HANDLE OF THE TURNOVER STAND. THIS CAN PREVENT THE ROTATION OF THE FAN FRAME AND FAN CASE ASSEMBLY AND INJURY TO PERSONS.Remove the 20 bolts and the four ring stoppers which attach the rear sling to the Fan Frame rear flange of the Fan Frame and Fan Case Assembly.

SUBTASK 72-32-00-430-251 Remove the Rear Sling from the Fan Frame and Fan Case Assembly

CAUTION

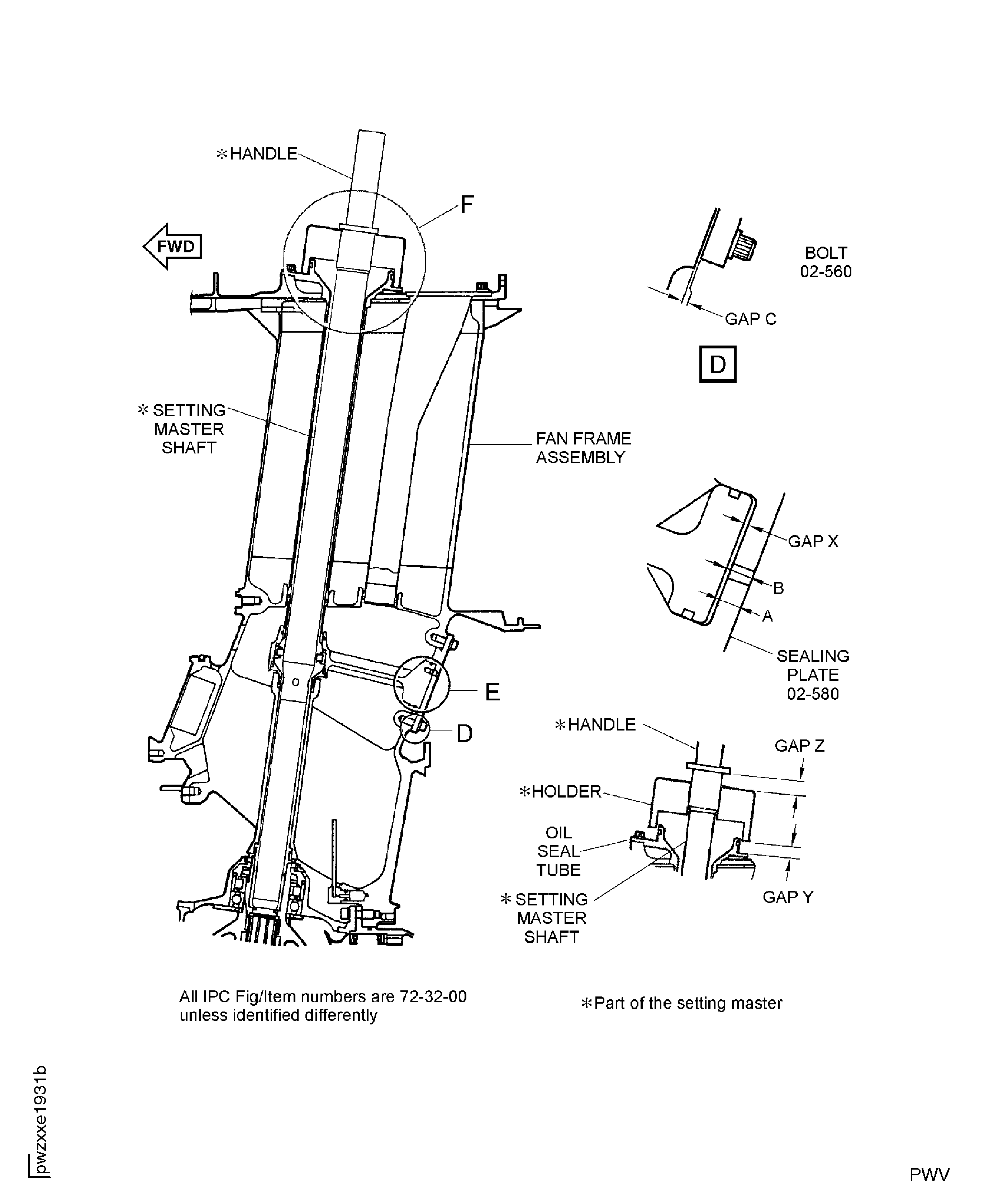

THE FAN FRAME AND FAN CASE ASSEMBLY MUST NOT BE SET IN ANY OTHER POSITION EXCEPT THE NO. 1 STRUT DOWN POSITION OR NO. 1 STRUT UP POSITION. THE CENTER BEARING ROLLERS CAN SAG DOWN DUE TO GRAVITY IF THE FAN FRAME AND FAN CASE ASSEMBLY IS NOT SET IN EITHER OF THESE POSITIONS. THIS CAN CAUSE DAMAGE TO THE CENTER BEARING ROLLERS WHEN INSTALLING THE SETTING MASTER SHAFT (PART OF IAE 1J12157 Setting Master).Refer to Figure.

NOTE

As an alternative, the fan frame and fan case assembly can be set with the No. 1 strut up position when sufficient space is available to install the setting master shaft (part of IAE 1J12157 Setting Master) from the bottom.As an alternative to the Step, turn the handle to the assembly horizontal with the No. 1 strut up.

NOTE

Make sure that the holes in the Support C and one of eight holes in the handle are aligned. If necessary, turn the handle to make the two holes aligned.

SUBTASK 72-32-00-430-252 Turn the Fan Frame and Fan Case Assembly to the No. 1 Strut Down Position

Install the Center Bearing Housing ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-300) to IAE 1J12432 Base holder 1 off.

Put IAE 1J12300 Installation pusher 1 off on to the outer roller bearing and push down the installation pusher by hand.

WARNING

TOUCH THE OUTER ROLLER BEARING WITH THE APPROVED GLOVES.Install the outer roller bearing ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-250) in to the Center Bearing Housing.

When the Center Bearing Housing becomes cool, install the retaining ring ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-230) in to the groove in the Center Bearing Housing.

Lubricate the outer roller bearing with CoMat 10-077 APPROVED ENGINE OILS.

Lubricate LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-610) sealing ring 1 off and ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-180) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the two sealing rings in to the groove in the seal carrier ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-170).

SUBTASK 72-32-00-430-253 Assemble the Center Bearing Housing Assembly

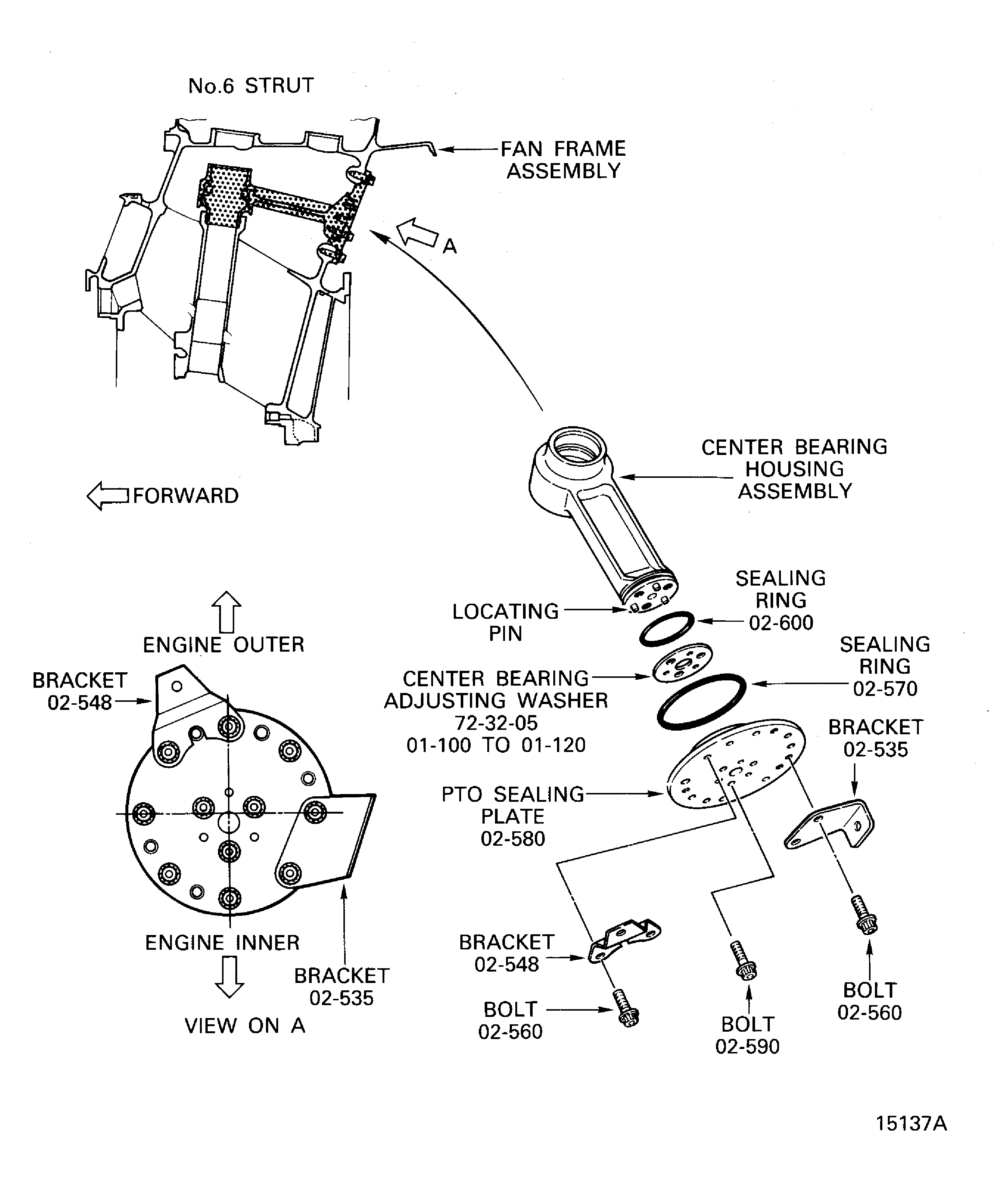

Lubricate LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-600) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the sealing ring in to the groove in the Center Bearing Housing Assembly.

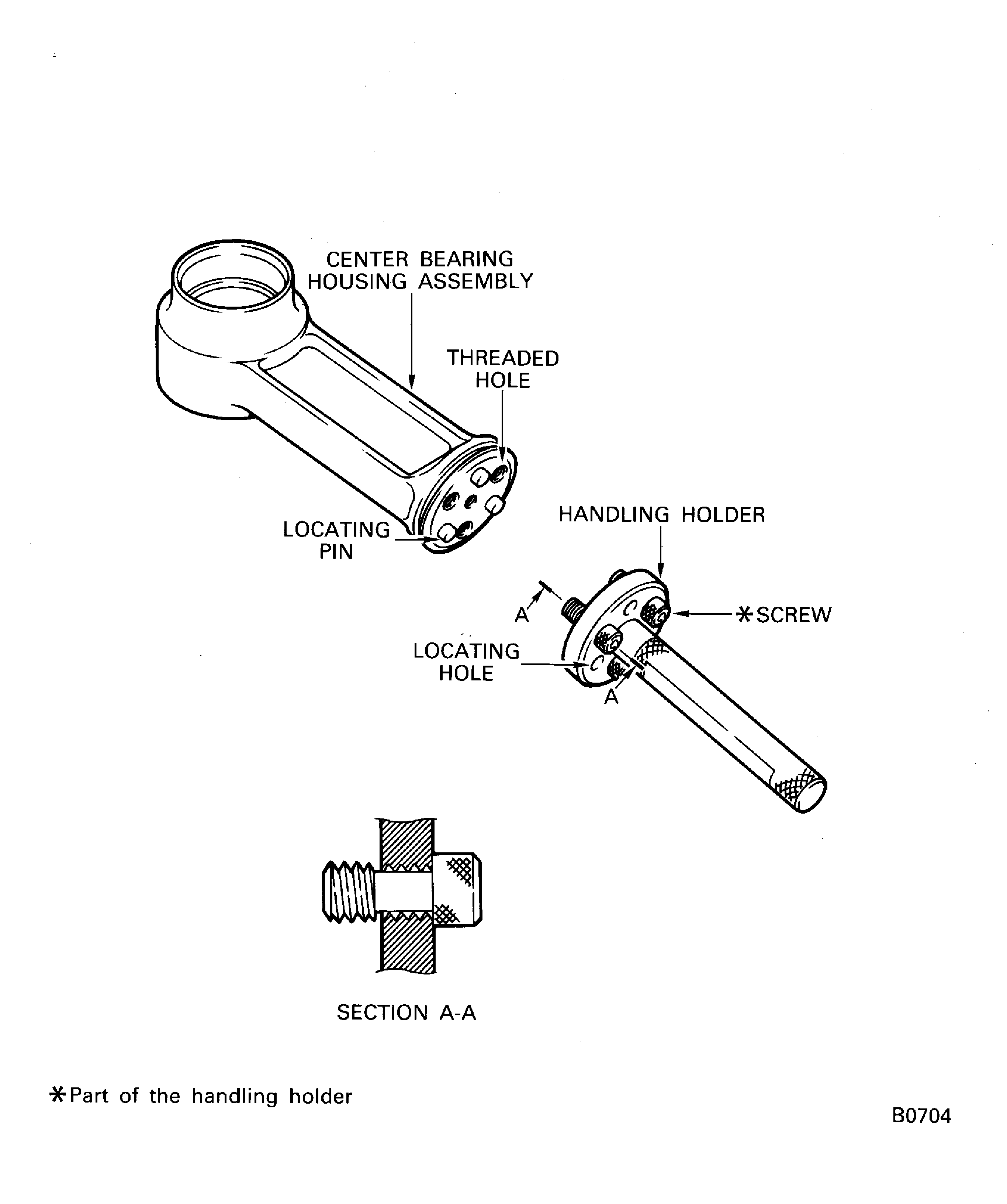

Engage the three screws in the handling holder with the threaded holes in the Center Bearing Housing. Tighten the screws.

NOTE

When you turn the screws, keep the threads of screws released from the threads of handling holder. If the threads of screws are engaged with the threads of housing assembly and handling holder, you can not turn the screws.

Attach IAE 1J12327 Handling holder 1 off to the Center Bearing Housing Assembly Figure.

Remove the Center Bearing Housing Assembly from the base holder, Figure.

Lubricate LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-615) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the sealing ring into the groove in the Center Bearing Housing, Figure.

Install the Center Bearing Housing Assembly in to position in the No. 6 Strut of the Fan Frame Assembly with the handling holder, Figure.

Put the PTO sealing plate on to the Fan Frame Assembly and attach with the eight bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-560). Torque the bolts to 85 lbfin to 105 lbfin (10.00 Nm to 12.00 Nm).

NOTE

Do not install the two brackets LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-535) and LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-548) at this step.

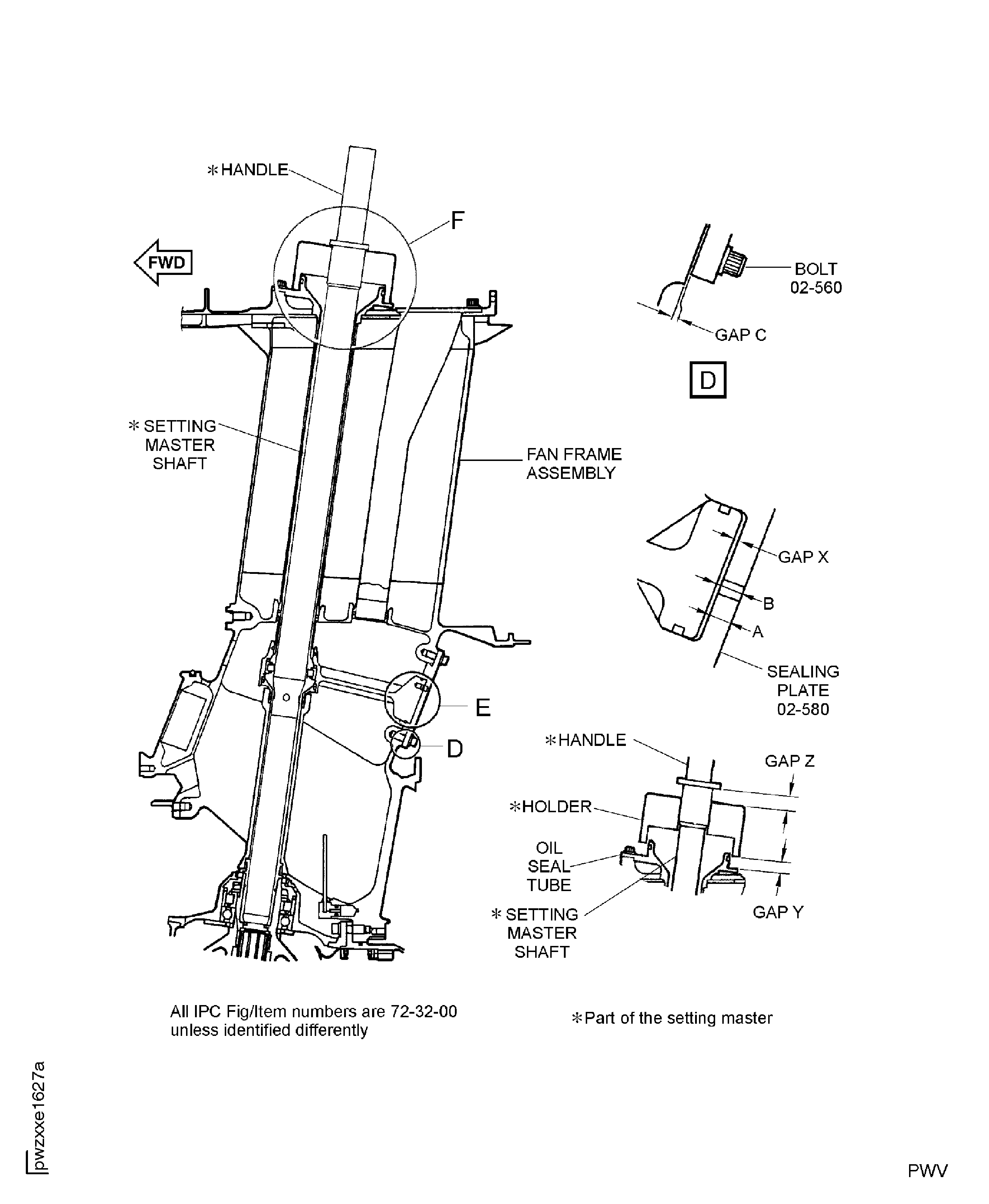

Install the PTO sealing plate LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-580) on to the Fan Frame Assembly, Figure.

SUBTASK 72-32-00-430-254 Install the Center Bearing Housing Assembly in to the Fan Frame

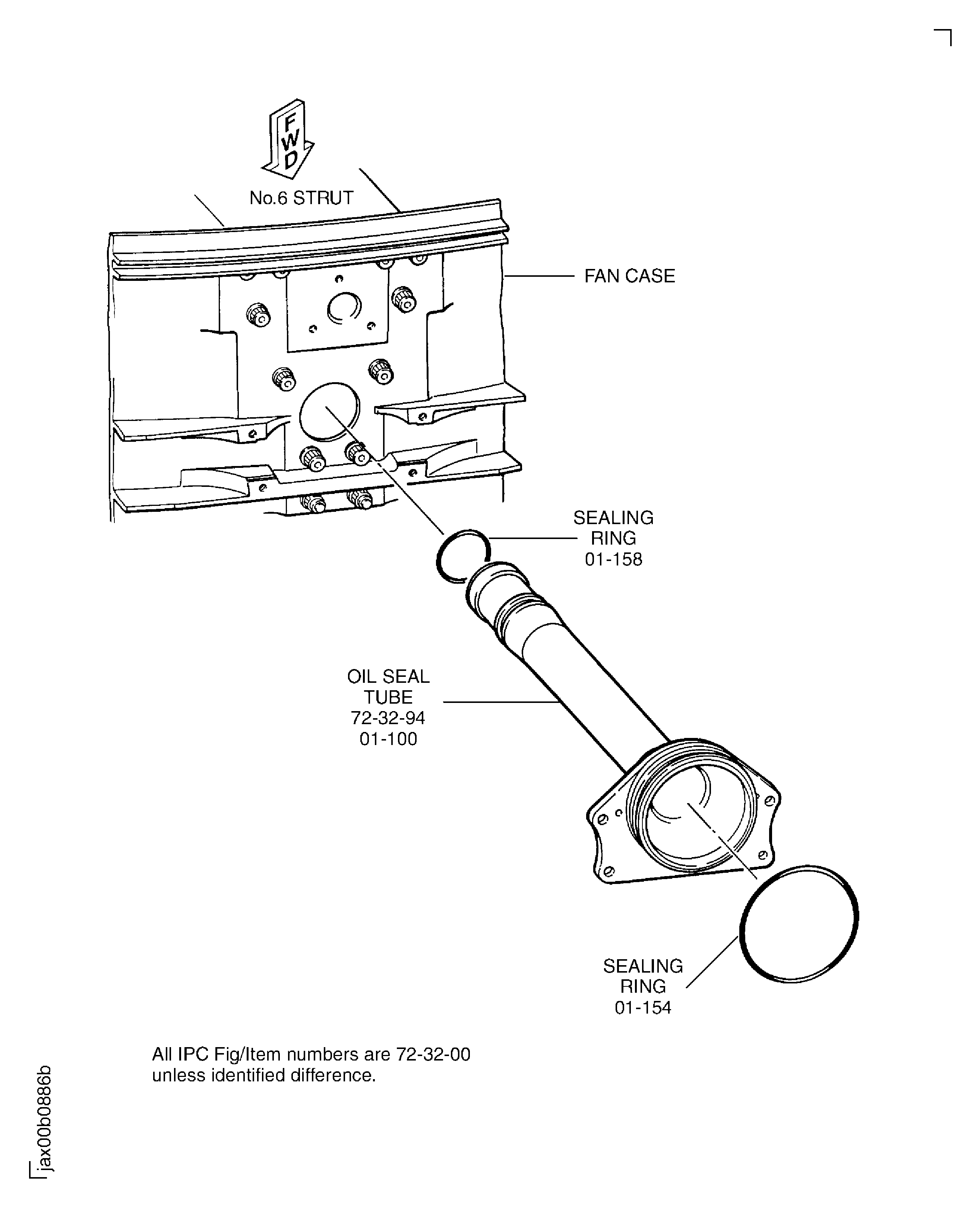

Lubricate (01-154) sealing ring 1 off and (01-158) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS.

Install the oil seal tube ENGINE-PTO SHAFT SEAL TUBE (72-32-94, 01-100), Figure.

Install the four bolts (part of the IAE 1J12470 Leak check fixture 1 off) on to the oil seal tube, Figure. Tighten the bolts.

SUBTASK 72-32-00-430-259 Install the Oil Seal Tube in to the Fan Frame Strut

CAUTION

THE FAN FRAME AND FAN CASE ASSEMBLY MUST NOT BE SET IN ANY OTHER POSITION EXCEPT THE NO. 1 STRUT DOWN POSITION OR NO. 1 STRUT UP POSITION. THE CENTER BEARING ROLLERS CAN SAG DOWN DUE TO GRAVITY IF THE FAN FRAME AND FAN CASE ASSEMBLY IS NOT SET IN EITHER OF THESE POSITIONS. THIS CAN CAUSE DAMAGE TO THE CENTER BEARING ROLLERS WHEN INSTALLING THE SETTING MASTER SHAFT (PART OF IAE 1J12157 Setting Master).Set the holder (part of IAE 1J12157 Setting master 1 off) to the oil seal tube.

Lubricate the outer faces except the handle on the setting master shaft (part of IAE 1J12157 Setting Master) with CoMat 10-077 APPROVED ENGINE OILS.

CAUTION

CAREFULLY AND SLOWLY INSERT THE SETTING MASTER SHAFT (PART OF IAE 1J12157 Setting Master) TO PREVENT ANY DAMAGE TO THE CENTER BEARING.Install the setting master shaft (part of IAE 1J12157 Setting Master 1 off) in to the oil seal tube, the Center Bearing Housing Assembly and the spline in the shaft bevel pinion gear.

Find the center bearing adjusting washer ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-100) to (72-32-05. 01-120) which thickness is the nearest the value of the gap X.

Remove the setting master shaft (part of IAE 1J12157 Setting Master 1 off) from the oil seal tube, the center bearing housing assembly and the spline in the shaft bevel pinion gear.

Remove the holder (part of IAE 1J12157 Setting Master 1 off) from the oil seal tube.

SUBTASK 72-32-00-430-256 Find the Center Bearing Adjusting Washer

Install the adjusting washer on to the Center Bearing Housing Assembly, Figure.

Lubricate LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-570) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the ring into the groove in the PTO sealing plate LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-580).

Put the PTO sealing plate on to the Fan Frame Assembly and attach with the eight bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-560). Torque the bolts to 85 lbfin to 105 lbfin (10.00 Nm to 12.00 Nm).

Install the PTO sealing plate LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-580) on to the Fan Frame Assembly.

SUBTASK 72-32-00-430-257 Make Sure that the Gap Between the PTO Sealing Plate and the Fan Frame Assembly is in the Limit

Refer to Figure.

Remove the four bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-560) which attach the PTO sealing plate to the Fan Frame Assembly.

Install the brackets LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-535) and LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-548) on to the PTO sealing plate with the four bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-560). Torque the bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-560) to 85 lbfin to 105 lbfin (10.00 Nm to 12.00 Nm).

Install the brackets on to the PTO sealing plate.

Install the PTO sealing plate to the Center Bearing Housing Assembly with the three bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-590). Torque the bolts to 85 lbfin to 105 lbfin (10.00 Nm to 12.00 Nm).

SUBTASK 72-32-00-430-384 Install the Bracket on to the PTO Sealing Plate

Set the holder (part of IAE 1J12157 Setting Master 1 off) to the oil seal tube.

Lubricate the outer faces except the handle on the setting master shaft (part of IAE 1J12157 Setting Master ) with CoMat 10-077 APPROVED ENGINE OILS.

CAUTION

CAREFULLY AND SLOWLY INSERT THE SETTING MASTER SHAFT (PART OF IAE 1J12157 Setting Master) TO PREVENT ANY DAMAGE TO THE CENTER BEARING.Install the setting master shaft (part of IAE 1J12157 Setting Master 1 off) in to the oil seal tube, the Center Bearing Housing Assembly and the spline in the shaft bevel pinion gear.

Pull the setting master shaft (part of IAE 1J12157 Setting Master 1 off) until the gap Z is approximately 0.8 in. (20 mm).

Push the setting master shaft (part of IAE 1J12157 Setting Master 1 off) until the gap Z is zero.

Remove the setting master shaft from the oil seal tube, the center bearing housing assembly and the spline in the shaft bevel pinion gear. Refer to Figure.

Remove the holder (part of IAE 1J12157 Setting Master 1 off) from the oil seal tube.

Remove the three bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-590) that attaches the PTO sealing plate.

Go to Step.

If the setting master shaft (part of IAE 1J12157 Setting Master 1 off) does not move lightly, do the following steps.

Slowly pull and push the setting master shaft (part of IAE 1J12157 Setting Master 1 off) by hand and make sure that the setting master shaft (part of IAE 1J12157 Setting Master 1 off) moves lightly.

Remove the setting master shaft (part of IAE 1J12157 Setting Master 1 off) from the oil seal tube, the center bearing housing assembly and the spline in the shaft bevel pinion gear. Refer to Figure.

Remove the holder (part of IAE 1J12157 Setting Master 1 off) from the oil seal tube.

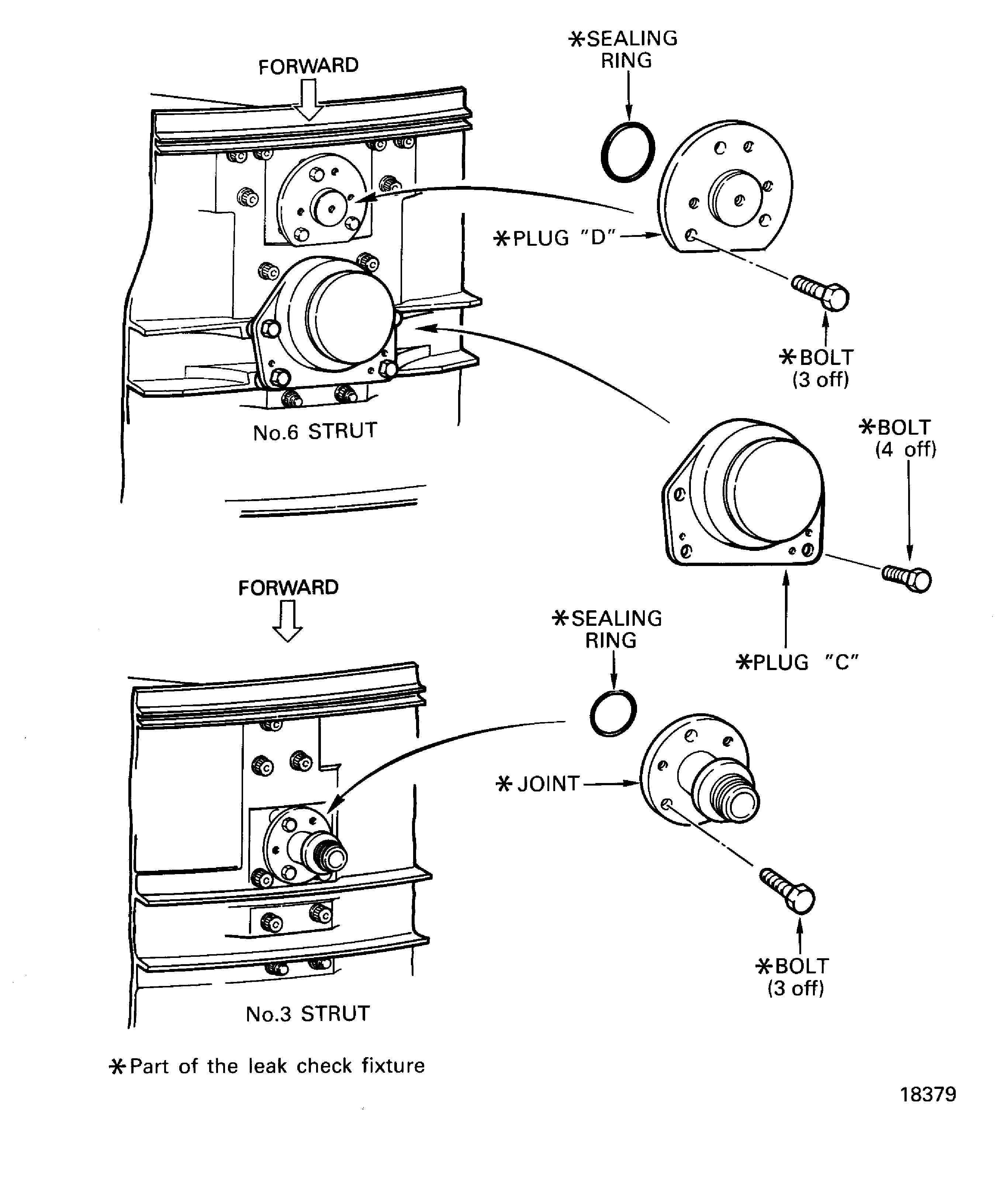

Install the plug "C" (part of the IAE 1J12470 Leak check fixture 1 off) on to the oil seal tube with the four bolts (part of the leak check fixture), Figure. Tighten the bolts.

SUBTASK 72-32-00-430-273 Make Sure that the Setting Master Shaft moves lightly

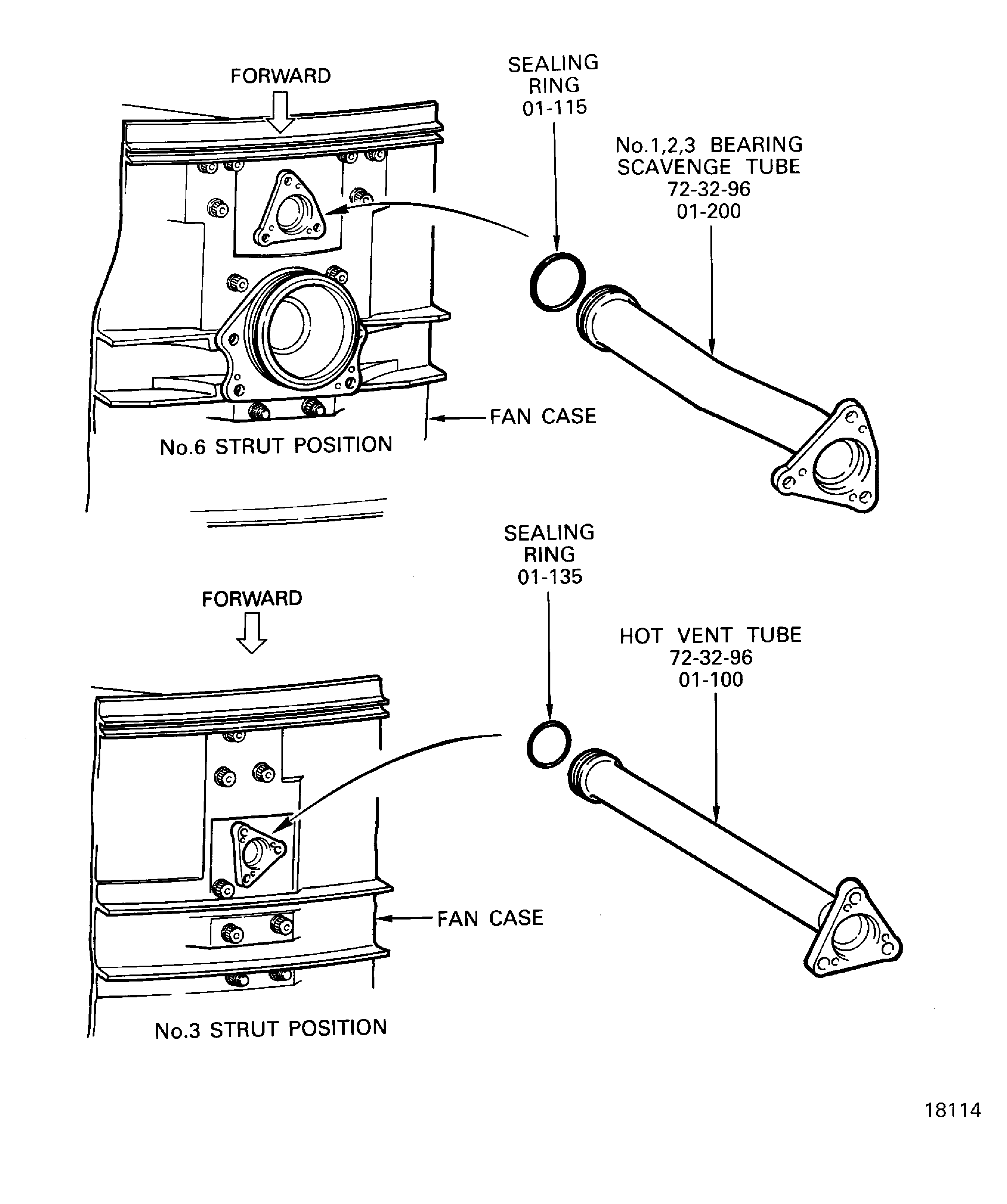

Lubricate (01-115) sealing ring 1 off with the CoMat 10-077 APPROVED ENGINE OILS.

Install the No. 1, 2, 3 Bearing Scavenge Tube INTERMEDIATE STRUCTURE OIL & AIR TRANSFER TUBES (72-32-96, 01-200), Figure.

Install the plug D (part of IAE 1J12470 Leak check fixture 1 off) on to the scavenge tube and attach with the three bolts (part of the leak check fixture), Figure.

Install the hot vent tube INTERMEDIATE STRUCTURE OIL & AIR TRANSFER TUBES (72-32-96, 01-100), Figure.

Install the joint (part of the leak check fixture) on to the hot vent tube and attach with the three bolts (part of the leak check fixture), Figure.

SUBTASK 72-32-00-430-260 Install the No. 1, 2, 3 Bearing Scavenge Tube, the Hot Vent Tube, the Plug D and the Joint to the Fan Frame Struts

Remove the three bolts which attach the oil tube cover to the oil feed adapter in the No. 4 Strut, Figure. Remove the oil tube cover.

Lubricate the sealing ring with CoMat 10-077 APPROVED ENGINE OILS.

Install the plug A (part of IAE 1J12470 Leak check fixture 1 off) on to the oil feed adapter, Figure.

SUBTASK 72-32-00-430-262 Install the Plug A and the Packing Seal C of the Leak Check Fixture to the Frame

Refer to Figure.

Make sure that the two sealing rings, the packing seat B, the washer and the handles B (part of the leak check fixture) are removed from the packing seat A and Mandrel Assembly. For the removal of them refer to Step.

Lubricate the sealing rings with CoMat 10-077 APPROVED ENGINE OILS.

Install the two sealing rings (part of the IAE 1J12470 Leak check fixture 1 off) to the packing seat A and Mandrel Assembly (part of the leak check fixture).

Make sure that the sealing ring, the handles B and the retainer are removed from the packing seat B. For the removal of them refer to Step.

Install the sealing ring on to the packing seat B (part of the leak check fixture).

SUBTASK 72-32-00-430-263 Install the Leak Check Fixture to the Stub Shaft and the Hydraulic Ring

Refer to Figure.

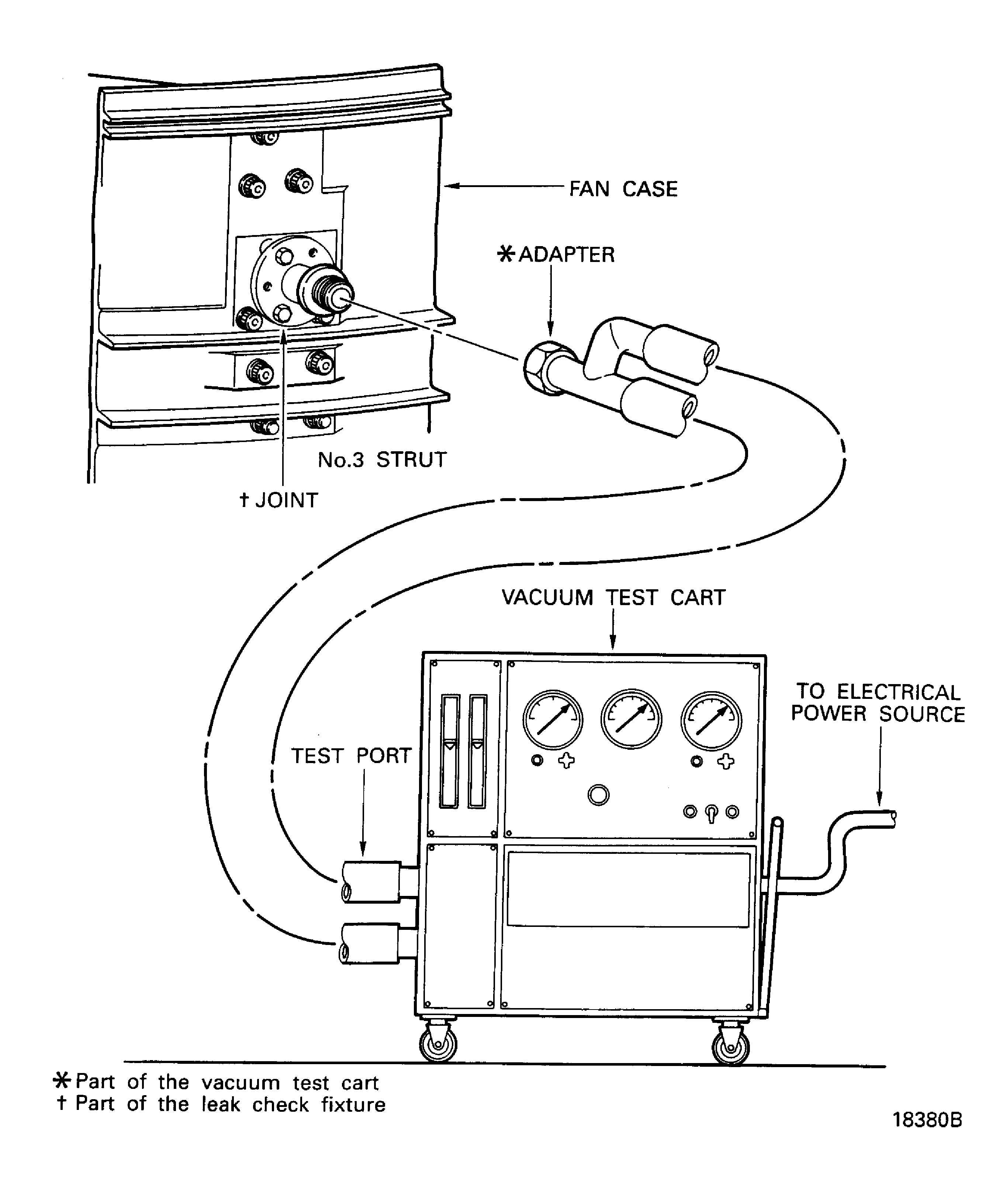

Connect adapter (part of IAE 6F10030 Vacuum test cart 1 off) to joint on hot vent tube.

NOTE

Refer to manufacturers manual for operation of vacuum test cart.Set the air pressure at test port to -20 in. Hg gage (-508 mm Hg gage). Based on the ambient pressure, refer to the table below for the vacuum pressure in psia.

Ambient Pressure of the Day (psia)

Vacuum Pressure (psia)

14.7

4.9

14.5

4.7

14.3

4.5

14.1

4.3

13.9

4.1

13.7

3.9

13.5

3.7

13.3

3.5

13.1

3.3

Vacuum pressure (psia) = Ambient pressure of the day (psia) - 9.8 psia

SUBTASK 72-32-00-790-054 Do an Evacuation check for the Front Bearing Compartment with the Leak Check Fixture in the Stub Shaft and the Hydraulic Ring

Refer to Figure.

SUBTASK 72-32-00-430-265 Turn the Fan Frame and Fan case Assembly to the Rear End Up Position

Remove the three bolts and the joint (part of the leak check fixture) from the hot vent tube, Figure. Remove the sealing ring (part of the leak check fixture) from the joint.

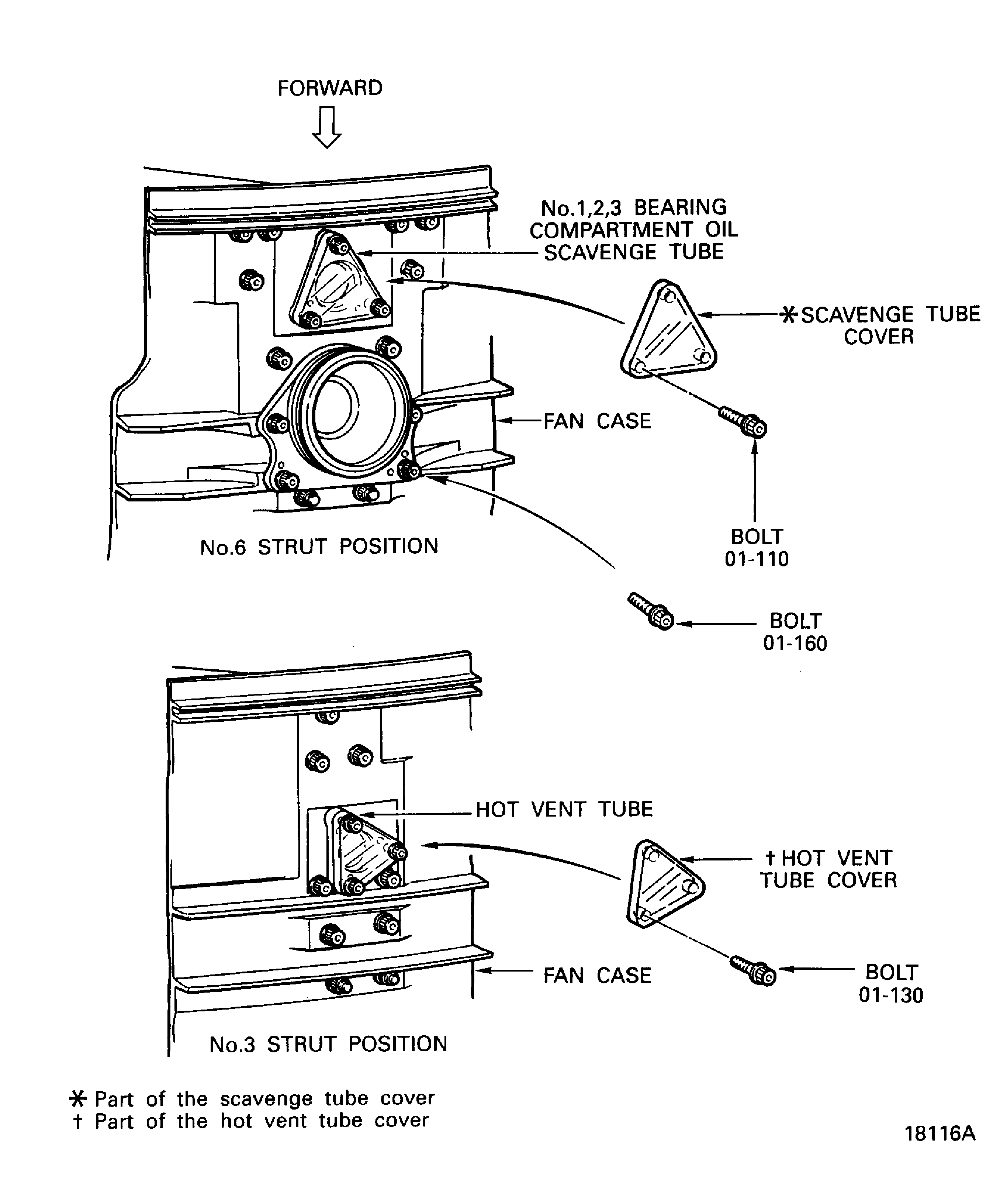

Install the four bolts (01-160) which attach the oil seal tube to the fan case, Figure. Torque the bolts to between 85 lbfin and 105 lbfin (10.00 Nm and 12.00 Nm).

Install IAE 1J12206 Scavenge tube cover 1 off on to the No. 1, 2 ,3 Bearing Scavenge Tube, Figure. Attach with the three bolts (01-110). Tighten the bolts by hand.

Install IAE 1J12207 Hot Vent tube cover 1 off on to the hot vent tube. Attach with the three bolts (01-130). Tighten the bolts by hand.

Install IAE 1J12205 Oil tube cover 1 off on to the oil feed adapter, Figure. Attach with the three bolts (part of the oil tube cover). Tighten the bolts by hand.

SUBTASK 72-32-00-430-266 Install the Covers to the Tubes in the Struts

CAUTION

THE FAN FRAME AND FAN CASE ASSEMBLY MUST NOT BE SET IN ANY OTHER POSITION EXCEPT THE NO. 1 STRUT DOWN POSITION OR NO. 1 STRUT UP POSITION. THE CENTER BEARING ROLLERS CAN SAG DOWN DUE TO GRAVITY IF THE FAN FRAME AND FAN CASE ASSEMBLY IS NOT SET IN EITHER OF THESE POSITIONS. THIS CAN CAUSE DAMAGE TO THE CENTER BEARING ROLLERS WHEN INSTALLING THE SETTING MASTER SHAFT (PART OF IAE 1J12157 Setting Master) OR THE PTO SHAFT.Refer to Figure.

NOTE

As an alternative, the fan frame and fan case assembly can be set with the No. 1 strut up position when sufficient space is available to install the PTO shaft from the bottom.As an alternative to Step, turn the handle to the assembly horizontal with the No. 1 strut up.

NOTE

Make sure that the holes in the Support C and one of eight holes in the handle are aligned. If necessary, turn the handle to make the two holes aligned.

SUBTASK 72-32-00-430-267 Turn the Fan Frame and Fan Case Assembly to the No. 1 Strut Down Position

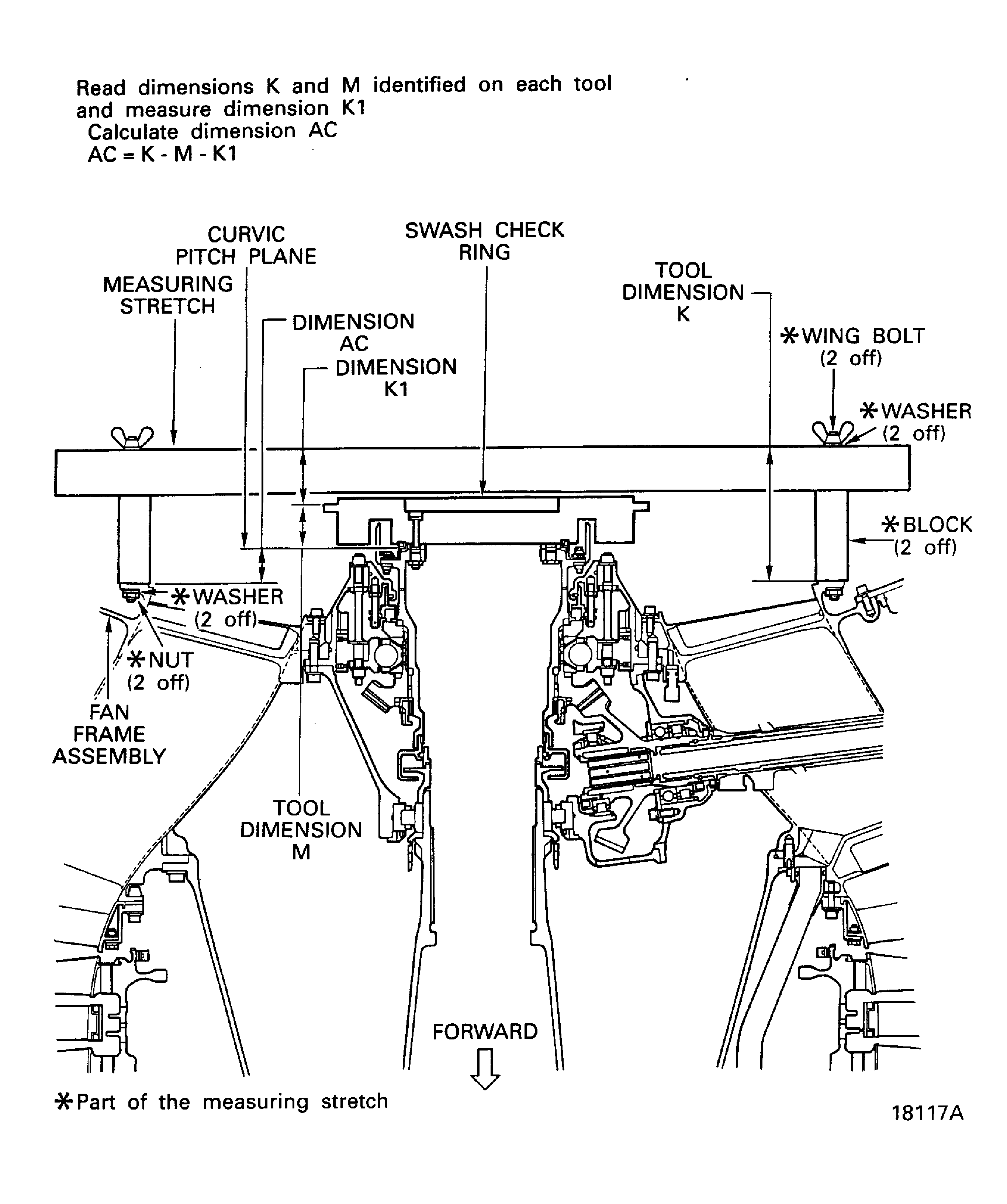

Refer to Figure.

Make sure that the curvic teeth on the HPC Front Shaft and Seal Assembly and the swash check ring are clean. Clean the curvic teeth with a clean cloth made moist with CoMat 01-124 ISOPROPYL ALCOHOL if the curvic teeth are not clean.

Install the IAE 1J12384 Swash check ring 1 off on the HPC Front Shaft and Seal Assembly.

Read the tool dimensions K and M identified on the swash check ring and IAE 1J12508 Measuring stretch 1 off.

Measure the dimensions K1 at 12 and 6 o'clock positions with the depth micrometer. Push the swash check ring to set the position of the HPC Front Shaft and Seal Assembly fully forward while you measure the dimension K1.

NOTE

Axial clearance in the No. 3 Bearing causes axial movement of the HPC Front Shaft and Seal Assembly. The HPC Front Shaft and Seal Assembly must be put fully forward when the dimensions K1 are measured.

SUBTASK 72-32-00-430-268 Measure the Module Interface Dimension for the Installation of the HP System Module

Refer to Figure.

Install the Seal Assembly ENGINE-BEARING COMPARTMENT REAR AIR SEAL (72-32-35, 01-100) on to the Fan Frame.

SUBTASK 72-32-00-430-269 Install the Seal Assembly on to the Fan Frame

Refer to Figure.

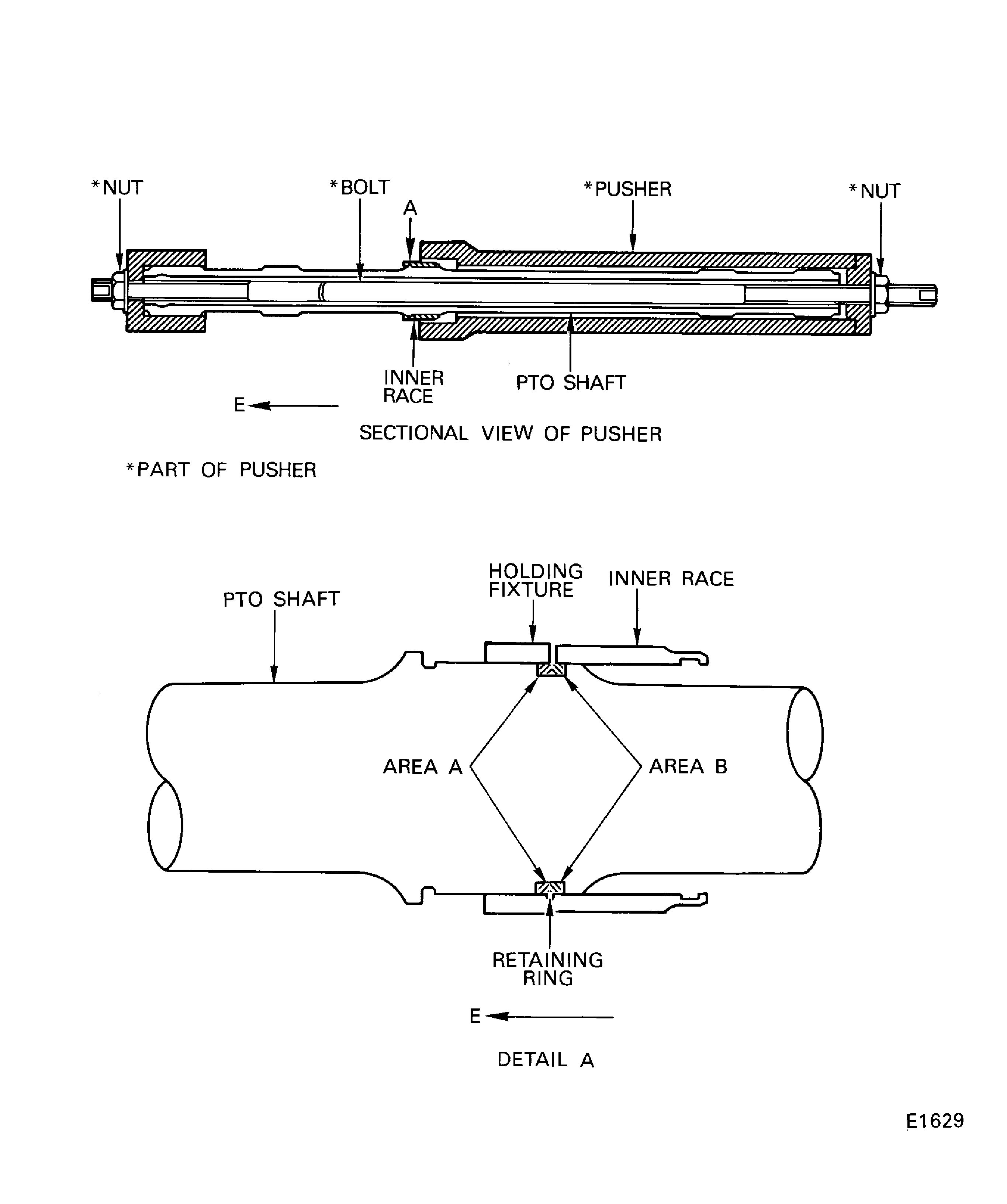

Lubricate the retaining ring with CoMat 10-077 APPROVED ENGINE OILS.

Install ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-275) retaining ring 1 off on to the PTO shaft.

Install IAE 1J12521 Holding fixture 1 off on to the area A on the retaining ring to push it in the groove fully.

Install IAE 1J12536 Mechanical pusher 1 off on to the PTO shaft and the inner race.

Install the inner race ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-270) on to the PTO shaft.

SUBTASK 72-32-00-430-270 Install the Inner Race on to the PTO Shaft

CAUTION

THE FAN FRAME AND FAN CASE ASSEMBLY MUST NOT BE SET IN ANY OTHER POSITION EXCEPT THE NO. 1 STRUT DOWN POSITION OR NO. 1 STRUT UP POSITION. THE CENTER BEARING ROLLERS CAN SAG DOWN DUE TO GRAVITY IF THE FAN FRAME AND FAN CASE ASSEMBLY IS NOT SET IN EITHER OF THESE POSITIONS. THIS CAN CAUSE DAMAGE TO THE CENTER BEARING ROLLERS WHEN INSTALLING THE SETTING MASTER SHAFT (PART OF IAE 1J12157 Setting Master) OR THE PTO SHAFT.Set the holder (part of IAE 1J12157 Setting Master 1 off) to the oil seal tube, Figure.

Lubricate the outer faces except the handle on the setting master shaft (part of IAE 1J12157 Setting Master) with CoMat 10-077 APPROVED ENGINE OILS.

CAUTION

CAREFULLY AND SLOWLY INSERT THE SETTING MASTER SHAFT (PART OF IAE 1J12157 Setting Master) TO PREVENT ANY DAMAGE TO THE CENTER BEARING.Install the setting master shaft (part of IAE 1J12157 Setting Master 1 off) in to the oil seal tube to move the center bearing rollers outward, Figure.

Remove the setting master shaft (part of IAE 1J12157 Setting Master 1 off) from the oil seal tube, Figure.

Remove the holder (part of IAE 1J12157 Setting Master 1 off) from the oil seal tube.

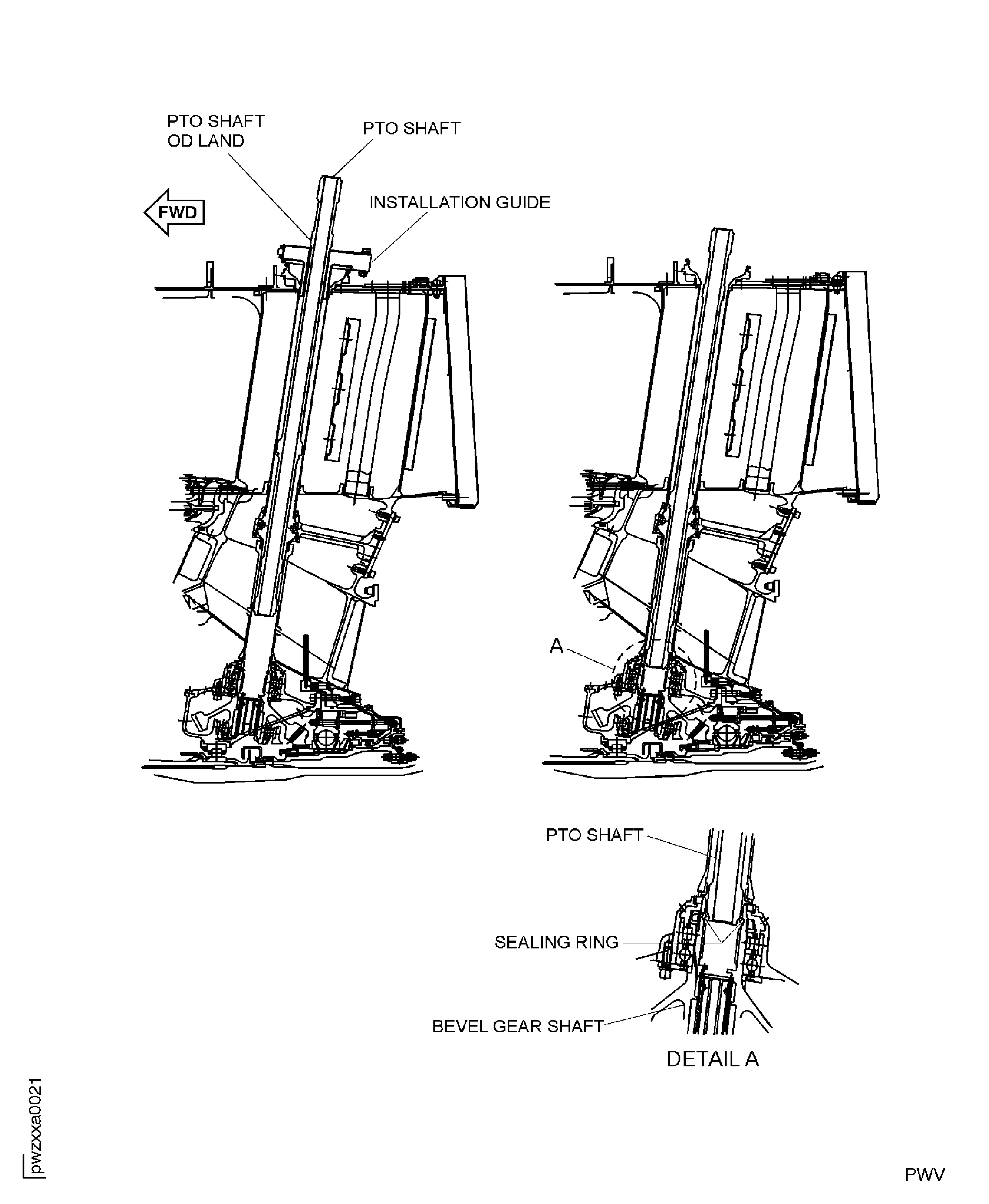

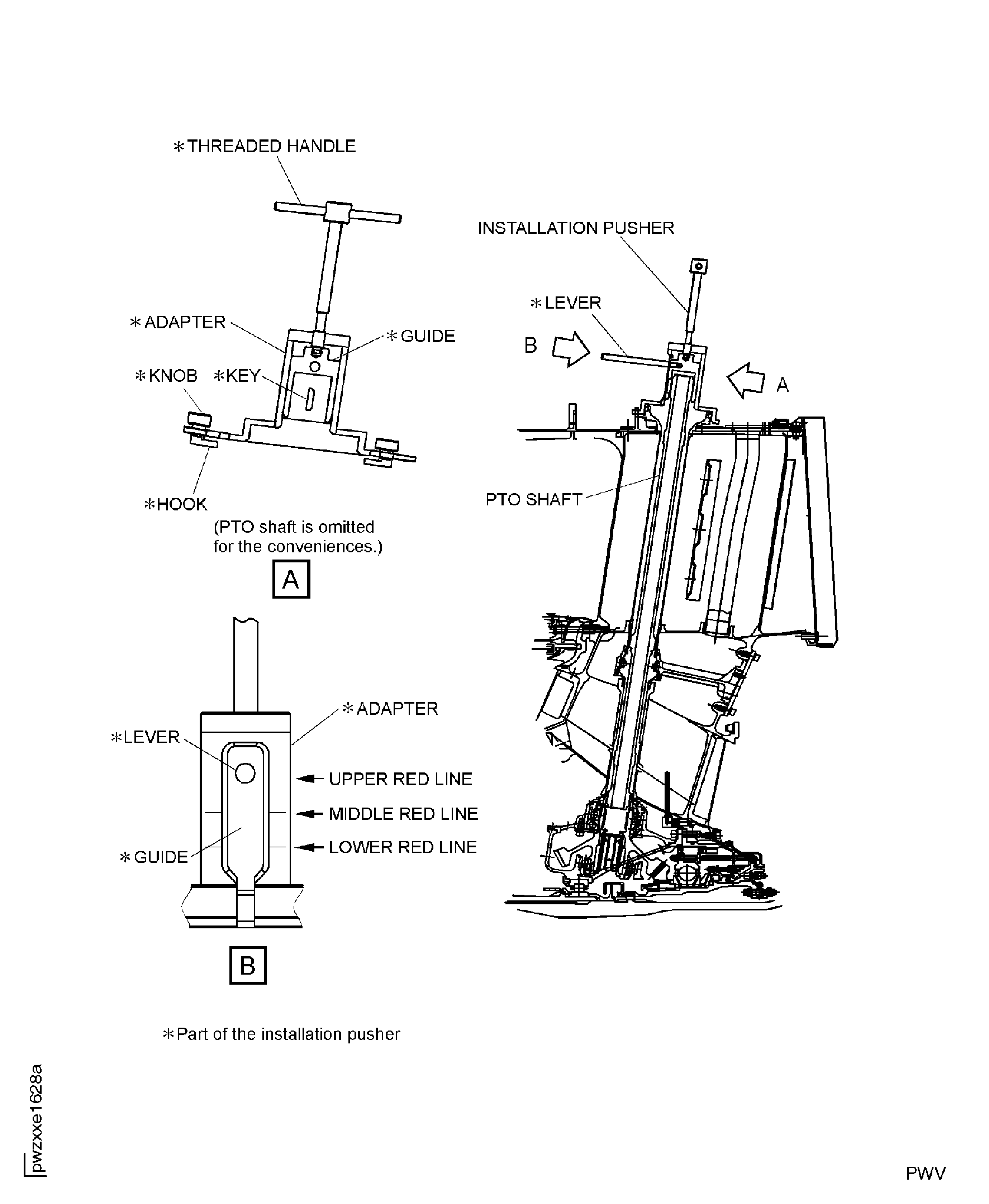

Lubricate the outer faces and spline teeth on the PTO shaft ENGINE-PTO SHAFT (72-32-95, 01-100) with CoMat 10-077 APPROVED ENGINE OILS, Figure.

NOTE

The PTO shaft has spline teeth at two ends of the shaft. The end, which has 24 spline teeth, must be installed in to the oil seal tube. The end, which has 28 spline teeth, must be out of the oil seal tube.Lubricate the outer faces and inner faces on the IAE 1J12158 Installation Guide 1 off with CoMat 10-077 APPROVED ENGINE OILS, Figure.

Make sure that there is no contamination and foreign object on contact surfaces on the IAE 1J12158 Installation Guide 1 off.

Set the installation guide IAE 1J12158 Installation Guide 1 off on the barrel outer diameter of the PTO shaft, Figure.

Latch the draw ratchet (part of IAE 1J12158 Installation Guide 1 off) and grip the PTO shaft end, Figure.

Slowly insert the PTO shaft and the IAE 1J12158 Installation Guide 1 off in to the oil seal tube until the installation guide touches the oil seal tube.

Slowly insert the PTO shaft by hand until the spline passes the center bearing.

NOTE

The PTO shaft is centered by the outer diameter and inner diameter of the IAE 1J12158 Installation Guide 1 off.Slowly insert the PTO shaft by hand until the land on shaft outer diameter touches the IAE 1J12158 Installation Guide 1 off, Figure.

Pull the PTO shaft and the IAE 1J12158 Installation Guide 1 off carefully to remove the installation guide.

NOTE

Pull the PTO shaft just enough to remove the IAE 1J12158 Installation Guide 1 off.Release the draw ratchet (part of IAE 1J12158 Installation Guide 1 off) and remove the IAE 1J12158 Installation Guide 1 off.

Remove the IAE 1J12158 Installation Guide 1 off from the PTO shaft.

Carefully insert the PTO shaft by hand until the PTO shaft touches the sealing ring in the bevel gear shaft, Figure.

Turn the threaded handle and set the guide so that the lever is to be at the position of upper red line marking on the adapter.

Slide the two hooks outward.

Put the IAE 1J12159 Installation Pusher 1 off on to the oil seal tube.

Slide the two hooks inward and turn the knobs to tighten hooks.

Align the key on the guide and the PTO shaft spline using lever and turn the threaded handle until the guide touches to the PTO shaft end.

Attach the IAE 1J12159 Installation Pusher 1 off to the PTO shaft and the oil seal tube, Figure.

NOTE

The threaded handle, guide, lever, adapter, hook, key and knob are parts of the IAE 1J12159 Installation Pusher 1 off.Turn the handle until the lever is to be at the position of middle red line marking on the adapter, Figure.

NOTE

The spline of PTO shaft goes over the sealing ring but not reach the spline of the bevel gear shaft.

Turn the threaded handle until first part of threads ends.

Align the spline of the bevel gear shaft and the PTO shaft using the lever.

Push the handle by hand until second part of threads starts.

NOTE

The inner race is not reaching the center bearing roller yet.Turn the handle until the lever is to be at the position of lower red line marking on the adapter, Figure.

Turn the threaded handle until the PTO shaft end touches the bevel gear shaft.

Remove the IAE 1J12159 Installation Pusher 1 off from the PTO shaft and the oil seal tube.

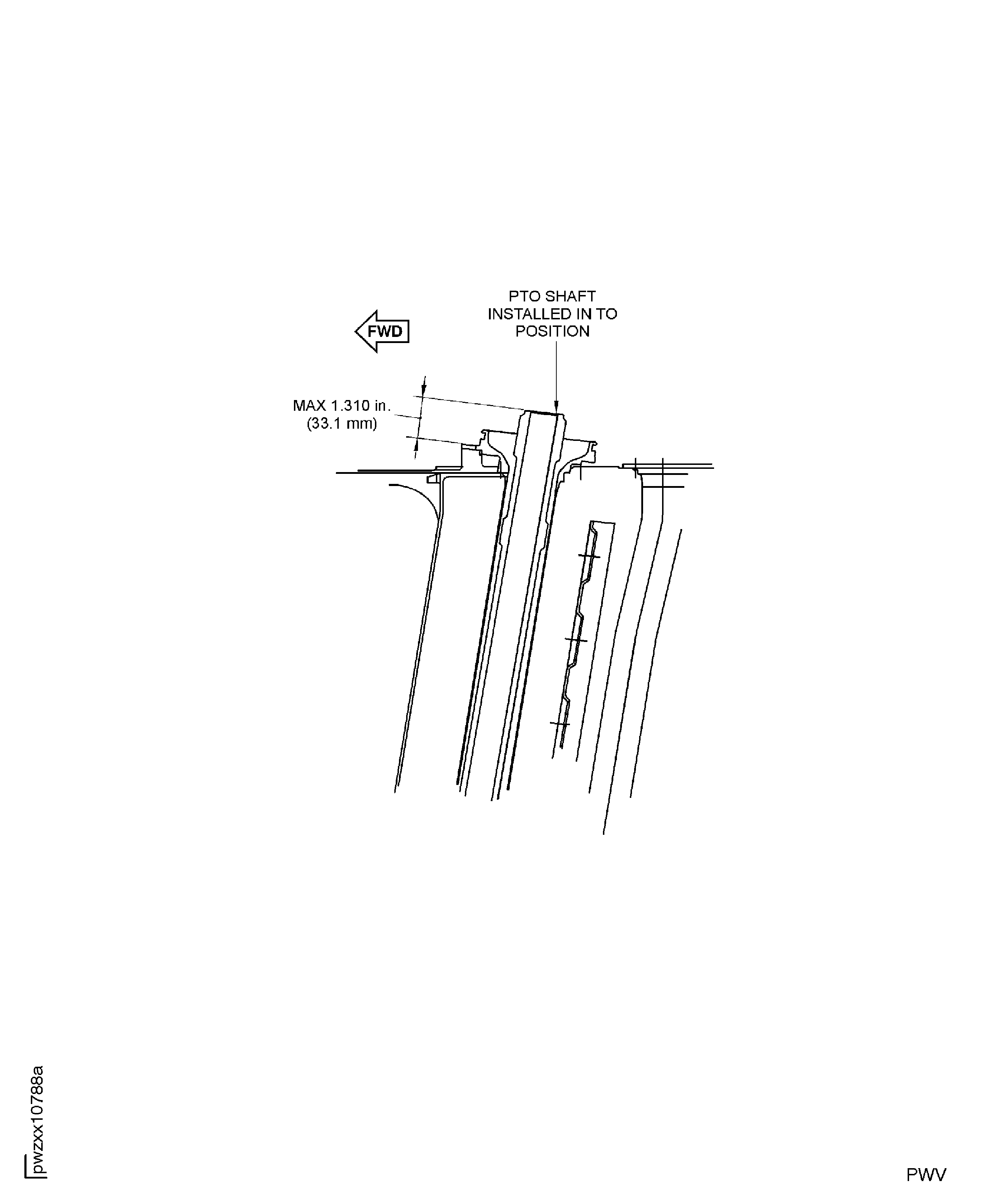

Make sure that the PTO shaft outer end is not more than 1.310 in. (33.1 mm) above the oil seal tube flange, Figure. If the PTO shaft outer end is more than 1.310 in. (33.1 mm) above the oil seal tube flange, install the IAE 1J12159 Installation Pusher 1 off and lower the PTO shaft.

Make sure that the PTO shaft is correctly installed, Figure.

SUBTASK 72-32-00-430-271 Install the PTO Shaft in to the Oil Seal Tube

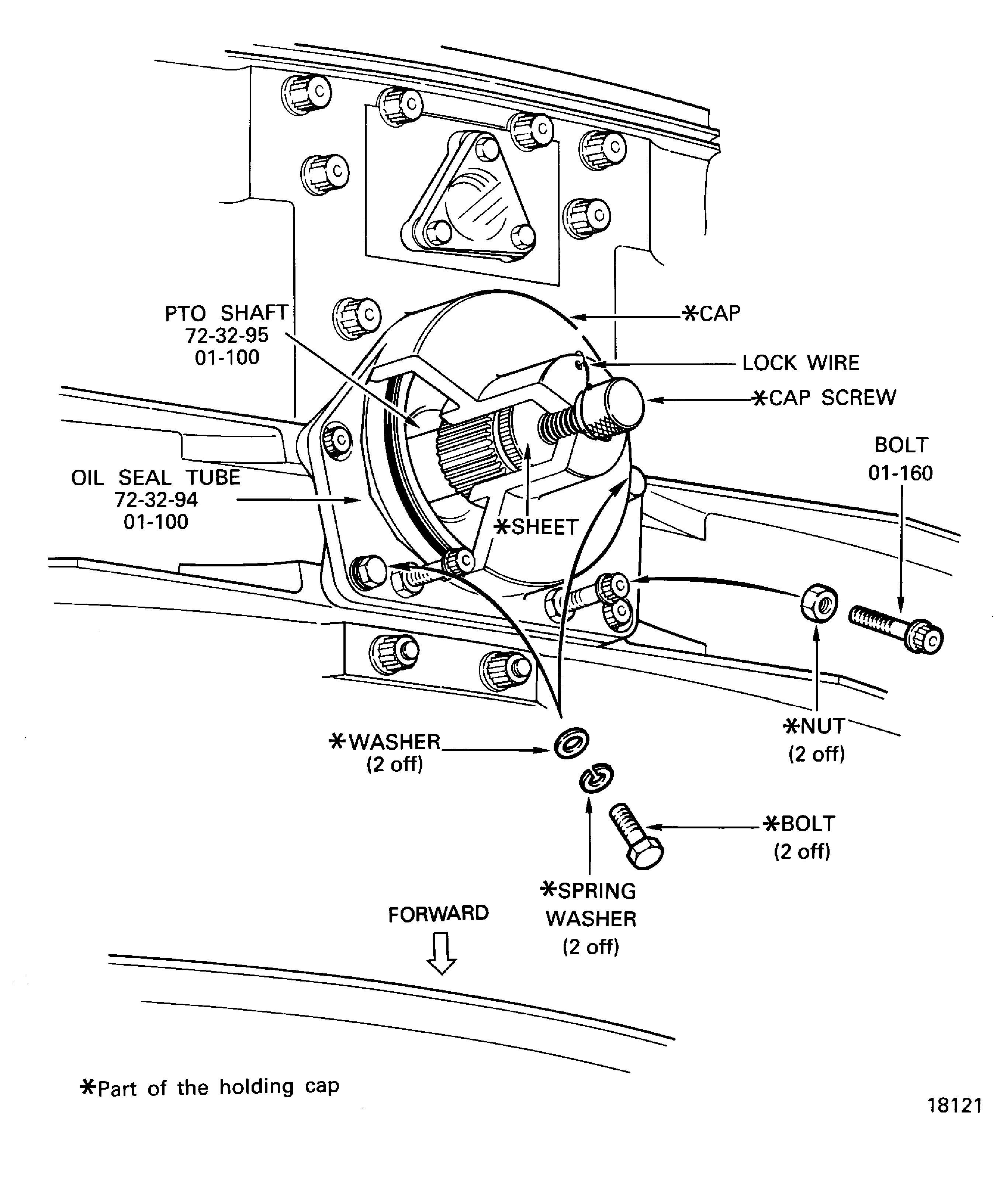

Refer to Figure.

Remove two of the four bolts (01-160) to replace them with the two bolts of the holding cap. Refer to Figure for the positions of the bolts to be replaced.

Turn the cap screw (part of IAE 1J12082 Holding cap 1 off) counterclockwise fully to move it out of the cap.

Safety the cap screw with CoMat 02-147 LOCKWIRE. Refer to SPM TASK 70-42-05-400-501.

Install the two nuts (part of the holding cap) on to the two bolts (01-160) which are removed in Step. Install the bolts in to the threaded holes in the cap and tighten the nuts.

NOTE

The holding cap is removed from the oil seal. The two bolts (01-160) are moved from the cap to the oil seal tube in TASKS which install the external gearbox to the Fan Case.

SUBTASK 72-32-00-430-272 Install Holding Cap on to the Oil Seal Tube to Hold the PTO Shaft

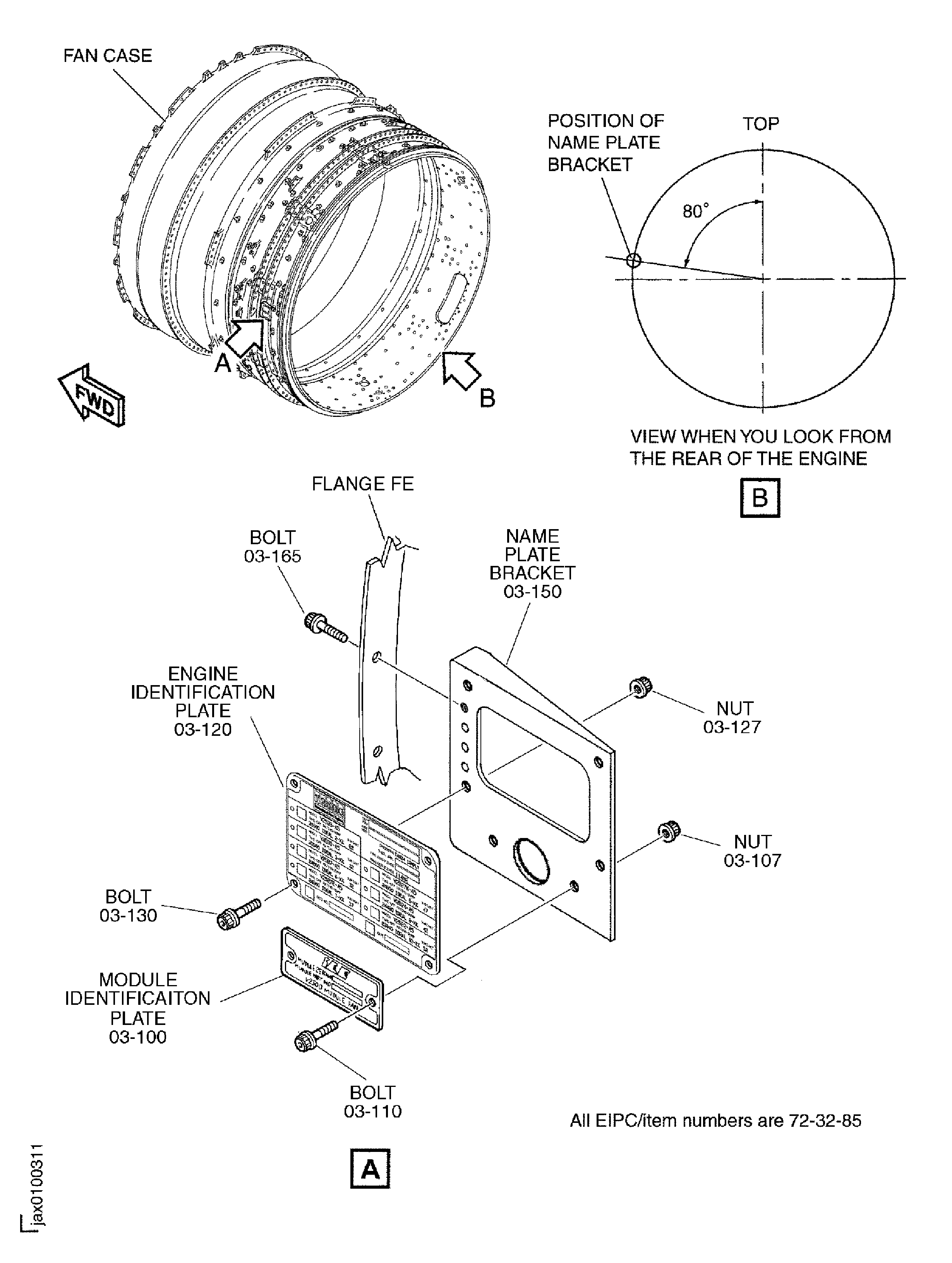

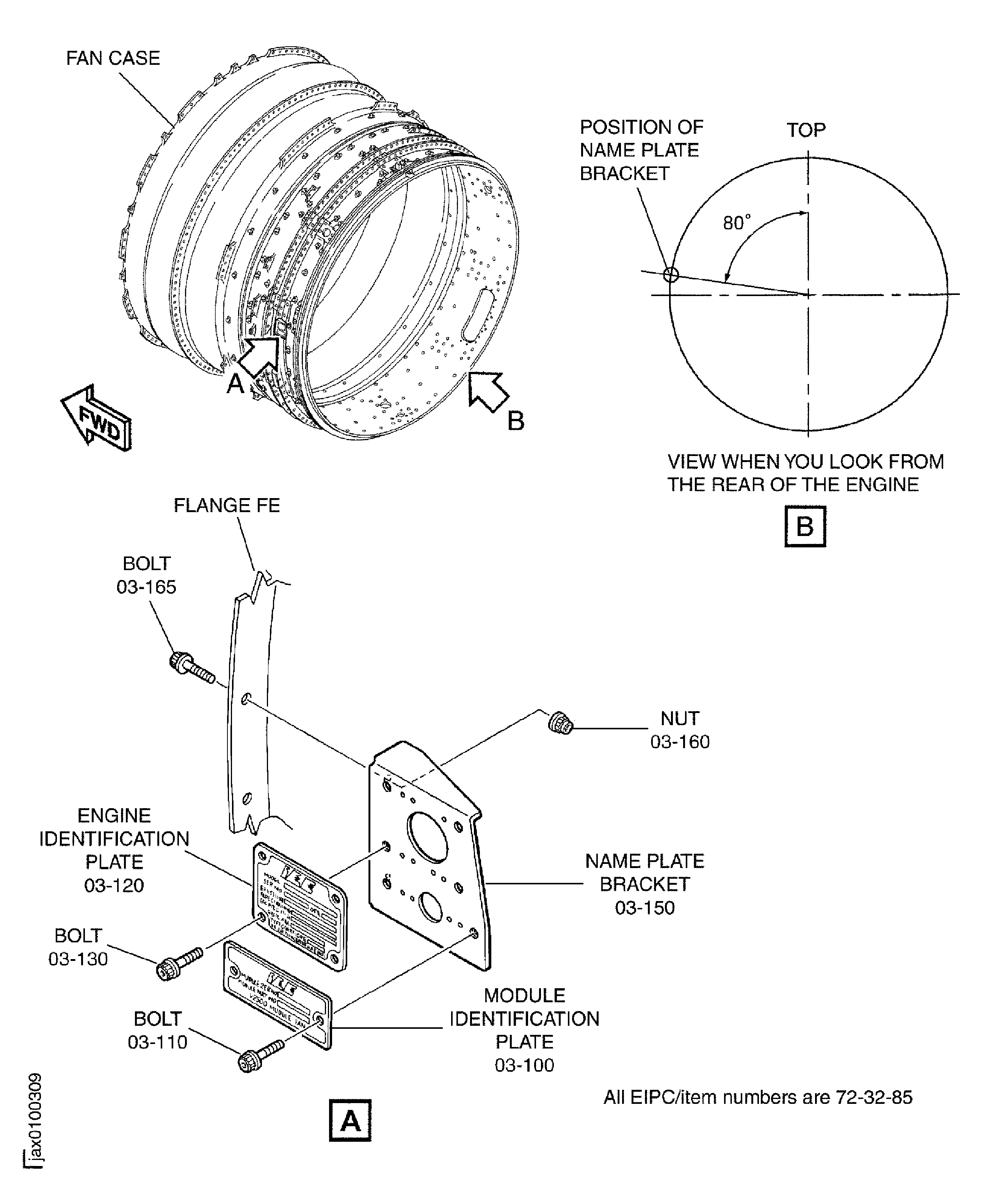

Refer to Figure.

Install the engine identification plate Fan Case And Related Parts (72-32-85, 03-120) to the name plate bracket Fan Case And Related Parts (72-32-85, 03-150) with the four bolts Fan Case And Related Parts (72-32-85, 03-130).

Install the module identification plate Fan Case And Related Parts (72-32-85, 03-100) to the name plate bracket with the two bolts Fan Case And Related Parts (72-32-85, 03-110).

Install the name plate bracket to the flange FE of the Fan Case with two bolts Fan Case And Related Parts (72-32-85, 03-165).

SUBTASK 72-32-00-430-327-A00 Install the Name Plate Bracket, the Engine Identification Plate and the Module Identification Plate to the Fan Case (Pre SBE 72-0378)

Refer to Figure.

Install the engine identification plate Fan Case And Related Parts (72-32-85, 03-150) with the four bolts Fan Case And Related Parts (72-32-85, 03-130) and nuts Fan Case And Related Parts (72-32-85, 03-127).

Install the model identification plate Fan Case And Related Parts (72-32-85, 03-100) to the name plate bracket with the two bolts Fan Case And Related Parts (72-32-85, 03-110) and nuts Fan Case And Related Parts (72-32-85, 03-107).

Install the name plate bracket to the flange FE of the Fan Case with the two bolts Fan Case And Related Parts (72-32-85, 03-165).

SUBTASK 72-32-00-430-327-B00 Install the Name Plate Bracket, the Engine Identification Plate and the Module Identification Plate to the Fan Case (SBE 72-0378)

SBE 72-0378: New engine identification plate with designation of all A5 model ratings.

Figure: Release the Lock Pin to Turn the Fan Frame from Horizontal to Vertical

Release the Lock Pin to Turn the Fan Frame from Horizontal to Vertical

Figure: Install the Rear Sling on to the Fan Frame

Install the Rear Sling on to the Fan Frame

Figure: Remove the Fan Frame from the Turnover Stand

Remove the Fan Frame from the Turnover Stand

Figure: Install the Fan Frame in to the Fan Case

Install the Fan Frame in to the Fan Case

Figure: Pre SBE 72-0435: Position of the Bolts to Attach the Fan Frame to the Fan Case

Sheet 1

Figure: SBE 72-0435: Position of the Bolts to Attach the Fan Frame to the Fan Case

Sheet 2

Figure: Install the Fan Frame and Fan Case Assembly to the Turnover Stand

Sheet 1

Figure: Install the Fan Frame and Fan Case Assembly to the Turnover Stand

Sheet 2

Figure: Install the Lock Pin in to Position to Lock the Handle of the Turnover Stand

Install the Lock Pin in to Position to Lock the Handle of the Turnover Stand

Figure: Install the Lock Pin in to Position to Lock the Handle and Hold the Fan Case Front Flange with the Stopper

Install the Lock Pin in to Position to Lock the Handle and Hold the Fan Case Front Flange with the Stopper

Figure: Use the Installation Pusher to Install the Outer Roller Bearing in to the Center Bearing Housing

Use the Installation Pusher to Install the Outer Roller Bearing in to the Center Bearing Housing

Figure: View of the Center Bearing Housing Assembly

View of the Center Bearing Housing Assembly

Figure: Install the Center Bearing Housing Assembly, the adjusting Washer and the PTO Sealing Plate to the No. 6 Strut

Install the Center Bearing Housing Assembly, the adjusting Washer and the PTO Sealing Plate to the No. 6 Strut

Figure: Attach the Handling Holder to the Center Bearing Housing Assembly

Attach the Handling Holder to the Center Bearing Housing Assembly

Figure: Measure the Gap X Between the Center Bearing Housing and the PTO Sealing Plate

Measure the Gap X Between the Center Bearing Housing and the PTO Sealing Plate

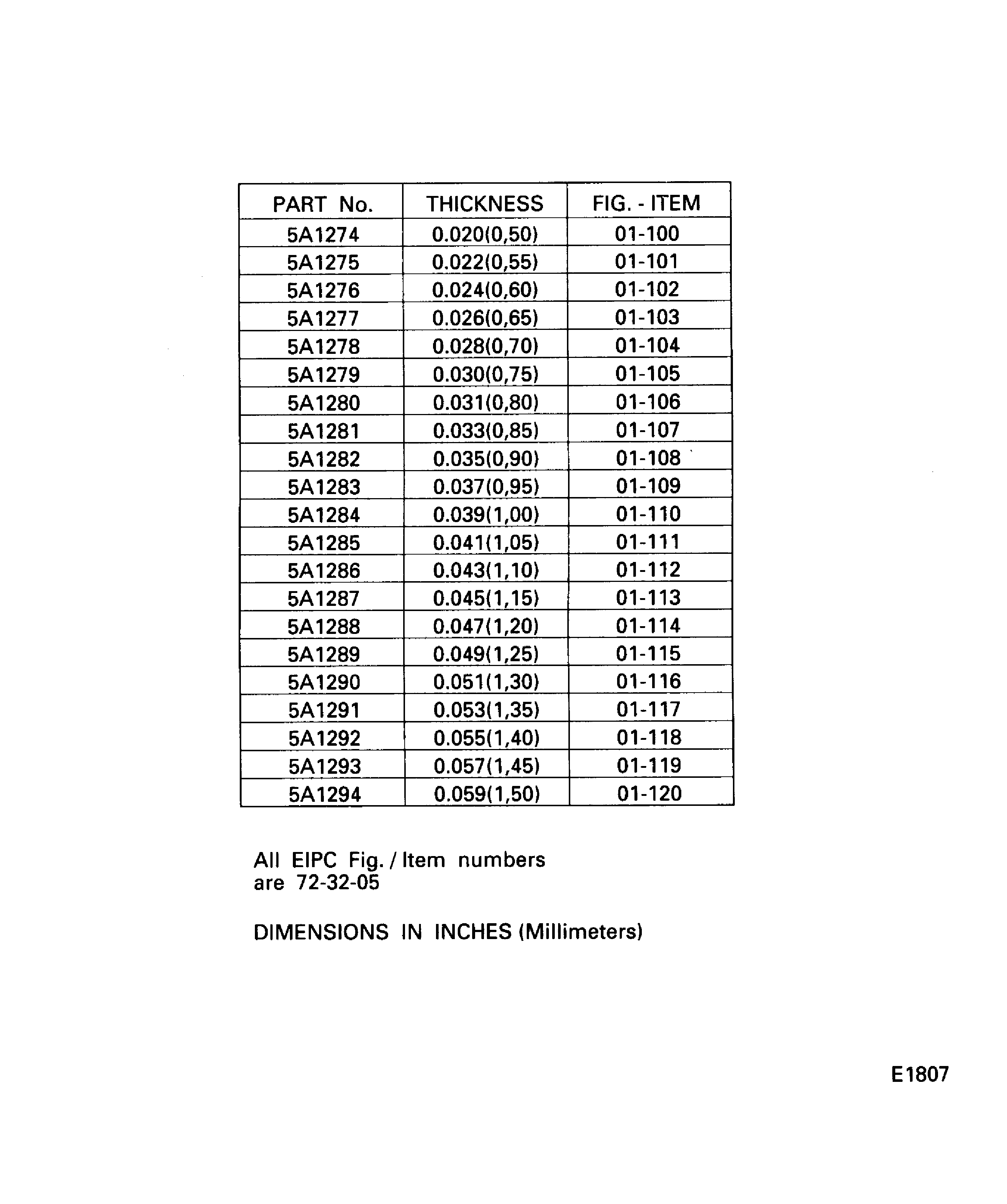

Figure: Center Bearing Adjusting Washer Thickness

Center Bearing Adjusting Washer Thickness

Figure: Install the Oil Seal Tube in to the No. 6 Strut of the Fan Frame

Install the Oil Seal Tube in to the No. 6 Strut of the Fan Frame

Figure: Install the Scavenge Tube and the Hot Vent Tube in to the No. 6 and No. 3 Struts

Install the Scavenge Tube and the Hot Vent Tube in to the No. 6 and No. 3 Struts

Figure: Install the Leak Check Fixture

Sheet 1

Figure: Install the Leak Check Fixture

Sheet 2

Figure: Remove the Oil Tube Cover From the Oil Feed Adapter

Remove the Oil Tube Cover From the Oil Feed Adapter

Figure: Connect the Fitting of the Vacuum Test Cart to the Joint

Connect the Fitting of the Vacuum Test Cart to the Joint

Figure: Install the Covers on to the Scavenge Tube and the Hot Vent Tube

Install the Covers on to the Scavenge Tube and the Hot Vent Tube

Figure: Measure the Module Interface Dimensions for the Installation of the HP System Module

Measure the Module Interface Dimensions for the Installation of the HP System Module

Figure: Install the Front Bearing Compartment Rear Air Seal Assembly to the Fan Frame

Install the Front Bearing Compartment Rear Air Seal Assembly to the Fan Frame

Figure: Install the Inner Race on to the PTO Shaft

Install the Inner Race on to the PTO Shaft

Figure: Install of PTO Shaft using Installation Guide

Install of PTO Shaft using Installation Guide

Install of PTO Shaft using Installation Guide

Figure: Engage of PTO Shaft using Installation Pusher

Engage of PTO Shaft using Installation Pusher

Figure: Check of PTO Shaft Position

Check of PTO Shaft Position

Figure: Install the Holding Cap on to the PTO Shaft to Hold the PTO Shaft

Install the Holding Cap on to the PTO Shaft to Hold the PTO Shaft

Figure: The Centre Bearing Housing and the Outer Roller Bearing Fits and Clearances

The Centre Bearing Housing and the Outer Roller Bearing Fits and Clearances

Figure: Pre SBE 72-0378: Install the Name Plate Bracket, the Engine Identification Plate and the Module Identification Plate to the Fan Case

Sheet 1

Figure: SBE 72-0378: Install the Name Plate Bracket, the Engine Identification Plate and the Module Identification Plate to the Fan Case

Sheet 2