Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-35-24-300-501-D01 "Replace Damaged Section Of Tube, Axially Greater than 0.500 in (12.70 mm), By insertion, Repair 1 (VRS7001)"

General

This TASK details the procedure for the replacement of a section of tube with axial damaged greater than 0.500 in. (12.70 mm) by insertion.

Refer to VRS7001 TASK 70-35-24-300-501 (REPAIR 001) for the following.

Effectivity.

Equipment and Materials.

General.

All illustrations/Figs ref the SPM TASK 70-35-24-300-501-D01 (REPAIR 001).

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-042 OIL | LOCAL | CoMat 10-042 | ||

| CoMat 02-347 METALLIC FILLER | IE424 | CoMat 02-347 | ||

| CoMat 01-025 NITRIC ACID HNO3, TECHNICAL GRADE | LOCAL | CoMat 01-025 | ||

| CoMat 03-204 WELDING FILLER WIRE | LOCAL | CoMat 03-204 | ||

| CoMat 05-135 POLISHING BOB | LOCAL | CoMat 05-135 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

Safety Requirements

NONEProcedure

Refer to SPM TASK 70-35-24-300-501 for limitations.

Mark off section of tube to replaced.

SUBTASK 70-35-24-350-009 Prepare Damaged Tube

Allow to drain.

Coat the tube internal surfaces with a film of CoMat 10-042 OIL.

Melt the CoMat 02-347 METALLIC FILLER and allow it to flow gently into the tube.

If you will not use a bending mandrel in the tube when you bend the tube, do the subsequent procedure.

SUBTASK 70-35-24-350-010 Prepare Repair Part

Pre-heat the tube to 122 deg F (50 deg C).

As an alternative to a bending mandrel in the tube, it is permitted to use CoMat 02-347 METALLIC FILLER in the tube. Refer to Step.

Use suitable lubrication and bending mandrels or blocks.

Bend the tube to suit location, as necessary.

SUBTASK 70-35-24-350-011 Shape the Tube

Dilute to a concentration of 500 gms per litre.

Refer to SPM TASK 70-33-89-100-501.

Other brazed tube features that do not require to be replaced must be protected from acid attack.

Remove any residues of metallic filler which may remain in the tube by filling the tube with or immersing the tube in nitric acid solution.

If the tube is filled with metallic filler from Step, do the subsequent procedure.

SUBTASK 70-35-24-350-012 Remove the Metallic Filler

Refer to SPM TASK 70-31-02-310-501-001, SUBTASK 70-31-02-120-001.

Prepare the surfaces for weld.

Use chemical cleaning equipment.

Refer to SPM TASK 70-11-26-300-503.

Clean the repair area.

Thickness of Tee ring allows for weld shrinkage at each joint.

Assembly will therefore be oversize on length at this stage.

Refer to TASK 70-35-24-300-501 (REPAIR 001), for repair parts.

For orbital welding assemble the tube portions in the jig with the replacement section and two appropriate sized Tee rings in the correct position.

For manual welding assemble the tube portion in the jig with the replacement section in the correct position.

Refer to SPM TASK 70-31-02-310-501-001.

Tack weld the components.

CoMat 03-204 WELDING FILLER WIRE if required

Filler wire

NOTE

Refer also to SPM TASK 70-31-02-310-501-001.An orbital weld will give a neater result, but is not mandatory.Use orbital welding equipment. To be determined by a suitable test piece.

Torch, Electrode, Argon backing flow, Argon torch flow, and Current

SUBTASK 70-35-24-310-005 Weld the Components

Use CoMat 05-135 POLISHING BOB or similar.

Remove weld discoloration by lightly polishing.

SUBTASK 70-35-24-140-003 Clean the Repair Area

Refer to SPM TASK 70-31-02-310-501-001.

Visually examine and measure the dimension using the jig.

SUBTASK 70-35-24-220-004 Examine the Repair

Use CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) or CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY), with penetrant crack test equipment.

Cracks are not permitted.

Refer to SPM TASK 70-23-05-230-501.

Do a local penetrant crack test on the weld.

SUBTASK 70-35-24-230-004 Do a Crack Test

Refer to SPM TASK 70-26-01-260-501 and SPM TASK 70-31-02-310-501-003, SUBTASK 70-31-02-260-003.

Radiographically examine the weld.

SUBTASK 70-35-24-260-003 Radiographically Examine the Weld

SUBTASK 70-35-24-780-004 Do an Air Leak Test on the Tube

WARNING

BLEED ALL THE AIR FROM THE TUBE BEFORE THE HYDRAULIC PRESSURE TEST IS STARTED.

WARNING

MAKE SURE THAT THE SAFETY GUARDS ARE IN POSITION AROUND THE TUBE BEFORE DOING THE HYDRAULIC PRESSURE TEST.

WARNING

STOP THE PRESSURE TEST IF A LEAK IS FOUND. DO NOT REPAIR THE LEAK, OR ADJUST THE ADPATERS OR THE BLANKS WHILST THE TUBE IS PRESSURIZED.

WARNING

BE CAREFUL WHEN YOU USE COMPRESSED AIR. PUT ON PROTECTIVE CLOTHING AND GOGGLES.

CAUTION

DO NOT PRESSURIZE THE TUBE ABOVE THE MAXIMUM PRESSURE GIVEN. IT CAN CAUSE DAMAGE TO THE TUBE. IF THE PRESSURE IN THE TUBE GETS TO MORE THAN THE MAXIMUM GIVEN, REJECT THE TUBE.Connect the tube to the hydraulic pressure test rig.

SUBTASK 70-35-24-780-007 Do a Hydraulic Pressure Test (If Required)

Use electrolytic etch equipment.

Alternatively it is permitted to use vibro-engraving equipment on cast or forged surfaces only.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Make a mark VRS7001/4 adjacent to the part number.

SUBTASK 70-35-24-350-013 Identify the Repair

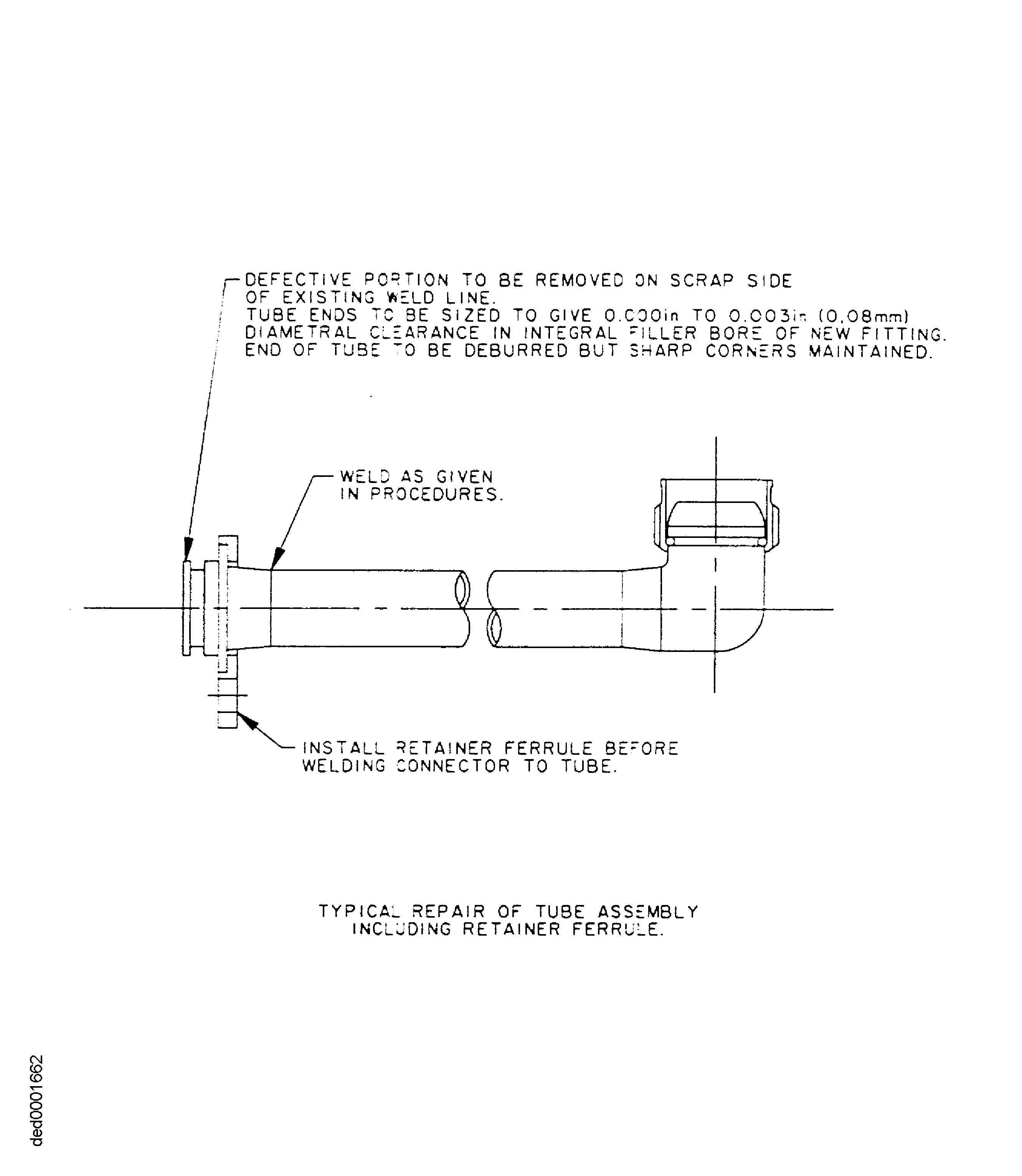

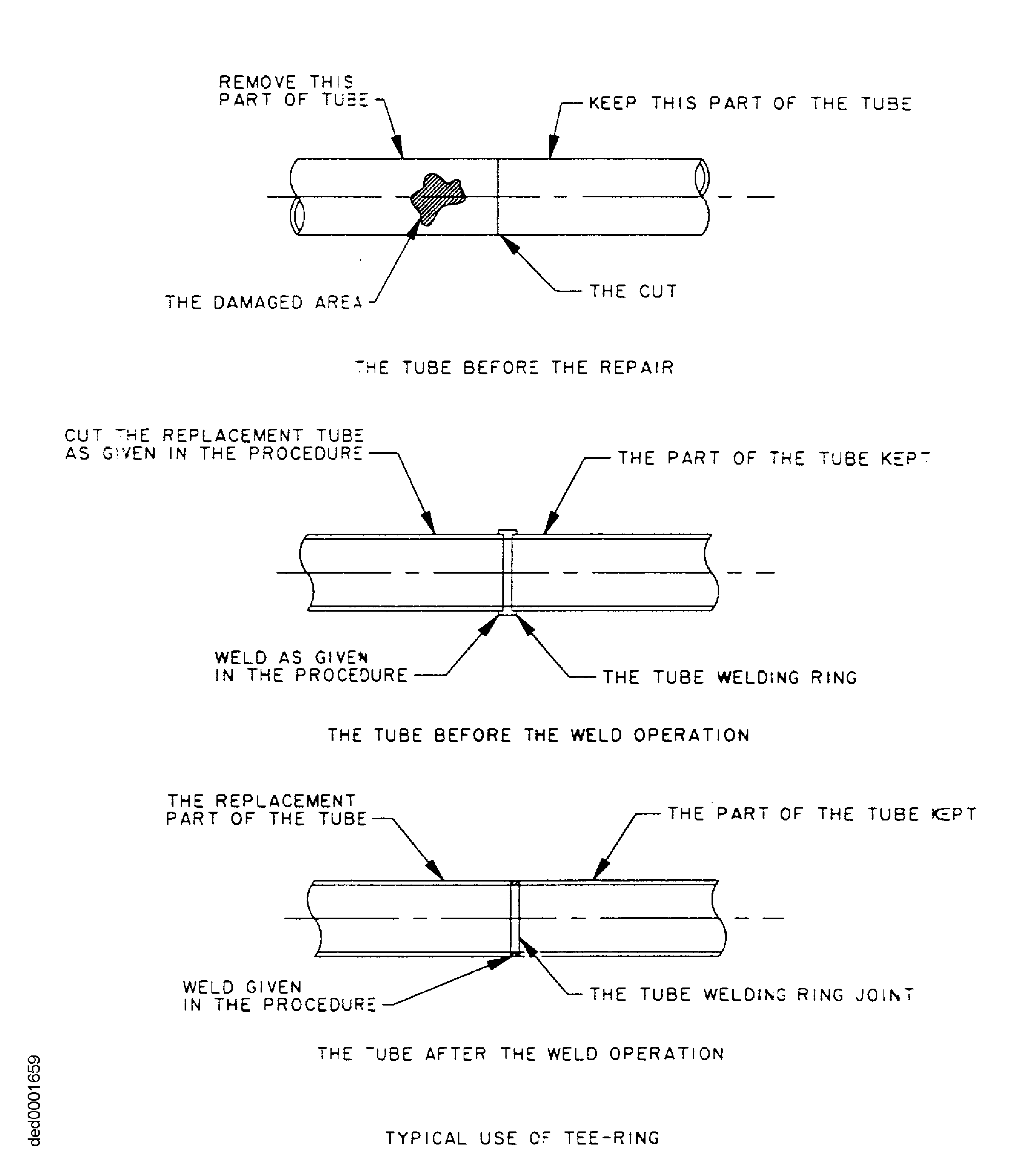

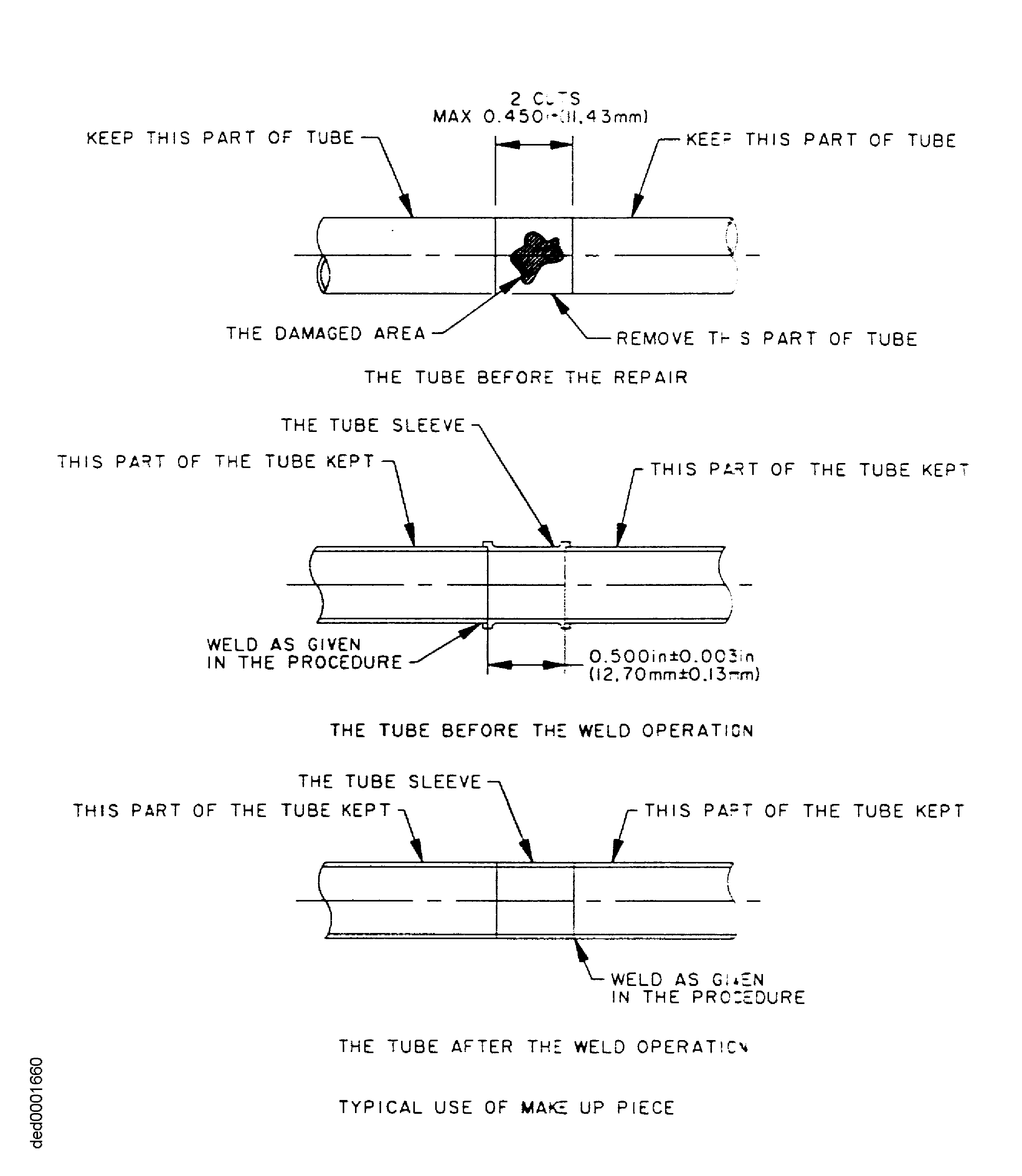

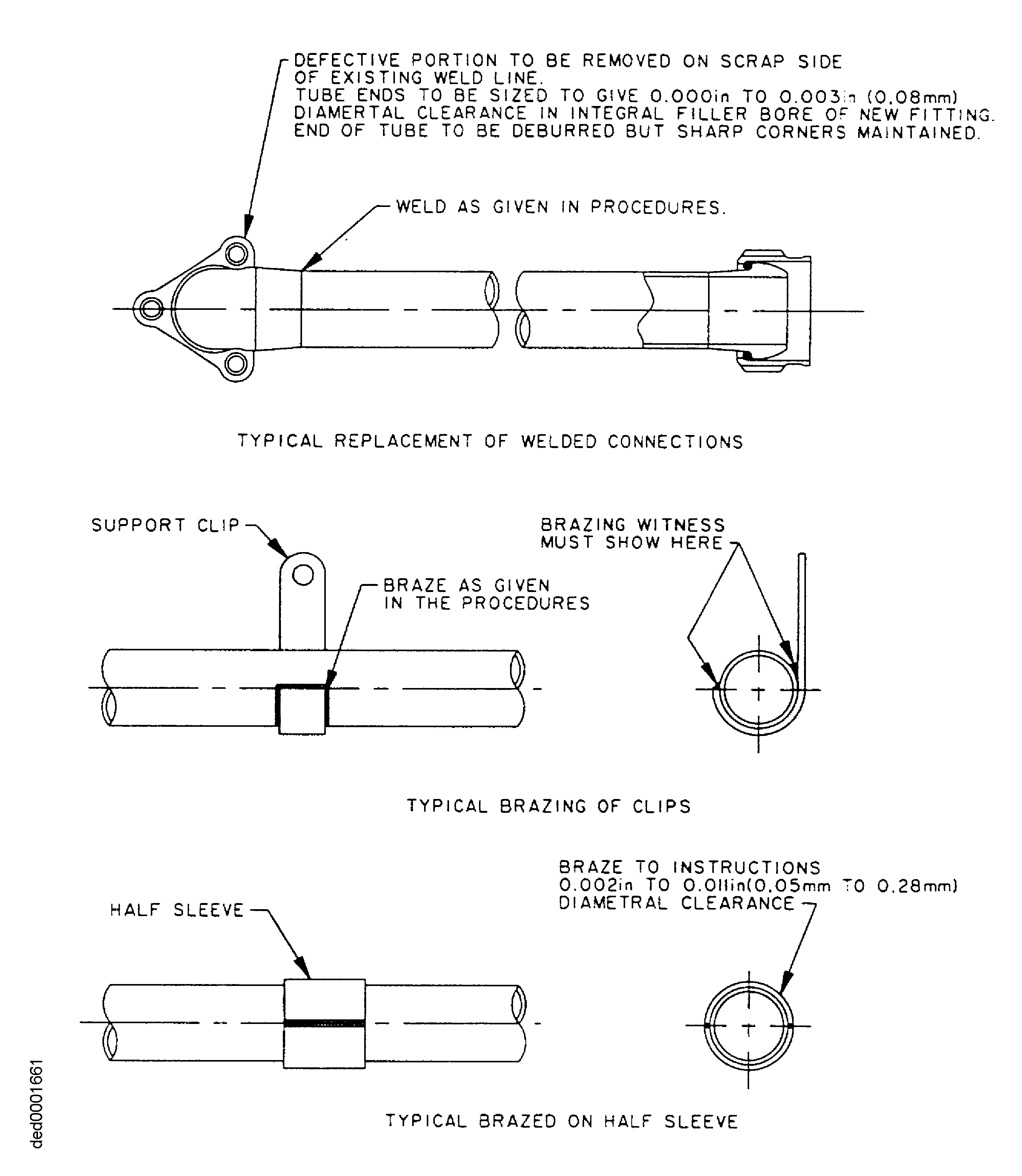

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions