Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-31-11-300-024 LPC Fan Blade - Restore Fatigue Strength Of The Root By Shot Peening, Repair 024 (VRS1723)

Effectivity

FIG/ITEM | PART NO. | ASSEMBLY |

|---|---|---|

01-300 | 6A3494 | A |

01-300 | 6A3971 | A |

01-300 | 6A5485 | B |

01-300 | 6A4700 | B |

01-300 | 6A6519 | B |

01-300 | 6A6521 | B |

01-300 | 6A7656 | B |

01-300 | 6A7403 | B |

01-300 | 6A7613 | C |

01-300 | 6A7614 | C |

01-300 | 6A7651 | C |

01-300 | 6A7652 | C |

01-300 | 6A7653 | C |

01-300 | 6A7654 | C |

01-300 | 6A7655 | C |

01-300 | 6A7658 | C |

01-300 | 6A7649 | D |

01-300 | 6A7650 | D |

Material of component

PART IDENT | IAE SYMBOL | MATERIAL |

|---|---|---|

LP compressor rotor blades | TFH | Titanium 6 per cent Aluminium 4 per cent Vanadium alloy |

General

This repair must only be done when the instruction to do so is given in 72-31-11 Inspection/Check, and/or SBE 72-0384

For Assembly C and Assembly D blades (post SB72-0375 and SB72-0384), make sure that the metal spray coating (Metco 58) has been removed before you carry out this Repair, refer to VRS1067 TASK 72-31-11-300-032.

To put back the surface condition on the dovetail root of the LP Compressor rotor blade(s), it is necessary to shot peen.

The shot peen part of this Repair requires to be source demonstrated and can only be done by approved vendors.

This repair can only be done four times on a blade root. When a blade root is shot peened for the first time to this repair, a code letter A is put on the blade adjacent to the part number, then B for the second time, C for the third time and finally D for the fourth time.

The practices and processes referred to in the procedures by the TASK numbers are in the SPM.

Price and availability - refer to IAE

Related repairs

LP Compressor Blades and Fillers - Replace the Chocking Pads, refer to VRS1028 TASK 72-31-11-300-013 (REPAIR-013) and VRS1022 TASK 72-31-11-300-009 (REPAIR-009).

LP Compressor Blades and Fillers - Replace the Dry Film Lubricant, refer to VRS1021 TASK 72-31-11-300-011 (REPAIR-011) and VRS1023 TASK 72-31-11-300-021 (REPAIR-021).

LP Compressor Blade - Remove and Replace the Metal Spray Coating on the Dovetail Working Flanks, refer to TASK 72-31-11-300-032 (VRS1067)

Repair Facilities

Only the shot peening part of this Repair requires Source Demonstration. This means that any facility not authorised to shot peen should either use the Authorized Repair Vendor in B. that follows or contact the IAE Repair Services Group to determine if a qualification program can be initiated at their facility.

IAE - INTERNATIONAL AERO ENGINES AG

C/O ROLLS-ROYCE PLC

P.O. BOX 31

DERBY DE14 8BJ

ENGLAND

ATTN: REPAIR SERVICES MANAGER

The Authorized Repair Vendor for the shot peening portion of VRS1723 is shown below:

METAL IMPROVEMENT COMPANY INC

DERBY DIVISION (UK)

ASCOT DRIVE

DERBY DE2 8ST

ENGLAND

ATTN: DIVISION MANAGER

GKN AEROSPACE CHEM-TRONICS INC

1150 WEST BRADLEY

EL CAJON

CA 92020

USA

ATTN: DIVISION MANAGER

HONG KONG AERO ENGINE SERVICES LIMITED (HAESL)

70 CHUN CHOI STREET

TSEUNG KWAN O INDUSTRIAL ESTATE

TSEUNG KWAN O

NEW TERRITORIES

HONG KONG

ATTN: DIVISION MANAGER

MTU MAINTENANCE GMBH

FLUGHAFEN HANNOVER

MUNCHER STRASSE 31

30855 LANGENHAGEN

GERMANY

ATTN: DIVISION MANAGER

SERMATECH REPAIR SERVICES LTD

HIGH HOLBORN ROAD

CODNOR

RIPLEY

DERBYSHIRE DE5 3NW

ATTN: DIVISION MANAGER

IHI corporation

229 TONOGAYA MIZUHO-MACHI, NISHITAMA-GUN,

TOKYO 190-1297

JAPAN

ATTN: CUSTOMER SUPPORT MANAGER, MAINTENANCE DEPARTMENT, CIVIL AERO-ENGINE DIVISION, AERO-ENGINE AND SPACE OPERATIONS

Tel: 81-42-568-7362

Fax: 81-42-568-7566

LUFTHANSA TECHNIK AG

POSTFACH 63 03 00

D-22313 HAMBURG

GERMANY

ATTN: DIVISION MANAGER

The designation by IAE of an Authorized Repair Vendor indicates that the Repair Vendor has demonstrated the necessary capability to enable it to carry out the listed repair work. However, IAE makes not warranties or representations concerning the qualifications or quality standards of the Repair Vendors to carry out the repair work and accepts no responsibility whatsoever for any work that may be carried out by a Repair Vendor other than when IAE is listed as the Repair Vendor. Authorized Repair Vendors do not act as agents or representatives of IAE.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Controlled shot peening equipment | LOCAL | Controlled shot peening equipment | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment | ||

| IAE 3R19129 Dummy blade | 0AM53 | IAE 3R19129 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF | LOCAL | CoMat 02-003 | ||

| CoMat 05-028 METALLIC SHOT (CAST STEEL), S230 | IE249 | CoMat 05-028 |

Spares

NONESafety Requirements

NONEProcedure

Refer to VRS1028 TASK 72-31-11-300-013 (REPAIR-013)

For Assembly A and Assembly D

Refer to VRS1022 TASK 72-31-11-300-009 (REPAIR-009)

For Assembly B and Assembly C

SUBTASK 72-31-11-350-112 Remove the Chocking Pads from the LP Compressor Rotor Blade(s)

More than in Step

Galled.

SUBTASK 72-31-11-220-101-A00 Examine the LP Compressor Rotor Blade, Assembly A and Assembly D

More than in Step.

Galled.

SUBTASK 72-31-11-220-101-B00 Examine the LP Compressor Rotor Blade(s), Assembly B and Assembly C

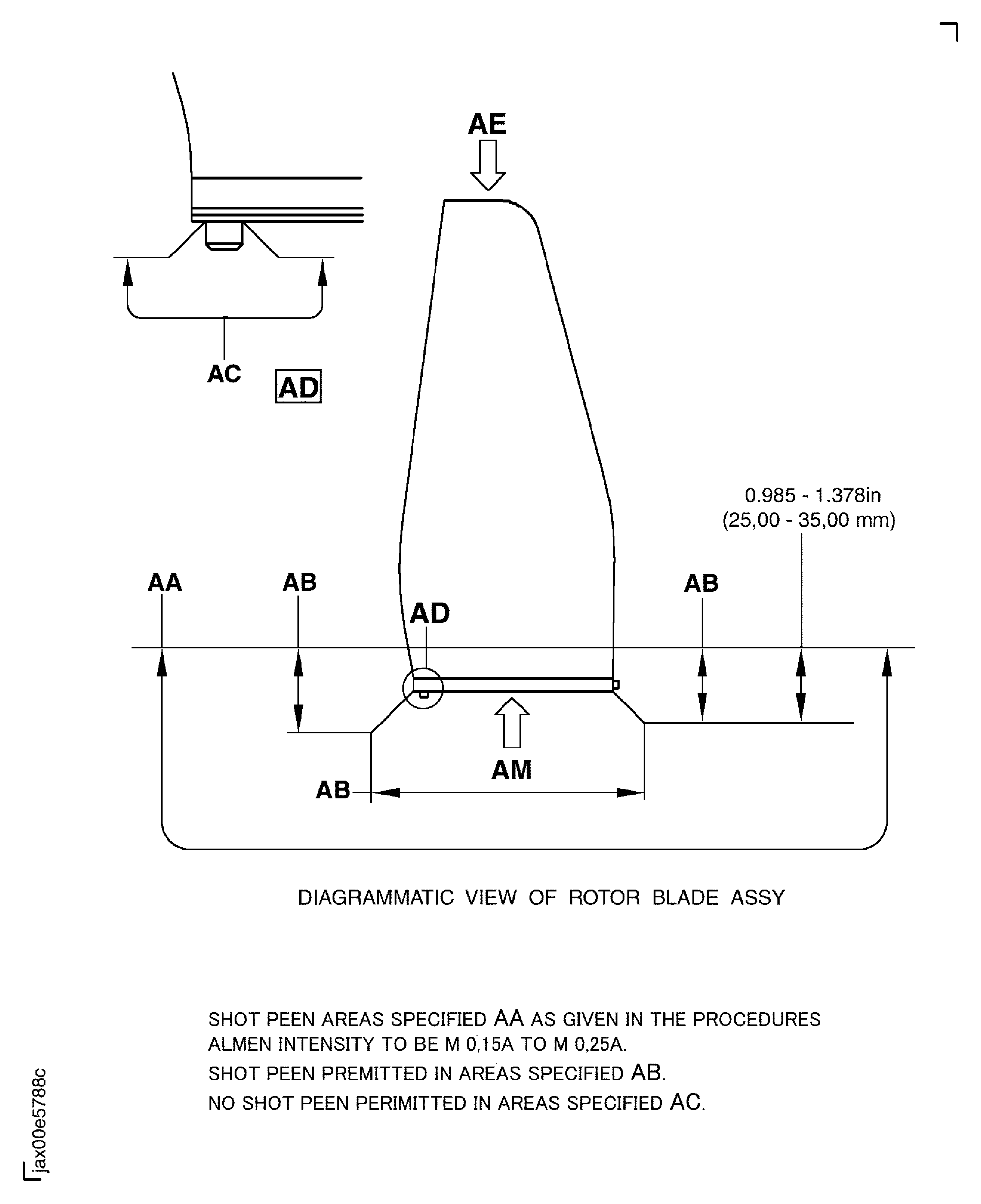

Refer to: Figure

SUBTASK 72-31-11-350-084-A00 Remove the Highspots, Galling and/or Burrs from the LP Compressor Rotor Blade, Assembly A and Assembly D

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOUR TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.DO NOT REMOVE THE BASE MATERIAL.Refer to: Figure

SUBTASK 72-31-11-350-084-B00 Remove the Highspots, Galling and/or Burrs from the LP Compressor Rotor Blade, Assembly B and Assembly C

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOUR TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.DO NOT REMOVE THE BASE MATERIAL.Use CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF or a locally made mechanical seal.

Patch mask all identification marks, symbols and location pin.

Seal the areas of the blade that are not to be shot peened.

Refer to the SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-002.

Use IAE 3R19129 Dummy blade 1 off and/or Authorized Repair Vendor

Use Co Mat 05-028 cast steel shot to get an Almen intensity of 0.006 to 0.010 in. (0.15 to 0.25 mm) on type "A" test strip.

A coverage of 200 percent must be applied.

Use controlled shot peening equipment.

NOTE

Unwanted shot-peen spray is permitted in area 'AB'.

Get the shot-peen parameter, to prove the equipment.

Shot peen the dovetail root of the LP Compressor rotor blade(s).

Shot - Peening Data

Machine type

Vacu-blast peening cabinet

Process type/mode

Dry / Auto

Shot type

Shot hardness

S230

Coverage

200 percent

Table speed

N/A

Oscillation speed

165 cycles per minute

Oscillation height

N/A

Oscillation type

N/A

Air pressure

21 to 22 p.s.i. (144.9 to 151.8 kPa)

Nozzle type / diameter

0.25 in. (6.35 mm)

Nozzle / work distance

7.24 to 11.96 in. (184 to 304 mm)

NOTE

The above depends on Nozzle Angles and position relative to the blade root.Number of nozzle

8

Almen intensity

0.006 to 0.010 in. (0.15 to 0.25 mm) using test strip "A"

NOTE

For information, the table speed and oscillation speed specified above may change if different equipment is being used.Refer to the SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-002 and Authorized Repair Vendor

Remove iron contamination as necessary, after you have shot peened.

SUBTASK 72-31-11-380-070-A00 Shot Peen the Dovetail Root of the LP Compressor Rotor Blade, Assembly A and Assembly D

Use CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF or a locally made mechanical seal.

Patch mask all identification marks, symbols and location pin.

Seal the areas of the blade that are not to be shot peened.

Refer to the SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-002.

Use IAE 3R19129 Dummy blade 1 off and/or Authorized Repair Vendor

Use CoMat 05-028 METALLIC SHOT (CAST STEEL), S230 to get an Almen intensity of 0.006 to 0.010 in. (0.15 to 0.25 mm) on type "A" test strip.

A coverage of 200 percent must be applied.

Use controlled shot peening equipment.

NOTE

Unwanted shot-peen spray is permitted in area 'AB'.

Get the shot-peen parameter, to prove the equipment.

Shot peen the dovetail root of the LP Compressor rotor blade(s).

Shot - Peening Data

Machine type

Vacu-blast peening cabinet

Process type/mode

Dry / Auto

Shot type

Shot hardness

S230

Coverage

200 percent

Table speed

N/A

Oscillation speed

165 cycles per minute

Oscillation height

N/A

Oscillation type

N/A

Air pressure

21 to 22 p.s.i. (144.9 to 151.8 kPa)

Nozzle type / diameter

0.25 in. (6.35 mm)

Nozzle / work distance

7.24 to 11.96 in. (184 to 304 mm)

NOTE

The above depends on Nozzle Angles and position relative to the blade root.Number of nozzle

8

Almen intensity

0.006 to 0.010 in. (0.15 to 0.25 mm) using test strip "A"

NOTE

For information, the table speed and oscillation speed specified above may change if different equipment is being used.Refer to the SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-002 and Authorized Repair Vendor

Remove iron contamination as necessary, after you have shot peened.

SUBTASK 72-31-11-380-070-B00 Shot-Peen the Dovetail Root of the LP Compressor Rotor Blade(s), Assembly B and Assembly C

Refer to the SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-002.

Do a visual examination of the shot peened dovetail root.

SUBTASK 72-31-11-220-102-A00 Examine the Shot Peened Dovetail Root of the LP Compressor Rotor Blade, Assembly A and Assembly D

Refer to the SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-002.

Do a visual examination of the shot peened dovetail root.

SUBTASK 72-31-11-220-102-B00 Examine the Shot Peened Dovetail Root of the LP Compressor Rotor Blade, Assembly B and Assembly C

Refer to VRS1067 TASK 72-31-11-300-032 (REPAIR-032).

Apply the metal spray coating to the dovetail root of the blade(s).

SUBTASK 72-31-11-340-005 Apply the Metal Spray Coating to the LP Compressor Rotor Blade(s), Assembly C and Assembly D

Refer, VRS1021 TASK 72-31-11-300-011 (REPAIR-011).

For Assembly A and Assembly D.

Refer, VRS1023 TASK 72-31-11-300-021 (REPAIR-021).

For Assembly B and Assembly C.

SUBTASK 72-31-11-380-071 Apply Dry Film Lubricant to the LP Compressor Rotor Blade

Refer, VRS1028 TASK 72-31-11-300-013 (REPAIR-013).

For Assembly A and Assembly D.

Refer, VRS1022 TASK 72-31-11-300-009 (REPAIR-009).

For Assembly B and Assembly C.

SUBTASK 72-31-11-350-085 Apply the Chocking Pads to the LP Compressor Rotor Blade

Refer to: Figure

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibro engraving equipment.

NOTE

The LP compressor rotor blade can only be shot peened four times to this Repair.

Mark the correct code symbol adjacent to the part number.

SUBTASK 72-31-11-350-086 Identify the Repair

Figure: Repair details and dimensions - Assembly A and Assembly D

Repair details and dimensions - Assembly A and Assembly D

Figure: Repair details and dimensions - Assembly B and Assembly C

Repair details and dimensions - Assembly B and Assembly C

Figure: Repair details and dimensions - Assemblies A, B, C and D

Repair details and dimensions - Assemblies A, B, C and D

Figure: Repair details and dimensions - Assemblies A, B, C and D

Repair details and dimensions - Assemblies A, B, C and D

Figure: Repair details and dimensions - Assemblies A, B, C and D

Repair details and dimensions - Assemblies A, B, C and D

Figure: Repair details and dimensions - Assemblies A, B, C and D

Repair details and dimensions - Assemblies A, B, C and D