Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-10-300-024 HPT Stage 1 Support Assembly - Weld Repair, Repair-024 (VRS3619)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-010 | 2A1292 |

01-010 | 2A1358 |

01-010 | 2A1664 |

01-010 | 2A2703 |

01-010 | 2A3360 |

01-010 | 2A3367 |

01-010 | 2A4085 |

General

Price and availability - refer to IAE

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fusion welding equipment | LOCAL | Fusion welding equipment | ||

| Machining equipment | LOCAL | Machining equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-284 WELDING FILLER WIRE, NiBASE | LOCAL | CoMat 03-284 |

Spares

NONESafety Requirements

CAUTION

Procedure

Wipe the area just before you weld it.

Refer to the SPM TASK 70-11-26-300-503.

Refer to the SPM TASK 70-11-03-300-503.

Clean the support.

SUBTASK 72-44-10-110-062 Clean the Stage 1 HPT Support

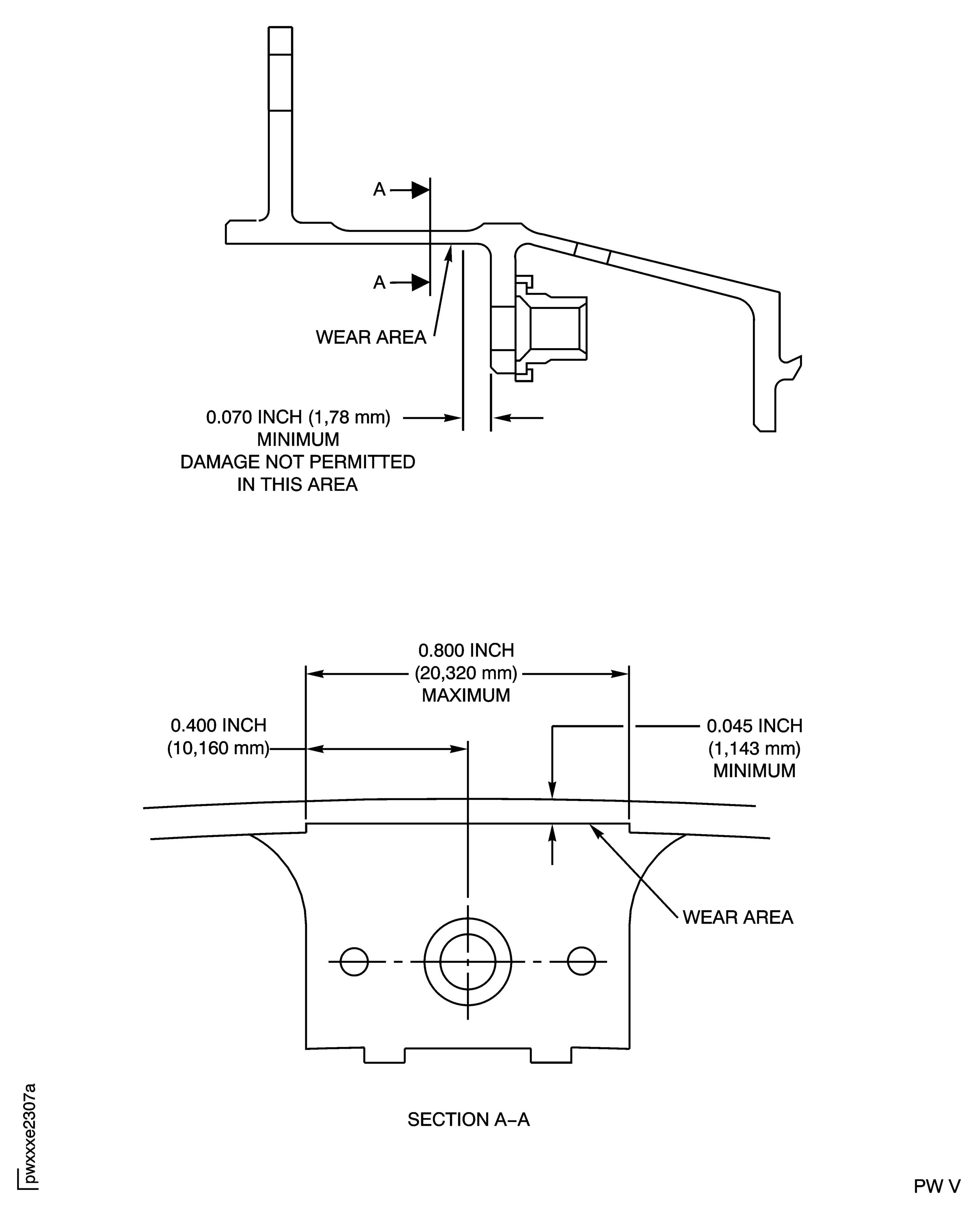

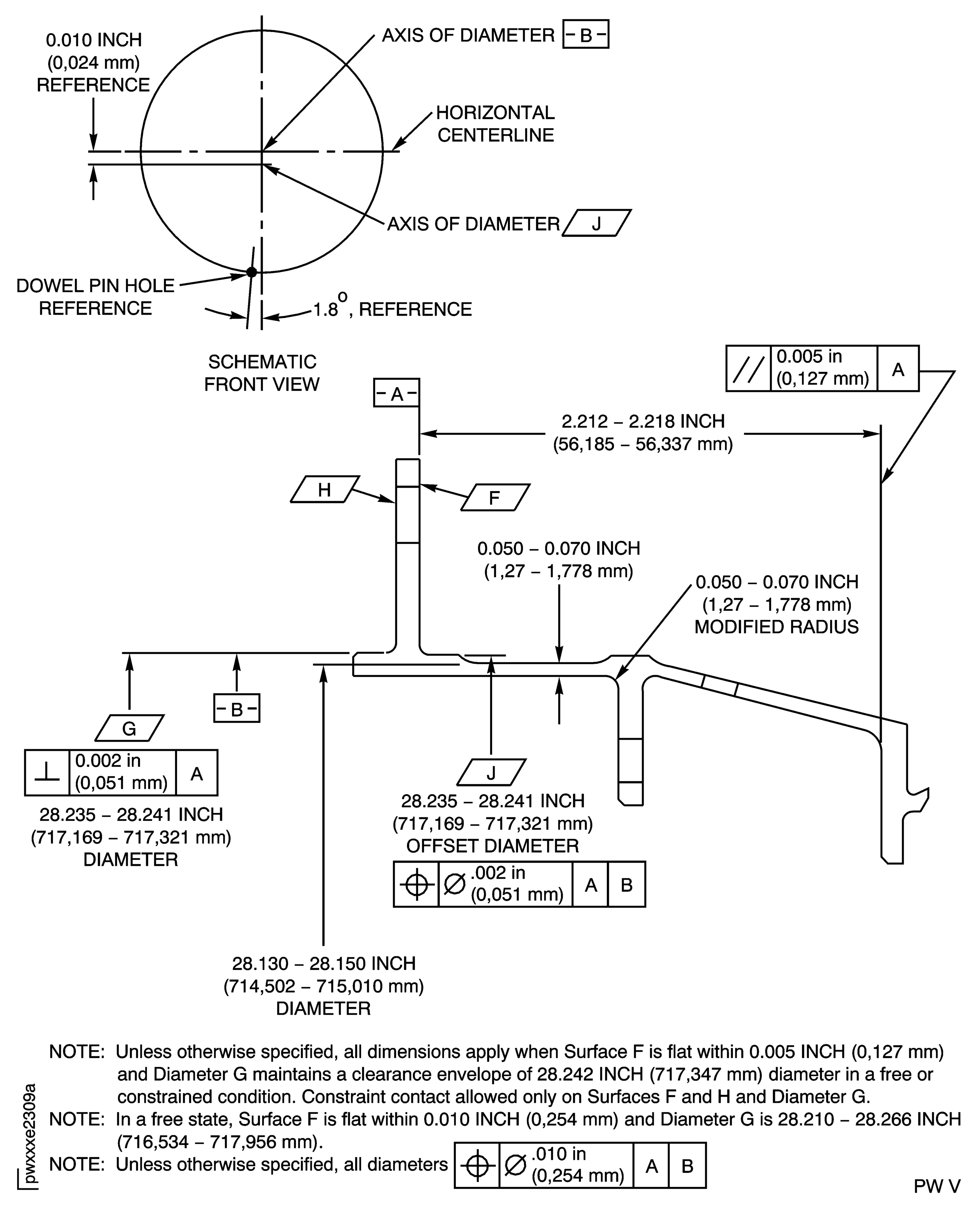

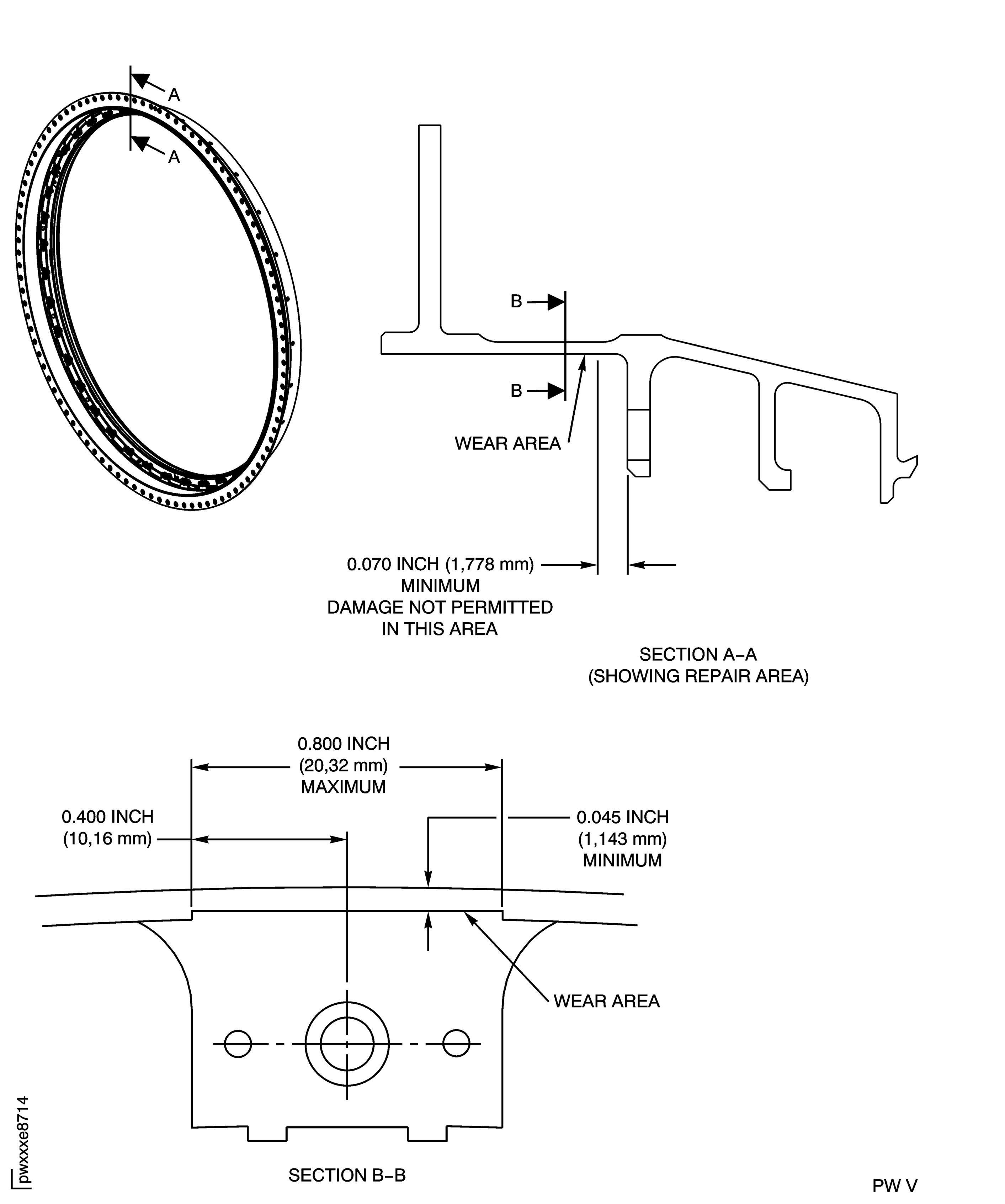

Use sufficient material to get the finish dimensions.

Refer to the SPM TASK 70-31-13-310-501.

Manually gas tungsten arc weld the worn area.

SUBTASK 72-44-10-310-007 Weld the Stage 1 HPT Support

Refer to the SPM TASK 70-37-01-370-501.

Stress-relieve the support.

SUBTASK 72-44-10-370-006 Stress-Relieve the Stage 1 HPT Support

Refer to the SPM TASK 70-11-03-300-503.

Clean the support.

SUBTASK 72-44-10-110-063 Clean the Stage 1 HPT Support

Use medium sensitivity.

No cracks are permitted.

Refer to the SPM TASK 70-23-01-230-501 or SPM TASK 70-23-02-230-501.

Fluorescent penetrant inspect the blended area.

SUBTASK 72-44-10-230-073 Fluorescent Penetrant Inspect the Blended Area

Refer to TASK 72-44-10-440-001 (ASSEMBLY-001).

Assemble the Stage 1 seal onto the Stage 1 support.

Refer to Repair, VRS3272 TASK 72-44-10-300-002 (REPAIR-002).

Install or replace the Stage 1 HPT support flange nuts.

Refer to Repair, VRS3129 TASK 72-44-10-300-007 (REPAIR-007).

If removed, apply plasma coat on the outside diameter bolt flange rear snap diameter.

Refer to Repair, VRS3270, TASK 72-44-10-300-008 (REPAIR-008).

If removed, apply plasma coat on the outside diameter bolt flange front snap diameter.

SUBTASK 72-44-10-350-070 Close Up

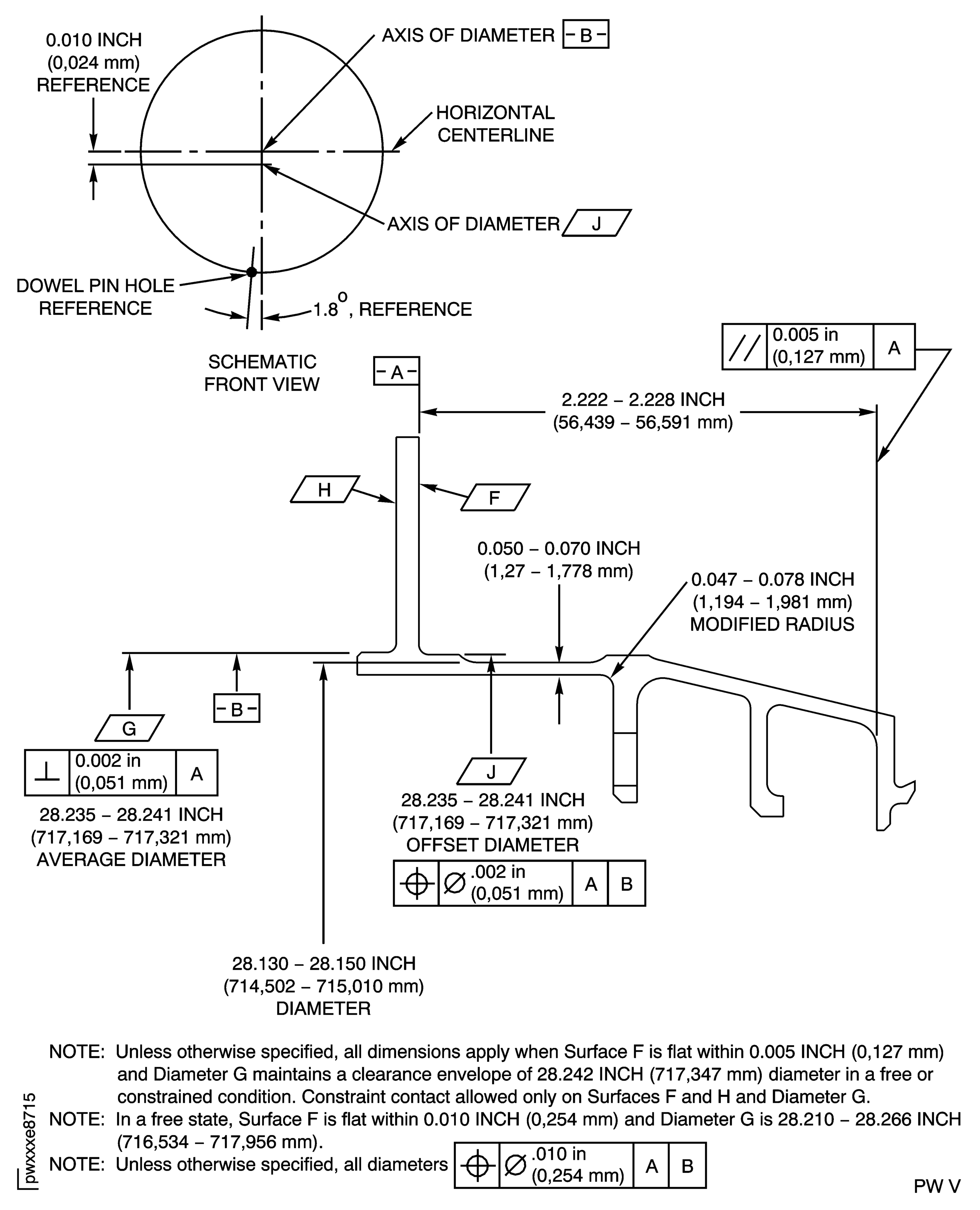

Figure: Repair Details and Dimensions (PN 2A1292, 2A1358 and 2A1664)

Sheet 1

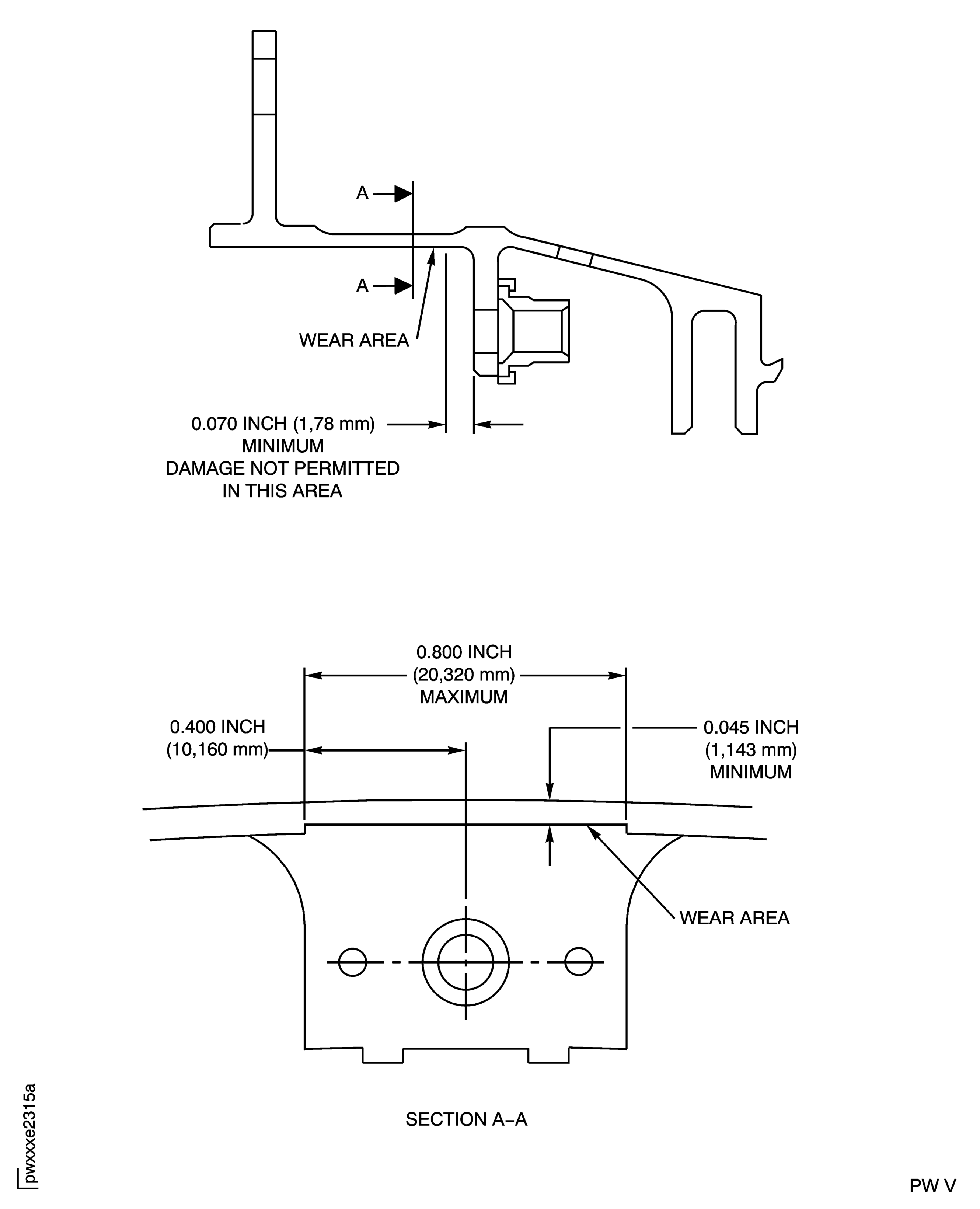

Figure: Repair Details and Dimensions (PN 2A1292, 2A1358 and 2A1664)

Sheet 2

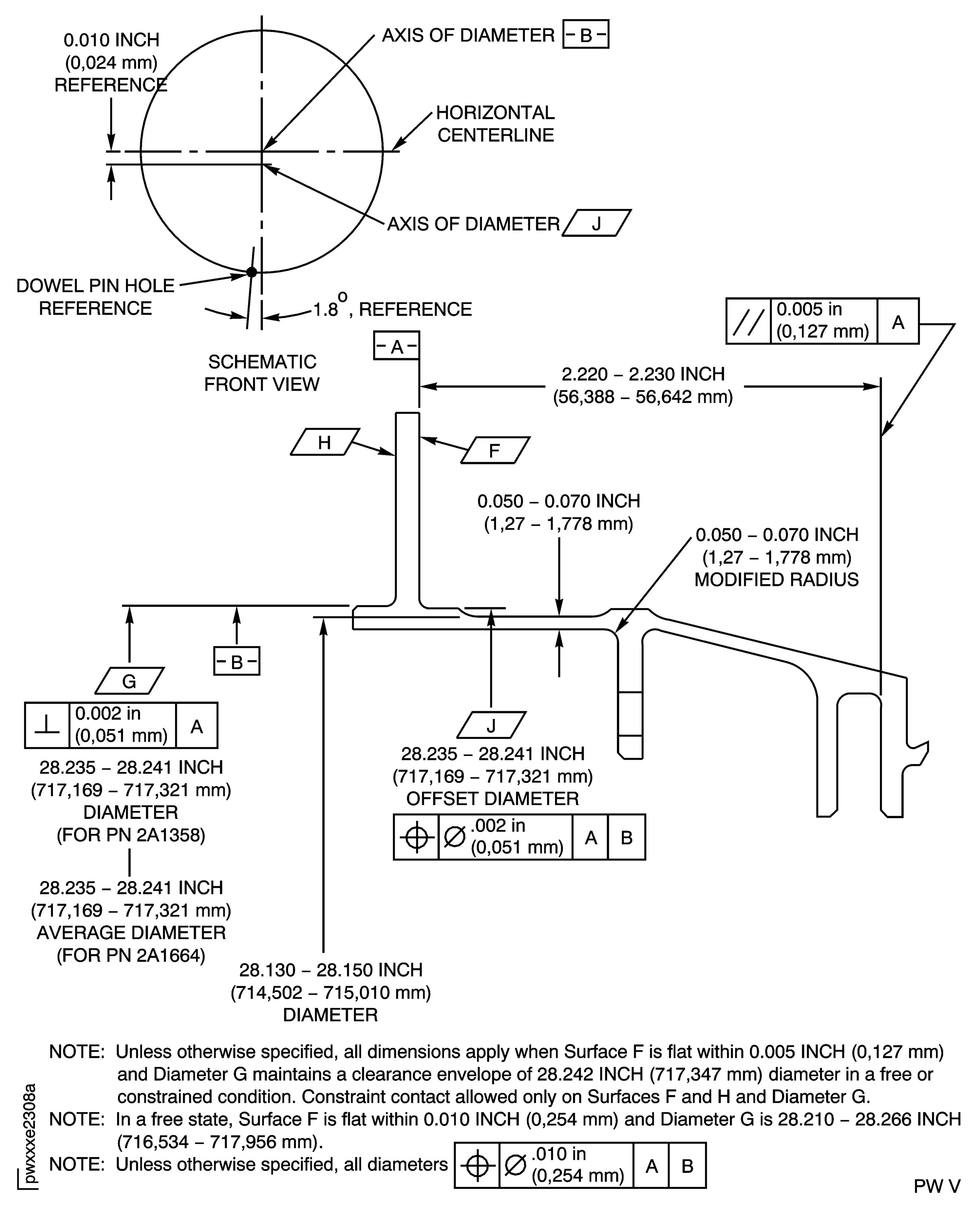

Figure: Repair Details and Dimensions (PN 2A1292)

Sheet 3

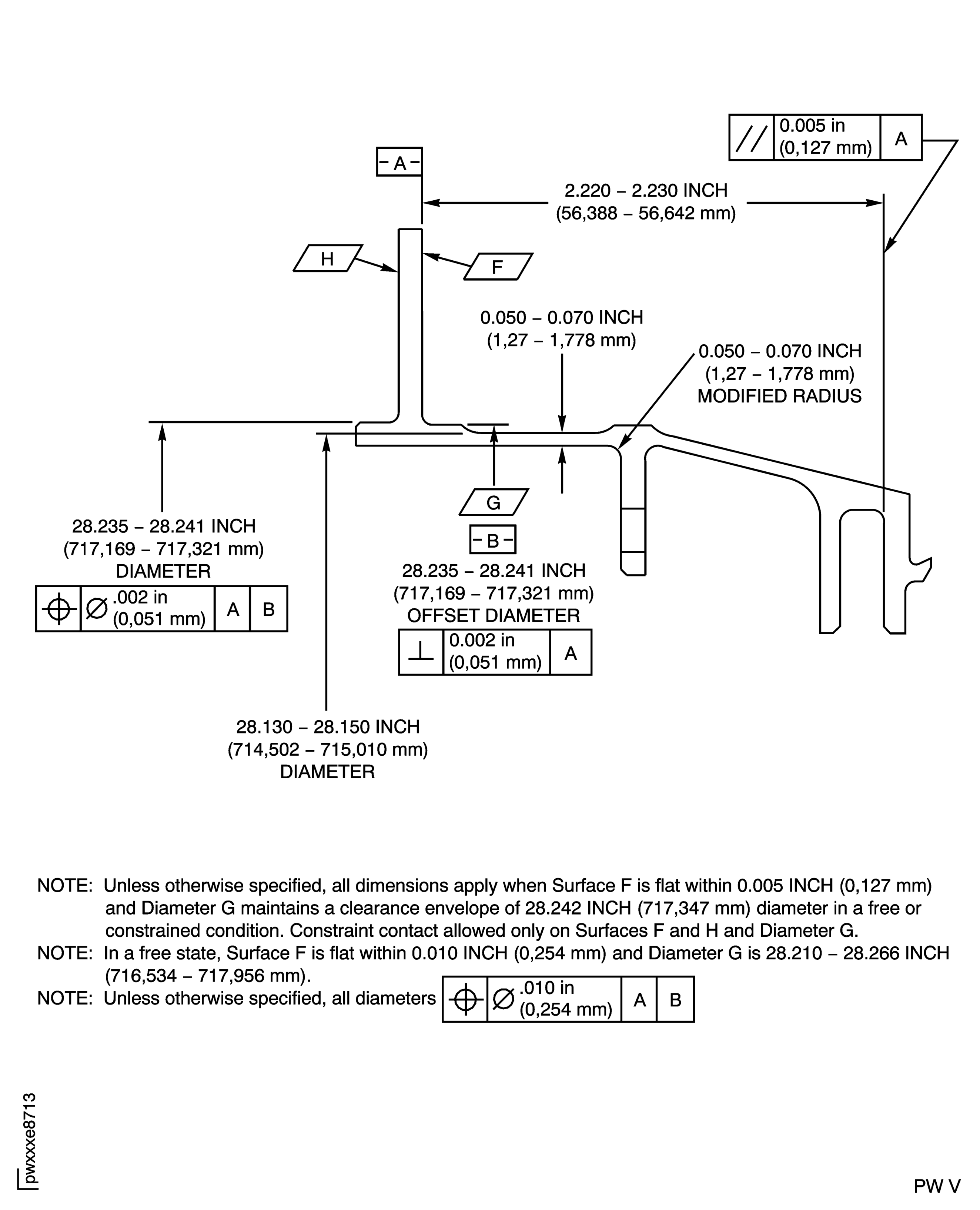

Figure: Repair Details and Dimensions (PN 2A2703, 2A3360 and 2A3367)

Sheet 1

Figure: Repair Details and Dimensions (PN 2A2703, 2A3360 and 2A3367)

Sheet 2

Figure: Repair Details and Dimensions (PN 2A4085)

Sheet 1

Figure: Repair Details and Dimensions (PN 2A4085)

Sheet 2