Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-53-300-083 Turbine Exhaust Case (TEC) - Weld Patch Repair The Strut, Repair-083 (VRS3743)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

02-300 | 4B8060 |

02-300 | 4B8068 |

21-300 | 2A1209-01 |

21-300 | 2A2620-01 |

21-300 | 2A3111-01 |

21-300 | 2A3183-01 |

21-300 | 2A3455-01 |

21-300 | 2A3183-101 |

21-300 | 2A4258-01 |

21-300 | 2A4263-01 |

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

Turbine exhaust case | - | Corrosion and heat resistant steel |

General

Price and availability - refer to IAE

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Remove adjacent hardware which will interfere with or be affected by the strut repair such as tubes, mount rail bushings, to nut plate details.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Silicon carbide rag wheel | LOCAL | Silicon carbide rag wheel | or equivalent |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-007 ETHYL ALCOHOL C2H5OH (DENATURED) | LOCAL | CoMat 01-007 | ||

| CoMat 03-378 WELDING WIRE | LOCAL | CoMat 03-378 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 | ||

| CoMat 06-061 DELETED | 0AM53 | CoMat 06-061 |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-37-28-370-501. The hardness must be Rockwell 30 to 38 or equivalent.

Stress-relieve the patch.

SUBTASK 72-50-53-320-165 Make a Patch to Repair the Damaged Strut Airfoil

Use a lint-free cloth. Refer to the SPM TASK 70-11-26-300-503. Use CoMat 01-007 ETHYL ALCOHOL C2H5OH (DENATURED).

Clean the weld areas inside and outside of the strut and the patch.

SUBTASK 72-50-53-110-187 Clean the Areas to be Welded

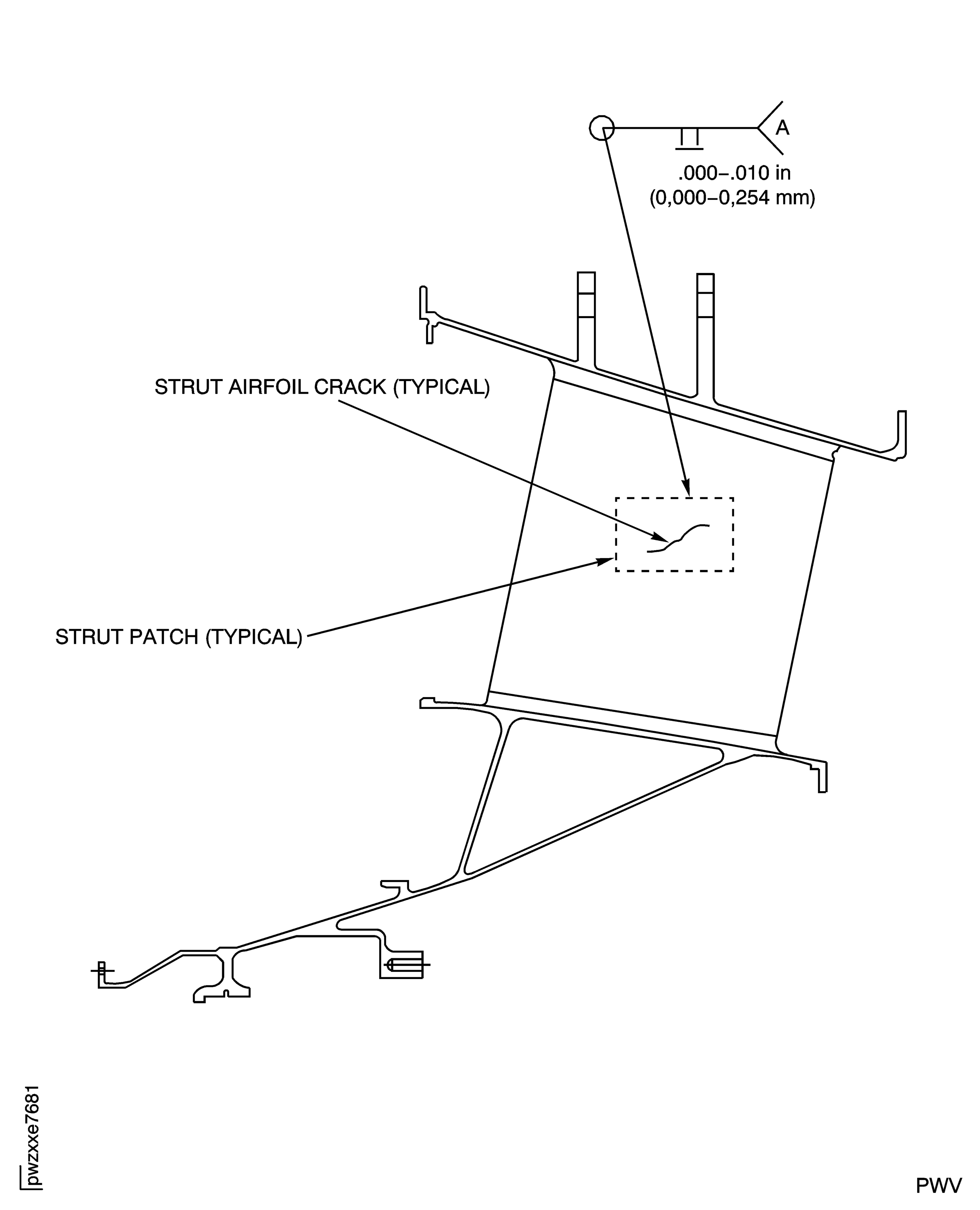

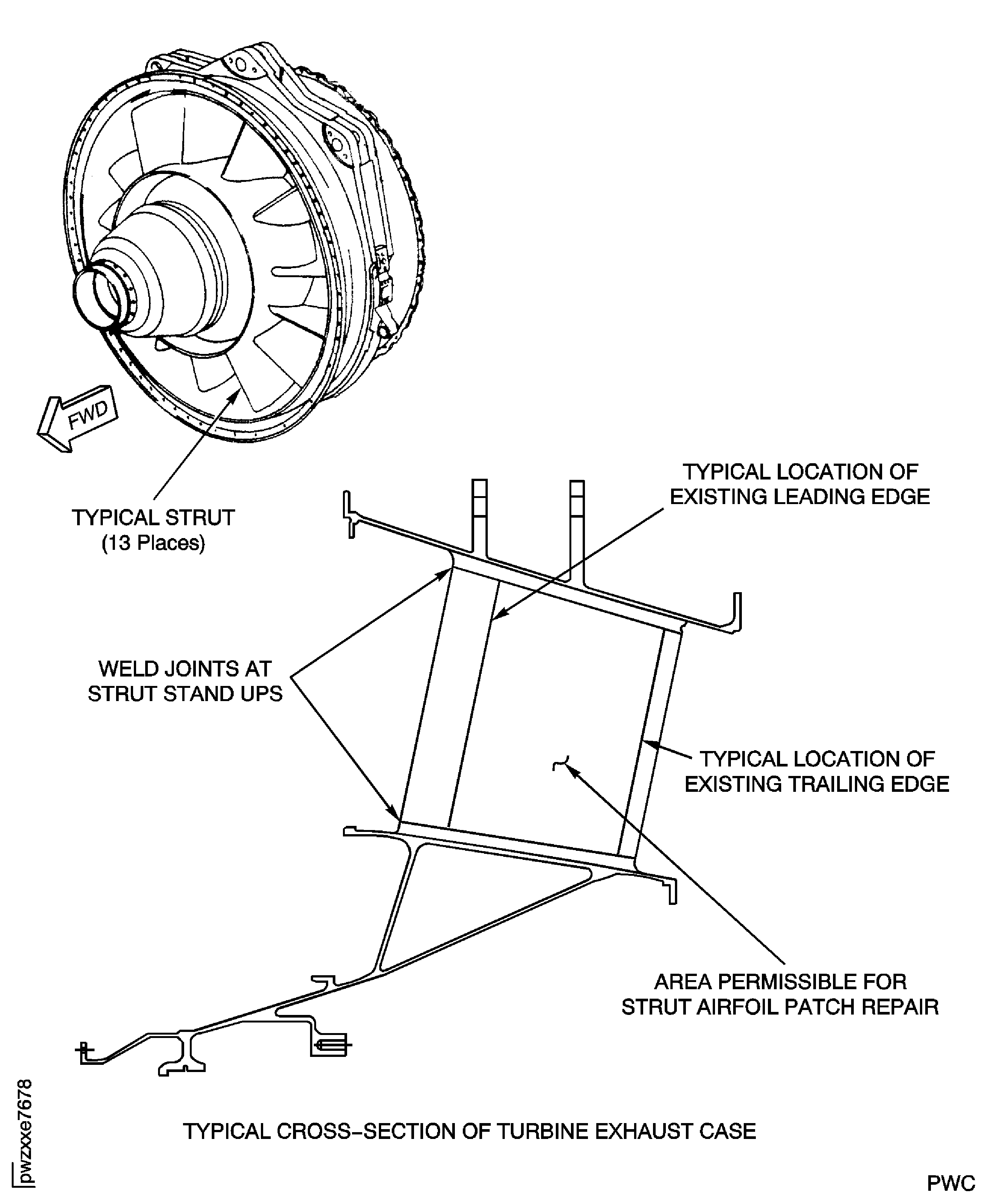

Refer to Figure.

Refer to the SPM TASK 70-31-02-310-501-008. Use CoMat 03-378 WELDING WIRE.

Tack weld the patch to replace the damaged area. Tack welds must be 1.5 to 2.0 in. (38.1 to 50.8 mm) apart around the patch.

Refer to the SPM TASK 70-31-02-310-501-008. Use CoMat 03-378 WELDING WIRE and the GTAW method. Full weld penetration is necessary.

Weld the patch onto the turbine exhaust case strut.

SUBTASK 72-50-53-310-083 Weld the Patches onto the Strut Airfoil

Refer to the SPM TASK 70-37-13-370-501, Cycle 6A.

Locally stress-relieve the repaired area.

SUBTASK 72-50-53-370-100-001 Stress-Relieve the Repaired Area (Local)

Repair, VRS3014 TASK 72-50-53-300-046 (REPAIR-046) or VRS5392 TASK 72-50-53-300-008 (REPAIR-008).

Remove the helicoils at the bearing compartment cover and at the bearing jumper tube boss.

Repair, VRS3019 TASK 72-50-53-300-054 (REPAIR-054) or VRS5413 TASK 72-50-53-300-029 (REPAIR-029).

Remove the nut plates from the inner rear flange.

Repair, VRS3256 TASK 72-50-53-300-069 (REPAIR-069).

Remove the three nut plates at the carbon seal flange.

Refer to the SPM TASK 70-37-13-370-501, Cycle 6A.

Stress-relieve the case in an oven.

SUBTASK 72-50-53-370-100-002 Stress-Relieve the Repaired Area (Oven)

Refer to the SPM TASK 70-23-05-230-501.

Use CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) or CoMat 06-061 DELETED.

No cracks are permitted.

Examine the case after local stress-relief.

SUBTASK 72-50-53-230-137-001 Examine the Repaired Areas (After Local Stress-Relief)

Refer to the SPM TASK 70-23-01-230-501 or SPM TASK 70-23-02-230-501.

Use CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) or CoMat 06-061 DELETED.

No cracks are permitted.

Examine the case after stress-relief in an oven.

SUBTASK 72-50-53-230-137-002 Examine the Repaired Areas (After Stress-Relief in an Oven)

Repair, VRS3256 TASK 72-50-53-300-069 (REPAIR-069).

Install the nutplates at the carbon seal flange, if applicable.

Repair, VRS3019 TASK 72-50-53-300-054 (REPAIR-054) or VRS5413 TASK 72-50-53-300-029 (REPAIR-029).

Remove the nut plates from the inner rear flange.

Repair, VRS3014 TASK 72-50-53-300-046 (REPAIR-046) or VRS5392 TASK 72-50-53-300-008 (REPAIR-008).

Remove the helicoils at the bearing compartment cover and at the bearing jumper tube boss.

SUBTASK 72-50-53-350-200 Install the Detail Parts

Refer to TASK 72-50-53-200-000 (INSPECTION/CHECK-000).

Examine the dimensions of the turbine exhaust case.

SUBTASK 72-50-53-220-250 Examine the Turbine Exhaust Case After Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions