Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-32-70-440-001-A00 LPC Bleed Valve And Actuating System - Assemble, Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures refer to the SPM TASK 70-64-02-640-501, SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

Special torque data and assembly tolerances are included in this procedure.

Special torque data is identified with the symbol * after the torque value.

Lubricate all the threads and mating faces of the nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify and install key washers, refer to SPM TASK 70-42-03-400-501.

The abbreviation Intf shows an interference or tight fit. This causes REJECT IF MORE THAN to become REJECT IF LESS THAN. The abbreviation Clear shows a clearance fit.

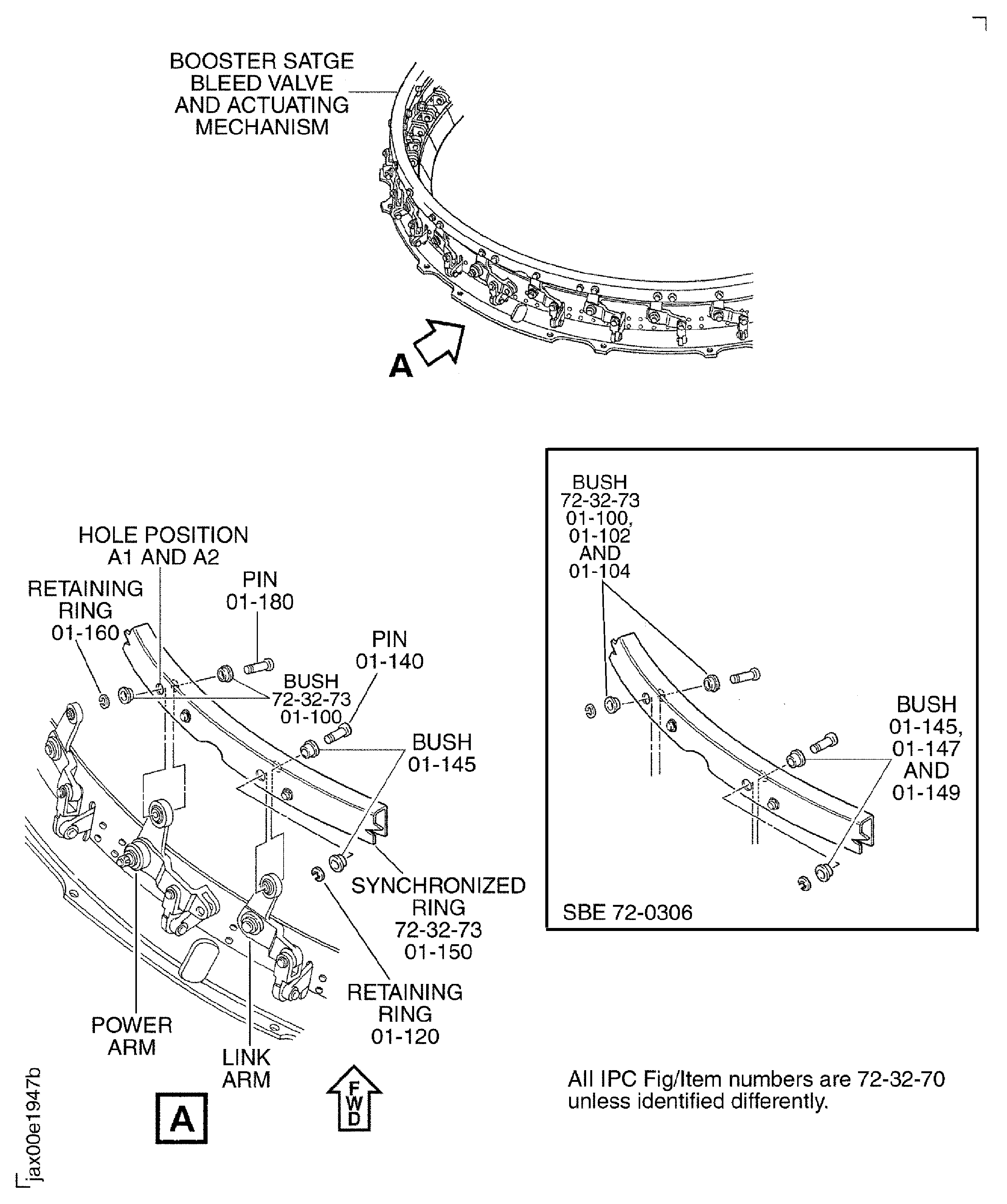

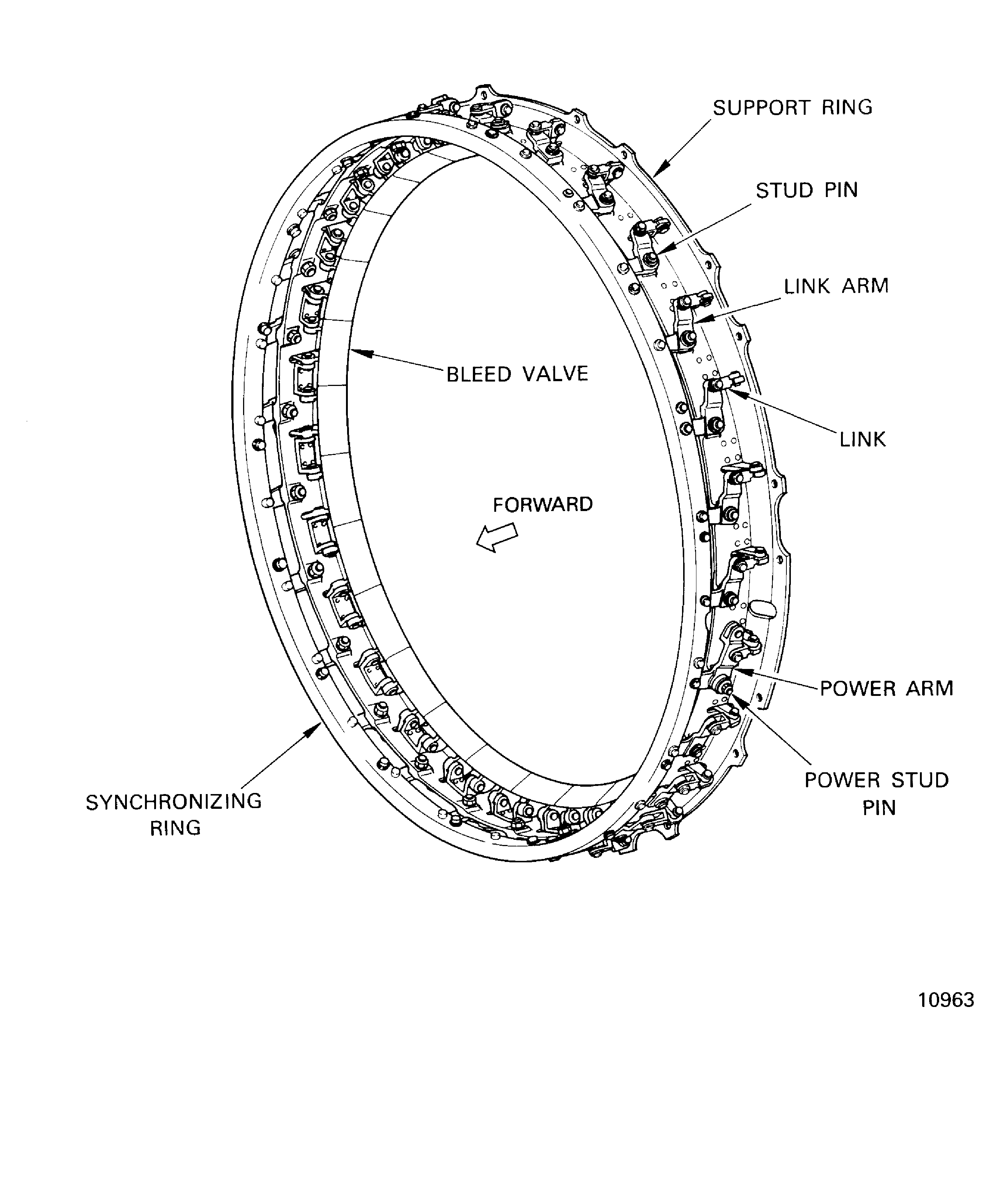

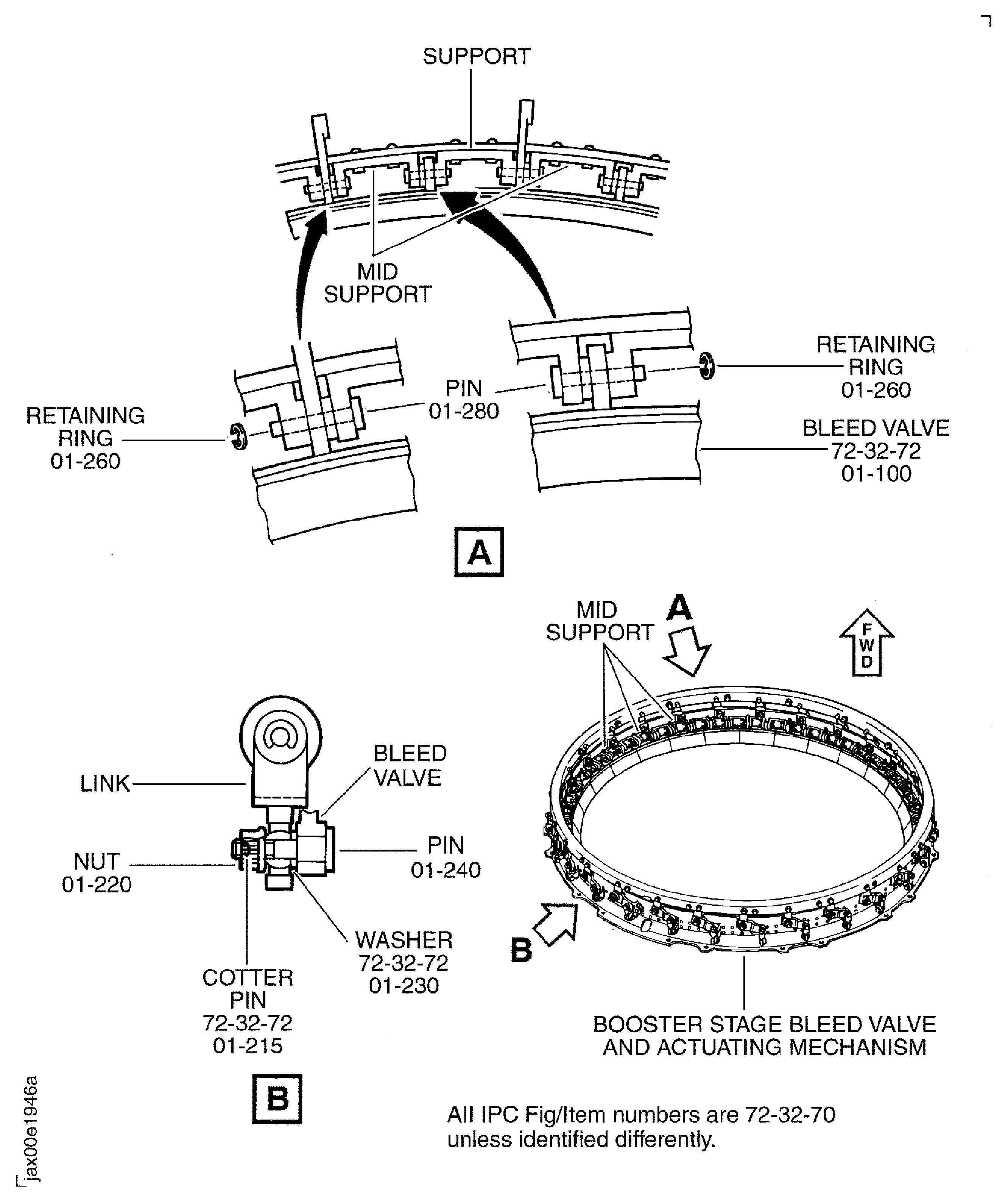

Refer to Figure for a view of the booster stage bleed valve and actuating mechanism, Pre SBE 72-0133.

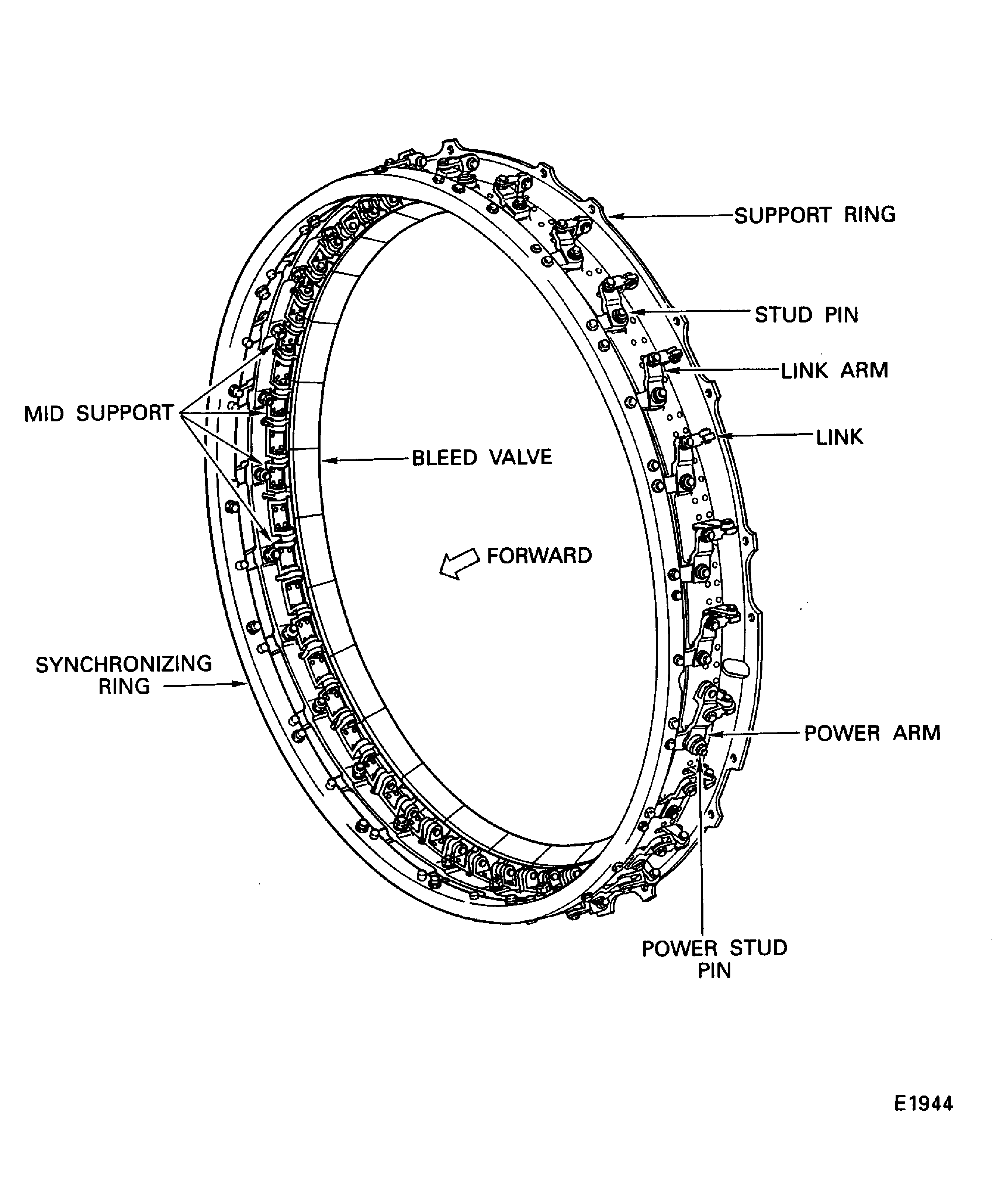

Refer to Figure for a view of the booster stage bleed valve and actuating mechanism, SBE 72-0133.

This TASK gives the procedure to assemble the booster stage bleed valve and actuating mechanism.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1J12209 Installation holder | 0AM53 | IAE 1J12209 | 1 | or equivalent |

| IAE 1J12216 Installation holder or equialent | 0AM53 | IAE 1J12216 | 1 | or equivalent |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

Safety Requirements

NONEProcedure

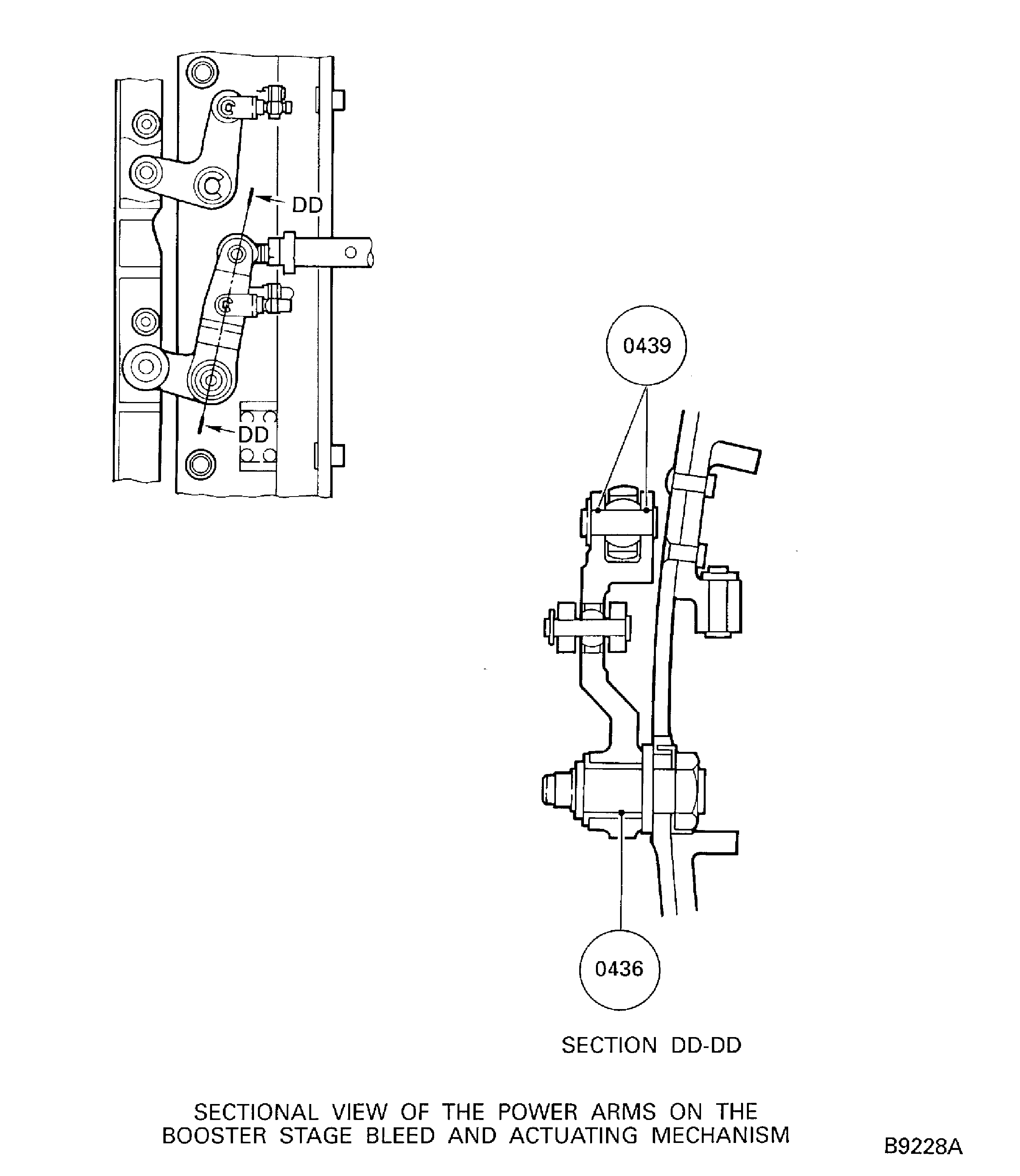

Refer to Figure.

Reference dimensions at location 0436. If required, use the data written as a note in TASK 72-32-71-200-000 (INSPECTION-000).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0436

Power Arm ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-300), Inner Diameter

Stud Pin ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-550), Stem Diameter

Power Arm Inner Diameter

0.5015

0.5005

0.0022

Stud Pin Stem Diameter

0.5000

0.0005

0.4993

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0436

Power arm ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-300), Inner Diameter

Stud Pin ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-550), Stem Diameter

Power Arm Inner Diameter

12.738

12.713

0.056

Stud Pin Stem Diameter

12.700

0.013

12.682

SUBTASK 72-32-70-220-073 Reference Fits and Clearances of the Power Arm and the Stud Pin at Location 0436

Refer to Figure.

Reference dimensions at location 0439. If required, use the data written as a note in TASK 72-32-71-200-000 (INSPECTION-000) and TASK 72-32-00-200-000 (INSPECTION-000).

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0439

Power Arm ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-300), Inner Diameter

Pin ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-720), Outside Diameter

Power Arm Inner Diameter

0.2505

0.2500

0.0031

Pin Outside Diameter

0.2480

0.0020

0.2474

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0439

Power Arm ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-300), Inner Diameter

Pin ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-720), Outside Diameter

Power Arm Inner Diameter

6.365

6.350

0.080

Pin Outside Diameter

6.300

0.050

6.285

SUBTASK 72-32-70-220-074-A00 Reference Fits and Clearances of the Power Arm and the Pin at Location 0439 (Pre SBE 72-0133)

Refer to Figure.

Reference dimensions at location 0439. If required, use the data written as a note in TASK 72-32-71-200-000 (INSPECTION-000) and TASK 72-32-00-200-000 (INSPECTION-000).

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0439

Power Arm ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-300), Inner Diameter

Pin ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-720), Outside Diameter

Power Arm Inner Diameter

0.2505

0.2500

0.0016

Pin Outside Diameter

0.2495

0.0005

0.2489

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0439

Power Arm ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-300), Inner Diameter

Pin ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-720), Outside Diameter

Power Arm Inner Diameter

6.365

6.350

0.043

Pin Outside Diameter

6.337

0.013

6.322

SUBTASK 72-32-70-220-074-B00 Reference Fits and Clearances of the Power Arm and the Pin at Location 0439 (SBE 72-0133)

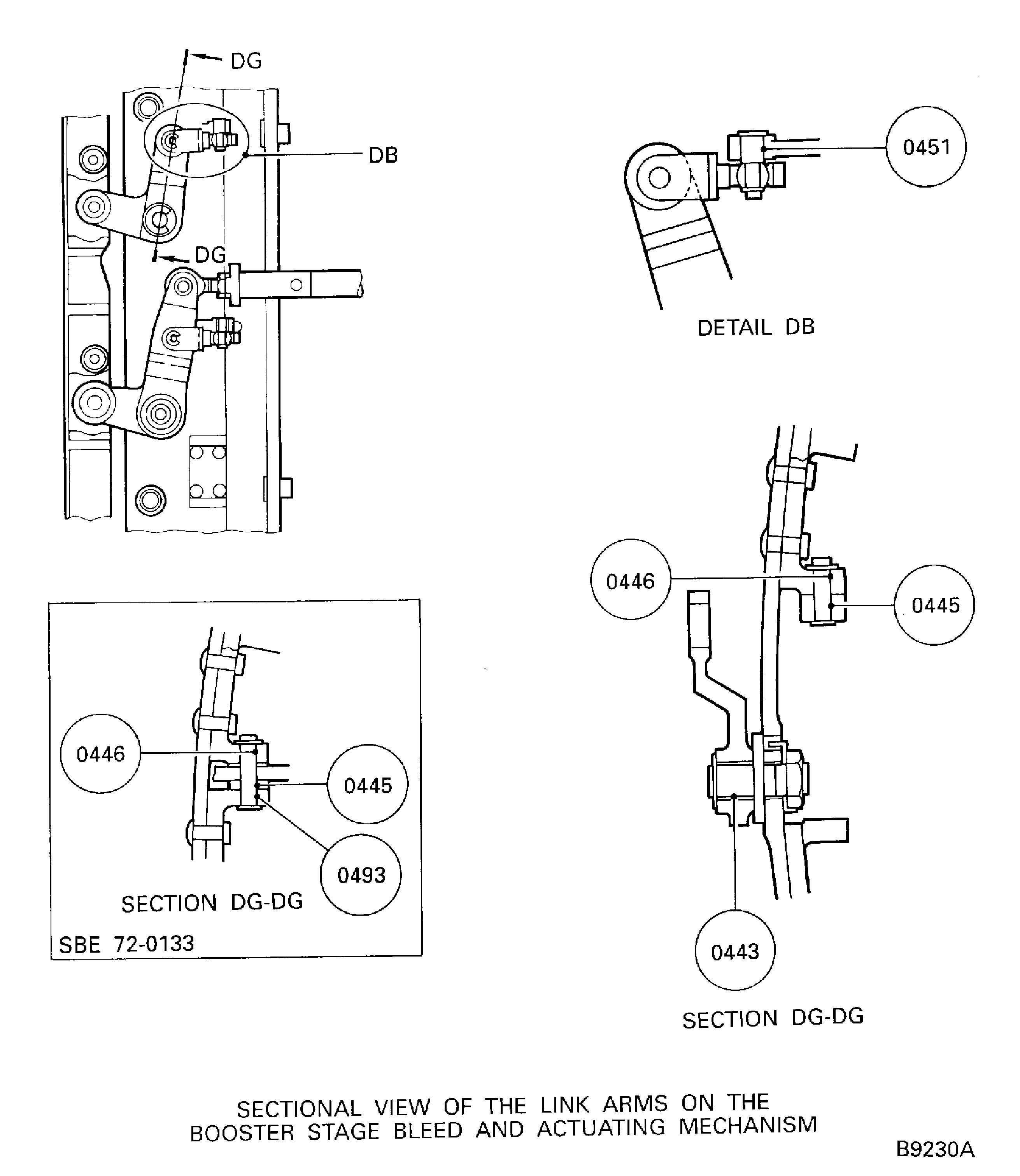

Refer to Figure.

Reference dimensions at location 0443. If required, use the data written as a note in TASK 72-32-71-200-000 (INSPECTION-000).

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0443

Link Arm ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-100), Sleeve Bearing Inside Diameter

Stud Pin ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-500), Stem Diameter

Link Arm Inside Diameter

0.3140

0.3130

0.0020

Stud Pin Outside Diameter

0.3125

0.0005

0.3120

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0443

Link Arm ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-100), Sleeve Bearing Inside Diameter

Stud Pin ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-500), Stem Diameter

Link Arm Inside Diameter

7.975

7.951

0.052

Stud Pin Outside Diameter

7.938

0.013

7.923

SUBTASK 72-32-70-220-075 Reference Fits and Clearances of the Link Arm and the Stud Pin at Location 0443

Refer to Figure.

Reference dimensions at location 0445. If required, use the data written as a note in TASK 72-32-72-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0445

Valve ENGINE-BLEED VALVE (72-32-72, 01-100), Hinge Pin Hole Diameter

Pin (01-280), Outside Diameter

Valve Hole Diameter

0.1885

0.1880

0.0010

Pin Outside Diameter

0.1880

0.0000

0.1875

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0445

Valve ENGINE-BLEED VALVE (72-32-72, 01-100), Hinge Pin Hole Diameter

Pin (01-280), Outside Diameter

Valve Hole Diameter

4.787

4.775

0.024

Pin Outside Diameter

4.775

0.000

4.763

SUBTASK 72-32-70-220-076-A00 Reference Fits and Clearances of the Valve and the Pin at Location 0445 (Pre SBE 72-0133)

Refer to Figure.

Reference dimension at location 0445. If required, use the data written as a note in TASK 72-32-72-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 11. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0445

Valve ENGINE-BLEED VALVE (72-32-72, 01-100), Hinge Pin Hole Diameter

Pin (01-280), Outside Diameter

Valve Hole Diameter

0.1885

0.1880

0.0019

Pin Outside Diameter

0.1888

0.0008

0.1866

Intf

Table 12. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0445

Valve ENGINE-BLEED VALVE (72-32-72, 01-100), Hinge Pin Hole Diameter

Pin (01-280), Outside Diameter

Valve Hole Diameter

4.787

4.775

0.048

Pin Outside Diameter

4.795

0.020

4.739

Intf

SUBTASK 72-32-70-220-076-B00 Reference Fits and Clearances of the Valve and the Pin at Location 0445 (SBE 72-0133)

Refer to Figure.

Reference dimensions at location 0446. If required, use the data written as a note in TASK 72-32-71-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 13. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0446

Support Ring ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-600), Pin Hole Diameter

Pin (01-280), Outside Diameter

Support Ring Hole Diameter

0.1891

0.1884

0.0016

Pin Outside Diameter

0.1880

0.0004

0.1875

Table 14. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0446

Support Ring ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-600), Pin Hole Diameter

Pin (01-280) Outside Diameter

Support Ring Hole Diameter

4.803

4.785

0.040

Pin Outside Diameter

4.775

0.010

4.763

SUBTASK 72-32-70-220-077-A00 Reference Fits and Clearances of the Support Ring and the Pin at Location 0446 (Pre SBE 72-0133)

Refer to Figure.

Referenced dimensions at location 0446. If required, use the data written as a note in TASK 72-32-71-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 15. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0446

Support Ring ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-600), Pin Hole Diameter

Pin (01-280), Outside Diameter

Support Ring Hole Diameter

0.1891

0.1884

0.0025

Pin Outside Diameter

0.1888

0.0004

0.1866

Intf

Table 16. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0446

Support Ring ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-600), Pin Hole Diameter

Pin (01-280), Outside Diameter

Support Ring Hole Diameter

4.803

4.785

0.064

Pin Outside Diameter

4.795

0.010

4.739

Intf

SUBTASK 72-32-70-220-077-B00 Reference Fits and Clearances of the Support Ring and the Pin at Location 0446 (SBE 72-0133)

Refer to Figure.

Referenced dimensions at location 0451. If required, use the data written as a note in TASK 72-32-72-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 17. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0451

Valve ENGINE-BLEED VALVE (72-32-72, 01-100), Link Pin Hole Diameter

Pin (01-240), Outside Diameter

Valve Hole Diameter

0.2367

0.2362

0.0010

Pin Outside Valve

0.2362

0.0000

0.2357

Table 18. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0451

Valve ENGINE-BLEED VALVE (72-32-72, 01-100), Link Pin Hole Diameter

Pin (01-240), Outside Diameter

Valve Hole Diameter

6.012

6.000

0.024

Pin Outside Diameter

6.000

0.000

5.988

SUBTASK 72-32-70-220-078 Referece Fits and Clearances of the Valve and the Pin at Location 0451

Refer to Figure.

Reference dimensions at location 0493. If required, use the data written as a note in TASK 72-32-71-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 19. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0493

Support Ring ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-600), Pin Hole Diameter

Pin (01-280), Outside Diameter

Support Ring Hole Diameter

0.1896

0.1884

0.0030

Pin Outside Diameter

0.1888

0.0004

0.1866

Intf

Table 20. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0493

Support Ring ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-600), Pin Hole Diameter

Pin (01-280), Outside Diameter

Support Ring Hole Diameter

4.815

4.785

0.076

Pin Outside Diameter

4.795

0.010

4.739

Intf

SUBTASK 72-32-70-220-079 Reference Fits and Clearances of the Support Ring and the Pin at Location 0493 (SBE 72-0133)

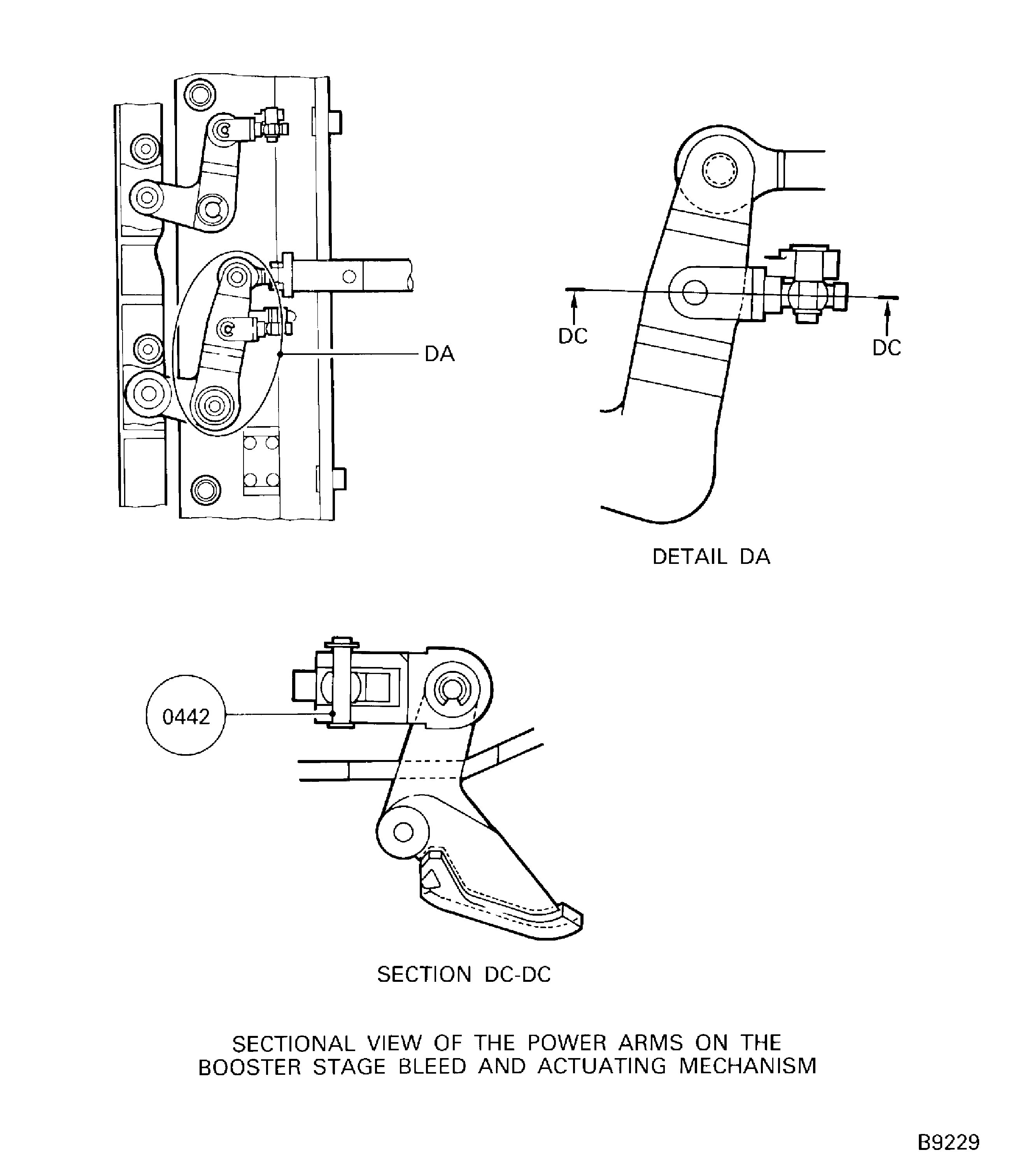

Refer to Figure.

Reference dimensions at location 0442. If required, use the data written as a note in TASK 72-32-71-200-000 (INSPECTION-000).

Table 21. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0442

Link ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-400), Pin Hole Diameter

Pin ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-430), Outside Diameter

Link Hole Diameter

0.1639

0.1634

0.0010

Pin Outside Diameter

0.1634

0.0000

0.1629

Table 22. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0442

Link ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-400), Pin Hole Diameter

Pin ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-430), Outside Diameter

Link Hole Diameter

4.162

4.150

0.024

Pin Outside Diameter

4.150

0.000

4.138

SUBTASK 72-32-70-220-080-A00 Reference Fits and Clearances of the Link and the Pin at Location 0442 (Pre SBE 72-0133)

Refer to Figure.

Reference dimensions at location 0442. If required, use the data written as a note in TASK 72-32-71-200-000 (INSPECTION-000).

Table 23. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0442

Link ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-400), Pin Hole Diameter

Pin ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-430), Outside Diameter

Link Hole Diameter

0.1639

0.1634

0.0002

Pin Outside Diameter

0.1642

0.0008

0.1637

Intf

Table 24. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0442

Link ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-400), Pin Hole Diameter

Pin ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-430), Outside Diameter

Link Hole Diameter

4.162

4.150

0.004

Pin Outside Diameter

4.170

0.020

4.158

Intf

SUBTASK 72-32-70-220-080-B00 Reference Fits and Clearances of the Link and the Pin at Location 0442 (SBE 72-0133)

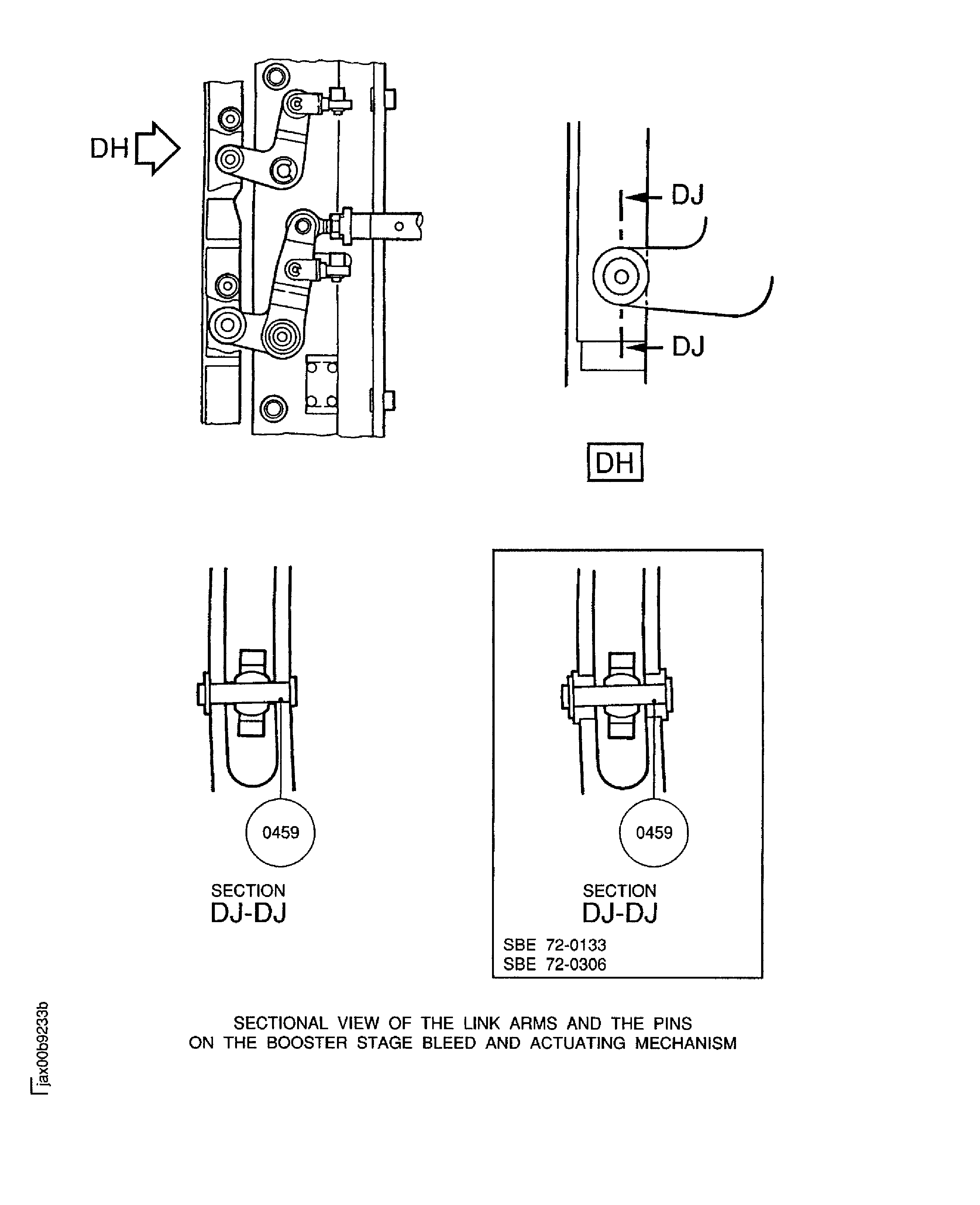

Refer to Figure.

Reference dimensions at location 0459. If required, use the data written as a note in TASK 72-32-73-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 25. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0459

Sychronize Ring ENGINE-BLEED VALVE ACTUATING RING (72-32-73, 01-150), Pin Hole Diameter

Pin (01-140), Outside Diameter

Ring Hole Diameter

0.1639

0.1634

0.0010

Pin Outside Diameter

0.1634

0.0000

0.1629

Table 26. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0459

Synchronize Ring ENGINE-BLEED VALVE ACTUATING RING (72-32-73, 01-150), Pin Hole Diameter

Pin (01-140), Outside Diameter

Ring Hole Diameter

4.162

4.150

0.024

Pin Outside Diameter

4.150

0.000

4.138

SUBTASK 72-32-70-220-081-A00 Reference Fits and Clearances of the Sychronize Ring and the Pin at Location 0459 (Pre SBE 72-0133)

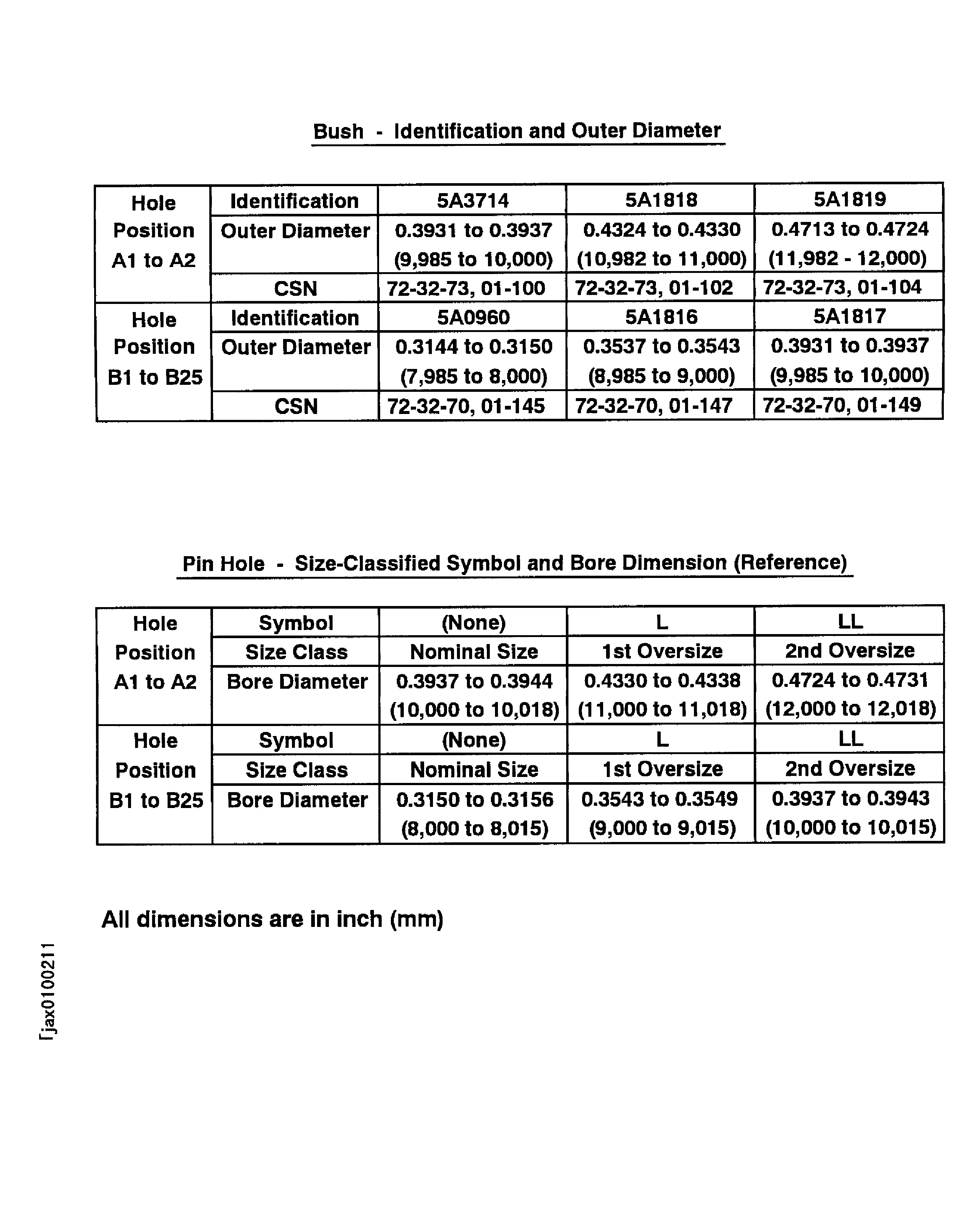

Refer to Figure.

Reference dimensions at location 0459. If required, use the data written as a note in TASK 72-32-70-200-000 (INSPECTION-000).

Table 27. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0459

Bush (01-145, 01-147 Or 01-149), Inside Diameter

Pin (01-140), Outside Diameter

Bush Inside Diameter

0.1650

0.1645

0.0010

Pin Outside Diameter

0.1645

0.0000

0.1640

Table 28. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0459

Bush (01-145, 01-147 Or 01-149), Inside Diameter

Pin (01-140), Outside Diameter

Bush Inside Diameter

4.190

4.178

0.024

Pin Outside Diameter

4.178

0.000

4.166

SUBTASK 72-32-70-220-081-B00 Reference Fits and Clearances of the Bush and the Pin at Location 0459 (SBE 72-0133 and SBE 72-0306)

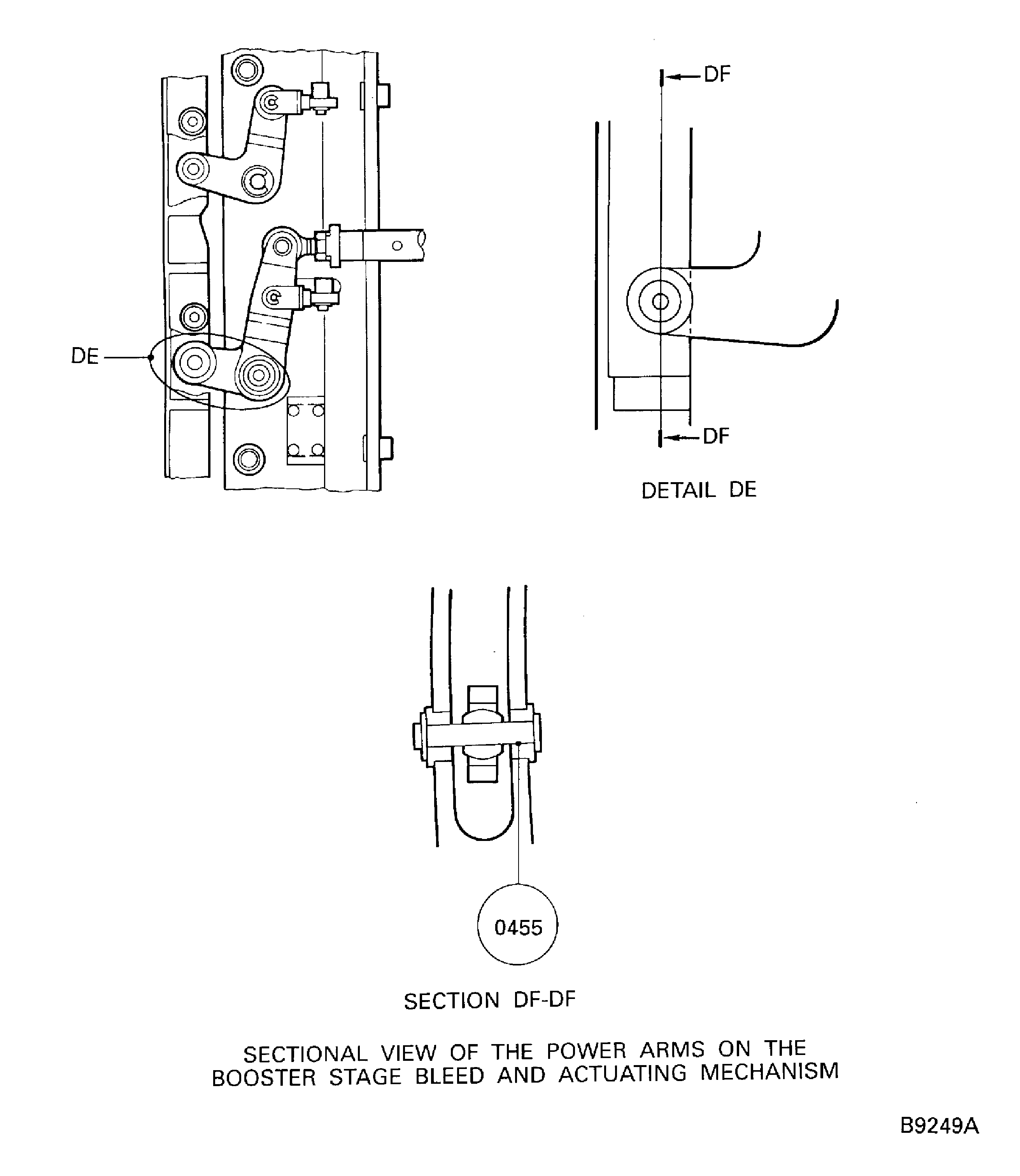

Refer to Figure.

Reference dimensions at location 0455. If required, use the data written as a note in TASK 72-32-73-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 29. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0455

Bush ENGINE-BLEED VALVE ACTUATING RING (72-32-73, 01-100), Inside Diameter

Pin (01-180), Outside Diameter

Bush Inside Diameter

0.2486

0.2480

0.0012

Pin Outside Diameter

0.2480

0.0000

0.2474

Table 30. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0455

Bush ENGINE-BLEED VALVE ACTUATING RING (72-32-73, 01-100), Inside Diameter

Pin (01-180), Outside Diameter

Bush Inside Diameter

6.315

6.300

0.030

Pin Outside Diameter

6.300

0.000

6.285

SUBTASK 72-32-70-220-082-A00 Reference Fits and Clearances of the Bush and the Pin at Location 0455 (Pre SBE 72-0133)

Refer to Figure.

Reference dimensions at location 0455. If required, use the data written as a note in TASK 72-32-73-200-000 (INSPECTION-000) and TASK 72-32-70-200-000 (INSPECTION-000).

Table 31. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0455

Bush ENGINE-BLEED VALVE ACTUATING RING (72-32-73, 01-100, ENGINE-BLEED VALVE ACTUATING RING 01-102 or ENGINE-BLEED VALVE ACTUATING RING 01-104), Inside Diameter

Pin (01-180), Outside Diameter

Bush Inside Diameter

0.2486

0.2480

0.0004

Pin Outside Diameter

0.2488

0.0008

0.2482

Intf

Table 32. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0455

Bush ENGINE-BLEED VALVE ACTUATING RING (72-32-73, 01-100 , ENGINE-BLEED VALVE ACTUATING RING 01-102 or ENGINE-BLEED VALVE ACTUATING RING 01-104), Inside Diameter

Pin (01-180), Outside Diameter

Bush Inside Diameter

6.315

6.300

0.010

Pin Outside Diameter

6.320

0.020

6.305

Intf

SUBTASK 72-32-70-220-082-B00 Reference Fits and Clearances of the Bush and the Pin at Location 0455 (SBE 72-0133 and SBE 72-0306)

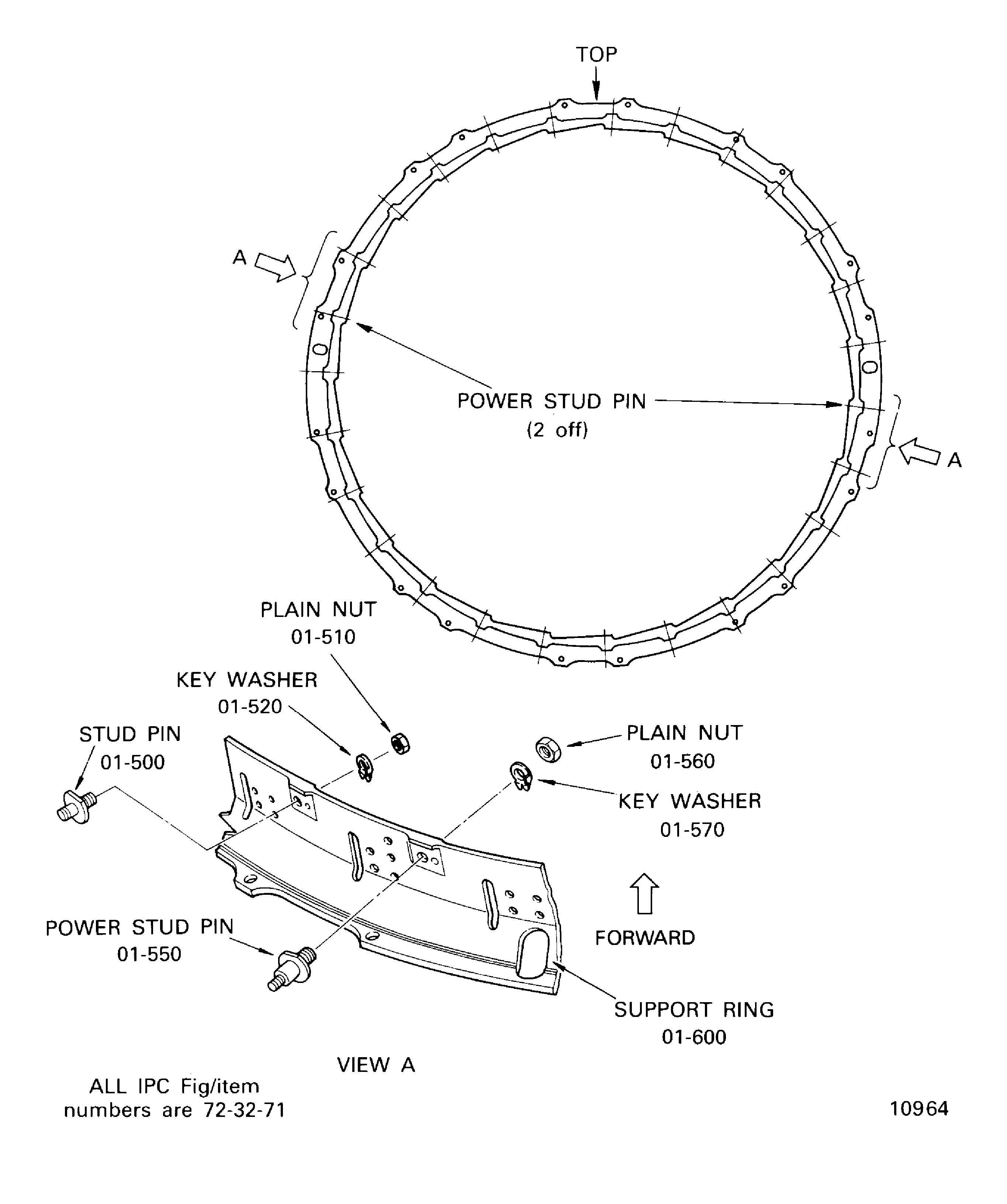

Refer to Figure.

Put the support ring ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-600) on a work bench with the rear flange down.

NOTE

Each power arm stud pin has a flat on its flange to engage with an anti-rotation tab on the support ring.Attach the power arm stud pins with new ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-570) key washers 2 off and the two nuts ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-560).

Install the two power arm stud pins ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-550).

Attach the link arm stud pins with new ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-520) key washers 25 off and the 25 nuts ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-510).

Install the 25 link arm stud pins ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-500).

SUBTASK 72-32-70-440-051 Install the Two Power Arm Stud Pins and the 25 Link Arm Stud Pins

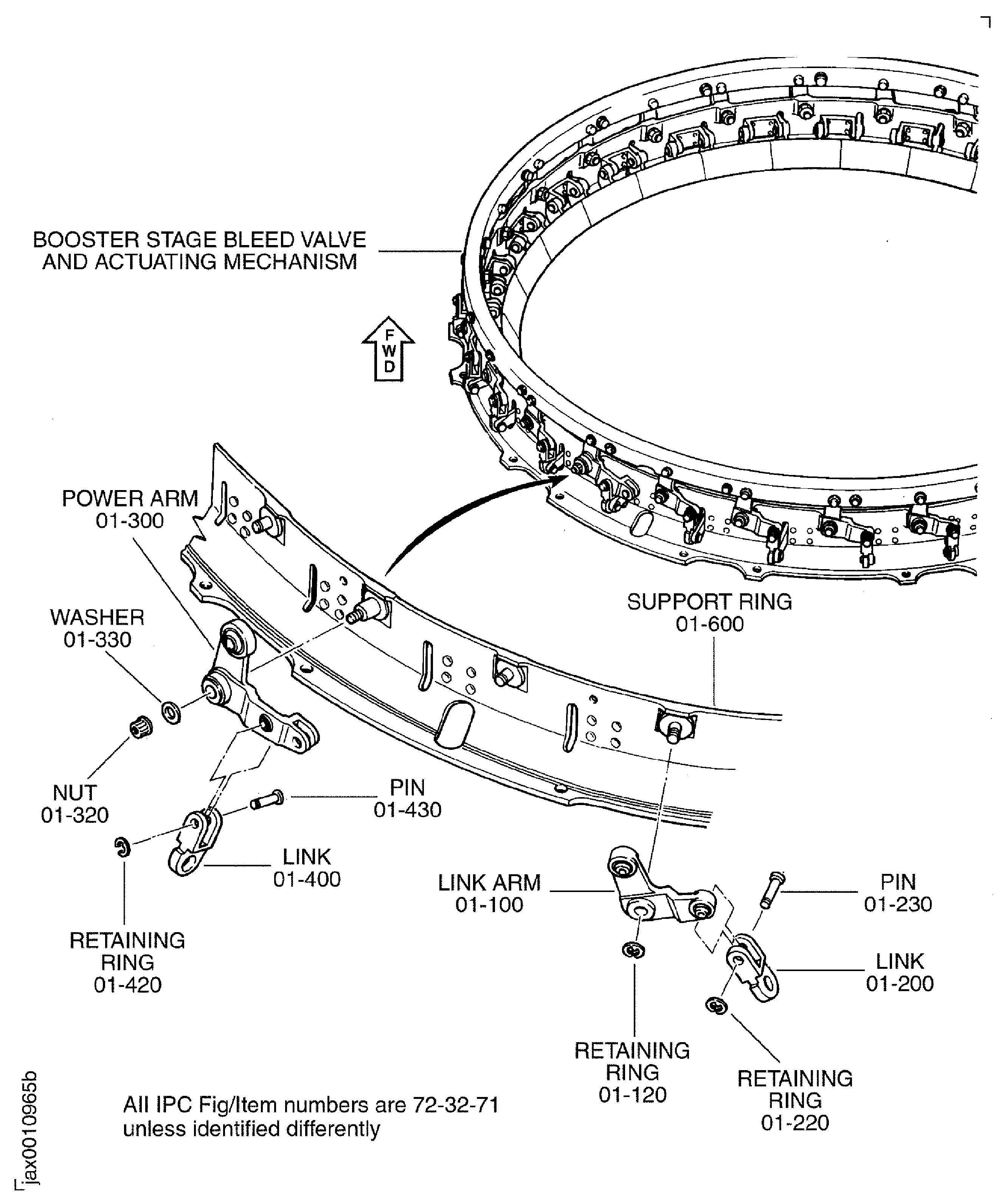

Refer to Figure.

Install the power arms on to the two stud pins and attach them with the two nuts ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-320) and washers ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-330).

Install the two power arms ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-300).

Install the link arms on to the stud pins and attach them with new ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-120) retaining ring 25 off. Use IAE 1J12209 Installation holder 1 off or equivalent to put the retaining rings in position.

Install the 25 link arms ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-100).

SUBTASK 72-32-70-440-052-A00 Install the Two Power Arms (72-32-71,01-300) and the 25 Link Arms (72-32-71,01-100) (Pre SBE 72-0133)

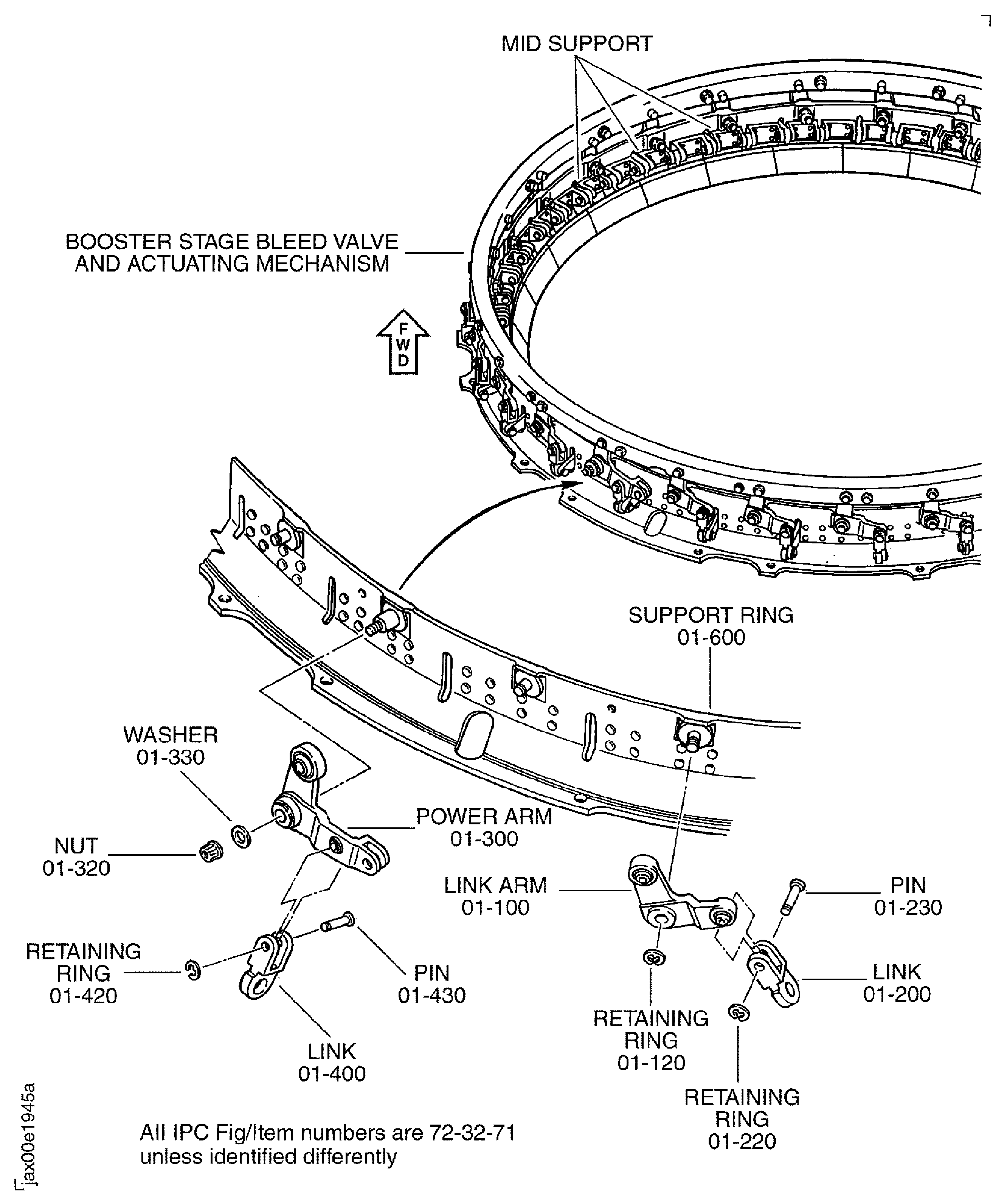

Refer to Figure.

Install the power arms on to the two stud pins and attach them with the two nuts ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-320) and washers ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-330).

Install the two power arms ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-300).

Install the link arms on to the stud pins and attach them with new ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-120) retaining ring 25 off. Use IAE 1J12209 Installation holder 1 off or equivalent to put the retaining rings in position.

Install the 25 link arms ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-100).

SUBTASK 72-32-70-440-052-B00 Install the Two Power Arms (72-32-71,01-300) and the 25 Link Arms (72-32-71,01-100) (SBE 72-0133)

Refer to Figure.

Install the 27 pins ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-230 and ENGINE-BLEED VALVE SUPPORT AND ARMS 01-430) through the spherical bearings of the power arms and the link arms and attach the pins with new ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-220 and ENGINE-BLEED VALVE SUPPORT AND ARMS 01-420) retaining ring 27 off. Use IAE 1J12216 Installation holder or equialent 1 off or equivalent to put the retaining rings in position.

Install the links on to the power arms and the link arms.

SUBTASK 72-32-70-440-053-A00 Install the 27 Links (72-32-71,01-200 and 01-400) (Pre SBE 72-0133)

Refer to Figure.

Install the 27 pins ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-230 and ENGINE-BLEED VALVE SUPPORT AND ARMS 01-430) through the spherical bearings of the power arms and the link arms and attach the pins with new ENGINE-BLEED VALVE SUPPORT AND ARMS (72-32-71, 01-220 and ENGINE-BLEED VALVE SUPPORT AND ARMS 01-420) retaining ring 27 off. Use IAE 1J12216 Installation holder or equialent 1 off or equivalent to put the retaining rings in position.

Install the links on to the power arms and the link arms.

SUBTASK 72-32-70-440-053-B00 Install the 27 Links (72-32-71, 01-200 and 01-400) (SBE 72-0133)

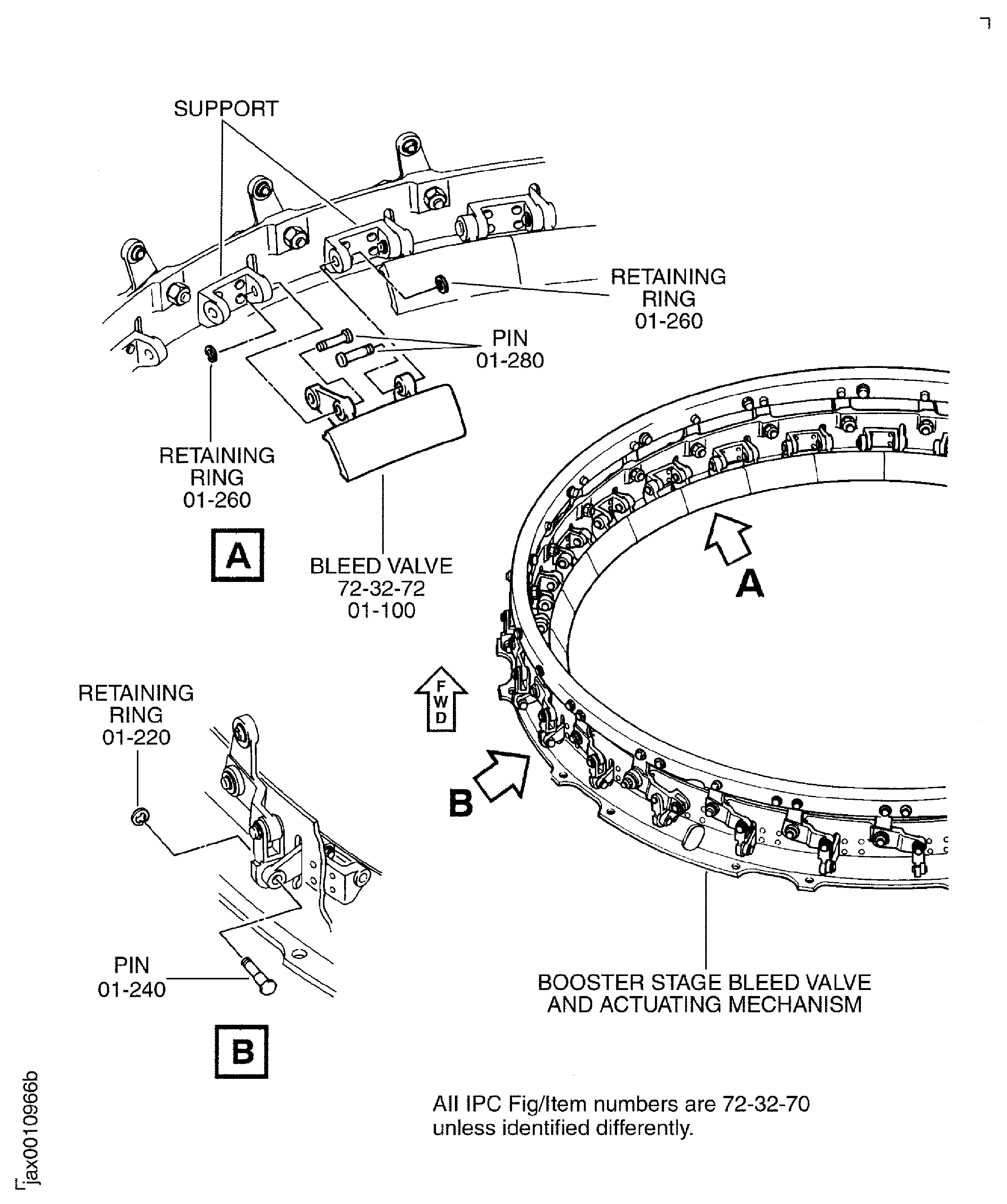

Refer to Figure.

Let each longer arm of the 27 bleed valves ENGINE-BLEED VALVE (72-32-72, 01-100) go through its slot in the support ring and put the bleed valves in position between the supports.

Install the 54 pins (01-280) through the supports and the bleed valves and attach them with new (01-260) retaining ring 54 off. Use the installation holder (IAE 1J12216 Installation holder or equialent) or equivalent to put the retaining rings in position.

Install the 27 pins (01-240) through the bleed valves and the spherical bearings of the links and attach them with new (01-220) retaining ring 27 off. Use the installation holder (IAE 1J12216 Installation holder or equialent) or equivalent to put the retaining rings in position.

Attach the bleed valves to the links.

SUBTASK 72-32-70-440-054-A00 Install the 27 Bleed Valves (72-32-72,01-100) (Pre SBE 72-0133)

Refer to Figure.

Let each longer arm of the 27 bleed valves ENGINE-BLEED VALVE (72-32-72, 01-100) go through its slot in the support ring and put the bleed valves in position between the supports and the mid support.

Install the 54 pins (01-280) through the mid supports, the bleed valves and the supports and attach them with new (01-260) retaining ring 54 off. Use the installation holder (IAE 1J12216 Installation holder or equialent) or equivalent to put the retaining rings in position.

Install the 27 pins (01-240) through the bleed valves, the washers ENGINE-BLEED VALVE (72-32-72,01-230) and the spherical bearings of the links and attach them with the 27 nuts (01-220).

Insert new ENGINE-BLEED VALVE (72-32-72, 01-215) cotter pin 27 off into the holes in the 27 pins (01-240) and fix the pins (01-240).

Attach the bleed valves to the links.

SUBTASK 72-32-70-440-054-B00 Install the 27 Bleed Valves (72-32-72,01-100) (SBE 72-0133)

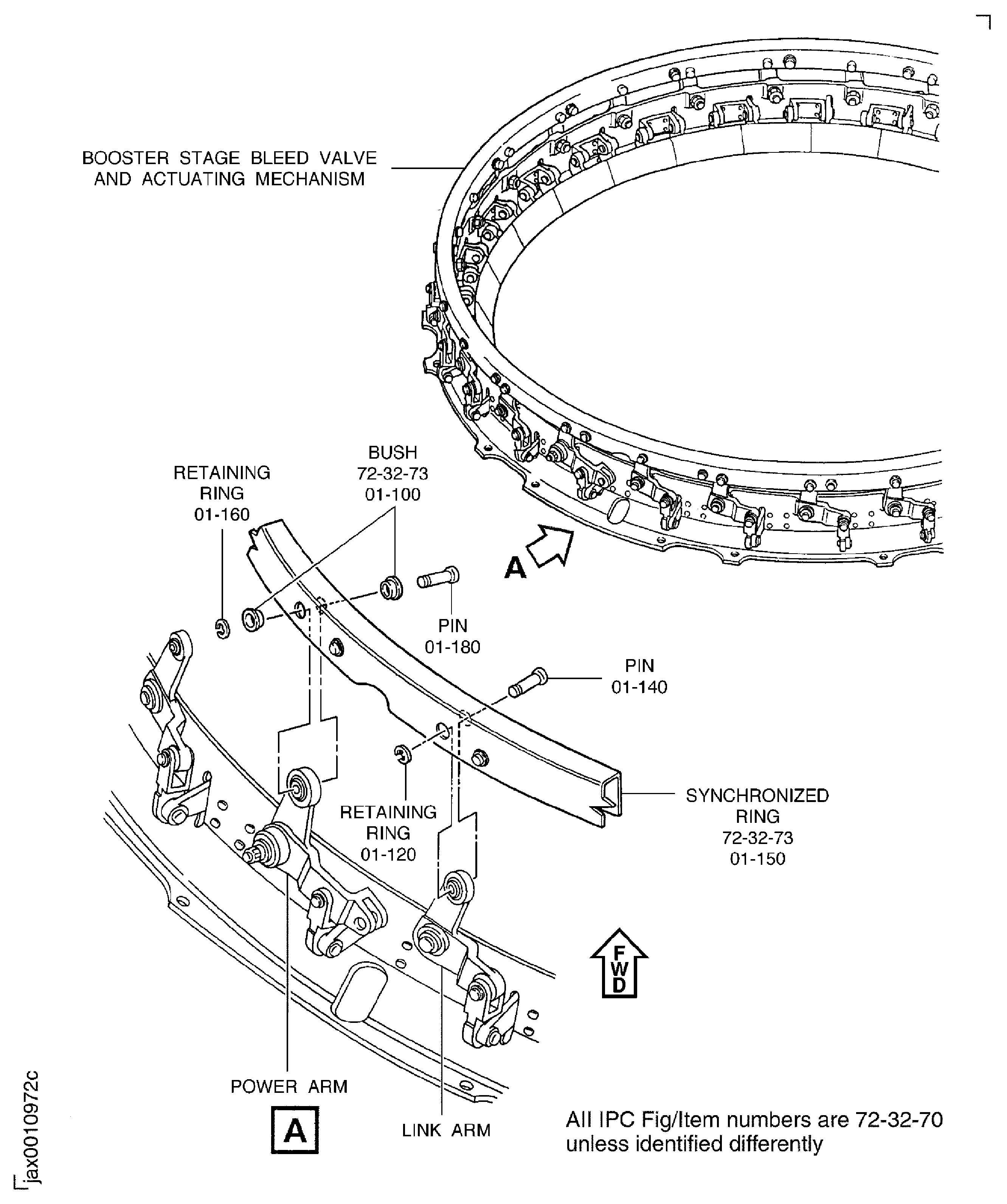

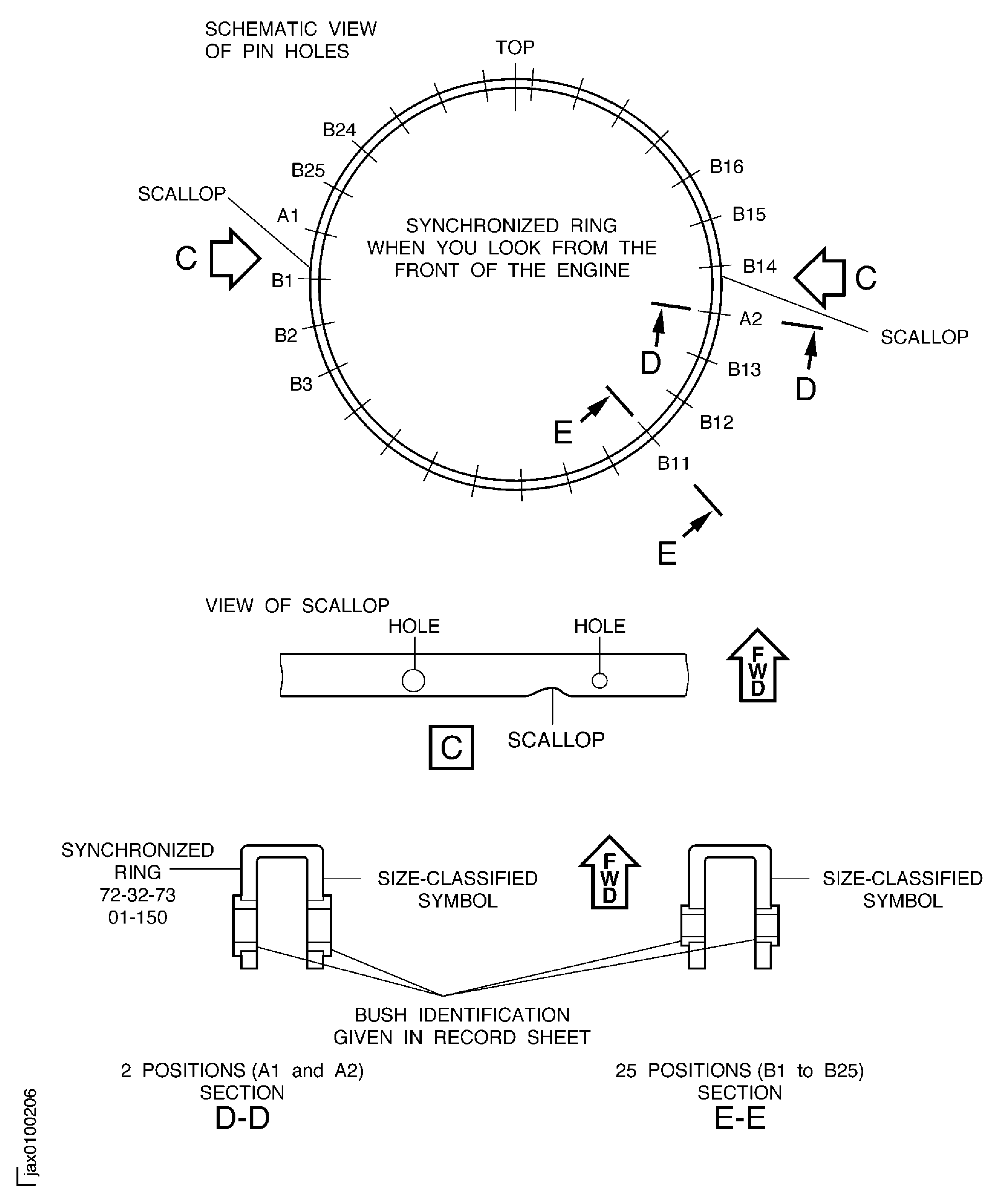

Refer to Figure.

Install the four bushes ENGINE-BLEED VALVE ACTUATING RING (72-32-73, 01-100) into the power arm holes in the synchronized ring at the two locations (two at each location).

Install the two pins (01-180) through the bushes on the synchronized ring and the spherical bearings of the power arms and attach them with new (01-160) retaining ring 2 off. Use the IAE 1J12216 Installation holder or equialent or equivalent to put the retaining rings in position.

Install the 25 pins (01-140) through the synchronized ring and the spherical bearings of the link arms and attach them with new (01-120) retaining ring 25 off. Use the IAE 1J12216 Installation holder or equialent to put the retaining rings in position.

Attach the synchronized ring to the power arms and the link arms.

SUBTASK 72-32-70-440-055-A00 Install the Synchronized Ring (72-32-73,01-150) (Pre SBE 72-0133)

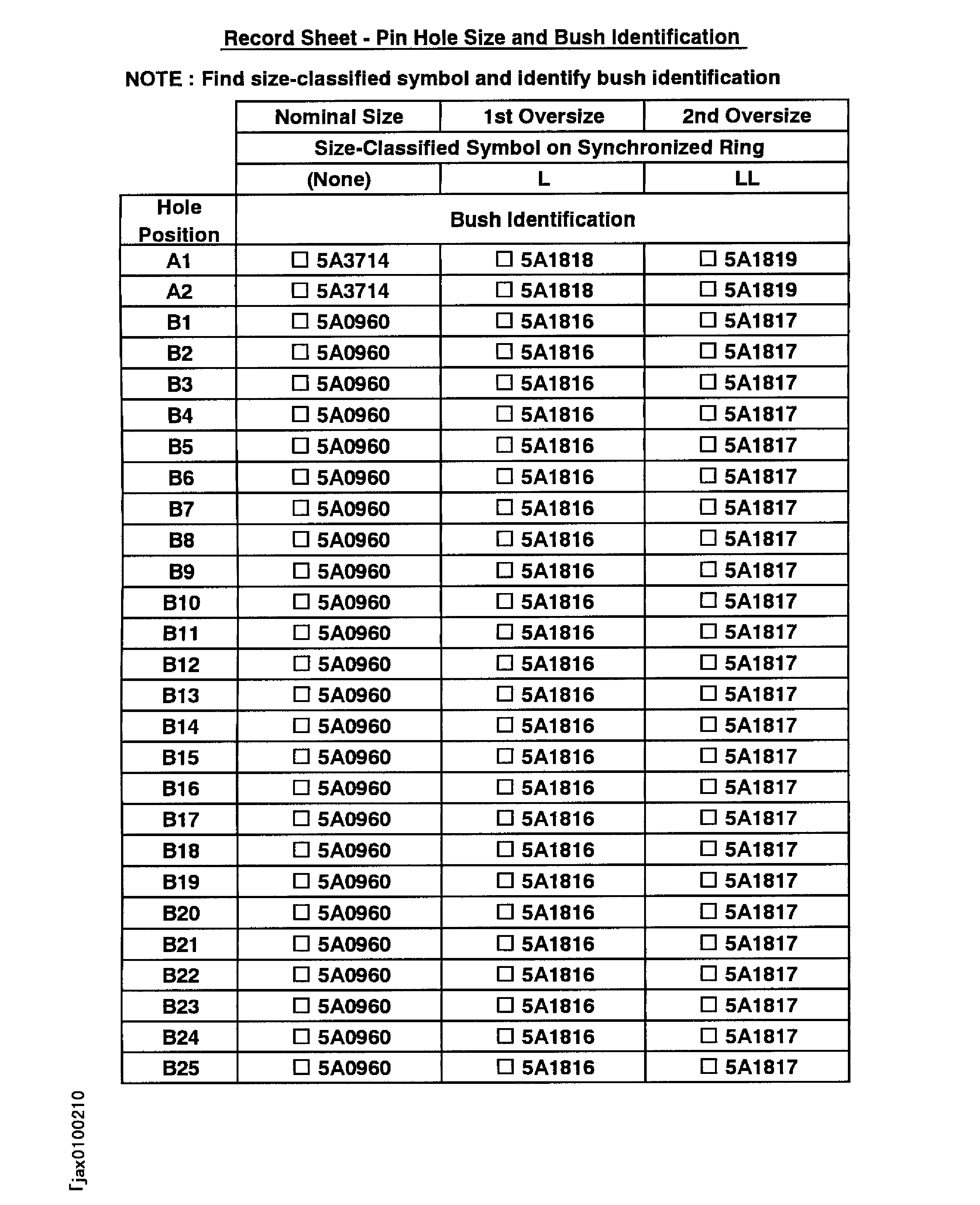

Install the four bushes ENGINE-BLEED VALVE ACTUATING RING (72-32-73, 01-100, ENGINE-BLEED VALVE ACTUATING RING 01-102 or ENGINE-BLEED VALVE ACTUATING RING 01-104) into the power arm holes in the synchronized ring ENGINE-BLEED VALVE ACTUATING RING (72-32-73,01-150) at the two locations (two at each location).

Install the two pins (01-180) through the bushes on the synchronized ring and the spherical bearings of the power arms and attach them with new (01-160) retaining ring 2 off. Use the IAE 1J12216 Installation holder or equialent to put the retaining rings in position.

Install the 25 pins (01-140) through the bushes on the synchronized ring and the spherical bearings of the link arms and attach them with new (01-120) retaining ring 25 off. Use the IAE 1J12216 Installation holder or equialent to put the retaining rings in position.

Attach the synchronized ring to the power arms and the link arms.

SUBTASK 72-32-70-440-055-B00 Install the Synchronized Ring (78-32-73,01-150) and (SBE 72-0133 and SBE 72-0306)

Figure: Booster Stage Bleed And Actuating Mechanism - Fits And Clearances

Sheet 1

Figure: Booster Stage Bleed And Actuating Mechanism - Fits And Clearances

Sheet 2

Figure: Booster Stage Bleed Actuating Mechanism - Fits And Clearances

Sheet 3

Figure: Booster Stage Bleed Actuating Mechanism - Fits And Clearances

Sheet 4

Figure: Booster Stage Bleed Actuating Mechanism - Fits And Clearances

Sheet 5

Figure: Pre SBE 72-0133: A View Of The Booster Stage Bleed Valve And Actuating Mechanism

Pre SBE 72-0133: A View Of The Booster Stage Bleed Valve And Actuating Mechanism

Figure: SBE 72-0133: A View Of The Booster Stage Bleed Valve And Actuating Mechanism

SBE 72-0133: A View Of The Booster Stage Bleed Valve And Actuating Mechanism

Figure: Install The Power Arm Stud Pins And The Link Arm Stud Pins

Install The Power Arm Stud Pins And The Link Arm Stud Pins

Figure: Pre SBE 72-0133: Install The Power Arms, The Link Arms And The Links

Pre SBE 72-0133: Install The Power Arms, The Link Arms And The Links

Figure: SBE 72-0133: Install The Power Arms, The Link Arms And The Links

SBE 72-0133: Install The Power Arms, The Link Arms And The Links

Figure: Pre SBE 72-0133: Install The Bleed Valves

Pre SBE 72-0133: Install The Bleed Valves

Figure: SBE 72-0133: Install The Bleed Valves

SBE 72-0133: Install The Bleed Valves

Figure: Pre SBE 72-0133: Install The Synchronized Ring

Pre SBE 72-0133: Install The Synchronized Ring

Figure: SBE 72-0133, SBE 72-0306: Install The Bushes Into The Synchronized Ring

Sheet 1

Figure: SBE 72-0133, SBE 72-0306: Install The Bushes Into The Synchronized Ring

Sheet 2

Figure: SBE 72-0133, SBE 72-0306: Install The Bushes Into The Synchronized Ring

Sheet 3

Figure: SBE 72-0133, SBE 72-0306: Install The Synchronized Ring

SBE 72-0133, SBE 72-0306: Install The Synchronized Ring