Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5 and Post SBE 79-0088

Common Information

TASK 72-00-40-020-002-C00 HP System Module - Remove And Disconnect The Components, Electrical Harnesses, And Tubes From The Front Of The HPC Case, Removal-002 - SBE 79-0088

General

This TASK gives the procedure to remove and disconnect the necessary components, the electrical harnesses and the tubes, so the HP system module can be removed from the LP compressor intermediate case module. Refer to the TASKs which follow for other related procedures:

TASK 72-00-40-020-001-B00 Remove the components, the electrical harnesses, the tubes and the brackets from the HP turbine.

TASK 72-00-40-020-003-B00 Remove the components, the electrical harnesses and the tubes from the HP compressor vertical splitline.

TASK 72-00-40-020-004 Remove the remaining HP system module components and air off-take ducts.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of threaded parts. Let the parts soak before removal.

Remove and discard the lockwire before the tube or connector is disconnected.

When electrical connections are disconnected, special plastic caps must be installed.

During the electrical harness removal remove the lacing tape that attaches the different harnesses together.

All tubes, hoses and ducts removed in this procedure must have their maintenance completed, as given in the Component Maintenance Manual (CMM-THD-V2500-1IA).

Seal all openings to prevent contamination from unwanted materials.

Discard all rubber seal rings removed in this procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| 0.937 in. (24.00 mm) crowsfoot spanner | LOCAL | 0.937 in. (24.00 mm) crowsfoot spanner | ||

| IAE 1N20014 Forward engine mount sling | 0AM53 | IAE 1N20014 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-058 PENETRATING OIL | 0AM53 | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

Remove the front mount assembly as detailed in TASK 71-00-32-350-001 (REMOVAL, PB301).

SUBTASK 72-00-40-020-131 Remove the Forward Mount Assembly

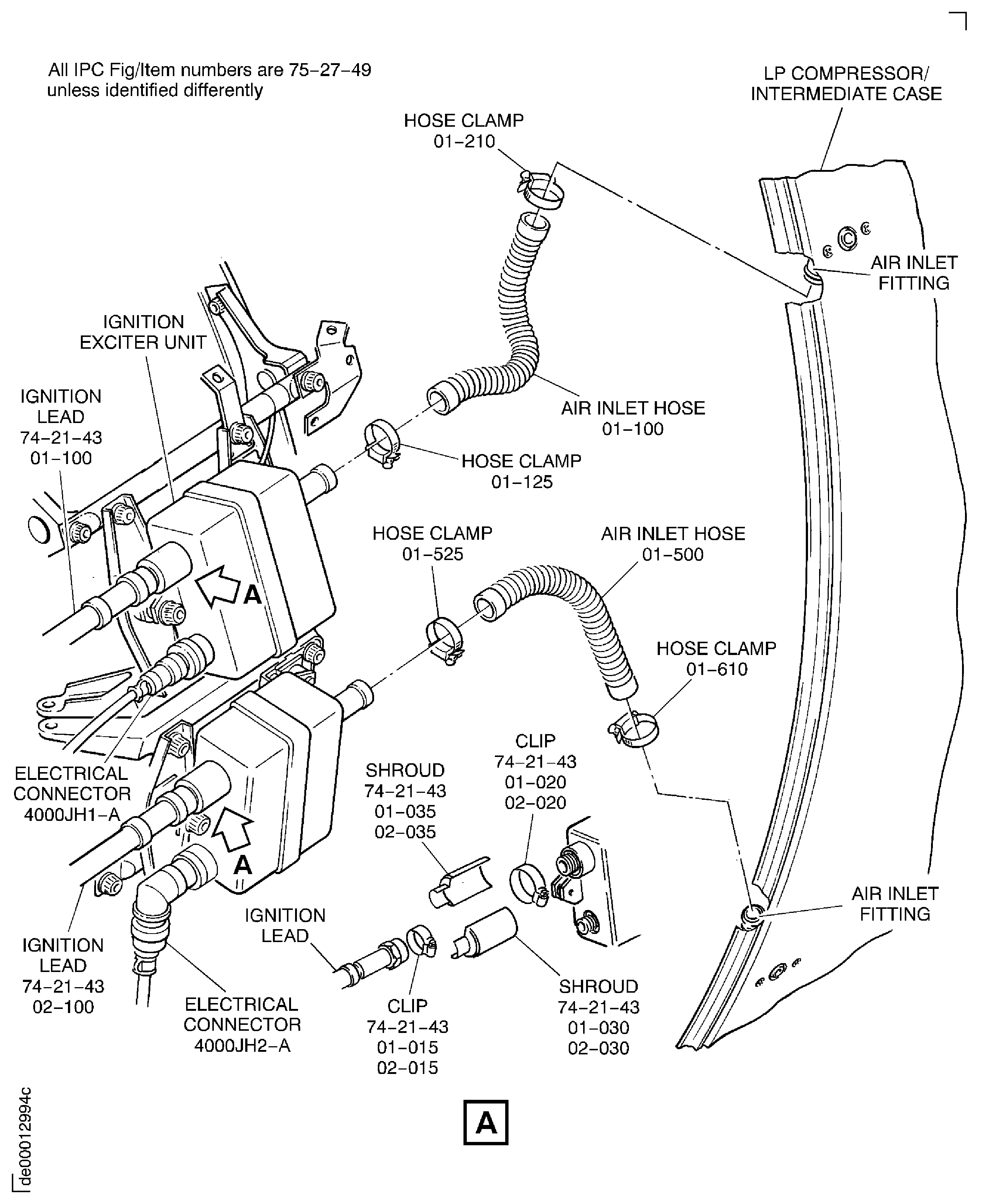

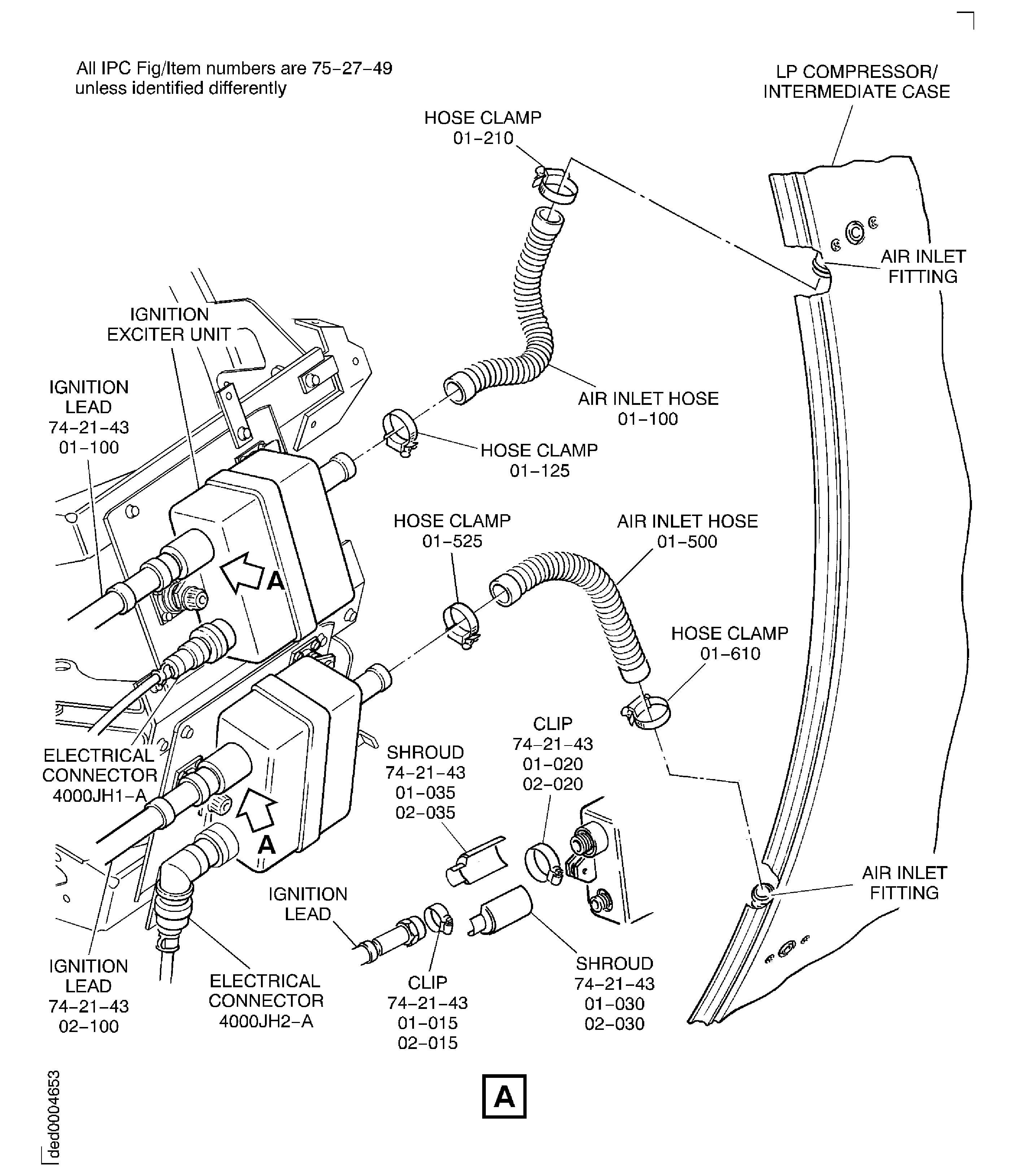

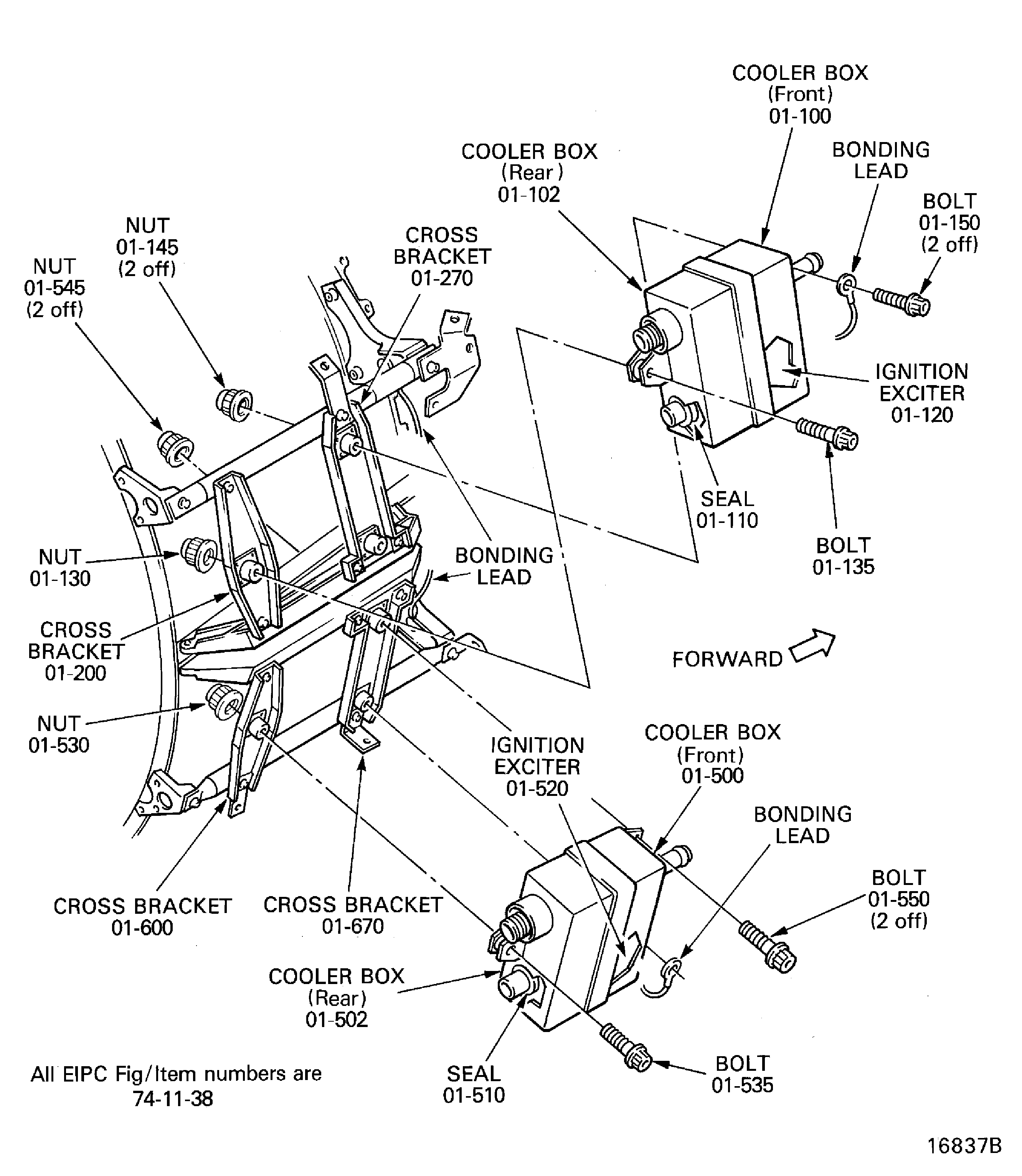

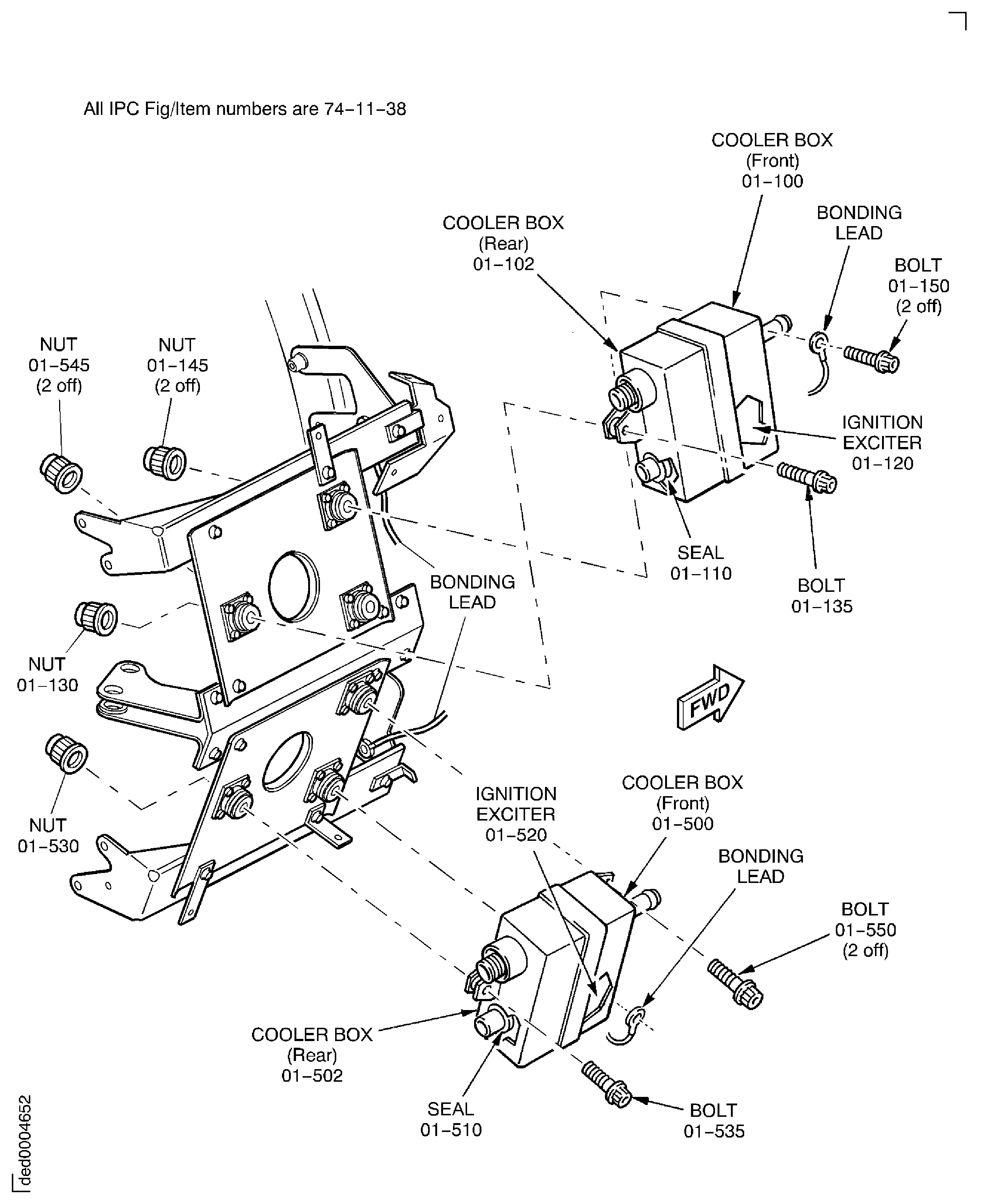

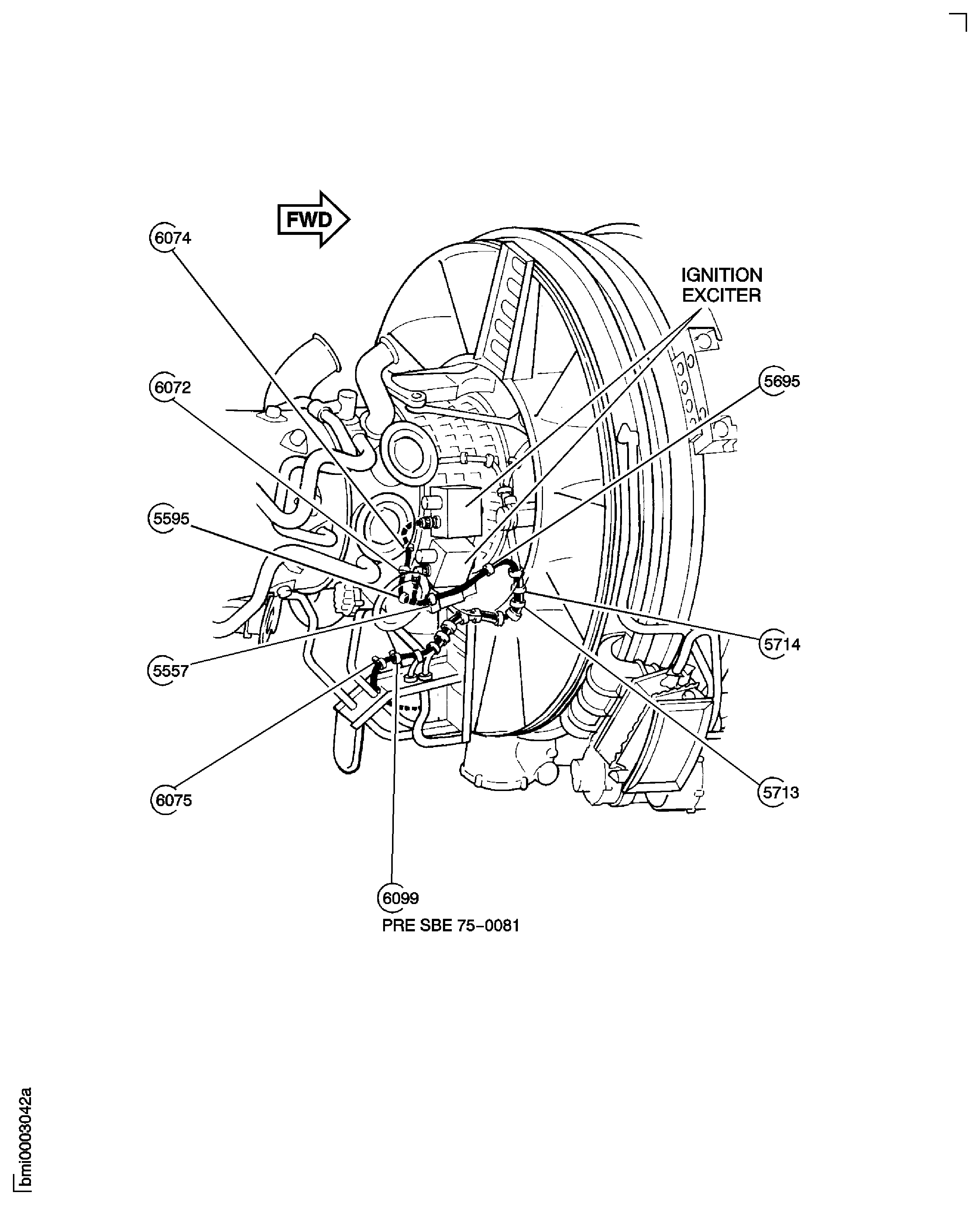

Pre SBE 74-0001: Remove the three bolts and nuts that attach each exciter box to the cross brackets and remove the exciter boxes.

NOTE

The ignition exciters must have their maintenance completed, as given in the Bendix Component Maintenance Manual (74-11-38).SBE 74-0001: Remove the three bolts and nuts that attach each exciter box to the support brackets and remove the exciter boxes.

CAUTION

DO NOT BEND THE HIGH ENERGY IGNITION HARNESS MORE THAN IS NECESSARY BECAUSE THIS CAN DAMAGE THE CONDUIT.Remove the two high energy ignition exciters.

SUBTASK 72-00-40-020-132 Remove the Ignition Exciters (Pre SBE 74-0001 and SBE 74-0001)

NOTE

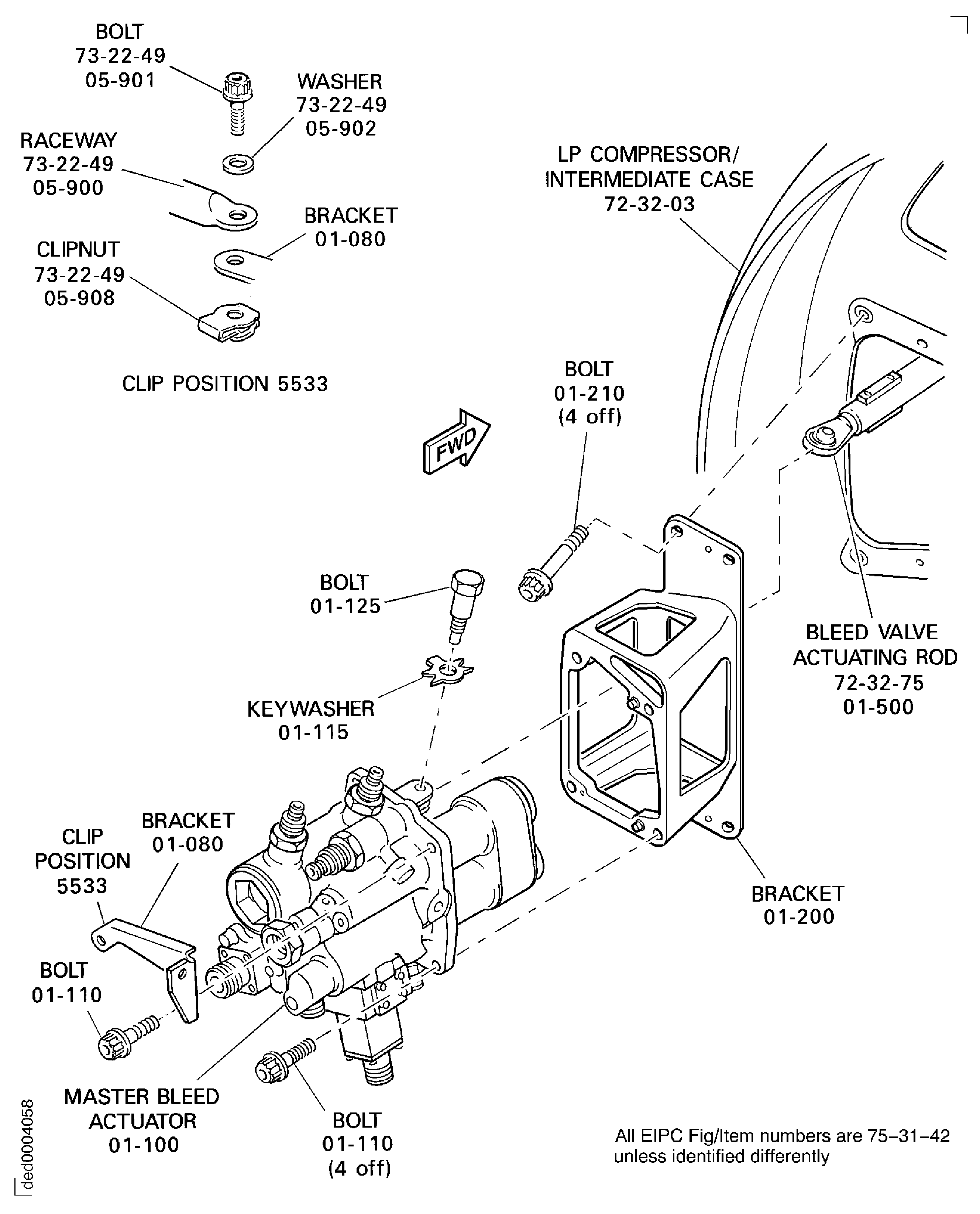

The LP compressor master bleed actuator must have its maintenance completed, as given in the D.S.I.C. Component Maintenance Manual (75-31-42).Remove the four bolts that attach the bleed actuator to the mount bracket and remove the bleed actuator and the bracket LPC Bleed Master Actuator (75-31-42, 01-080).

Remove the LP compressor master bleed actuator.

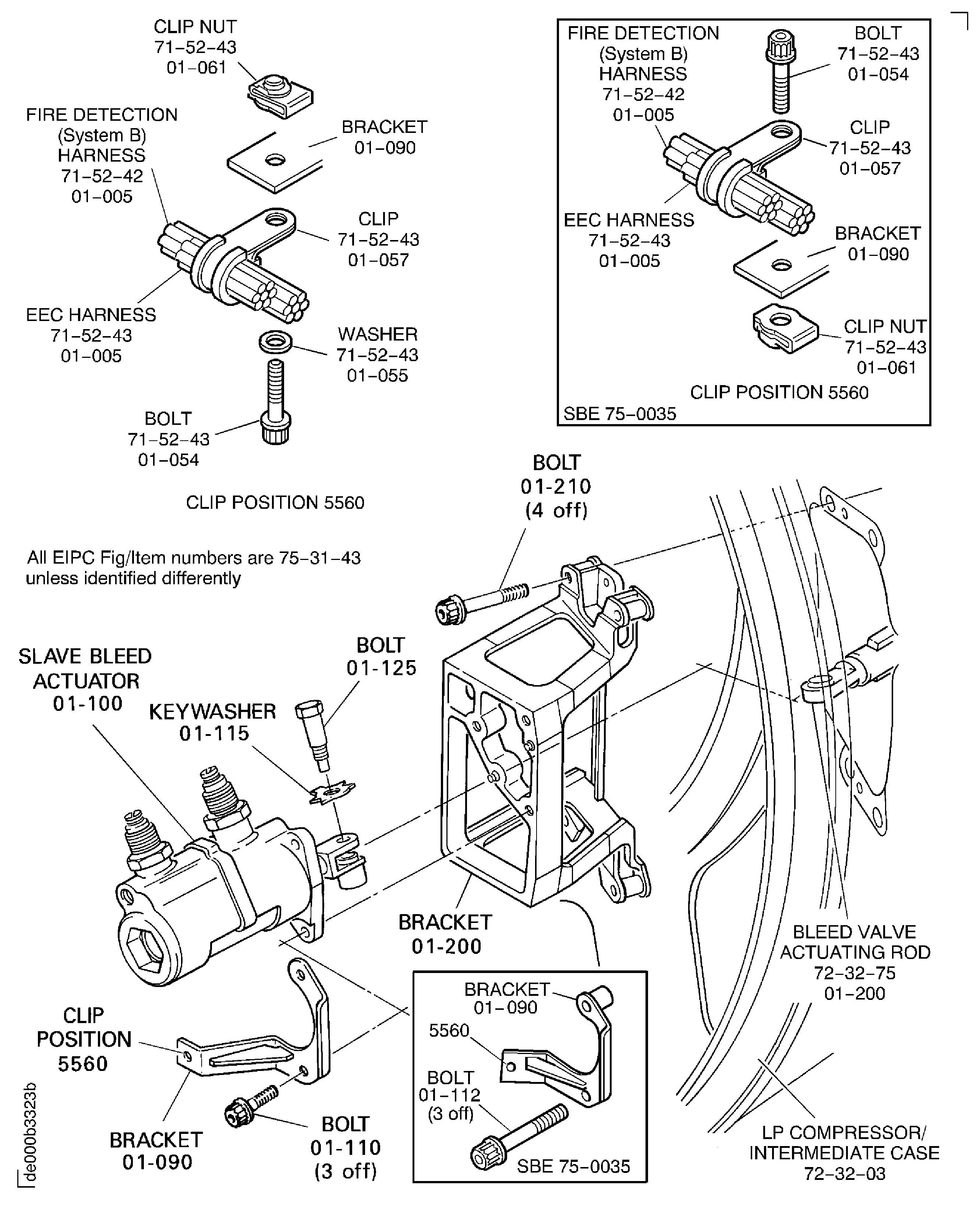

Pre SBE 75-0035: Remove the bolt, the washer, the clip and the clipnut from the clip position 5560.

SBE 75-0035: Remove the bolt, the clip and the clipnut from the clip position 5560.

NOTE

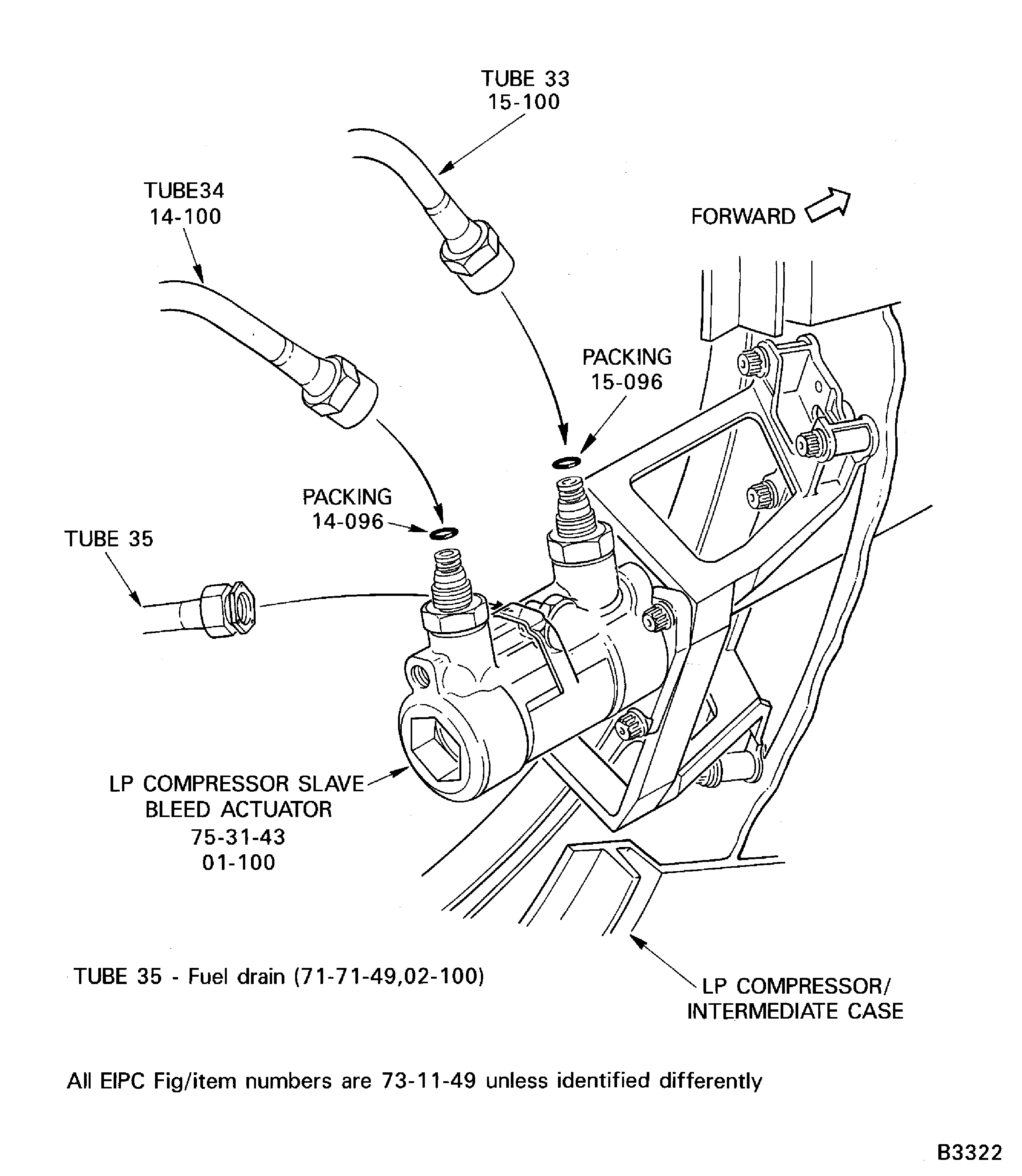

The LP compressor slave bleed actuator must have its maintenance completed, as given in the D.S.I.C. Component Maintenance Manual (75-31-43).Remove the three bolts that attach the bleed actuator to the mount bracket and remove the bleed actuator and the bracket LPC Bleed Slave Actuator(75-31-43, 01-090).

Remove the LP compressor slave bleed actuator.

SUBTASK 72-00-40-020-133 Remove the LP Compressor Bleed Actuators (Pre SBE 75-0035 and SBE 75-0035)

NOTE

The two bleed actuator mount brackets must have their maintenance completed, as given in the Component Maintenance Manual (CMM-MECH-V2500-1IA).Remove the lockwire and the four bolts that attach the mount bracket to the LP compressor/intermediate case rear frame and discard the lockwire. Remove the mount bracket.

Remove the slave bleed actuator mount bracket.

SUBTASK 72-00-40-020-134 Remove the LP Compressor Bleed Actuator Mount Brackets

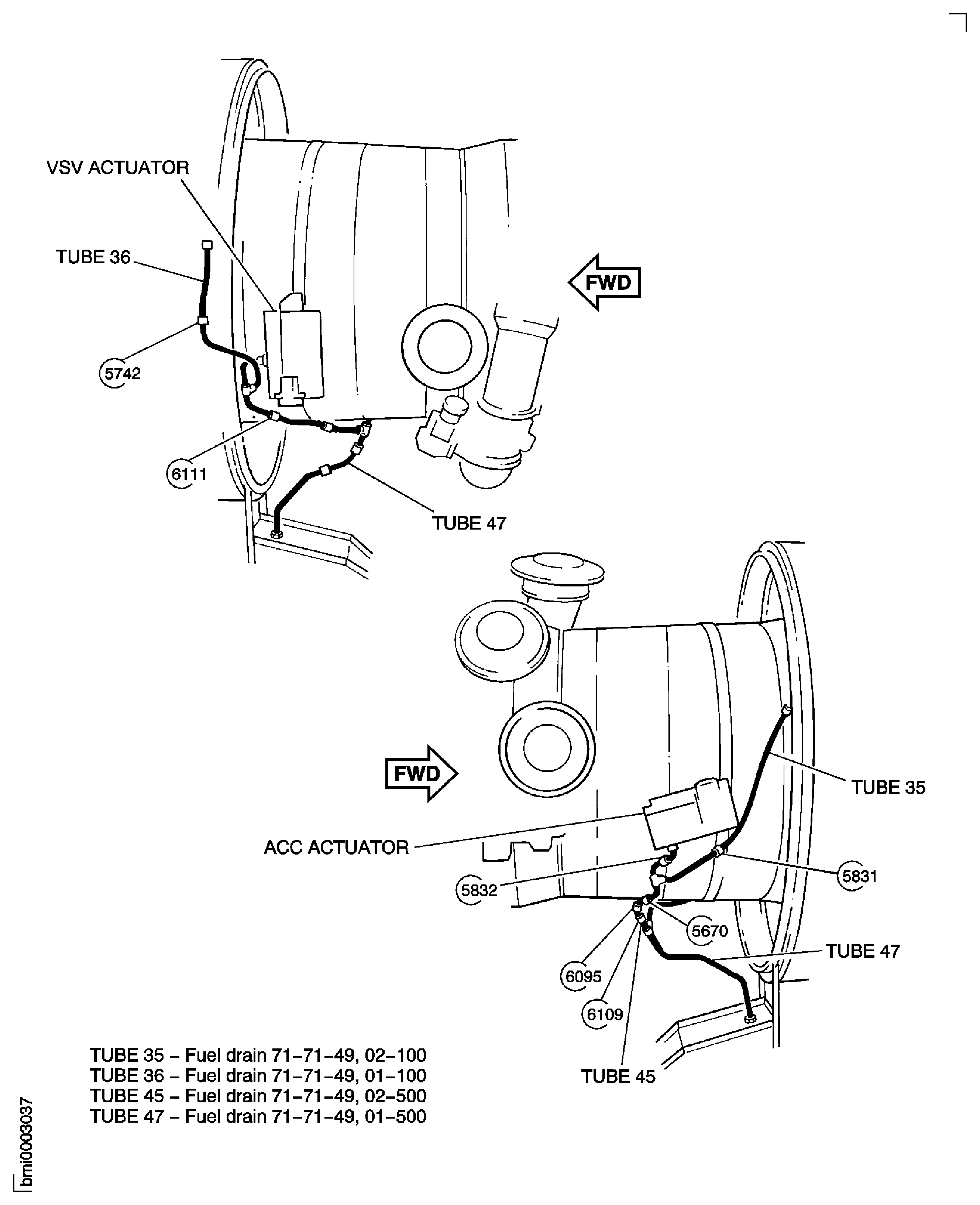

Refer to Figure.

SUBTASK 72-00-40-020-135 Remove the Fuel Drain Tubes

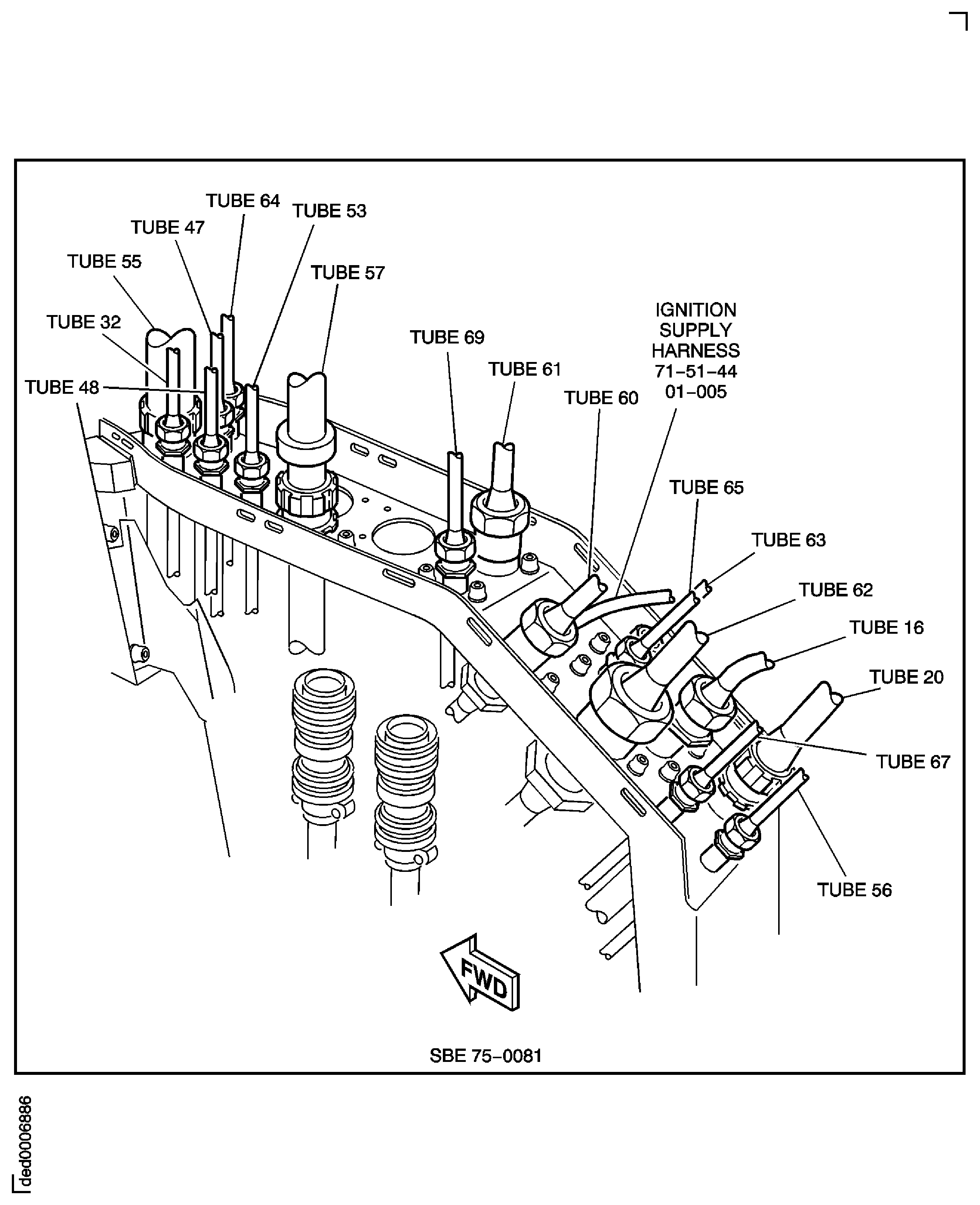

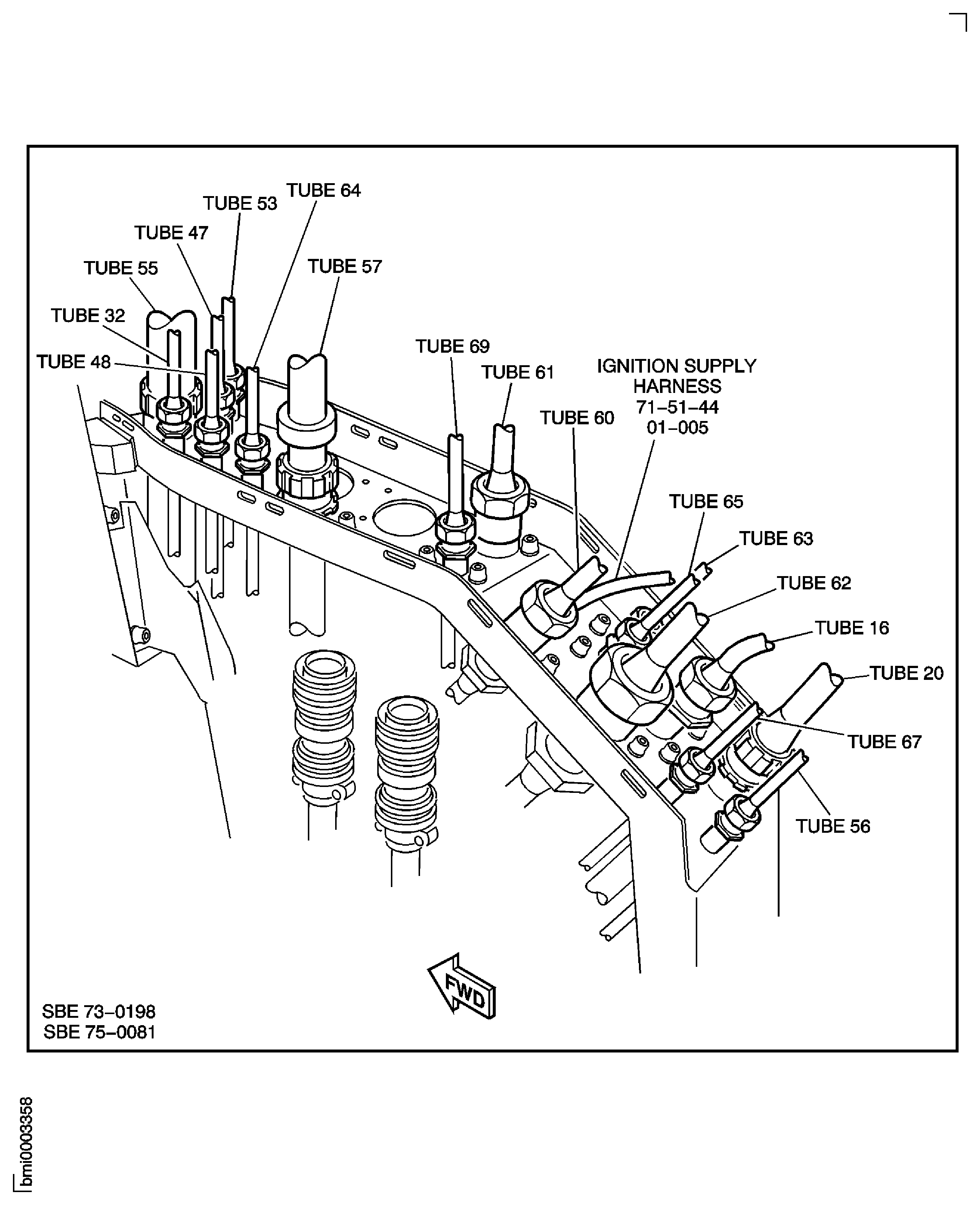

Remove the ignition supply harness Ignition Supply Harness (71-51-44, 01-005).

SUBTASK 72-00-40-020-221-A00 Remove the Ignition Supply Harness (Pre SBE 71-0288)

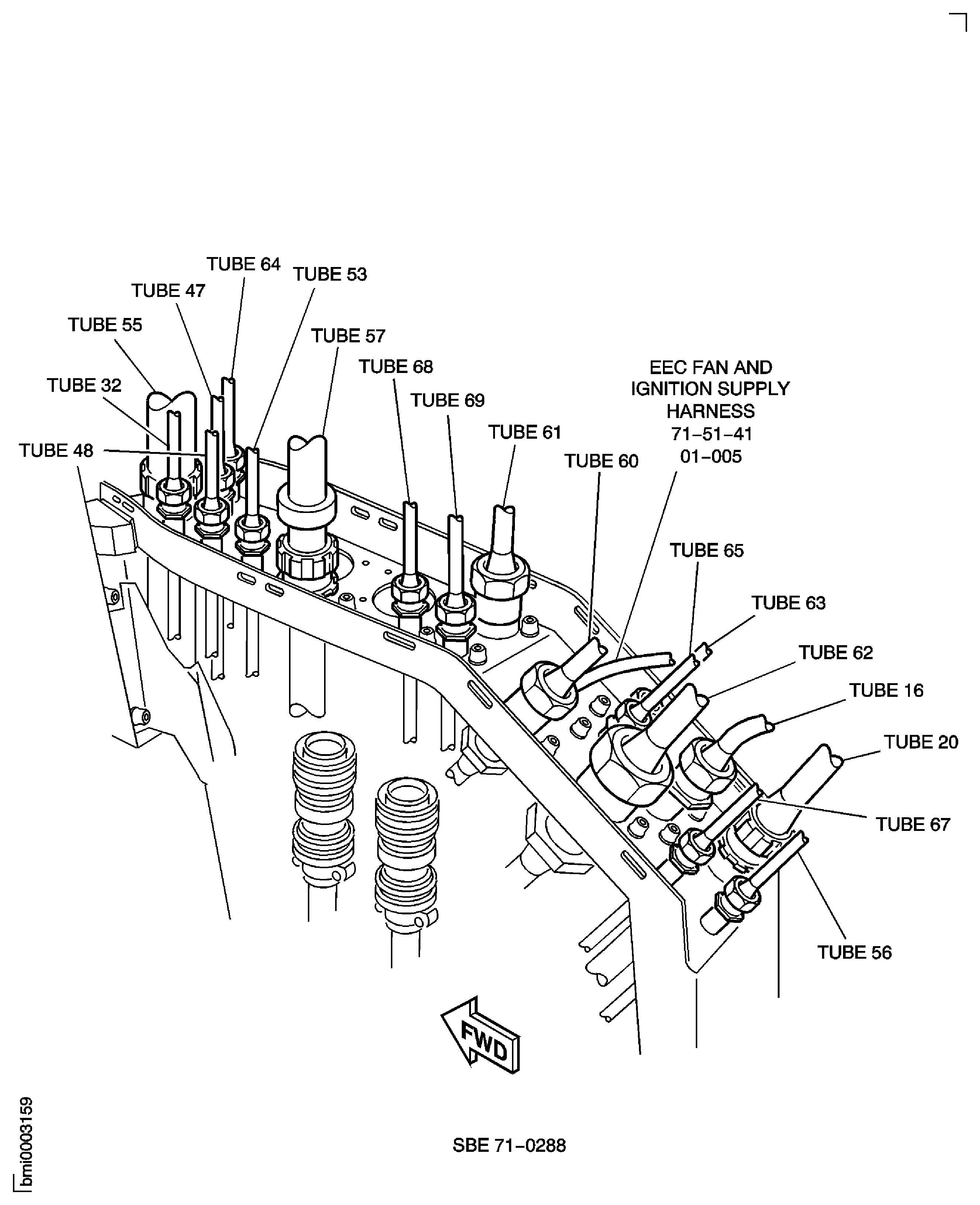

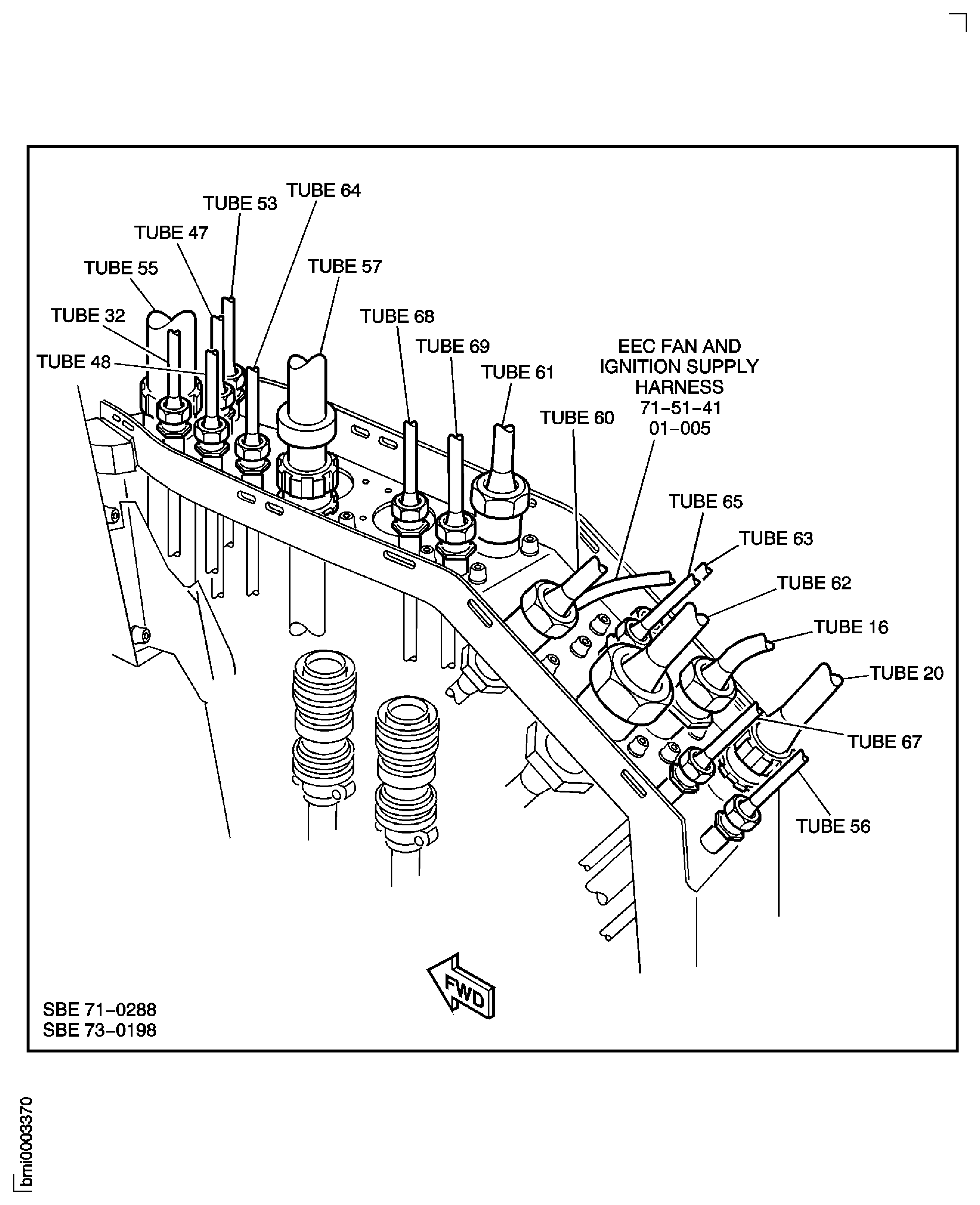

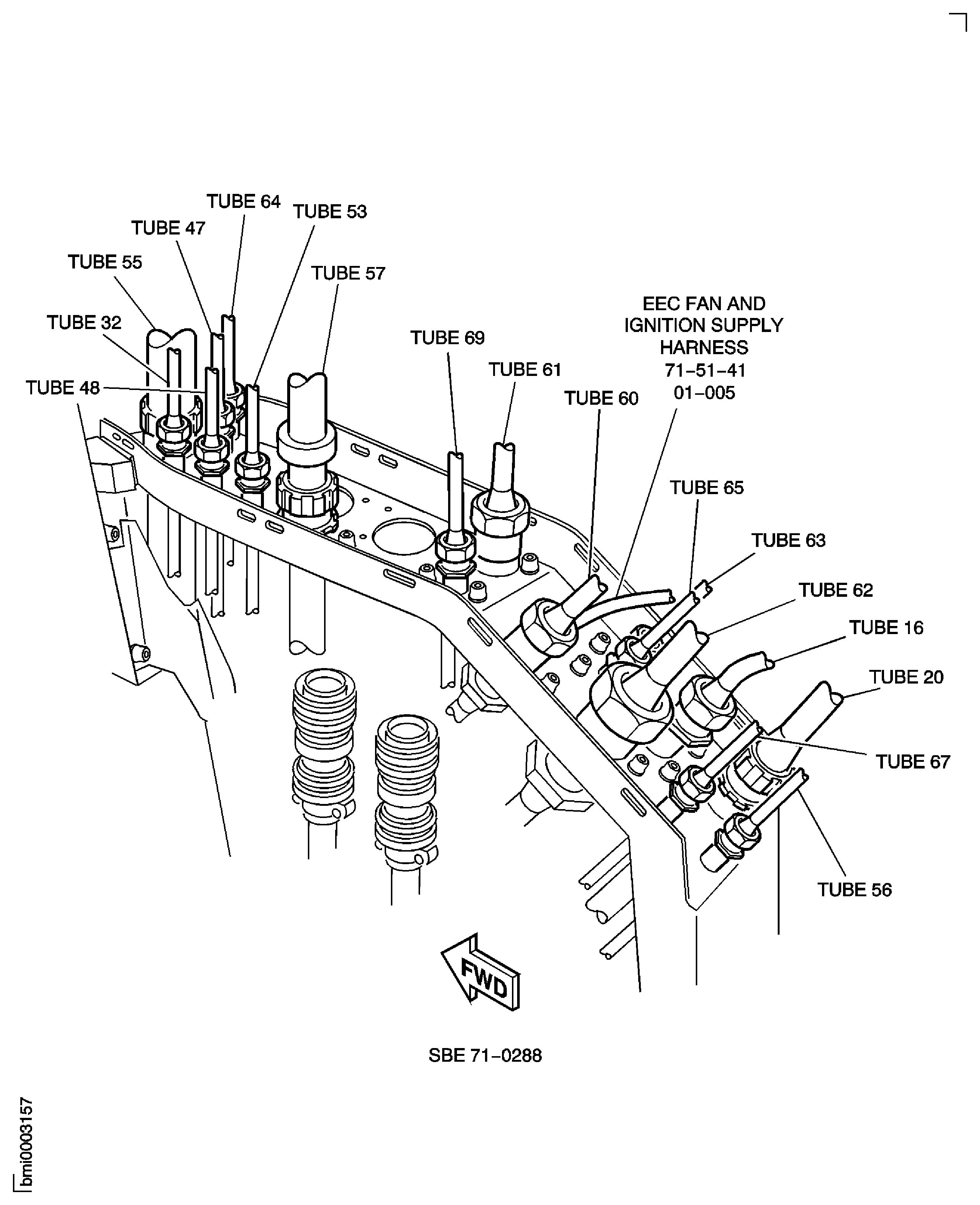

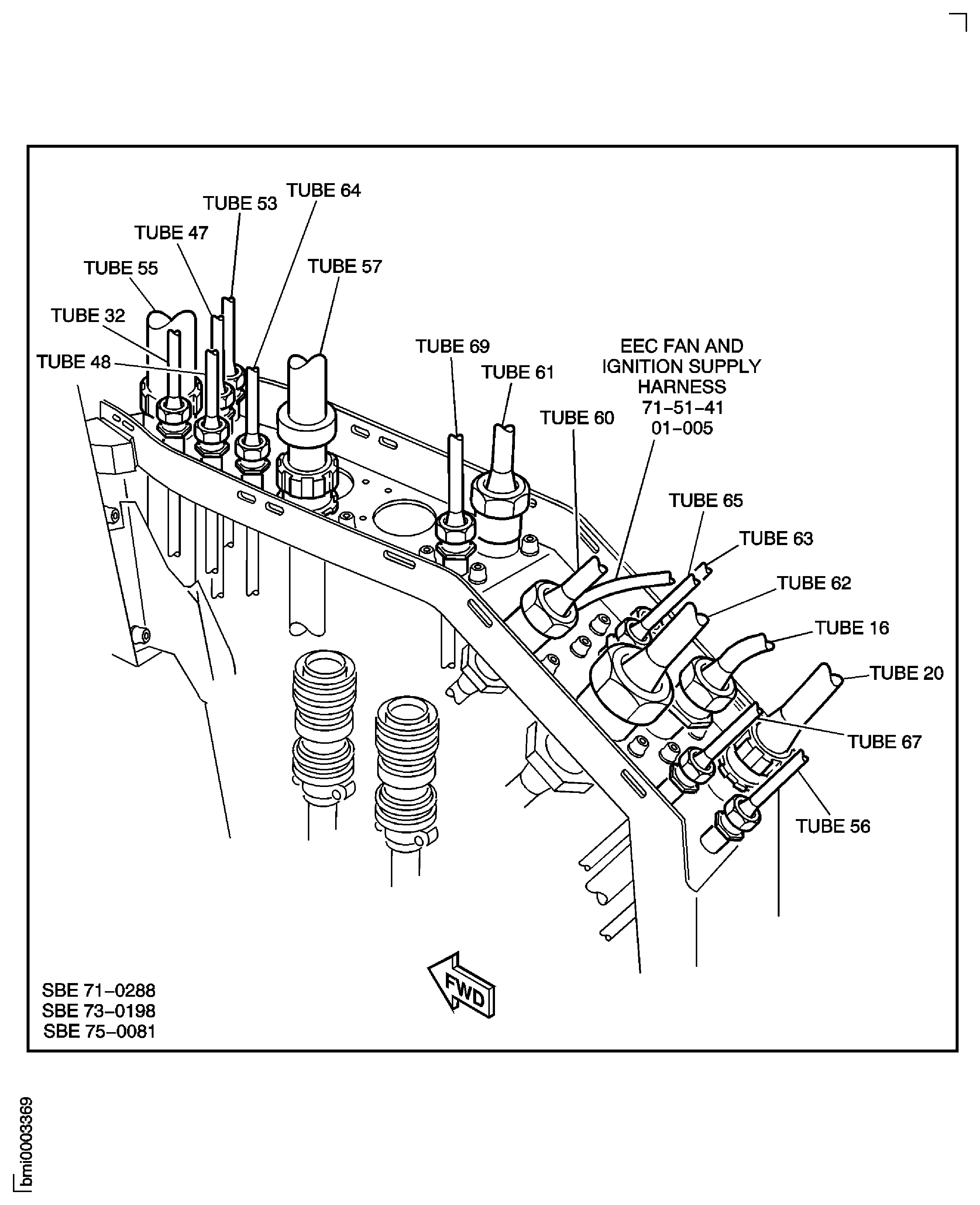

Remove the EEC fan case and ignition supply harness EEC Fan Harness (71-51-41, 01-005).

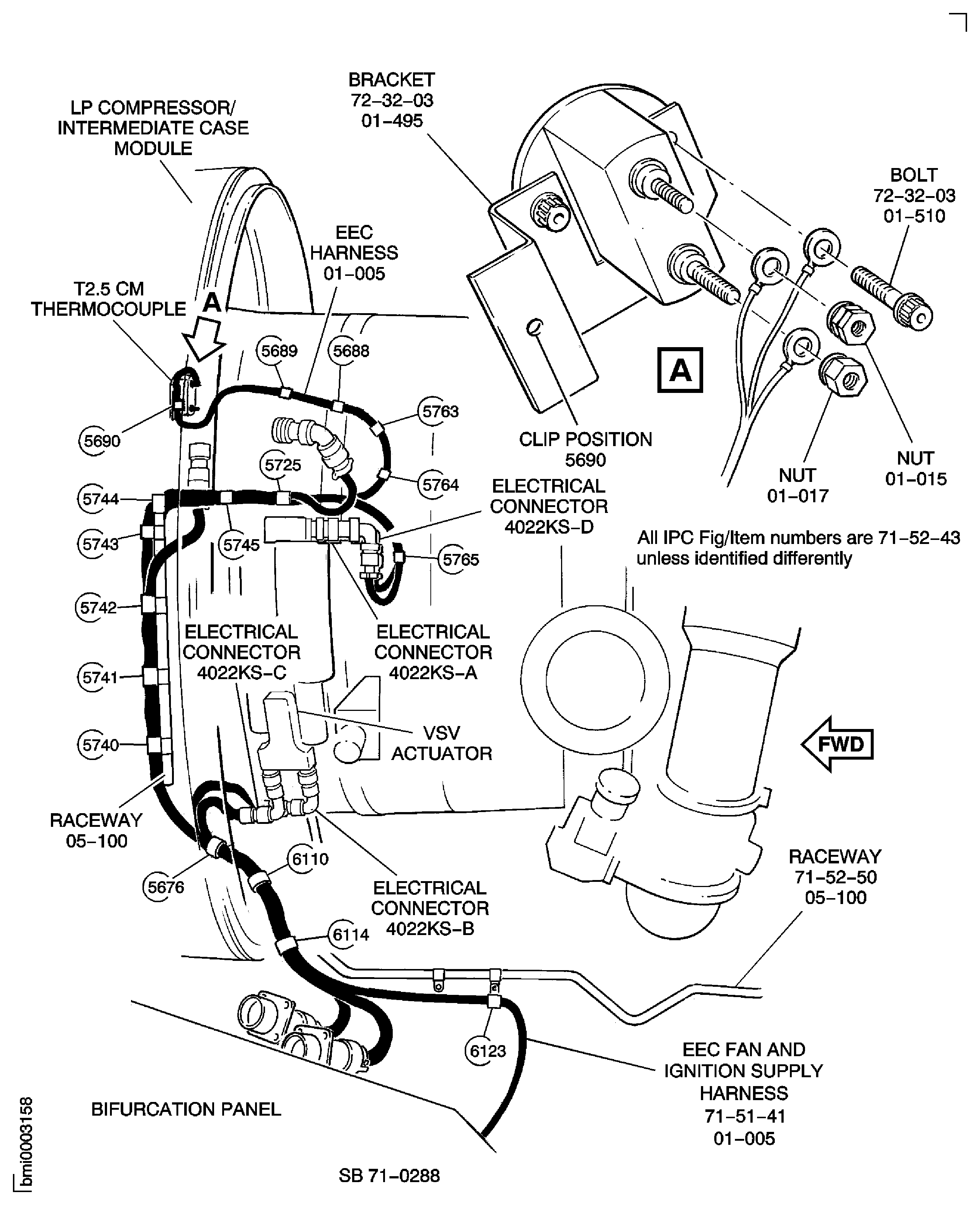

SUBTASK 72-00-40-020-221-B00 Remove the EEC Fan Case and Ignition Supply Harness (SBE 71-0288)

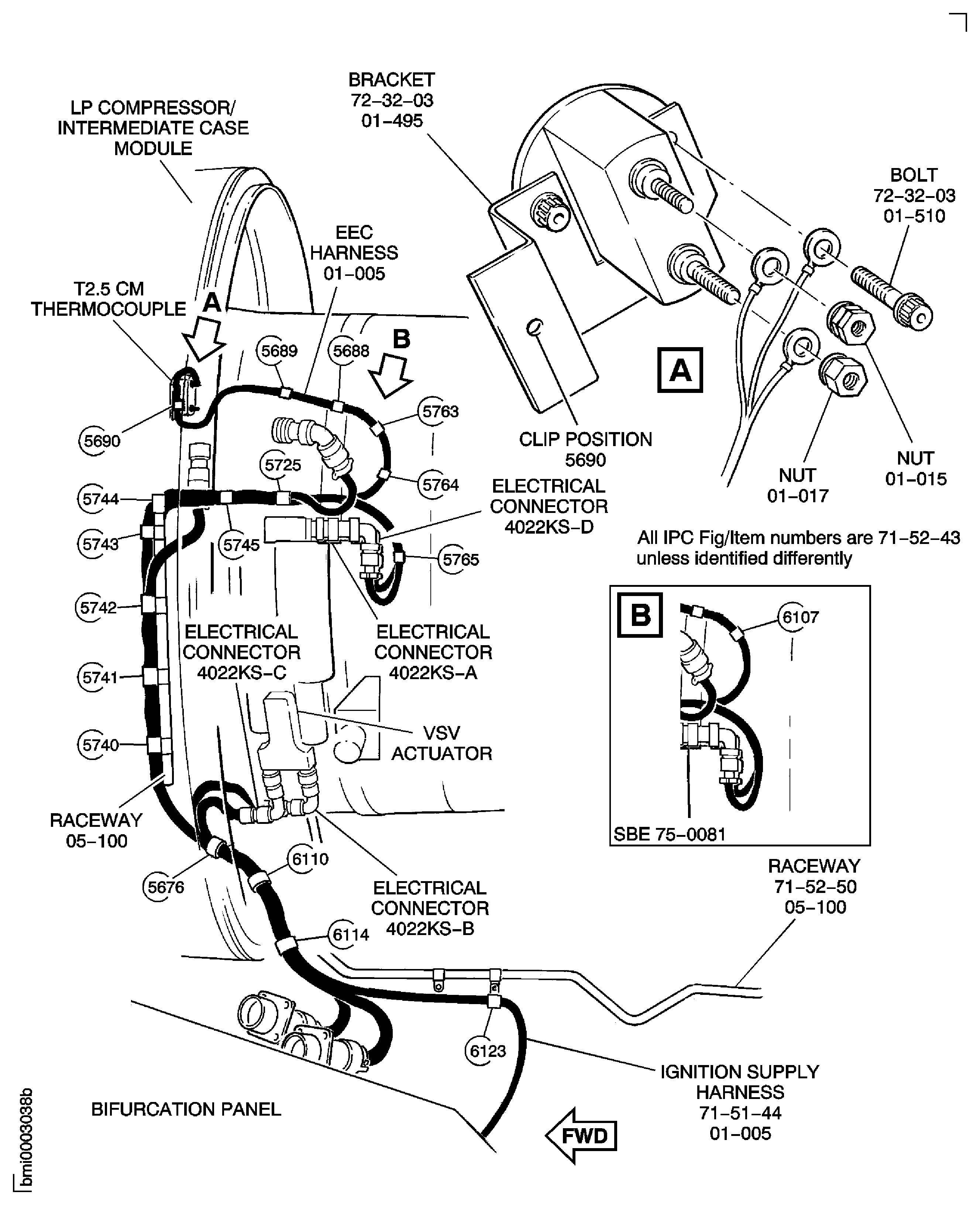

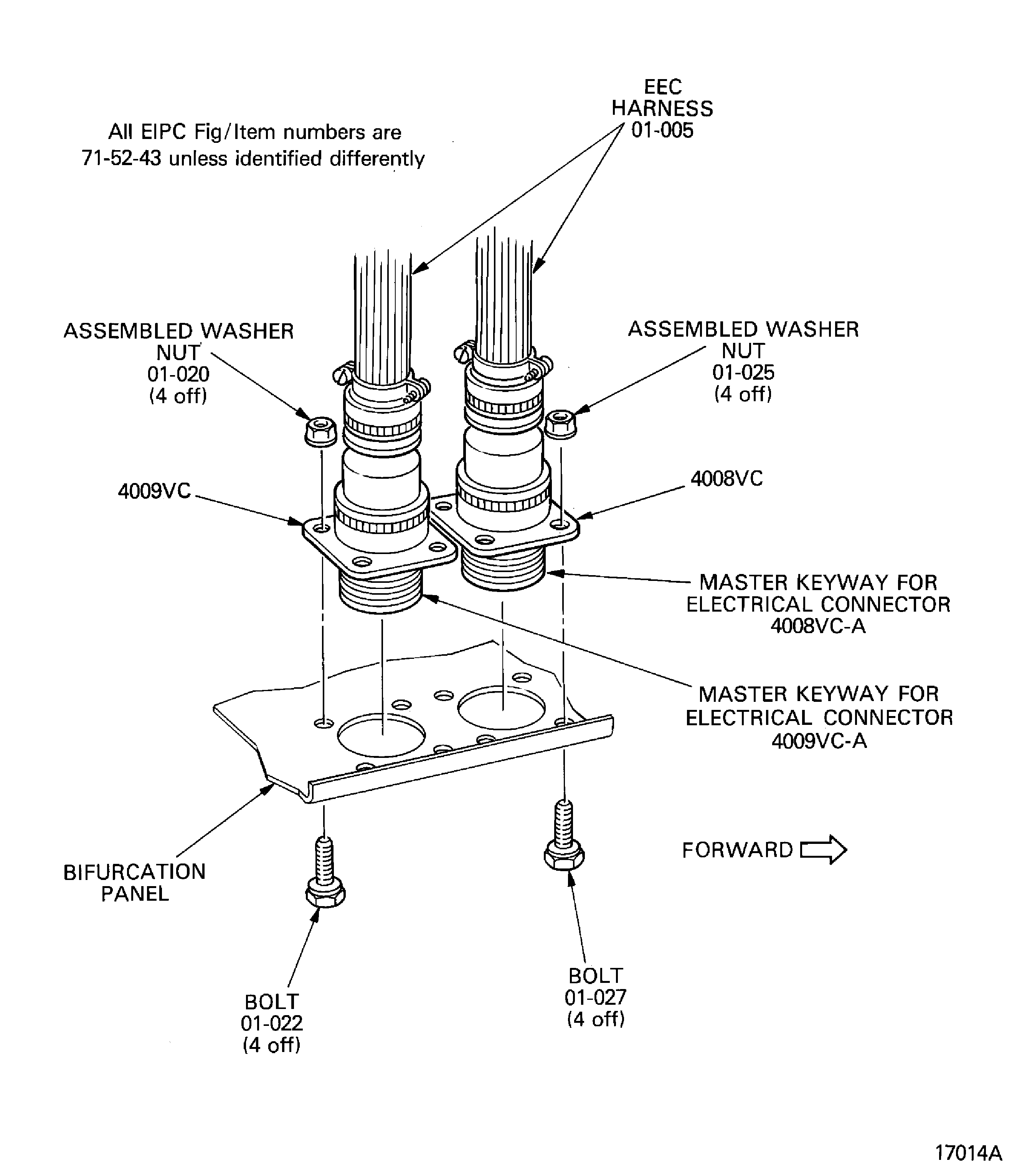

Pre SBE 71-0111: Disassemble and remove the bolts, the clips, the nuts and the washers which attach the electrical connectors together at the bracket. Remove and discard the lockwire at the bracket, refer to the Figure, view at A.

SBE 71-0111: Remove and discard the lockwire from the connectors 4022KS-A, 4022KS-D, 4022KS-B and 4022KS-C. Remove and discard the lockwire at the bracket, refer to the Figure, view at A.

Remove the bolt, the washer, the nut and the clip from the clip position 5744 and remove the raceway EEC Core Harness And Voltage Divider Harness Assembly (71-52-43, 05-100).

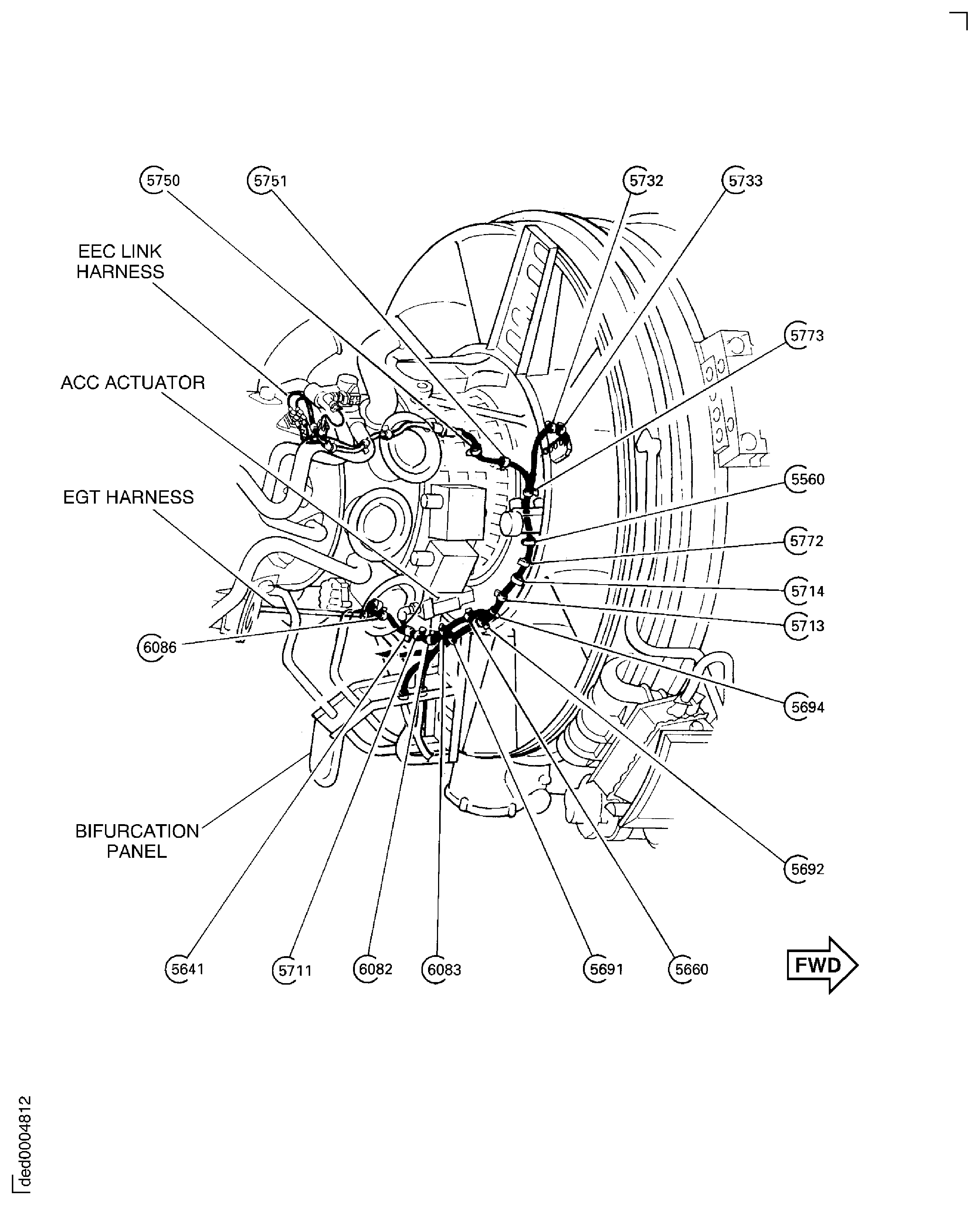

Pre SBE 75-0081: 5560, 5641, 5660, 5679, 5688, 5689, 5691, 5692, 5694, 5711, 5713, 5714, 5725, 5732, 5733, 5742, 5745, 5750, 5751, 5763, 5764, 5765, 5773, 6073, 6082, 6083, 6086, 6110 and 6114.

SBE 75-0081: 5560, 5641, 5660, 5679, 5688, 5689, 5691, 5692, 5694, 5711, 5713, 5714, 5725, 5732, 5733, 5742, 5745, 5750, 5751, 5773, 6073, 6082, 6083, 6086, 6107, 6110 and 6114.

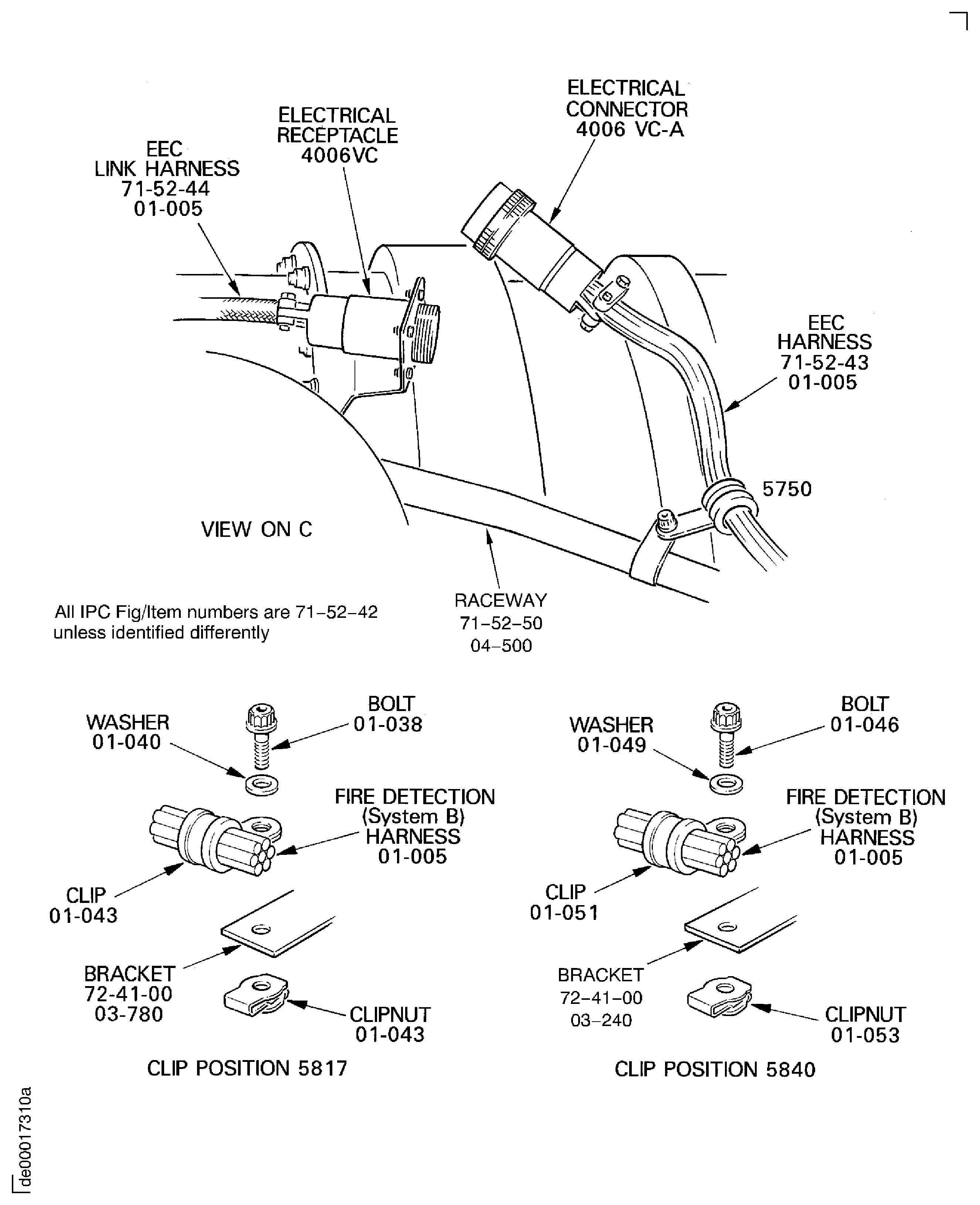

Remove the bolts, the washers, the spacers, the clips, the clipnuts and the nuts from the clip positions that follow:

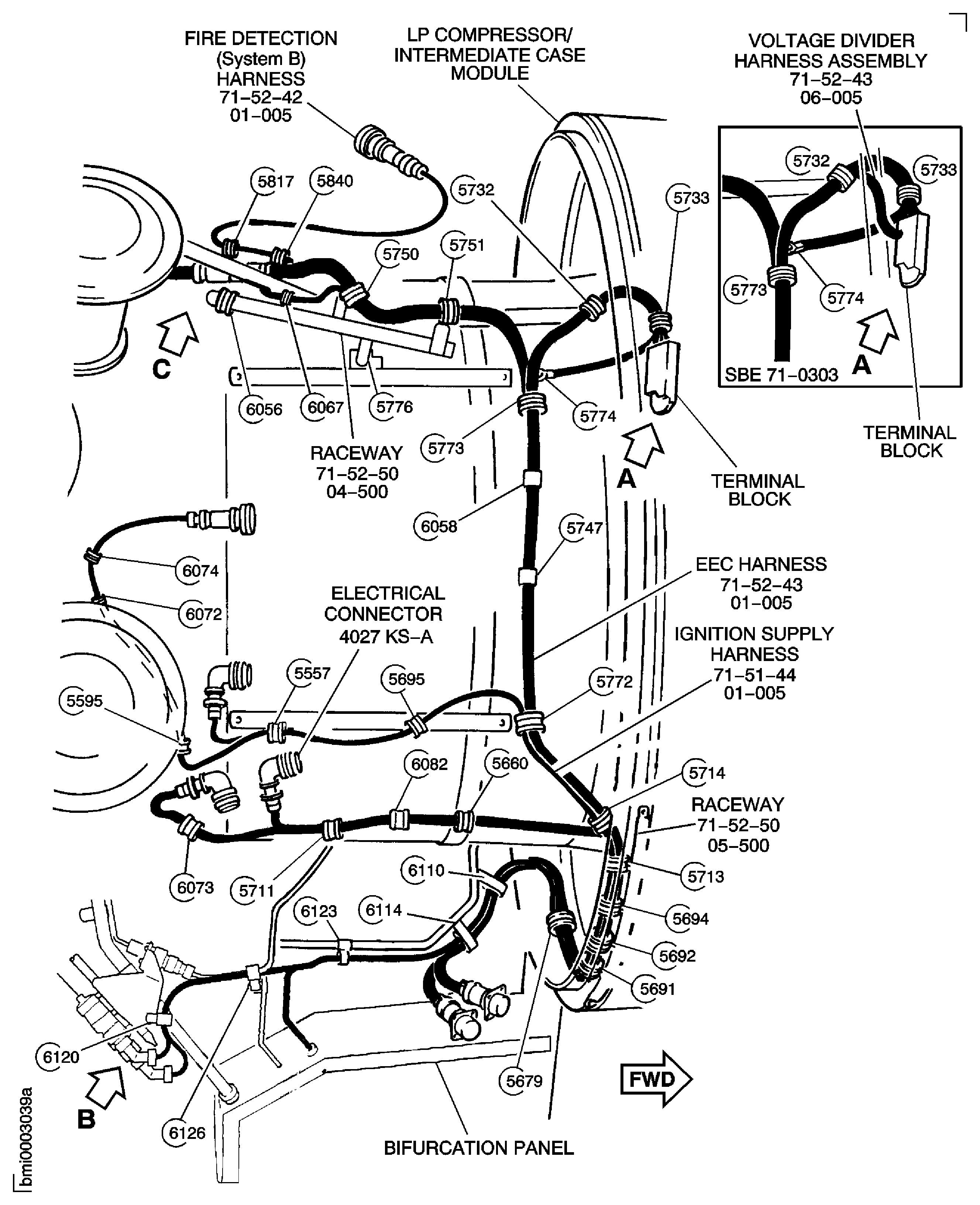

Remove the EEC harness EEC Core Harness And Voltage Divider Harness Assembly (71-52-43, 01-005) and the fire detection harnesses Fire Detection (System B) Harness (71-52-42, 01-005).

SUBTASK 72-00-40-020-136-A00 Remove the EEC Harness (71-52-43,01-005) and Fire Detection Harness (71-52-42,01-005) (Pre SBE 71-0111, SBE 71-0111, Pre SBE 71-0303, Pre SBE 75-0081, SBE 75-0081 and SBE 72-0553)

Pre SBE 71-0111: Disassemble and remove the bolts, the clips, the nuts and the washers which attach the electrical connectors together at the bracket. Remove and discard the lockwire at the bracket, refer to the Figure, view at A.

SBE 71-0111: Remove and discard the lockwire from the connectors 4022KS-A, 4022KS-D, 4022KS-B and 4022KS-C. Remove and discard the lockwire at the bracket, refer to the Figure, view at A.

Remove the bolt, the washer, the nut and the clip from the clip position 5744 and remove the raceway EEC Core Harness And Voltage Divider Harness Assembly (71-52-43, 05-100).

Pre SBE 75-0081: 5560, 5641, 5660, 5679, 5688, 5689, 5691, 5692, 5694, 5711, 5713, 5714, 5725, 5732, 5733, 5742, 5745, 5750, 5751, 5763, 5764, 5765, 5773, 6073, 6082, 6083, 6086, 6110 and 6114.

SBE 75-0081: 5560, 5641, 5660, 5679, 5688, 5689, 5691, 5692, 5694, 5711, 5713, 5714, 5725, 5732, 5733, 5742, 5745, 5750, 5751, 5773, 6073, 6082, 6083, 6086, 6107, 6110 and 6114.

Remove the bolts, the washers, the spacers, the clips, the clipnuts and the nuts from the clip positions that follow:

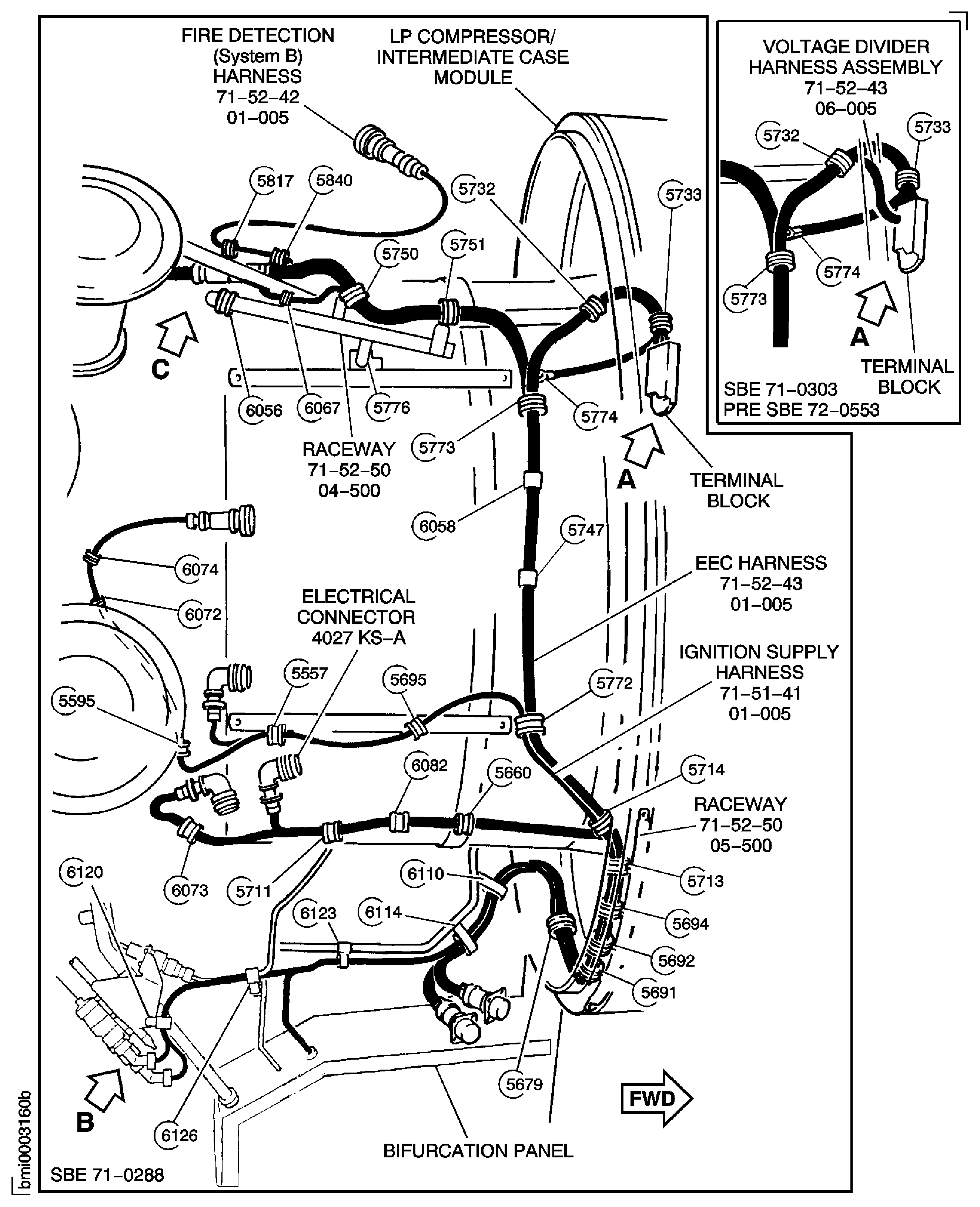

Remove the EEC harnessEEC Core Harness And Voltage Divider Harness Assembly (71-52-43, 01-005), the voltage divider harness ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 06-005) and the fire detection harnesses Fire Detection (System B) Harness (71-52-42, 01-005).

SUBTASK 72-00-40-020-136-B00 Remove the EEC Harness (71-52-43,01-005), the Voltage Divider Harness (71-52-43,06-005) and the Fire Detection Harness (71-52-42,01-005) (Pre SBE 71-0111, SBE 71-0111, SBE 71-0303, Pre SBE 75-0081, SBE 75-0081 and Pre SBE 72-0553)

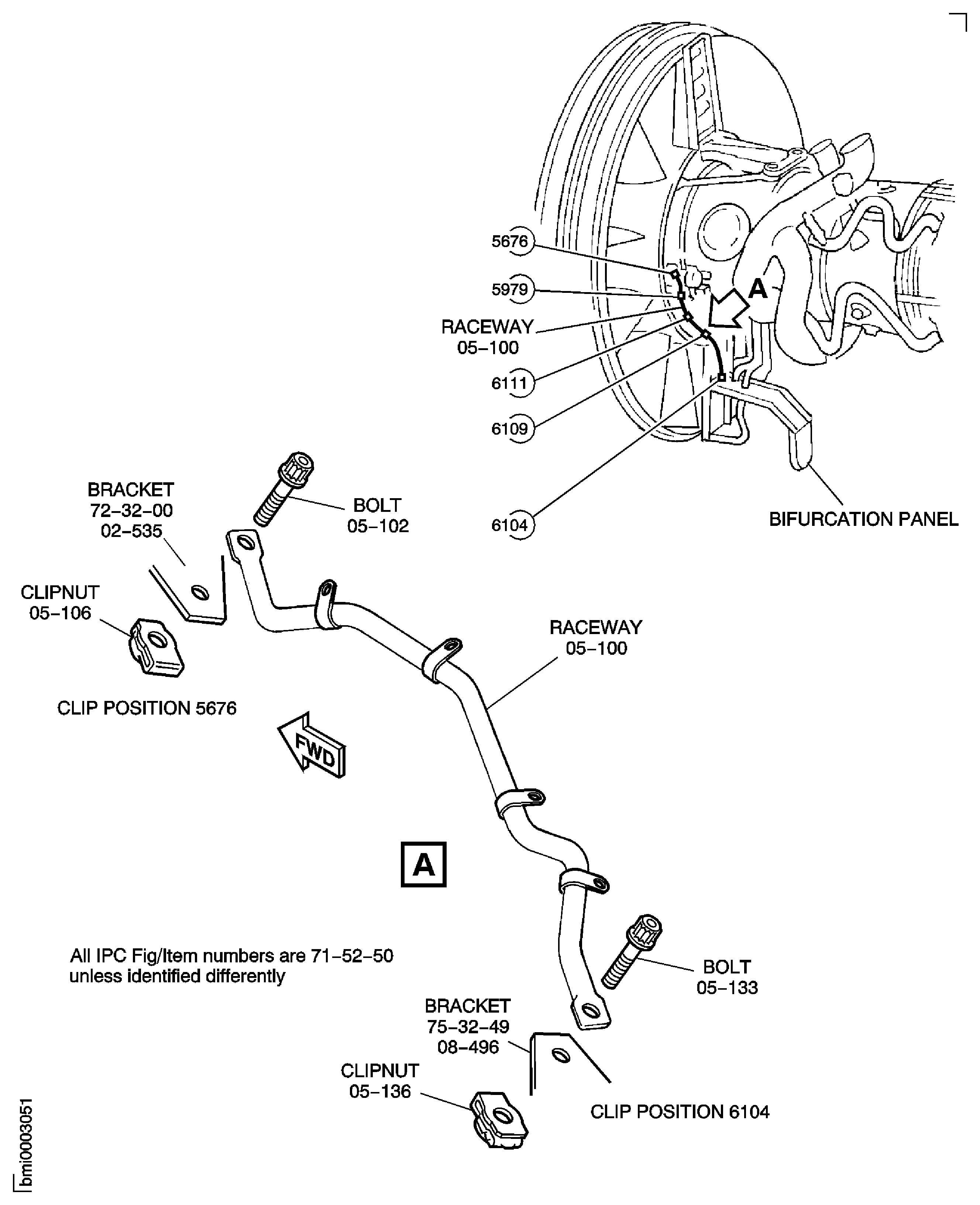

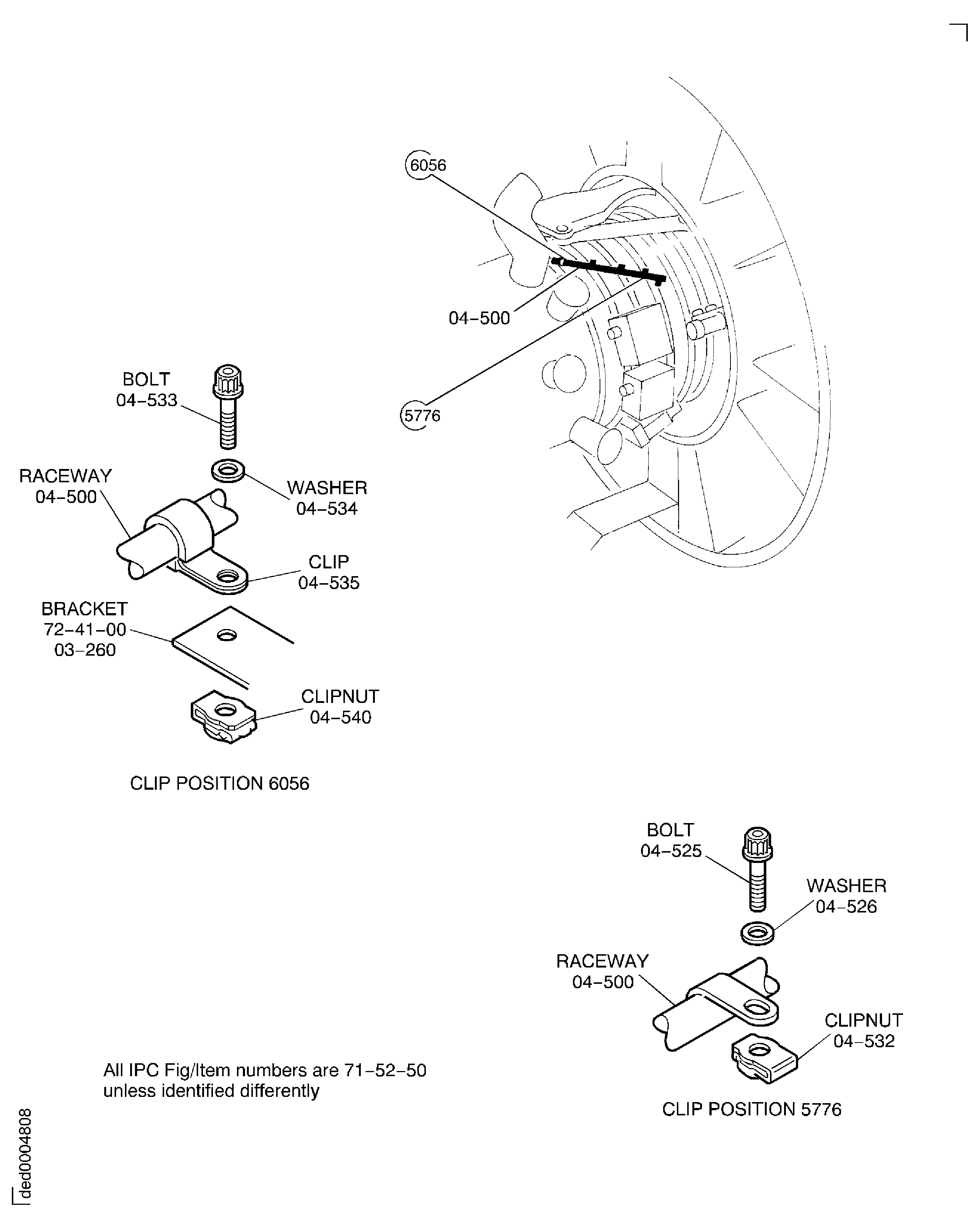

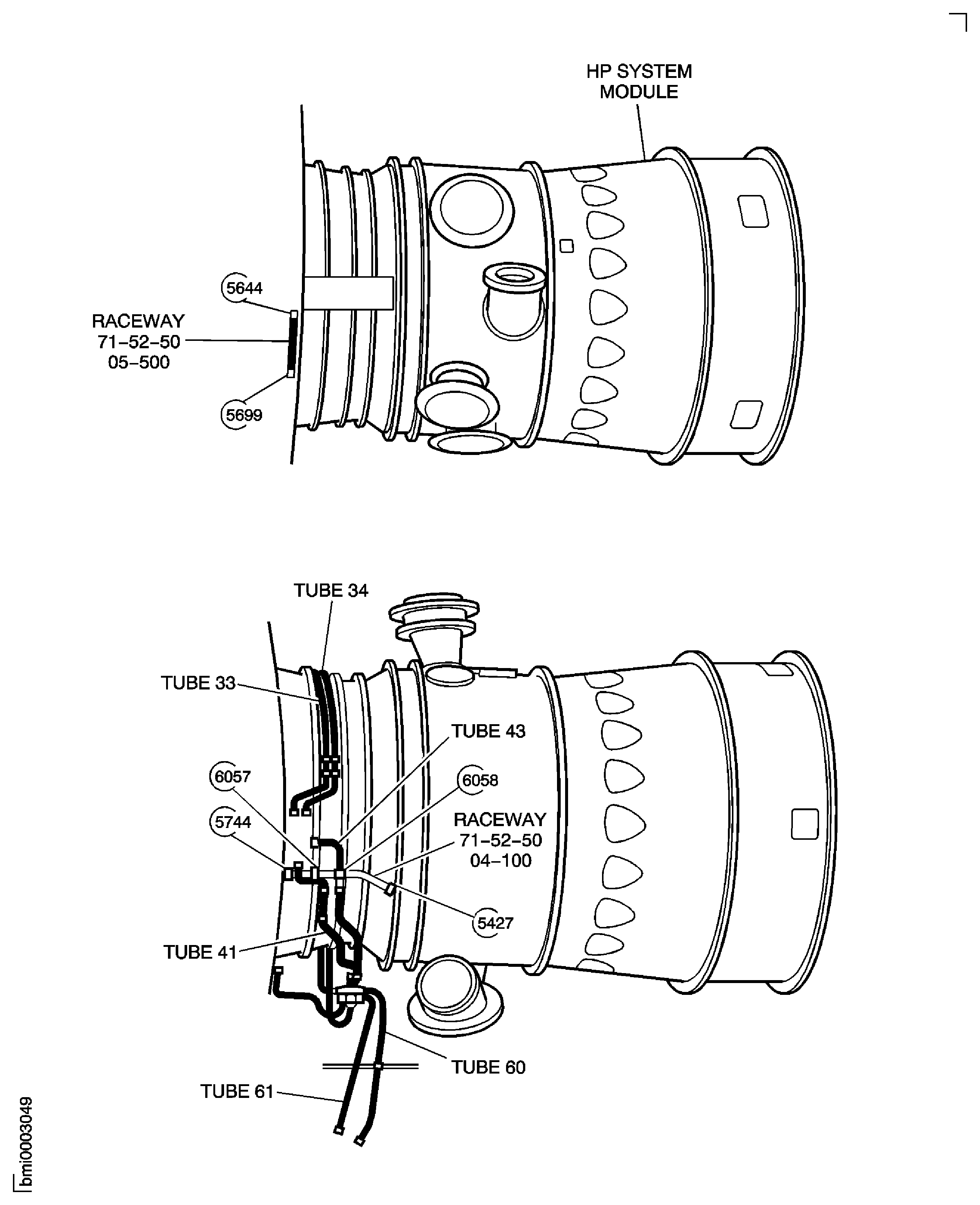

Refer to Figure.

Remove the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE (71-52-50, 04-500).

SUBTASK 72-00-40-020-222 Remove the Raceway (71-52-50,04-500)

Refer to Figure.

NOTE

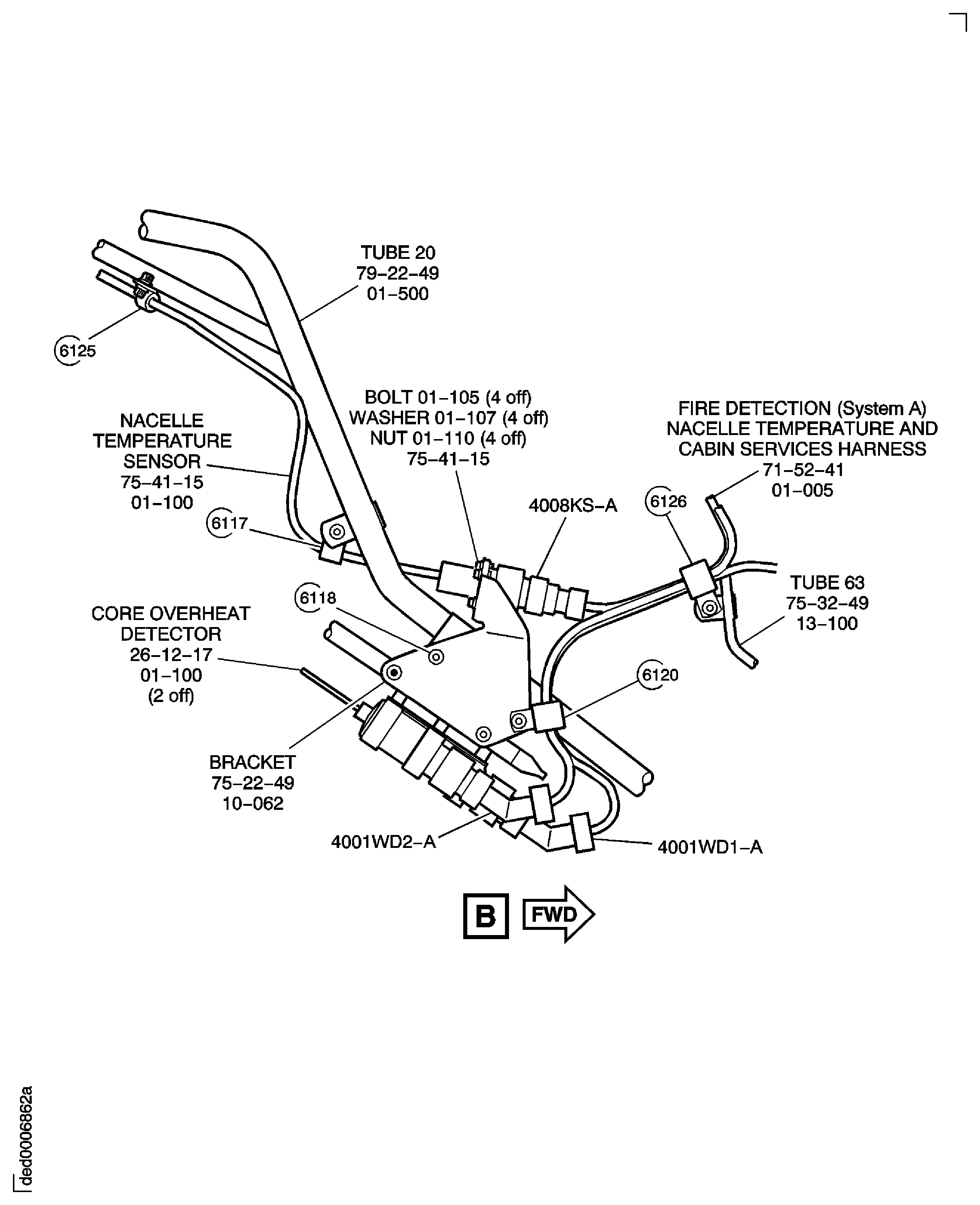

The core fire detector must have its maintenance completed, as given in the Rohr Industries Component Maintenance Manual (26-12-19).Remove the four nuts, bolts and washers that attach the core overheat detector to the bracket AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 10-062).

Remove the core overheat detector NACELLE TEMPERATURE SENSOR (75-41-15, 01-100).

SUBTASK 72-00-40-020-223 Remove the Core Overheat Detector (75-41-15,01-100)

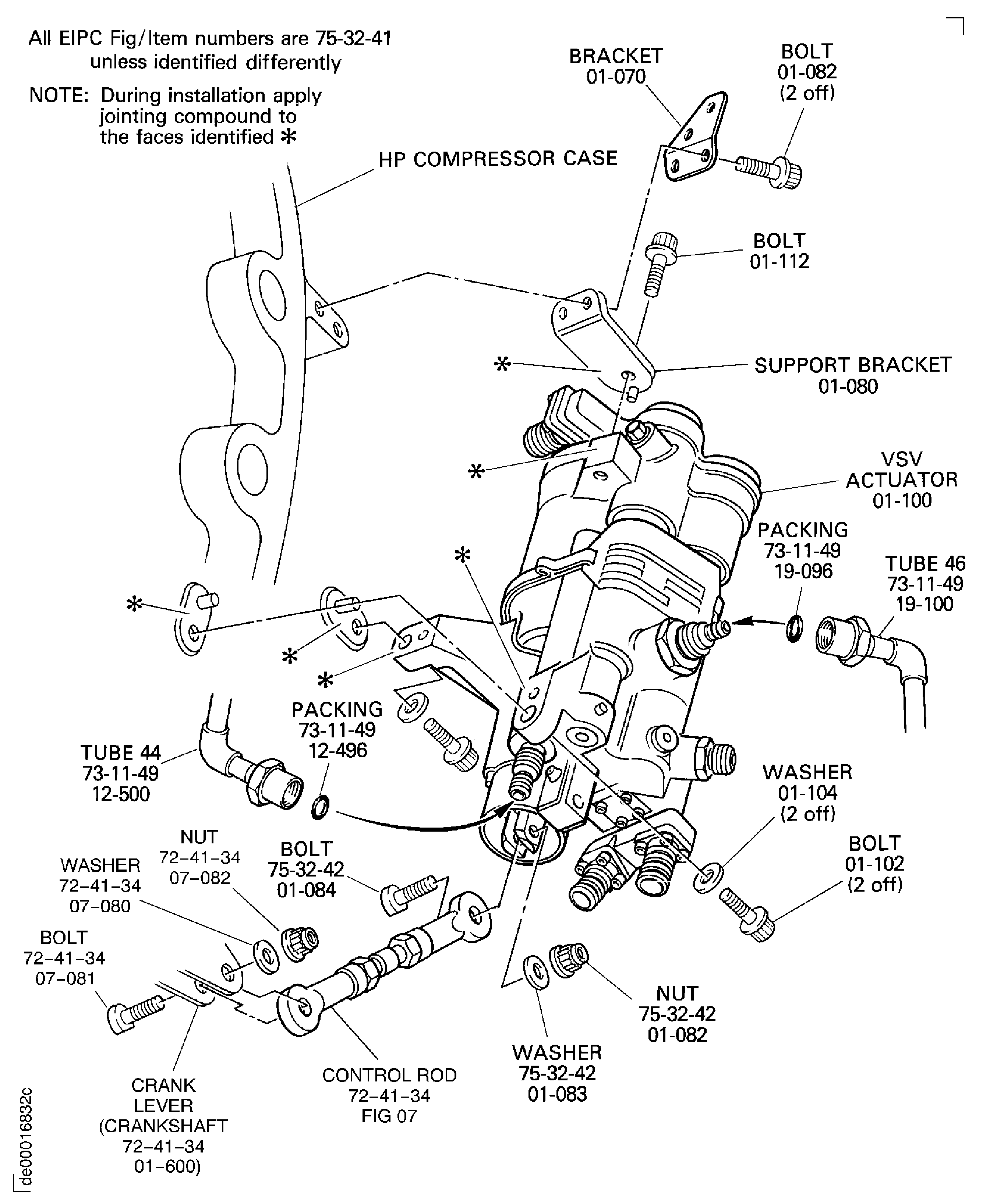

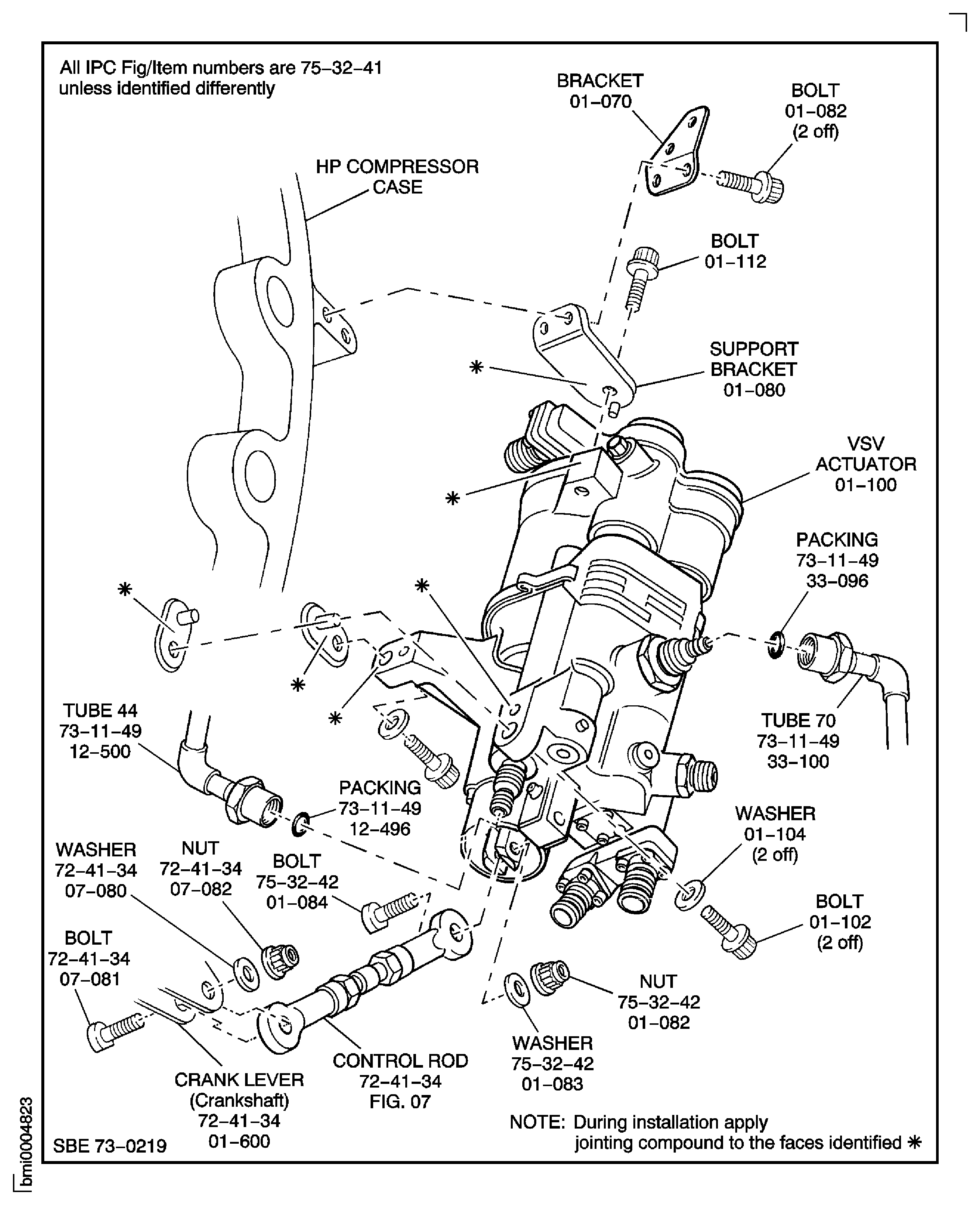

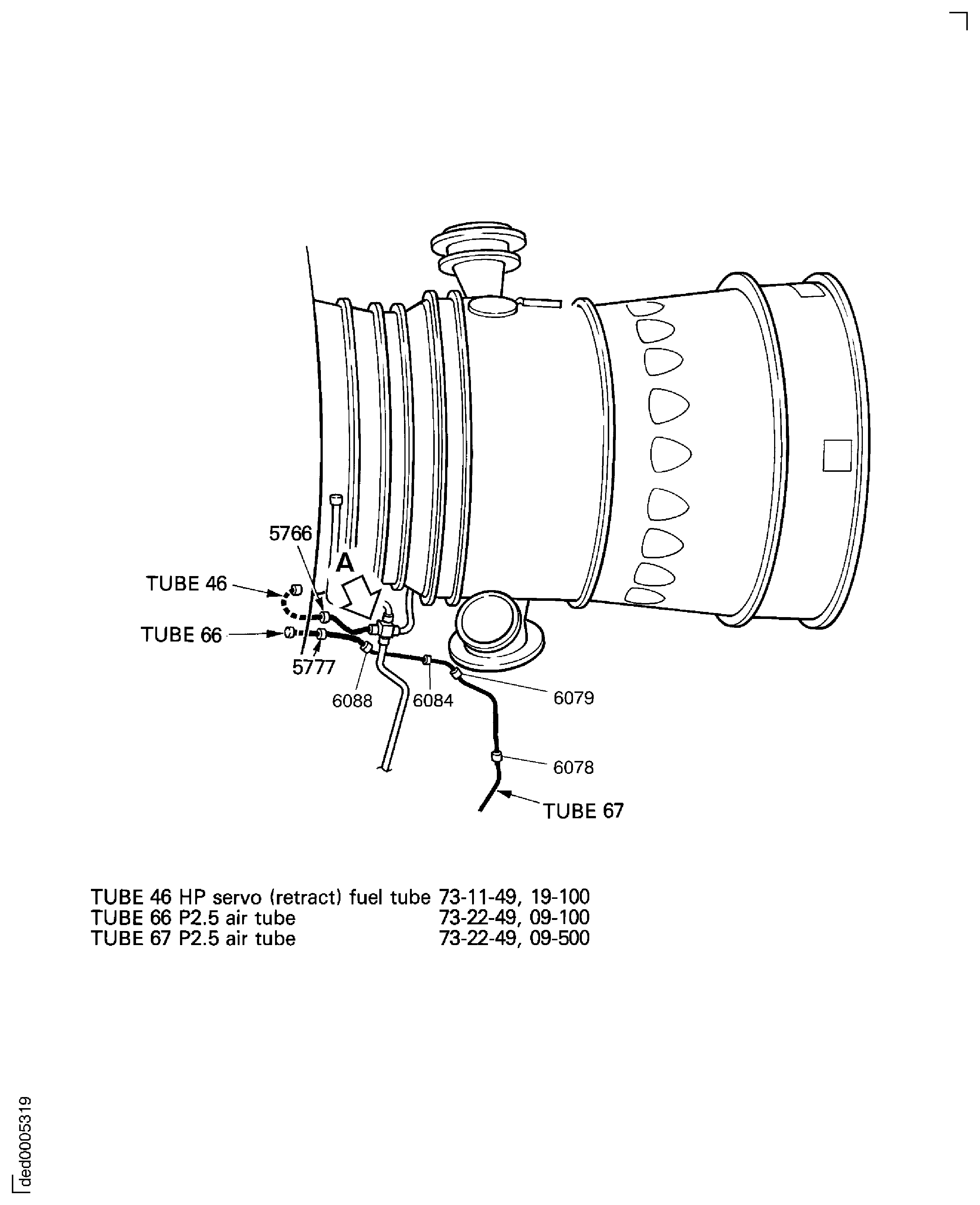

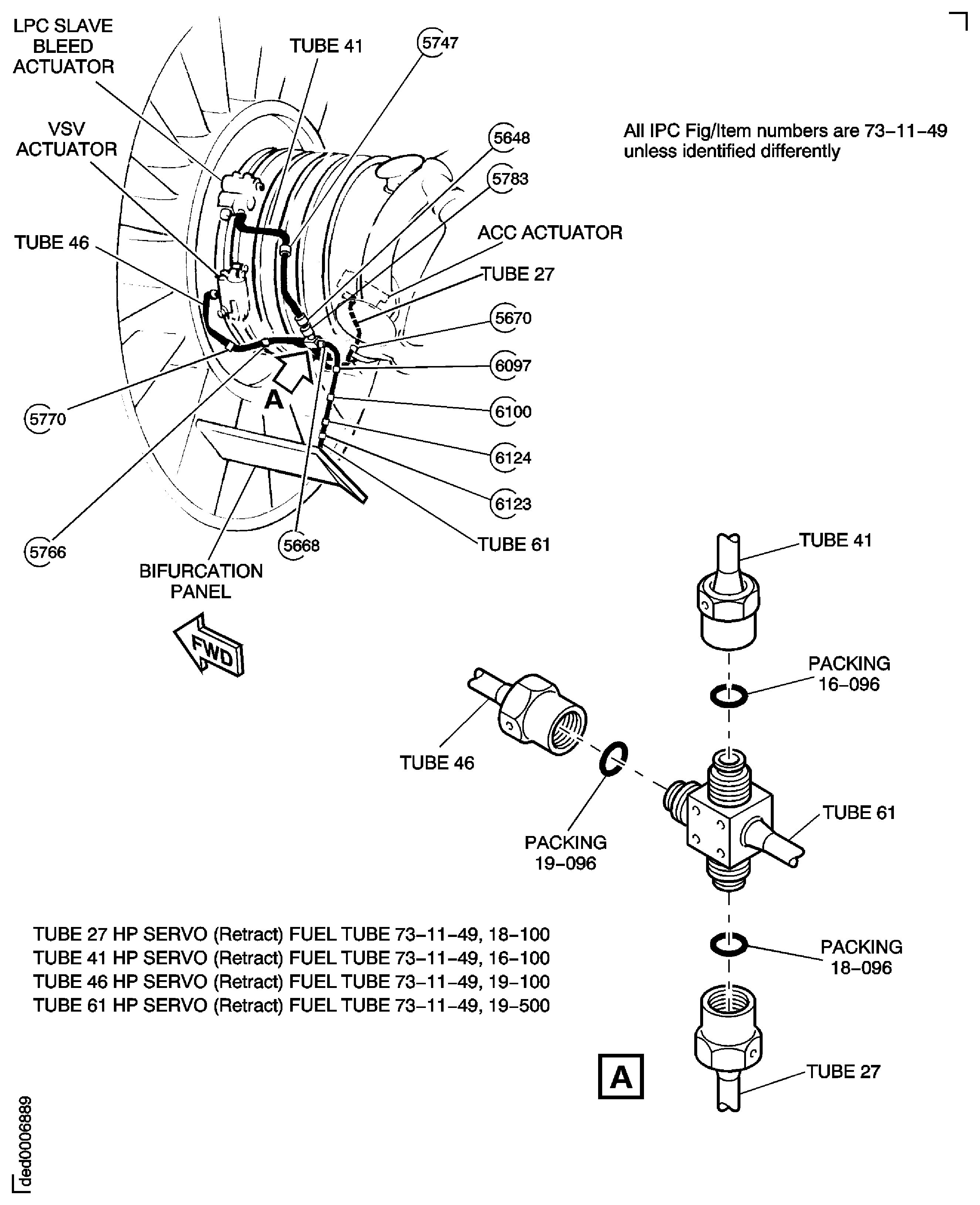

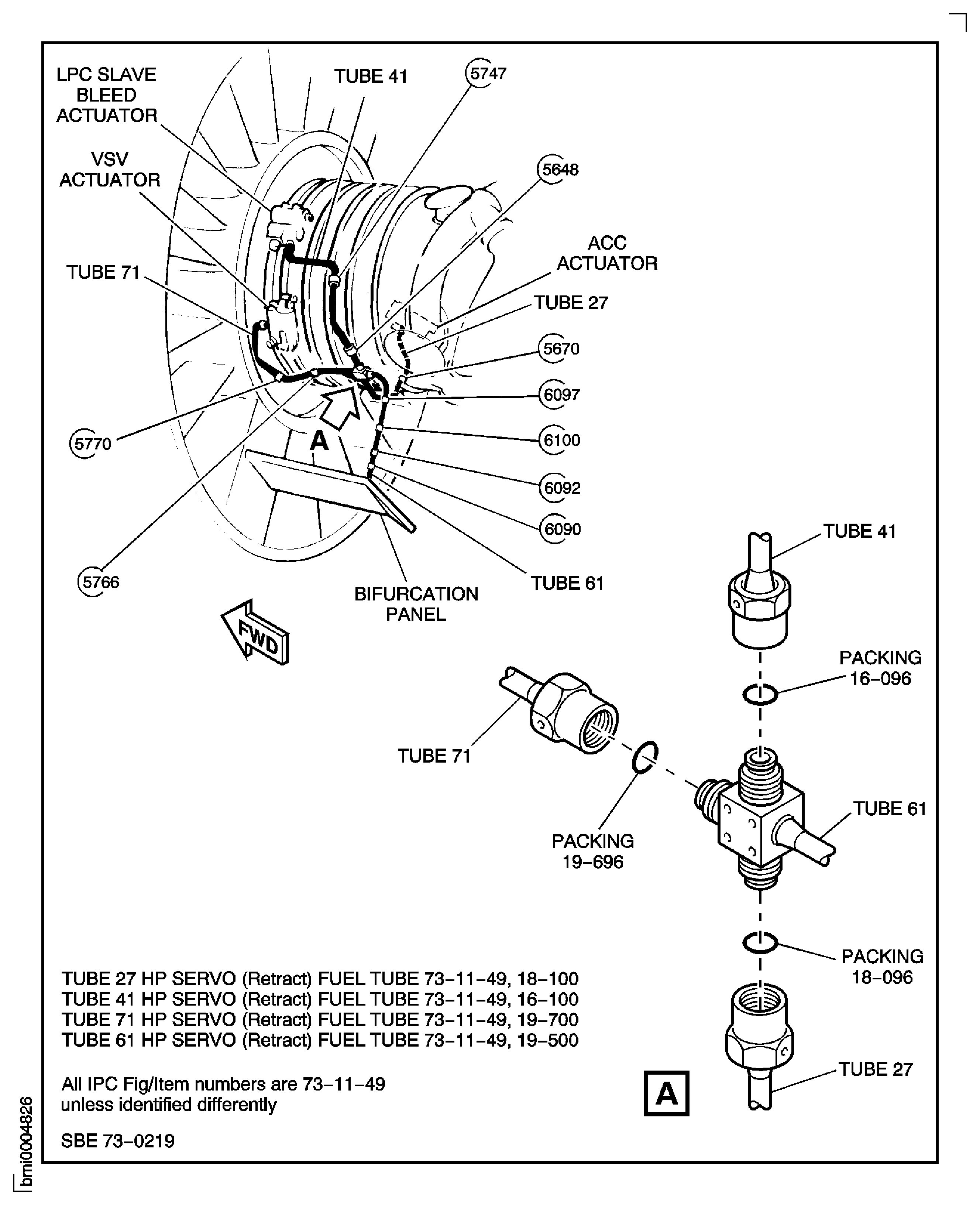

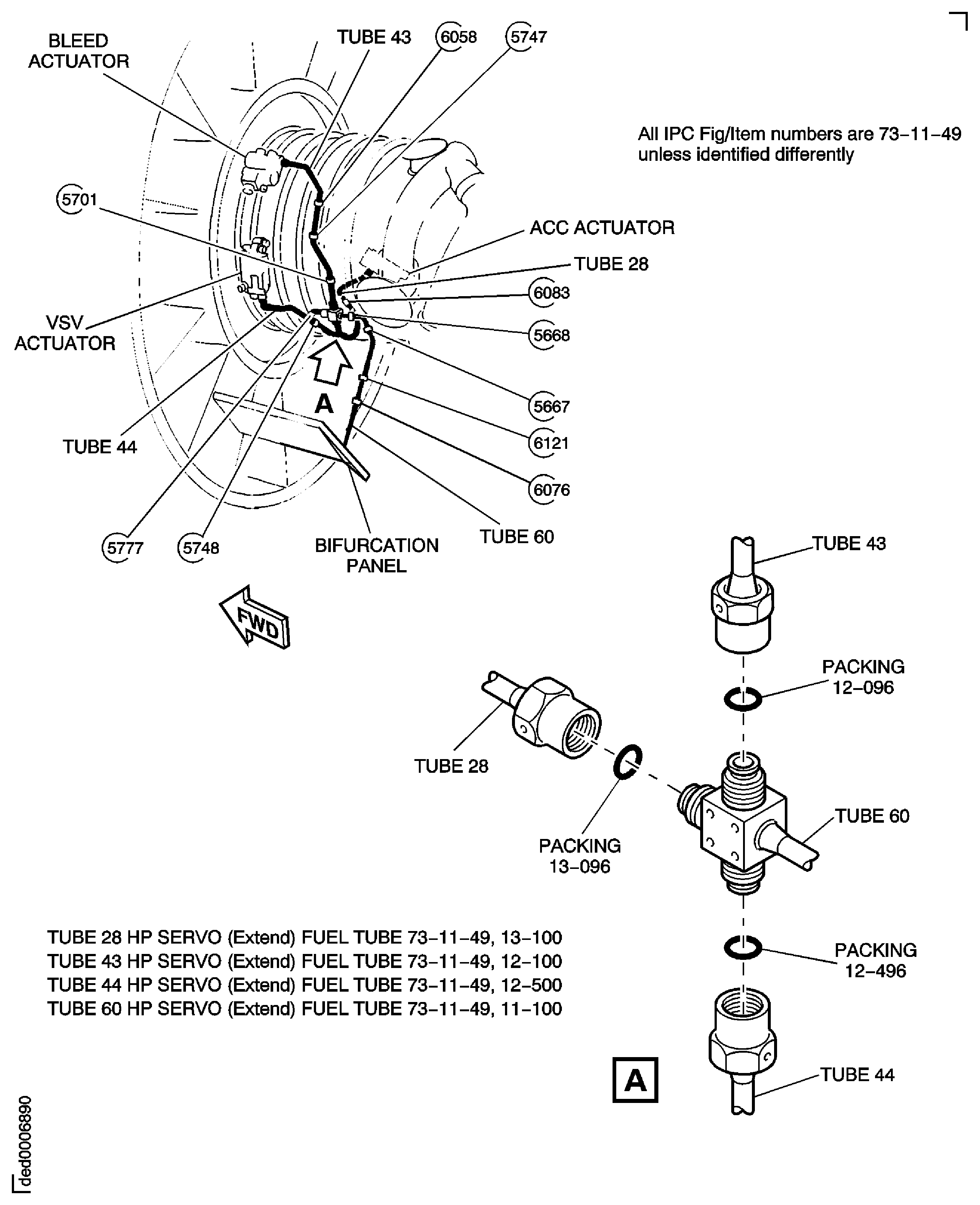

Pre SBE 73-0219 and SBE 73-0235: Disconnect the fuel servo tubes 44 and 46 from the VSV actuator and remove the two packings.

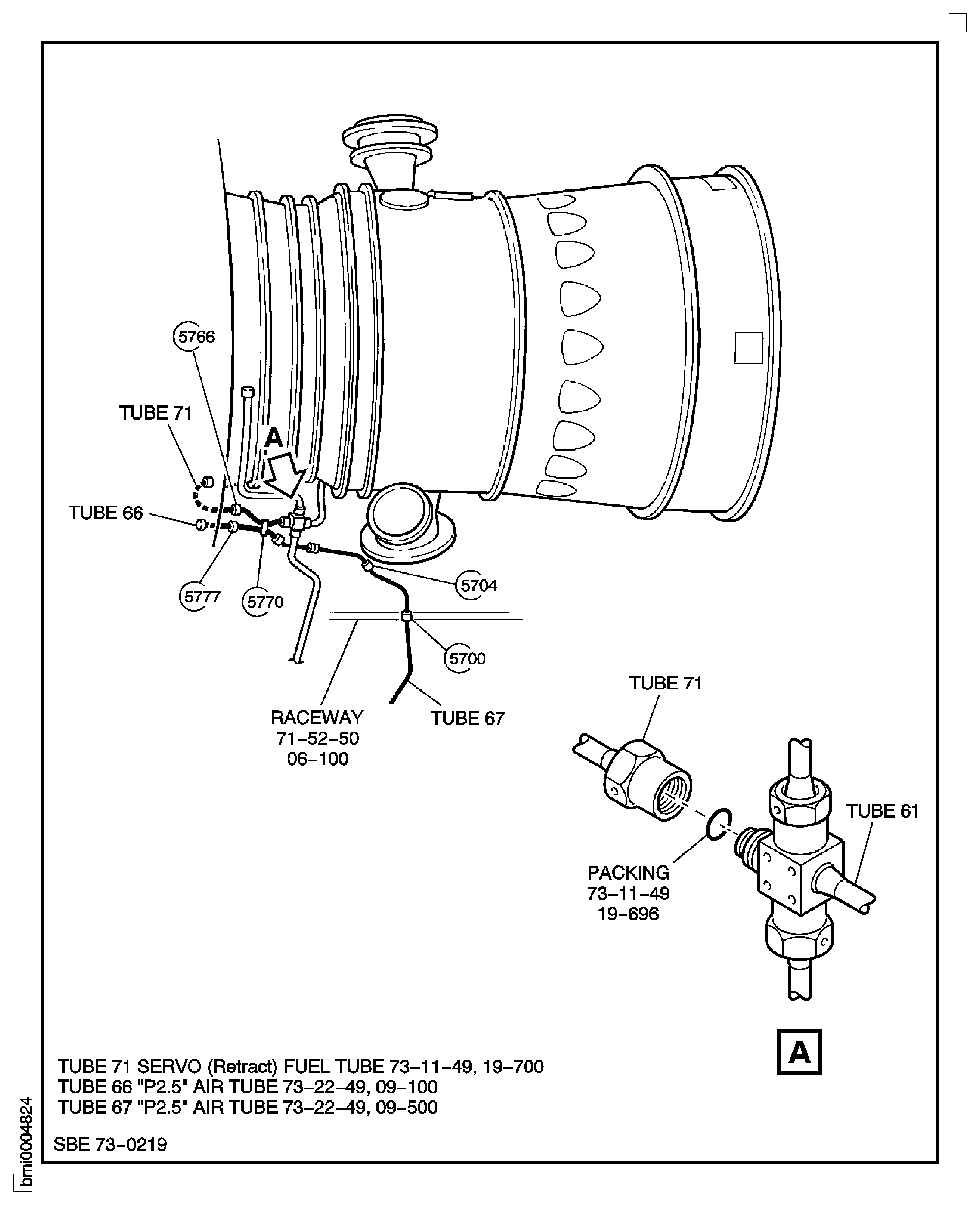

SBE 73-0219: Disconnect the fuel servo tubes 44 and 70 from the VSV actuator and remove the two packings.

Hold the VSV actuator, remove the four bolts and the two washers that attach the actuator to the HP compressor case and remove the actuator. Remove the bracket HPC Variable Stator Vane Actuator (75-32-41, 01-070).

NOTE

The VSV actuator must have its maintenance completed, as given in the D.S.I.C. Component Maintenance Manual (75-32-41).Remove the bolt and the washer that attaches the bracket HPC Variable Stator Vane Actuator (75-32-41, 01-080) to the actuator and remove the bracket.

SUBTASK 72-00-40-020-137 Remove the Variable Stator Vane (VSV) Actuator (Pre SBE 73-0219SBE 73-0235 and SBE 73-0219

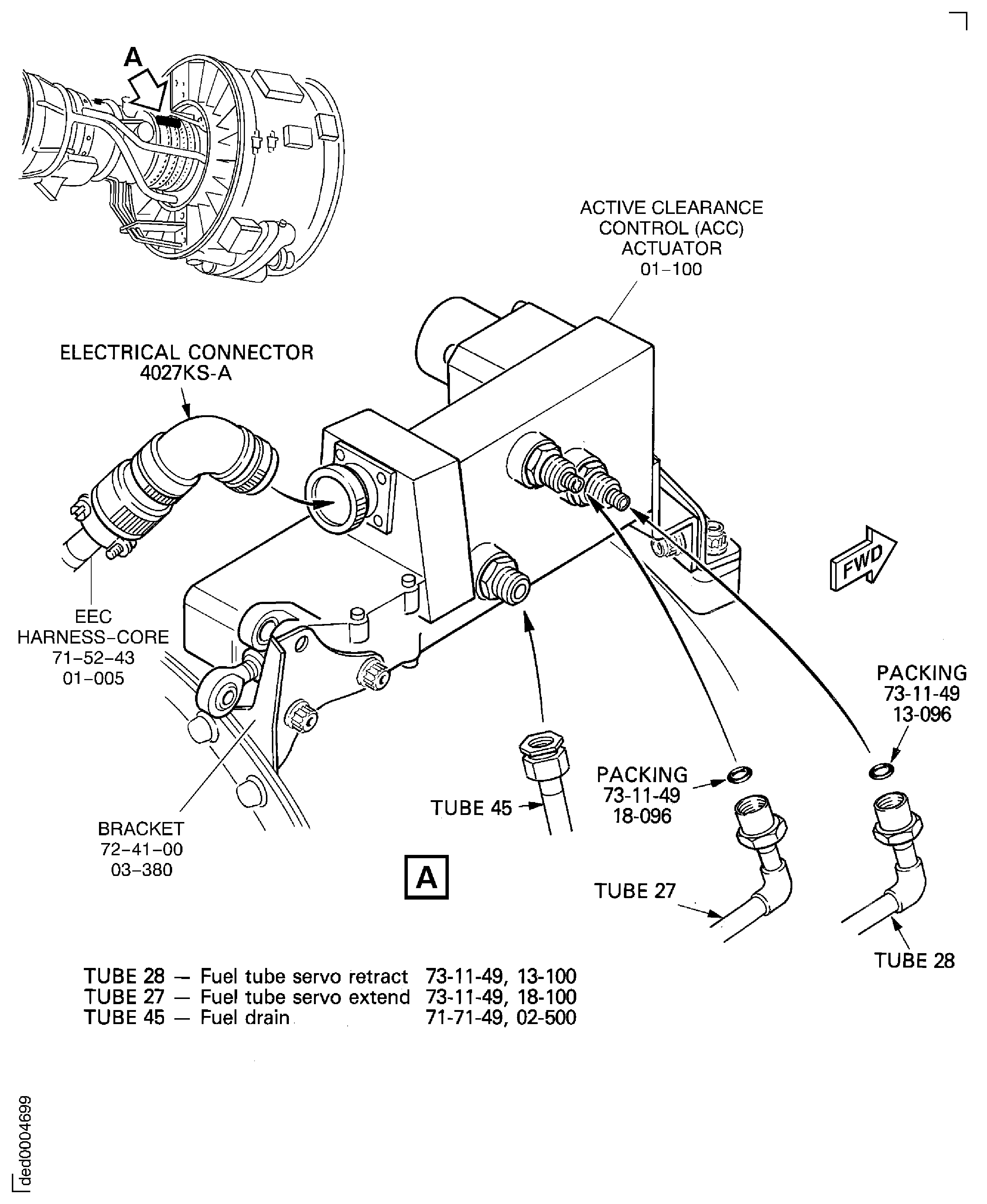

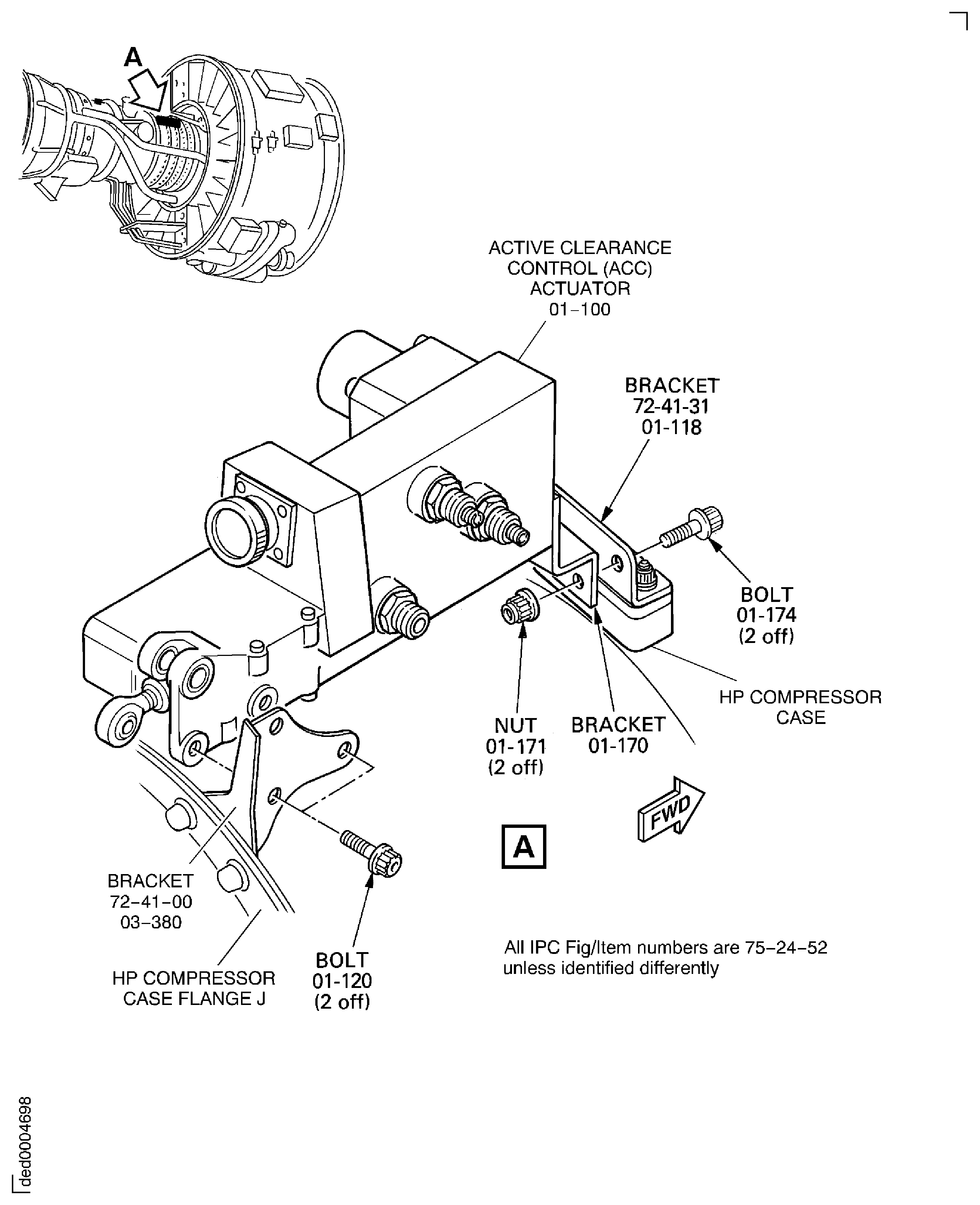

Remove the two bolts that attach the ACC actuator to the bracket HPC Assembly (72-41-00, 03-380) on flange FJ.

NOTE

The ACC actuator must have its maintenance completed, as given in the Parker Hannifin Component Maintenance Manual (75-24-52).Remove the two nuts and bolts that attach the ACC actuator to the bracket HP COMPRESSOR SPLIT CASE (72-41-31, 01-118) on the HP compressor case. Remove the ACC actuator.

SUBTASK 72-00-40-020-138 Remove the Active Clearance Control (ACC) Actuator

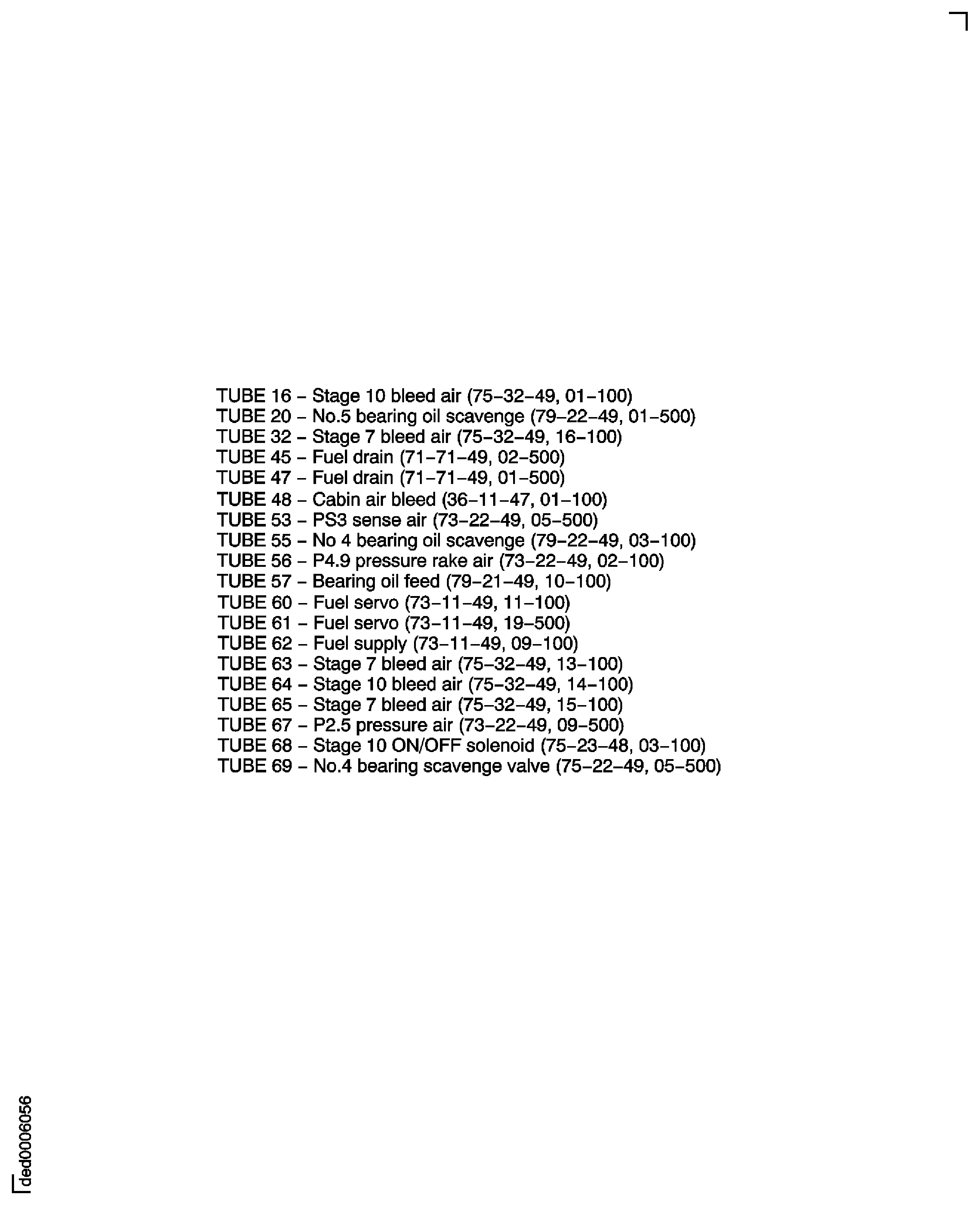

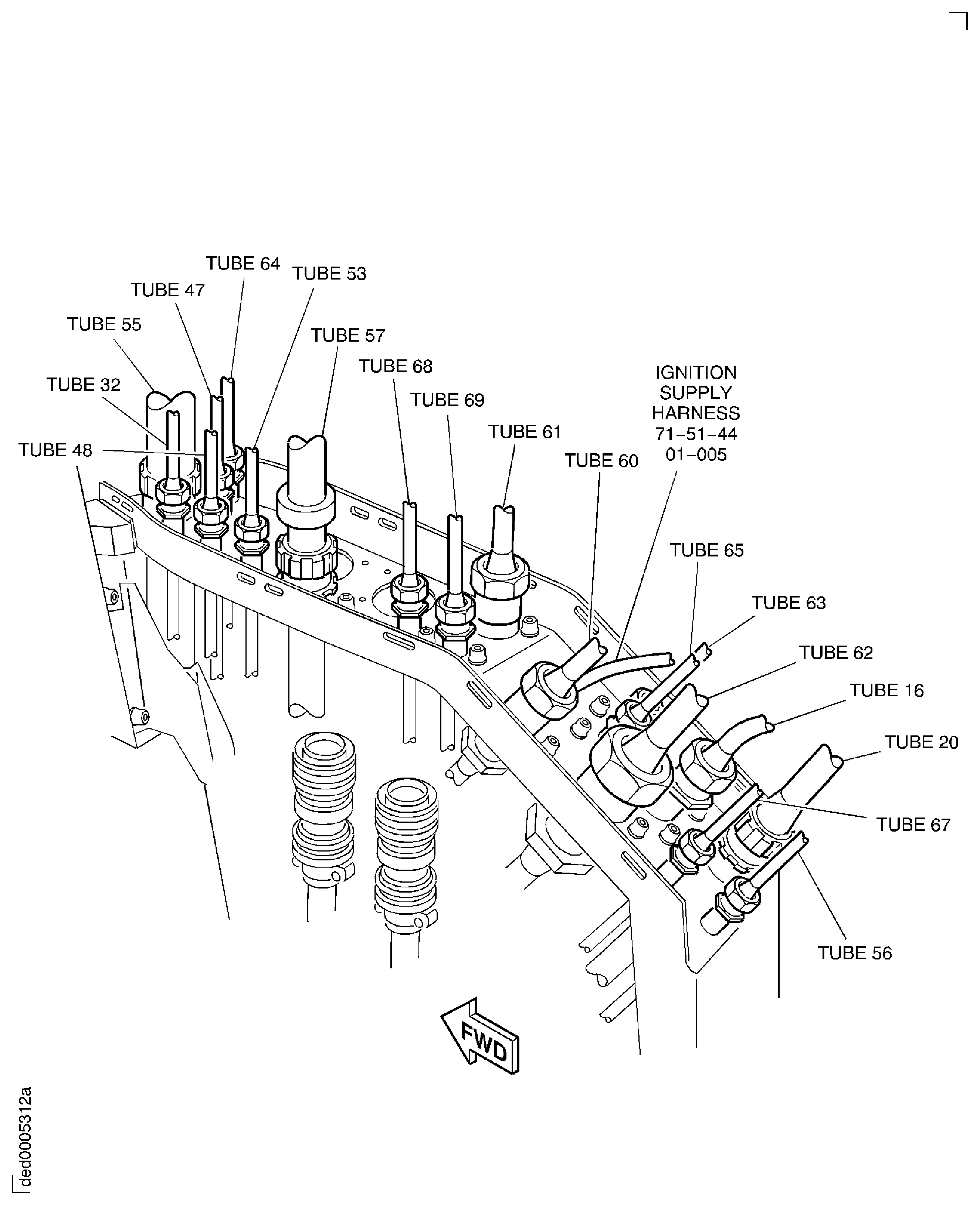

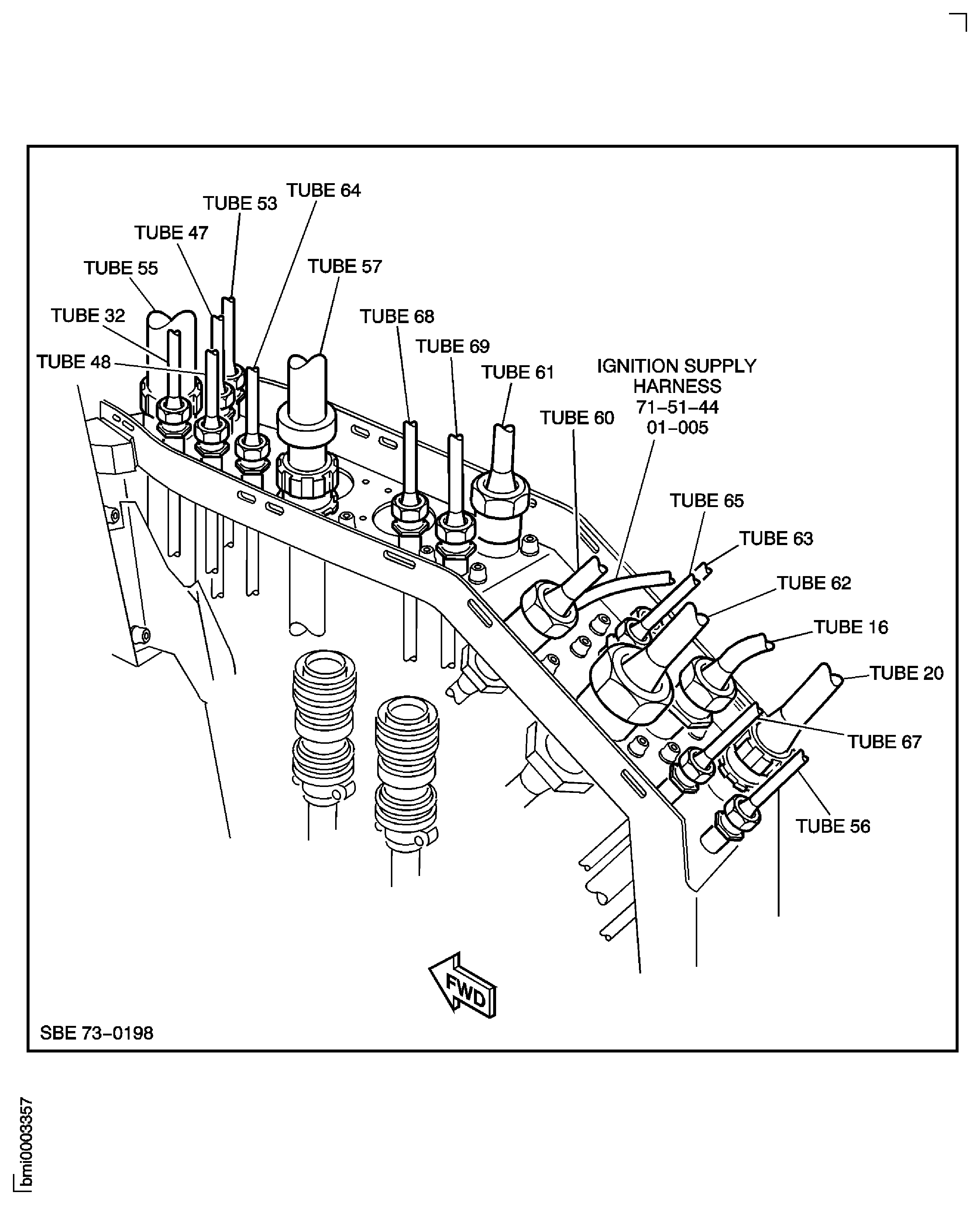

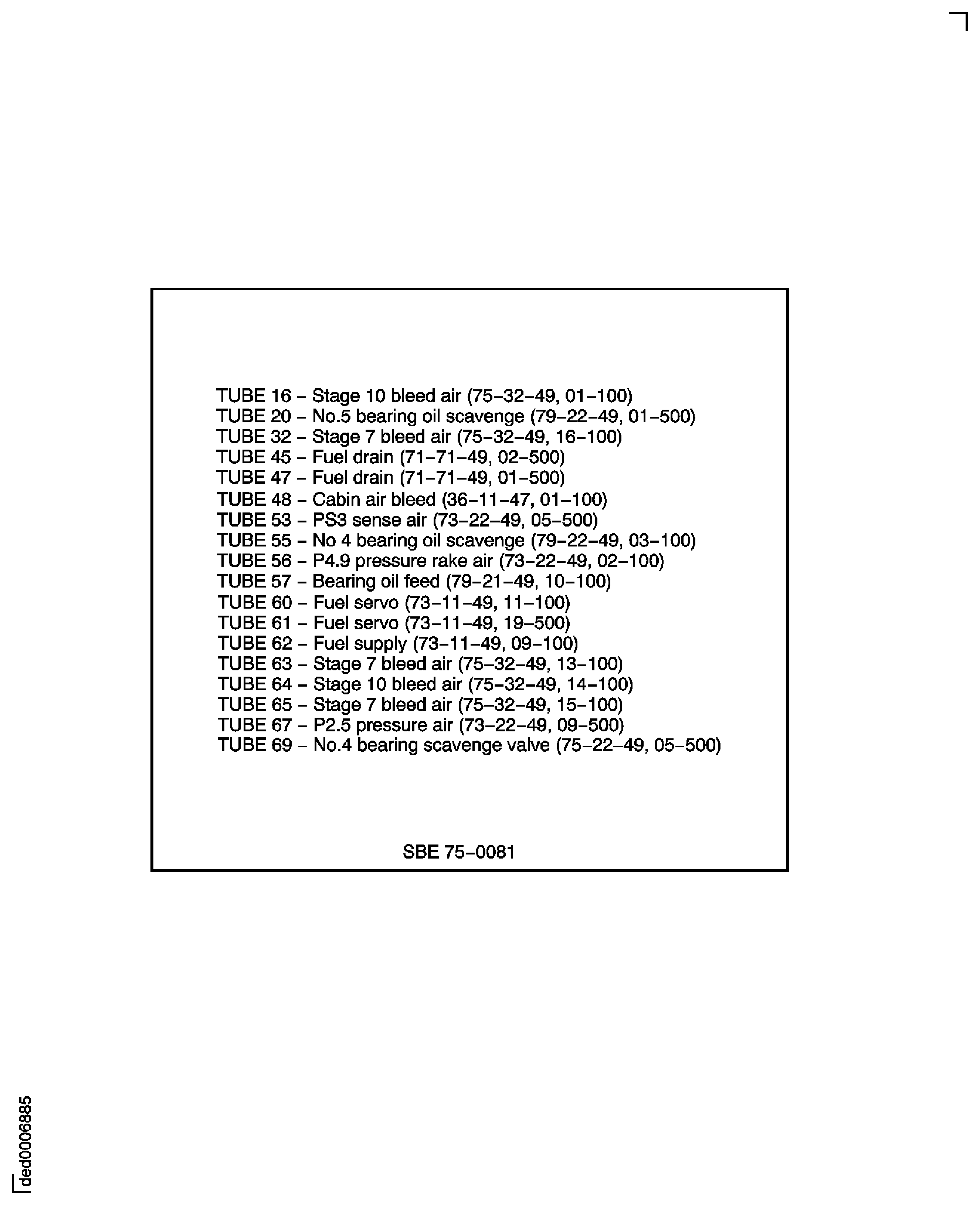

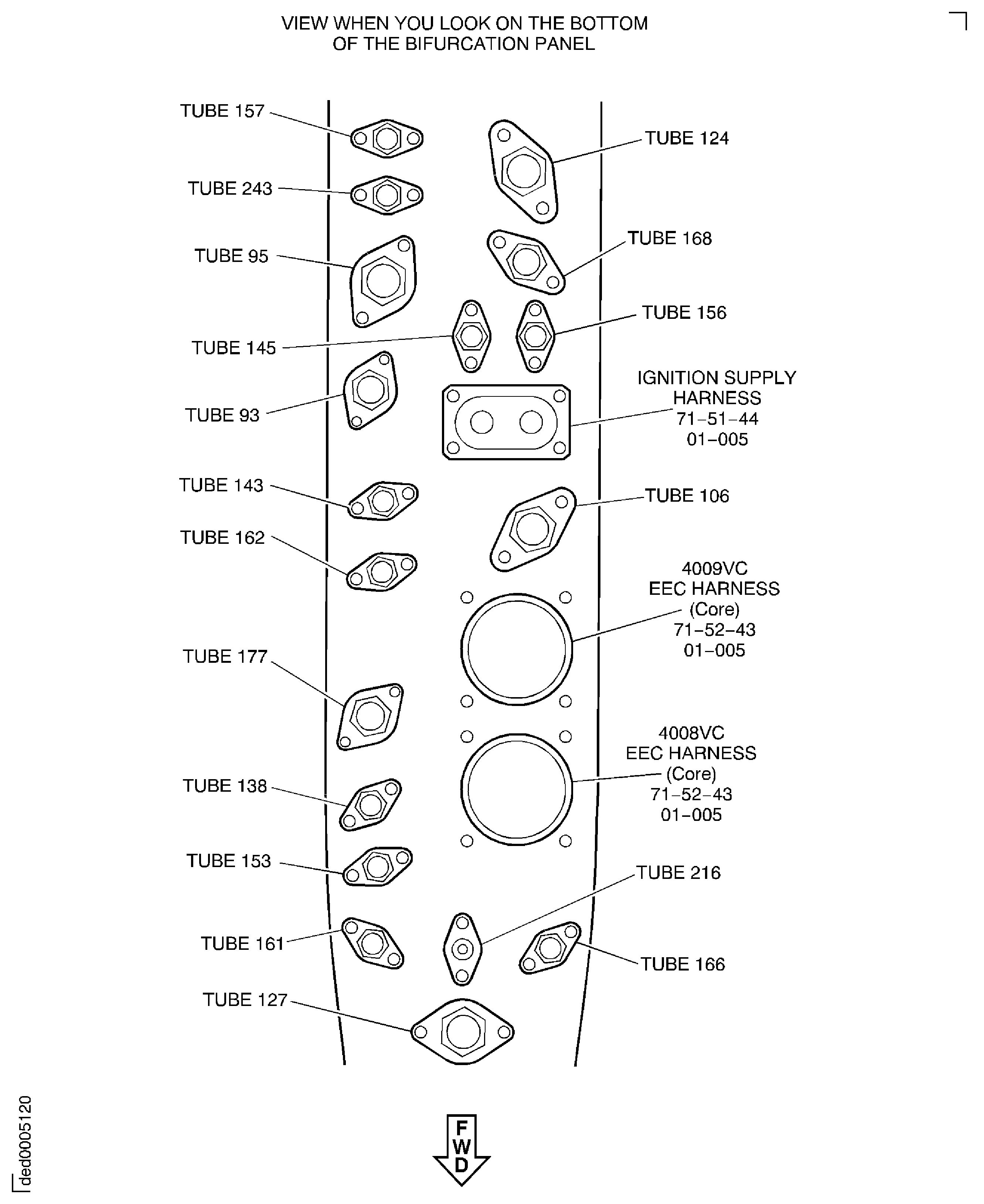

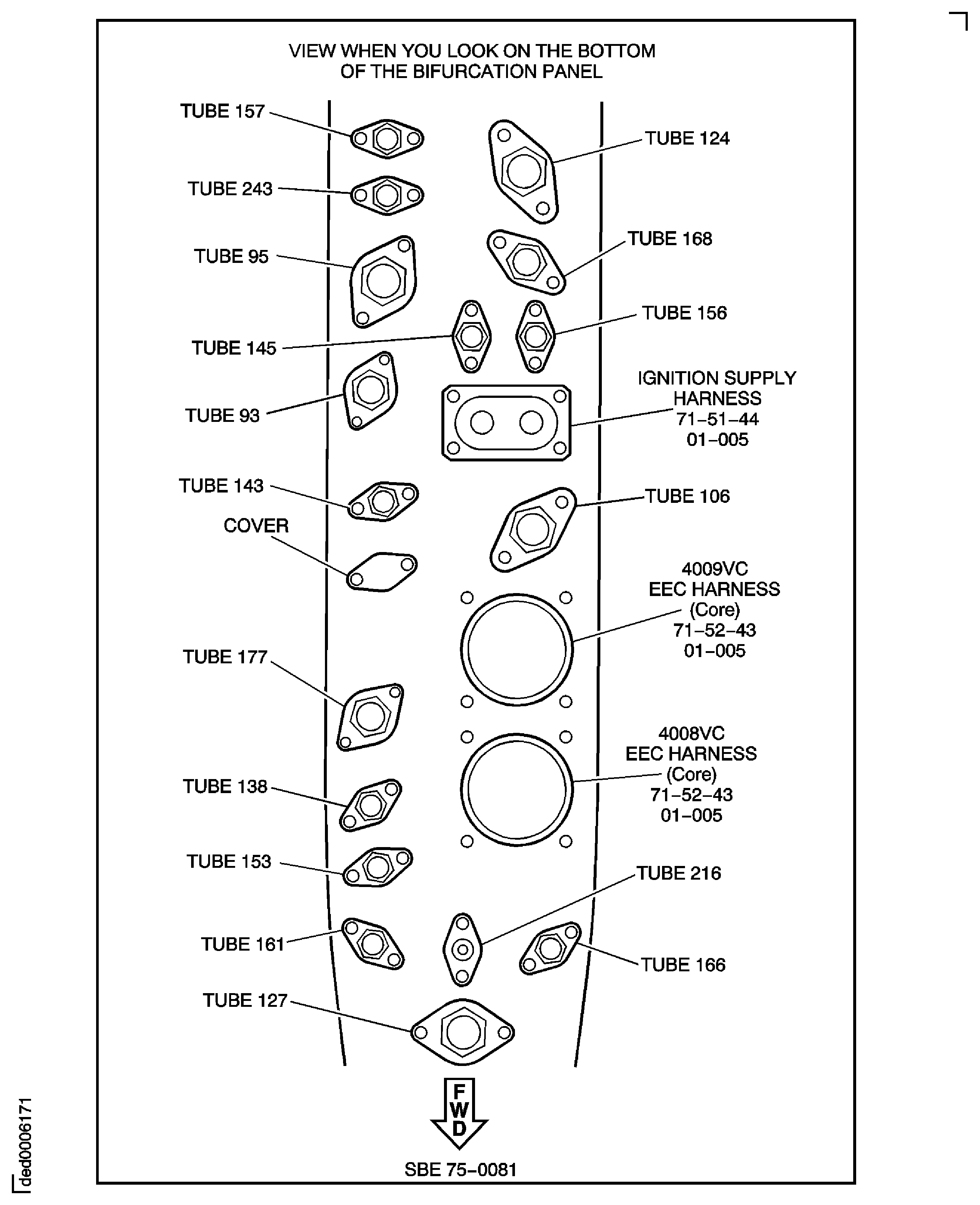

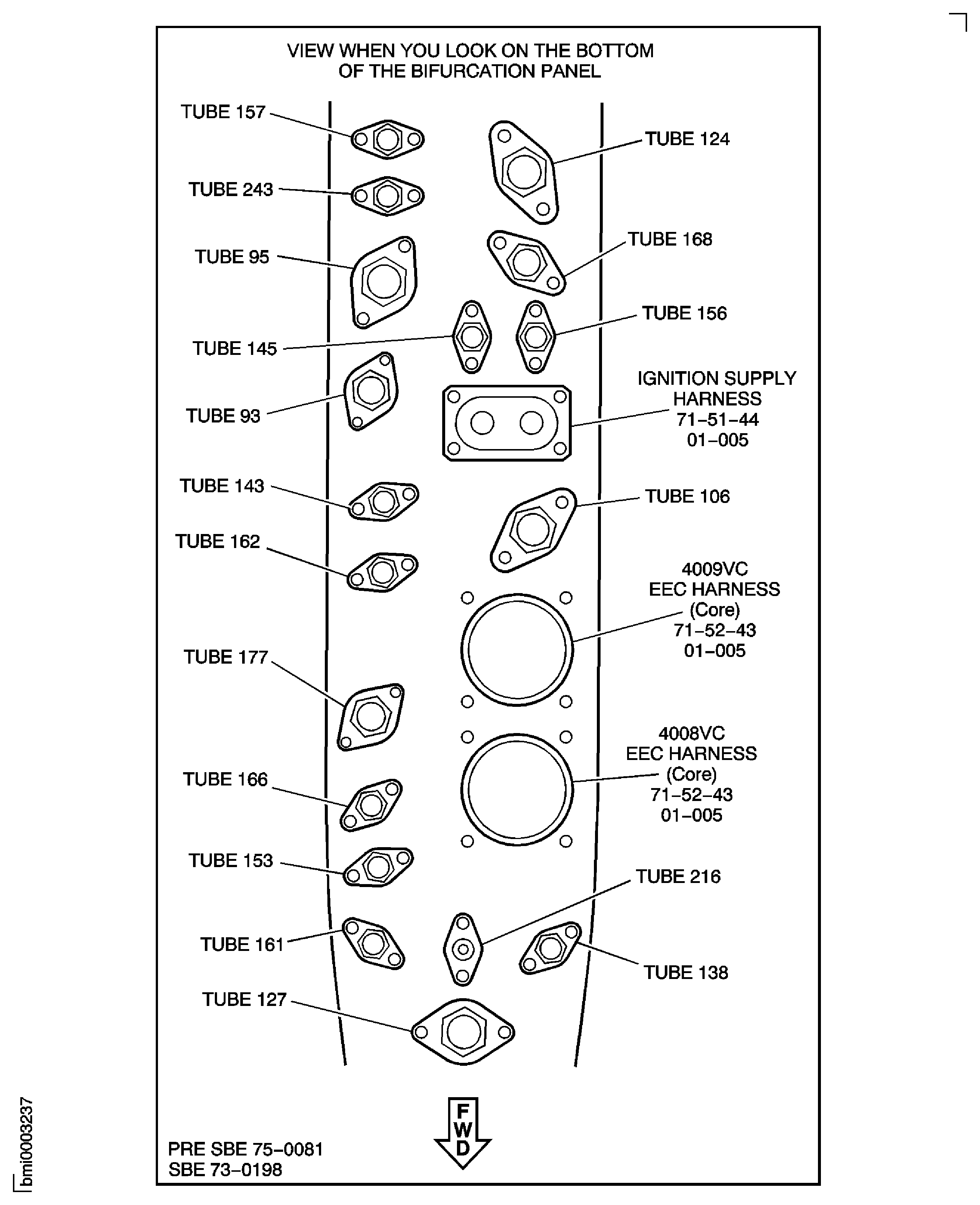

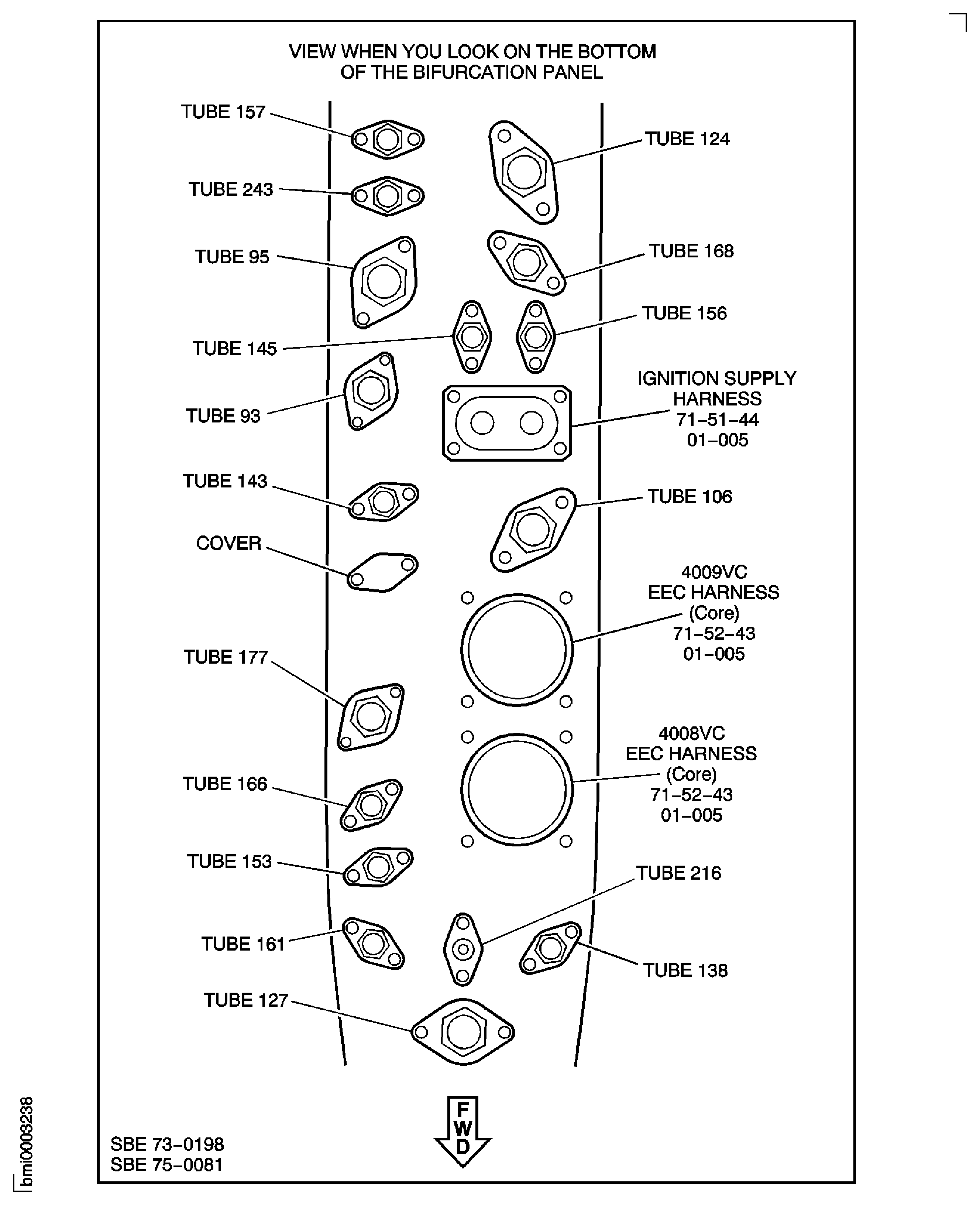

The stage 10 bleed air tube 16 from the tube 168.

The No. 5 bearing oil tube 20 from the tube 124.

The stage 7 bleed air tube 32 from the tube 161.

The cabin bleed air tube 48 from the tube 153.

The PS3 sense tube 53 from the tube 138.

The No. 4 bearing scavenge oil tube 55 from the tube 127.

The P4. 9 pressure rake air tube 56 from the tube 157.

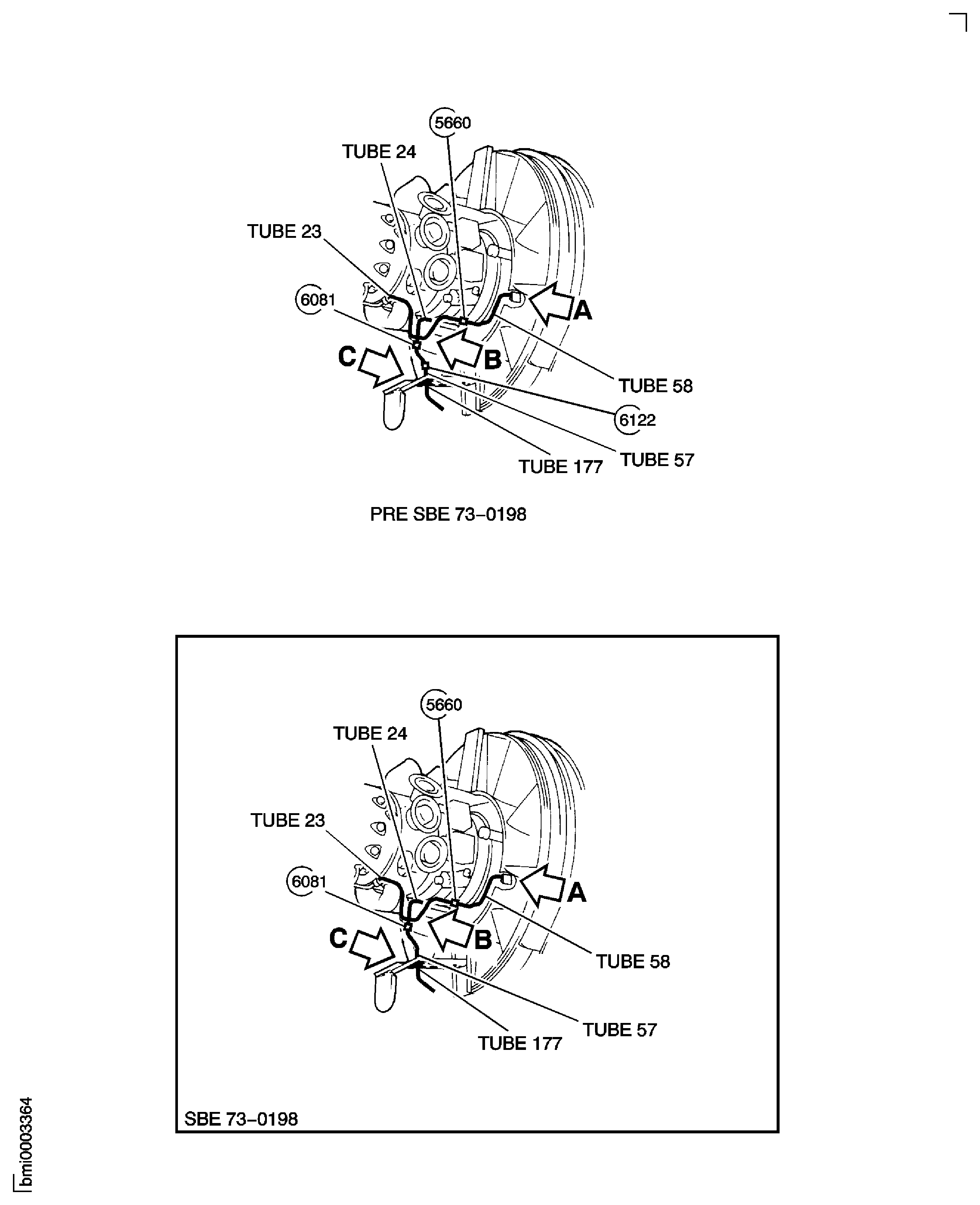

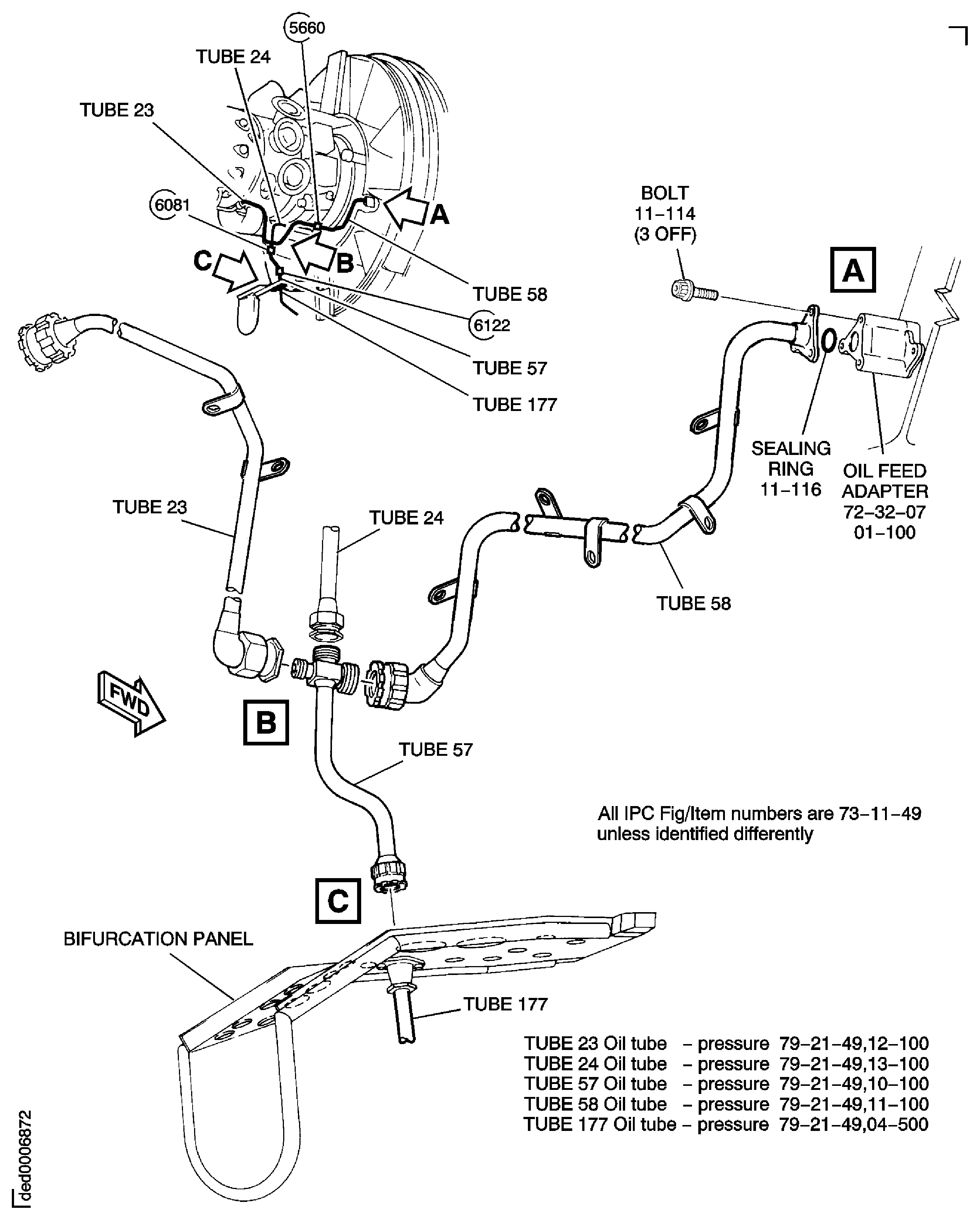

The bearing oil feed tube 57 from the tube 177.

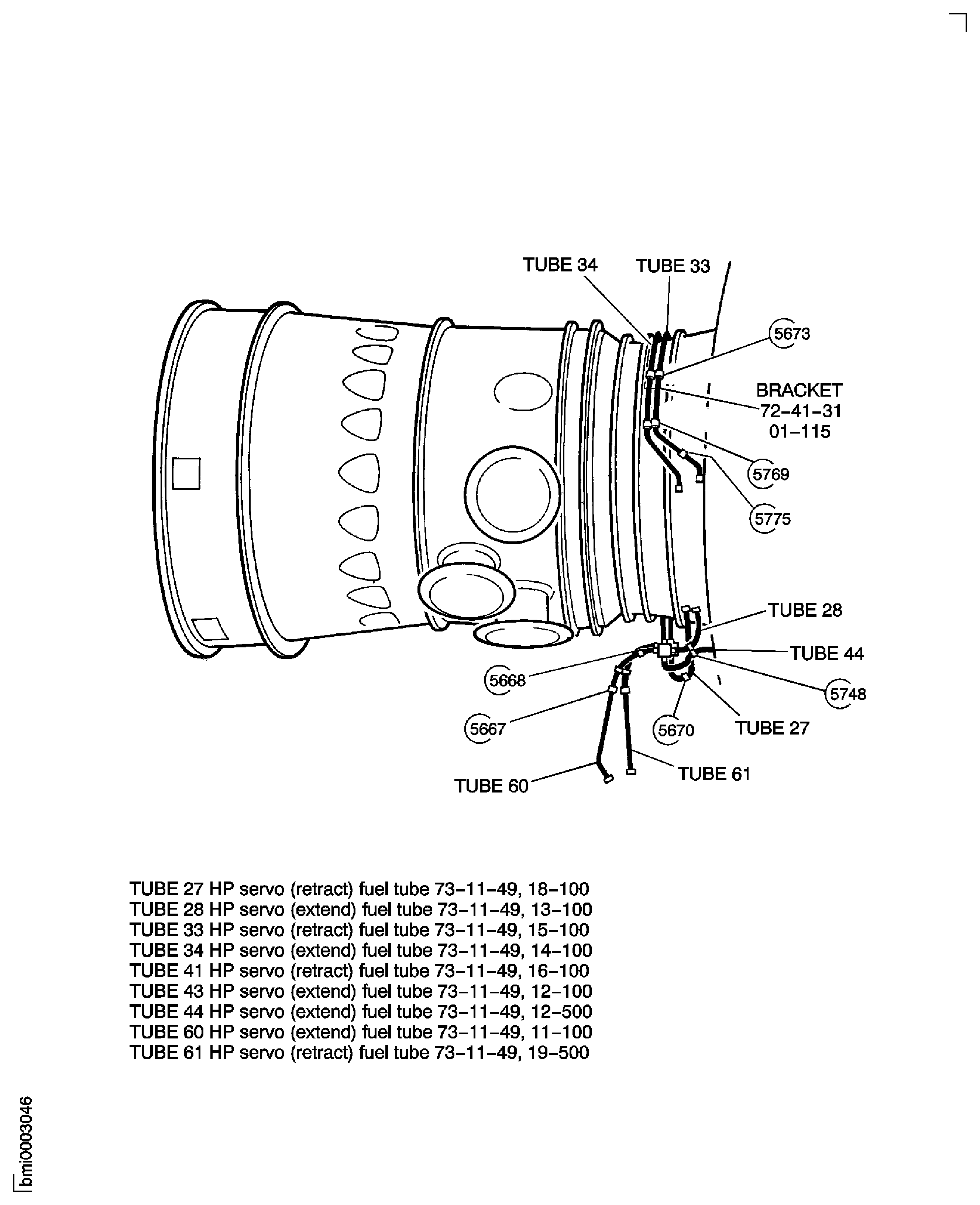

The servo extend fuel tube 60 from the tube 93.

The servo extend fuel tube 61 from the tube 106.

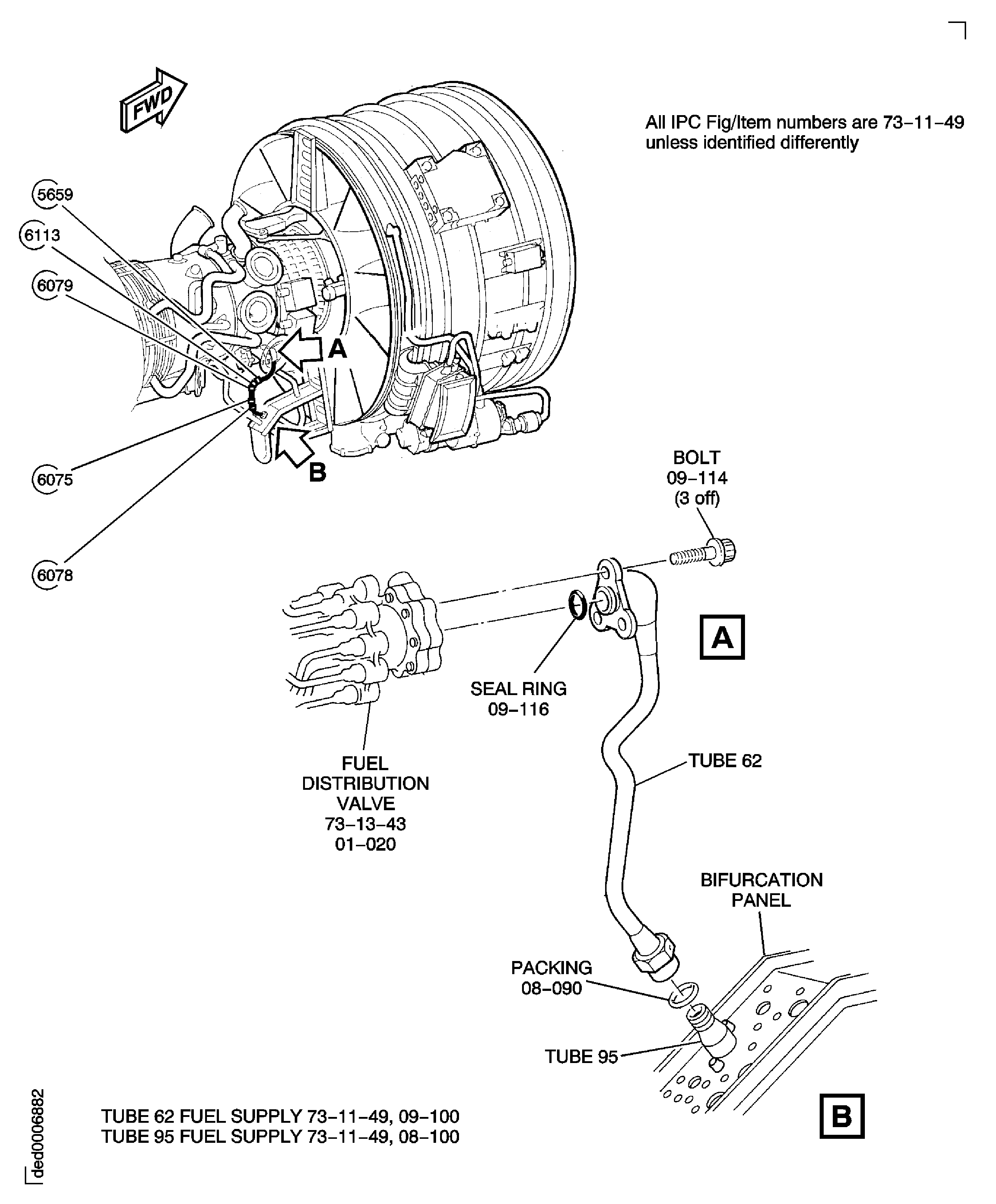

The fuel supply tube 62 from the tube 95.

The stage 7 bleed air tube 63 from the tube 156.

The stage 10 bleed air tube 64 from the tube 166.

The stage 7 bleed air tube 65 from the tube 145.

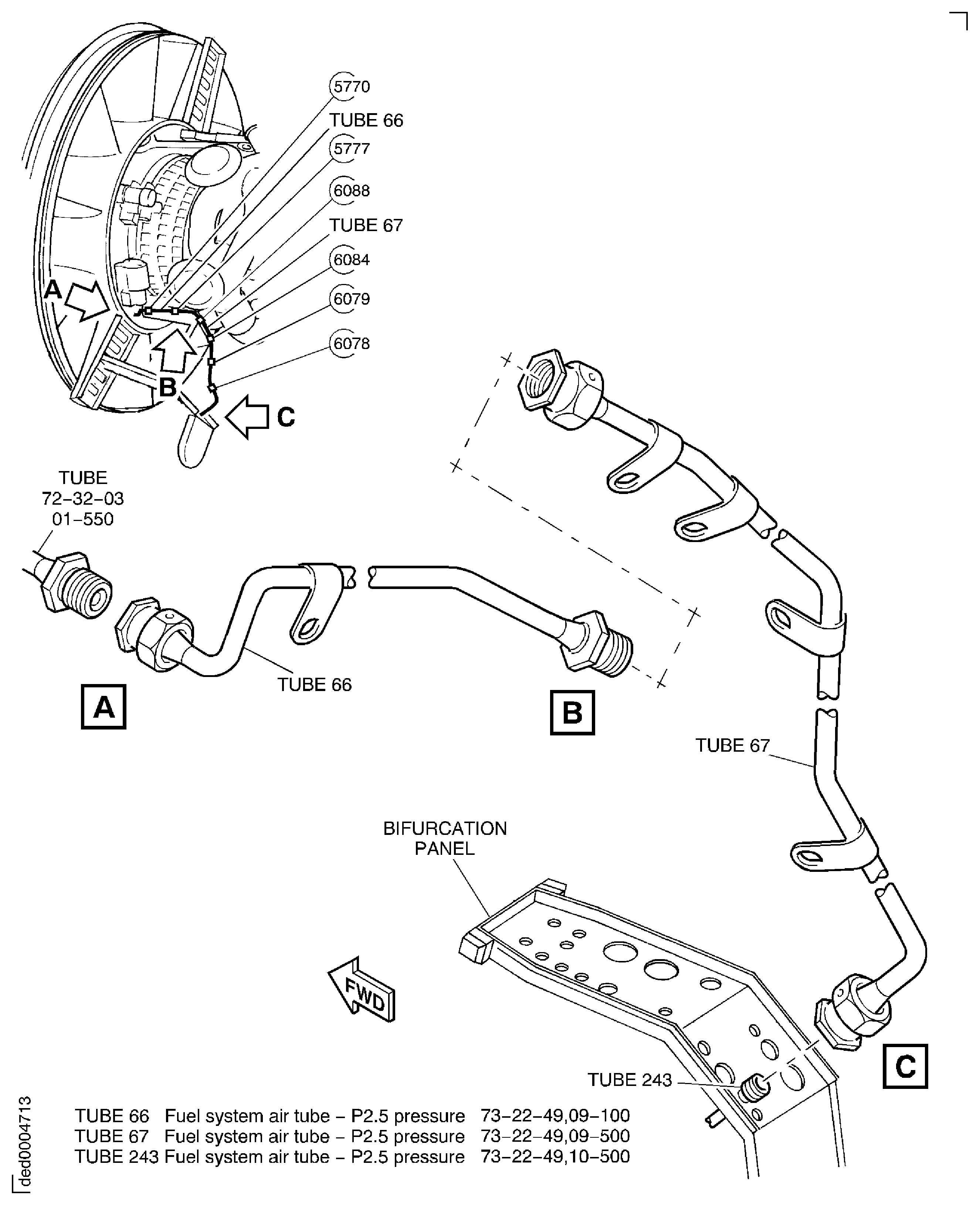

The P2.5 pressure air tube 67 from the tube 243.

The stage 10 on/off solenoid air tube 68 from the tube 162.

The No. 4 bearing scavenge valve air tube 69 from the tube 143.

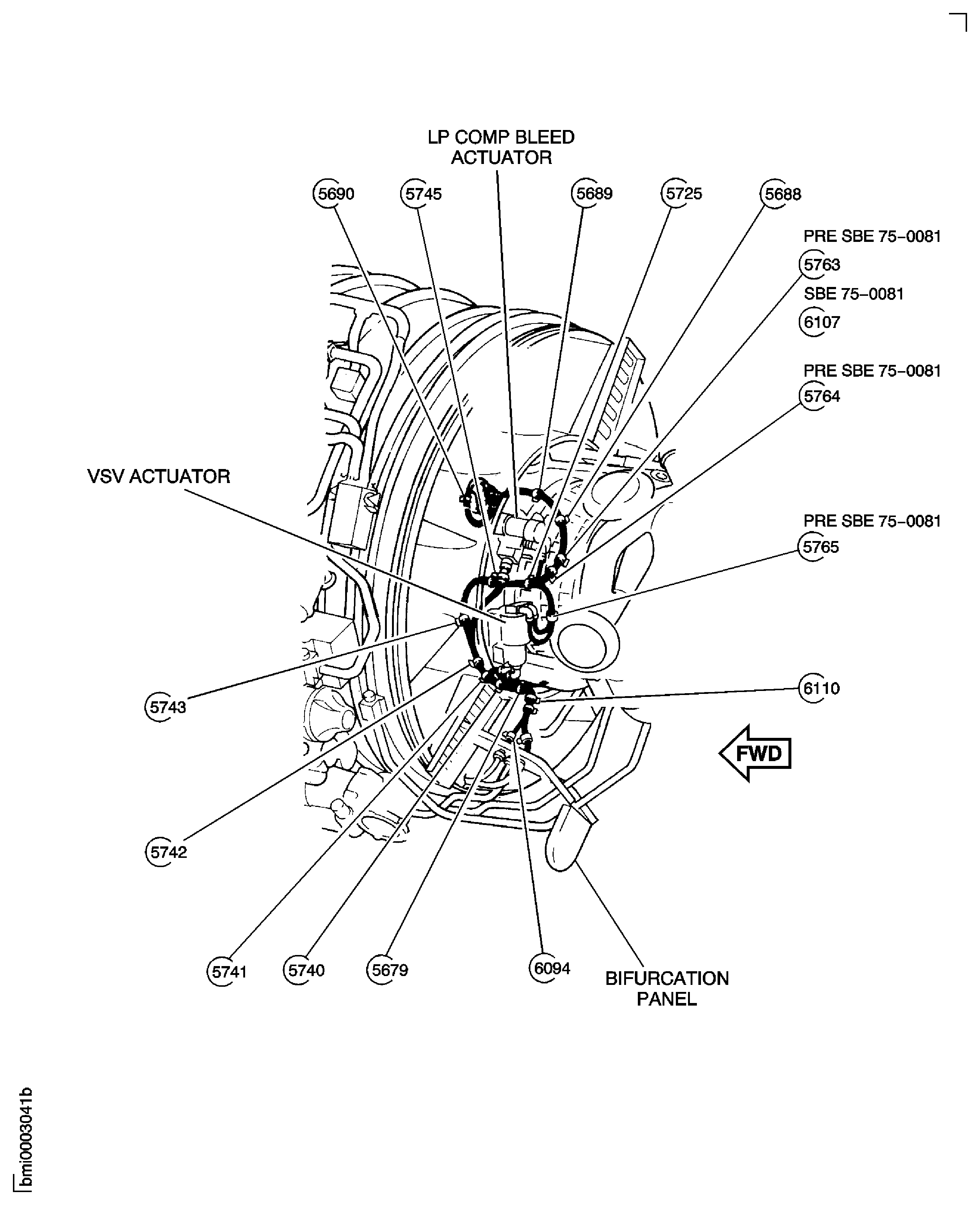

Disconnect the tubes at the bifurcation panel:

SUBTASK 72-00-40-020-139-A00 Disconnect the Tubes at the Bifurcation Panel (Pre SBE 75-0081)

The No. 5 bearing oil tube 20 from the tube 124.

The stage 7 bleed air tube 32 from the tube 161.

The cabin bleed air tube 48 from the tube 153.

The PS3 sense tube 53 from the tube 138.

The No. 4 bearing scavenge oil tube 55 from the tube 127.

The P4.9 pressure rake air tube 56 from the tube 157.

The bearing oil feed tube 57 from the tube 177.

The servo extend fuel tube 60 from the tube 93.

The servo extend fuel tube 61 from the tube 106.

The fuel supply tube 62 from the tube 95.

The stage 7 bleed air tube 63 from the tube 156.

The stage 10 bleed air tube 64 from the tube 166.

The stage 7 bleed air tube 65 from the tube 145.

The P2.5 pressure air tube 67 from the tube 243.

The No. 4 bearing scavenge valve air tube 69 from the tube 143.

SUBTASK 72-00-40-020-139-B00 Disconnect the Tubes at the Bifurcation Panel (SBE 75-0081)

Pre SBE 73-0198: Remove the bolts, the washers, the clips and the nuts from clip positions 6081 and 6122.

SBE 73-0198: Remove the bolt, the washer, the clip and the nut from clip position 6081.

SUBTASK 72-00-40-020-140 Remove the No. 1, 2 and 3 Bearing Oil Feed Tubes 58 and 57 (Pre SBE 73-0198 and SBE 73-0198)

Pre SBE 73-0219 and SBE 73-0235: Remove the tube 46.

SUBTASK 72-00-40-020-142-A00 Remove the HP Servo Fuel Tube 46 and the P2.5 Air Tubes 66 and 67 (Pre SBE 73-0219 and SBE 73-0235)

SBE 73-0219: Remove the tube 71.

SUBTASK 72-00-40-020-142-B00 Remove the HP Servo Fuel Tube 71 and the P2.5 Air Tubes 66 and 67 (SBE 73-0219)

Remove the bolts, the washers, the clips and the clipnuts from the clip positions 5644 and 5699. Remove the raceway Core Harness Support Raceways (71-52-50, 05-500).

Remove the bolts, the washer, the clips, the nuts and the clipnuts from the clip positions 5676 and 6104. Remove the raceway Core Harness Support Raceways (71-52-50, 05-100).

NOTE

The raceways must have their maintenance completed, as given in the Component Maintenance Manual (CMM-MECH-V2500-1IA).Remove the bolts, the washers, the clips and the clipnuts from the clip positions 5427, 5746 and 6057. Remove the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE (71-52-50, 04-100).

SUBTASK 72-00-40-020-145 Remove the Raceways

Figure: Pre SBE 74-0001: Remove the Ignition Exciters

Pre SBE 74-0001: Remove the Ignition Exciters

Figure: SBE 74-0001: Remove the Ignition Exciters

SBE 74-0001: Remove the Ignition Exciters

Figure: Pre SBE 74-0001: Remove the Ignition Exciters

Pre SBE 74-0001: Remove the Ignition Exciters

Figure: SBE 74-0001: Remove the Ignition Exciters

SBE 74-0001: Remove the Ignition Exciters

Figure: Remove the LP Compressor Bleed Actuators

Remove the LP Compressor Bleed Actuators

Figure: Remove the LP Compressor Bleed Actuators

Remove the LP Compressor Bleed Actuators

Figure: Remove the LP Compressor Bleed Actuators

Remove the LP Compressor Bleed Actuators

Figure: Remove the LP Compressor Bleed Actuators

Remove the LP Compressor Bleed Actuators

Figure: Remove the Fuel Drain Tubes

Remove the Fuel Drain Tubes

Figure: Remove the ACC Actuator

Remove the ACC Actuator

Figure: Remove the ACC Actuator

Remove the ACC Actuator

Figure: Pre SBE 71-0288, Pre SBE 75-0081 and SBE75-0081: Remove the Electrical Harnesses

Pre SBE 71-0288, Pre SBE 75-0081 and SBE75-0081: Remove the Electrical Harnesses

Figure: SBE 71-0288: Remove the Electrical Harnesses

SBE 71-0288: Remove the Electrical Harnesses

Figure: Pre SBE 71-0288, Pre SBE 71-0303, SBE 71-0303 Pre SBE 72-0553 and SBE 72-0553: Remove the Electrical Harnesses

Pre SBE 71-0288, Pre SBE 71-0303, SBE 71-0303 Pre SBE 72-0553 and SBE 72-0553: Remove the Electrical Harnesses

Figure: SBE 71-0288, Pre SBE 71-0303 and SBE 71-0303 Pre SBE 72-0553 and SBE 72-0553: Remove the Electrical Harnesses

SBE 71-0288, Pre SBE 71-0303 and SBE 71-0303 Pre SBE 72-0553 and SBE 72-0553: Remove the Electrical Harnesses

Figure: Pre SBE 71-0303, SBE 71-0303, Pre SBE 72-0553 and SBE 72-0553: Remove the Electrical Harnesses

Pre SBE 71-0303, SBE 71-0303, Pre SBE 72-0553 and SBE 72-0553: Remove the Electrical Harnesses

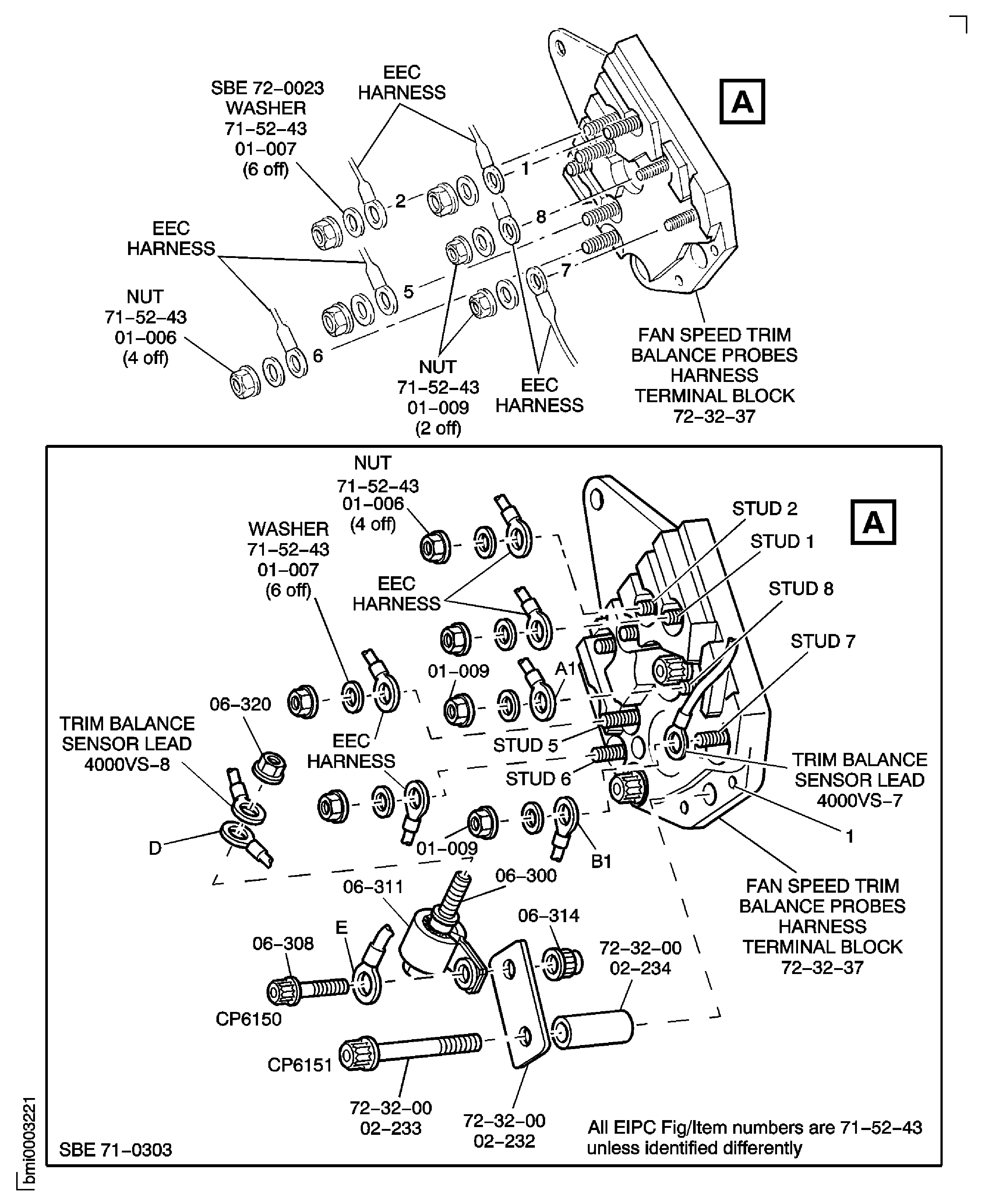

Figure: Remove the Electrical Harnesses

Remove the Electrical Harnesses

Figure: Remove the Electrical Harnesses

Remove the Electrical Harnesses

Figure: Remove the Electrical Harnesses

Remove the Electrical Harnesses

Figure: Pre SBE 75-0081 and SBE 75-0081: Remove the Electrical Harnesses

Pre SBE 75-0081 and SBE 75-0081: Remove the Electrical Harnesses

Figure: Remove the Electrical Harnesses

Remove the Electrical Harnesses

Figure: Remove the Electrical Harnesses

Remove the Electrical Harnesses

Figure: Pre SBE 71-0111: Remove the Electrical Harnesses

Pre SBE 71-0111: Remove the Electrical Harnesses

Figure: Pre SBE 71-0288: Remove the Ignition Supply Harness

Pre SBE 71-0288: Remove the Ignition Supply Harness

Figure: Pre SBE 73-0219 and SBE 73-0235: Remove the VSV Actuator

Pre SBE 73-0219 and SBE 73-0235: Remove the VSV Actuator

Figure: SBE 73-0219: Remove the VSV Actuator

SBE 73-0219: Remove the VSV Actuator

Figure: Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: Pre SBE 71-0288, Pre SBE 73-0198 and Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Pre SBE 71-0288, Pre SBE 73-0198 and Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: Pre SBE 71-0288, SBE 73-0198 and Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Pre SBE 71-0288, SBE 73-0198 and Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: SBE 71-0288, Pre SBE 73-0198 and Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

SBE 71-0288, Pre SBE 73-0198 and Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: SBE 71-0288, SBE 73-0198 and Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

SBE 71-0288, SBE 73-0198 and Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: Pre SBE 71-0288, Pre SBE 73-0198 and SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Pre SBE 71-0288, Pre SBE 73-0198 and SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: Pre SBE 71-0288, SBE 73-0198 and SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Pre SBE 71-0288, SBE 73-0198 and SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: SBE 71-0288, Pre SBE 73-0198 and SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

SBE 71-0288, Pre SBE 73-0198 and SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: SBE 71-0288, SBE 73-0198 and SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

SBE 71-0288, SBE 73-0198 and SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: Pre SBE 73-0198 and Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Pre SBE 73-0198 and Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: Pre SBE 73-0198 and SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Pre SBE 73-0198 and SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: SBE 73-0198 and Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

SBE 73-0198 and Pre SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: SBE 73-0198 and SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

SBE 73-0198 and SBE 75-0081: Disconnect the Tubes at the Bifurcation Panel

Figure: Pre SBE 73-0198 and SBE 73-0198: Remove the No.1, 2 and 3 Bearing Oil Feed Tubes 57 and 58

Pre SBE 73-0198 and SBE 73-0198: Remove the No.1, 2 and 3 Bearing Oil Feed Tubes 57 and 58

Figure: Remove the No.1, 2 and 3 Bearing Oil Feed Tubes 57 and 58

Remove the No.1, 2 and 3 Bearing Oil Feed Tubes 57 and 58

Figure: Pre SBE 73-0219 and SBE 73-0235: Remove the HP Servo Fuel Tube 46 and the P2.5 Air Tubes 66 and 67

Pre SBE 73-0219 and SBE 73-0235: Remove the HP Servo Fuel Tube 46 and the P2.5 Air Tubes 66 and 67

Figure: SBE 73-0219: Remove the HP Servo Fuel Tube 46 and the P2.5 Air Tubes 66 and 67

SBE 73-0219: Remove the HP Servo Fuel Tube 46 and the P2.5 Air Tubes 66 and 67

Figure: Remove the HP Servo Fuel Tube 46 and the P2.5 Air Tubes 66 and 67

Remove the HP Servo Fuel Tube 46 and the P2.5 Air Tubes 66 and 67

Figure: Remove the Fuel Distribution Feed Tube 62

Remove the Fuel Distribution Feed Tube 62

Figure: Remove the HP Servo Fuel Tubes

Remove the HP Servo Fuel Tubes

Figure: Pre SBE 73-0219 and SBE 73-0235: Remove the HP Servo Fuel Tubes

Pre SBE 73-0219 and SBE 73-0235: Remove the HP Servo Fuel Tubes

Figure: SBE 73-0219: Remove the HP Servo Fuel Tubes

SBE 73-0219: Remove the HP Servo Fuel Tubes

Figure: Remove the HP Servo Fuel Tubes

Remove the HP Servo Fuel Tubes

Figure: Remove the Raceways

Remove the Raceways

Figure: Remove the Raceways

Remove the Raceways