Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-21-300-043 HPC Stage 10 Rotor Path Case Assembly - Replace The Hardcoat On The Rear Flange Rear Face, Repair-043 (VRS9042)

General

This Repair must only be done when the instruction to do so is given in TASK 72-41-21-200-010-D00 (INSPECTION-010).

Price and Availability

Refer to International Aero Engines

Related repairs

REPAIR SCHEME No | TITLE |

|---|---|

VRS6022 | HPC Stage 10 Rotor Path Ring - Replace The Lining, refer to TASK 72-41-21-300-016. |

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-439 ALKALINE PERMANGANATE | LOCAL | CoMat 01-439 | ||

| CoMat 03-239 METAL SPRAYING POWDER, CHROMIUM CARBIDE/NICHROME 75/25, FINE | 00BB6 | CoMat 03-239 | ||

| CoMat 03-240 METAL SPRAYING POWDER, CHROMIUM CARBIDE/NICHROME 75/25, FINE | X111X | CoMat 03-240 | ||

| CoMat 03-298 METAL SPRAYING POWDER, CHROMIUM CARBIDE/NICHROME 75/25, FINE | X111X | CoMat 03-298 | ||

| CoMat 03-322 METAL SPRAYING POWDER, CHROMIUM CARBIDE/NICHROME 75/25, FINE | X111X | CoMat 03-322 | ||

| CoMat 03-323 METAL SPRAYING POWDER, CHROMIUM CARBIDE/NICHROME 75/25, FINE | X111X | CoMat 03-323 |

Spares

NONESafety Requirements

NONEProcedure

Apply maskant. Refer to SPM TASK 70-11-35-110-501.

Apply maskant. Refer to SPM TASK 70-38-24-300-503.

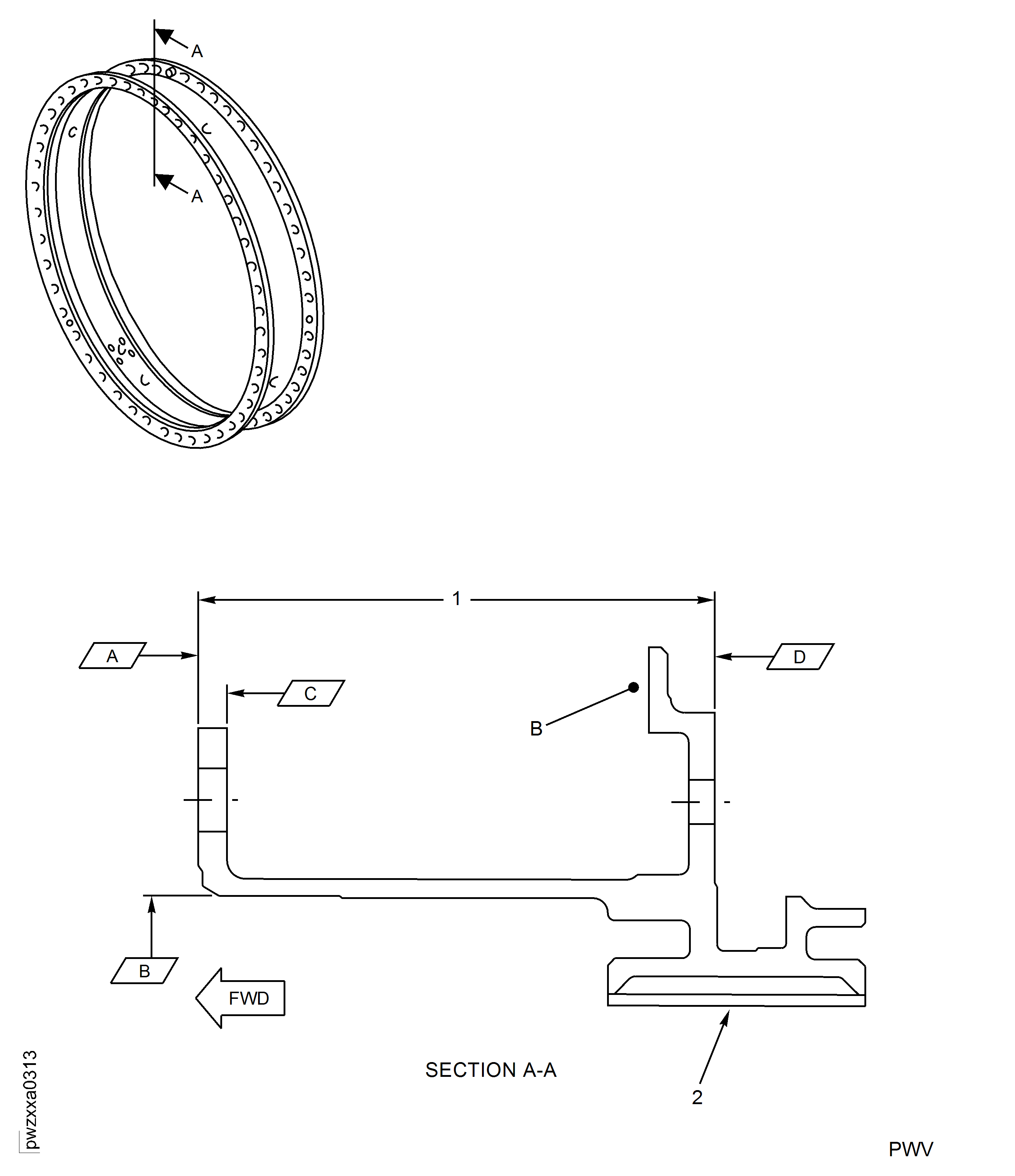

If abradable lining is present/intact, protect the abradable lining by sealing the lining with one of the following options. See Figure index [2]. Refer to TASK 70-11-35-110-501 in the V2500 Standard Practices Manual, PN 2A4414 (P&W)/SPM-V2500-1IA (IAE).

SUBTASK 72-41-21-380-122 Apply Surface Protection

Chemically remove the coat using CoMat 01-439 ALKALINE PERMANGANATE. Refer to SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-007.

Machine or grind to remove the coat. Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-003.

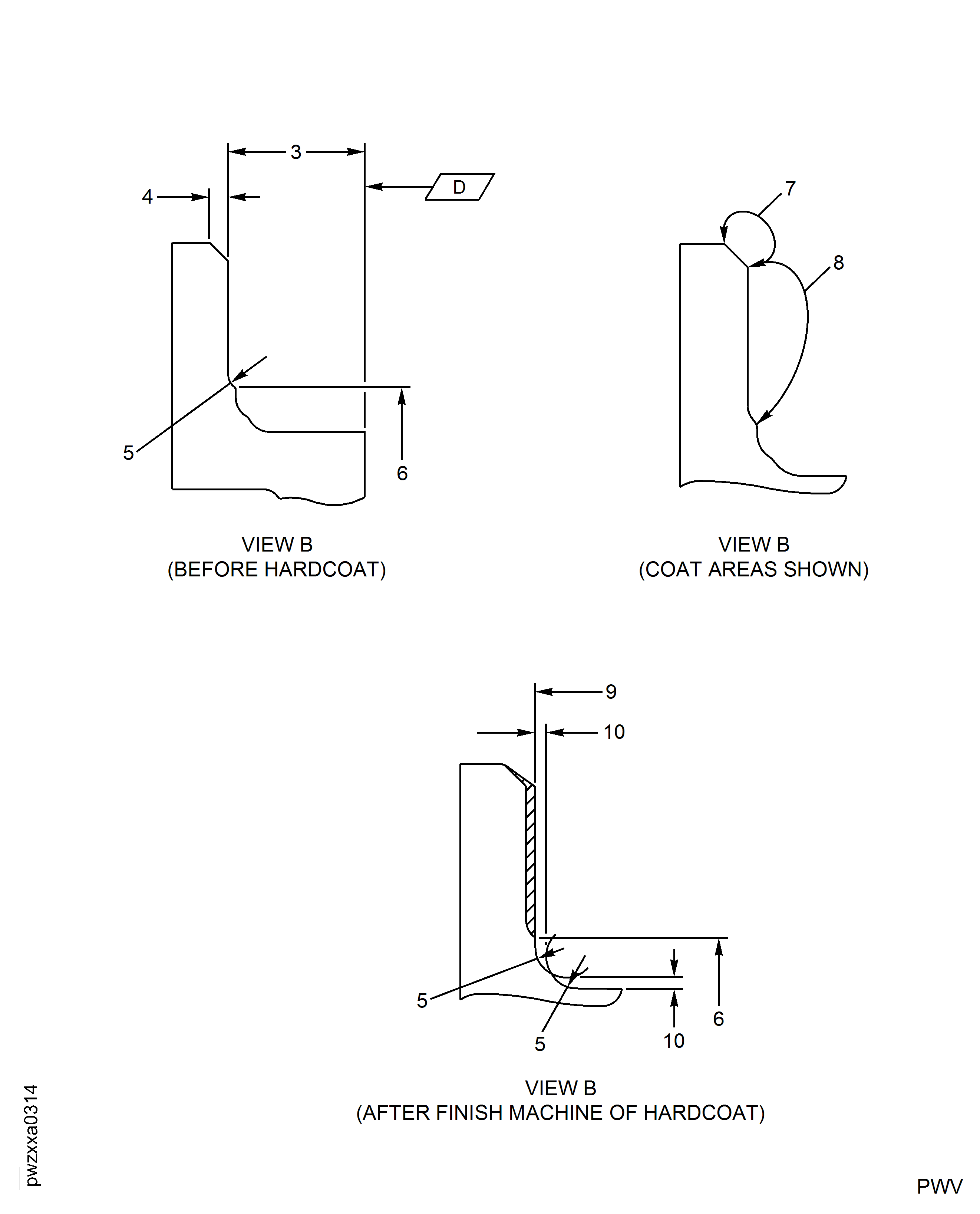

Remove hardcoat from the rear flange rear face of the HPC Stage 10 Rotor Path Case Assembly to the limits shown in Figure by one of the options that follow:

SUBTASK 72-41-21-322-002 Remove the Hard Coat

Refer to SPM TASK 70-11-03-300-503.

Clean the part by aqueous degrease.

SUBTASK 72-41-21-100-020 Clean the Part by Aqueous Cleaning Method

Refer to TASK 72-41-21-200-010-D00 in the V2500-A1/A5 Series Engine Manual, PN 2A4407 (P&W)/E-V2500-1IA (IAE).

If you did a grind operation, do a fluorescent penetrant inspection of the part.

SUBTASK 72-41-21-230-253 Fluorescent Penetrant Inspect the Repair Area

Refer to Figure.

Do a dimensional inspection of the repair area.

SUBTASK 72-41-21-220-768 Do an Inspection of the Repair Area

Refer to SPM TASK 70-34-18-380-501.

Shotpeen is not permitted.

Prepare the part for hardcoat.

SUBTASK 72-41-21-220-768 Prepare the Part for Coat

Refer to SPM TASK 70-34-01-340-501.

Coat the repair area using CoMat 03-239 METAL SPRAYING POWDER, CHROMIUM CARBIDE/NICHROME 75/25, FINE or CoMat 03-240 METAL SPRAYING POWDER, CHROMIUM CARBIDE/NICHROME 75/25, FINE or CoMat 03-298 METAL SPRAYING POWDER, CHROMIUM CARBIDE/NICHROME 75/25, FINE or CoMat 03-322 METAL SPRAYING POWDER, CHROMIUM CARBIDE/NICHROME 75/25, FINE or CoMat 03-323 METAL SPRAYING POWDER, CHROMIUM CARBIDE/NICHROME 75/25, FINE.

Coat out of the repair area is not permitted. Use masks.

Apply sufficient coat for finishing.

Apply hardcoat using plasma spray procedure by one of the coat options that follow:

SUBTASK 72-41-21-340-071 Apply Hardcoat On The Part

Remove the tape residue.

Refer to SPM TASK 70-11-26-300-503.

After the coat is applied and the part is cool, remove the mask or maskants.

SUBTASK 72-41-21-110-282 Remove the Masks or Maskants

Refer to Figure.

Refer to SPM TASK 70-34-01-340-501.

Finished coat thickness must be 0.0032 in. to 0.0102 in. (0.08 mm to 0.26 mm).

Coat over the chamfer must be blended out. Refer to Figure, index [7].

Finish the coat to the dimensions shown.

SUBTASK 72-41-21-320-006 Finish the Repair Area

Refer to SPM TASK 70-11-03-300-503.

Clean the part by aqueous degrease.

SUBTASK 72-41-21-100-283 Clean the Part by Aqueous Cleaning Method

Refer to Figure.

Refer to SPM TASK 70-11-35-110-501 or SPM TASK 70-38-24-300-503.

Remove the seal protection from the abradable lining. Refer to Figure index [2].

SUBTASK 72-41-21-380-122 Remove Surface Protection

Refer to SPM TASK 70-34-03-340-501-002.

Do a visual inspection of the repaired area.

Do a dimensional inspection of the repaired area. Refer to Figure.

SUBTASK 72-41-21-220-769 Do a Visual and a Dimensional Inspection of the Rear Flange Rear Face

Replace the abradable lining. Refer to Repair, VRS6022 TASK 72-41-21-300-016 (REPAIR-016).

If the abradable lining is damaged.

SUBTASK 72-41-21-380-123 Replace the Lining

Use the vibration peen method.

Refer to SPM TASK 70-09-00-400-501.

Permanently mark the part with "VRS9042" adjacent to the existing assembly part number.

SUBTASK 72-41-21-350-276 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions