Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-10-440-001 HPC Rotor Assembly - Measure The Rotor Assembly Parts, Assembly-001

General

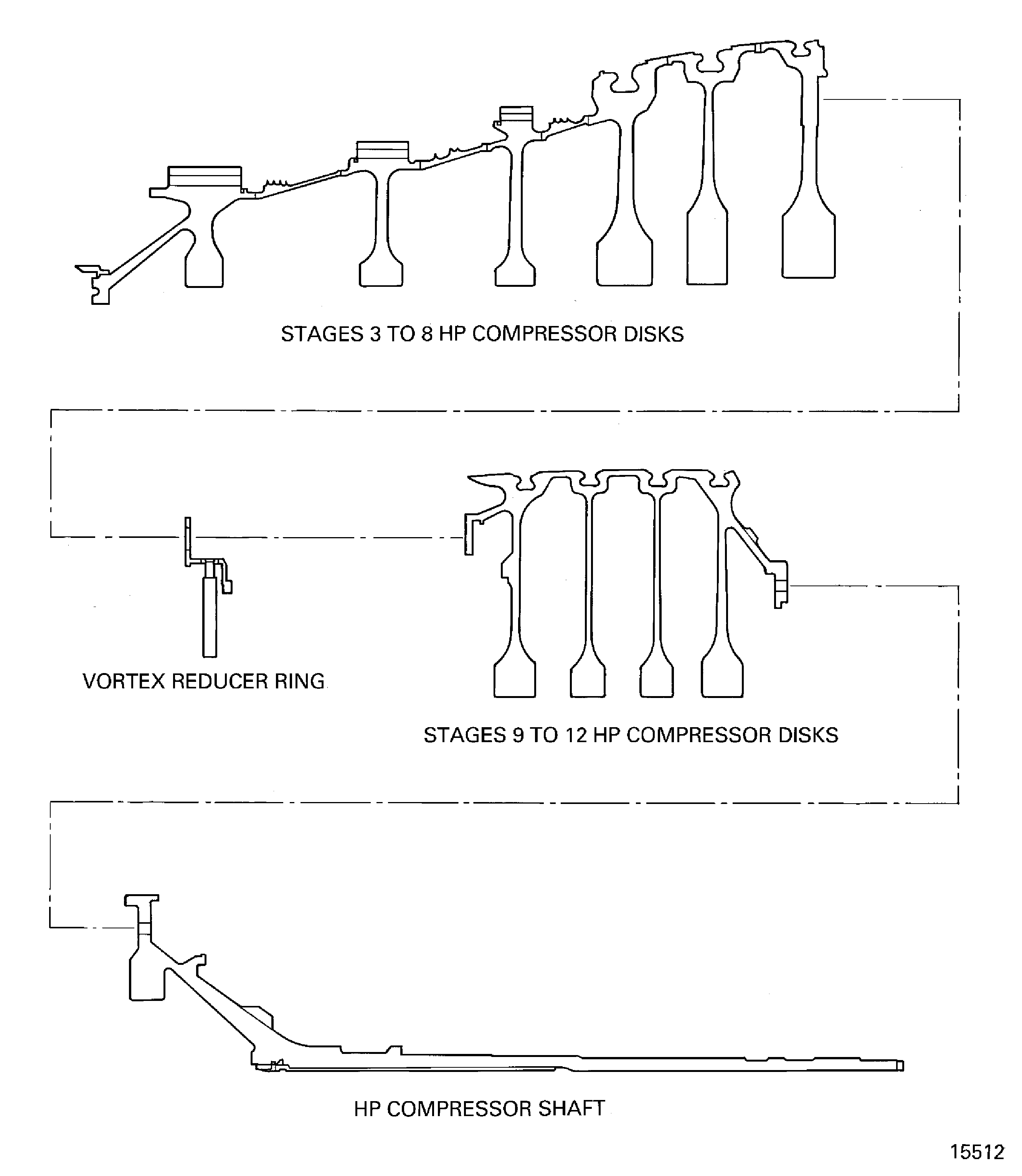

This TASK gives the procedure to measure the stages 3 to 8 HP compressor disks HPC Stage 3 - 8 Drum Disk And Wire Seals (72-41-11,01-200), the vortex reducer ring HPC Stage 9 - 12 Drum Disk And Vortex Reducer Ring (72-41-12,01-575), the stages 9 to 12 HP compressor disks HPC Stage 9 - 12 Drum Disk And Vortex Reducer Ring (72-41-12,01-600) and the HP compressor shaft HPC Rear Shaft And Heatshield Assembly (72-41-13,01-850). This data is used when you assemble the HP compressor rotor assembly.

The procedure to assemble and balance the HP compressor rotor assembly is given in the subsequent TASKS.

TASK 72-41-10-440-002-A00 (ASSEMBLY-002, CONFIG-001). Assemble the HP compressor rotor assembly.

TASK 72-41-10-440-003-A00 (ASSEMBLY-003, CONFIG-001). Do a balance check of the HP compressor rotor assembly and install the blades.

TASK 72-41-10-440-004-A00 (ASSEMBLY-004, CONFIG-001). Grind the tips of the HP compressor blades.

TASK 72-41-10-440-005-A00 (ASSEMBLY-005, CONFIG-001). Final balance the HP compressor rotor assembly.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Overhaul Processes referred to in the procedure by the TASK/SUBTASK number are in SPM.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is identified with the symbol * after the torque value.

Special assembly tolerances are included in this procedure.

Lubricate all threads and mating faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS unless other lubricants are referred to in the procedure.

All the mating faces and curvic teeth must be cleaned with CoMat 01-001 SOLVENT, DELETED or CoMat 01-002 SOLVENT, DELETED. before assembly. Refer to SPM TASK 70-11-01-300-503. They must also be dry assembled unless told differently in the procedure.

All of the temporary marks made in this procedure must be removed after completion of this task.

Data when you measure the HP compressor rotor assembly parts.

The data found in this procedure when used during assembly will cause the rotor assembly to be assembled with all of the parts concentric to specified limits.

It is important to prevent unwanted swash and run-out during this procedure. Thus, all of the rotor parts, tools and equipment used in this procedure must be kept very clean.

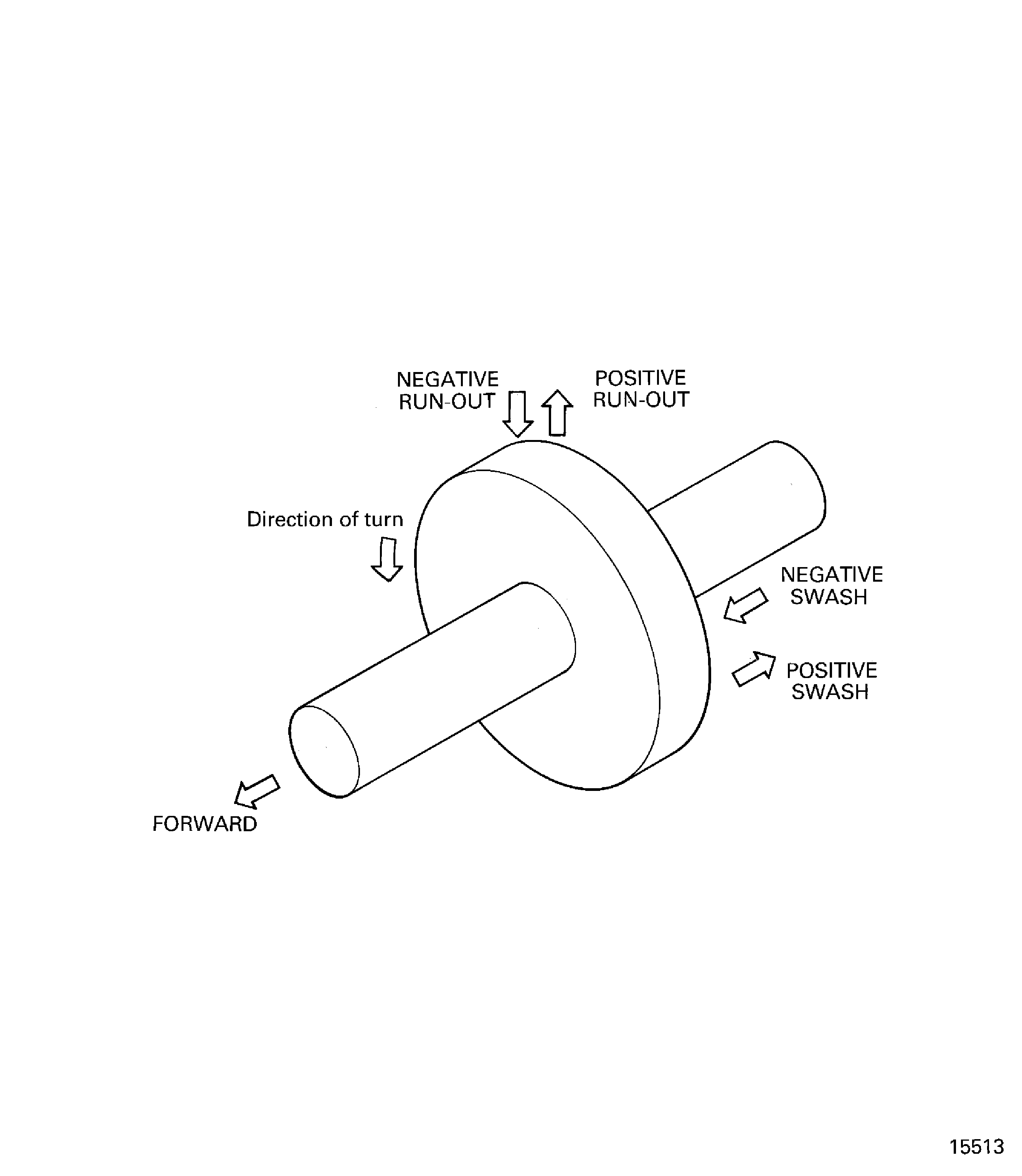

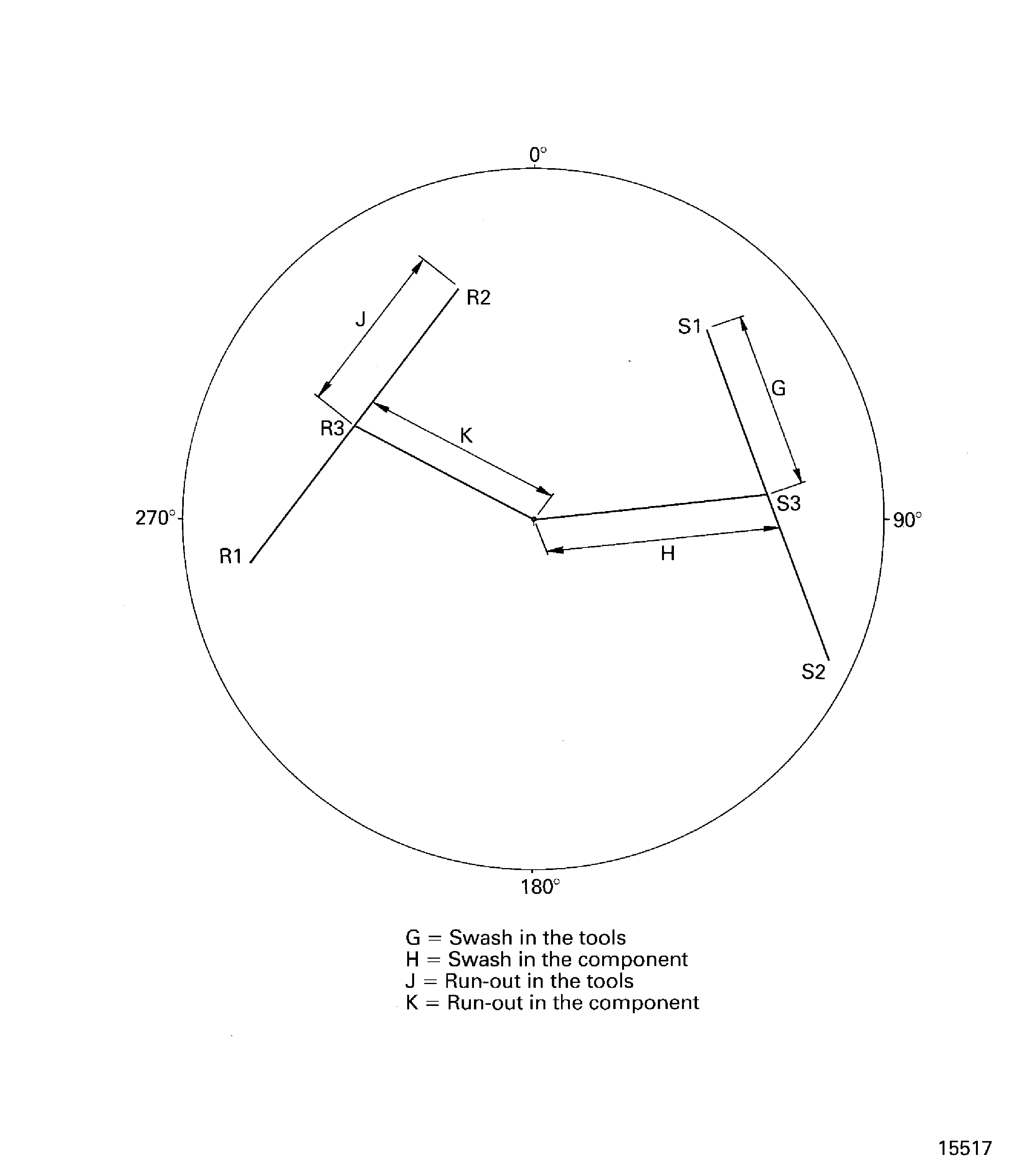

Run-out.

Run-out is the total movement of the measuring equipment display, in relation to a location diameter, when a part is turned. Run-out includes eccentricity.

Swash.

Swash is the total movement of the measuring equipment display, in relation to a mating face, when a part is turned.

Run-out and Swash data.

The subsequent data must be used when you measure run-out and swash, to permit the values to be put in to a computer.

All of the measured values are to be known as positive, if the location diameter moves radially out and/or the mating face moves rearwards in relation to a datum face.

This is correct if the measuring equipment display reads positive or negative values. Refer to Figure.

A minimum of nine values for run-out and swash must be read at eight equally spaced positions, for all components. The first and last values must be the same. If the first and last values are not the same, then continue as follows:

Read all of the nine values again and again until the first and last values are the same.

Refer to Figure for example views of the HP compressor rotor assembly parts.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Rotary air table | LOCAL | |||

| Computer | LOCAL | |||

| IAE 1R18025 Turnover stand adapter | 0AM53 | IAE 1R18025 | 1 | |

| IAE 1R18026 Lifting fixture | 0AM53 | IAE 1R18026 | 1 | |

| IAE 1R18062 Master curic base | 0AM53 | IAE 1R18062 | 1 | |

| IAE 1R18063 Location piece | 0AM53 | IAE 1R18063 | 1 | |

| IAE 1R18064 Bolt | 0AM53 | IAE 1R18064 | 20 | |

| IAE 1R18065 Lifter | 0AM53 | IAE 1R18065 | 1 | |

| IAE 1R18067 Extractor | 0AM53 | IAE 1R18067 | 3 | |

| IAE 1R18068 Height block | 0AM53 | IAE 1R18068 | 3 | |

| IAE 1R18085 Adjusting unit | 0AM53 | IAE 1R18085 | 4 | |

| IAE 1R18086 Clamp assembly | 0AM53 | IAE 1R18086 | 4 | |

| IAE 1R18087 Block | 0AM53 | IAE 1R18087 | 4 | |

| IAE 1R18088 Pillar | 0AM53 | IAE 1R18088 | 1 | |

| IAE 1R18090 Safety support stand | 0AM53 | IAE 1R18090 | 1 | |

| IAE 1R18091 Support stand | 0AM53 | IAE 1R18091 | 1 | |

| IAE 1R18092 Support tool | 0AM53 | IAE 1R18092 | 1 | |

| IAE 1R18322 Turnover stand | 0AM53 | IAE 1R18322 | 1 | |

| IAE 1R18441 Lifting adapter | 0AM53 | IAE 1R18441 | 1 | |

| IAE 1R18691 Lifting fixture | 0AM53 | IAE 1R18691 | 1 | |

| IAE 1R19810 Computer program | 0AM53 | IAE 1R19810 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-001 SOLVENT, DELETED | LOCAL | CoMat 01-001 | ||

| CoMat 01-002 SOLVENT, DELETED. | LOCAL | CoMat 01-002 | ||

| CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON | IE304 | CoMat 02-121 | ||

| CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON | K6835 | CoMat 02-122 | ||

| CoMat 02-130 POLAR GRAPH PAPER | LOCAL | CoMat 02-130 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

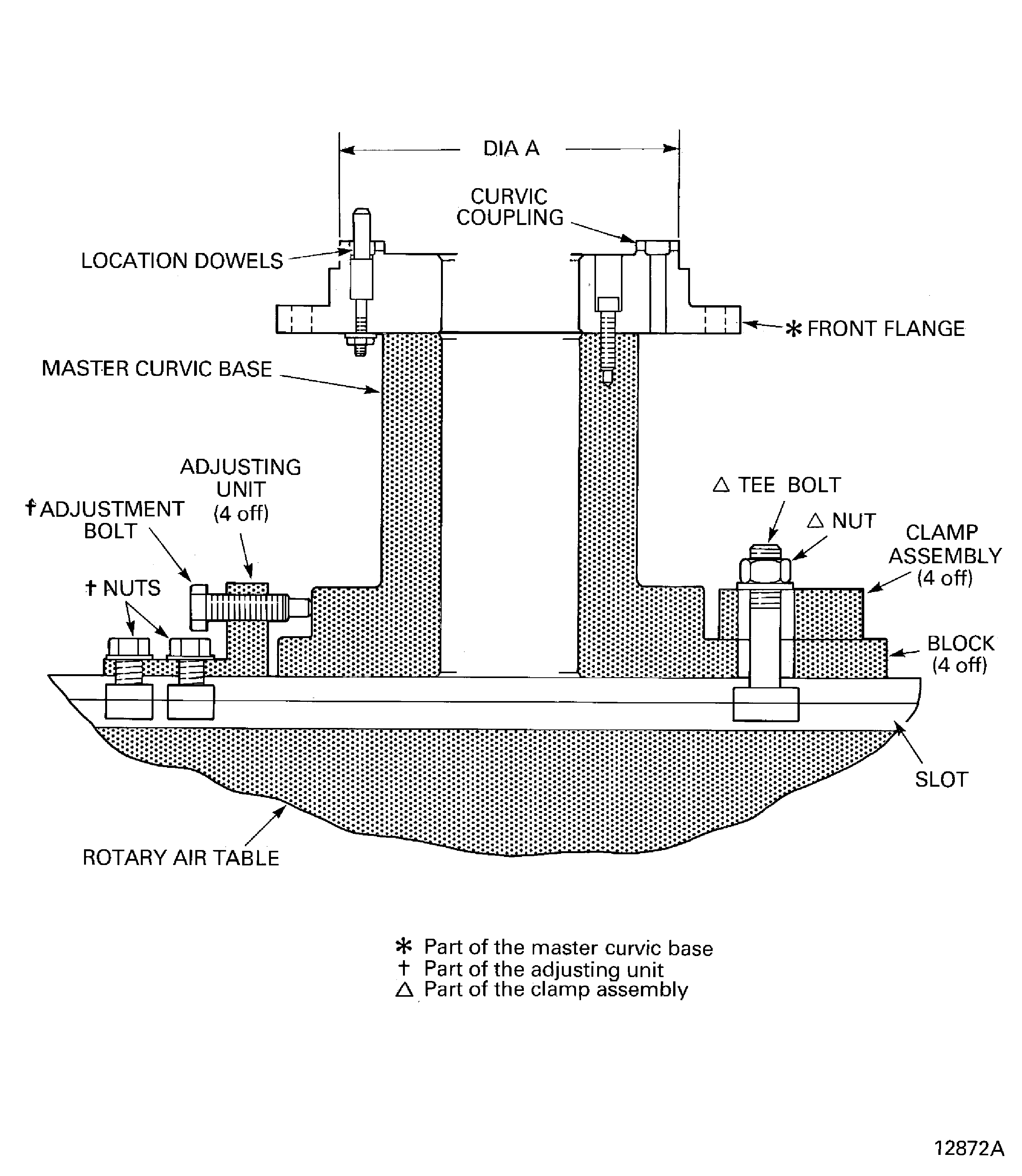

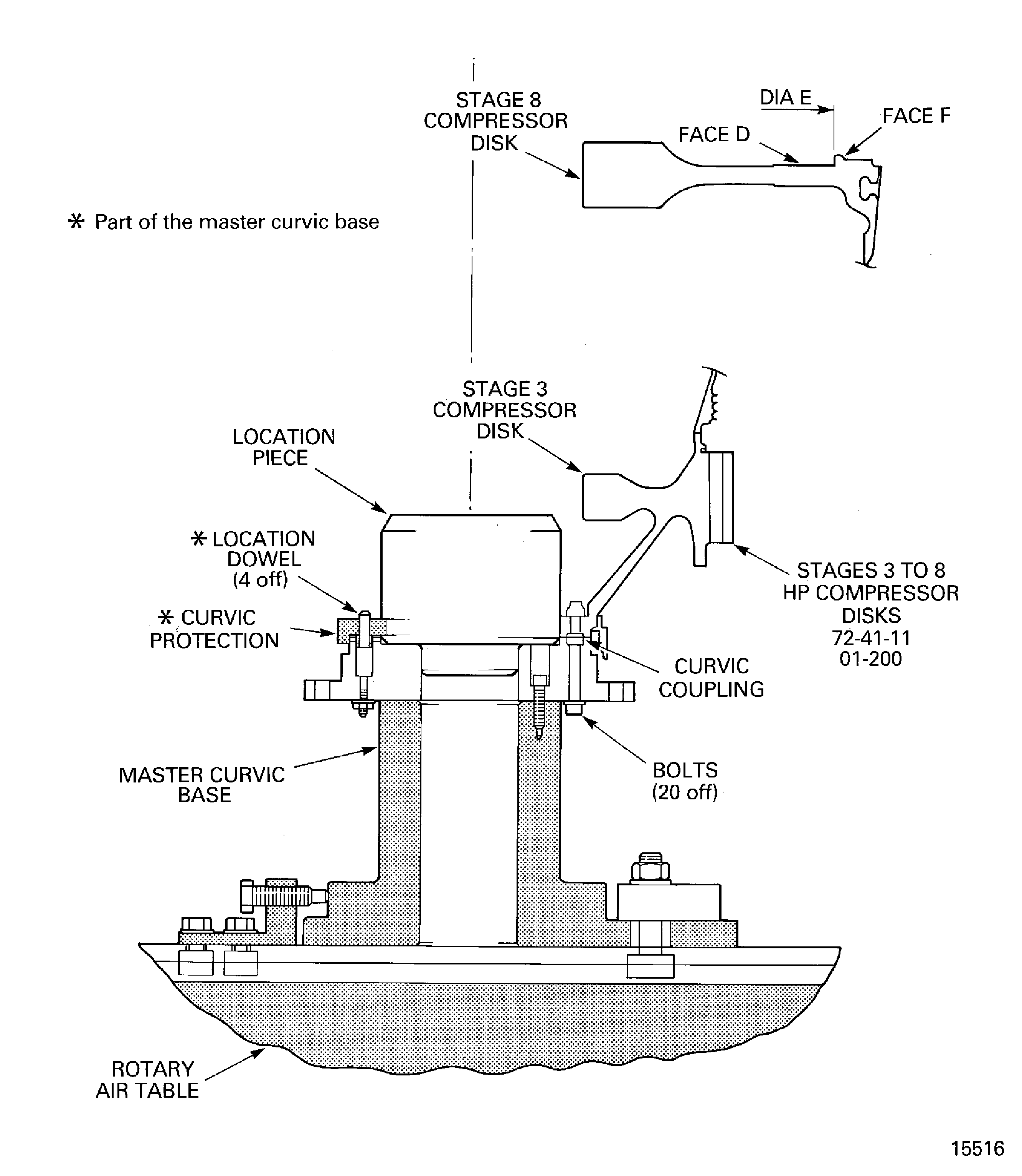

Refer to Figure.

Examine the bottom faces of IAE 1R18062 Master curic base 1 off and the rotary air table for contamination and/or high metal. If there is contamination, the mating faces must be cleaned. If there is high metal, use a stone to make the surface smooth.

Put one of IAE 1R18087 Block 4 off behind each 'tee' bolt.

Install IAE 1R18086 Clamp assembly 4 off on to the rotary air table.

Install IAE 1R18085 Adjusting unit 4 off on to the rotary air table.

SUBTASK 72-41-10-440-051 Assemble the Tools Used to Measure the Swash and Run-out of the Stages 3 to 8 HP Compressor Disks

Refer to Figure.

Use IAE 1R18088 Pillar 1 off and measuring equipment to measure the run-out of diameter A of the master curvic base. The run-out must not be more than 0.0002 in. (0.005 mm).

SUBTASK 72-41-10-440-052 Correct the Run-out of the Assembled Tools

Install IAE 1R18063 Location piece 1 off on to the master curvic base. Refer to Figure.

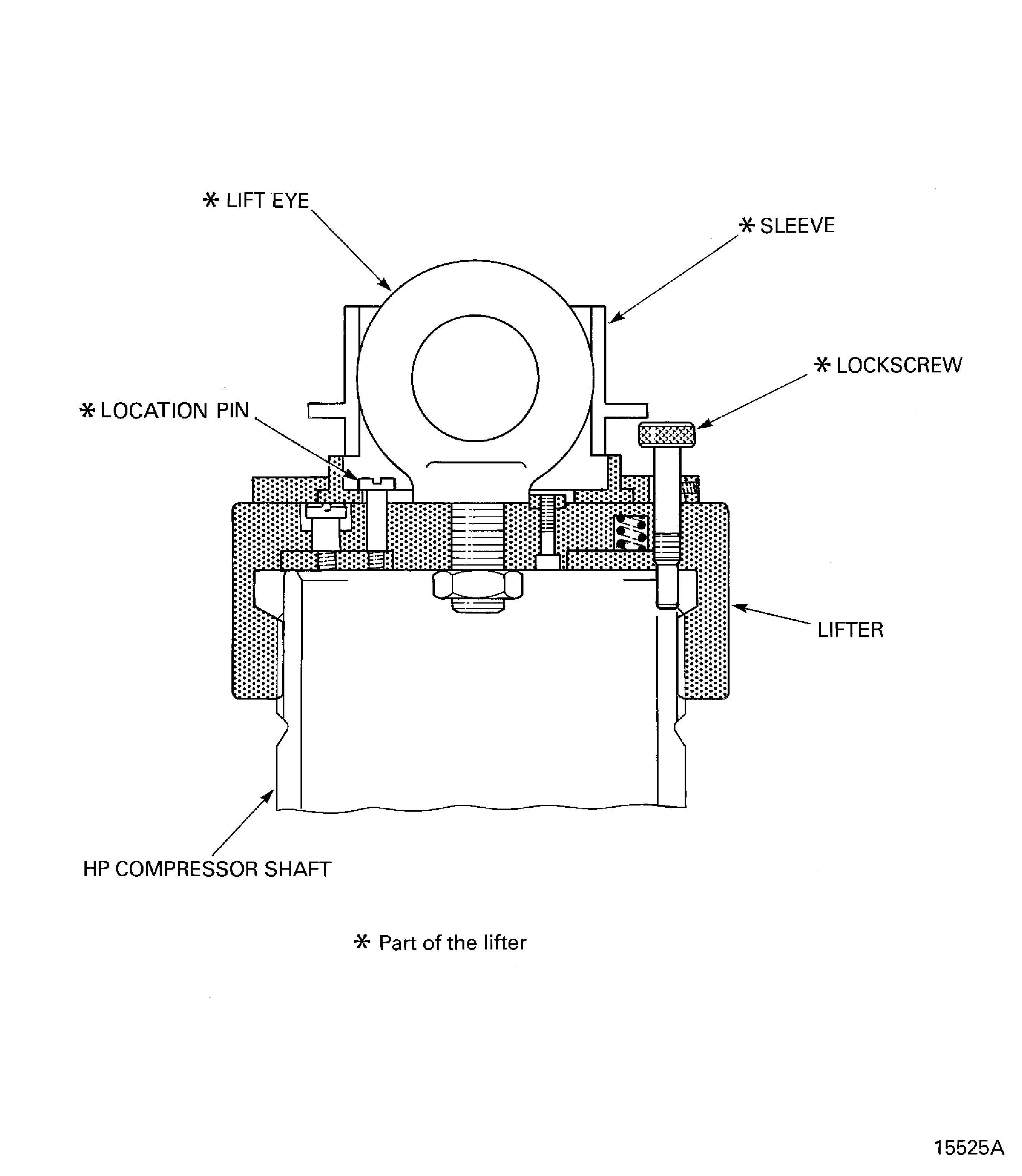

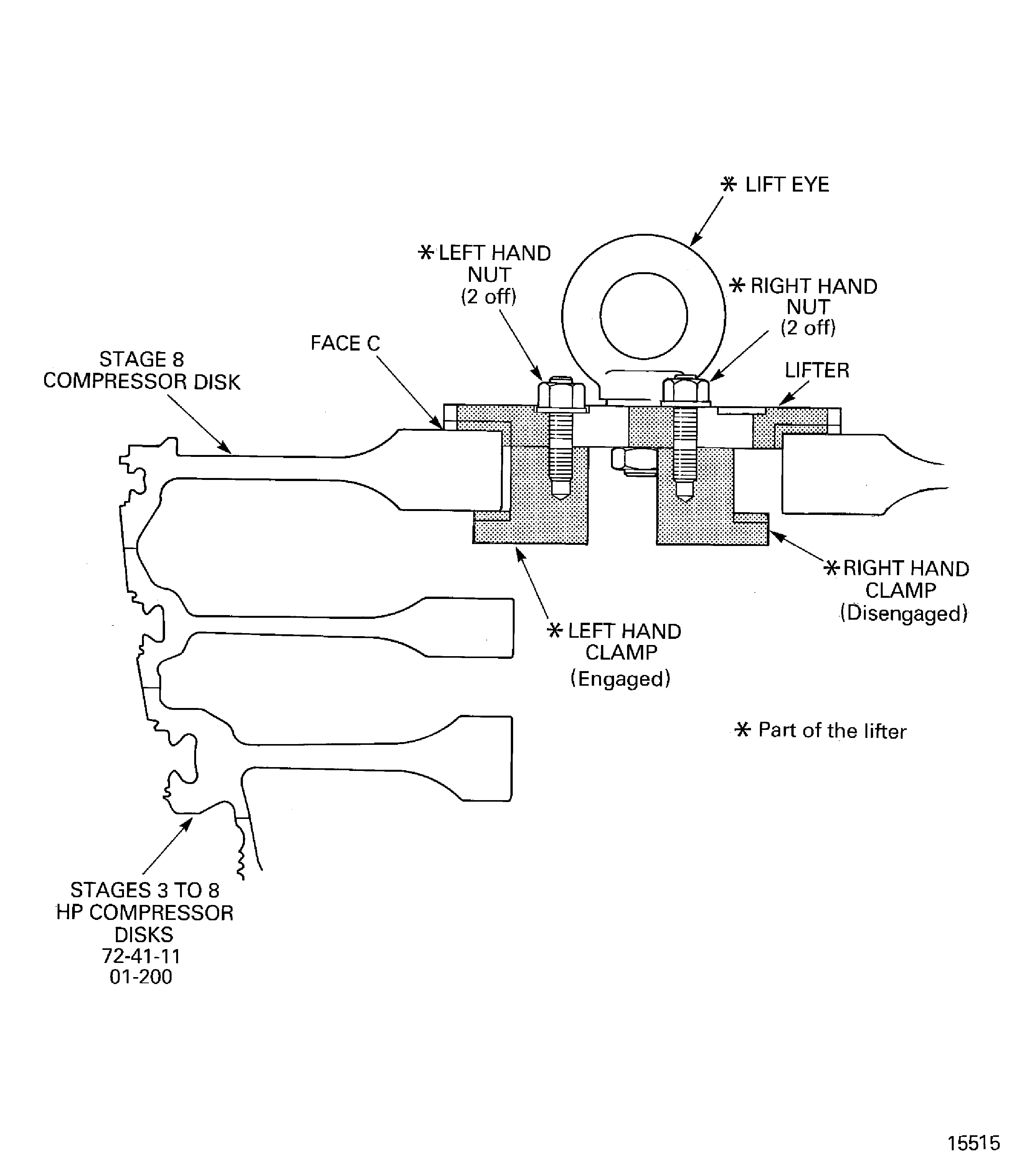

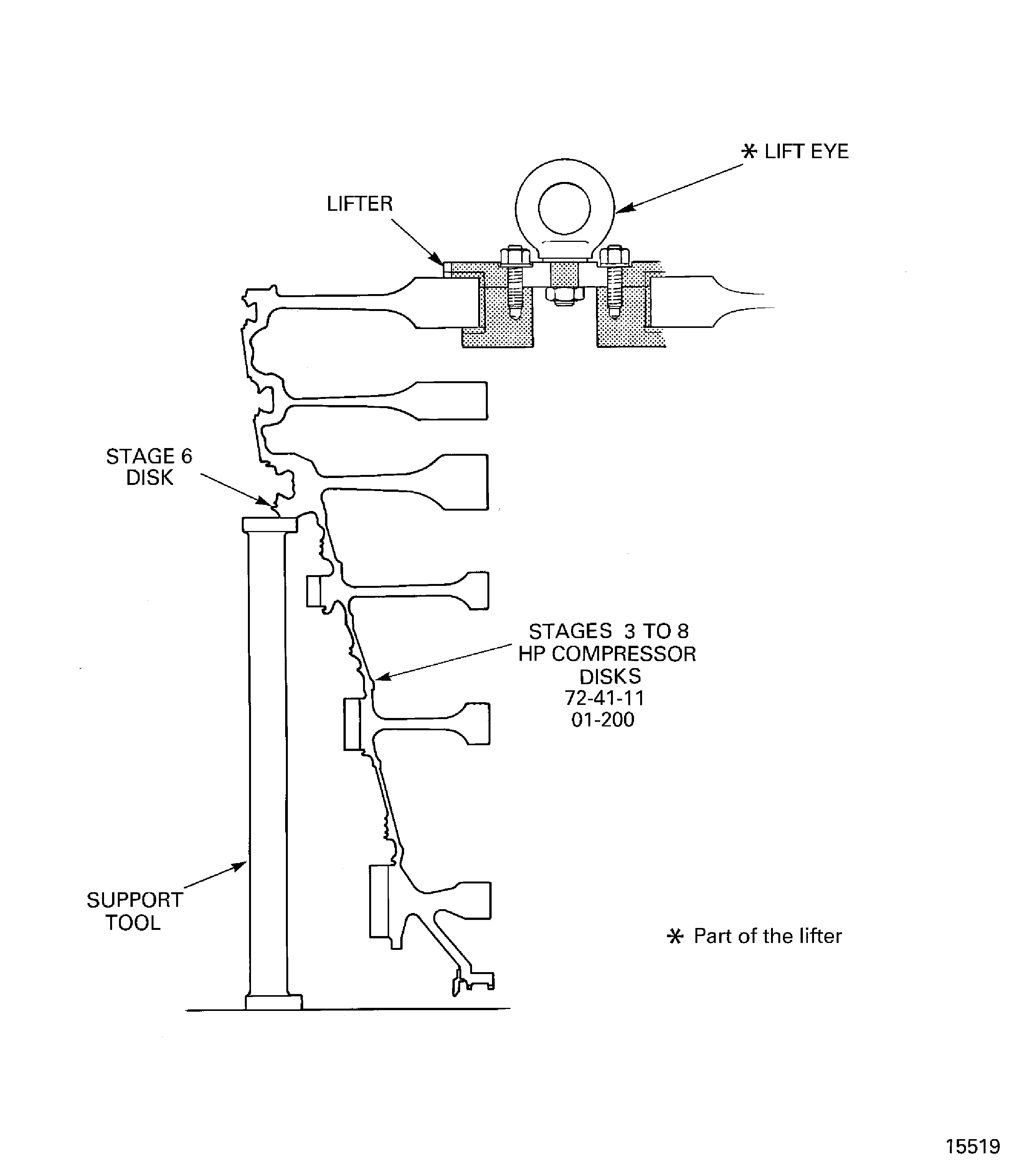

Attach IAE 1R18065 Lifter 1 off on to the rear of the stages 3 to 8 compressor disks. Refer to Figure.

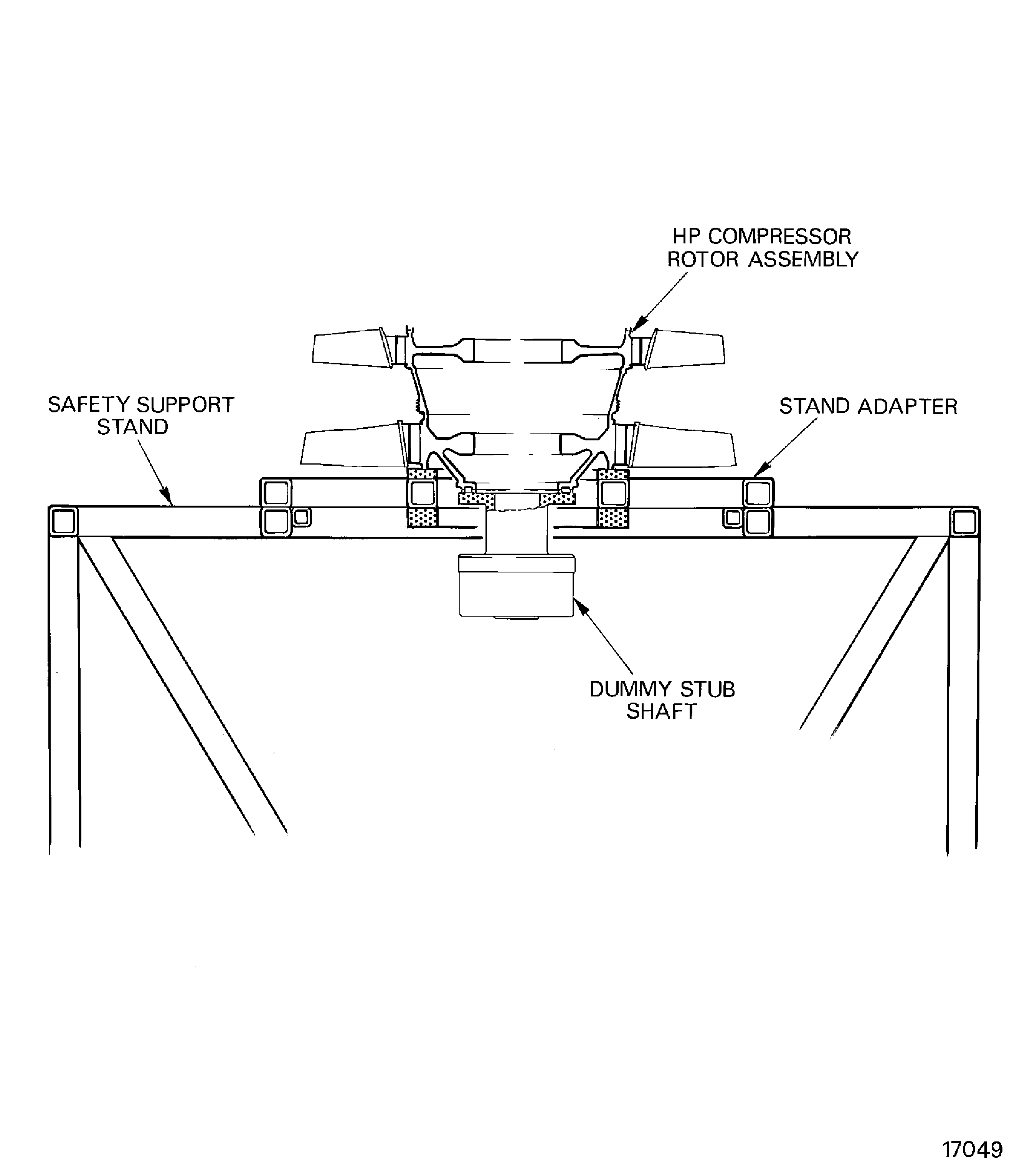

Install IAE 1R18091 Support stand 1 off on to the top of IAE 1R18090 Safety support stand 1 off. Make sure that the stand adapter is correctly engaged in the safety support stand. Refer to Figure.

Examine the curvic teeth of the stage 3 disk and the master curvic base curvic coupling.

CAUTION

YOU MUST NOT LET THE STAGES 3 TO 8 COMPRESSOR DISKS HIT THE MASTER CURVIC BASE.Slowly lower the stages 3 to 8 compressor disks until the location piece is engaged in the bore of the stage 3 compressor disk. Make sure that the four location dowels in the master curvic base are aligned with the four holes in the stage 3 disk curvic coupling. Refer to Figure.

Install IAE 1R18064 Bolt 20 off through the master curvic base, in to the stage 3 disk curvic coupling. Lightly tighten the bolts.

NOTE

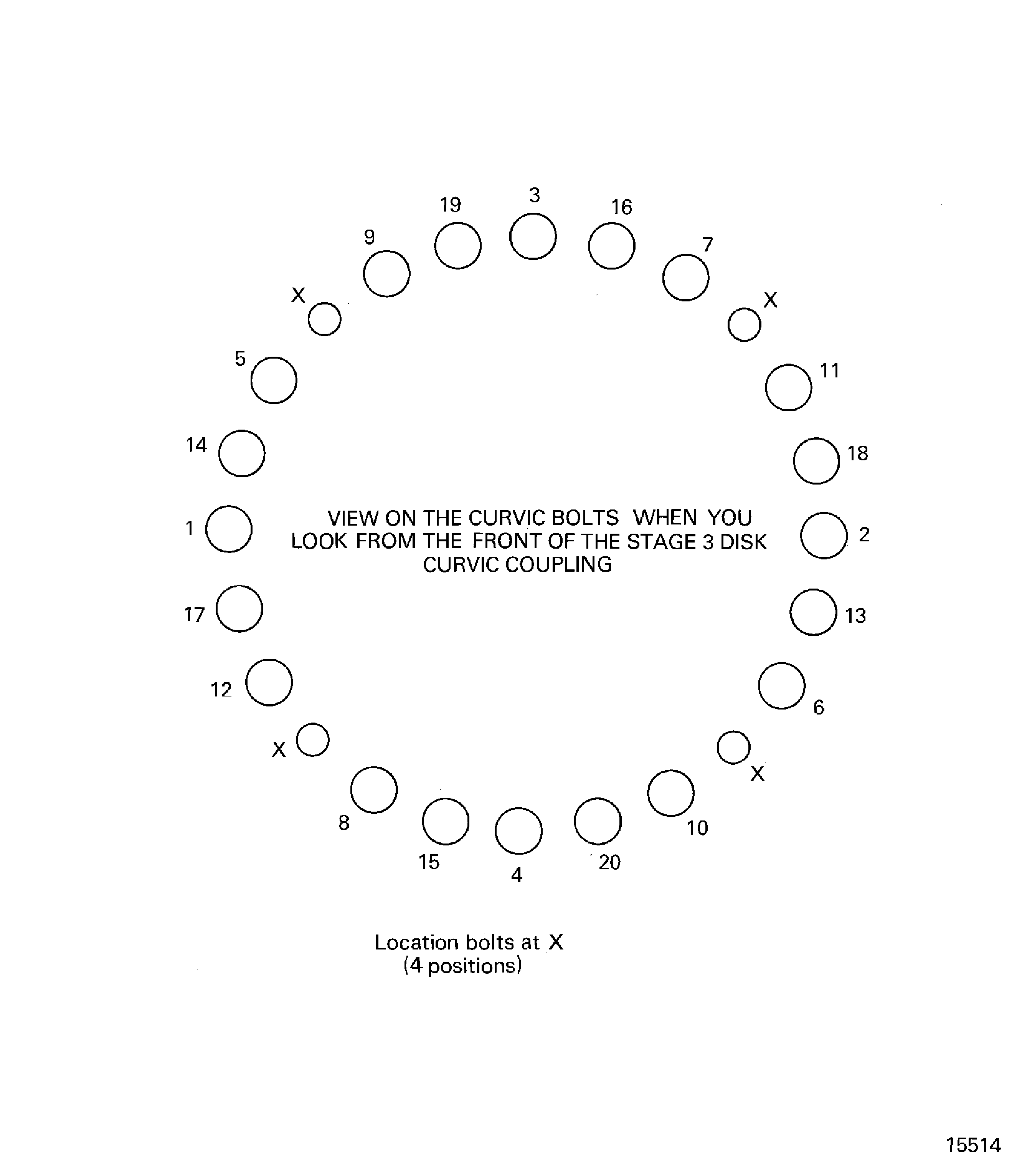

The torque sequence is identified on the outer diameter of the master curvic base front flange.Torque all of the bolts. Do these three steps in the sequence shown. Refer to Figure.

Remove the lifter from the rear of the stages 3 to 8 compressor disks. Refer to Figure.

SUBTASK 72-41-10-440-053 Install the Stages 3 to 8 HP Compressor Disks (72-41-11,01-200) on to the Master Curvic Base

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON to identify the eight equally spaced positions. Give a number to each position in sequence. Refer to SPM TASK 70-09-01-400-501. Make the marks on the face F.

NOTE

The start and finish position (0 degrees) is the center line of the stage 3 disk, No. 1 dovetail location.Identify eight position numbers on the rear of the stages 3 to 8 compressor disks.

Use the temporary marker to identify the position of the stages 3 to 8 compressor disks in relation to the master curvic base. Make the marks on the stage 3 disk and the master curvic base curvic couplings outer diameters. Refer to SPM TASK 70-09-01-400-501.

Measure the swash at the eight positions identified in Step.

Use IAE 1R19810 Computer program 1 off and put the swash values in the computer. The computer will calculate the FIR and the angle of the swash. Make a mark on CoMat 02-130 POLAR GRAPH PAPER to show the FIR and angle and identify it as S1.

Measure the run-out at the eight positions identified in Step.

Use IAE 1R18088 Pillar 1 off and measuring equipment to measure the swash of face D and the run-out of diameter E.

Measure the swash and run-out, refer to Step Identify the swash as S2 and the run-out as R2 on the polar graph paper.

Examine the mating faces of the stage 3 disk and master curvic base curvic couplings. Refer to Step.

Make sure that the run-out of the assembled tools is in limits. Refer to Step.

NOTE

To make sure the stages 3 to 8 compressor disks are in the initial position, align the temporary marks made in step C.Install the stages 3 to 8 compressor disks on to the assembled tools in the initial position. Refer to Step.

The maximum permitted swash is 0.0060 in. (0.152 mm) and run-out is 0.0070 in. (0.178 mm). If the swash and/or run-out is more than these values, then continue as follows:

SUBTASK 72-41-10-220-051 Measure the Swash and Run-out of the Stages 3 to 8 HP Compressor Disks (72-41-11, 01-200)

Install IAE 1R18065 Lifter 1 off on to the rear of the stages 3 to 8 compressor disks. Refer to Figure and Step.

Remove the stages 3 to 8 compressor disks from the master curvic base. Refer to Figure.

Remove the lifter from the stage 8 compressor disk. Refer to Step.

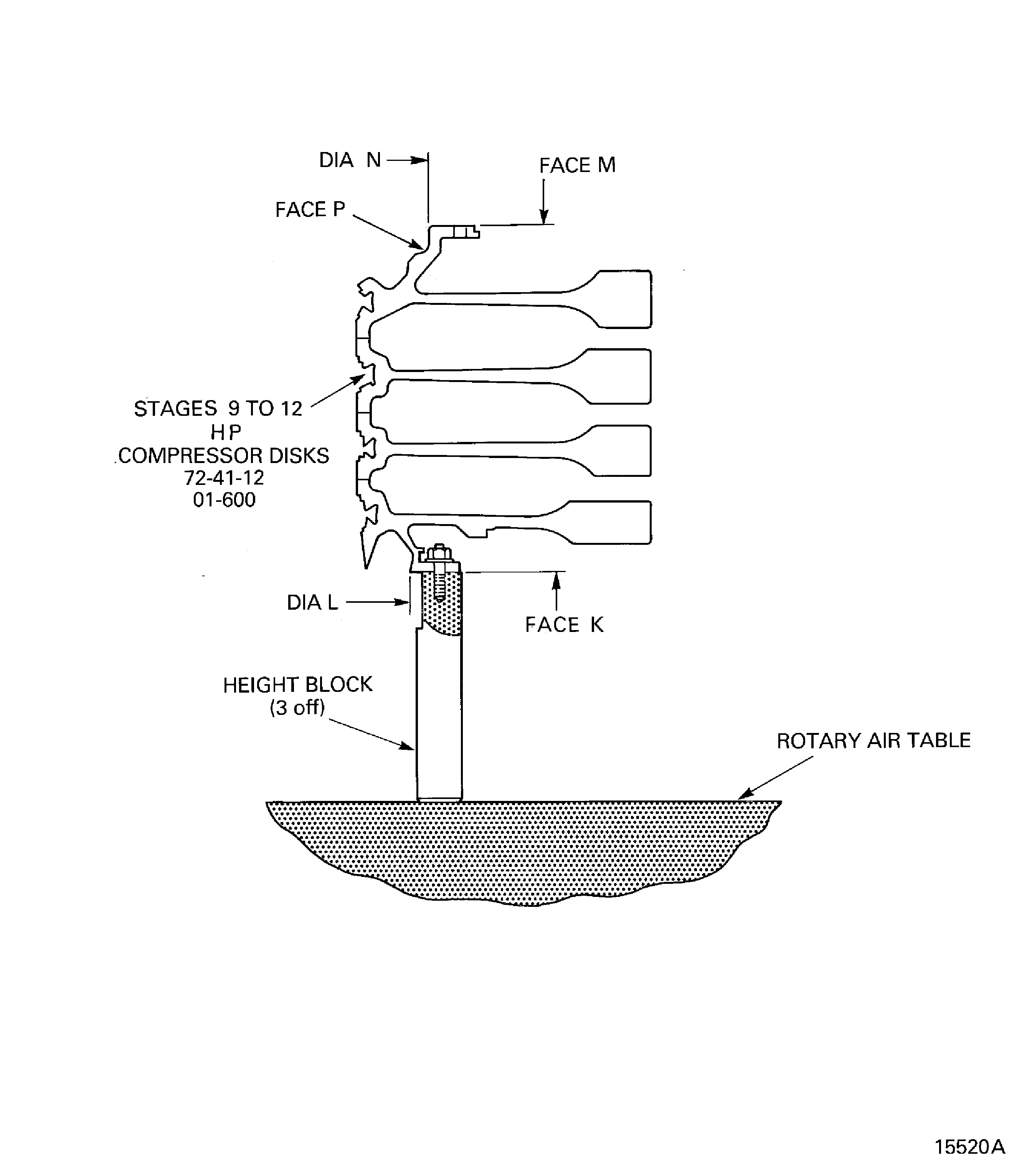

Install the stages 3 to 8 compressor disks on to IAE 1R18092 Support tool 1 off. Refer to Figure.

SUBTASK 72-41-10-440-054 Install the Stages 3 to 8 HP Compressor Disks (72-41-11,01-200) on to the Support Tool

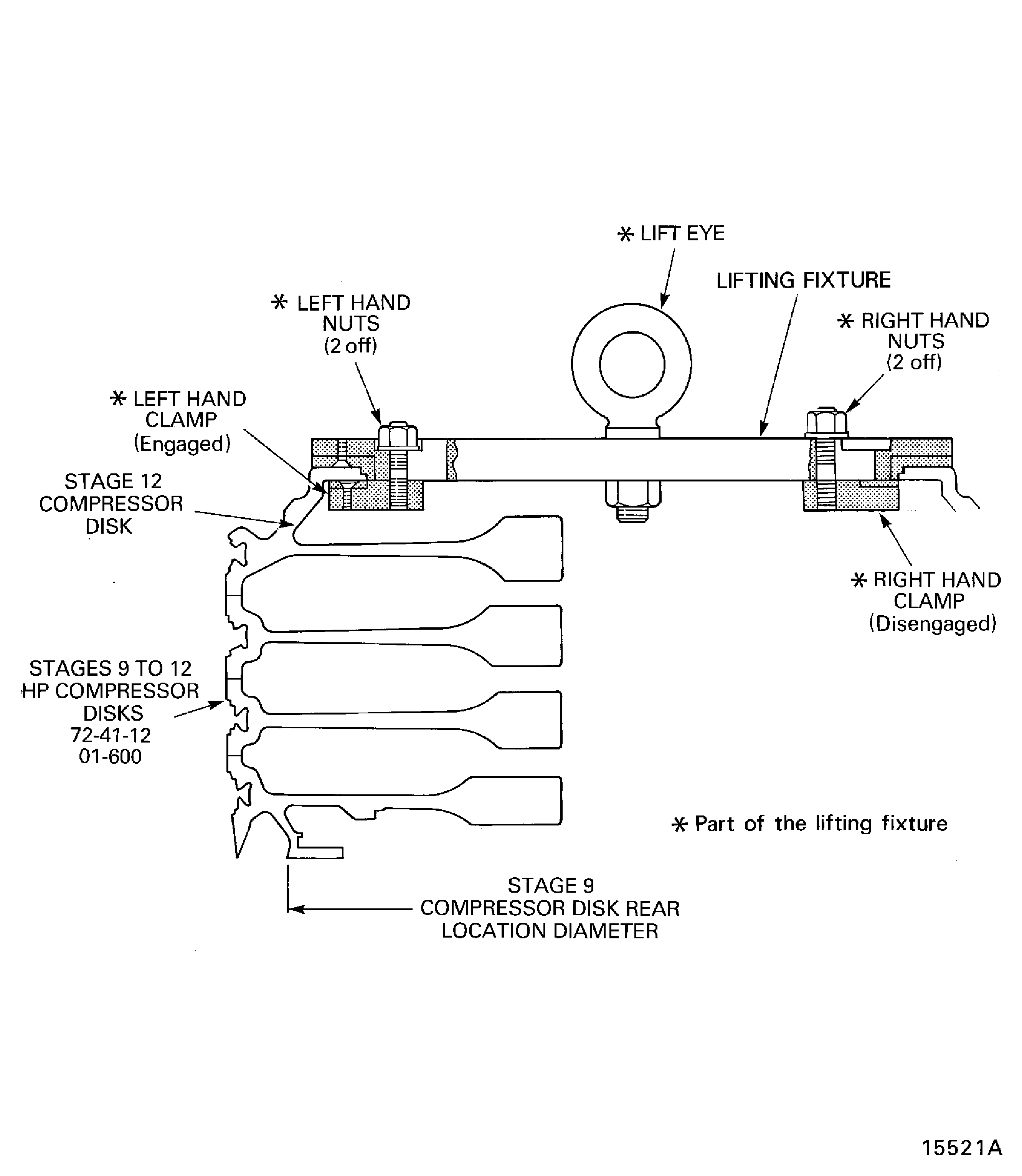

Install IAE 1R18026 Lifting fixture 1 off onto the stage 12 compressor disk rear flange.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON to identify eight equally spaced positions. Give a number to each position in sequence. Refer to SPM TASK 70-09-01-400-501. Make the marks on the face P.

NOTE

The start and finish position (0 degrees) is the stage 12 blade installation slot center line.Identify eight position numbers on the rear of the stages 9 to 12 compressor disks.

Use IAE 1R18088 Pillar 1 off and measuring equipment to measure the run-out of diameter L.

Set the run-out of the stage 9 compressor disk front flange outer diameter (diameter L).

Use IAE 1R19810 Computer program and put the swash values in to the computer. The computer will calculate the FIR and the angle of the swash.

Use the pillar and measuring equipment to measure the swash of face M and the run-out of diameter N.

If the calculated value of swash is less than 0.0011 in. (0.028 mm), the HP compressor stages 9 to 12 drum assembly is acceptable if the final swash, refer to TASK 72-41-10-440-002-A00 and the static unbalance of the HP compressor rotor assembly are in specified limits, refer to TASK 72-41-10-440-003.

If the calculated value of swash is more than 0.0011 in. (0.028 mm) the stages 9 to 12 compressor disks must be rejected and a new one used.

NOTE

If new stages 9 to 12 compressor disks are used, then its swash and run-out must be measured. Thus, do this SUBTASK again.

If the swash is more than 0.0008 in. (0.019 mm), then do as follows:

The maximum permitted swash is 0.0008 in. (0.019 mm). If the calculated value of swash is more than this value, then do the subsequent steps.

If the calculated value of run-out is less than 0.0020 in. (0.050 mm), the HPC 9 to 12 drum assembly is acceptable if the final run-out, refer to TASK 72-41-10-440-002-A00 and the static unbalance of the HPC rotor assembly are within defined limits, refer to TASK 72-41-10-440-003-A00.

If the calculated value of run-out is more than 0.0020 in. (0.050 mm) the stage 9 to 12 compressor disks must be rejected and a new one used.

NOTE

If new stages 9 to 12 compressor disks are used, then its swash and run-out must be measured. Thus, do this SUBTASK again.If the run-out is more than 0.0010 in. (0.025 mm), then

The maximum permitted run-out is 0.0010 in. (0.025 mm). If the calculated value of run-out is more than this value, then do the subsequent steps.

SUBTASK 72-41-10-220-052-A00 V2500-A1: Measure the Swash and Run-out of the Stages 9 to 12 HP Compressor Disks (72-41-12,01-600)

Install the IAE 1R18691 Lifting fixture 1 off on the stage 12 compressor disk rear flange.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON to identify eight equally spaced positions. Give a number to each position in sequence. Refer to SPM TASK 70-09-01-400-501. Make the marks on the face P.

NOTE

The start and finish position (0 degrees) is the stage 12 blade installation slot center line.Identify eight position numbers on the rear of the stages 9 to 12 compressor disks.

Use IAE 1R18088 Pillar 1 off and measuring equipment to measure the run-out of diameter L.

Set the run-out of the stage 9 compressor disk front flange outer diameter (diameter L).

Measure the swash at the eight positions identified in Step.

Use IAE 1R19810 Computer program and put the swash values into the computer. The computer will calculate the FIR and the angle of the swash.

Measure the run-out at the eight positions identified in Step.

Use the pillar and measuring equipment to measure the swash of face M and the run-out of diameter N.

If the calculated value of swash is less than 0.0011 in. (0.028 mm), the HP compressor stages 9 to 12 drum assembly is acceptable if the final swash, refer to TASK 72-41-10-440-002-B00 and the static unbalance of the HP compressor rotor assembly are in specified limits, refer to TASK 72-41-10-440-003.

If the calculated value of swash is more than 0.0011 in. (0.028 mm) the stages 9 to 12 compressor disks must be rejected and a new one used.

NOTE

If new stages 9 to 12 compressor disks are used, then its swash and run-out must be measured; do this SUBTASK again.

If the swash is more than 0.0008 in. (0.019 mm), then do as follows:

The maximum permitted swash is 0.0008 in. (0.019 mm). If the calculated value of swash is more than this value, then do the subsequent steps.

If the calculated value of run-out is less than 0.0020 in. (0.050 mm), the HPC 9 to 12 drum assembly is acceptable if the final run-out, refer to TASK 72-41-10-440-002-B00 and the static unbalance of the HPC rotor assembly are within defined limits, refer to TASK 72-41-10-440-003-A00.

If the calculated value of run-out is more than 0.0020 in. (0.050 mm) the stage 9 to 12 compressor disks must be rejected and a new one used.

NOTE

If new stages 9 to 12 compressor disks are used, then its swash and run-out must be measured. Thus, do this SUBTASK again.If the run-out is more than 0.0010 in. (0.025 mm), then

The maximum permitted run-out is 0.0010 in. (0.025 mm). If the calculated value of run-out is more than this value, then do the subsequent steps.

SUBTASK 72-41-10-220-052-B00 V2500-A5: Measure the Swash and Run-out of the Stages 9 to 12 HP Compressor Disks (72-41-12,01-600)

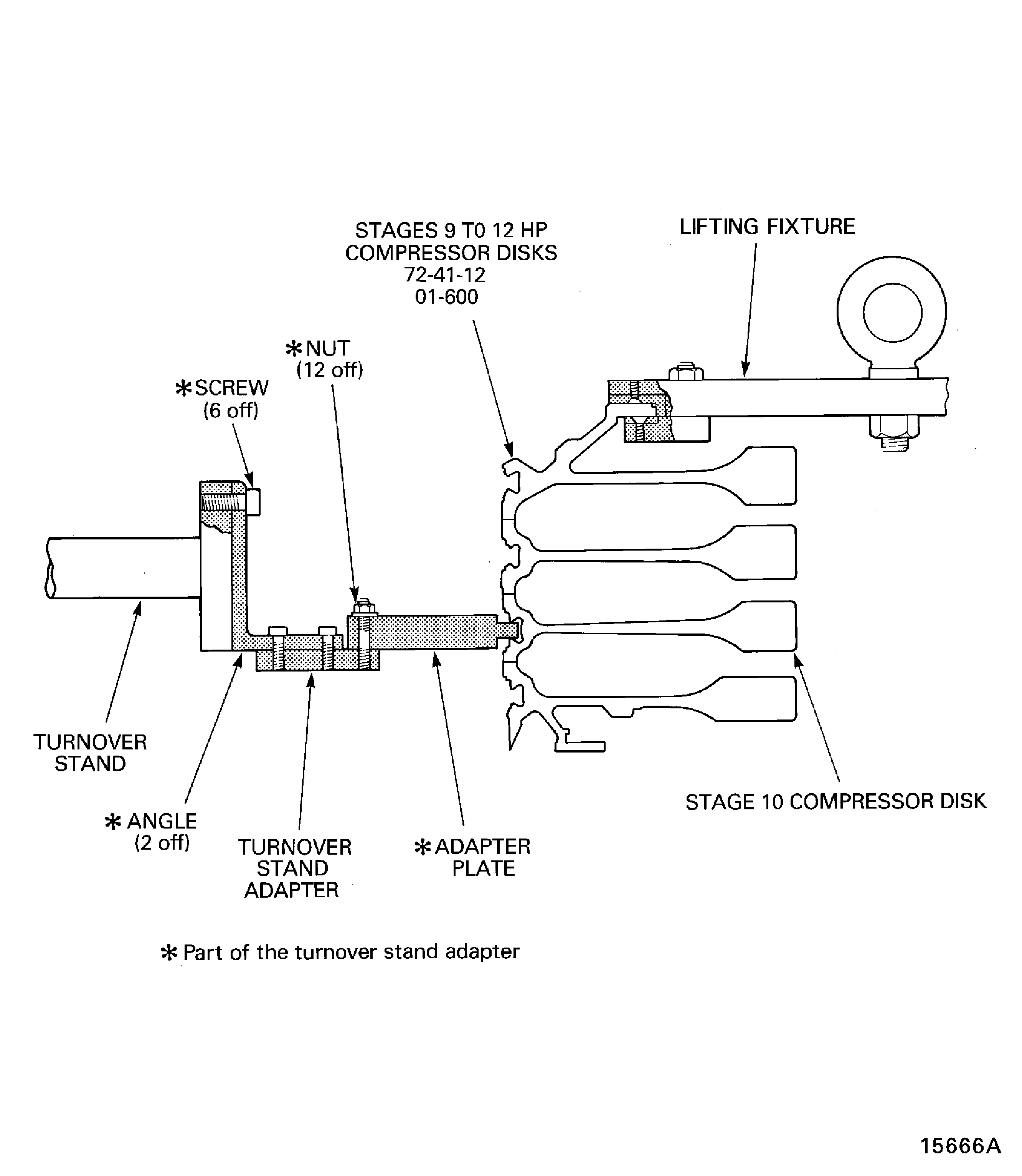

Install IAE 1R18026 Lifting fixture 1off on to the stage 12 compressor disk rear flange. Refer to Figure and Step.

Attach IAE 1R18025 Turnover stand adapter 1 off on to IAE 1R18322 Turnover stand 1 off. Refer to Figure.

Remove the three height blocks from the stage 9 compressor disk front flange. Refer to Figure.

Install the stages 9 to 12 compressor disks in to the turnover stand. Refer to Figure.

SUBTASK 72-41-10-440-055-A00 V2500-A1: Install the Stages 9 to 12 HP Compressor Disks (01-500) on to the Turnover Stand

Install IAE 1R18691 Lifting fixture 1 off on to the stage 12 compressor disk rear flange. Refer to Figure and Step.

Attach IAE 1R18025 Turnover stand adapter 1 off on to IAE 1R18322 Turnover stand 1 off. Refer to Figure.

Remove the three height blocks from the stage 9 compressor disk front flange. Refer to Figure.

Install the stages 9 to 12 compressor disks in to the turnover stand. Refer to Figure.

SUBTASK 72-41-10-440-055-B00 V2500-A5: Install the Stages 9 to 12 HP Compressor Disks (01-500) on to the Turnover Stand

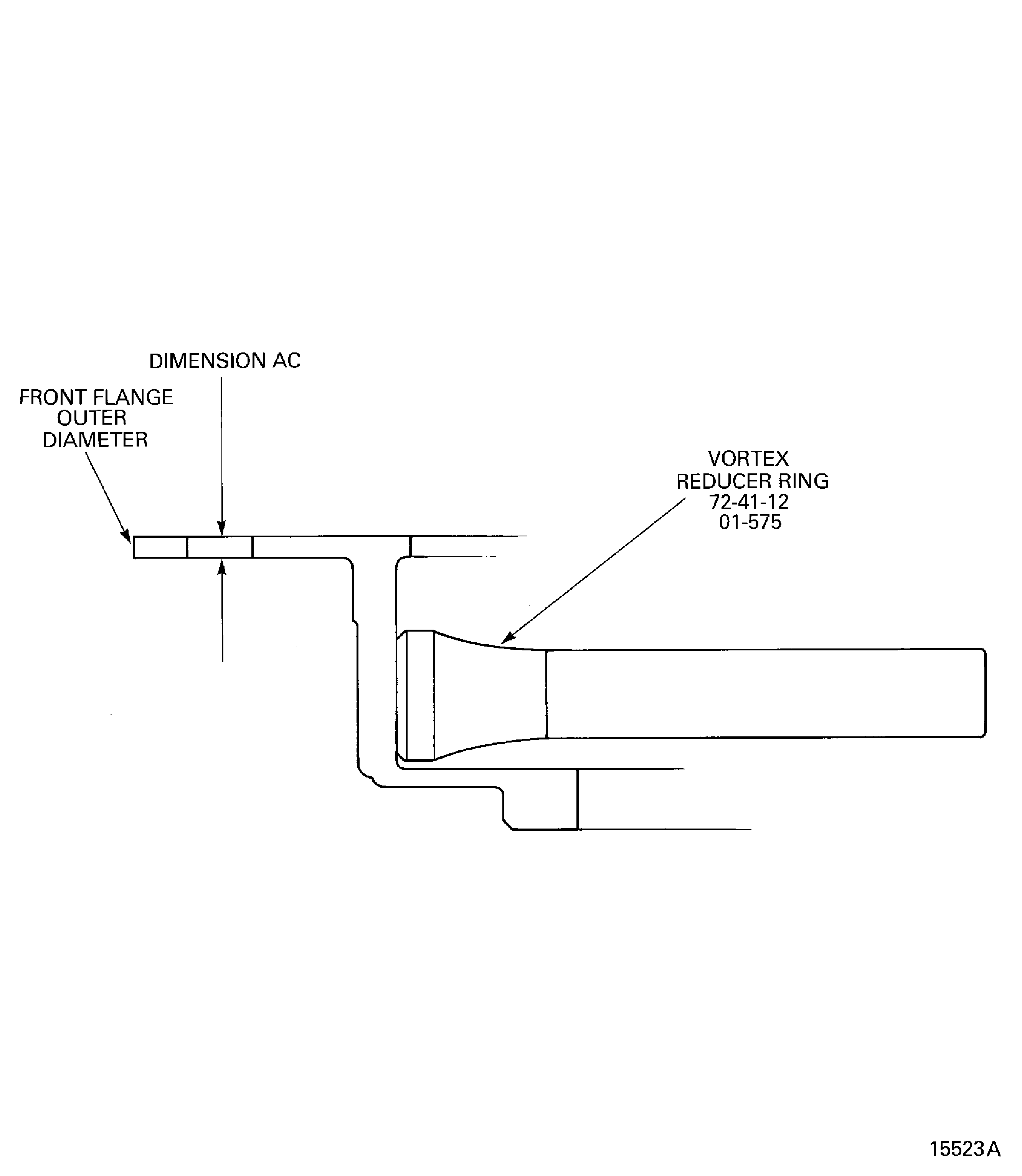

Refer to Figure.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON to make a mark 'T'. Make the mark on the front flange outer diameter at the position of the maximum flange thickness. Refer to SPM TASK 70-09-01-400-501.

Identify the angular position of the maximum flange thickness.

SUBTASK 72-41-10-220-053 Measure the Vortex Reducer Ring (72-41-12,01-575)

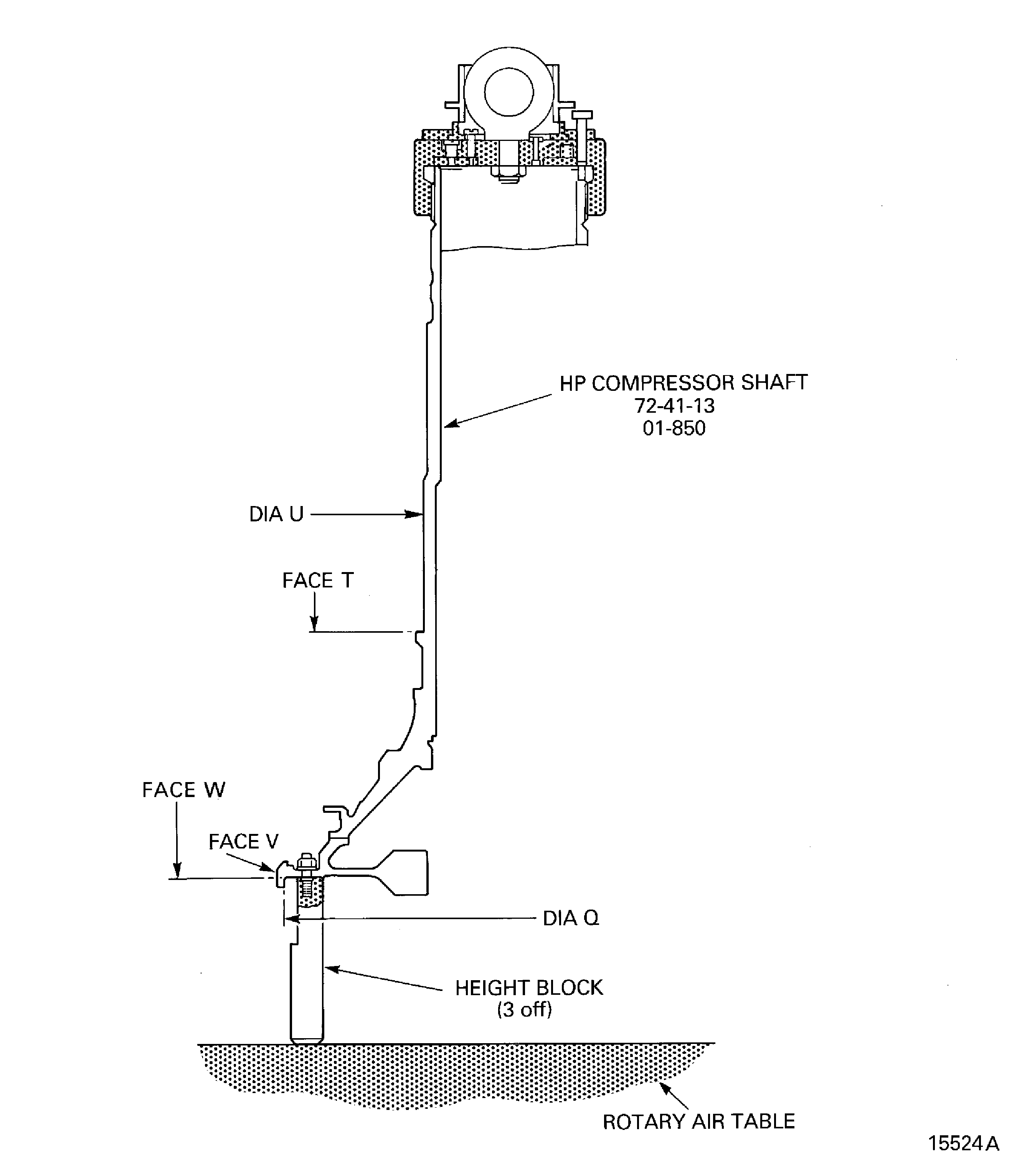

Examine the mating faces of IAE 1R18068 Height block 3 off and the compressor shaft front flange for contamination and/or high metal. If there is contamination, then the surface must be cleaned. If there is high metal, use a stone to make the surface smooth.

Install IAE 1R18441 Lifting adapter 1 off onto the end of the compressor shaft.

Make a mark on the front flange adjacent to the part number. This mark shows the start and finish point (0 degrees). Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON to make the mark. Refer to SPM TASK 70-09-01-400-501.

Identify the eight position numbers on the compressor shaft.

Use IAE 1R18088 Pillar 1 off and measuring equipment to measure the run-out of diameter Q.

Set the run-out of the compressor shaft front flange inner diameter (diameter Q).

Use IAE 1R19810 Computer program and put the swash values into the computer. The computer will calculate the FIR and the angle of the swash.

Use the pillar and measuring equipment to measure the swash of face T and the run-out of diameter U.

If the calculated value of run-out is less than 0.0020 in. (0.050 mm), the HP compressor rear shaft assembly is acceptable if the final run-out, refer to TASK 72-41-10-440-002-B00 and the static unbalance, refer to TASK 72-41-10-440-003, of the HP compressor rotor assembly are in specified limits.

If the calculated value of run-out is more than 0.0020 in. (0.050 mm) the HP compressor rear shaft assembly must be rejected and a new one used.

NOTE

If a new compressor shaft is used, then its swash and run-out must be measured. Thus, do this SUBTASK again.

If the run-out is more than 0.0010 in. (0.025 mm), then do as follows:

The maximum permitted run-out is 0.0010 in. (0.025 mm). If the calculated value of run-out is more than this value, then do the subsequent steps.

SUBTASK 72-41-10-220-054 Measure the Swash and Run-out of the HP Compressor Shaft (72-41-13,01-850)

Figure: Example view of the HP compressor rotor assembly parts

Example view of the HP compressor rotor assembly parts

Figure: Swash and run-out data

Swash and run-out data

Figure: Assemble the tools used to measure the swash and run-out of the stages 3 to 8 HP compressor disks

Assemble the tools used to measure the swash and run-out of the stages 3 to 8 HP compressor disks

Figure: Stage 3 disk curvic coupling bolts torque sequence

Stage 3 disk curvic coupling bolts torque sequence

Figure: Install the lifter on to the stages 3 to 8 HP compressor disks

Install the lifter on to the stages 3 to 8 HP compressor disks

Figure: Measure the swash and run-out of the stages 3 to 8 HP compressor disks

Measure the swash and run-out of the stages 3 to 8 HP compressor disks

Figure: Calculate the correct swash and run-out values

Calculate the correct swash and run-out values

Figure: Assemble the tools used to clean the stage 3 disk curvic coupling

Assemble the tools used to clean the stage 3 disk curvic coupling

Figure: Install the stages 3 to 8 HP compressor disks in to the support tool

Install the stages 3 to 8 HP compressor disks in to the support tool

Figure: Measure the swash and run-out of the stages 9 to 12 HP compressor disks

Measure the swash and run-out of the stages 9 to 12 HP compressor disks

Figure: Install the lifting fixture on to the stages 9 to 12 HP compressor disks

Install the lifting fixture on to the stages 9 to 12 HP compressor disks

Figure: Install the stages 9 to 12 HP compressor disks in to the turnover stand

Install the stages 9 to 12 HP compressor disks in to the turnover stand

Figure: Measure the vortex reducer ring

Measure the vortex reducer ring

Figure: Measure the swash and run-out of the HP compressor shaft

Measure the swash and run-out of the HP compressor shaft

Figure: Install the lifter on to the HP compressor shaft

Install the lifter on to the HP compressor shaft