Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-12-200-002-C00 HPC Stage 9 - 12 Drum Disk - Examine, Inspection-002

General

This TASK gives the procedure for the inspection of the rear HPC disks.

Fig/Item numbers in parentheses in the procedure agree with those used in the IPC.

The policy that is necessary for inspection is given in SPM TASK 70-20-01-200-501.

All the parts must be cleaned before any part is examined. Refer to SPM TASK 70-10-00-100-501.

All parts must be visually examined for damage, corrosion and wear. Any defects that are not identified in the procedure must be referred to IAE.

Do not discard any part until you are sure there are no repairs available. Refer to the instructions in the Repair before a discarded part is used again or oversize parts are installed.

Parts which should be discarded can be held although no repair is available. The repair of a discarded part could be shown to be necessary at a subsequent date.

All parts must be examined to make sure that all the repairs have been completed satisfactorily.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in SPM.

References

Refer to SPM for data on these items:

Definition of Damage, SPM TASK 70-02-02-350-501,

Record and Control of the Lives of Parts, SPM TASK 70-05-00-220-501,

Inspection of parts, SPM TASK 70-20-01-200-501.

Some data on these items are contained in this TASK. For more data on these items refer to SPM:

Method of Testing for Crack Indications,

Chemical Processes,

Surface Protection.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 |

Spares

NONESafety Requirements

CAUTION

Procedure

NOTE

The examination of the whole component using Ultra High Sensitivity Fluorescent Penetrant is required.Clean the Part. Refer to the TASK 72-41-12-100-000 (CLEANING-000).

SUBTASK 72-41-12-230-064 Examine the Rear HPC Disk for Cracks, Assembly A, and Assembly B

Clean the parts. Refer to TASK 72-41-12-100-000 (CLEANING-000).

Mask the areas adjacent to inspection locations with CoMat 02-005 ADHESIVE TAPE (MASKING). This will prevent glare during inspection from Fluorescent Penetrant which may have soaked into the ceramic.

Do a focus crack inspection of the Rear HPC Disk for cracks according to TASK 72-41-12-200-004, Subtask 72-41-12-230-079.

SUBTASK 72-41-12-230-082 Examine the Rear HPC Disk for Cracks, Assembly A, and Assembly B

Refer to Figure.

Other than Step

Examine the disk at Locations 1, 2 and 4 for damage.

Repair, VRS6087 TASK 72-41-12-300-016 (REPAIR-016)

Other than Step

Examine the disk at Locations 3 and 5 for damage.

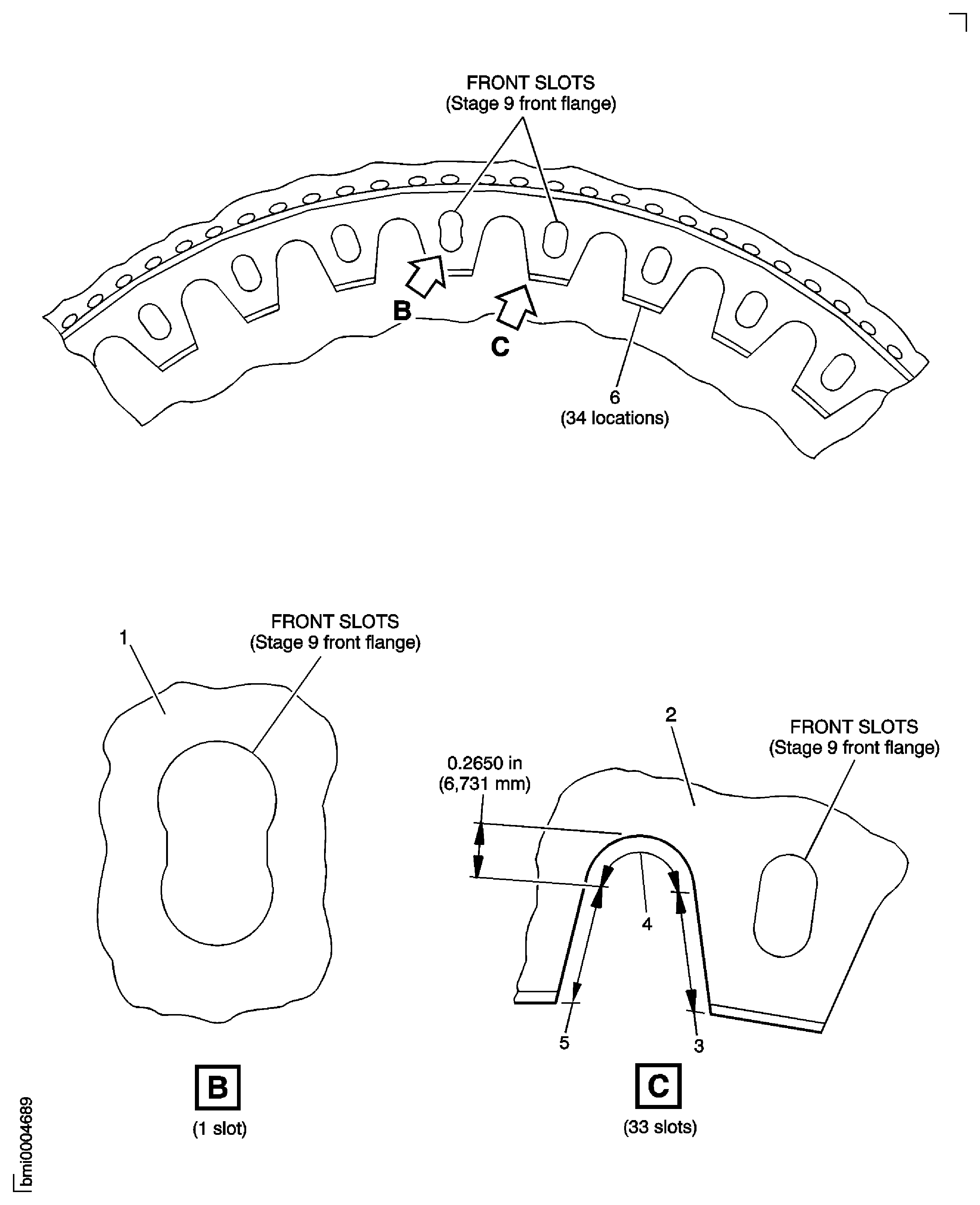

SUBTASK 72-41-12-220-091 Examine the Rear HPC Disk for Damage on the Front Slots, Assembly A, and Assembly B

Refer to Figure.

Repair, VRS6087 TASK 72-41-12-300-016 (REPAIR-016)

Examine the disk at Location 6 for damage on the front flange.

SUBTASK 72-41-12-220-092 Examine the Rear HPC Disk for Damage on the Front Flange and Bent Segments, Assembly A, and Assembly B

Refer to Figure.

SUBTASK 72-41-12-220-094 Examine the Rear HPC Disk for Damage on the Rear Flange, Assembly A, and Assembly B

Refer to Figure.

Repair, VRS6087 TASK 72-41-12-300-016 (REPAIR-016)

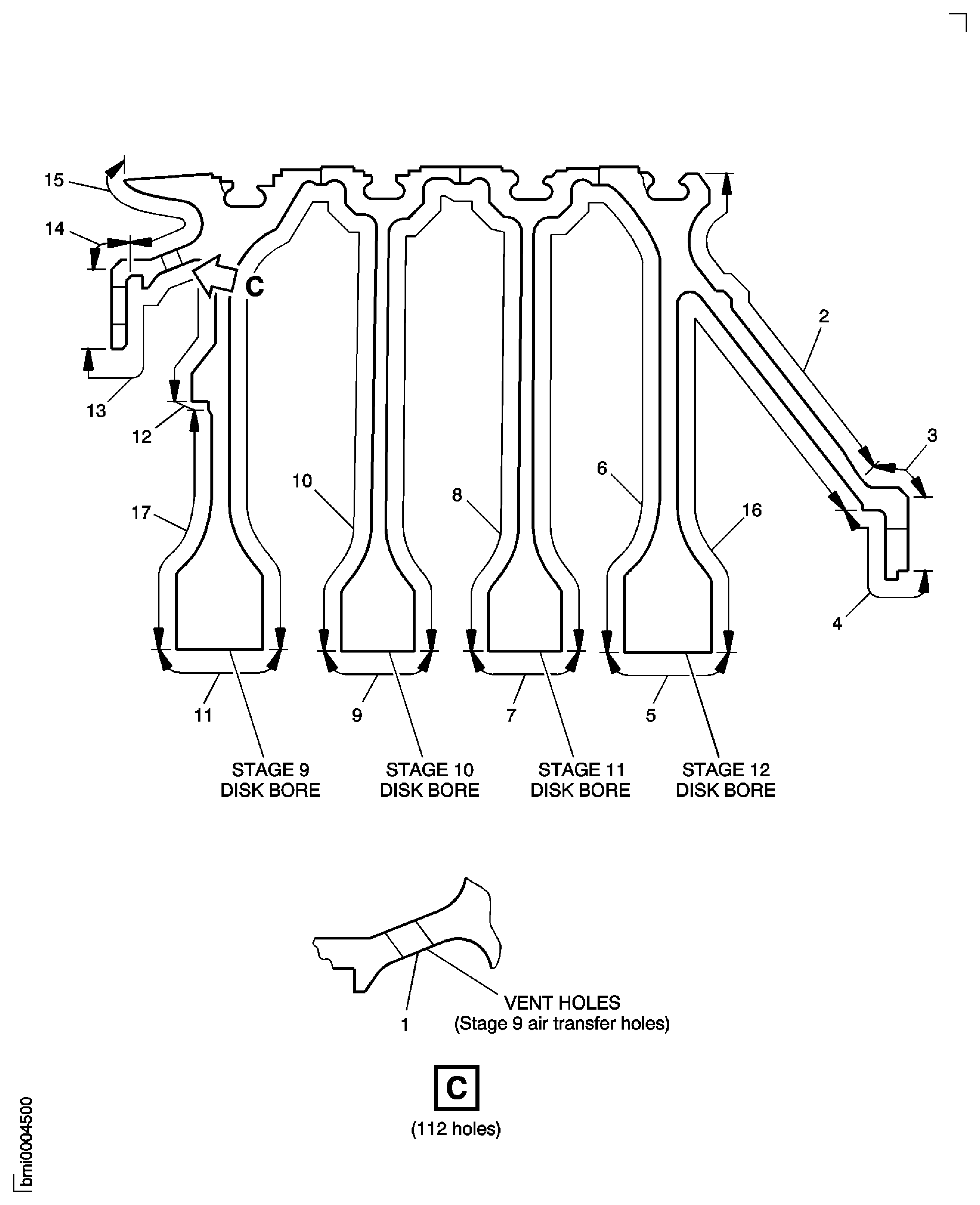

Other than Step

Examine the disk at Location 1 for damage in the vent holes.

SUBTASK 72-41-12-220-095 Examine the Rear HPC Disk for Damage in the Vent Holes, Assembly A, and Assembly B

Refer to Figure.

Repair, VRS6087 TASK 72-41-12-300-016 (REPAIR-016).

Examine the disk at Locations 2, 4, 13 and 15 for damage.

For locations 3 and 16, other than Step

Repair, VRS6087 TASK 72-41-12-300-016 (REPAIR-016).

For locations 12, 14 and 17, other than Step.

Examine the disk at locations 3, 12, 14, 16 and 17 for damage.

Other than Step.

Examine the disk at locations 5, 7, 9 and 11 for damage.

SUBTASK 72-41-12-220-119 Examine the Rear HPC Disk for Internal Damage, Assembly A, and Assembly B

Refer to Figure.

Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

Not more than 0.002 in. (0.05 mm) in depth

More than in Step.

Galled.

Examine the slots at zone A.

Zone A

-

Dovetail slot bedding area plus 0.050 in. (1.27 mm) below the bottom limit and the complete length of the slot on both sides

NOTE

All disks that have been used in service will have bedding areas that are easy to see.Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

More than in Step.

Galled or fretted.

Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

Not more than 0.002 in. (0.05 mm) in depth.

More than in Step.

Scored, nicked or dented.

Examine the slots at zone B.

Zone B

-

The area in the center of the dovetail slot

Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

Not more than 0.002 in. (0.05 mm) in depth.

More than in Step.

Galled or fretted.

Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

Not more than 0.0010 in. (0.025 mm) in depth.

More than in Step.

Scored, nicked or dented.

Examine the slots at Zone C.

Zone C

-

The blade loading and blade locking slot(s) and an area around it, on all surfaces of the dovetail, 0.040 in. (1.00 mm) away from the edges of the slot(s).

More than in Step

Scored, nicked, dented, galled or fretted.

Examine the slots at Zone D.

Zone D

-

The area between Zone A and B

Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

Not more than 0.0050 in. (0.127 mm).

More than in Step.

Scored, nicked, dented, galled or fretted.

Examine the slots at Zone E.

Zone E

-

The remaining areas of the disk around the dovetail slots that are not in Zones A and C.

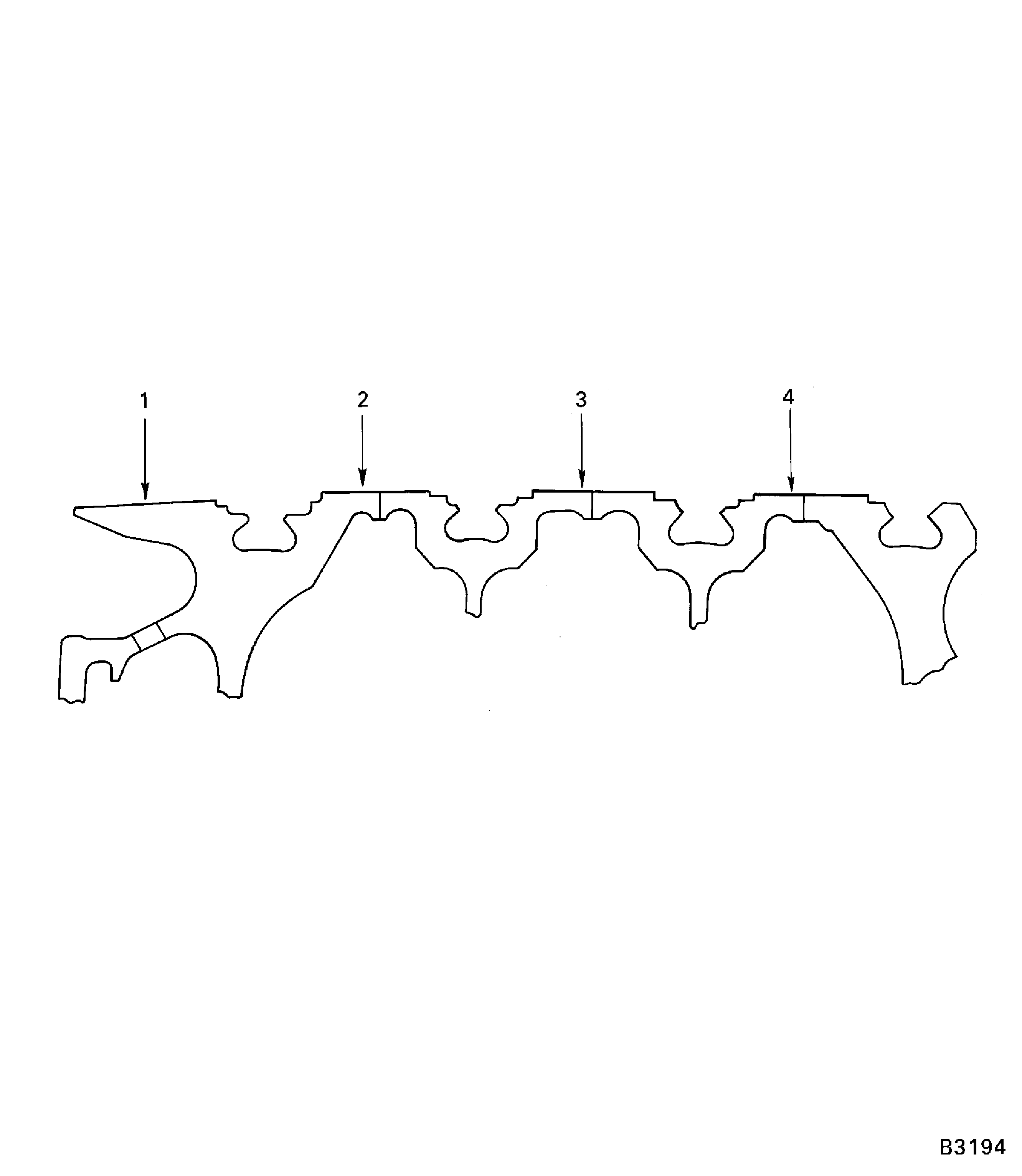

SUBTASK 72-41-12-220-097 Examine the Rear HPC Disk (72-41-12, 01-600) for Damage in the Blade Slots, the Loading Slots, and the Locking Slots, Assembly A

Refer to Figure.

Examine the HPC disk for damage in the blade slots, loading slots, and the locking slots.

Accept.

Bedding witness or mark to no discernible depth.

Accept.

Not more than 0.001 in. (0.03 mm) in depth.

Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

Not more than 0.002 in. (0.05 mm) in depth.

Reject.

More than in Step.

Galled.

Examine the slots at Zone A.

Zone A

-

Dovetail slot bedding area plus 0.050 in. (1.27 mm) below the bottom limit and the full length of the slot on each side.

NOTE

All disks that are in service will have bedding areas that are easy to see.Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

More than in Step.

Galled or fretted.

Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

Not more than 0.002 in. (0.05 mm) in depth.

Reject.

More than in Step.

Scored, nicked, or dented.

Examine the slots at Zone B.

Zone B

-

The area in the center of the dovetail slot.

Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

Not more than 0.002 in. (0.05 mm) in depth.

Reject.

More than in Step.

For loading slots: Galled or fretted.

Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

Not more than 0.0010 in. (0.025 mm) in depth.

Reject.

More than in Step.

For loading slots: Scored, nicked, or dented.

Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

Not more than 0.005 in. (0.127 mm) in depth.

Reject.

More than in Step.

For locking slots: Galled, fretted, scored, nicked, or dented for stage 9 thru stage 12 front and stage 9 thru stage 11 rear.

Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

Not more than 0.002 in. (0.051 mm) in depth.

Reject.

More than in Step.

For locking slots: Galled, fretted, scored, nicked, or dented for stage 12 rear.

Examine the slots at Zone C.

Zone C

-

The blade loading, blade locking slot(s), and an area around it, on all surfaces of the dovetail, 0.040 in. (1.00 mm) away from the edges of the slot(s).

Reject.

More than in Step.

Scored, nicked, dented, galled, or fretted.

Examine the slots at Zone D.

Zone D

-

The area between Zone A and Zone B.

Repair, VRS9136 TASK 72-41-12-300-019 (REPAIR-019).

Not more than 0.0050 in. (0.127 mm) in depth.

Reject.

More than in Step.

Scored, nicked, dented, galled, or fretted.

Examine the slots at Zone E.

Zone E

-

The remaining areas of the disk around the dovetail slots that are not in Zone A and Zone C.

SUBTASK 72-41-12-220-213 Examine the Rear HPC Disk (72-41-12, 01-600) for Damage in the Blade Slots, the Loading Slots, and the Locking Slots, Assembly B

Refer to Figure.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step

Chipped.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Pitted.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Scratched.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Loose coating or blisters.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Rub track.

Examine the disk at location 1 for damage on the stage 8 ceramic rub strip.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Chipped.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Pitted.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Scratched.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Loose coating or blisters

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Rub track.

Examine the disk at location 2 for damage on the stage 9 ceramic rub strip.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Chipped.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Pitted.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Scratched.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Loose coating or blisters.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Rub track.

Examine the disk at location 3 for damage on the stage 10 ceramic rub strip.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Chipped.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Pitted.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Scratched.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Loose coating or blisters.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Rub track.

Examine the disk at location 4 for damage on the stage 11 ceramic rub strip.

SUBTASK 72-41-12-220-098 Examine the Rear HPC Disk for Damage on the Ceramic Rub Strips, Assembly A, and Assembly B

Refer to Figure.

Repair, VRS6134 TASK 72-41-12-300-017 (REPAIR-017).

Other than Step.

Examine the disk at location 1 for the front outside diameter.

Repair, VRS6137 TASK 72-41-12-300-020 (REPAIR-020).

Other than Step.

Examine the disk at location 2 for the rear outside diameter.

Repair, VRS6135 TASK 72-41-12-300-018 (REPAIR-018).

Other than Step.

Examine the disk at location 3 for the front inside diameter.

SUBTASK 72-41-12-220-099 Examine the Rear HPC Disk for the Diameters, Assembly A, and Assembly B

CAUTION

DO NOT USE A PI TAPE TO MEASURE THE DIAMETERS, THE DIAMETERS ARE ON A CONICAL SURFACE.Refer to Figure.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Examine the disk at location 1 for the outside diameter of the stage 8 ceramic rub strip.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Examine the disk at location 2 for the outside diameter of the stage 9 ceramic rub strip.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Examine the disk at location 3 for the outside diameter of the stage 10 ceramic rub strip.

Repair, VRS6008 TASK 72-41-12-300-015 (REPAIR-015).

Other than Step.

Examine the disk at location 4 for the outside diameter of the stage 11 ceramic rub strip.

SUBTASK 72-41-12-220-100 Examine the Rear HPC Disk for the Outside Diameters, Assembly A, and Assembly B

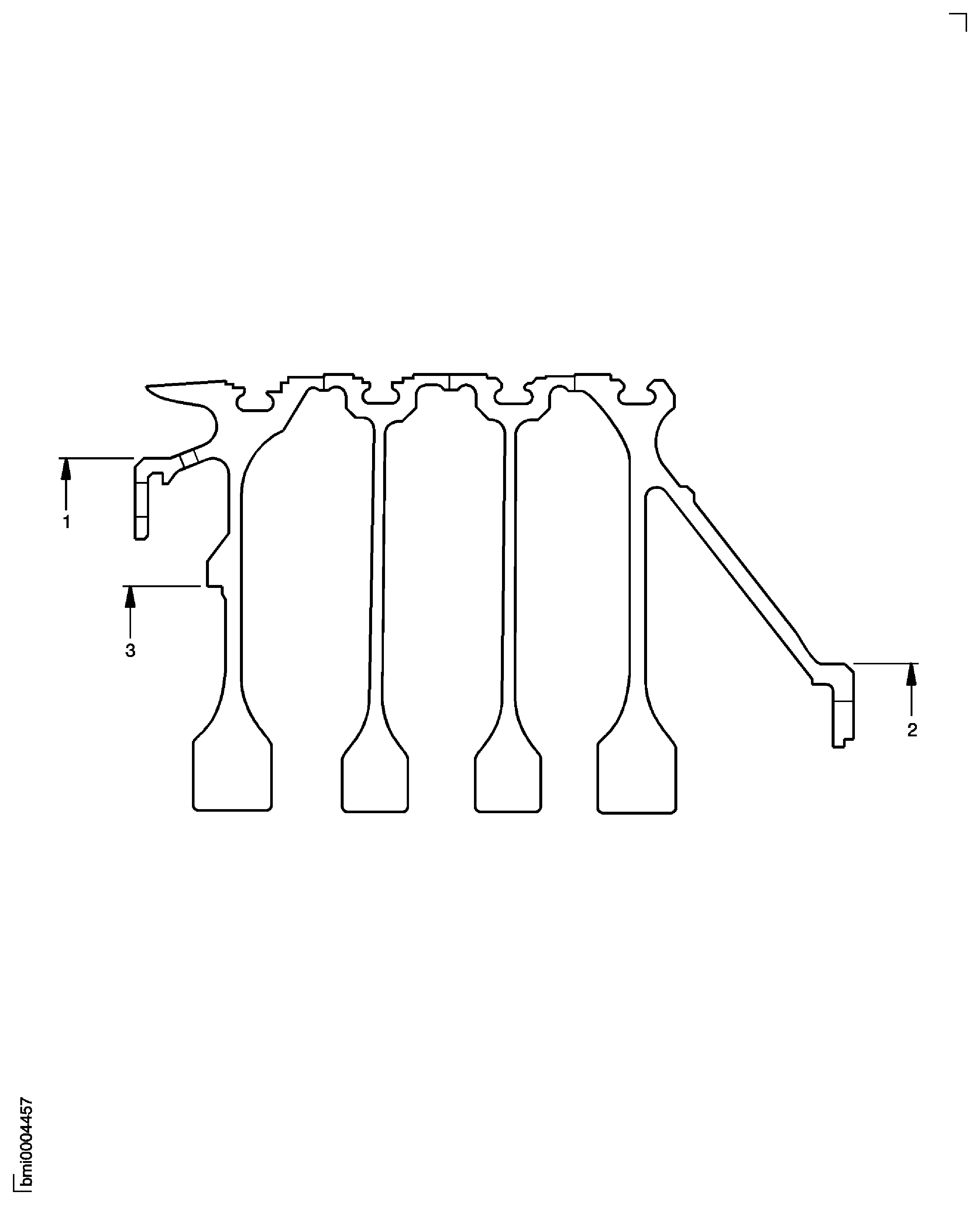

Figure: Rear HPC Disk Inspection Locations - Front Flange Slots

Rear HPC Disk Inspection Locations - Front Flange Slots

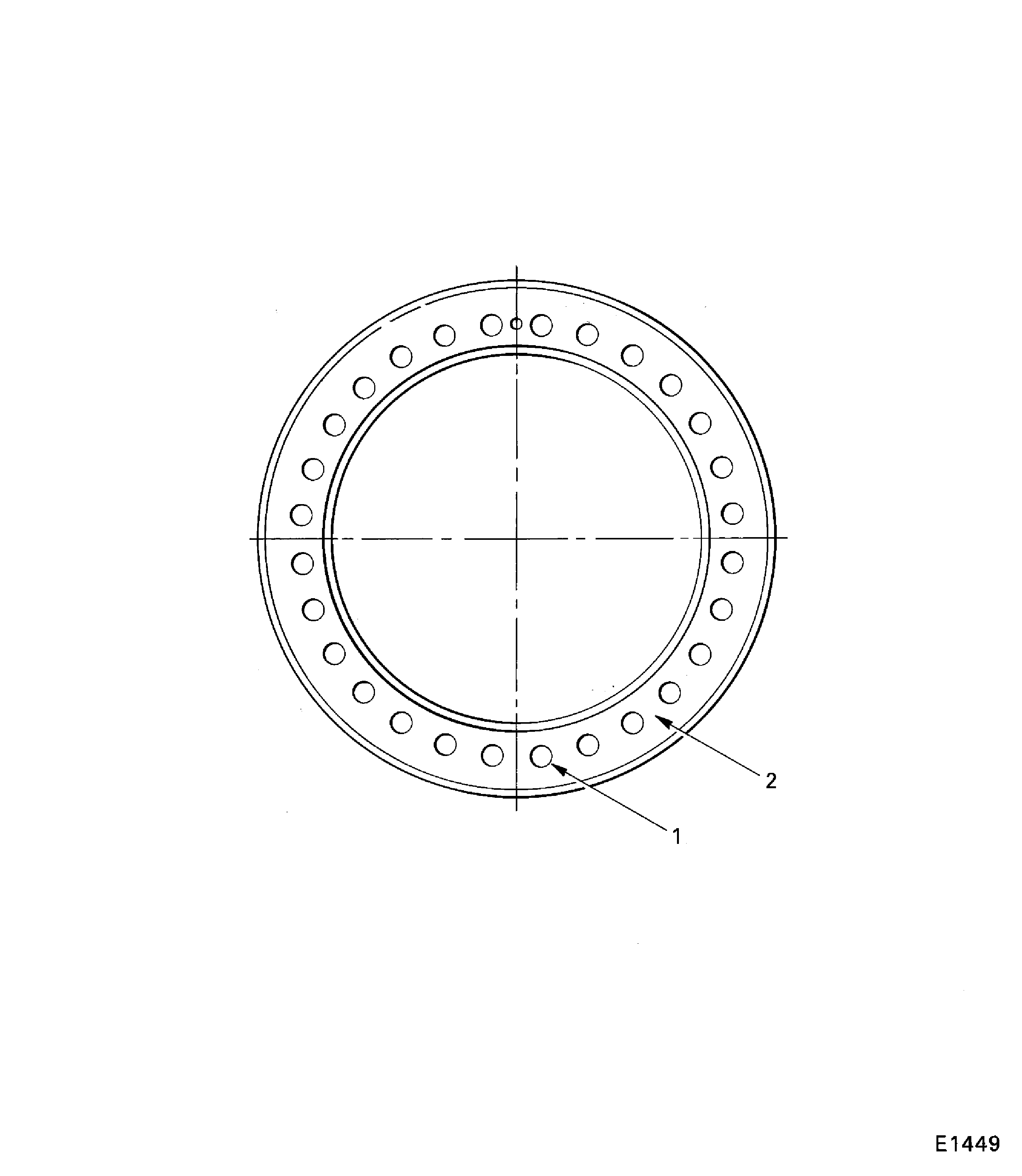

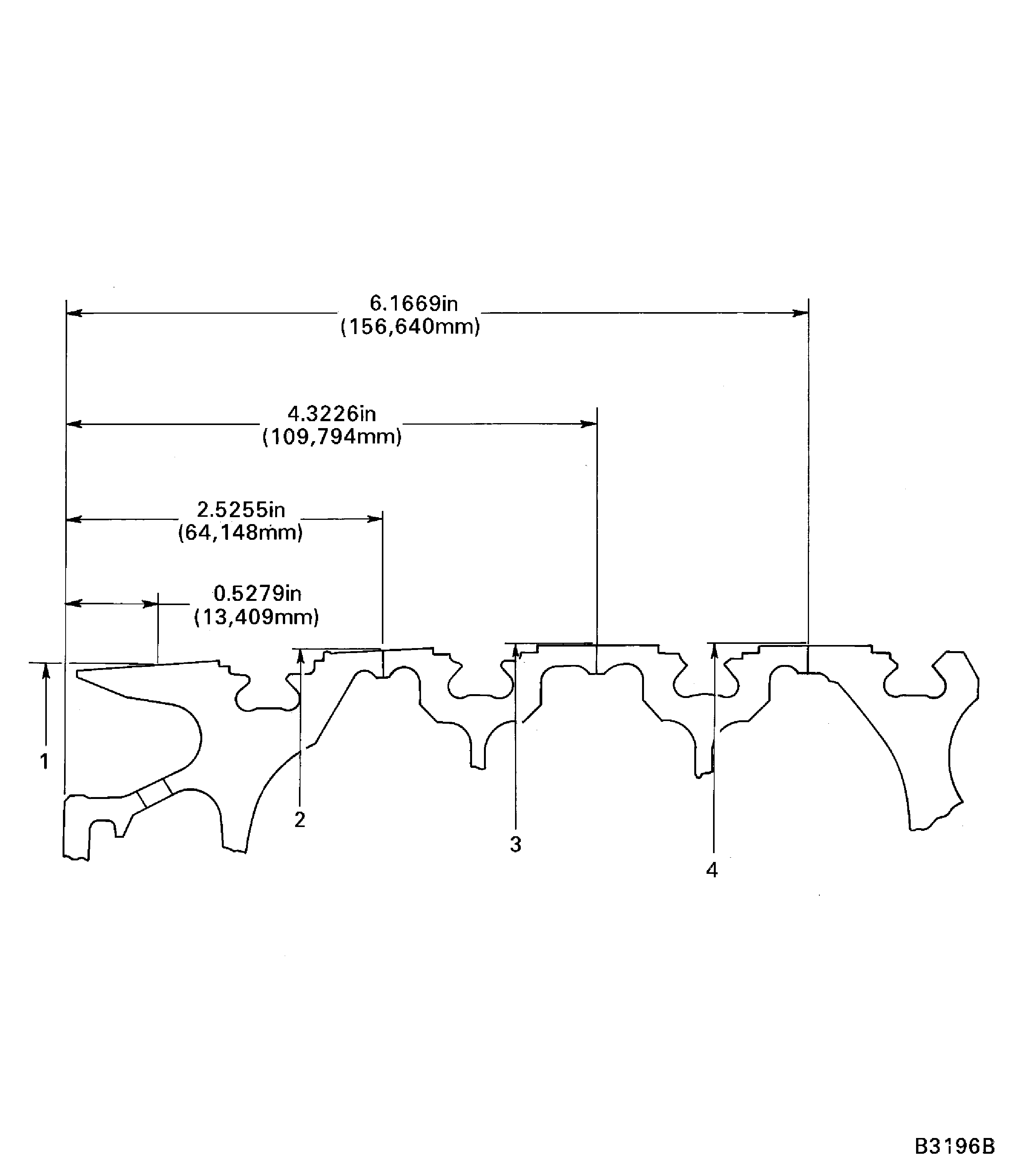

Figure: Rear HPC Disk Inspection Locations

Rear HPC Disk Inspection Locations

Figure: Rear HPC Disk Inspection Locations

Rear HPC Disk Inspection Locations

Figure: Focused Inspection - Blade Loading and Locking Slots Stages 9, 10, 11 and 12

Focused Inspection - Blade Loading and Locking Slots Stages 9, 10, 11 and 12

Figure: Rear HPC Disk Inspection Locations

Rear HPC Disk Inspection Locations

Figure: Rear HPC Disk Inspection Locations

Rear HPC Disk Inspection Locations

Figure: Rear HPC Disk Inspection Locations

Rear HPC Disk Inspection Locations

Figure: Focused Inspection - Stages 9, 10, 11 and 12 Disks Bore and Stage 9 Air Transfer Holes (Vent Holes)

Focused Inspection - Stages 9, 10, 11 and 12 Disks Bore and Stage 9 Air Transfer Holes (Vent Holes)

Figure: Focused Inspection - Blade Loading and Locking Slots Stages 9, 10, 11 and 12

Focused Inspection - Blade Loading and Locking Slots Stages 9, 10, 11 and 12

Figure: Focused Inspection - Front Flange Slots

Focused Inspection - Front Flange Slots

Figure: Focused Inspection - Rear Bolt Holes

Focused Inspection - Rear Bolt Holes