Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-15-300-011 HPC Stage 3 Rotor Blade - Weld Repair The Airfoil, Repair-011 (VRS6049)

Effectivity

FIG/ITEM | PART NO. | ASSEMBLY |

|---|---|---|

01-200 | 6A3513 | A |

01-200 | 6A3938 | A |

Deleted | Deleted | Deleted |

Deleted | Deleted | Deleted |

Deleted | Deleted | Deleted |

01-200 | 6A8353 | B |

Deleted | Deleted | Deleted |

Material of component

The HP compressor rotor blades - stage 3, are made from titanium alloy.

General

This repair must only be done when the instruction to do so is given in 72-41-15 Inspection/Check.

This repair restores the HP compressor rotor blade, stage 3 tip length by welding.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

This is a source demonstrated repair which can only be done by approved vendors.

To keep the HP compressor efficiency, rotor blades are repaired as near to the new blade condition as possible.

Rotor blades must be repaired as soon as damage or wear is monitored, to get back HP compressor efficiency and extend the rotor blade life.

This repair can be done again to the welded rotor blades if:

- The minimum airfoil dimensions are as given in 72-41-15 Inspection.

- The airfoil surface has been polished up to two times, refer to VRS6150, TASK 72-41-15-300-040 (REPAIR-040).

Discard the blades if, during the weld procedure, arcing has occurred on any part of the blades.

Price and Availability

Refer to International Aero Engines.

Related Repairs:

HP Compressor - Stages 3 to 12 - Rotor Blades - Restore airfoil surface finish. Refer to VRS6150, TASK 72-41-15-300-040 (REPAIR-040).

HP Compressor Rotor Blades - Stage 3 to 6 - Shot peen root of blade to restore fatigue strength. Refer to VRS6151, TASK 72-41-15-300-041 (REPAIR-041).

HP Compressor Blades - Stage 3 to 5 - Restore anti-fret treatment. Refer to VRS6486, TASK 72-41-15-300-046 (REPAIR-046).

HP Compressor - Stage 3 Rotor Blade - Replace clapper coating. Refer to Repair, VRS6236 TASK 72-41-15-300-035 (REPAIR-035) or Repair, VRS9297 TASK 72-41-15-300-058 (REPAIR-058).

HP Compressor - Stage 3 Rotor Blade - Remove clapper coating. Refer to VRS6635, TASK 72-41-15-300-053 (REPAIR-053).

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the necessary cleaning and inspection procedures are done before this repair. |

Support Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Abrasive Blast Equipment | LOCAL | Abrasive Blast Equipment | ||

| Argonarc Welding Equipment | LOCAL | Argonarc Welding Equipment | ||

| Heat Treatment Equipment | LOCAL | Heat Treatment Equipment | ||

| Hardness Tester | LOCAL | Hardness Tester | ||

| Grinding Machine | LOCAL | Grinding machine | ||

| Standard Workshop Equipment | LOCAL | Standard Workshop Equipment | ||

| Radiographic Equipment | LOCAL | Radiographic Equipment | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 03-195 WELDING WIRE TITANIUM | LOCAL | CoMat 03-195 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | X222X | CoMat 05-003 | ||

| CoMat 06-018 FLUORESCENT PENETRANT (POST-EMULSIFIED HIGH SENSITIVITY) | X222X | CoMat 06-018 |

Spares

NONESafety Requirements

NONEProcedure

The designation by IAE of an Authorized Repair Vendor indicates that the Repair Vendor has demonstrated the necessary capability to enable it to carry out the listed repair work. However, IAE makes no warranties or representations concerning the qualifications or quality standards of the Repair Vendors to carry out the repair work, and accepts no responsibility whatsoever for any work that may be carried out by a Repair Vendor other than when IAE is listed as the Repair Vendor. Authorized Repair Vendors do not act as agents or representatives of IAE.

Authorized Repair Vendors for repair VRS6049 are listed below:

Chromalloy Dallas

14042 Distribution Way

Dallas, TX 75234

U.S.A.

MTU Maintenance GmbH

Flughafen Hannover

Muncher Strasse 31

30855 LANGENHAGEN

GERMANY

Rolls-Royce Aero-Engine Services Ltd.

Component Refurbishment

Mavor Avenue

Nerston

East Kilbride

Glasgow G74 4PY

SCOTLAND

Sermatech Repair Services Ltd

High Holborn Road

Codnor

Ripley

Derbyshire

DE5 3NW

ENGLAND

Ishikawajima-Harima Heavy Industries Co. Ltd.

229 Tonogaya, Mizuho-Machi

Nishitama-Gun

Tokyo 190-1297

JAPAN

TURBINE OVERHAUL SERVICES PTE, LTD. (TOS)

5 TUAS DRIVE TWO - MAIL STOP 107-58

SINGAPORE 638639

TEL: 65-6860-2260

FAX: 65-6862-1068

Rolls-Royce Inchinnan

Inchinnan Drive

Inchinnan Business Park

Inchinnan, PA4 9AF

Scotland

The Source Demonstration requirements of this repair means that any facility not authorized to accomplish this repair either, utilize the Authorized Repair Vendors listed below or contact the IAE Repair Services Group to determine if a qualification program can be initiated at their facility.

IAE International Aero Engines AG

400 Main Street

M/S 121-10

East Hartford CT 06118

U.S.A.

Attn: Manager Technical Services

Repair Facilities

Use chemical cleaning equipment.

Refer to TASK 72-41-15-100-000 (CLEANING-000).

Chemically clean the blades.

SUBTASK 72-41-15-110-087 Clean the Stage 3 Rotor Blades

Refer to Repair, VRS6635 TASK 72-41-15-300-053 (REPAIR-053).

Remove the clapper coating.

SUBTASK 72-41-15-330-053 Remove the Clapper Coating

Refer to the SPM TASK 70-23-03-230-501.

Use penetrant crack test equipment.

No cracks are permitted.

Do a penetrant crack test.

SUBTASK 72-41-15-230-074 Do a Crack Test

Refer to Figure.

Use CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE with abrasive blast equipment.

Refer to the SPM TASK 70-12-01-120-501.

Vapor blast areas of the blade to be welded.

SUBTASK 72-41-15-120-056-A00 Vapor Blast the Stage 3 Rotor Blades, Assembly A

Refer to Figure.

Use CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE with abrasive blast equipment.

Refer to the SPM TASK 70-12-01-120-501.

Vapor blast areas of the blade to be welded.

SUBTASK 72-41-15-120-056-B00 Vapor Blast the Stage 3 Rotor Blades, Assembly B

Refer to Figure.

Use CoMat 03-195 WELDING WIRE TITANIUM with argon arc welding equipment.

Weld data:

Refer to approved vendor in Step, Repair Facilities, for weld parameters.

Refer to the SPM TASK 70-31-02-310-501-001.

CAUTION

YOU MUST PREVENT ARCING ON THE BLADE DURING THE WELD PROCEDURE.Build up the blade tip with weld to restore the length.

SUBTASK 72-41-15-310-051-A00 Weld the Stage 3 Rotor Blade Tips, Assembly A

Refer to Figure.

Use CoMat 03-195 WELDING WIRE TITANIUM with argonarc welding equipment.

Weld data:

Refer to approved vendor in Step, Repair Facilities, for weld parameters.

CAUTION

YOU MUST PREVENT ARCING ON THE BLADE DURING THE WELD PROCEDURE.Build up the blade tip with weld to restore the length. Refer to SPM TASK 70-31-02-310-501-001.

SUBTASK 72-41-15-310-051-B00 Weld the Stage 3 Rotor Blade Tips, Assembly B

Use heat treatment equipment.

Heat to a temperature of 1283 to 1301 deg.F. (695 to 705 deg.C.) for 2 hours.

Cool down to room temperature in Argon.

Heat-treat data:

Refer to the SPM TASK 70-31-02-310-501-001.

Heat-treat the blade in a vacuum or a controlled atmosphere.

SUBTASK 72-41-15-370-051 Heat-Treat the Stage 3 Rotor Blades

The hardness variation must be within 30 HV across the weld material, heat affected zone and parent material.

This is a guide for quality control and is not an absolute limit.

Use a hardness tester.

Use a sample blade.

NOTE

If the sample blade is outside the hardness variation limits, additional blades must be sampled, if more than 10% have a variation in hardness greater than 30 HV, then the cause must be investigated.

Do a hardness check on a longitudinal cross section of a sample blade.

SUBTASK 72-41-15-220-208 Do a Hardness Check

Refer to Figure.

Use a grinding machine.

Grind the blade tip to the correct height.

SUBTASK 72-41-15-310-095-A00 Put the Shape Back on the Stage 3 Rotor Blade Contour and Height, Assembly A

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Refer to Figure.

Use a grinding machine.

Grind the blade tip to the correct height.

SUBTASK 72-41-15-310-095-B00 Put the Shape Back on the Stage 3 Rotor Blade Contour and Height, Assembly B

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.If scratches or scores are shown on the airfoil surface, do Step.

SUBTASK 72-41-15-220-209-A00 Examine the Stage 3 Rotor Blades, Assembly A

If scratches or scores are shown on the airfoil surface, do Step.

SUBTASK 72-41-15-220-209-B00 Examine the Stage 3 Rotor Blades, Assembly B

Refer to Figure.

Refer to approved vendor in Step, Repair Facilities, for special machines to make the blade contour.

Hand methods are permitted to polish the blade contour.

Polish the blade airfoil surface and contour.

SUBTASK 72-41-15-350-096 Polish the Stage 3 Rotor Blade Airfoil Surface and Contour

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Refer to SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-001.

Use chemical cleaning equipment.

Chemically clean.

Refer to SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-002.

Use chemical cleaning equipment.

Swab etch the repaired area.

SUBTASK 72-41-15-110-141 Do a Swab Etch

Refer to SPM TASK 70-23-03-230-501.

Use penetrant crack test equipment.

Discard any cracked blades.

Do a penetrant crack test.

SUBTASK 72-41-15-230-075 Do a Crack Test

Pores larger than 0.006 in. (0.15 mm) diameter are not permitted.

Pores with a distance of less than 0.200 in. (5.10 mm) between them, are not permitted.

Surfaces broken by pores are not permitted.

Pores are not permitted less than 0.040 in. (1.00 mm) from the leading and trailing edges.

Use radiographic equipment.

Refer to approved vendor in Step, Repair Facilities, for the appropriate data card, and Radiographic Examination parameters.

Radiographic Data:

Radiographically examine the welded blade tip.

SUBTASK 72-41-15-260-072 Radiographically Examine the Stage 3 Rotor Blades

Refer to VRS6150, TASK 72-41-15-300-040 (REPAIR-040).

Restore the airfoil surface finish.

SUBTASK 72-41-15-380-079 Restore the Airfoil Surface Finish

Refer to VRS6151, TASK 72-41-15-300-041 (REPAIR-041).

Shot-peen the dovetail root of the HP compressor stage 3 rotor blade.

SUBTASK 72-41-15-380-115 Shot-Peen the Dovetail Root of the HP Compressor Stage 3 Rotor Blade

Refer to Repair, VRS6236 TASK 72-41-15-300-035 (REPAIR-035) or Repair, VRS9297 TASK 72-41-15-300-058 (REPAIR-058).

Apply the clapper coating.

SUBTASK 72-41-15-340-053 Apply the Clapper Coating

Refer to VRS6486, TASK 72-41-15-300-046 (REPAIR-046).

Apply the dry film lubricant to the blade root.

SUBTASK 72-41-15-380-080 Apply the Dry Film Lubricant

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibro-engraving equipment.

CAUTION

DO NOT VIBRO-ENGRAVE ON THE BLADE AIRFOIL OR LOCATION FACES.Make a mark VRS6049 adjacent to the assembly number.

SUBTASK 72-41-15-350-097 Identify the Repair

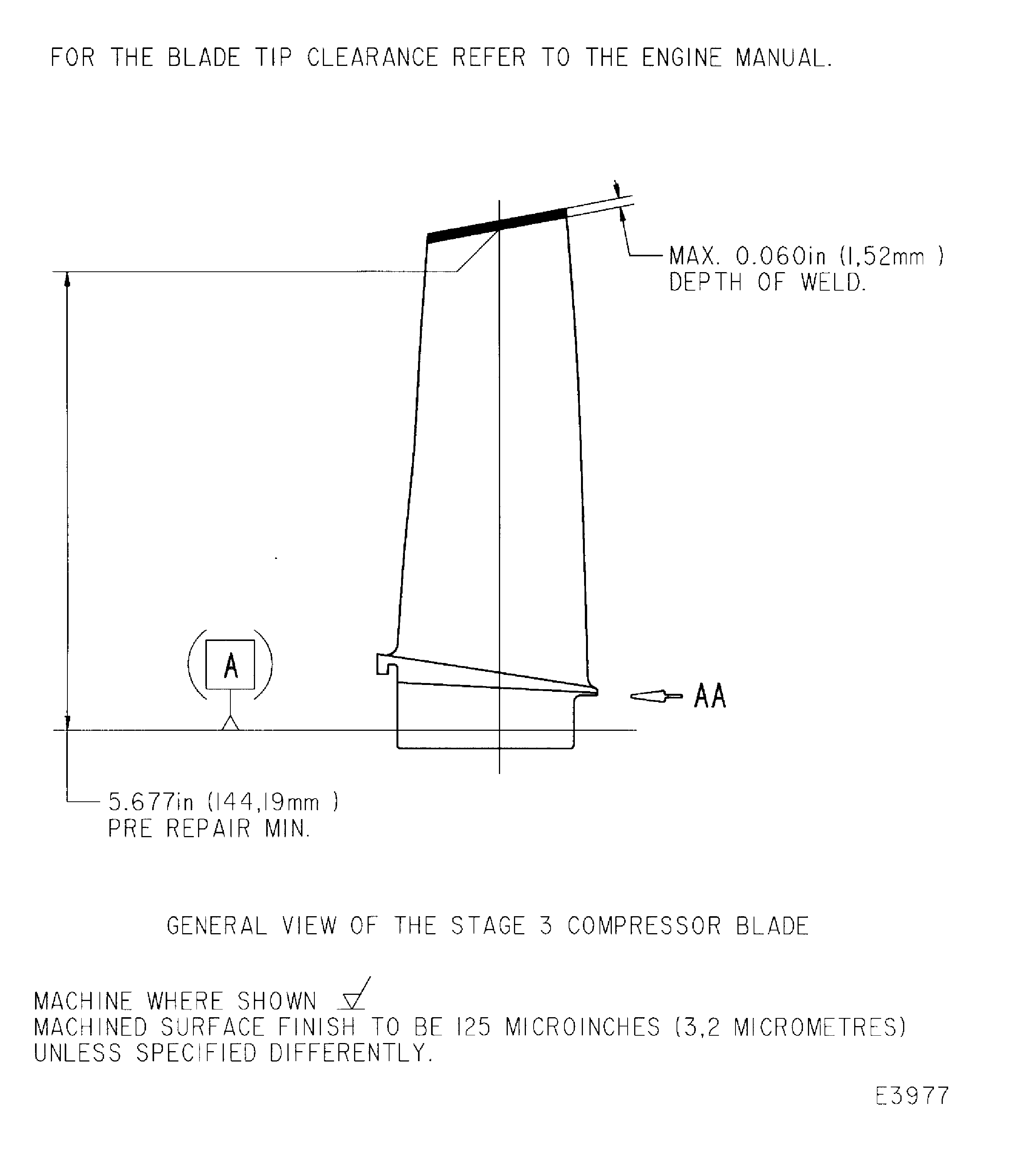

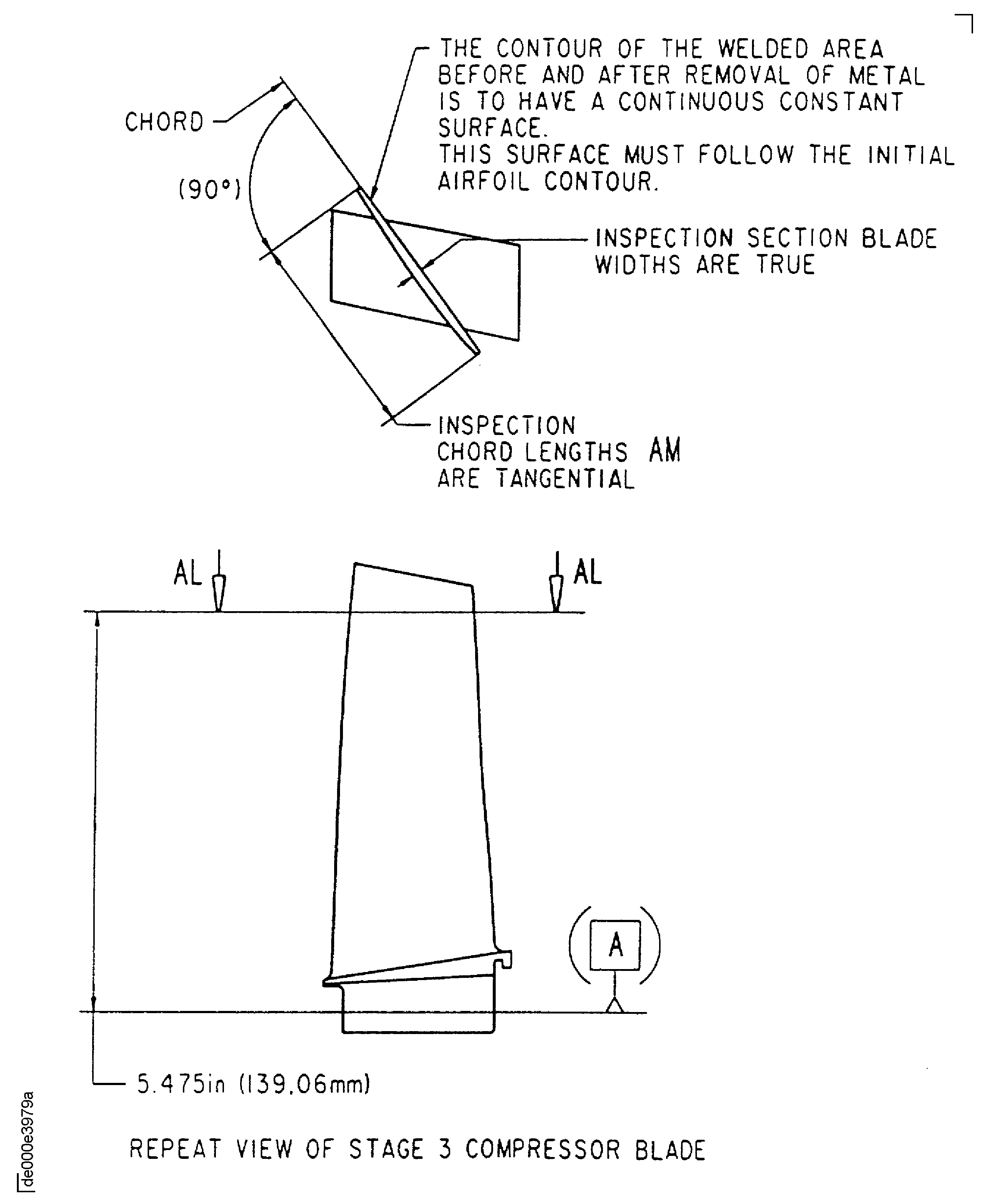

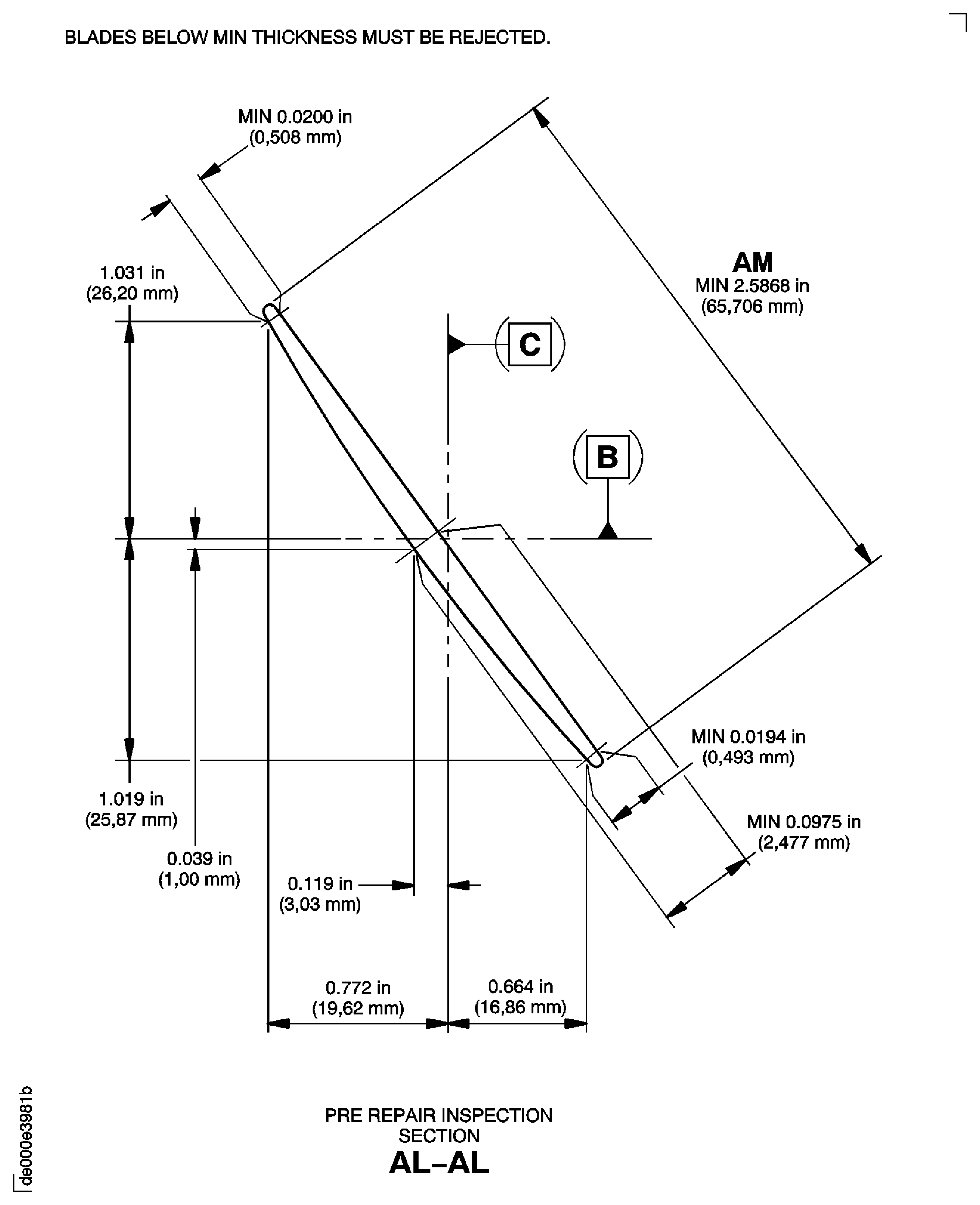

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

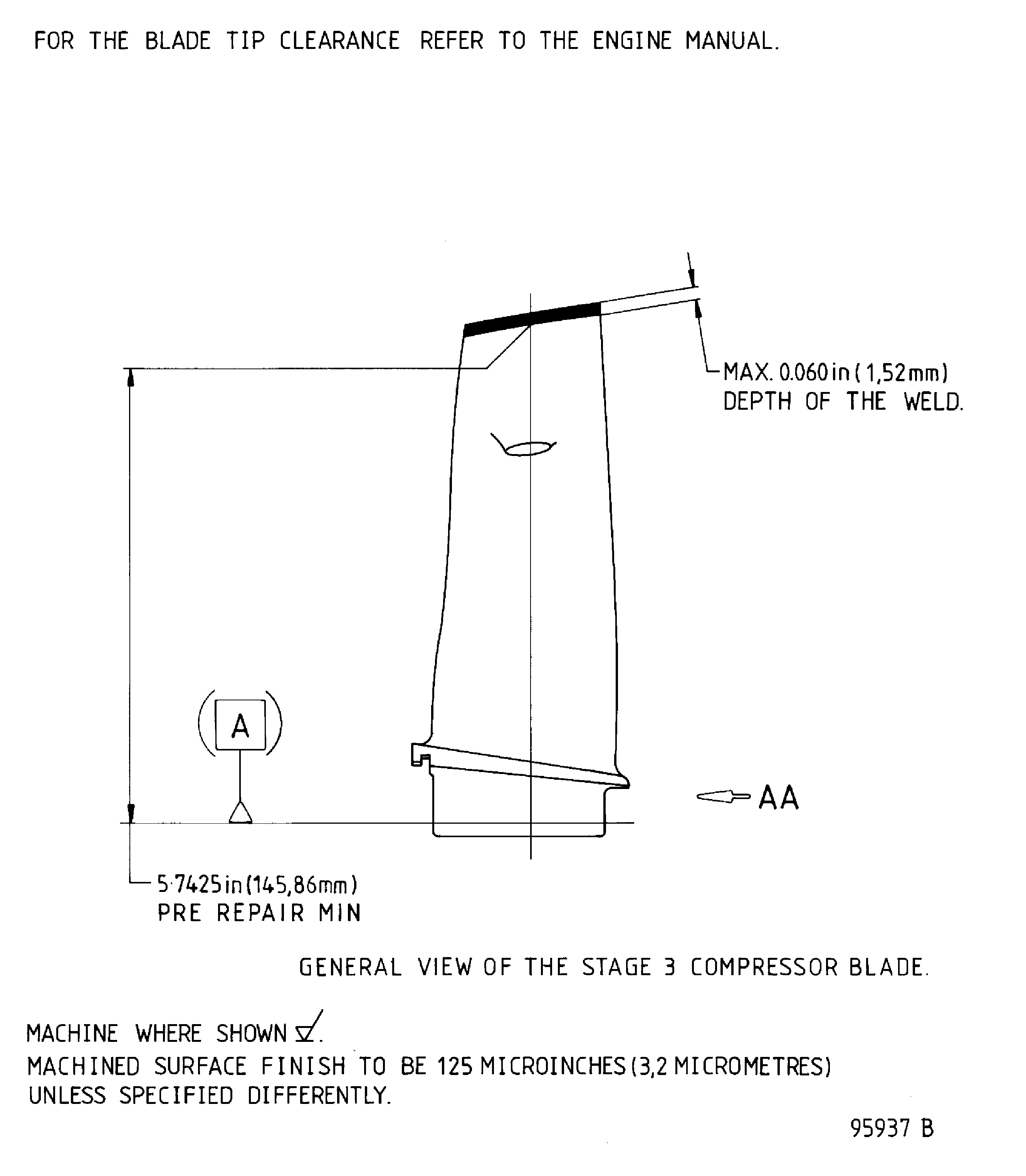

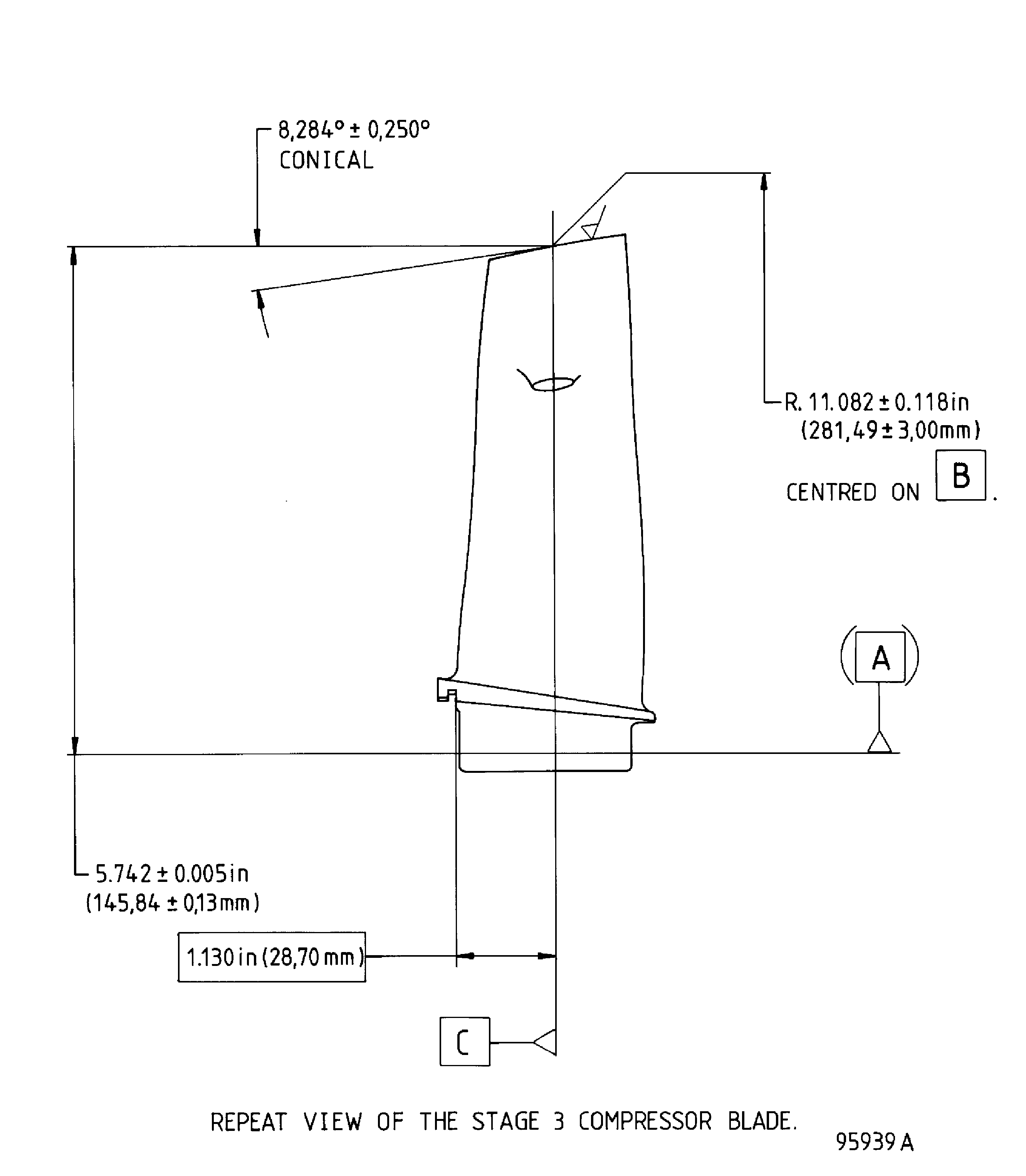

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

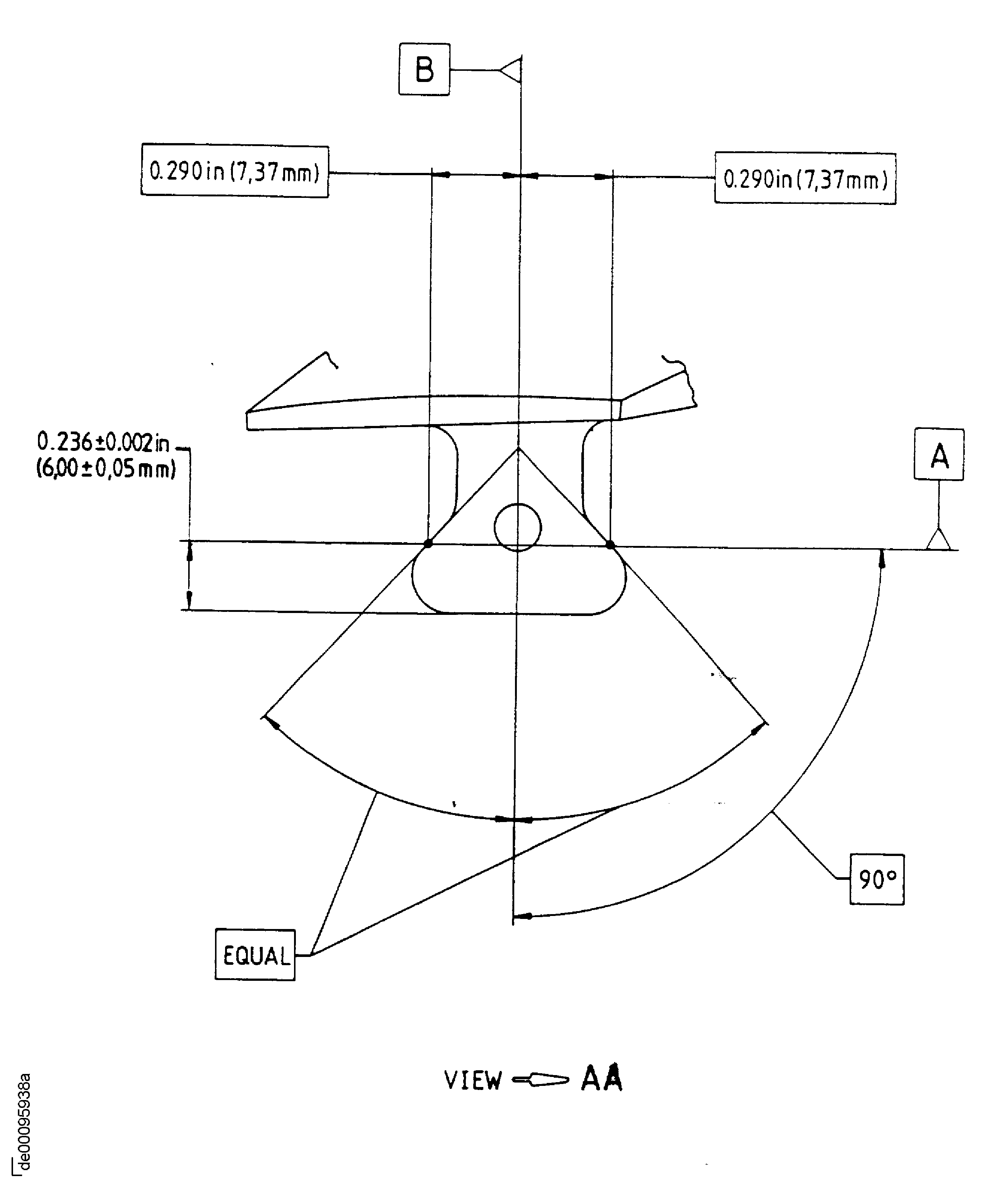

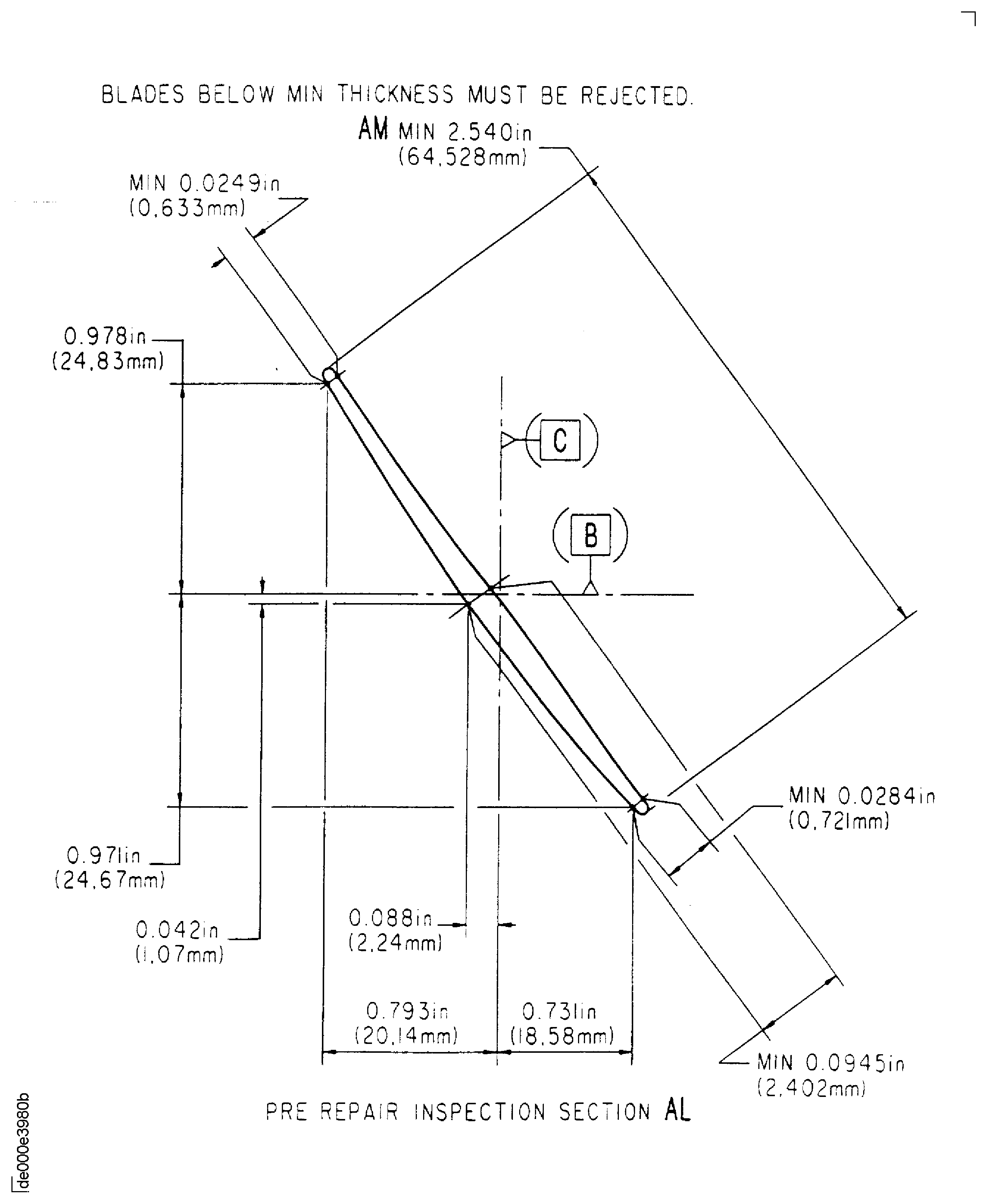

Figure: Repair Details and Dimensions - Assembly A And Assembly B

Repair Details and Dimensions - Assembly A And Assembly B

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

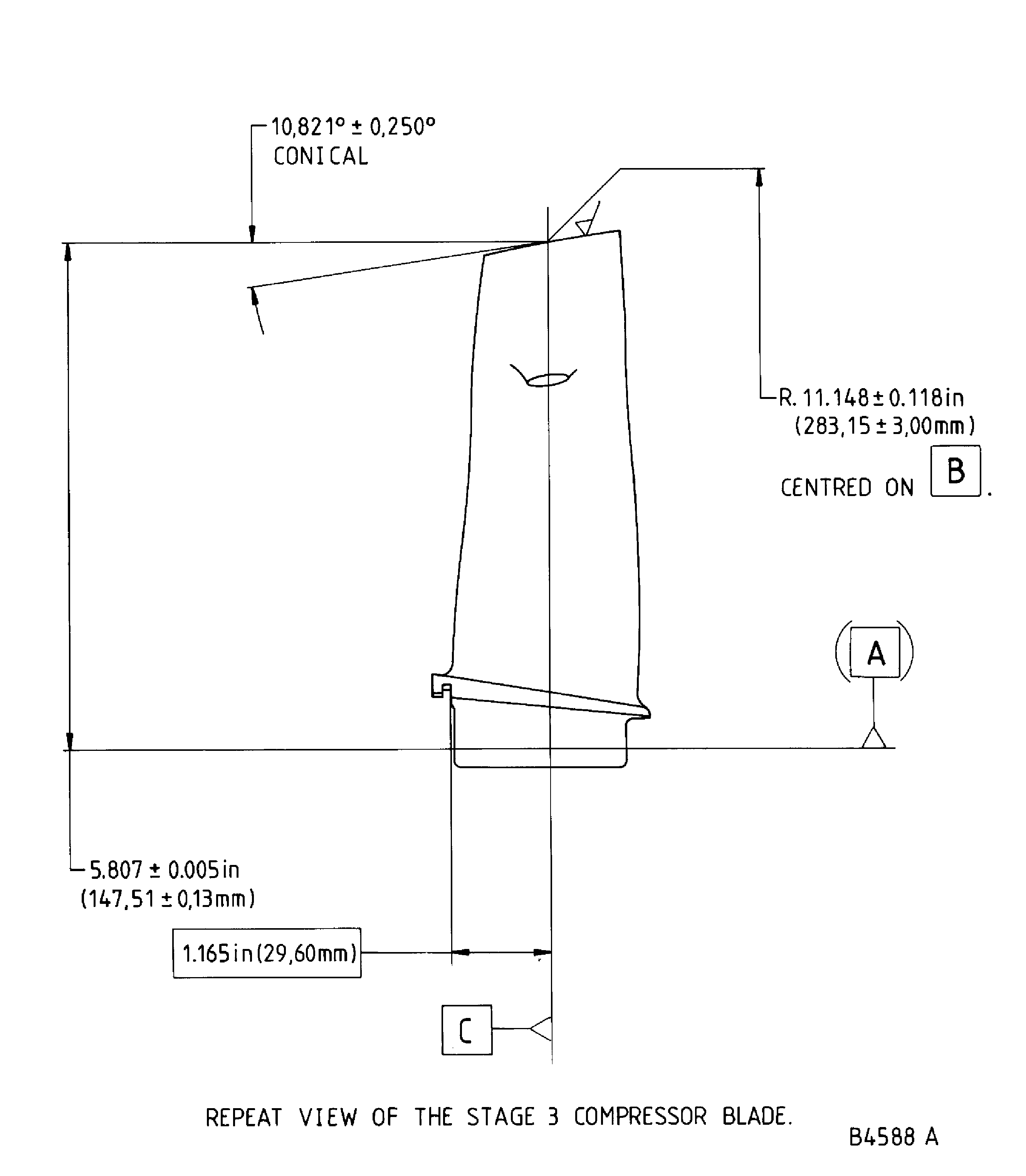

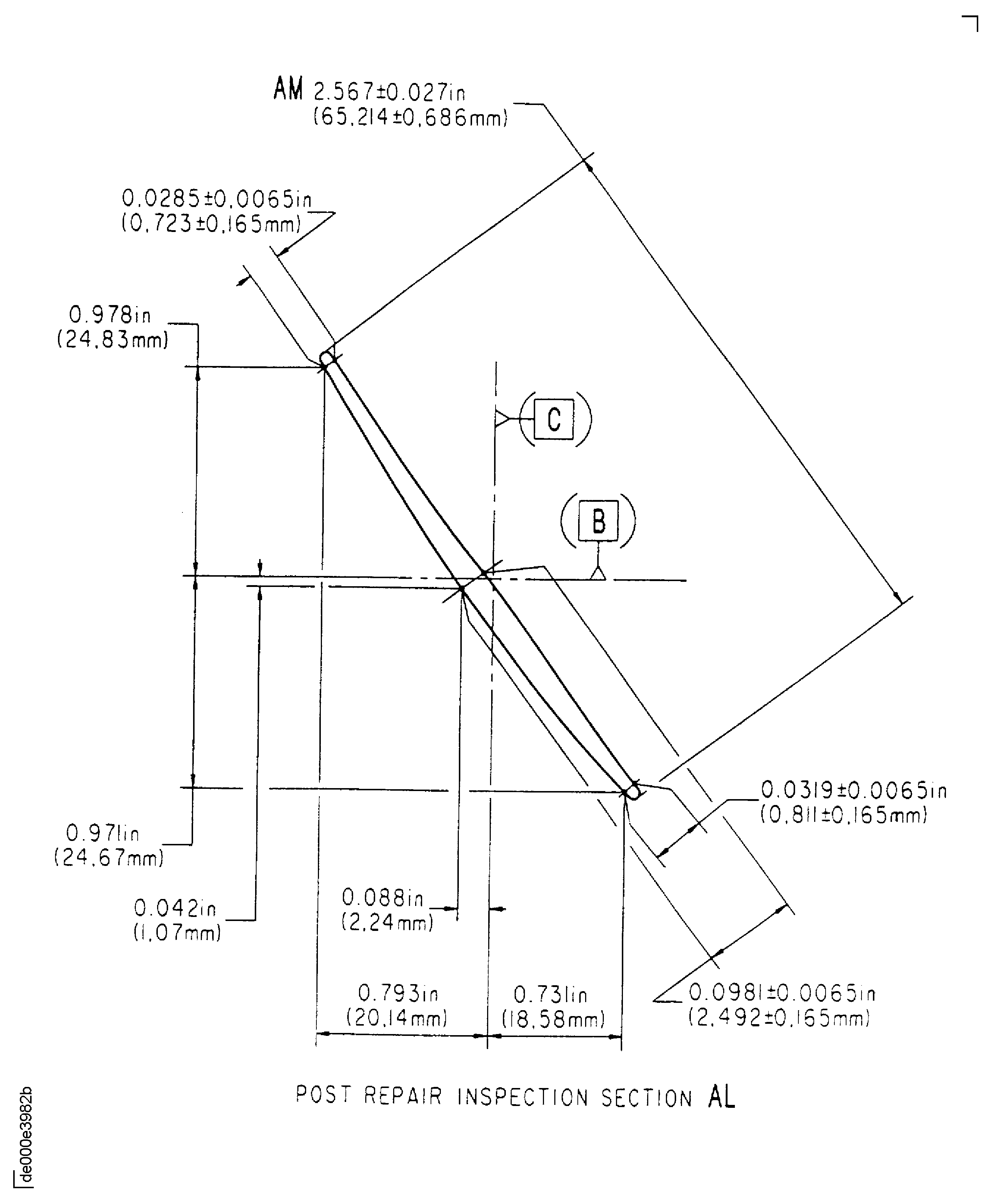

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

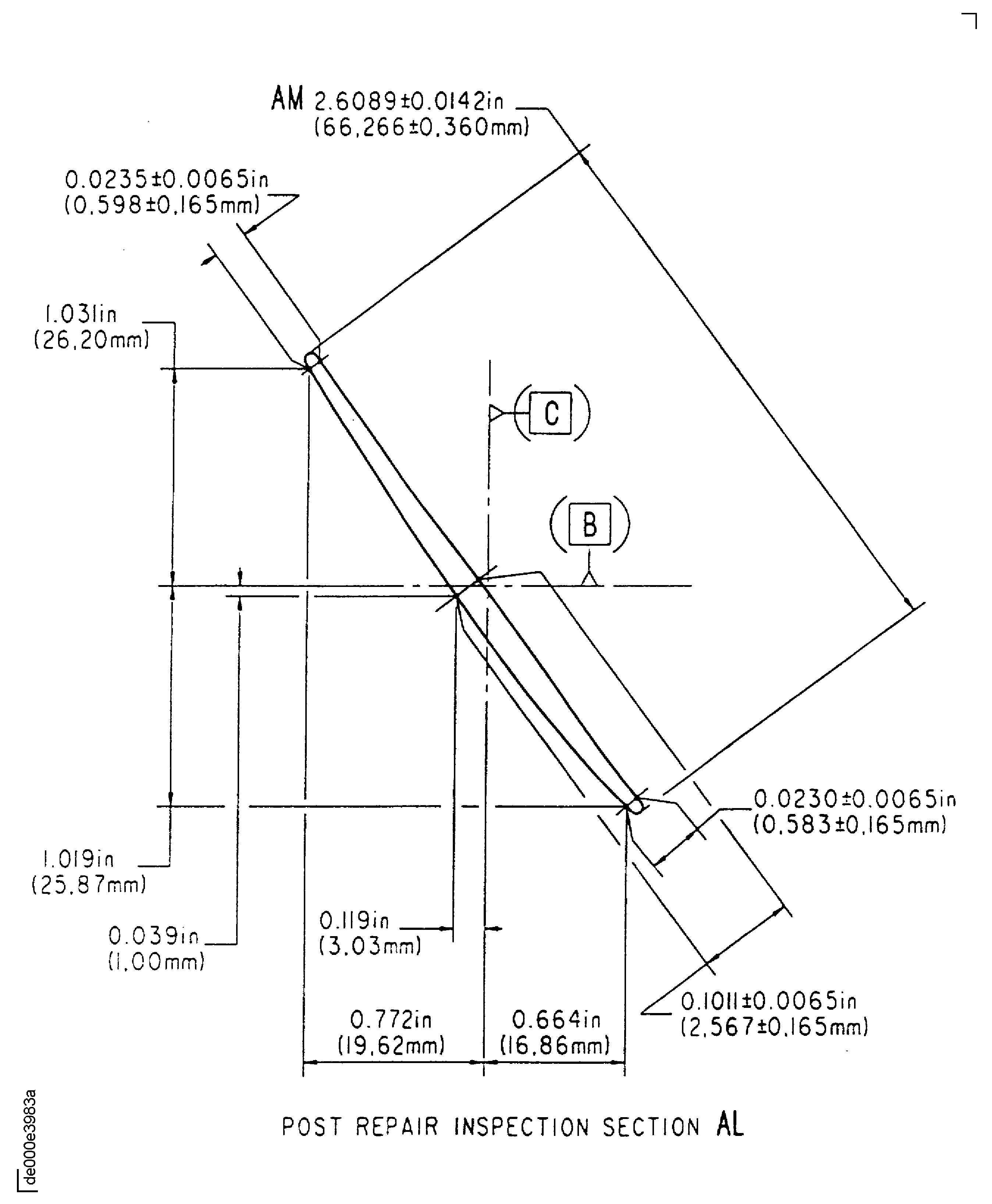

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

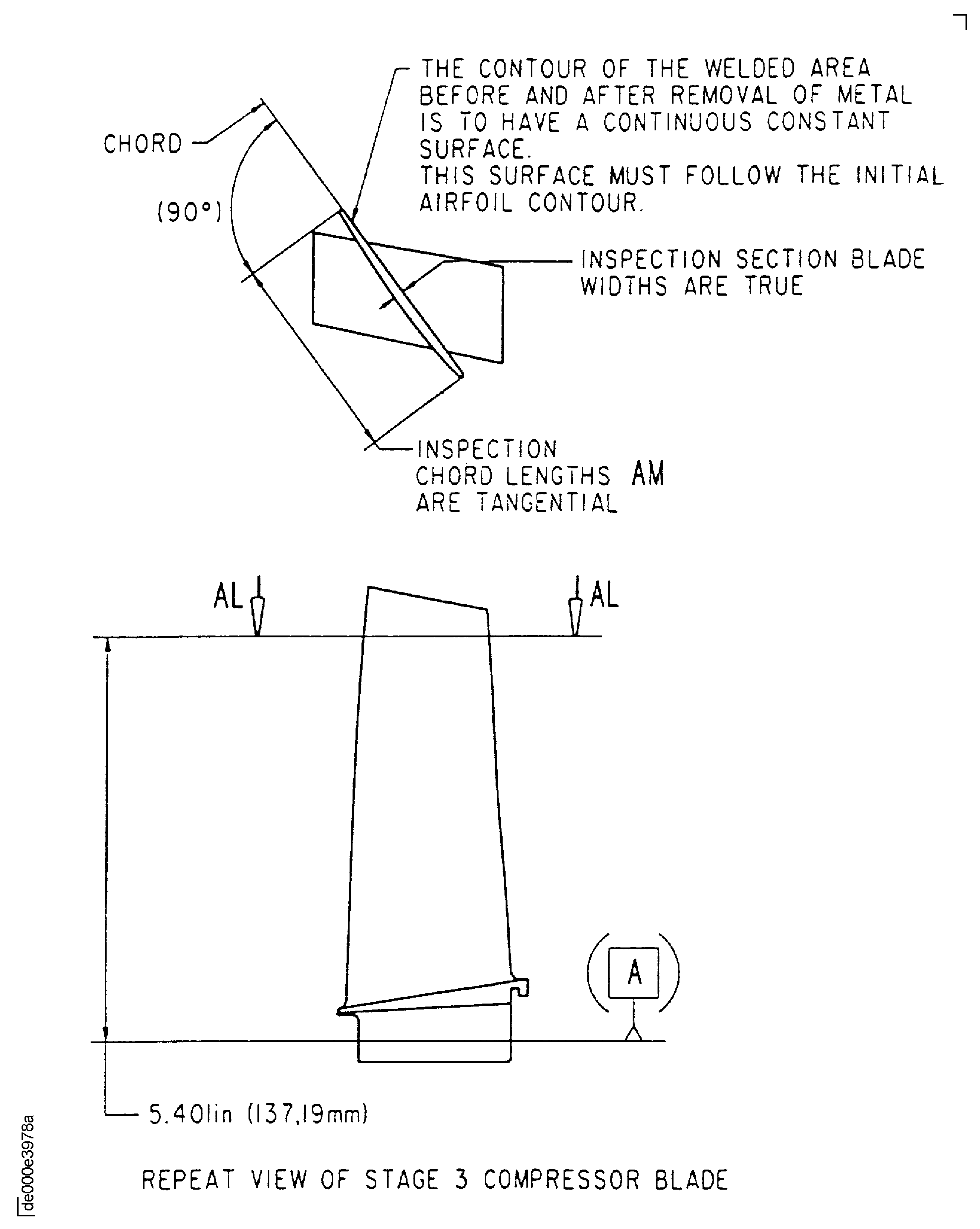

Figure: Repair Details and Dimensions - Assembly A And Assembly B

Repair Details and Dimensions - Assembly A And Assembly B

Figure: Repair Details and Dimensions - Assembly A And Assembly B

Repair Details and Dimensions - Assembly A And Assembly B